Straw crushing device with combined bed knife

A crushing device and bottom knife technology, which is applied in cutting equipment, grain processing, agricultural machinery and implements, etc., can solve the problems of affecting the shearing effect, jamming between cutter heads, reducing shearing uniformity, etc., and achieve smooth crushing process , Shock vibration is small, and the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

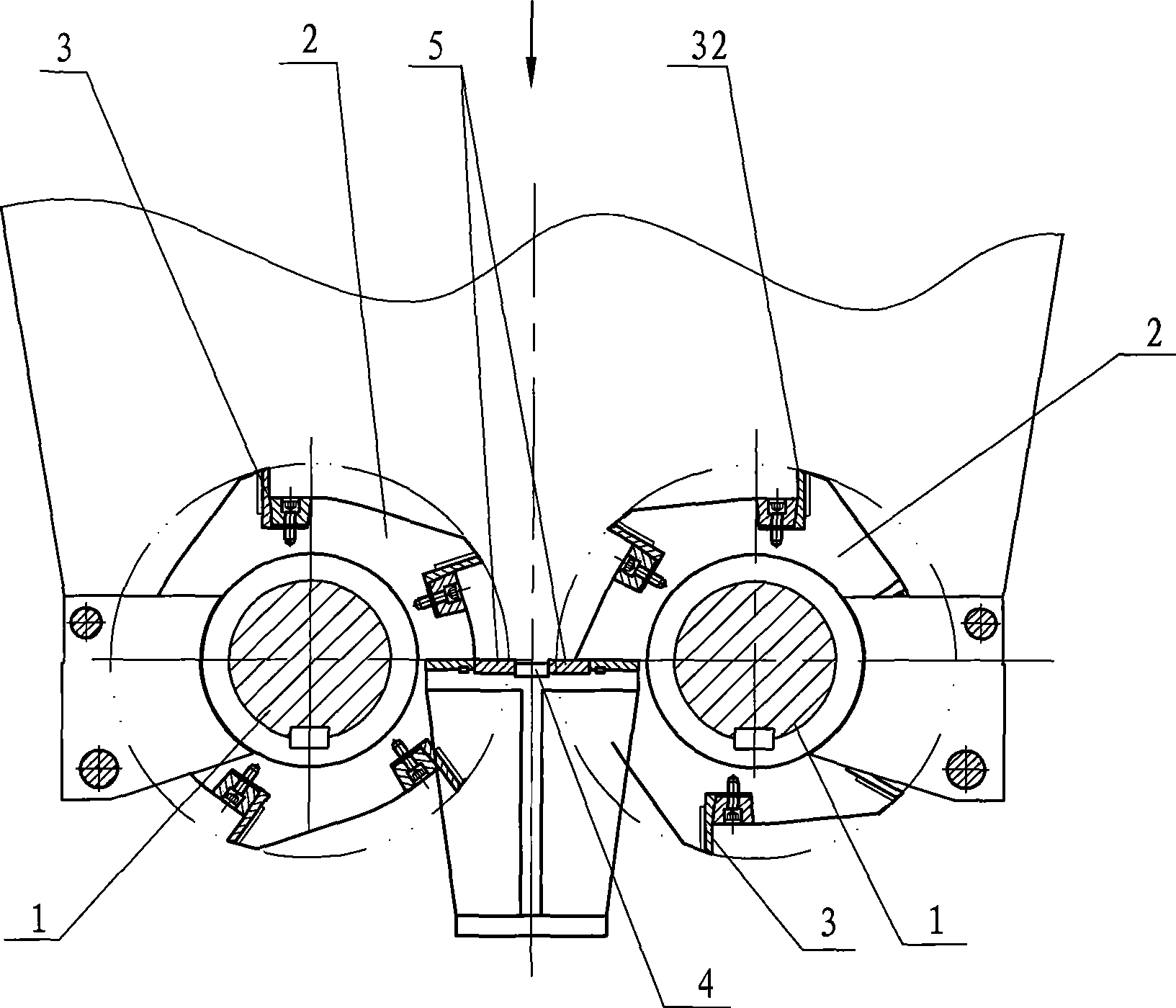

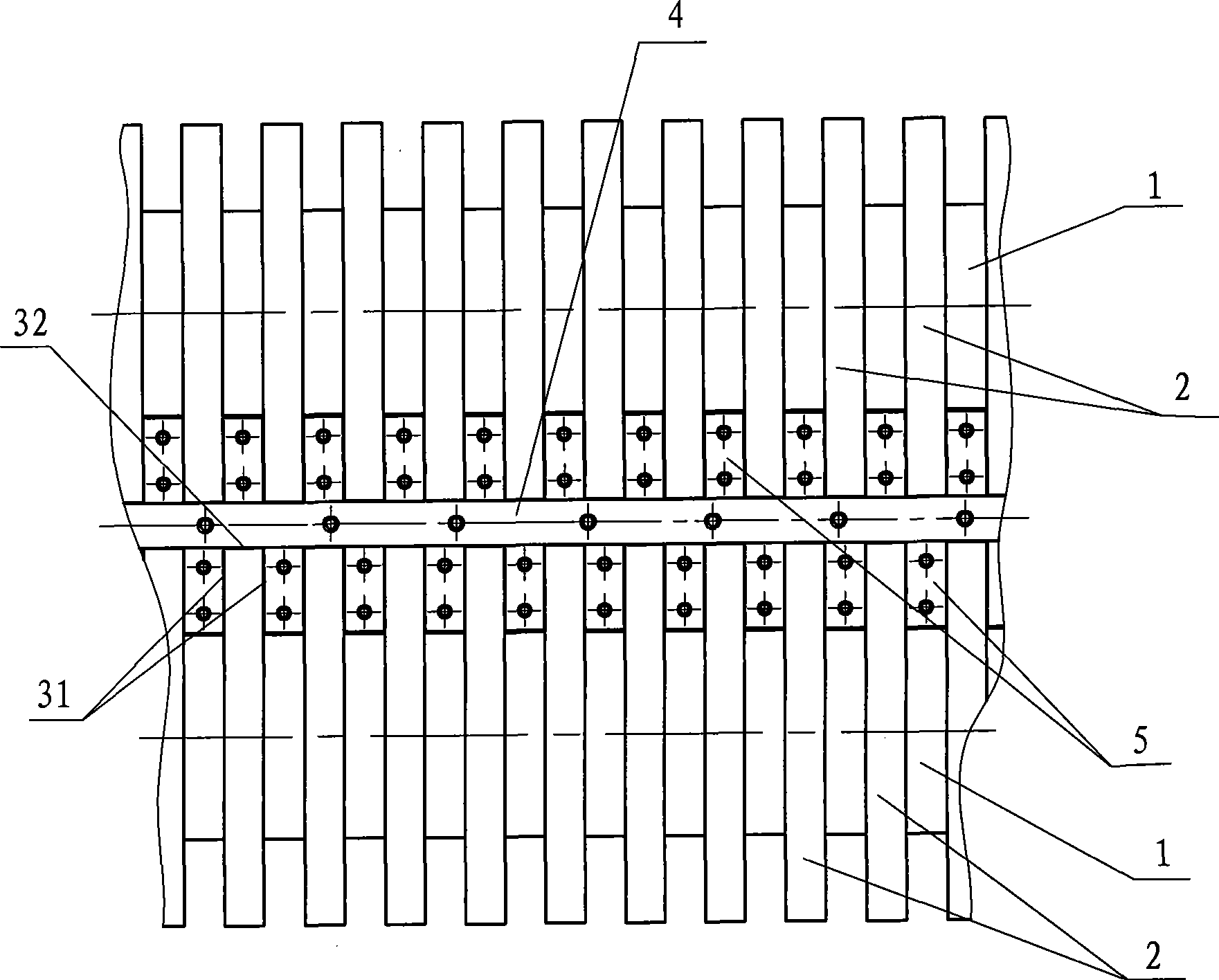

