Splitting method for ultrathin electronic grade glass fiber cloth

A glass fiber cloth, electronic grade technology, applied in fiber processing, fabric elongation, heating/cooling fabric, etc., can solve the problems of weft yarn distortion, long impregnation time, high air permeability, etc., to increase the width of warp and weft yarns, reduce Effect of impregnation time and air permeability reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

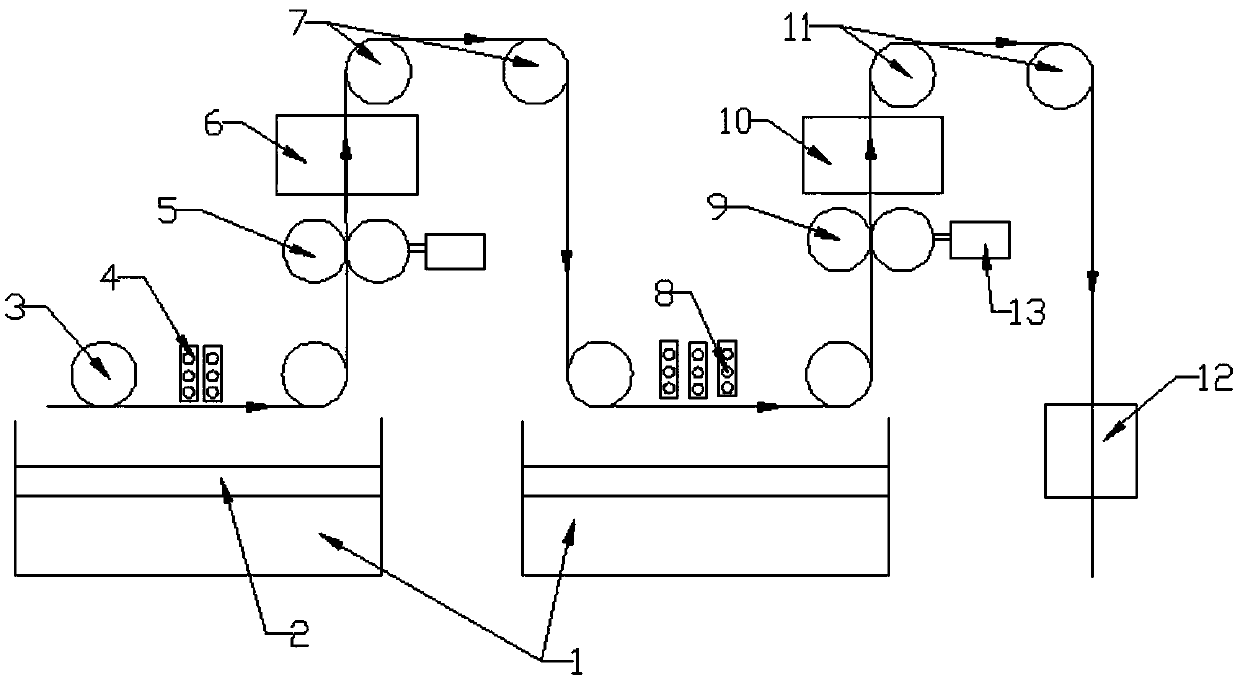

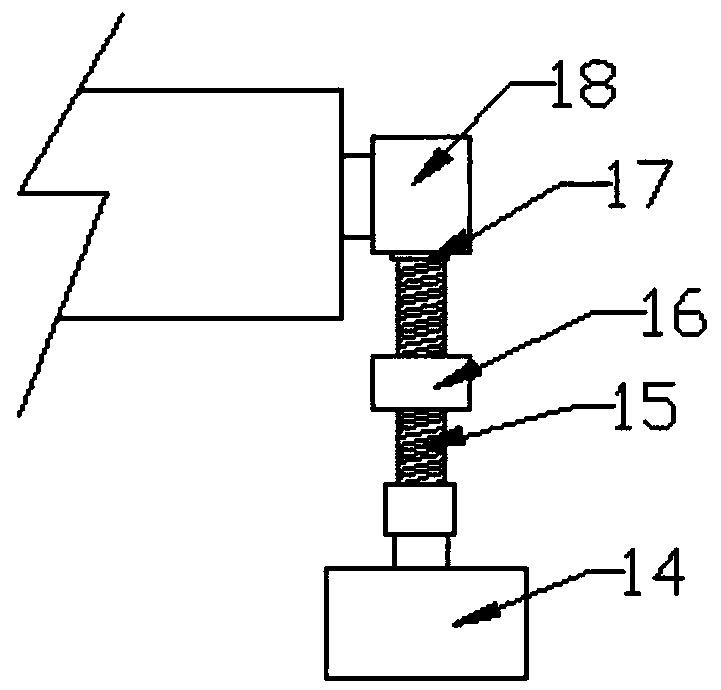

[0025] Such as figure 1 As shown, an ultra-thin electronic grade glass fiber cloth fiber opening method, the specific steps of the glass fiber cloth fiber opening method are as follows:

[0026] Step 1: Desizing the woven ultra-thin glass fiber cloth once at a high temperature, the desizing temperature is 340°-390°, the line speed is 90m / min-100m / min, and the residual amount of the size is controlled within the range of 0.15-0.2%. Expansion rollers are used for expansion before winding;

[0027] Step 2: Smolder the ultra-thin glass fiber cloth after high-temperature desizing for the second time, the smoldering temperature is 320°-360°, the residual amount of slurry is controlled within the range of 0.02-0.03%, and the smoldering time is 40 ~50 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com