Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96results about How to "Smooth and reliable action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

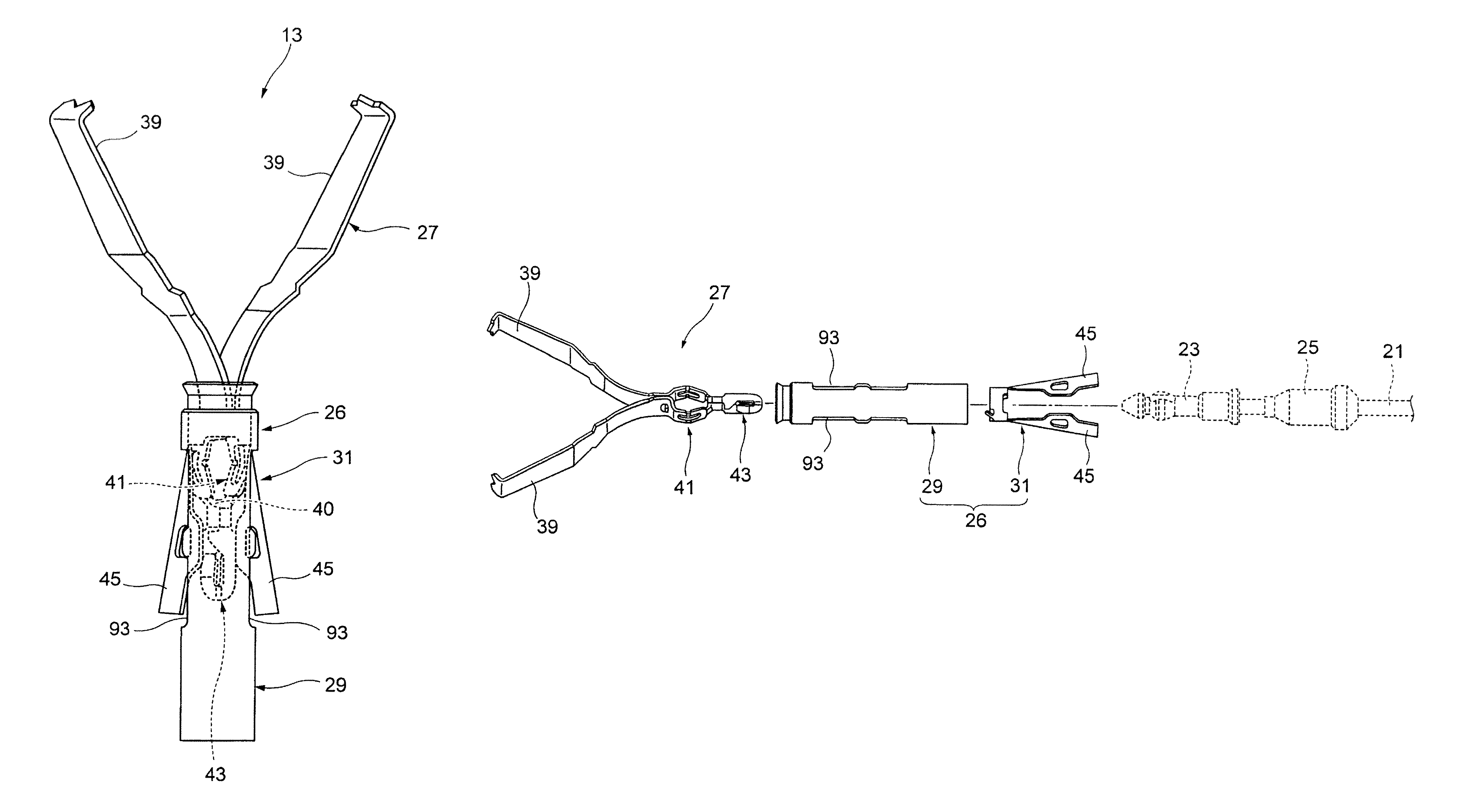

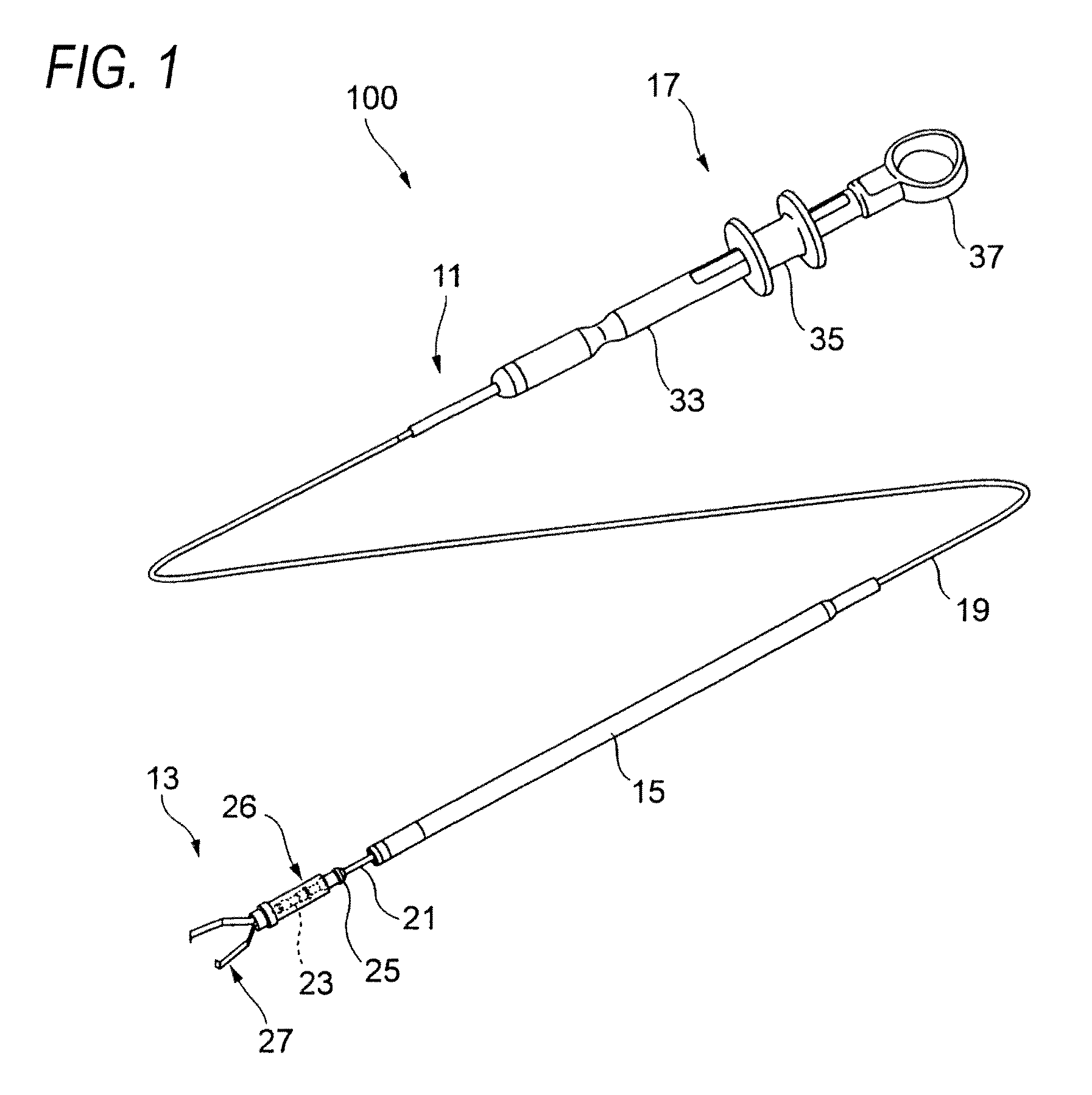

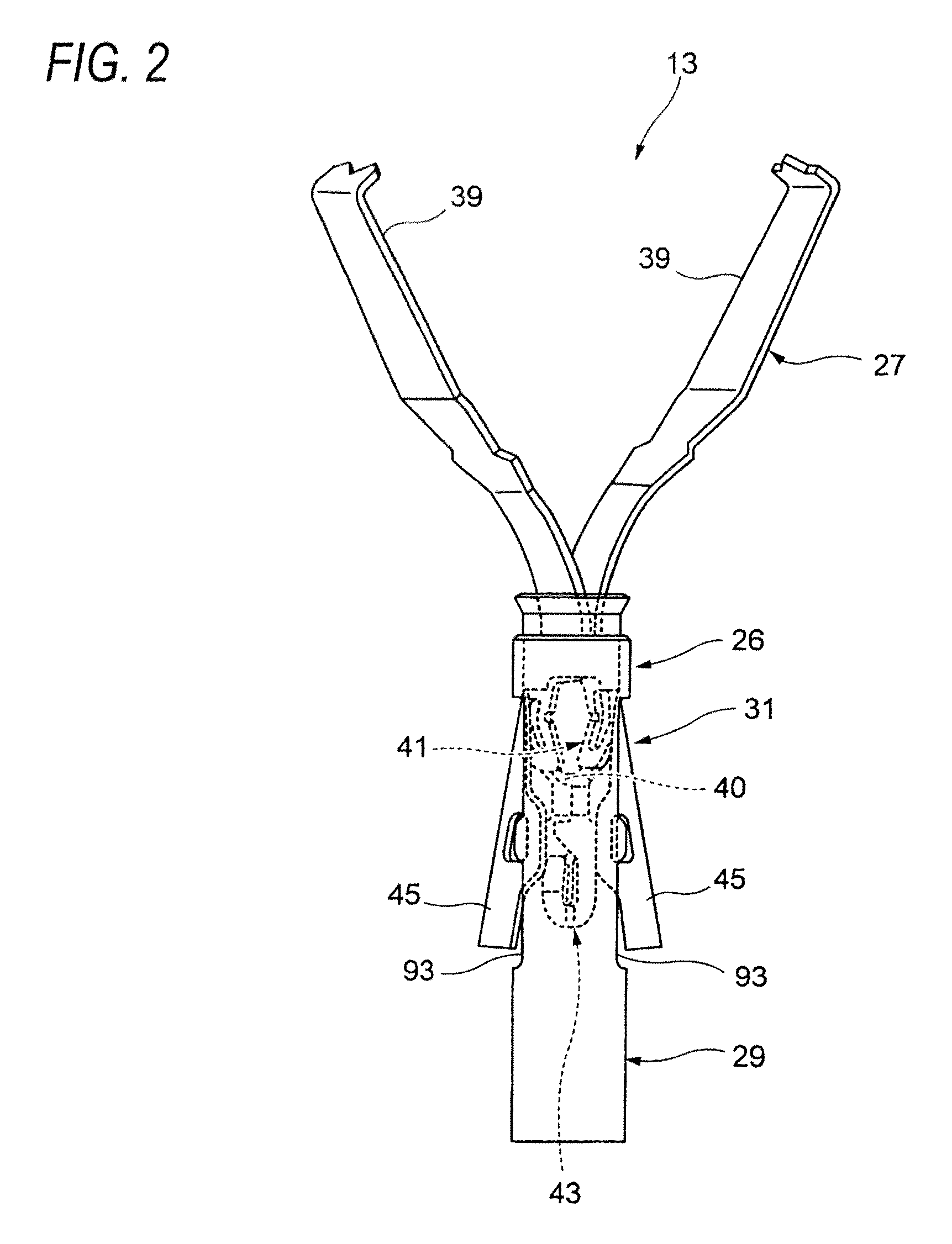

Clip unit and ligation device using the same

ActiveUS20130072945A1Smooth and reliable ligation actionSmooth and reliable actionSurgical forcepsWound clampsBiological bodyEngineering

A clip unit for ligating a biological body includes: a clip body having a pair of arm parts; and a fastening ring arranged in an outside of the clip body, and configured to fasten the arm parts, in which: the fastening ring includes a flap part configured to expand diametrically outward from the fastening ring, and a flap retaining unit configured to retaining an expansion extent of the flap part at a given extent.

