Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

92results about How to "Small control force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

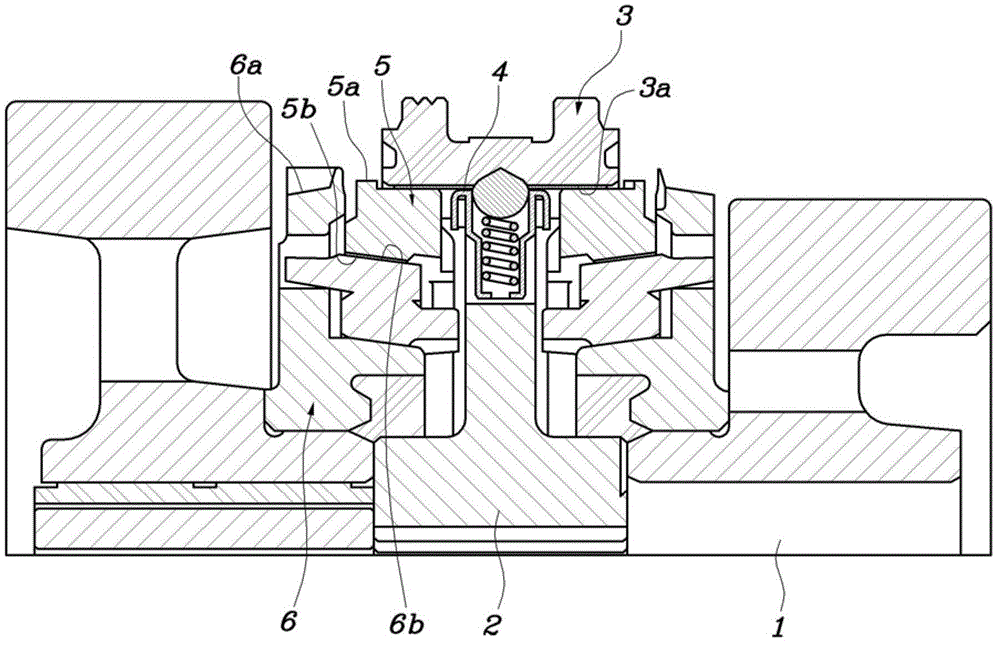

Synchronizer used for transmission

ActiveCN103912601AIncreased durabilityShorten the travel distanceMechanical actuated clutchesEngineeringGear tooth

The present invention discloses a synchronizer used for a transmission. The synchronizer comprises a sleeve having a gear-shifting gear. A synchronization key is arranged to a hub so as to protrude towards the sleeve. A synchronizer locking ring is arranged around the circumference of the hub. A transmission gear can be arranged around the synchronizer locking ring in a freely rotating way, and is provided with a clutch gear facing to the sleeve in the circumferential direction. The gear-shifting gear can have different gear teeth thicknesses based on a contact state relative to the synchronization key, so that the gear teeth thicknesses when the gear-shifting gear is contacted with the synchronization key is larger than the gear teeth thicknesses when the gear-shifting gear is not contacted with the synchronization key.

