Plastic production equipment

A technology for production equipment and plastics, which is applied in the field of plastics, and can solve the problems of reduced crushing effect of plastic shredders and difficulty in crushing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] For example figure 1 -example Figure 5 Shown:

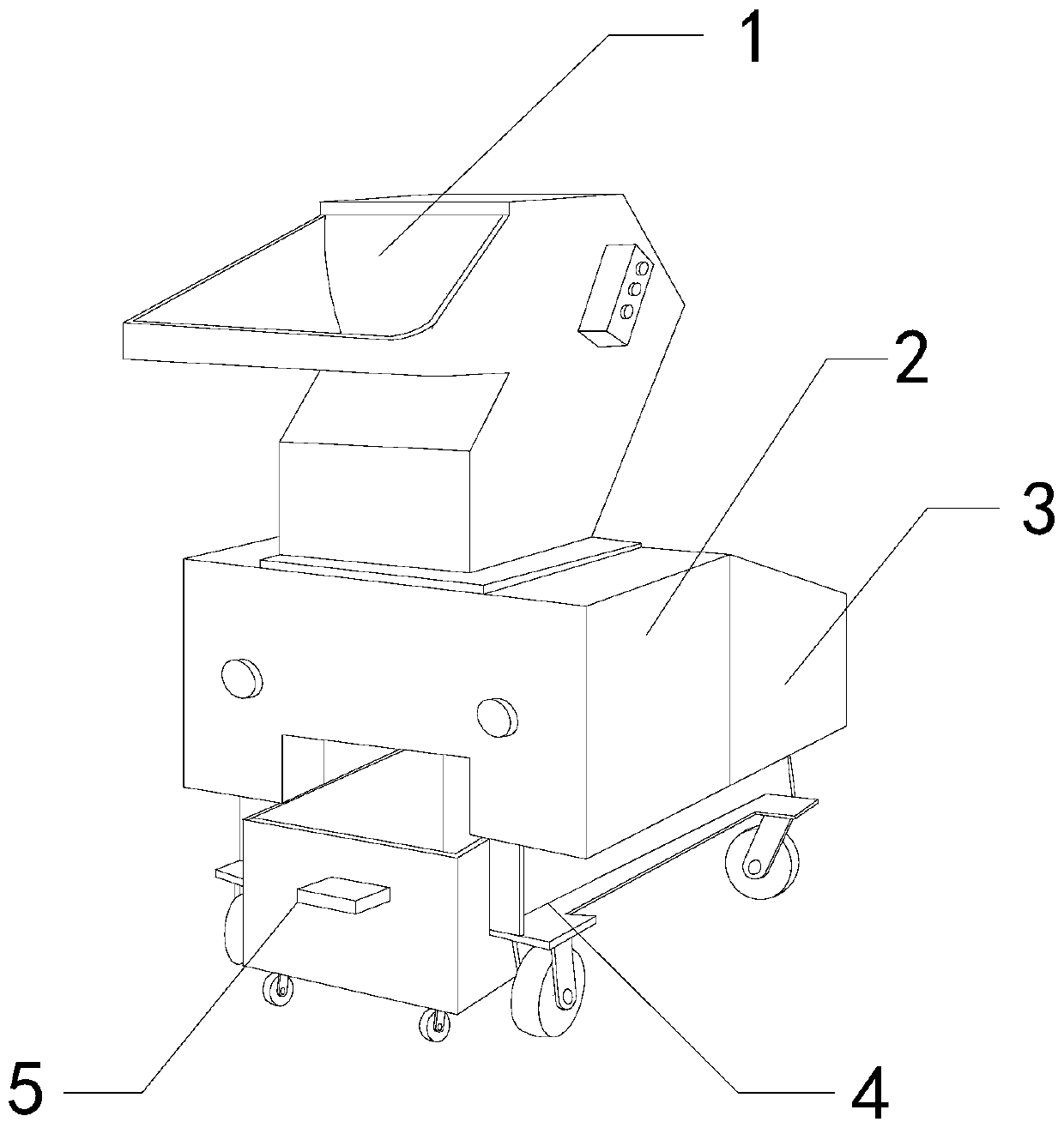

[0028] The present invention provides a kind of plastic production equipment, its structure comprises feeding hopper 1, crushing bin 2, power bin 3, base support 4, collecting bucket 5, described power bin 3 is installed in the back end position of crushing bin 2, and described base The bracket 4 is embedded and fixed at the lower end of the crushing bin 2 , the collecting bucket 5 is in clearance fit with the base bracket 4 , and the crushing bin 2 is welded at the lower end of the feeding hopper 1 .