Owner:FUJIFILM CORP

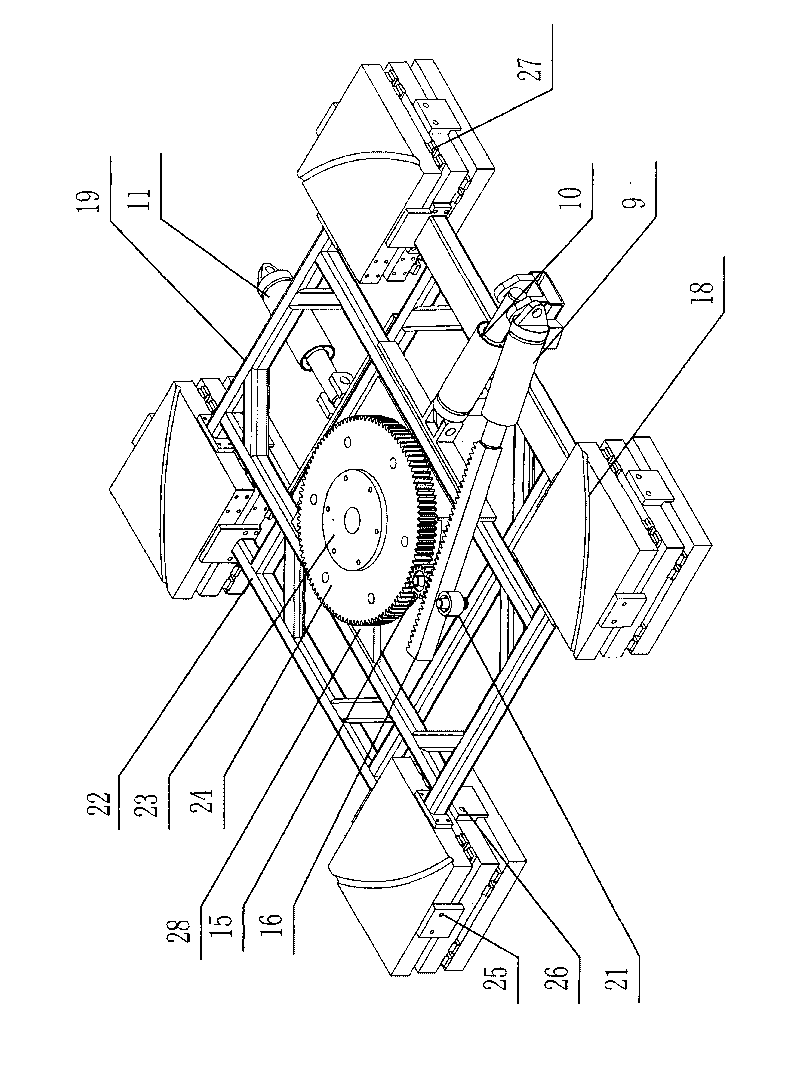

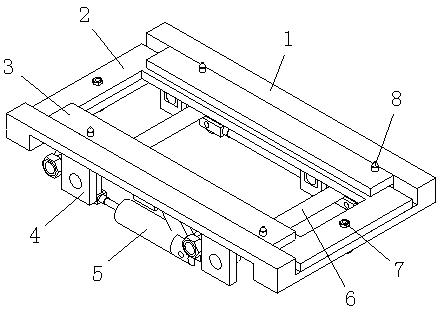

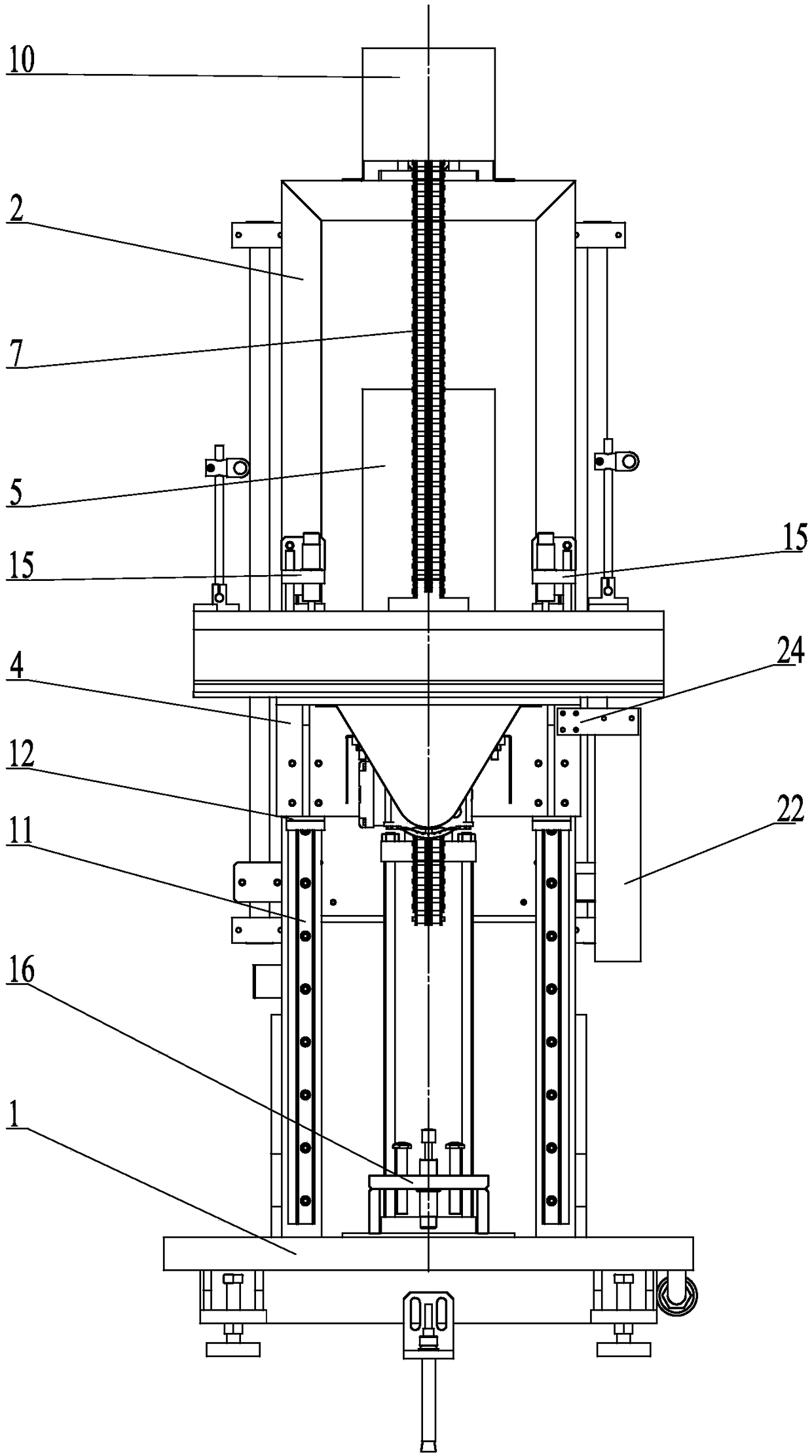

Fork hydraulic lifting platform

The invention relates to a fork hydraulic lifting platform. An upper working table is improved on the basis of the traditional fork hydraulic lifting platform and provided with an upper layer, a middle layer and a lower layer which are provided with thrust bearings and motion guide rails; the upper layer, the middle layer and the lower layer are respectively provided with a transversely-moving oil cylinder, a longitudinally-moving oil cylinder, a rotary oil cylinder, a transverse guide rail, a longitudinal guide rail, a rotary gear and a rack motioning mechanism; with a hydraulic motor as thepower source, the transversely-moving oil cylinder and the longitudinally-moving oil cylinder directly push a platform face to make transverse movement and longitudinal movement; the rotary oil cylinder utilizes the oil cylinder to drive a rack, and the engagement of the rack with a toothed disc enables the toothed disc to rotate; and a floating platform face is driven to rotate through the rotation of the toothed disc. The fork hydraulic lifting platform realizes the transverse and longitudinal+ / -50 mm movement of the floating platform face and micro adjustment of 1mm every time as well as the rotation of + / -10 degrees, has stable and reliable action, overcomes the shortcoming that the operation platform only can finish the up-down lifting in the vertical direction in the prior art, and enlarges the application range of the hydraulic lifting platform.

Owner:TAIZHOU HAILING HYDRAULIC MACHINERY

Clip unit and ligation device using the same

A clip unit for ligating a biological body includes: a clip body having a pair of arm parts; and a fastening ring arranged in an outside of the clip body, and configured to fasten the arm parts, in which: the fastening ring includes a flap part configured to expand diametrically outward from the fastening ring, and a flap retaining unit configured to retaining an expansion extent of the flap part at a given extent.

Owner:FUJIFILM CORP

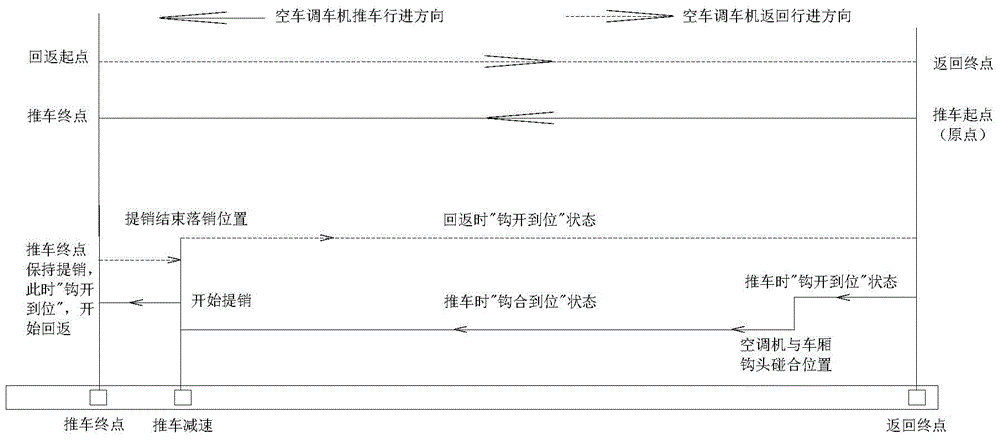

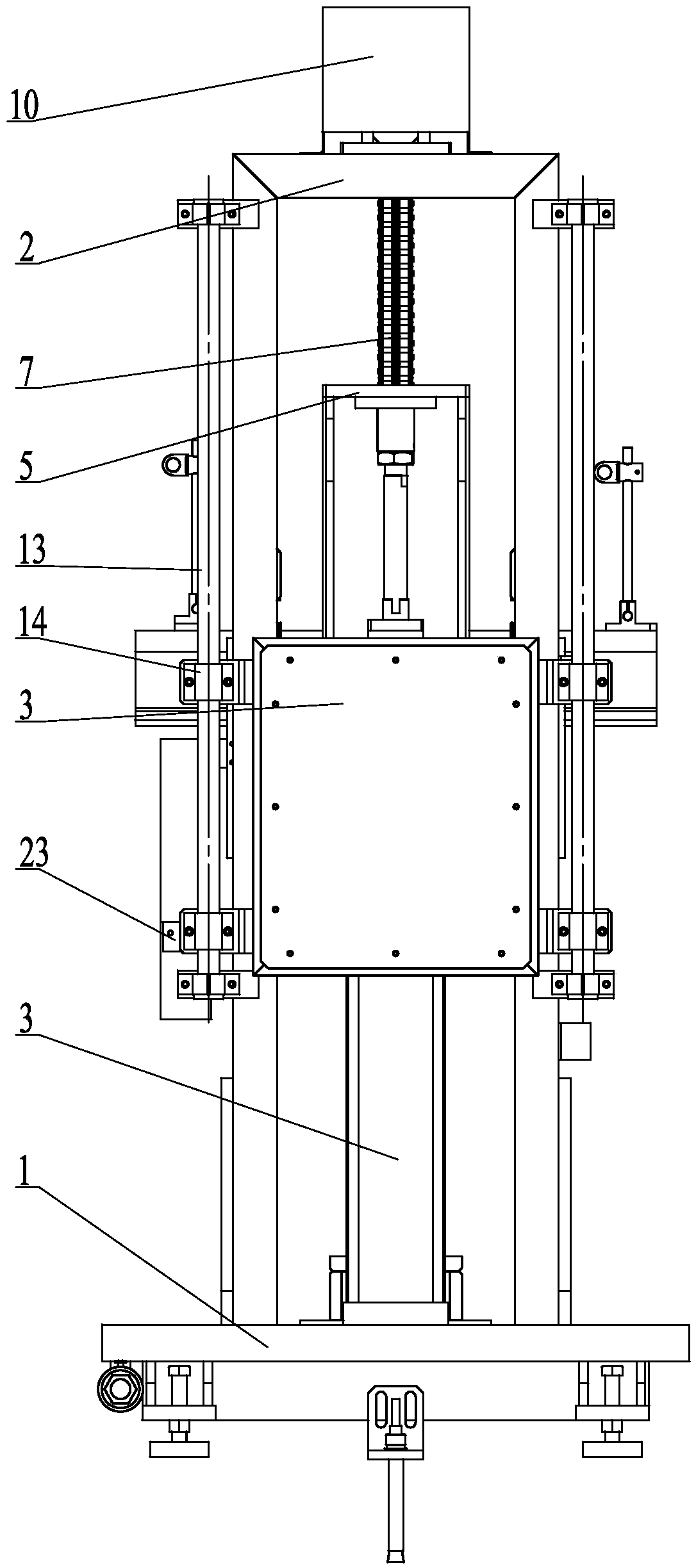

Hydraulic automatic coupler lifting device for empty car shunting machine and control method

InactiveCN104787080AImprove unloading efficiencyEasy to transformTrain hauling devicesRailway coupling accessoriesControl systemOperation safety

The invention discloses a hydraulic automatic coupler lifting device for an empty car shunting machine and a control method. The device comprises a coupler lifting control mechanism and a positioning detection mechanism, wherein the coupler lifting control mechanism is composed of a coupler lifting mechanism and a coupler lifting hydraulic control system, and the positioning detection mechanism comprises a coupler opening in-place proximity switch, a coupler closing in-place proximity switch, a coupler lifting in-place proximity switch and induction stop iron. During working, control over lifting and dropping of a car coupler is achieved through a PLC system by acquiring induction signals, under different working conditions, of a coupler opening in-place switch, a coupler closing in-place switch, a coupler lifting in-place switch, a car pushing starting point switch, a car pushing speed reduction position switch and a car pushing terminal point switch of an empty car shunting machine hook head, and automatic and steady coupler touching and removal of the empty car shunting machine are achieved. The problem of direct collision between the empty car shunting machine hook head and a compartment is solved, and operation safety is improved. The reliability of equipment is ensured, and the damage rate of equipment is reduced.