Owner:HYUNDAI MOTOR CO LTD

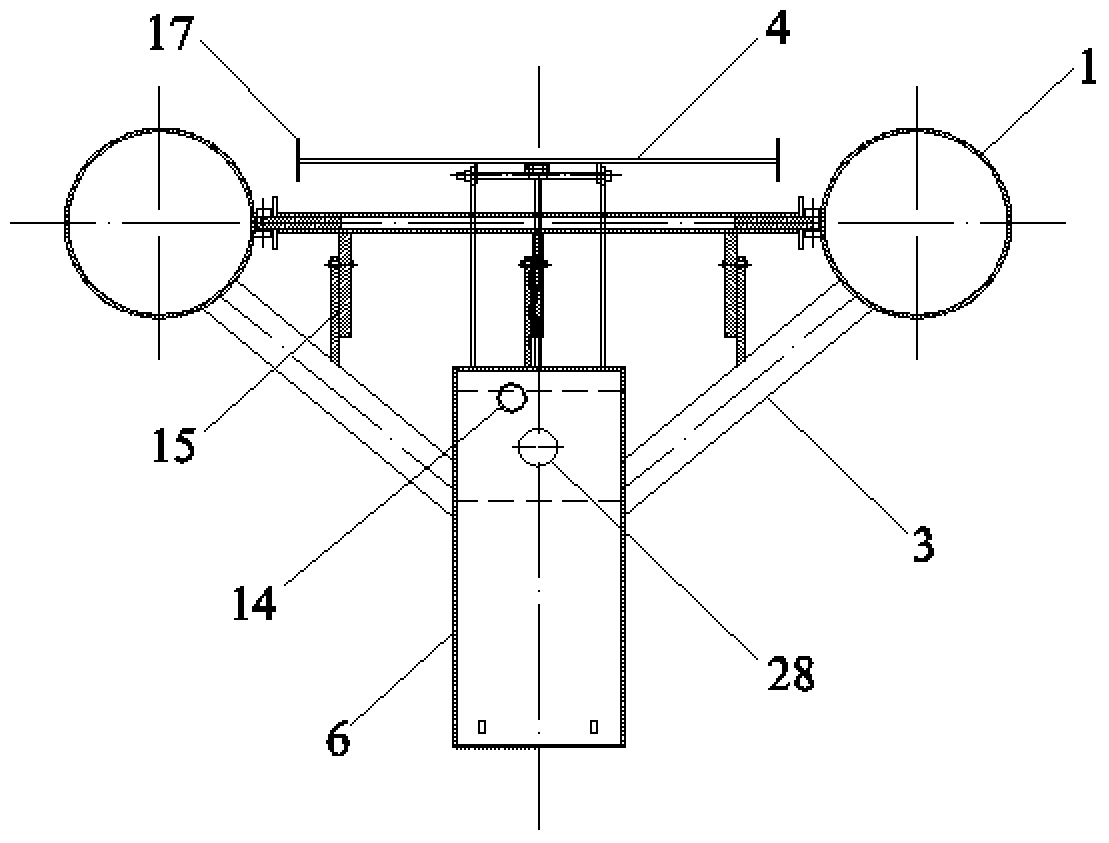

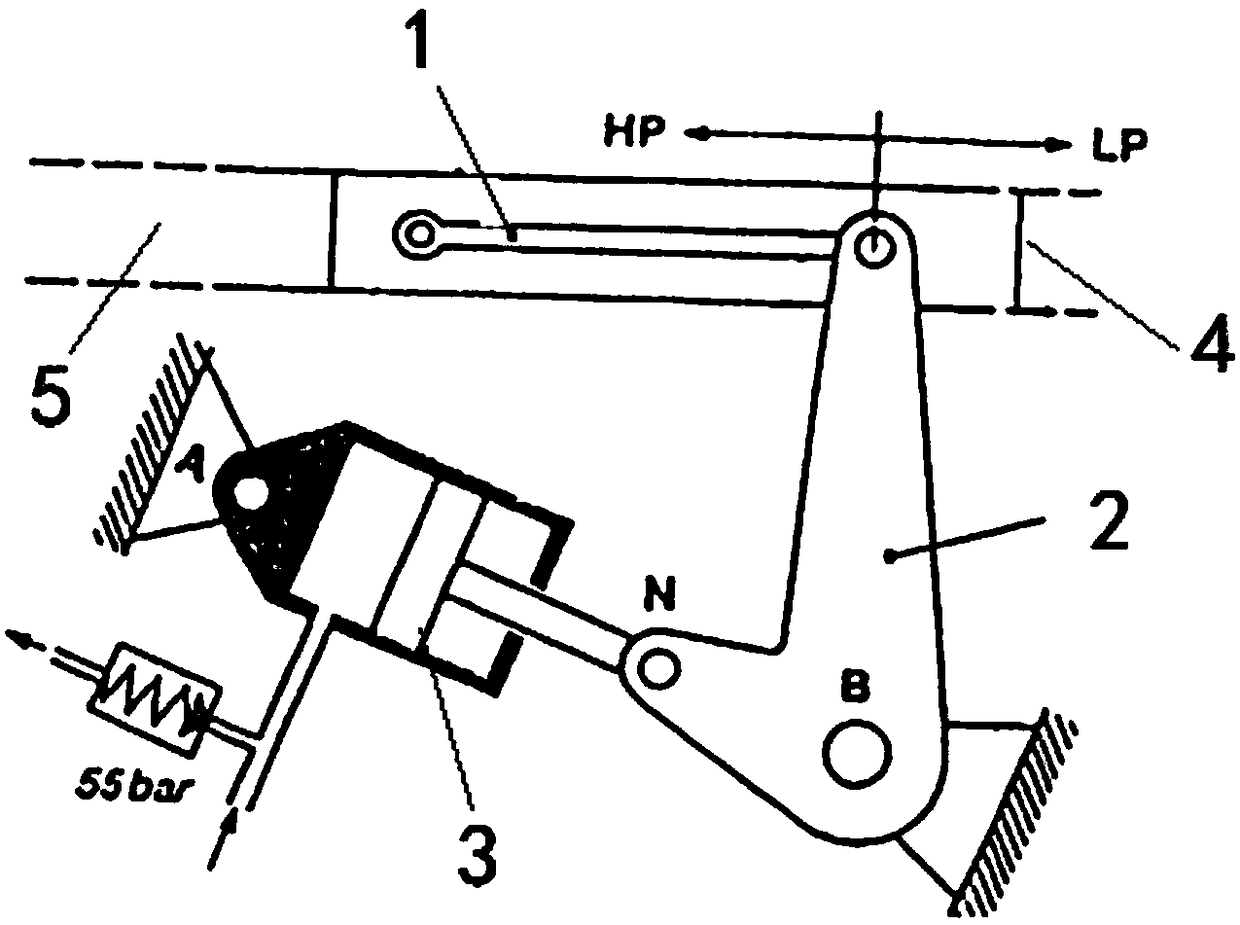

Operating method for tractor clutch operating device with hydraulic assistance

ActiveCN104728309AEasy to controlIncreased torque reserve factorClutchesDriver/operatorPressure difference

The invention discloses an operating method for a tractor clutch operating device with hydraulic assistance. A booster cylinder is connected with a clutch pull rod through a clevis by a clutch pedal, an output pipeline of a steering constant flow pump of a tractor provides pressure for the booster cylinder, and a piston rod of the booster cylinder is connected with the clutch pull rod through the clevis. When a driver steps on the clutch pedal, firstly power is provided for a throttling valve in the piston rod to enable an upper cavity and a lower cavity in an assistance oil cylinder to generate a pressure difference, the piston rod is pushed to pull the clutch pull rod, the clutch is separated, the easy control of the clutch is achieved, the torque reserve coefficient of the clutch is increased, the operating force of the driver is reduced, and the operating comfort of the driver is improved.

