Automatic leveling mechanism for plastic pipe raw material conveying

A technology for conveying raw materials and plastic pipes, applied in the field of plastic pipe processing, can solve the problems of scattered raw materials on the sides, different total amount of raw materials, inability to achieve centralized feeding, etc., and achieve the effect of avoiding scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

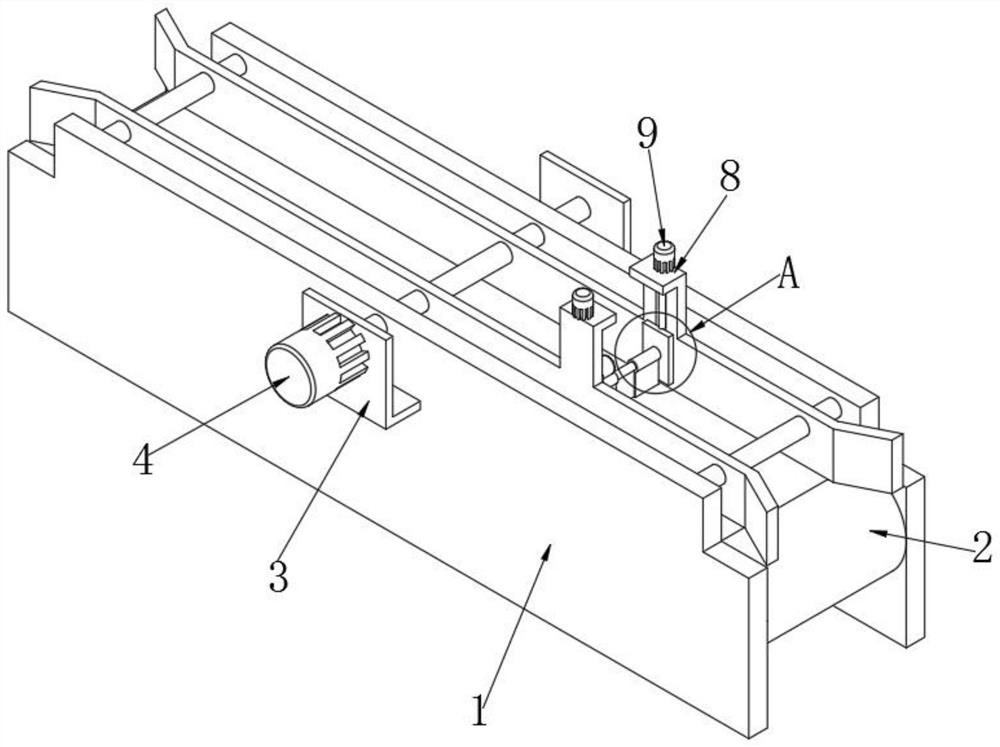

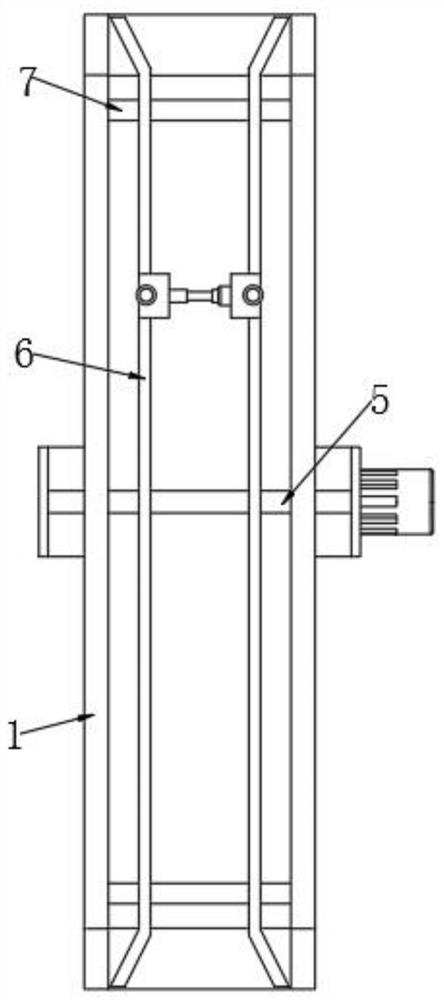

Image

Examples

Embodiment approach

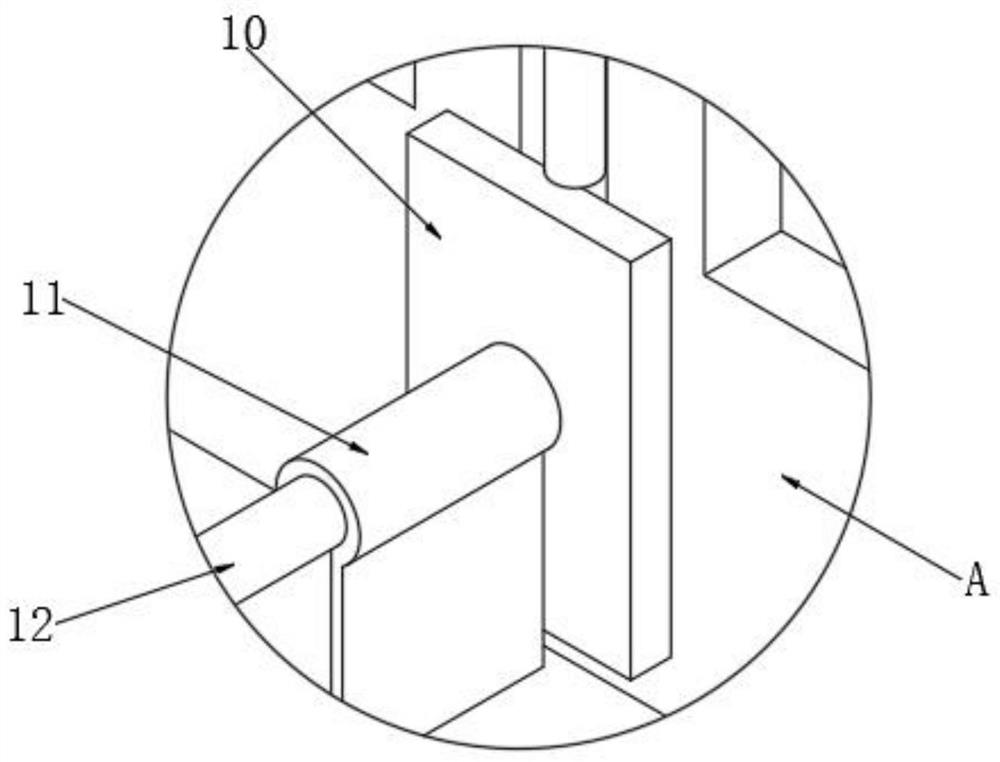

[0030] As an embodiment of the present invention, a third servo motor 16 is installed above the inside of one side of the slide 10, the output end of the third servo motor 16 is located inside the side of the slide 10 and is equipped with a driving tooth 17, and the outer sides of the outer rotating bases 11 on both sides are The top is equipped with a rotating shaft 19, and the rotating shaft 19 is connected to the slide plate 10 through a bearing. One end of the rotating shaft 19 on one side is installed with a driven tooth 18 inside the slide plate 10, and the driven tooth 18 and the driving tooth 17 are meshed. The third servo motor 16 The work drives the driving gear 17 to rotate, and the meshing transmission drives the driven gear 18 and the rotating shaft 19 to rotate, and then the outer swivel base 11 and the inner swivel base 12 are rotated between the two slide plates 10 to adjust the angle.

[0031] As an embodiment of the present invention, the specific operation st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com