Owner:DATANG TAIYUAN CO GENERATION POWER PLANT

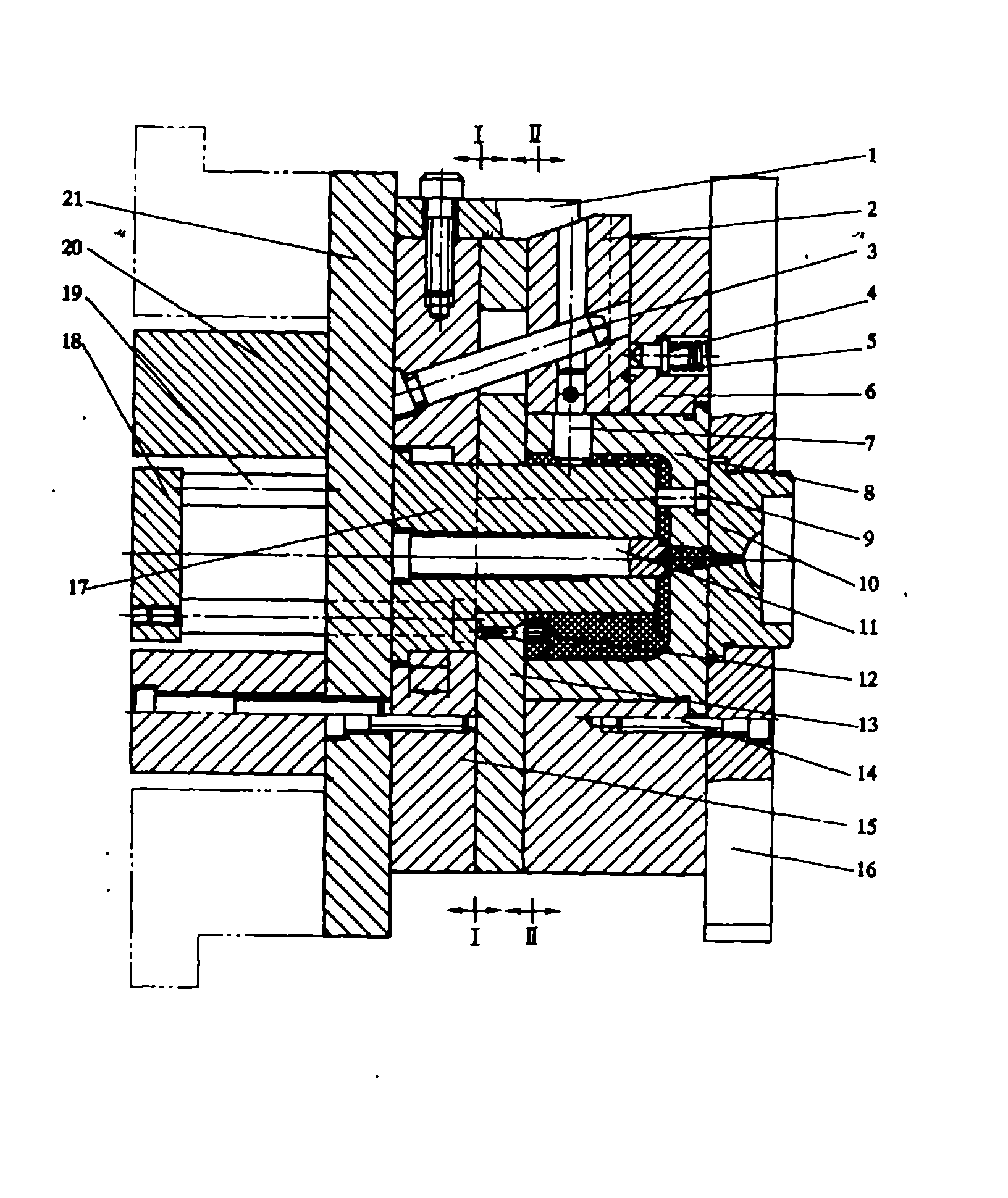

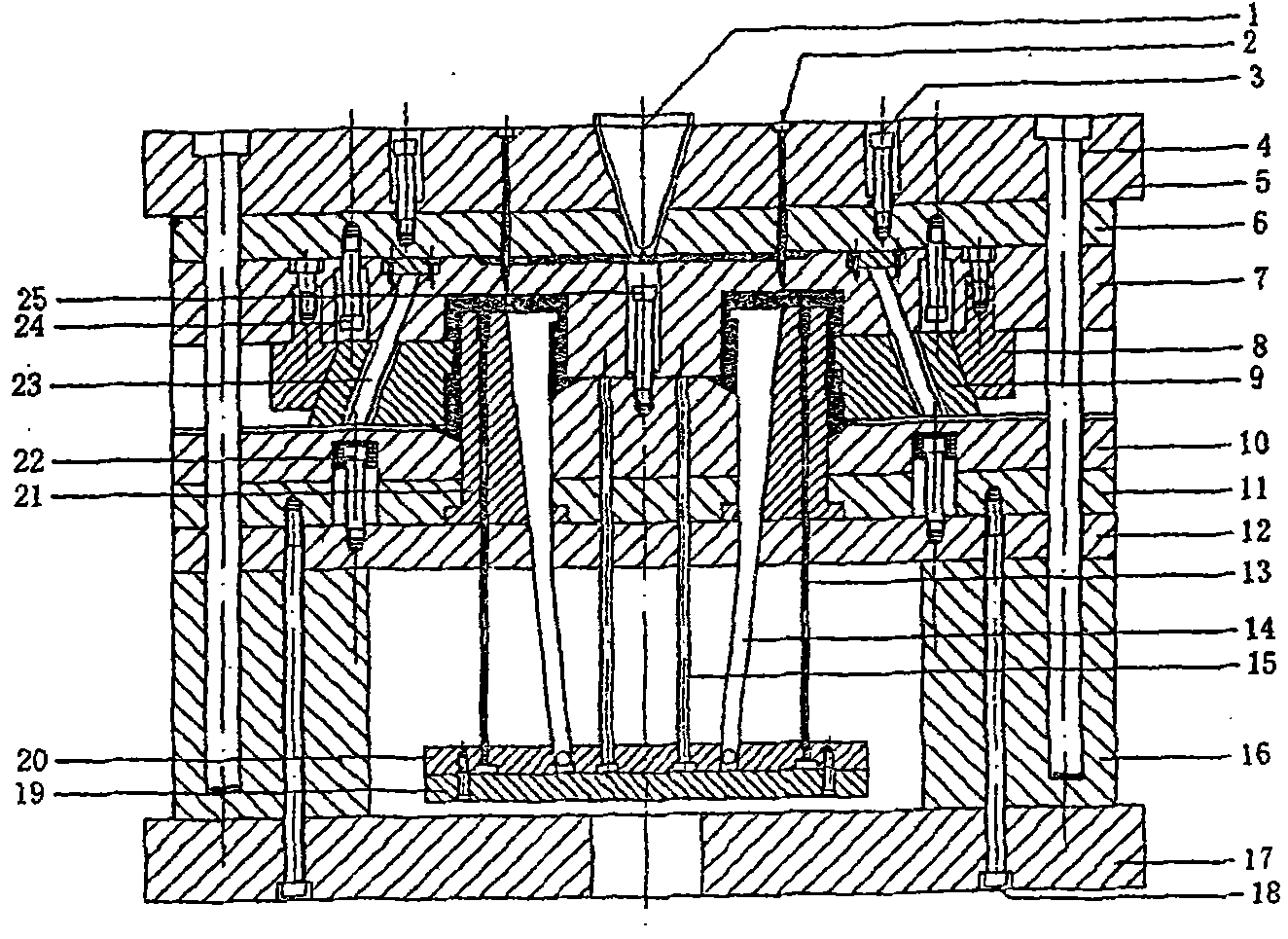

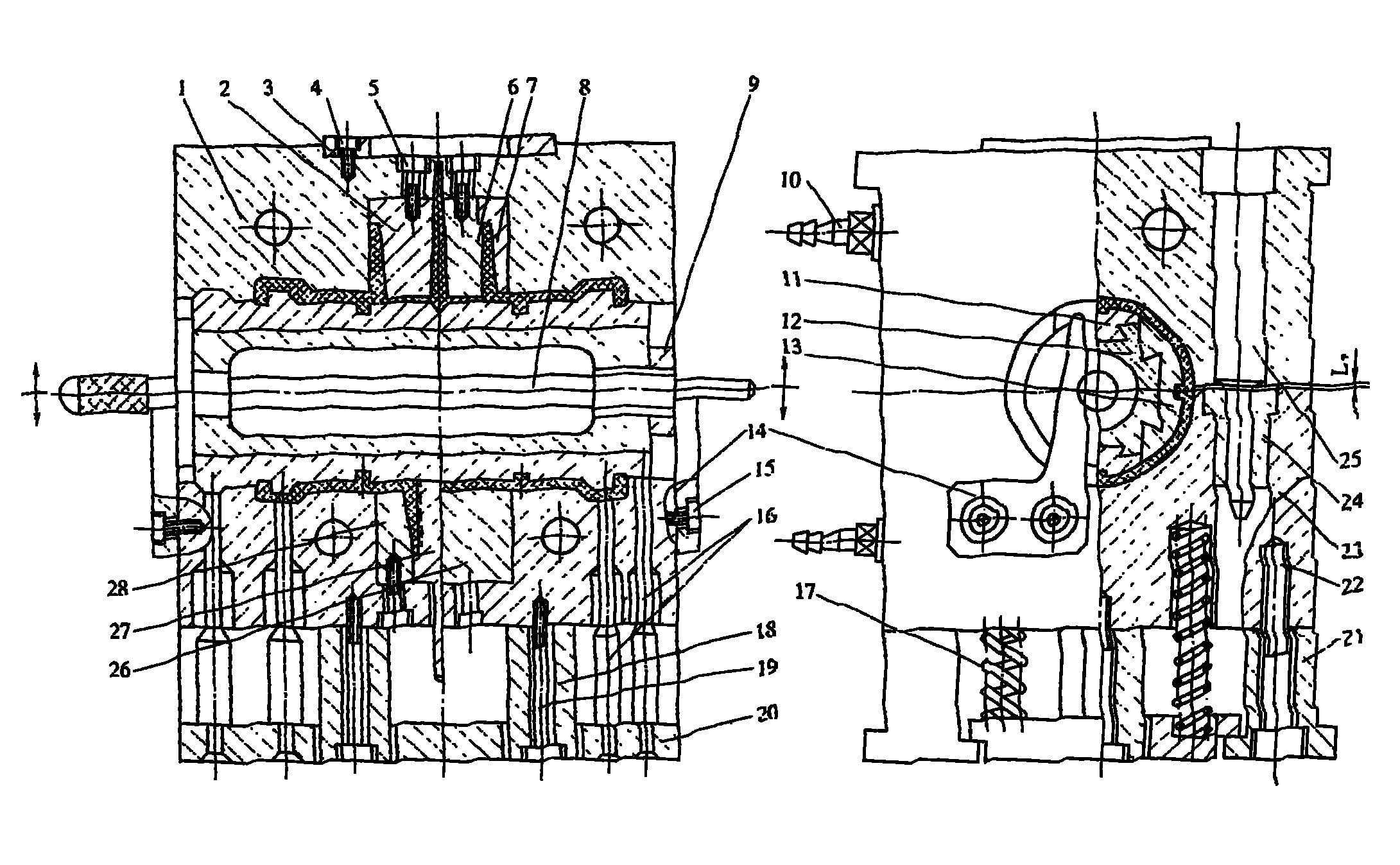

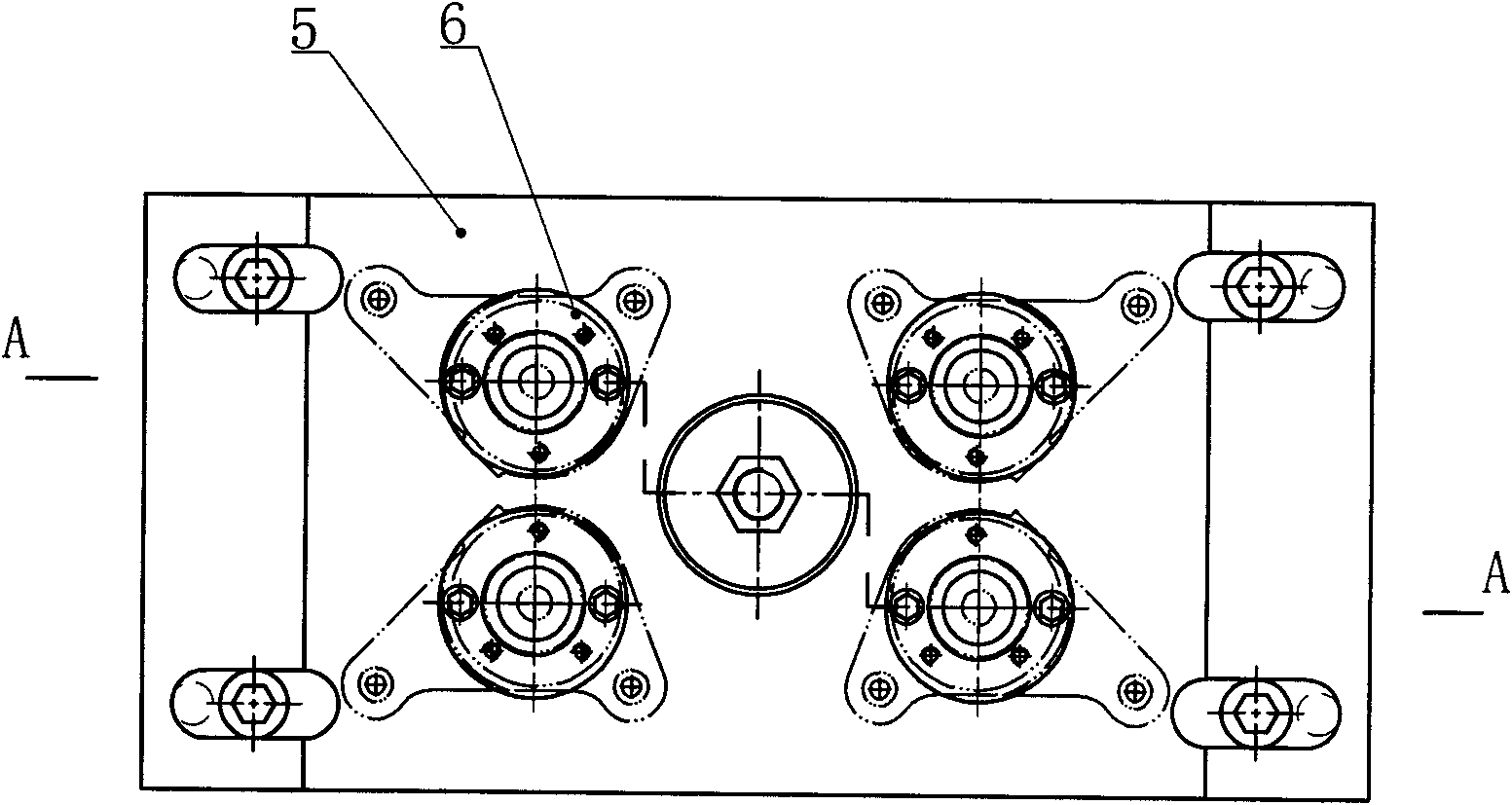

Mold mechanism using inclined guide pillar and sliding block for secondary pushing out

The invention discloses a mold mechanism using an inclined guide pillar and a sliding block for secondary pushing out. The mold mechanism comprises mechanisms of a push rod fixing plate, the sliding block, the inclined guide pillar, a movable mold supporting plate, a spring, a center push rod, a mold core, a movable mold cavity plate, a push rod, a movable mold base plate, a fixed mold plate, a pouring gate bush and the like. The connection mode of the mold mechanism is that: the push rod fixing plate 1 is in clearance fit with the push rod 9; the push rod 9 is in clearance fit with the movable mold supporting plate 4 and is in slide fit with a mold core fixing plate; and then the push rod 9 is tightly connected with the movable mold cavity plate 8 by using screws. The sliding block 2 is in slide fit with the push rod fixing plate 1. The inclined guide pillar 3 is tightly fixed in an inclined hole of the movable mold supporting plate 4 and is in clearance fit with an inclined hole on the sliding block 2. The center push rod 6 is in clearance slide fit with the mold core, and the tail end is in slope movement with the sliding block 2. The mold core 7 is in clearance slide fit with the movable mold cavity plate 8, and the spring 5 is fixed in inner holes of the mold core 7 and the movable mold supporting plate 4. The mold mechanism is very reliable in motion, is simple in mold structure, and is suitable for molding injection molds and metal die-casting molds.

Owner:牟维军

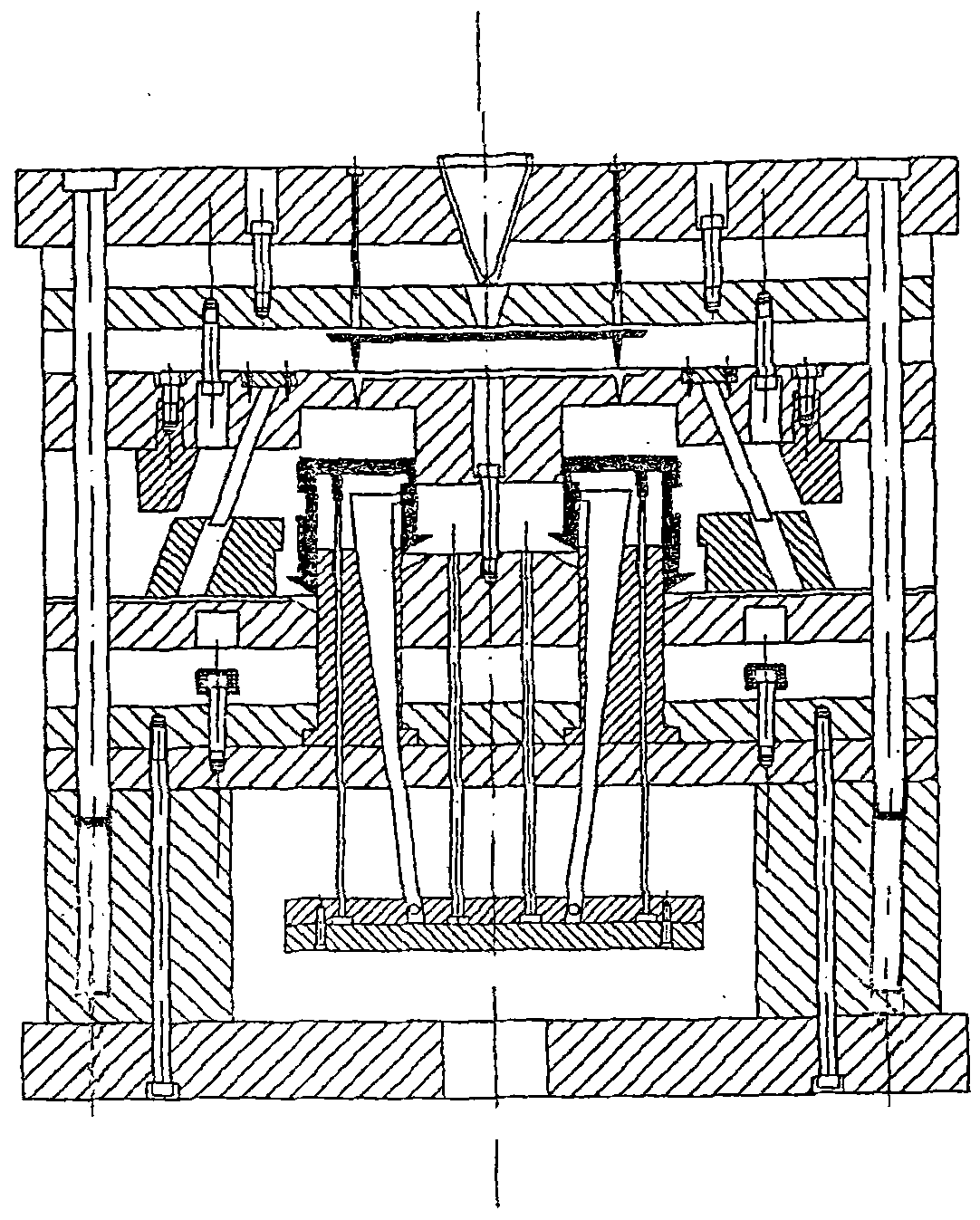

Mechanism with side mold core and sliding seat installed in fixing die and angle pin installed in moving die

The invention relates to a die mechanism with a side mold core and a sliding seat installed in a fixing die and an angle pin installed in a moving die. The die mechanism comprises the parts, such as a bolt, a guide post, a mold core, a mold insert, a supporting plate, a supporting block, a connecting push rod, a push plate, a main mold core, a fixing mold seat plate, a moving die plate, a locating screw rod, a mold core, a sprue bush, a concave die, the side mold core, a fixing die fixing plate, a spring locating pin, the angle pin, the sliding seat, a locking wedge, and the like showing the connecting mode in attached drawings of the specification). Two horizontal parting surfaces are designed for a die, wherein one parting surface is used for withdrawing a side loose core, and the other parting surface is used for taking out a product. The side mold core and the sliding seat are installed in the direction of the fixing die, and the angle pin is installed on one side of the moving die. Meanwhile, the main mold core is designed for the die to do delay action, thereby ensuring that the product is separated without remaining in the fixing die.

Owner:牟维军

Automatic outer packing removing mechanism of bagged powder