Owner:LUOYANG WEILIN HYDRAULIC MACHINERY

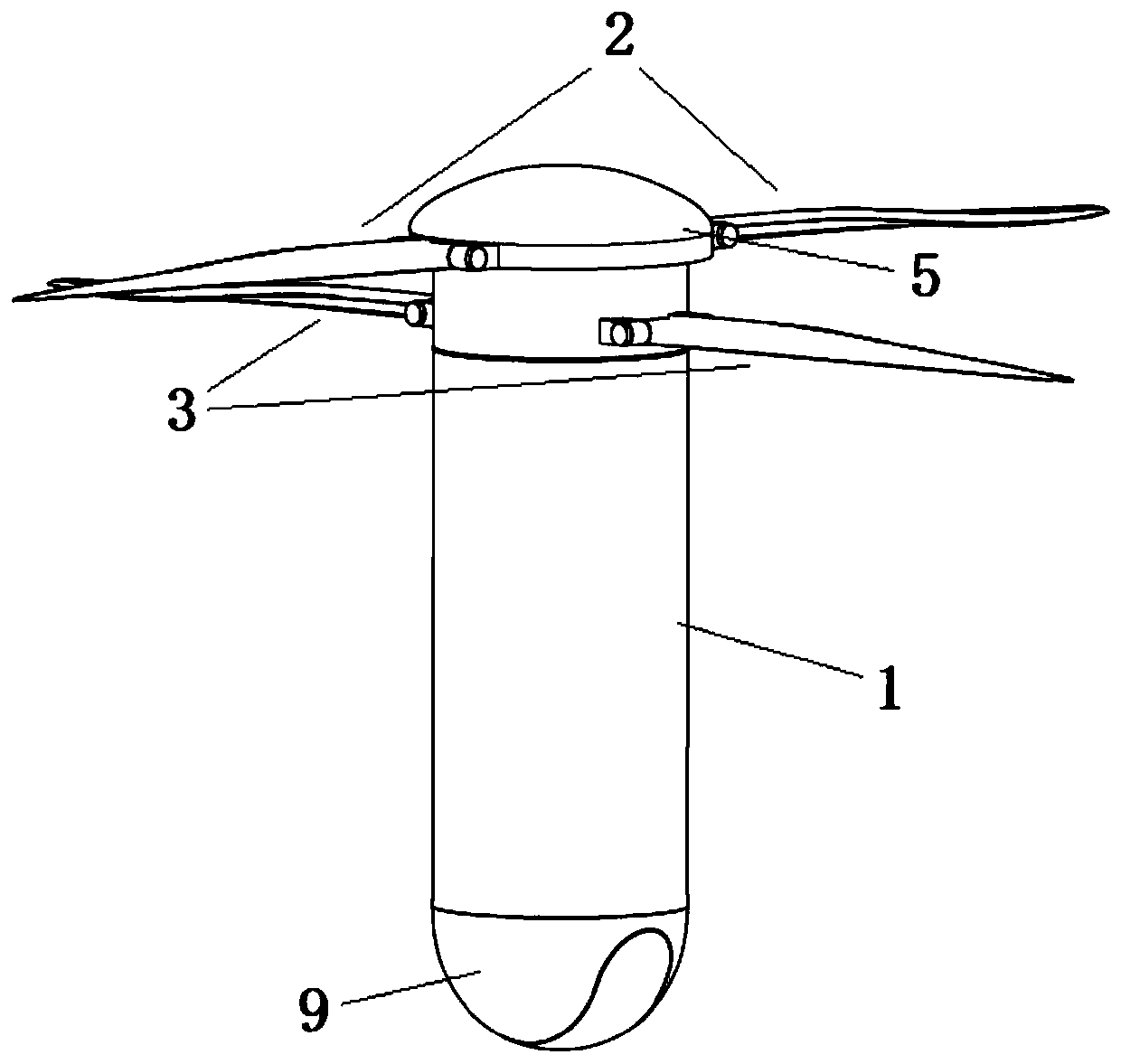

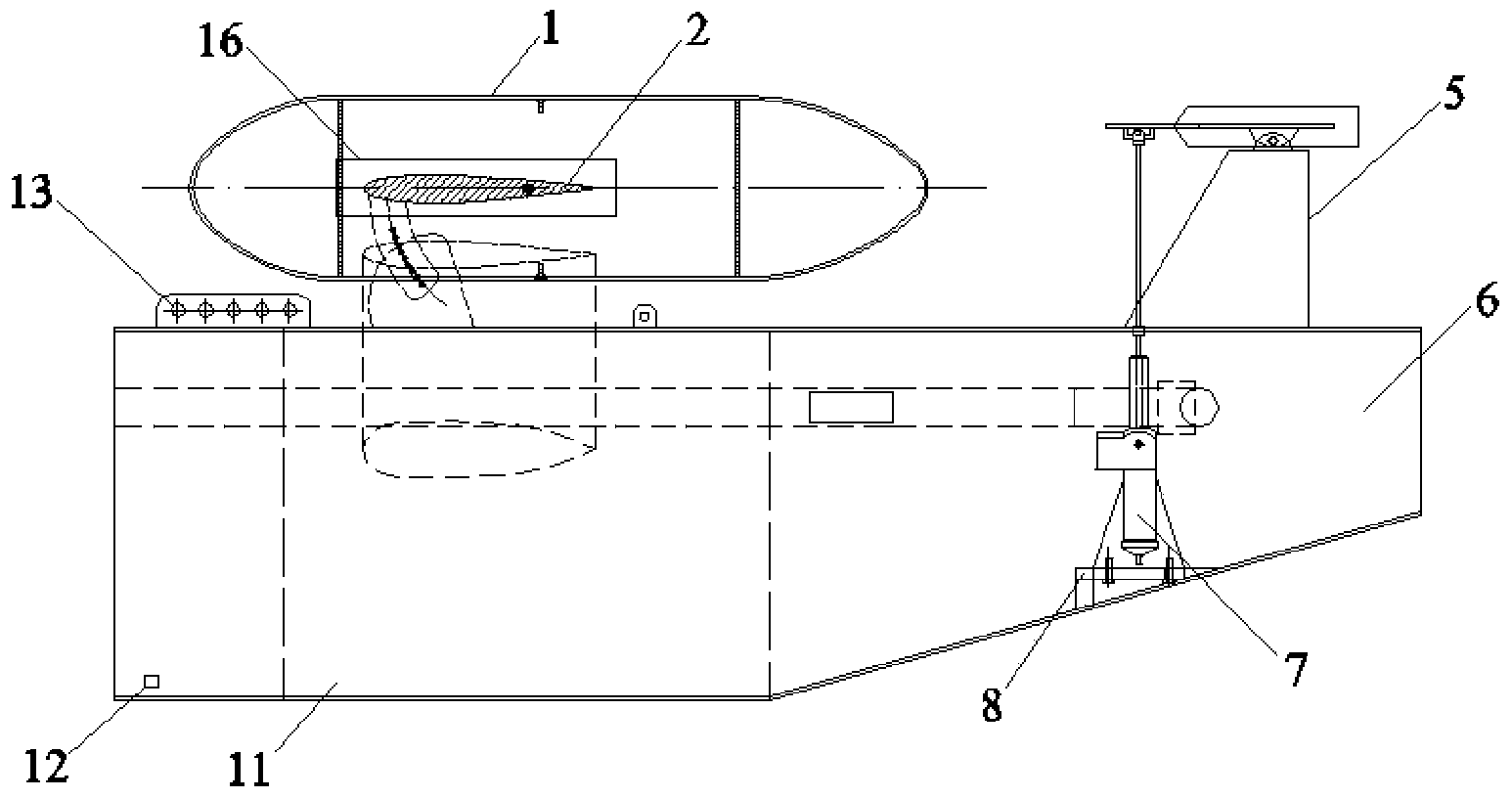

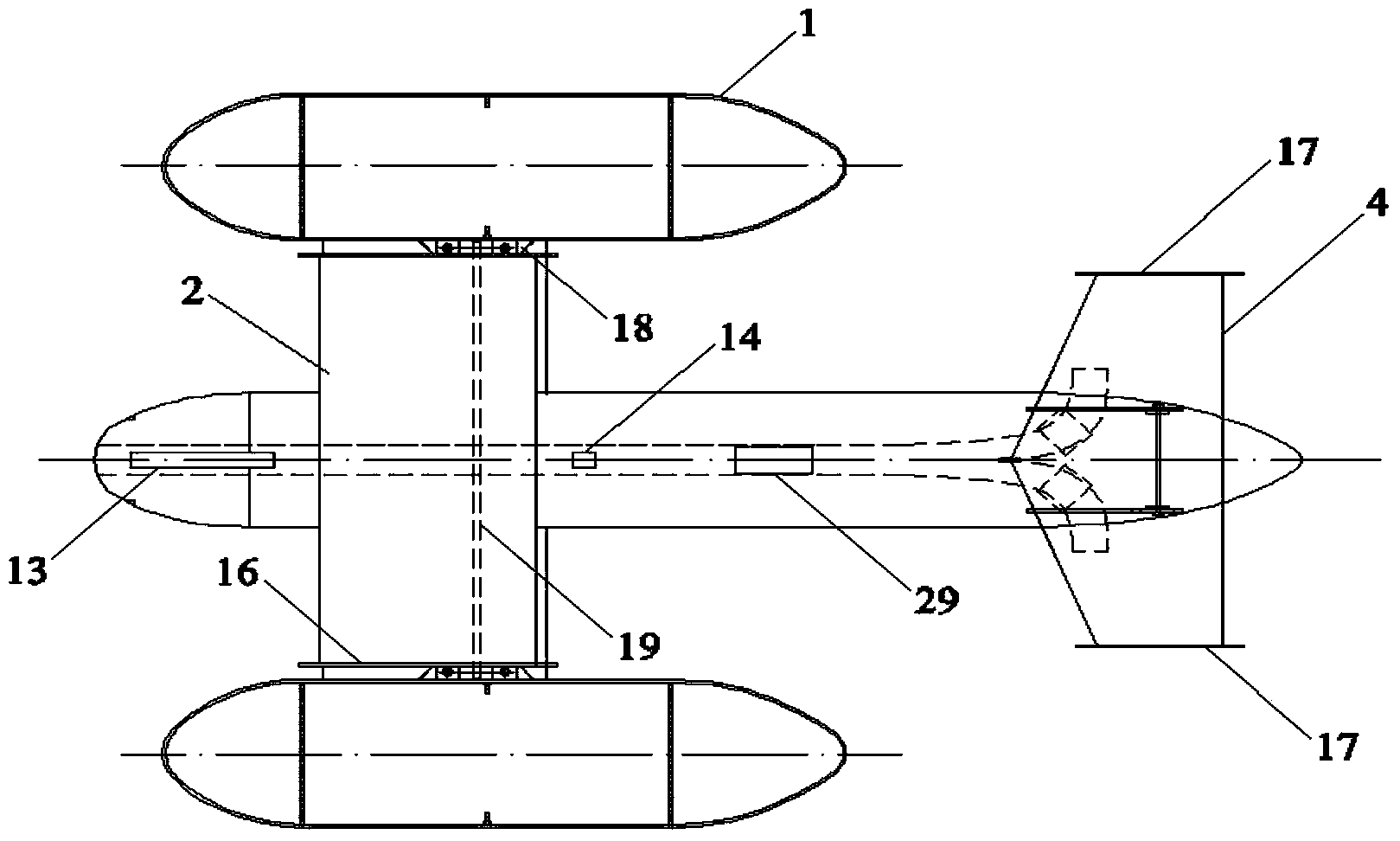

Coaxial double-propeller vertical take-off and landing aircraft adopting moving mass control and control method

PendingCN110155316AReduced Power RequirementsReduce weightPropellersDepending on number of propellersPower batteryCoaxial cable

The invention provides a coaxial double-propeller vertical take-off and landing aircraft adopting moving core control and a control method. The aircraft comprises a machine body and a coaxial double-propeller mechanism; the machine body is of a columnar structure, and a flight control and communication device, and a task load and a power battery are contained in the machine body; and the power battery is arranged on a metamorphic core driving mechanism inside the machine body and can drive the power battery to move in the radial direction of the machine body, so that the gravity center of theaircraft is deviated from the center axis of the machine body; and the coaxial double-propeller mechanism comprises an upper and lower double-rotor motor, a foldable upper propeller and a foldable lower propeller. According to the aircraft, a propeller blade is small and portable after being folded, flight control is carried out by dynamically changing the mass center of the aircraft by adopting abuilt-in metamorphic core driving control device, no additional control device is additionally arranged outside the machine body during flight, and the flying resistance is small. The power battery is used as a moving mass of the metamorphic core without other additional weighting amount, the required operating force and torque required by mass movement are small, and the power requirement and the weight of a steering engine can be reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

