Hoisting structure for inner cone hole flange

A technology of inner tapered hole and flange, applied to the field of hoisting structure of inner tapered hole flange, can solve the problems affecting the work health of employees, the loss of company labor, and the crushing of employees' fingers, so as to ensure the health of workers, reduce labor losses, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

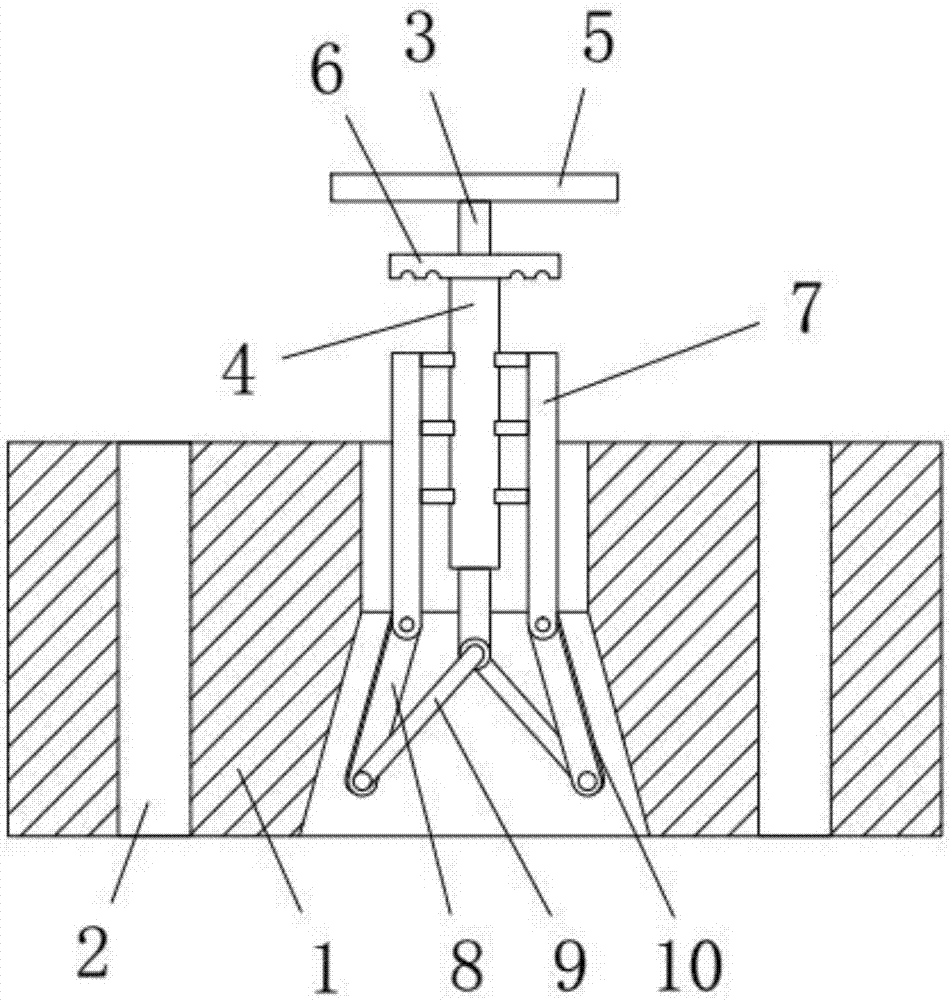

[0014] as attached figure 1 As shown, the hoisting structure of a flange with an inner tapered hole according to the present invention includes a flange 1 and a hoisting tool, the flange 1 is provided with a plurality of bolt connection holes 2, and the middle part of the flange 1 is provided with a through hole; The lower part of the through hole is a tapered hole; the lifting tool includes a boom 3, a sleeve 4 and multiple sets of boom assemblies; the sleeve 4 is set on the boom 3, and the upper end of the boom 3 is provided with an upper handle 5 , the upper end of the sleeve 4 is provided with a lower handle 6; the boom assembly includes a fixed rod 7, a matching rod 8 and a connecting rod 9, the fixed rod 7 is fixedly connected with the sleeve 4, and the two ends of the matching rod 8 are respectively connected to the fixed rod 7 is hinged with connecting rod 9, and the two ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com