PendingCN109835560ARealize centralized deliveryReduce labor intensityArticle unpackingEngineeringOverwrap

The invention relates to an automatic outer packing removing mechanism of bagged powder. The automatic outer packing removing mechanism of the bagged powder includes an outer packing supporting platform, and outer packing supporting platform is used for conveying material bags; the critical point lies in the fact that a clamping turn-over mechanism and a bag sucking and bag cutting mechanism are arranged on the upper part of the outer packing supporting platform, the bag sucking and bag cutting mechanism comprises a turntable rotatably limited on a machine frame and a lifting sucking disc arranged on the turntable, a sliding cutter is arranged at the bottom of the sucking disc, inner air hole groups and outer air hole groups are arranged in the bottom of the sucking disc, and the inner airhole groups and the outer air hole groups are correspondingly arranged on the two sides of the sliding cutter and correspondingly connected with respective vacuum generators; and by cutting outer packing bags with the help of the cutter, the inner air hole groups and the outer air hole groups cooperate with each other in an on-off mode to form a single-sided bag-pulling and bag-throwing structure, and with the help of turning over of the clamping turn-over mechanism, a removing structure is formed for the remaining outer packing bags. According to the automatic outer packing removing mechanism of the bagged powder, the outer packing bags are cut and removed by the bag sucking and bag cutting mechanism, the packing bags are turned by the clamping turn-over mechanism, so that the outer packing bags can be automatically removed, the time and the labor are saved, and the work efficiency is high.

Owner:石家庄燕科生物科技有限公司

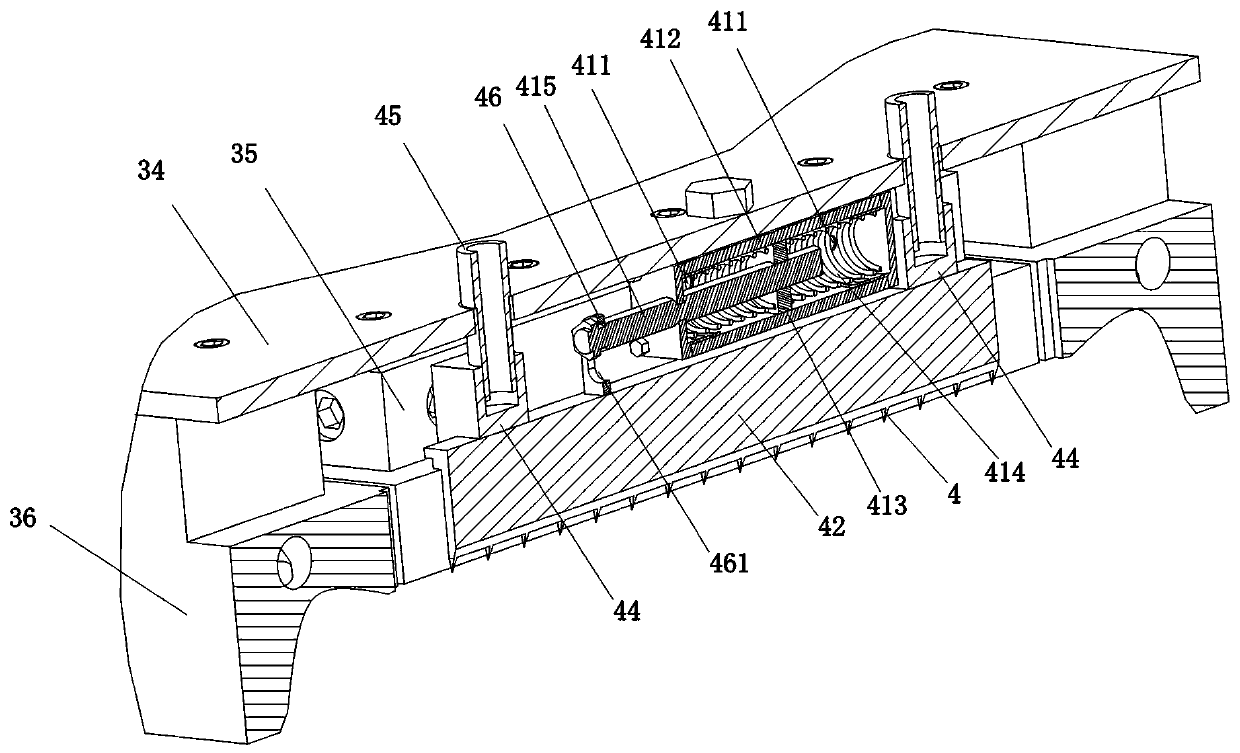

Draw hook-type two-stage ejection die mechanism

InactiveCN102019397ASmooth and reliable actionGood pressure transferEngineeringMechanical engineering

A draw hook-type two-stage ejection die mechanism comprises a support plate, screws, an extension spring, a draw hook, cylindrical pins, wedges, a sprue bush, a guide pillar, a guide sleeve, a core, a push rod, a reset rod, a cushion block, a backing plate, a moving template, stop nails, stop pins, a one-stage spread plate, a fixed plate, a two-stage push plate, a support plate, push blocks, an ejector sleeve, a fixed template, a female die, etc. (the connection mode is shown in specification figures). The mechanism utilizes the draw hook to perform the die opening for a certain distance and then to grab a push plate, realizing the first pushing. The second pushing is completed by a partial movable die ejecting mechanism. Meanwhile, when the first pushing is performed, the deformation and the damage of products are effectively prevented by employing the mechanism. The ejection force can be dispersed by the mechanism, and the products can be demoulded successfully. The mechanism is characterized in that the pressure force transmission is fine, the motion is very safe, and maintenance and regulation is very convenient.