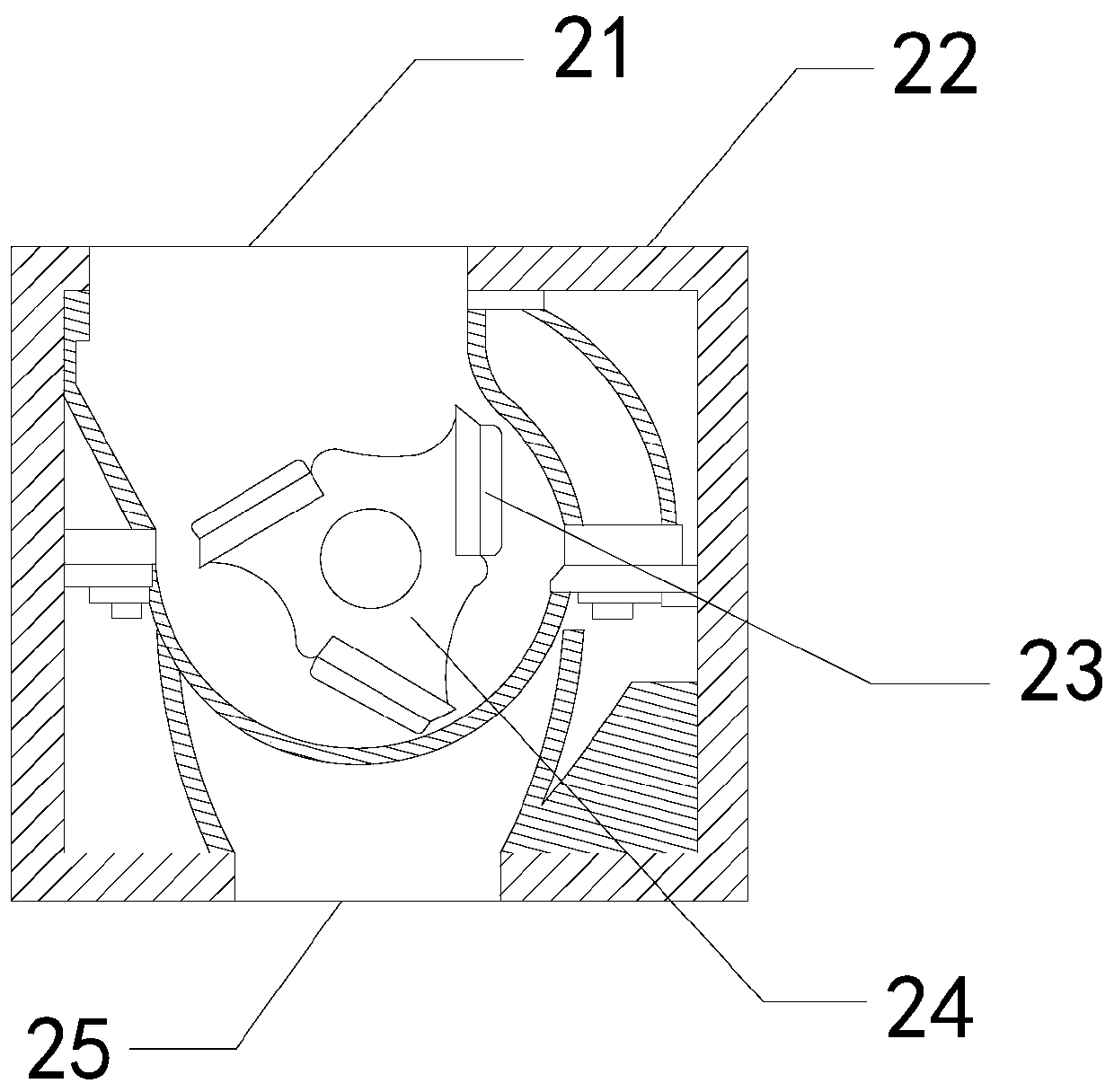

[0029] Wherein, the crushing bin 2 includes an inlet 21, a casing 22, a crushing cutter 23, a rotating block 24, and a discharge port 25. The inlet 21 and the casing 22 are an integrated structure, and the crushing cutter 23 is embedded in the rotating block 24. The position of the outer surface of the rotating block 24 is movably engaged with the inner position of the casing 22, the discharge port 25 is installed at the...

Embodiment 2

[0036] For example Figure 6 -example Figure 8 Shown:

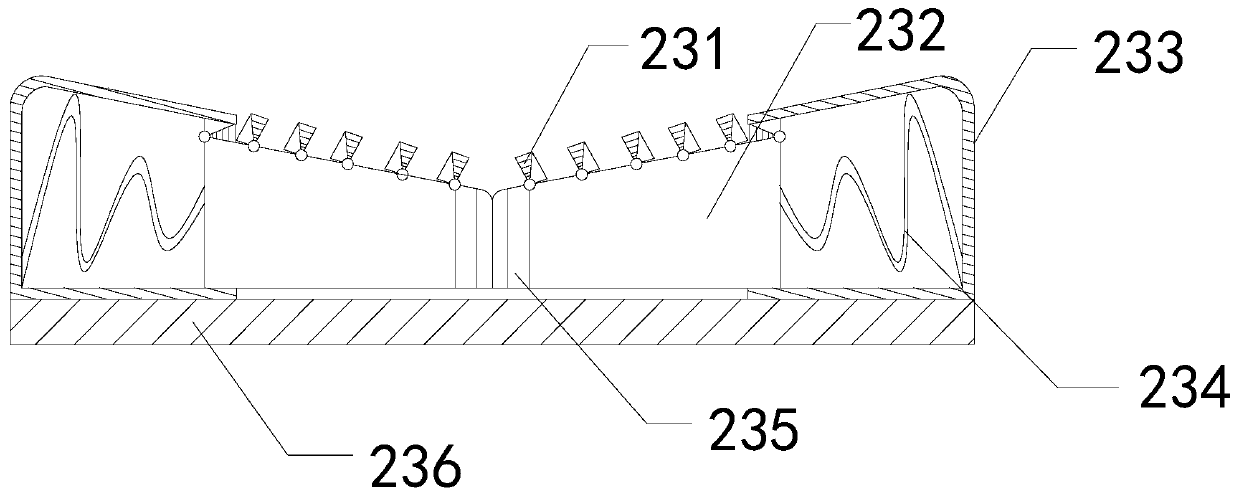

[0037] Wherein, the crushing mechanism 231 includes a movable plate b1, a rotating wheel b2, a cleaning block b3, a cutter head b4, a connecting rod b5, and a movable groove b6. The movable wheel b2 is movably engaged with the movable plate b1, and the cleaning block b3 The gap fits between two adjacent connecting rods b5, the cutter head b4 is welded to the bottom position of the connecting rod b5, the connecting rod b5 and the movable plate b1 are an integrated structure, and the movable groove b6 is installed on the corresponding Between the two adjacent connecting rods b5, the cutter head b4 on the connecting rod b5 can cut the spherical polyethylene plastic with smaller volume, and the movable groove b6 is filled with polyether sponge with stronger resilience, The removal block b3 can be pushed to remove the spherical polyethylene plastic cut by the cutter head b4.

[0038] Wherein, the cutter head b4 includes an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com