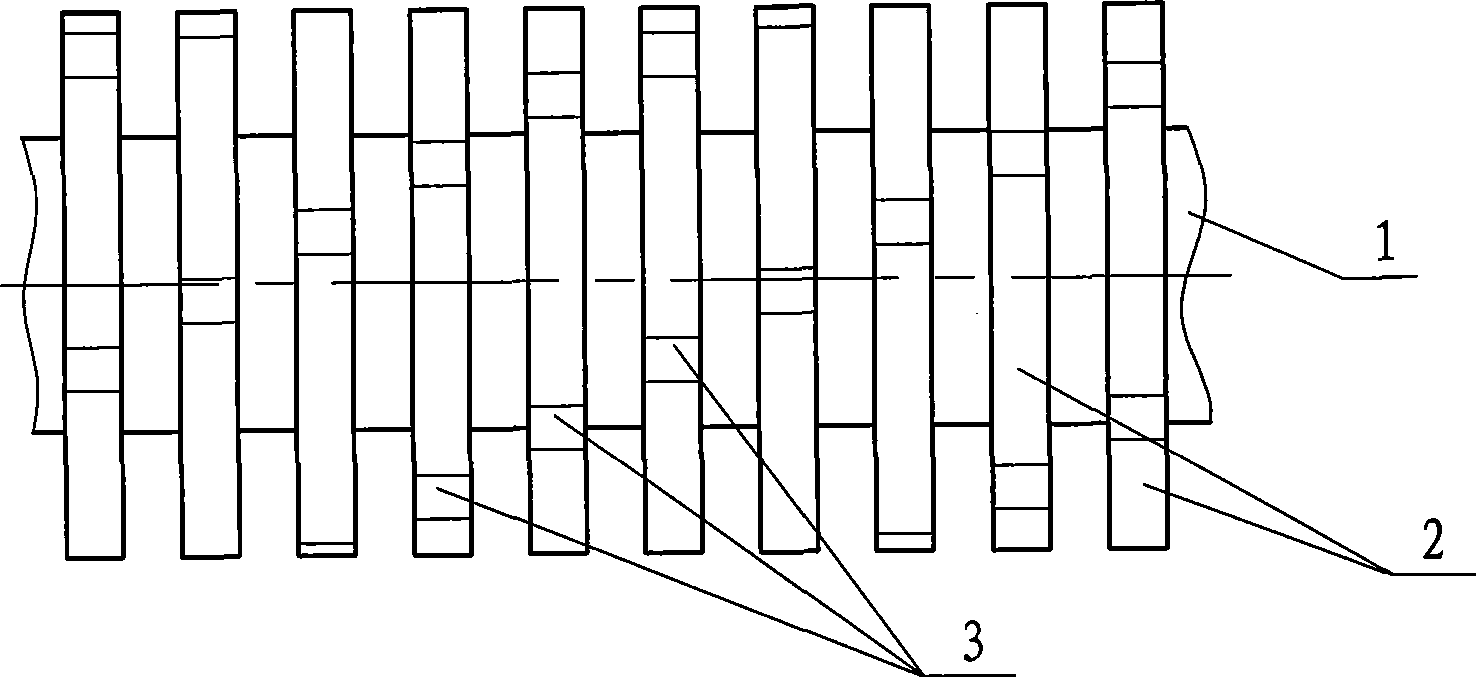

[0011] Such as figure 1 , figure 2 As shown, the embodiment of the present invention has two cutter rollers 1 arranged side by side, and a plurality of cutterheads 2 are arranged at intervals along the axial direction on the cutter rollers, and a plurality of flying blades 3 are uniformly arranged on the circumference of the cutterheads. The two side edges of the flying blade have transverse blades 31, and the radially outer edge of the flying blade has a longitudinal blade 32; a longitudinal vertical bottom knife 4 is arranged between the two knife rollers, and two sets of horizontally extending knives are arranged on both sides of the vertical bottom knife. The horizontal bottom knife 5 in the space between the discs. In the course of work, the horizontal blade 31 of the flying blade cooperates with the horizontal bottom knife 5 to effectively shear the straw fed vertically, and the vertical blade 32 of the flying blade cooperates with the vertical bottom knife 4 to effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com