Owner:牟维军

Mold mechanism realizing inner core extraction by oblique ejectors and outer core extraction by outer sliding blocks

The invention discloses a mold mechanism realizing inner core extraction by oblique ejectors and outer core extraction by outer sliding blocks. The mold mechanism comprises a sprue bush, sprue pullers, bolts, a fixed mold base plate, a movable mold base plate, the outer sliding blocks, the oblique ejectors, ejector pins, a guide pillar, support plates, a fixed mold plate, a movable mold plate, a mold core and oblique press blocks. The outer sliding blocks installed on the outer side of the mold mechanism realize outer core extraction. The oblique ejectors installed in the mold mechanism carry out oblique sliding thereby finishing inner core extraction. The mold mechanism realizes firm and reliable operation, has good pressure transmission, is greatly simplified, is convenient for manufacture, installation, adjustment and maintenance, reduces a production cost, and is safe and environmentally friendly.

Owner:牟维军

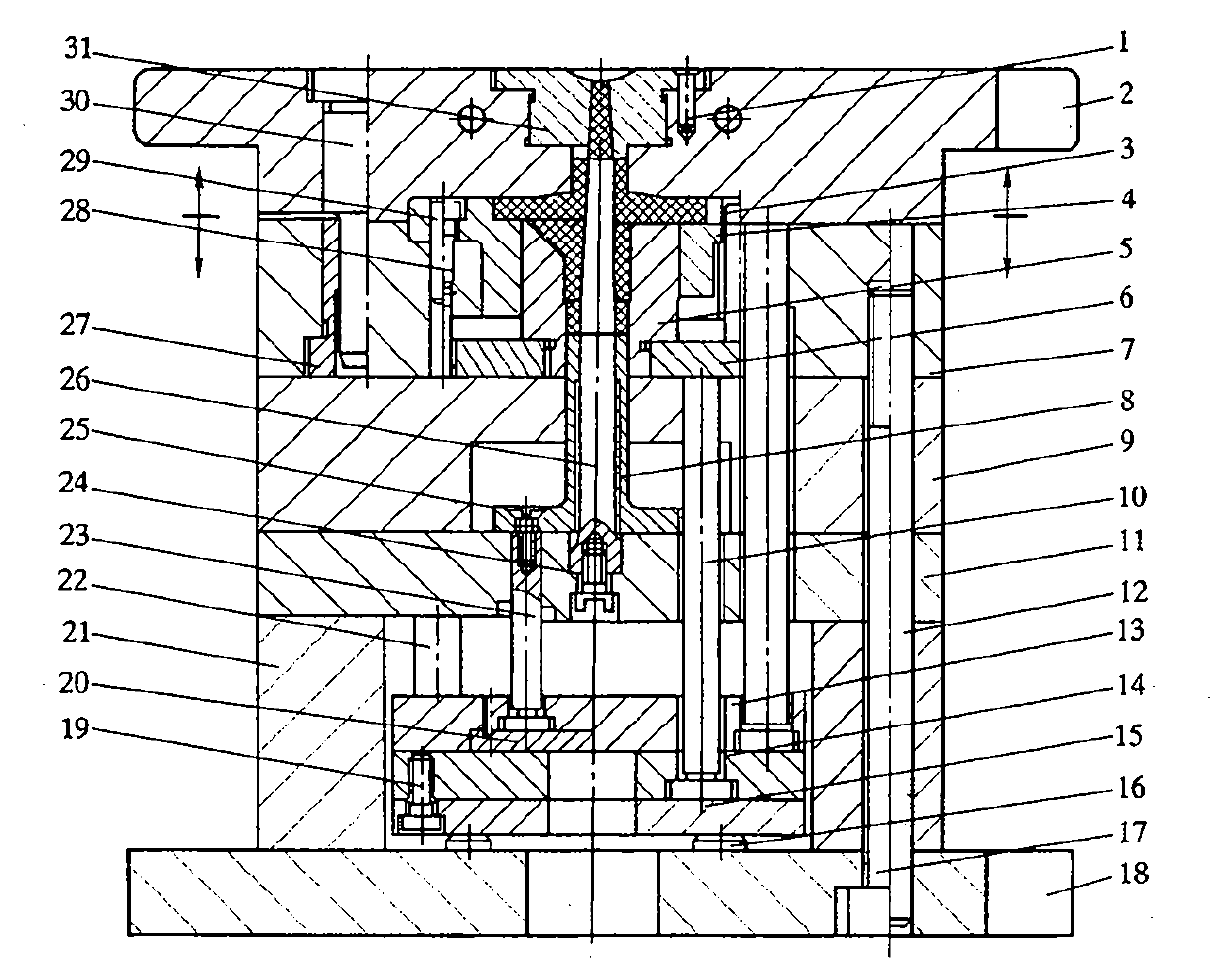

Metal die-casting die capable of internally and automatically cutting off sprue

The invention discloses a metal die-casting die capable of internally and automatically cutting off a sprue. The die is composed of a fixed clamping plate, a moving clamping plate, a stripper plate, a pull needle, pull rods, a guide column, a resin die opener, a sliding block and a pressing block. The first pull rod (7), the second pull rod (6), the resin die opener (18) and the pull needle (21) are communicated to form an automatic cut-off mechanism of a die gating system. The pull needle (21) and the stripper plate form a gating system freezing material disengagement device. A first ejector pin (15), a second ejector pin (33), a rack core (32), an ejector pin plate and an ejector pin fixing plate are communicated to form a die ejecting mechanism. An inclined guide column (26), an inclined pressing block (27), a sliding block (30) and a first spring (31) are communicated to form a die side face core-pulling mechanism. According to the metal die-casting die, the action is firm and reliable, pressure transfer is good, the automatic sprue shearing efficiency of the die is high, and by means of optimized module design, the structure is compact, and manufacturing, installation, debugging and maintenance are convenient.

Owner:牟维军

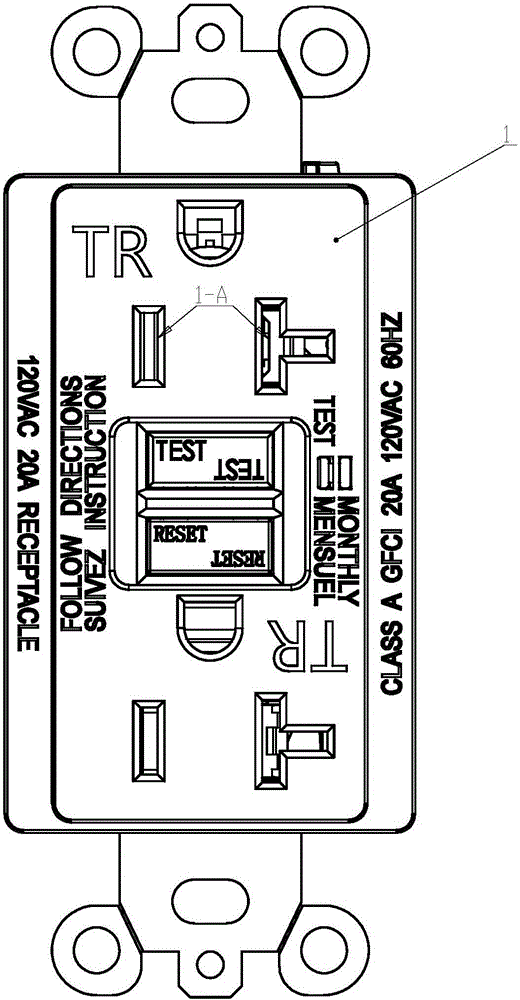

Electric leakage protection socket with function of reverse wiring protection

ActiveCN106252964AReasonable structureIngenious and reasonable structureProtective switch detailsTwo pole connectionsEngineeringMechanical engineering

The invention provides an electric leakage protection socket with a function of reverse wiring protection, and the socket comprises a main loop switch and an electromagnetic release mechanism, and also comprises a lifting part. Two sides of the lifting part are respectively provided with a metal rod in a sleeving manner. The lower end of the metal rod is sleeved by a reset spring, and the upper end of the metal rod is in contact connection with a movable metal piece. The reset spring of a zero line metal rod and a static metal piece form a reverse wiring loop switch. The lifting part is cooperatively provided with a locking part, and the head of the locking part abuts against a side wall of the lifting part. The electromagnetic release mechanism comprises an iron core, and the iron core is provided with a driving disc. During reverse wiring, the iron core pulls the lifting part downwards, and the head of the locking part covers the top of the lifting part under the action of an elastic resetting mechanism. The beneficial effects of the invention are that a main loop switching mechanism is reasonable and ingenious in structure, and is quick in response; during reverse wiring, the lifting part is driven by the iron core to sinks for automatic releasing; moreover, the locking part automatically locks the lifting part; the reset button cannot achieve the resetting; the socket is safe for use.

Owner:黄金和

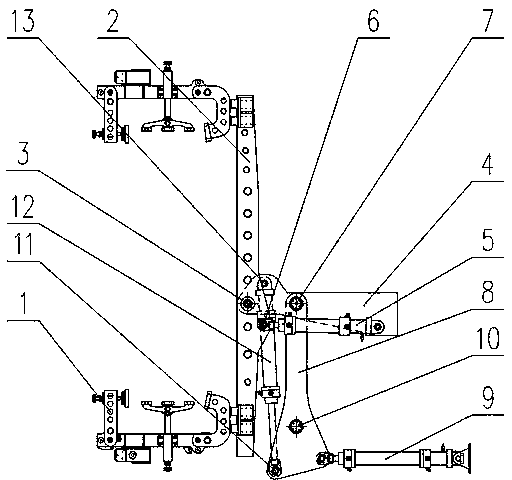

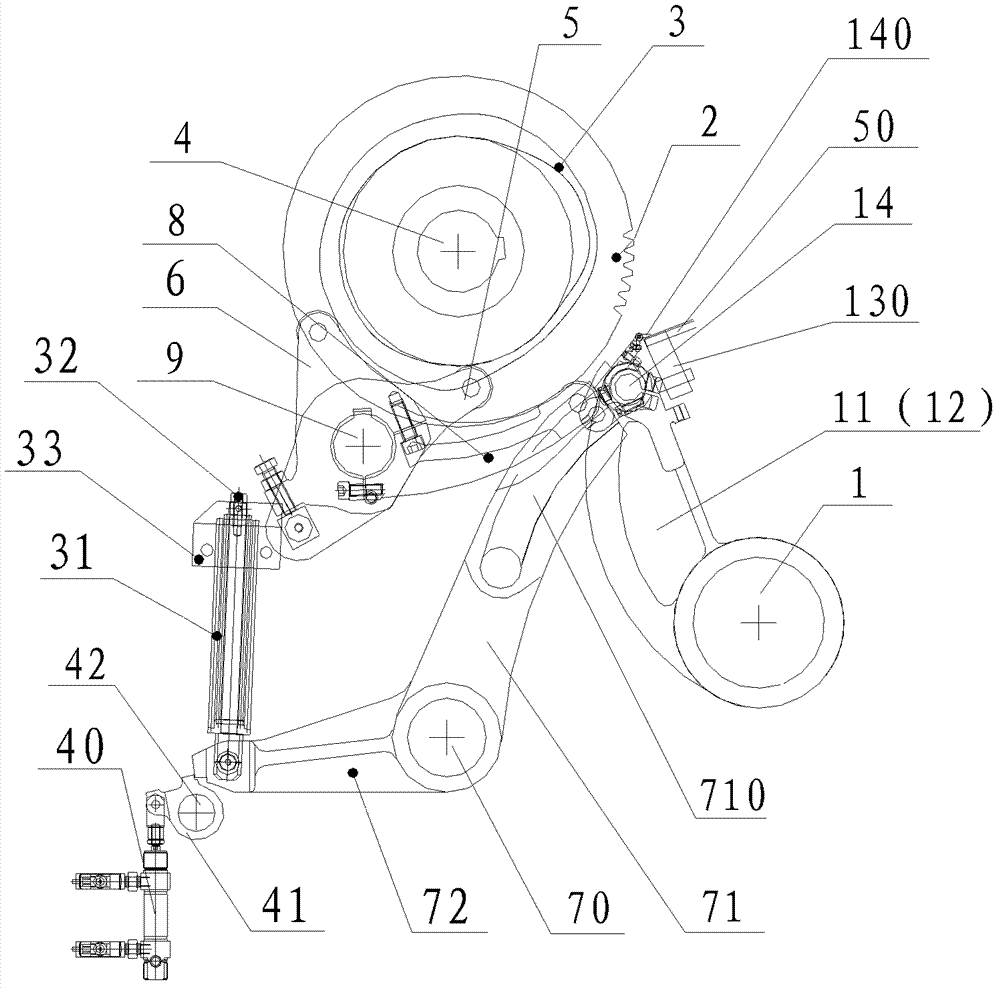

Three-axis automatic carrying robot

ActiveCN104162886AQuick flipImprove accuracyProgramme-controlled manipulatorHydraulic cylinderEngineering

The invention discloses a three-axis automatic carrying robot. The robot comprises a swinging arm with clamps, and the three-axis automatic carrying robot is characterized in that the swinging arm is hinged to a first supporting arm through a first rotating shaft. A first hydraulic cylinder is hinged to one end, away from the first rotating shaft, of the first supporting arm, the working end of the first hydraulic cylinder and the swinging arm are hinged through a second rotating shaft, a second supporting arm is hinged to the first supporting arm through a third rotating shaft, and the lower end of the second supporting arm is hinged to the working end of a turnover hydraulic cylinder. A turnover hydraulic cylinder body is hinged to a fixed foundation, the middle of the second supporting arm is further hinged to the fixed foundation through a master rotating shaft, the lower end of the second supporting arm is further hinged to the working end of a second hydraulic cylinder through a fourth rotating shaft, and a second hydraulic cylinder body is hinged to the first supporting arm through a fifth rotating shaft.

