Inner side roof-propping type car carrier

A car carrier and carrier technology, which can be applied to the buildings, building types, buildings, etc. where cars are parked, and can solve the problems of tire wear, complex structure, affecting efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention will be described below in conjunction with the above-mentioned drawings.

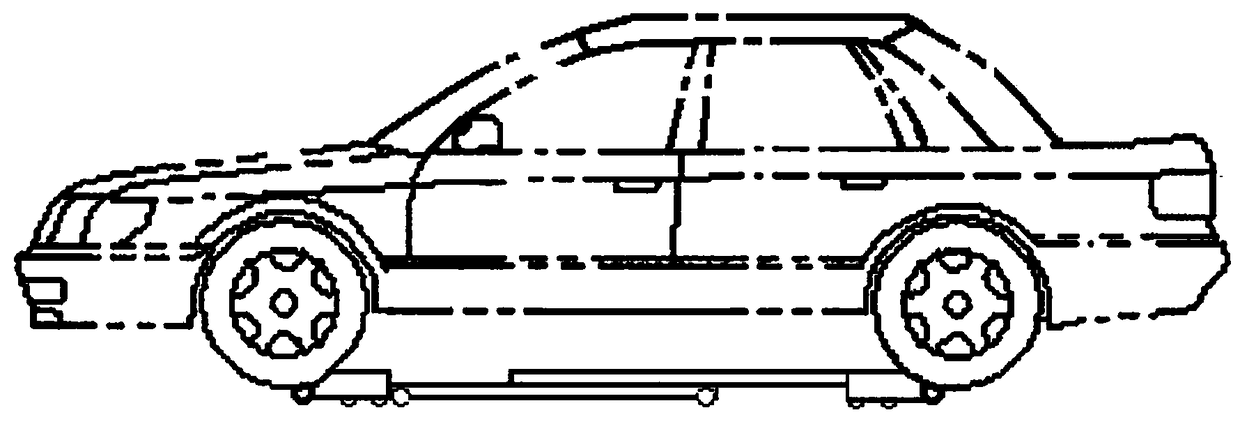

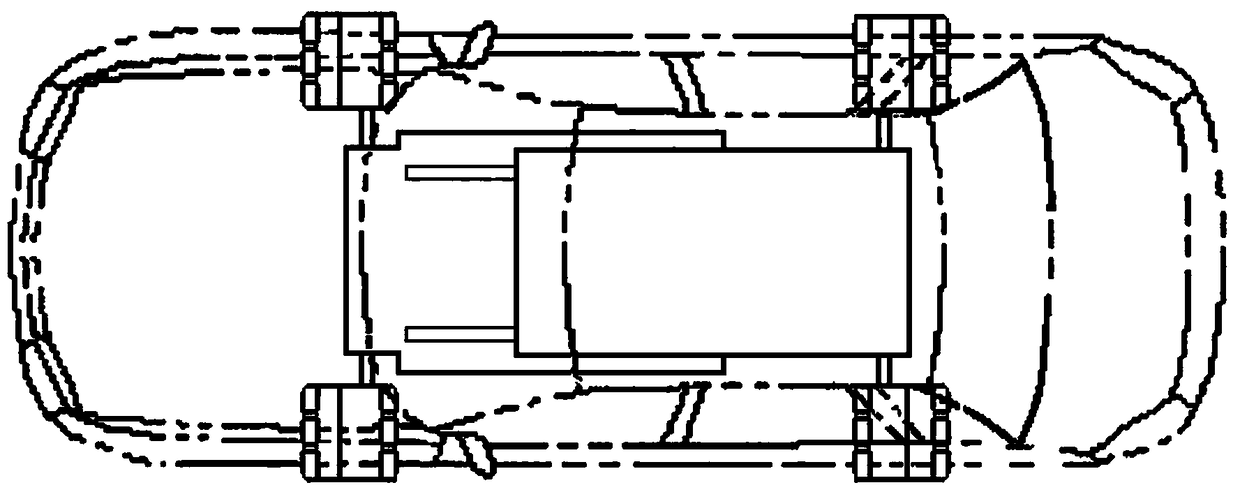

[0034] Such as Figure 1 to Figure 14 As shown, the inner roof support type vehicle carrier of the present invention has an underframe 1, and a two-way traveling mechanism 2 is installed on the underframe 1, and the front frame 11 and the rear frame 12 that can move relatively on the underframe 1 are connected by slide rail moving pairs. , or, connected by a scissors and fork mechanism. Due to the different use environments of the three-dimensional garage, there are also different requirements for the way the vehicle is carried by the carrier. On the four traveling wheels 22 on the double outer sides of the front frame 11, two traveling motors 21 separately drive the two traveling wheels 22 located at opposite corners, or on the same side, or at the same end. The following embodiments focus on longitudinal transport as an example. illustrate. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com