Pneumatic fixture

A pneumatic tooling and pneumatic clamping technology, applied in the field of machining, can solve the problems of clamping multiple workpieces, lengthening the loosening time, manual operation for clamping and loosening, and high labor intensity, and achieves compact structure, tooling The effect of simplifying the structure and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

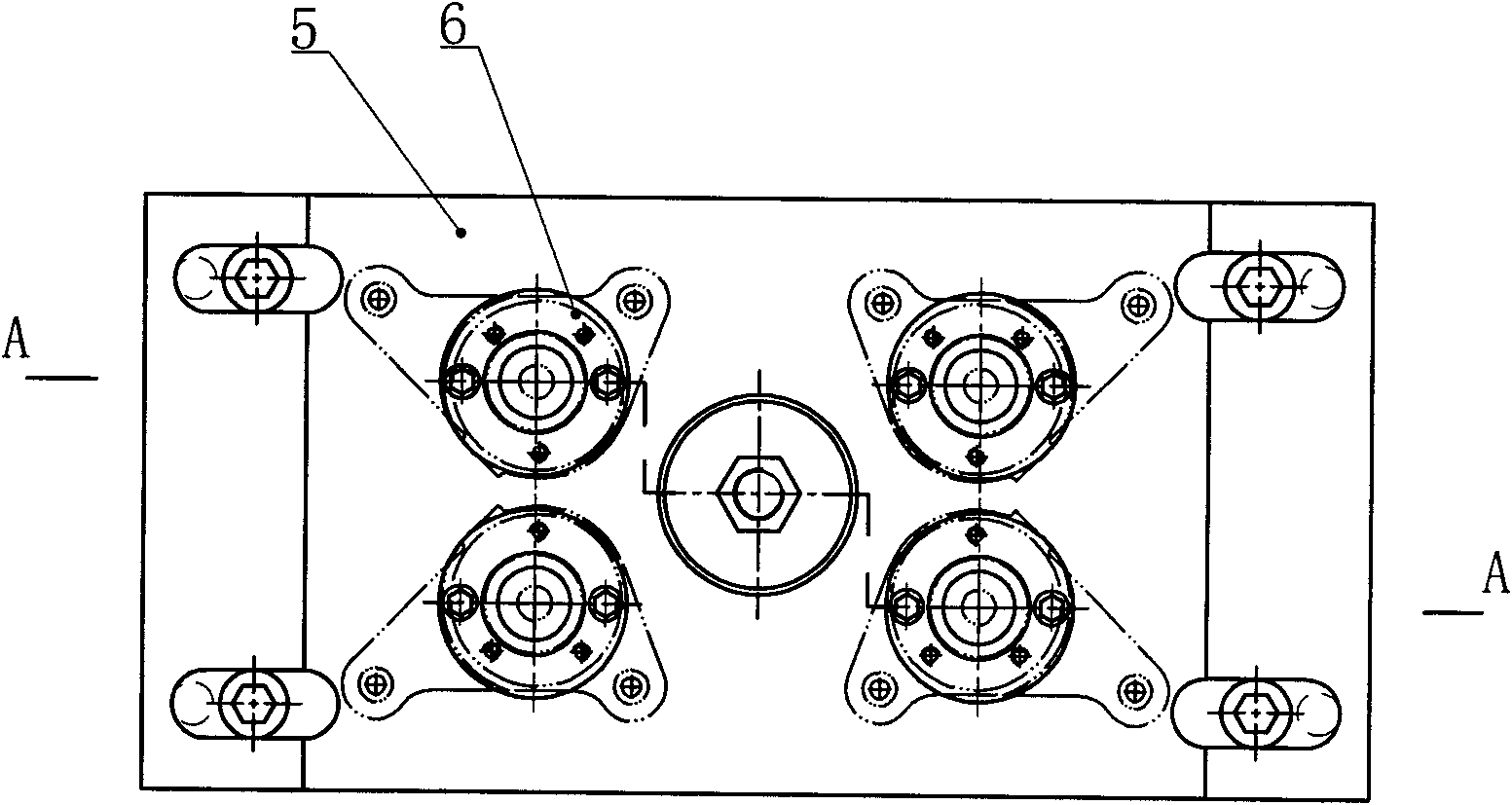

[0023] A pneumatic tooling is composed of a bottom plate 1 , legs 11 , a body 5 , a positioning sleeve 6 , a pneumatic clamping mechanism and a cylinder 13 . The outriggers are fixed on the lower part of the bottom plate. The main body is horizontally fixed on the upper surface of the bottom plate through the surrounding pressure plate 3, pads 2 and bolts 4. The cylinder is fixedly installed by bolts 12 at the bottom of the base plate. A pneumatic clamping mechanism is installed in the middle of the body, and 2-6 positioning sleeves are embedded on the body of the outer periphery of the pneumatic clamping mechanism, and four positioning sleeves are shown in this embodiment. The pneumatic clamping mechanism consists of a tapered sleeve 10, a wedge block 8 and a return spring 14. The tapered sleeve is installed vertically upside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com