Owner:大连四达高技术发展有限公司

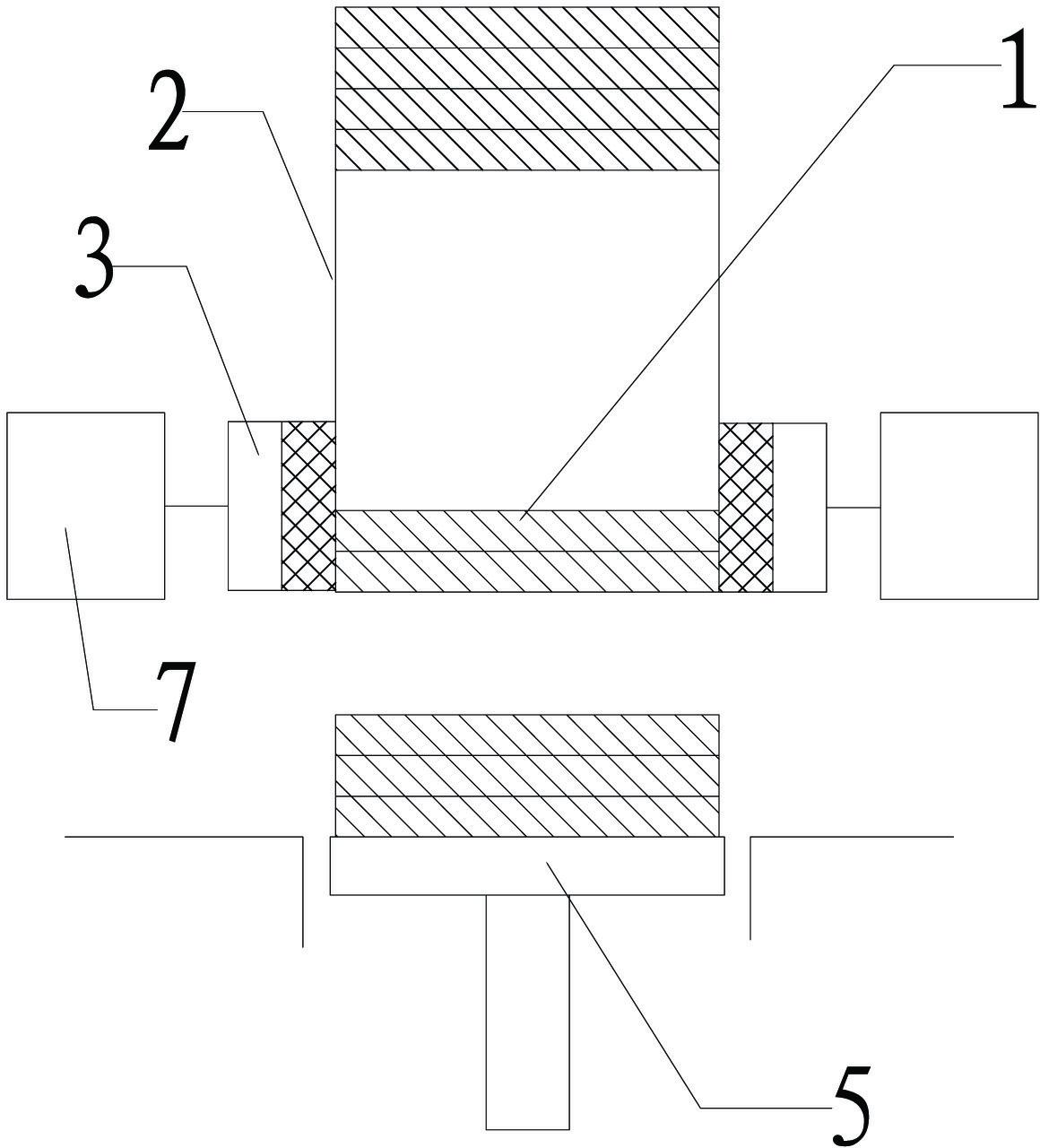

Pin hole locking device for preventing vehicle body from falling off

InactiveCN102431779AHigh positioning accuracySmooth and reliable actionMechanical conveyorsEngineeringMechanical engineering

The invention discloses a pin hole locking device for preventing a vehicle body from falling off, which is used for solving the problems of poor fixing reliability of the vehicle body and easiness in scratching the surface of the vehicle body existing in the conventional device. The pin hole locking device comprises a hanger arm (11) and a base (1), wherein the end part of the hanger arm (11) below a pin hole (14) of the vehicle body (13) is provided with a locking shaft installation seat (10) and a locking shaft (9); the top end of the locking shaft (9) is provided with an eccentric locking cap (12); the eccentric locking cap (12) is movably arranged in the pin hole (14); the base (1) is provided with a linear slide rail (2), an L-shaped slide block (3) and a rotary motor (4); an output shaft (6) of the rotary motor (4) is connected with one end of a shifting block (7); the side face of the other end of the shifting block (7) is provided with an inverted-L-shaped shifting rod (8); and the upper end of the inverted-L-shaped shifting rod (8) is fixedly connected with the bottom end of the locking shaft (9). The pin hole locking device has high positioning precision, and can adapt to the requirement on automatic production operation.

Owner:SHANXI ORIENTAL MATERIAL HANDLING

Molding die for telescoping pipe composite structure

The invention relates to a set of molding die for a telescoping pipe composite structure. The molding die comprises an insert ring, a silk core, an end cap, a guide post, a guide sleeve, a movable die block, screws, a movable die seat block, a roof plate, a support column, a spring, an ejector rod, a supporting plate, a big slice block, a major slice block, a small slice block, a water faucet, fastening nuts, a core rod, a 3' insert ring, a 3' core, a positioning ring, a mold core, a fixed die plate, and the like. The connection mode is shown in the attached drawing of the specification. The die for the structure is quite practical, and can be used for manufacturing plastic pipes and die casting pipes of various specifications. By changing parts, molded pipes of dozens of specifications such as direct connection, diameter change connection, diameter change cross tee and diameter change five-way connection can be produced. Therefore, the multiple purposes of the die are fulfilled and the economic benefit is improved.

Owner:牟维军

Pneumatic fixture

InactiveCN101786248AAchieve clampingAchieve relaxationPositioning apparatusMetal-working holdersEngineeringBlind hole

The invention relates to a pneumatic fixture, which consists of support legs, a base plate, a main body, positioning sleeves, a pneumatic fastening device and an air cylinder, wherein the support legs are fixedly arranged under the base plate; the main body is horizontally and fixedly arranged on the upper surface of the base plate; the middle part of the main body is provided with the pneumatic fastening device; the air cylinder is fixedly arranged under the base plate; the main body on the periphery of the pneumatic fastening device is inlaid with a group of positioning sleeve; the pneumatic fastening device consists of a cone-shaped sleeve, wedges and return springs, wherein the cone-shaped sleeve is movably arranged on the middle part of the base plate in a longitudinally inversed way, and is coaxially fixed with an air cylinder push rod; the wedge is inlaid between the cone-shaped sleeve and each positioning sleeve, the inclined plane of the wedge is in sliding fit with the cone-shaped sleeve, and the right angle face of the wedge is inlaid in the radial slot formed by each positioning sleeve; one end on which each wedge is inlaid into the positioning sleeve is machined with a radial blind hole; and the blind hole is provided with the return spring. The invention is applicable to the positioning and fastening of the part with more working procedures, higher precision and larger batch, and has the advantages of simple operation, high efficiency and stable and reliable running.

Owner:天津市中马骏腾精密机械制造有限公司

Plate grid ejection mechanism of lead-acid battery plate grid die casting machine

The invention discloses a plate grid ejection mechanism of a lead-acid battery plate grid die casting machine, and the mechanism comprises a fixed framework and a movable framework, wherein two working shafts which are parallel mutually and are arranged at an interval and a driving device for driving the working shafts to rotate are arranged on the fixed framework; and the movable framework is supported on an eccentric mechanism arranged on the two working shafts and can rotate in a reciprocating manner along with the two working shafts under the drive of the driving device, and the eccentricmechanism on the working shafts is used for pushing the movable framework to enable a thimble carried on the movable framework to move up and down. The plate grid ejection mechanism of the lead-acid battery plate grid die casting machine can regulate the ejection time, ejection speed and ejection distance of the thimble according to the requirements; furthermore, the smooth lifting and smooth falling of the thimble can be ensured on the structure, and the balanced and smooth ejection of a plate grid can be further ensured; and in addition, the plate grid ejection mechanism further has the advantages of simple structure, convenience in manufacturing, convenience in maintenance and mounting, smooth and reliable actions, high controllability and the like, thereby creating conditions for realizing automatic production of a whole plate grid production line.

Owner:JIANGSU SANHUAN IND HLDG CO LTD

Two-door-leaf manual folding car door device for elevator

InactiveCN105197746AGuaranteed uptimeSimple and beautiful structureBuilding liftsElectromagnetic lockEngineering

The invention relates to a two-door-leaf manual folding car door device for an elevator. The two-door-leaf manual folding car door device comprises a car door, wherein the car door is composed of a hanging wheel door and a rotating shaft door which are arranged side by side and hinged to each other; a door hanging rail is arranged at the upper end of a car entrance / exit; the upper end of the outer side of the rotating shaft door is rotationally connected with the door hanging rail through an upper door shaft; the lower end of the outer side of the rotating shaft door is rotationally connected with a sill sliding groove through a lower door shaft; a door hanging wheel is arranged at the upper end of the outer side of the hanging wheel door; a guiding shaft is fixed at the lower end of the outer side of the hanging wheel door; an electromagnetic lock and a door closing in-place verification switch are mounted at the bottom end of the front side surface of a door head beam; an electromagnetic lock suction plate is mounted on the front side surface of the upper end of the rotating shaft door; after the door is closed in place, the door closing in-place verification switch is switched on, the electromagnetic lock and the electromagnetic lock suction plate attract mutually, and safety loop of the elevator is switched on, so that the elevator can run, and high safety and reliability are realized. According to the two-door-leaf manual folding car door device, the hanging wheel door and the rotating shaft door are hinged through a hinge, so that the folding door is formed and mounted at the position of the car entrance / exit, therefore, shearing and squeezing risks during running of the elevator car are prevented.

Owner:XJ SCHINDLER XUCHANG ELEVATOR

Armature opening and closing mechanism for paper transferring mechanism swinging downward

InactiveCN103085465ASimple structureSmooth and reliable actionPrinting press partsDrive shaftTransfer mechanism

The invention discloses an armature opening and closing mechanism for a paper transferring mechanism swinging downward. The armature opening and closing mechanism for the paper transferring mechanism swinging downward comprises a paper transferring hand, a driving mechanism, a driven mechanism and a stop motion mechanism. The paper transferring hand comprises an engaging shaft and an opening and closing armature ball connected with a driving end of the engaging shaft. A driving gear of the driving mechanism and a paper transferring armature control cam are fixedly installed on a driving shaft. A pair of swing rods of the driven mechanism is fixedly installed on a swing arm shaft, and end heads of the pair of swing rods are respectively arranged on periphery surfaces of the main curve and the conjugate curve of the paper transferring armature control cam in fit mode. A swing rod cam comprises a main body and a tail rod portion, wherein the swing rod cam is fixedly installed on an installing shaft, and a curved groove is arranged on the inner side face of the main body of the swing rod cam, so that the opening and closing armature ball is inserted in the curved groove in scrollable mode. A swing arm is fixedly installed on the swing arm shaft, and the end head of the swing arm is arranged on the periphery surface of the main body of the swing rod cam in fit mode. The stop motion mechanism comprises a protective air cylinder installed on the inner side face of a wallboard on a driving side and a stop block connected onto the end head of a piston rod of the protective air cylinder.