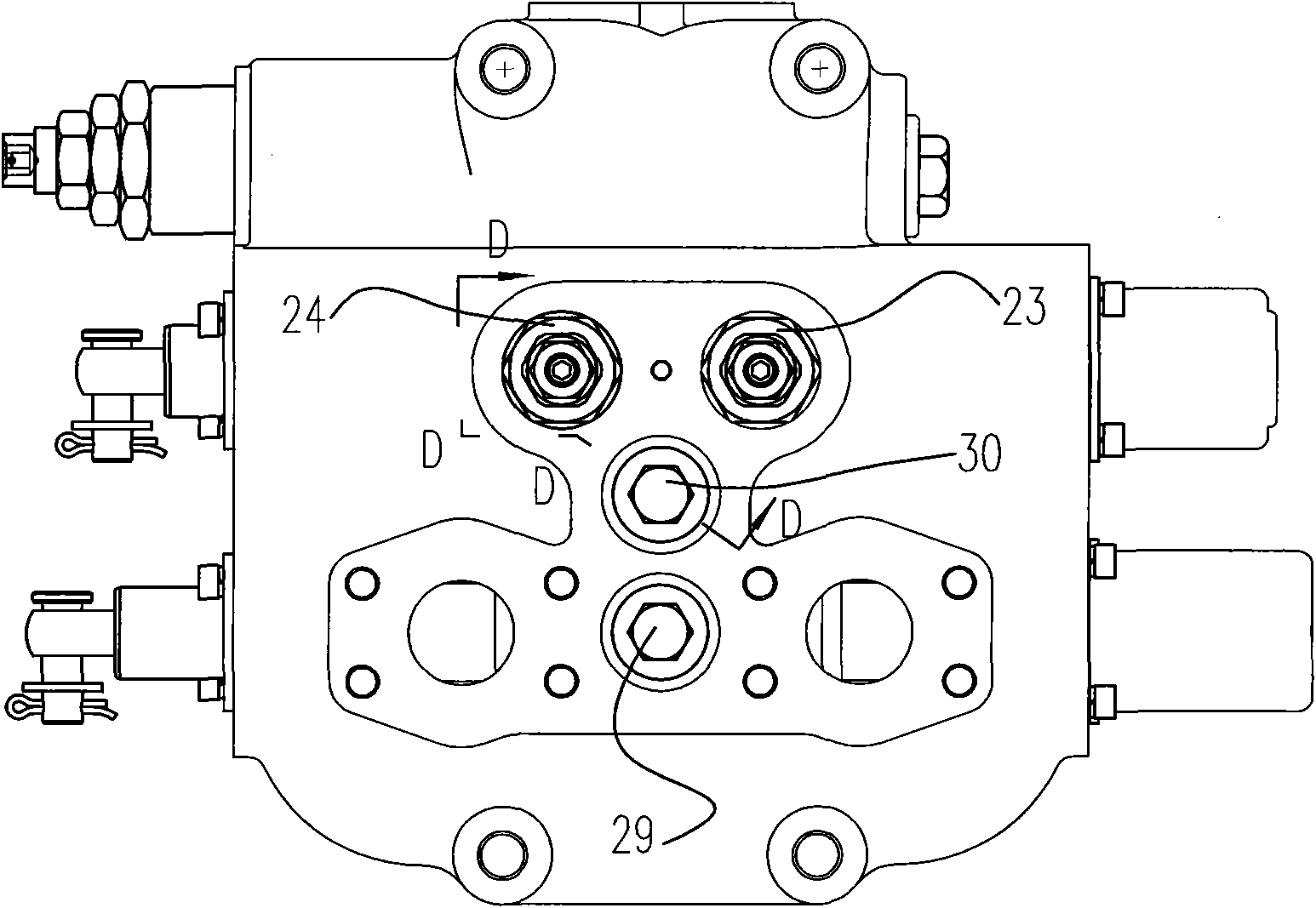

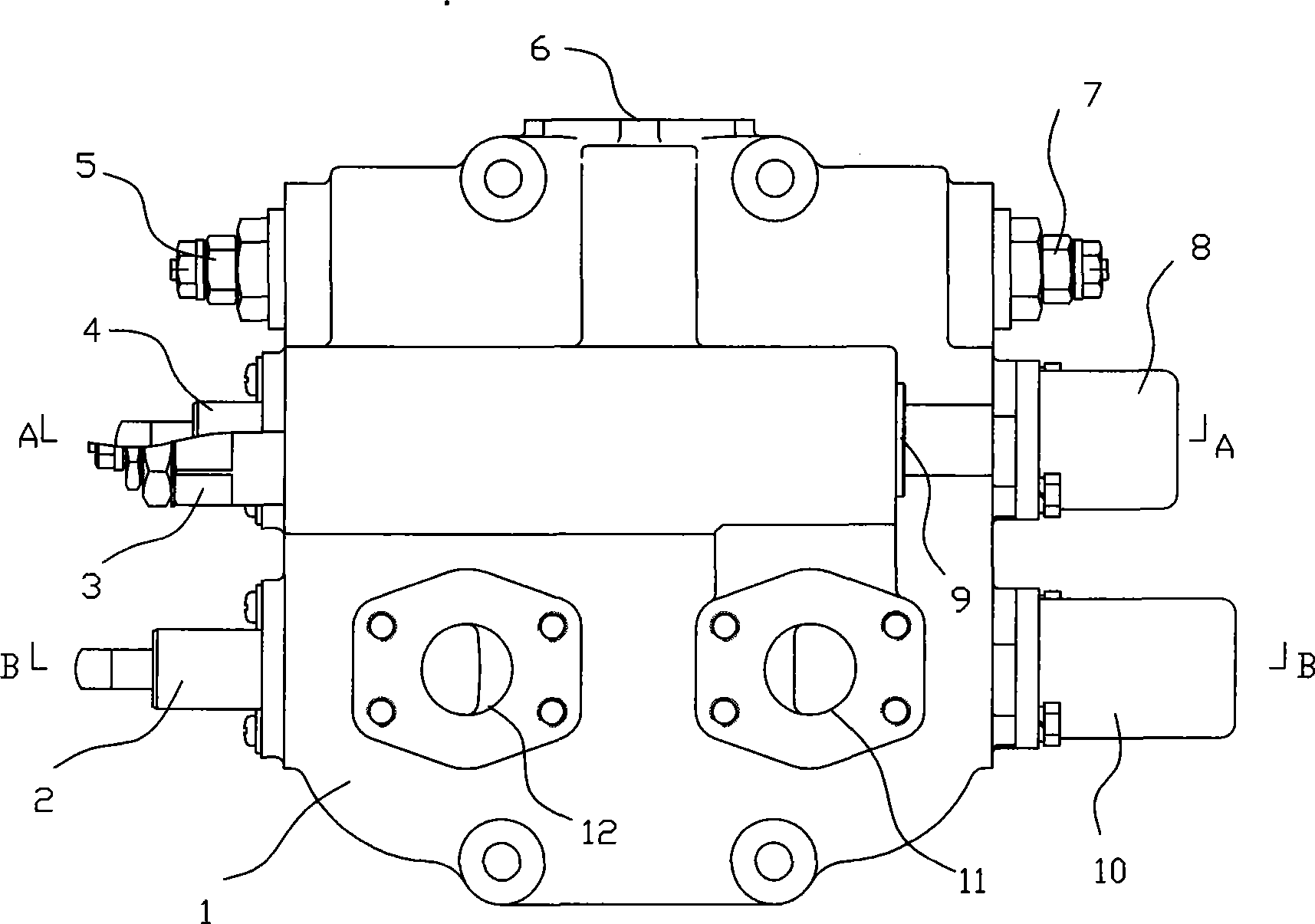

Plane sealing type reversing valve

ActiveCN104344017ACommutation is reliableAchieving Zero LeakageServomotor componentsMultiple way valvesFluid controlBall screw

The invention discloses a plane sealing type reversing valve which belongs to hydraulic control valves and is used for the fluid switching of a plurality of channels and solving the problem that the reversing valves at present are relatively large in reversing operation force, bad in anti-pollution capacity, high in processing difficulty and high in cost. The plane sealing type reversing valve comprises a lower valve seat, a support seat, a sliding block, an upper valve seat, a fixed valve element, a disc spring, a floating valve element, a sleeve, a ball screw assembly, a connection threaded sleeve, a push rod and a gear motor. According to the plane sealing type reversing valve, plane sealing is used, and the small rotary gear motor with the ball screw assembly is used for linear driving to drive the sliding block to move straightly and control the reversing of the oil path. The plane sealing type reversing valve is simple in structure, convenient in interface form and good in manufacturability, is capable of reliably realizing the sealing of the entire life cycle and ensuring the reliable reversing of the hydraulic systems, is suitable for standard and serial production and suitable for the high-temperature high-pressure severe environments and working conditions such as petroleum and natural gas extraction, and can be used for the fluid control of various hydraulic systems.

