Waste treatment equipment used for magnetic materials

A technology for waste disposal and magnetic materials, which is applied in the direction of grain processing, etc., can solve the problems of magnetic material waste being pulled into and smashed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] For example figure 1 -example Figure 5 Shown:

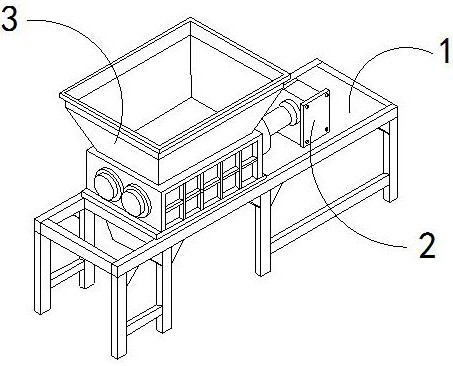

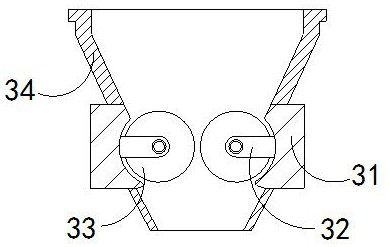

[0029] The present invention provides a kind of processing equipment for magnetic material waste, its structure includes laying a base and laying a base 1, a driver 2, and a crushing mechanism 3, the driver 2 is fixed on the right side of the crushing mechanism 3, and the bottom of the crushing mechanism 3 It is welded with the upper end of the base 1; the crushing mechanism 3 includes a shell 31, a fixed shaft 32, a crushing roller 33, and a feed hopper 34, and the rear end of the fixed shaft 32 is welded with the inner wall of the shell 31, and the crushed The middle part of the roller 33 is movably engaged with the front end of the fixed shaft 32 , and the bottom of the feeding hopper 34 is connected with the upper end of the casing 31 .

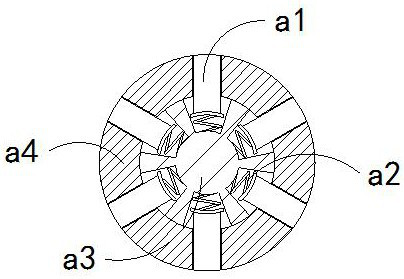

[0030] Wherein, the crushing roller 33 includes an outreach rod a1, a rebound bar a2, a middle block a3, and a circumscribed ring a4. Between the rear end of the outrigger a1 and ...

Embodiment 2

[0036] For example Figure 6 -example Figure 9 Shown:

[0037] Wherein, the receiving plate b2 includes an outer pushing block b21, a connecting plate b22, and an inner fixing plate b23. The inner wall of the plate b22 is embedded and connected. There are four pusher blocks b21, and two of them are evenly distributed in an arc on the inner side of the joint plate b22. The pushing block b21 slides outward along the inner solid plate b23.

[0038]Wherein, the extrapolation block b21 includes an outer ring c1, a slotted block c2, a reset piece c3, and an engaging block c4, the slotted block c2 is slidingly matched with the inside of the outer ring c1, and the reset piece c3 is installed on Between the slotted block c2 and the inner wall of the outer ring c1, the connecting block c4 is installed at the inner center of the outer ring c1, and there are four slotted blocks c2, which are uniformly inside the outer ring c1 Distributed in a circular shape, the slotted block c2 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com