Owner:SHANGHAI GUANGHUA PRINTING MACHINERY +1

Winding type windscreen wiper for automobile

InactiveCN102616211AStable and flexible powerEasy to use and flexibleVehicle cleaningElectric machineNatural state

The invention discloses an automobile part and more particularly relates to a winding type windscreen wiper for an automobile. The winding type windscreen wiper for the automobile comprises a glass body mounted on an automobile body and further comprises a winding mechanism wound with a rainwater wiping device; the rainwater wiping device extends out of the winding mechanism, is pressed on the glass body and is capable of swinging back and forth on the glass body; a slide rail is arranged behind the glass body; a slide block capable of sliding along the slide rail is arranged in the slide rail; the rainwater wiping device is connected with the slide block; a pull rope is connected to two ends of the slide block respectively; and the pull ropes are driven by a motor. After such a structure is adopted, the transmission stability and flexibility are achieved; under the natural state of a windscreen wiper skeleton, a downward pressure is generated at a middle section; during use process, the whole windscreen wiper is flattened and is flexibly and conveniently used; and the design is smart, the motor, a transmission part and the like are effectively combined, and the structure design is simple, so that the action is stable and reliable; and the winding type windscreen wiper can be applied to various occasions, such as a rearview mirror of an automobile or a windscreen of the automobile, and the like requiring glass surface wiping and meets the use requirement of people.

Owner:韦崴

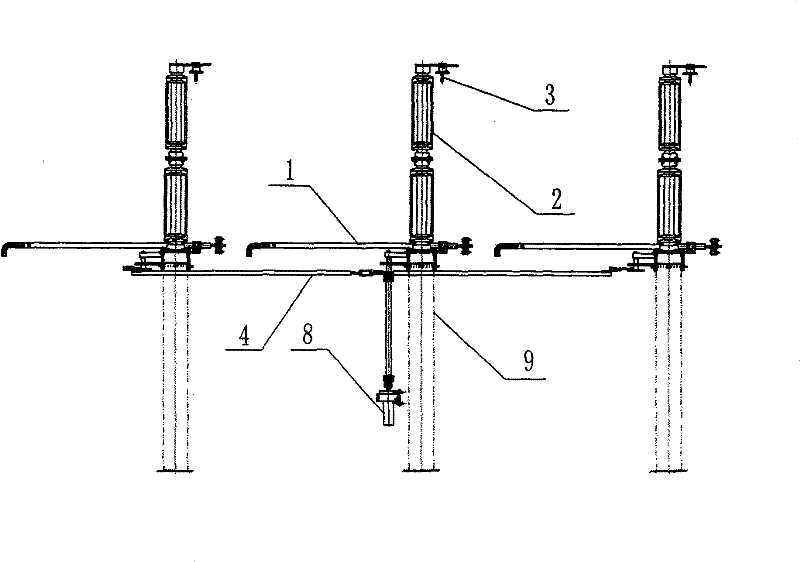

Automatic stacking mechanism for solar glass tubes

The invention discloses an automatic stacking mechanism for solar glass tubes and belongs to the field of electromechanical devices. The automatic stacking mechanism for the solar glass tubes comprises an air cylinder base, a supporting rod, a transverse air cylinder, a vertical air cylinder, an axial air cylinder, a ram, a power motor, a reduction gear, a decelerating belt, a machine tool underframe, a left main transmission rod, a right main transmission rod, a main conveying belt, a left auxiliary transmission rod, a right auxiliary transmission rod, a constant-speed belt, a toothed belt, a rubber strip and a tube frame. The motor is connected with the decelerating belt through the reduction gear and is installed below the machine tool underframe, the left main transmission rod is arranged on the side portion of the machine tool underframe and is matched with the decelerating belt, and the right main transmission rod is connected with the left auxiliary transmission rod through the constant-speed belt. The main conveying belt is arranged between the two main transmission rods, the toothed belt is arranged between the two auxiliary transmission rods, the supporting rod is arranged on the air cylinder base and used for supporting the transverse air cylinder, the vertical air cylinder is connected with the transverse air cylinder piston rod, the axial air cylinder is connected with a piston rod of the vertical air cylinder, and the ram is connected with a piston rod of the axial air cylinder. The automatic stacking mechanism can complete the automatic stacking work of the solar glass tubes.

Owner:张明磊

Temperature regulating valve

ActiveCN107448642ASmooth and reliable actionNo shakingOperating means/releasing devices for valvesGear lubrication/coolingEngineeringActuator

The invention discloses a temperature regulating valve. The temperature regulating valve comprises a valve body and a thermal actuator, wherein the thermal actuator is mounted in the valve body; a cavity communicates with the outside through at least three interfaces; the three interfaces comprise a first interface, a second interface and a third interface; the thermal actuator comprises an ejector pin and a body; the cavity comprises a first cavity and a second cavity; the second cavity is away from an end cap assembly relative to the first cavity; one end of the thermal actuator is limited by the end cap assembly; the other end of the thermal actuator supports or is propped against a spring; a guiding part is arranged on a relatively fixed part of the temperature regulating valve; the thermal actuator which acts relatively is provided with a guiding and matching part which is in sliding fit with the guiding part; the body of the thermal actuator comprises a matching section which is in sliding fit with the second cavity; and the matching section is away from the end cap assembly relatively, is smaller than the second cavity and is in sliding fit with the second cavity. The temperature regulating valve only needs one spring, and is stable and reliable relatively when acting.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

Fork hydraulic lifting platform

Owner:TAIZHOU HAILING HYDRAULIC MACHINERY

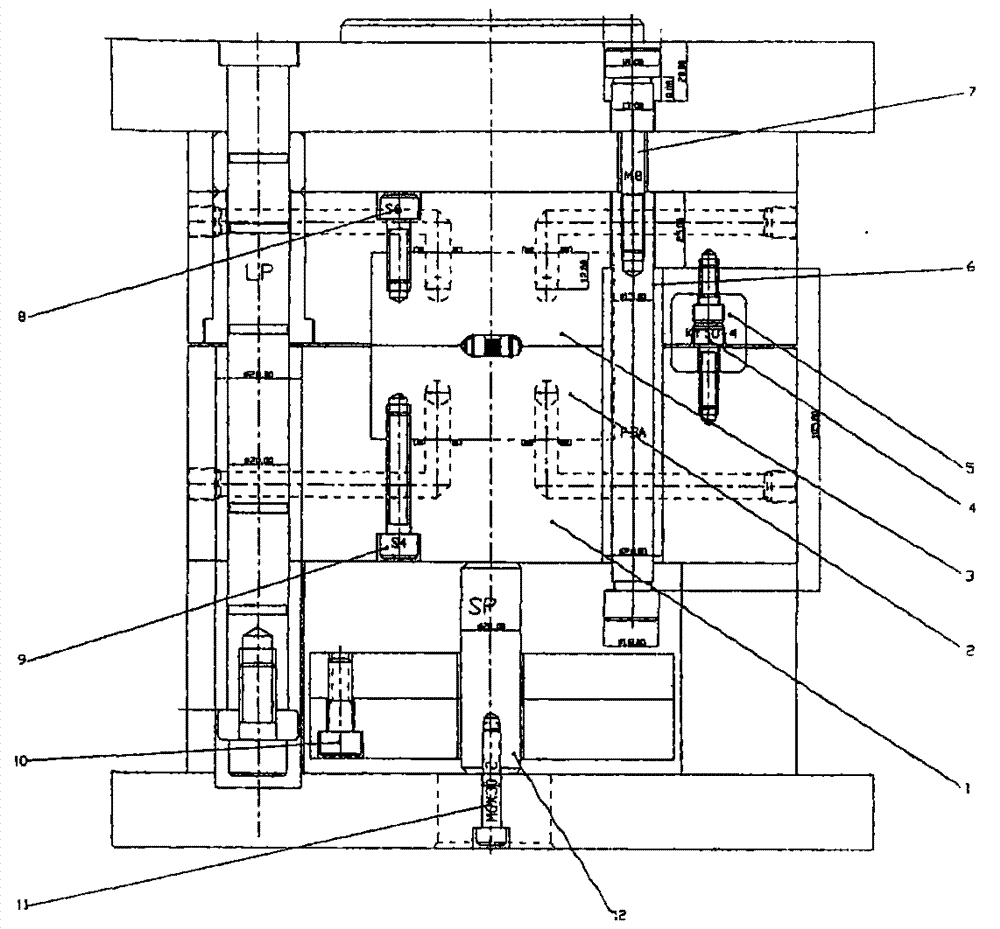

Die mechanism capable of realizing core-pulling by adopting sliding blocks combined with angle lifters

InactiveCN106994769AReduce production efficiencySmooth and reliable actionEngineeringMechanical engineering

Owner:牟维军

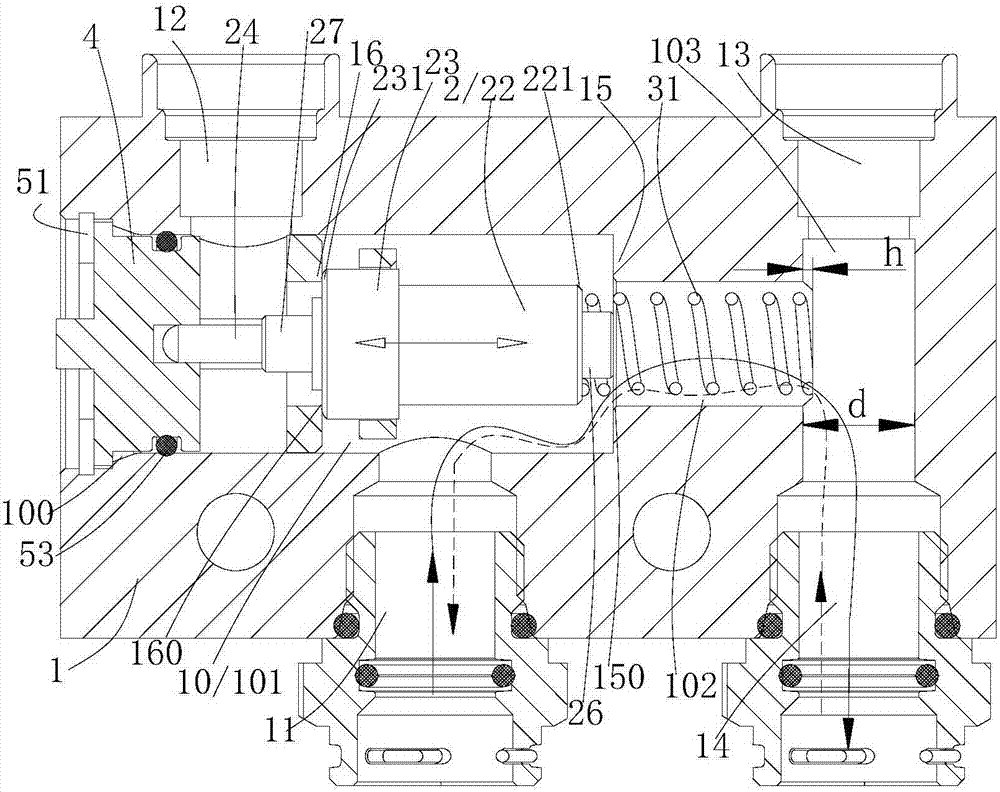

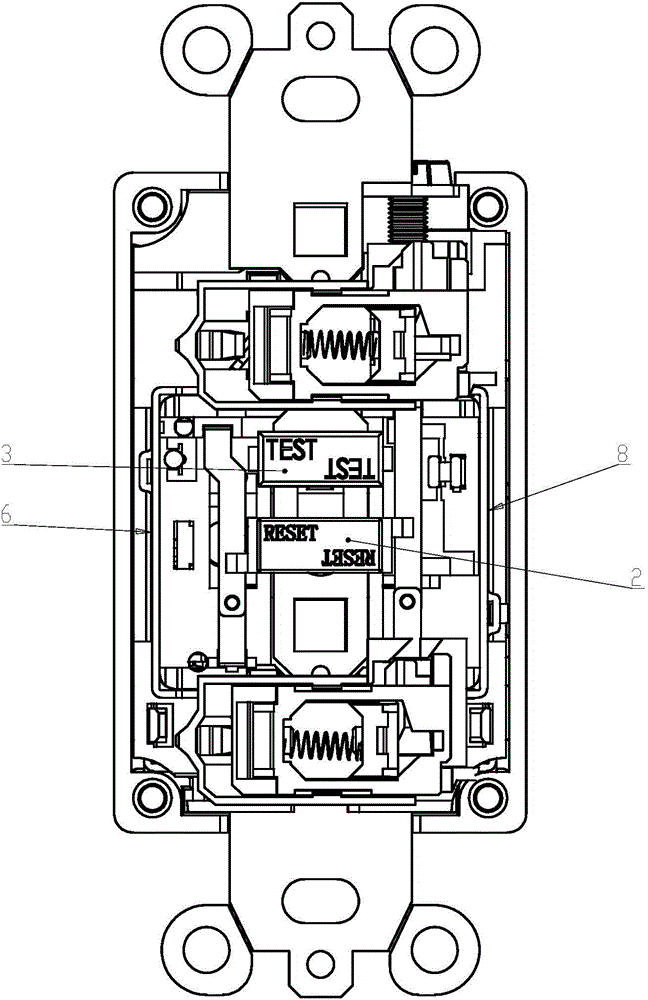

Leakage protection socket

ActiveCN104682126ASimple structureReasonable structureCoupling device detailsElectrical conductorStructural engineering

The invention provides a leakage protection socket which comprises a shell, output conductors, power input ends, power output ends, a resetting button and an electromagnetic tripping mechanism, wherein a main loop switch comprises a pair of movable metal sheets; the movable metal sheets are elastically arranged in a clamping piece in a penetrating manner; a positioning base plate is arranged below the clamping piece; a convex ridge and a limiting groove are arranged and formed between the clamping piece and the positioning base plate; movable contact ends are arranged on the two sides, extending out of the clamping piece, of the movable metal sheets; the output conductors and the power input ends are led out to form fixed contact ends; the power output ends are led out to form fixed contact ends; the electromagnetic tripping mechanism comprises an iron core, a lock catch and a tripper; the iron core is provided with a driving disk and a lifting piece; a lifting piece window is provided with a slope and rib slots; the movable metal sheets are clamped in the lifting piece rib slots. The leakage protection socket has the beneficial effects that the clamping piece drives the movable metal sheets to swing, and the operation is successful and reliable; no transitional conductive element is needed, and the processing cost is low; the resetting button is pressed down to turn on the main loop switch, and the operation is quick and stable.