Owner:HUAZHONG UNIV OF SCI & TECH

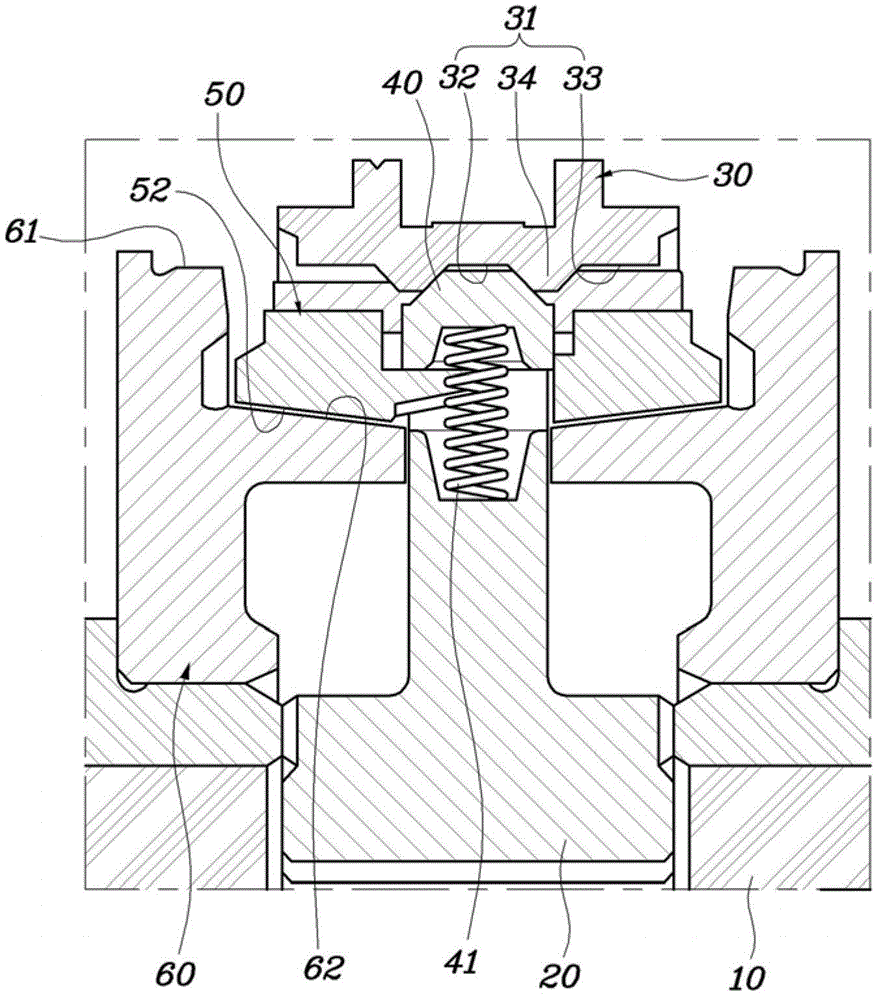

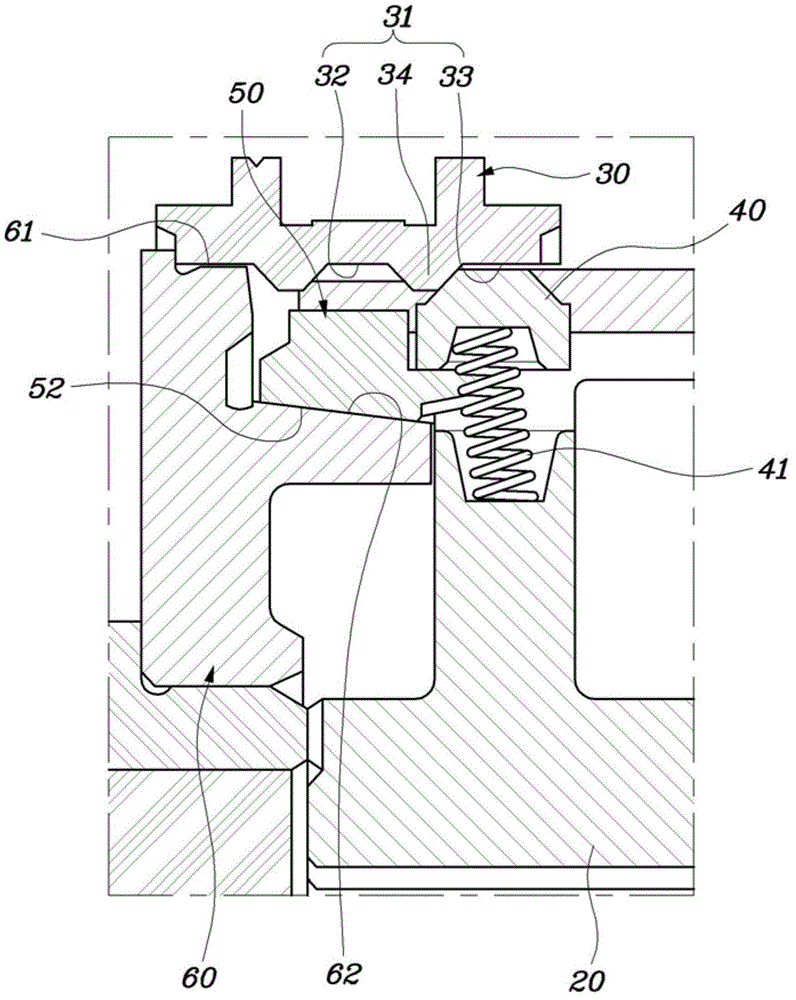

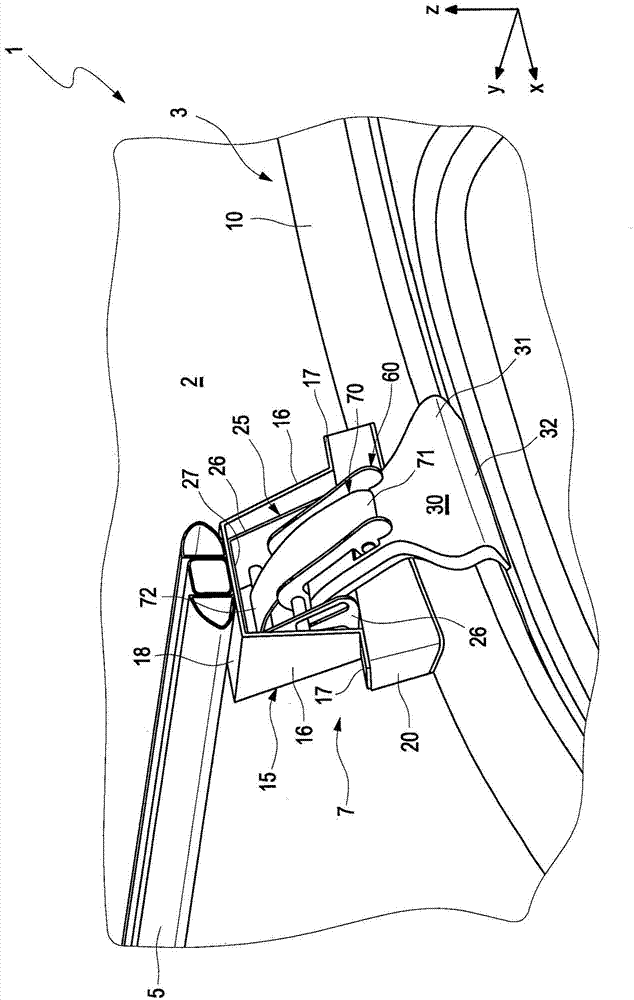

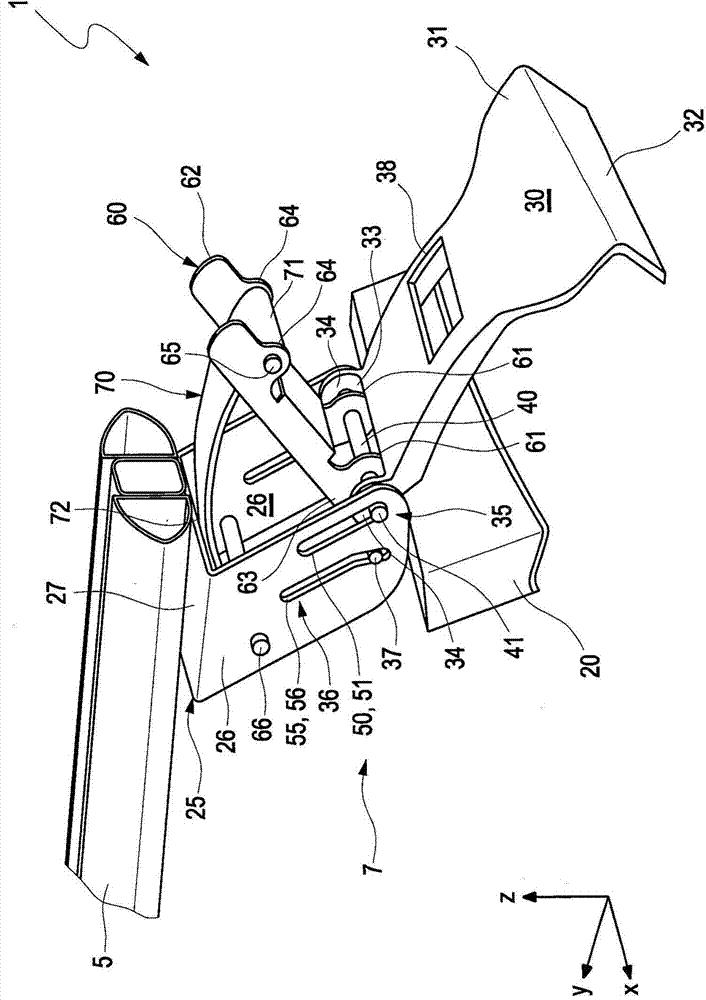

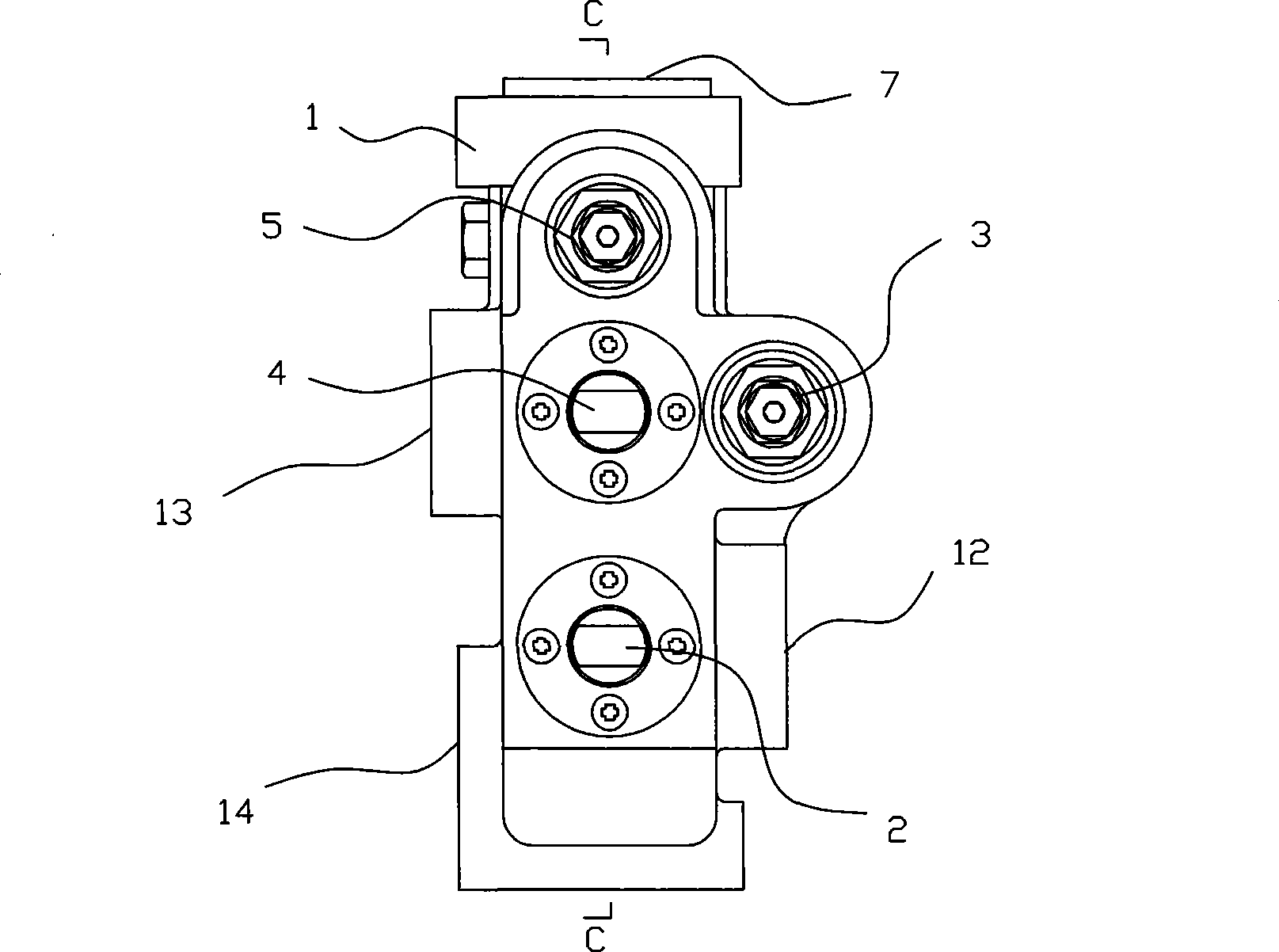

Roof bars for a motor vehicle

InactiveCN104853958ASmall control forceEasy to operate with one handSupplementary fittingsEngineeringMotor vehicle crash

Roof bars (1) for a motor vehicle, having a support structure (7) for a roof bar element (5) with an attachment claw (30) which engages at a first end (31) on a side wall rail (10) of a vehicle body (3) and is connected in an articulated fashion to a clamping lever (60). According to the invention, the attachment claw (30) is guided in a guide (50) in the support structure (7) and a leaf spring (70) is provided which, on the one hand, engages on the clamping lever (60) in the region of its free end (62) and, on the other hand, is supported on the support structure (7), wherein when the clamping lever (60) is pressed down towards the attachment claw (30) by the spring force the attachment claw (30) is clamped on the side wall rail (10).

