Automatic outer packing removing mechanism of bagged powder

An external packaging and automatic technology, applied in the field of powder veterinary drug preparation production line, can solve the problems of manual bag opening, low production efficiency, time-consuming and laborious, etc., and achieve the effect of reducing labor intensity, improving work efficiency and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] Referring to the accompanying drawings, an automatic unpacking mechanism for bagged powder includes an outsourcing platform 1 for transporting material bags, and a clamping turning mechanism and a suction bag cutting mechanism are arranged above the outsourcing platform 1 .

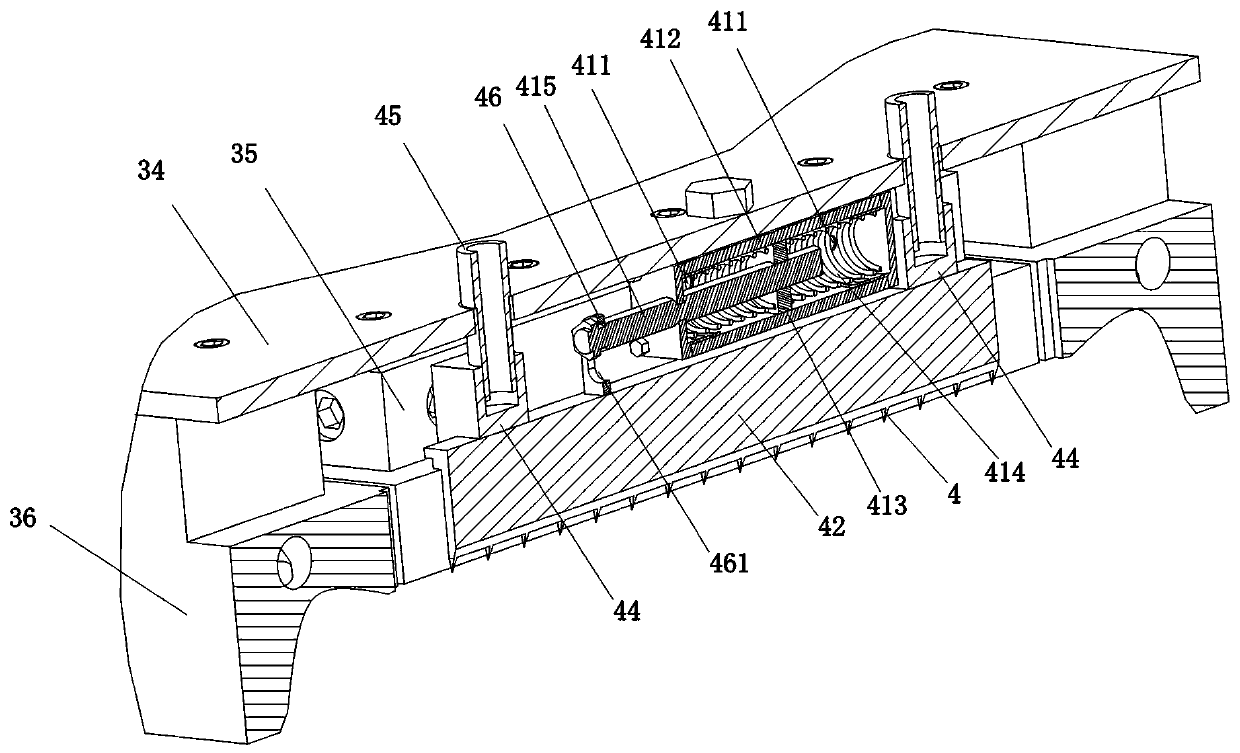

[0025] The suction bag cutting mechanism includes a turntable 2 whose rotation is limited on the frame 11 and a lifting suction cup 3 arranged on the turntable 2. The bottom of the suction cup 3 is provided with a sliding cutter 4 and inner and outer air hole groups 31, 32. Air hole groups 31, 32 are respectively arranged on both sides of the sliding cutter 4, and are respectively connected with respective vacuum generators. The installation of the turntable 2 is to set up a door-shaped frame 12 on the frame 11 on both sides of the outsourcing platform 1. There are chute o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com