Owner:WENZHOU VAN SHEEN ELECTRIC APPLIANCE

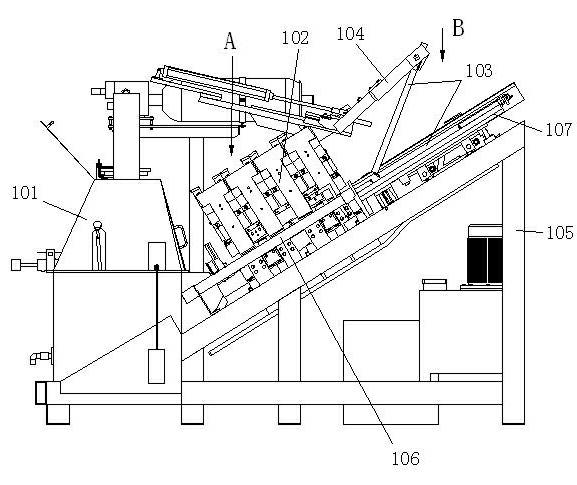

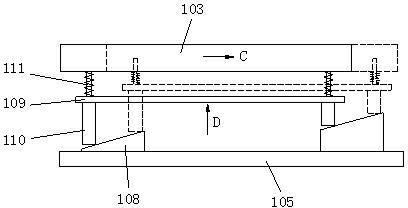

Polar plate feeding mechanism for lead acid battery plate packing machine

InactiveCN102556616ARealize orderly feedingSimple structureCharge manipulationConveyor partsEngineeringMechanical engineering

The invention provides a polar plate feeding mechanism for a lead acid battery plate packing machine, which comprises a bin, clamping jaws or supporting plates used for clamping or supporting polar plates in the bin, a stock supporting plate capable of being longitudinally lifted, and a horizontally pushing device used for horizontally pushing the polar plates dropping onto the stock supporting plate, wherein a plurality of polar plates are vertically laminated in the bin. The clamping jaws or the supporting plates are arranged at the two opposite sides of the bin, and simultaneously, power sources at respective sides supply pressure to jointly clamp or support the polar plates in the bin; the stock supporting plate is correspondingly arranged below the bin and used for catching the polar plates dropping from the bottom of the bin; and the horizontally pushing device is correspondingly arranged at one side of the stock supporting plate and is matched with the stock supporting plate to move. By adopting the scheme, the polar plate feeding mechanism has the advantages that the structure is simple, the motion is stable and reliable, material supplying is convenient, can be performed during the operation process and is not limited by the thicknesses of the polar plates, the ordered feeding of the vertically laminated polar plates is properly realized through the matched action of the supporting plates, the clamping jaws and the horizontally pushing device, and the operation efficiency is high.

Owner:崔锋

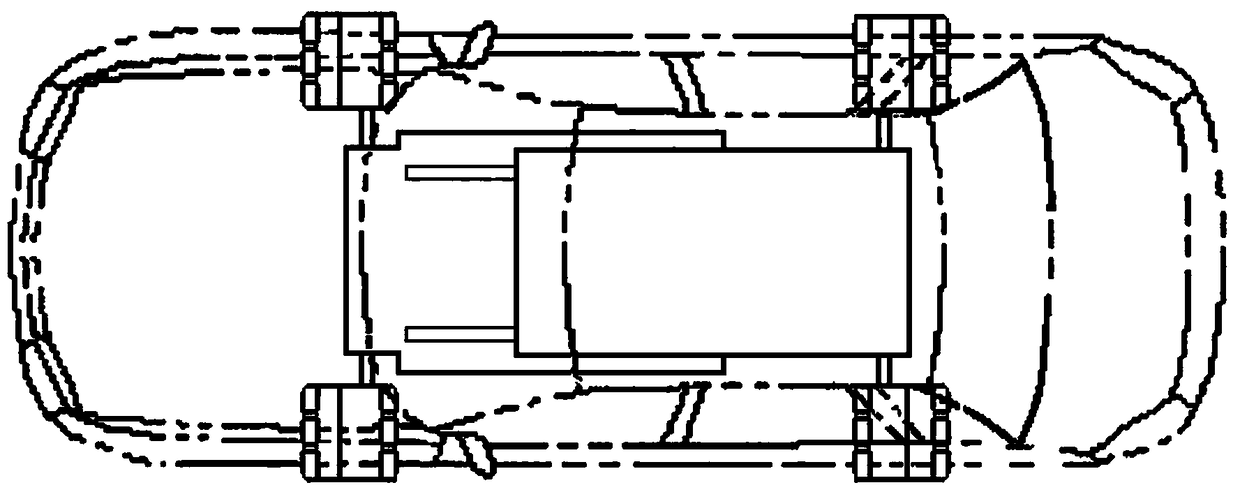

Inner side roof-propping type car carrier

InactiveCN108149988AQuick liftStable and reliable liftingParkingsHorizontal transmissionComposite structure

The invention discloses an inner side roof-propping type car carrier, and belongs to the technical field of parking equipment. The inner side roof-propping type car carrier comprises an underframe supported by a group of walking wheels, the under frame is driven by a propel machinery to move horizontally, the underframe is of a composite structure and comprises a front frame and a rear frame, a roof-propping mechanism is arranged between the front frame and the rear frame, and the roof-propping mechanism drives the front frame and the rear frame to move relatively to achieve the longitudinal extension of the underframe; and the tail ends of the front frame and the rear frame are separately connected with an expanding-and-contracting mechanism, each expanding-and-contracting mechanism comprises a pair of expanding-and-contracting arms arranged symmetrically, the expanding-and-contracting arms are driven by power to contract or expand horizontally, the carrier enters the bottom of the car during working, two pairs of expanding-and-contracting arms are expanded between front and rear tires of the car, the underframe extends longitudinally to drive the expanding-and-contracting arms separately contact the tires of the car and pushes the car off the ground, and then the walking mechanism drives the underframe to realize the horizontal transmission of the car. The mode of inner sideroof-propping wheels is adopted to lift a car to be transported, the lifting of the car is quick, the lifting force is large, the structure of the carrier is simplified, and cost is reduced.

Owner:SHANDONG JIANZHU UNIV

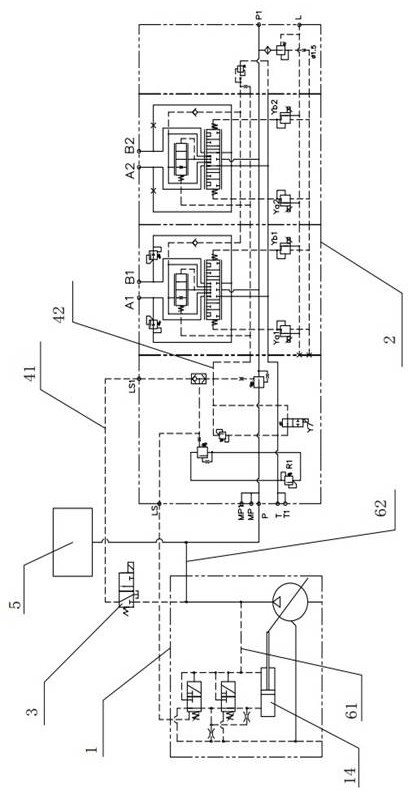

Hydraulic system capable of achieving constant pressure control and load sensitive control and control method

PendingCN113212093AAvoid settingAvoid working all the timeResilient suspensionsControl systemEngineering

The invention discloses a hydraulic system capable of achieving constant pressure control and load sensitive control and a control method. The invention solves the problem that an auxiliary pump and a hydraulic control oil way need to be additionally arranged in an existing suspension control system. The system comprises a load-sensitive variable pump, a multi-way valve, a reversing valve, a first feedback oil way and a suspension module, the multi-way valve comprises a control module, a second feedback oil way, a shuttle valve and at least one working module, the load-sensitive variable pump comprises a variable pump, a control valve, a stop valve and a control oil cylinder, the control oil cylinder comprises a piston rod, a rod cavity and a rodless cavity, the shuttle valve selects pressure oil of the first feedback oil way or the second feedback oil way and inputs the pressure oil into a control valve spring cavity, and the pressure oil of the first oil way enters the rodless cavity by overcoming the pressure of a stop valve spring cavity and interacts with the pressure oil in the rod cavity to enable the piston rod to move. The system also has the advantages of simple structure, convenience in assembly, reliable action, long service life and the like.

Owner:SHENGBANG GRP +3

Side driving lifting roller bed with low energy consumption and high stability

PendingCN109335617ASmooth and reliable actionAvoid vibrationConveyor partsRoller-waysReciprocating motionEngineering

The invention relates to the technical field of roller bed conveying and provides a side driving lifting roller bed with the low energy consumption and high stability in order to solve the problems that an existing lifting roller bed structure is large in occupied space, high in energy consumption and not stable enough in operation. The side driving lifting roller bed comprises a base, a support,a cylinder, a roller bed mounting rack, a cylinder connecting rack, a weight box, a chain, a chain transmission mechanism, a roller bed guide mechanism, a balance weight guide mechanism and a roller bed operating mechanism. The support is vertically and fixedly connected to one side of the upper end face of the base. The cylinder is arranged in the middle portion of the inner side of the support.The roller bed mounting rack is horizontally arranged at the front end of the support. The roller bed operating mechanism is arranged on the roller bed mounting rack. The rear end of the roller bed mounting rack is fixedly connected with a piston rod of the cylinder through the cylinder connecting rack. The weight box is arranged at the rear end of the support. The middle portion of the chain is rotatably connected with the support through the chain transmission mechanism. The two ends of the chain does reciprocating motion in the vertical direction of the support. The weight box and the roller bed mounting rack are fixedly connected with the chain correspondingly. The side driving lifting roller bed is applied to a roller bed conveying line.

Owner:HARBIN SHIMADA BIG BIRD IND

Single columns vertical straight-wheel outdoor high voltage AC earthing switch

InactiveCN101604593BAvoid rebound phenomenonIncrease cooling areaSwitches with movable electrical contactsHorizontal transmissionThree-phase

A straight-wheel outdoor high voltage AC earthing switch with single columns vertical relates to outdoor high voltage electrical apparatuses with three-phase AC of 50Hz and rated voltage of 252kV and below, is used for high voltage electrical apparatus earthing and comprises three single poles; wherein, the single poles are connected by a horizontal transmission rod (4); each single pole comprises a post insulator (2), a static contact (3), a bracket (9), a square board (6), an earthing switchgear rotating shaft (14), a transmission link (10) and an earthing switchgear tube (1); torque generated by an operating mechanism (8) of the mid-phase single pole is transmitted to the earthing switchgear tube (1) for switching closing via the transmission link (10) and the earthing switchgear rotating shaft (14); other two single poles carry out synchronous operation through the horizontal transmission rod (4); a dynamic contact of an earthing switchgear comprises bending boards (15), touch blocks (16) and guard boards (17); the touch blocks (16) are bolted at the inner sides of the bending boards (15); the two bending boards (15) are fixedly connected with the guard boards (17) through fixing bolts; adjustment of the clamping force of the dynamic contact of the earthing switchgear can be realized by adjusting nuts (20) at the outer sides of the bending boards (15). The earthing switch has the characteristics of reasonable structure, reliable and steady switching closing, excellent electrical property, safety, durability and convenient maintenance.

Owner:山东泰开隔离开关有限公司

Construction method of double-type maintenance warehouse for PC component assembly line

ActiveCN110565647AConvenience guaranteedImprove efficiencyCeramic shaping apparatusExcavationsAssembly lineRebar

The invention belongs to the technical field of PC component assembly line construction, and particularly relates to a construction method of a double-type maintenance warehouse for a PC component assembly line. The construction method includes the following steps: a foundation pit is dug up; steel bar mesh frames are pre-buried, and foundation steel bar frames are placed; positioning tools and all the foundation steel bar frames are fixed, and the level and elevation are adjusted; first-time concrete pouring is conducted; the positioning tools are removed; second-time concrete pouring is conducted; a front warehouse and a rear warehouse are formed; and a mold table storing and taking device is mounted in an area between the front warehouse and the rear warehouse. According to the construction method, labor can be effectively saved, and the construction accuracy demands for vertical columns can be met through one-time construction; and meanwhile, under the premise of ensuring externalsealing of a maintenance environment inside a maintenance kiln, the occupied area of the maintenance warehouse is smaller, and the advantages of high automation degree and low operation threshold areachieved.

Owner:上海持云工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com