Metal die-casting die capable of internally and automatically cutting off sprue

An automatic cutting and die-casting mold technology, which is applied in the field of metal die-casting, can solve the problems of inconvenient exhaust, affecting the strength and appearance of products, and the inconvenience of removing residual materials from castings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

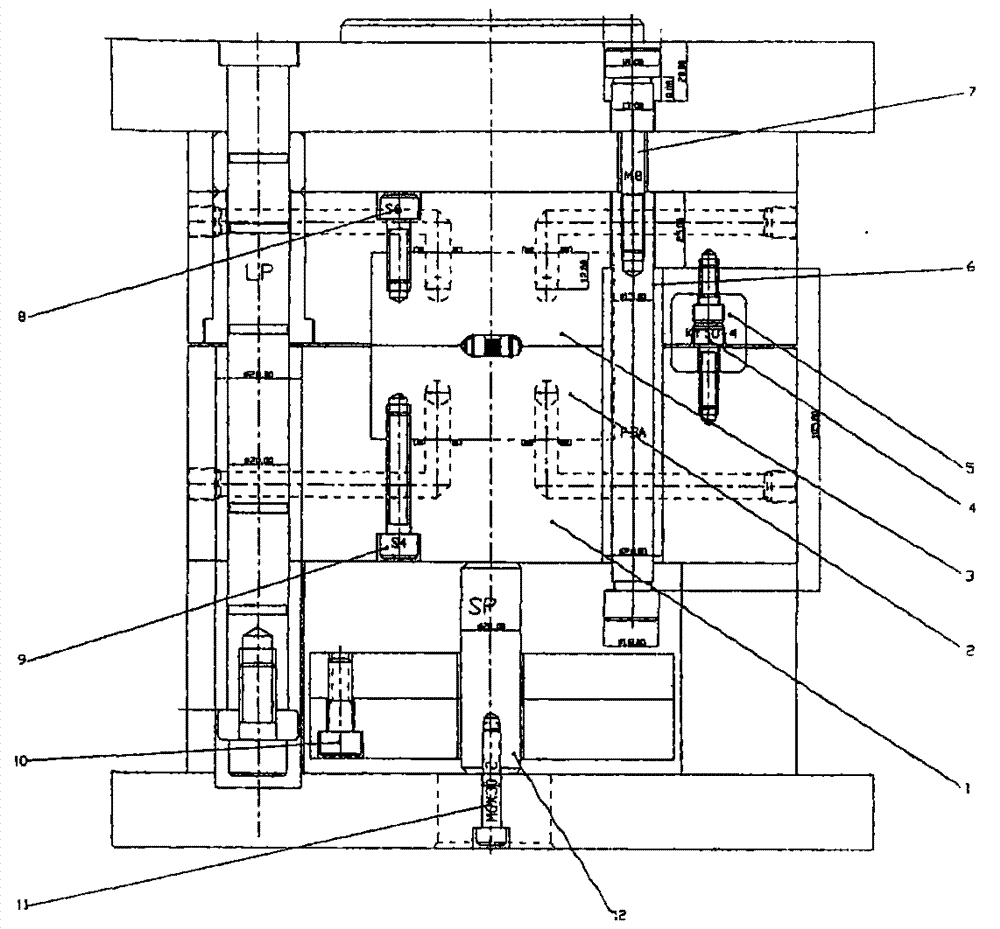

[0021] As shown in the figure, it is a metal die-casting mold that automatically cuts off the gate. In order to achieve the purpose of automatically cutting off the casting and the gating system in the mold, the fixed mold side of the mold adopts a three-plate structure, and the fixed mold seat plate on the fixed mold side The well-type main runner sleeve (22) is set on the top, the runner is set behind the fixed template, and then the gate connected with the casting is set behind the fixed template. (22) is provided with the pulling needle (21) that breaks gate. For the purpose of the mold coming out of the mold automatically after the gating system is cut off, the first pull rod (7) is set so that the first pull rod (7) drives the runner plate to push the remaining material of the gating system out of the mold when the mold is opened. For the flexible and reliable movement of the runner plate and the cavity plate, four guide posts are set on the fixed side of the mold to ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com