Owner:AUDI AG

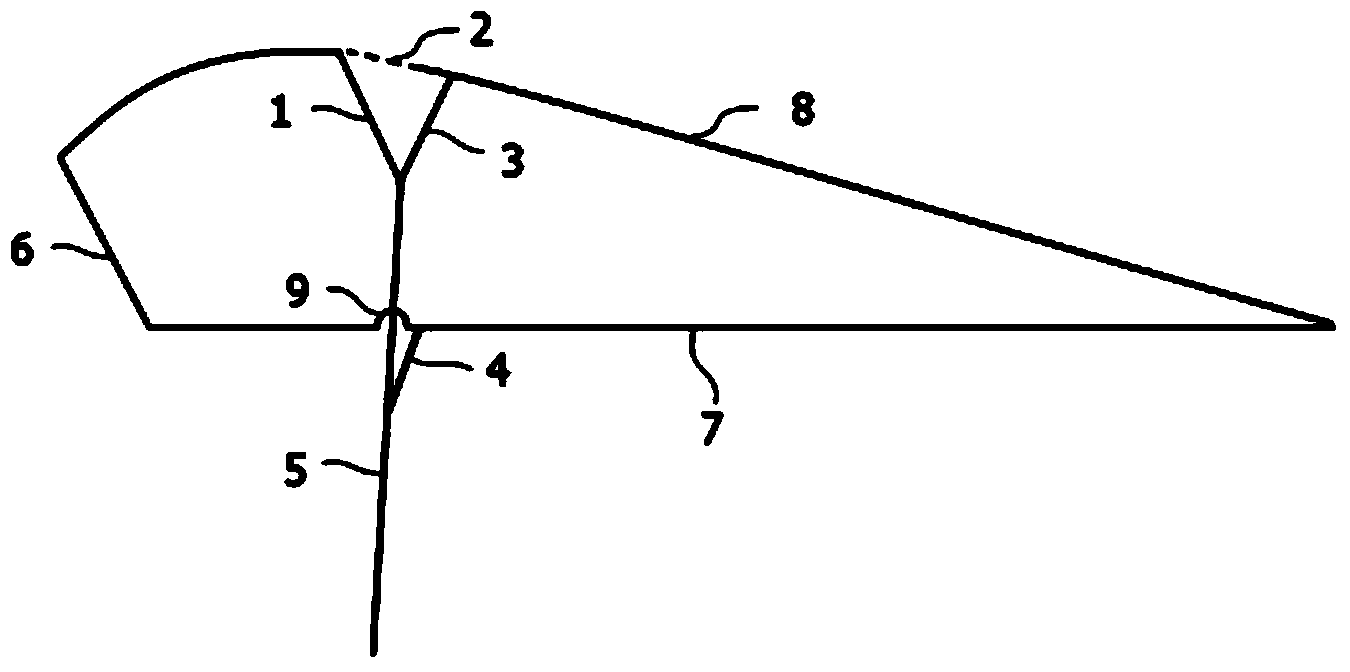

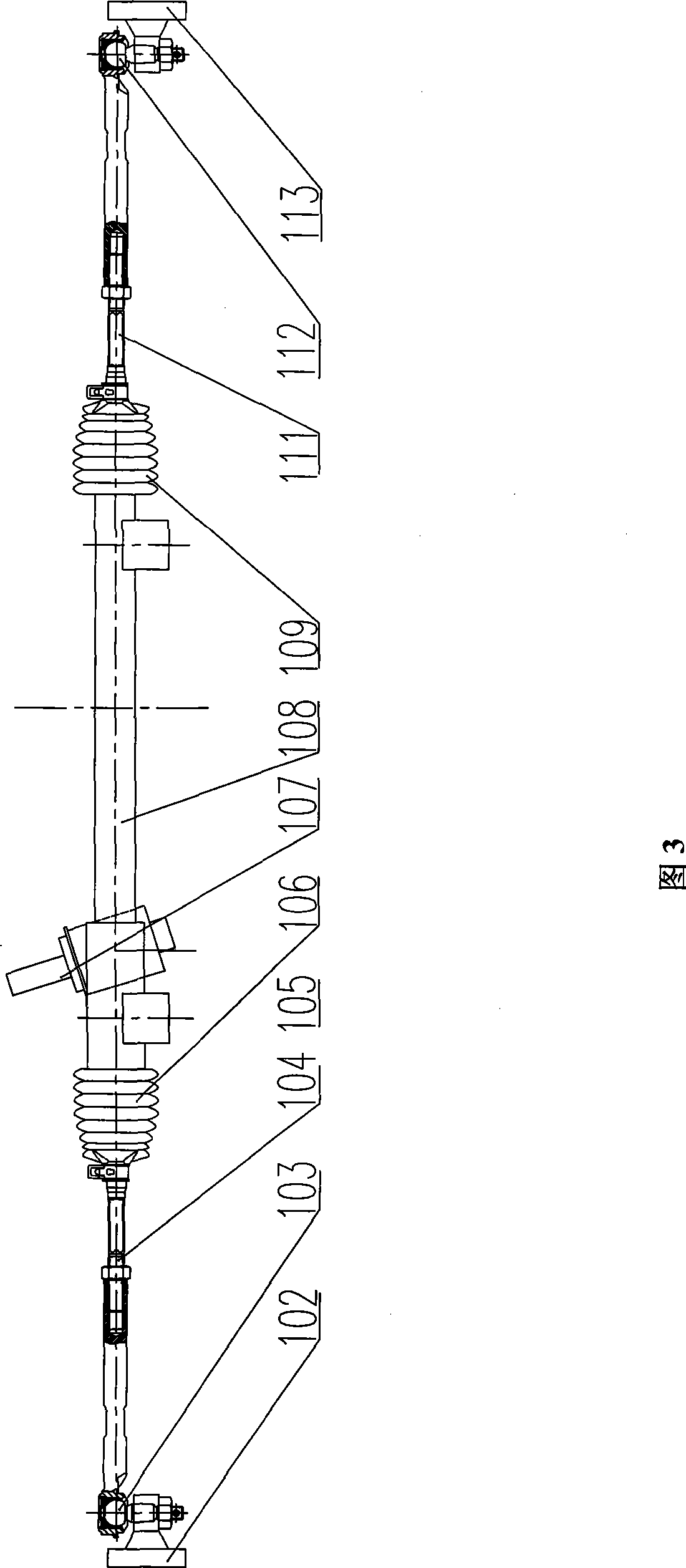

Tail control force induced control pull-type cable remote control underwater vehicle

ActiveCN104044715AEasy to place verticallyTow heading stabilizationUnderwater vesselsUnderwater equipmentRemote controlMovement control

The invention discloses a tail control force induced control pull-type cable remote control underwater vehicle which comprises torpedo type floating bodies, a fixed tilt wing type support, a fixed horizontal main wing, a fixed vertical tail wing, a controllable attack angle horizontal tail wing, a tail horizontal thrust water sprayer pipe system and a main cavity capable of realizing a pull course stabilization function, wherein the main cavity is of a vertical rudder shape, the two torpedo type floating bodies are arranged at two sides above a vertical symmetric surface of the main cavity of the underwater vehicle, the fixed horizontal main wing is connected with the two torpedo type floating bodies through a fixed shaft, two support short plates are arranged between the front part of the fixed horizontal main wing and the main cavity, the fixed tilt wing type support is used for connecting the torpedo type floating bodies with the upper part of the main cavity, and the controllable attack angle horizontal tail wing and the fixed vertical tail wing are arranged above the rear part of the main cavity. The tail control force induced control pull-type cable remote control underwater vehicle is flexible and reliable in control mechanism, better in pull course stability, strong in autonomous stabilizing capacity, high in bow steering, heaving, and swaying movement control efficiencies, and higher in business development value.

Owner:SOUTH CHINA UNIV OF TECH +1

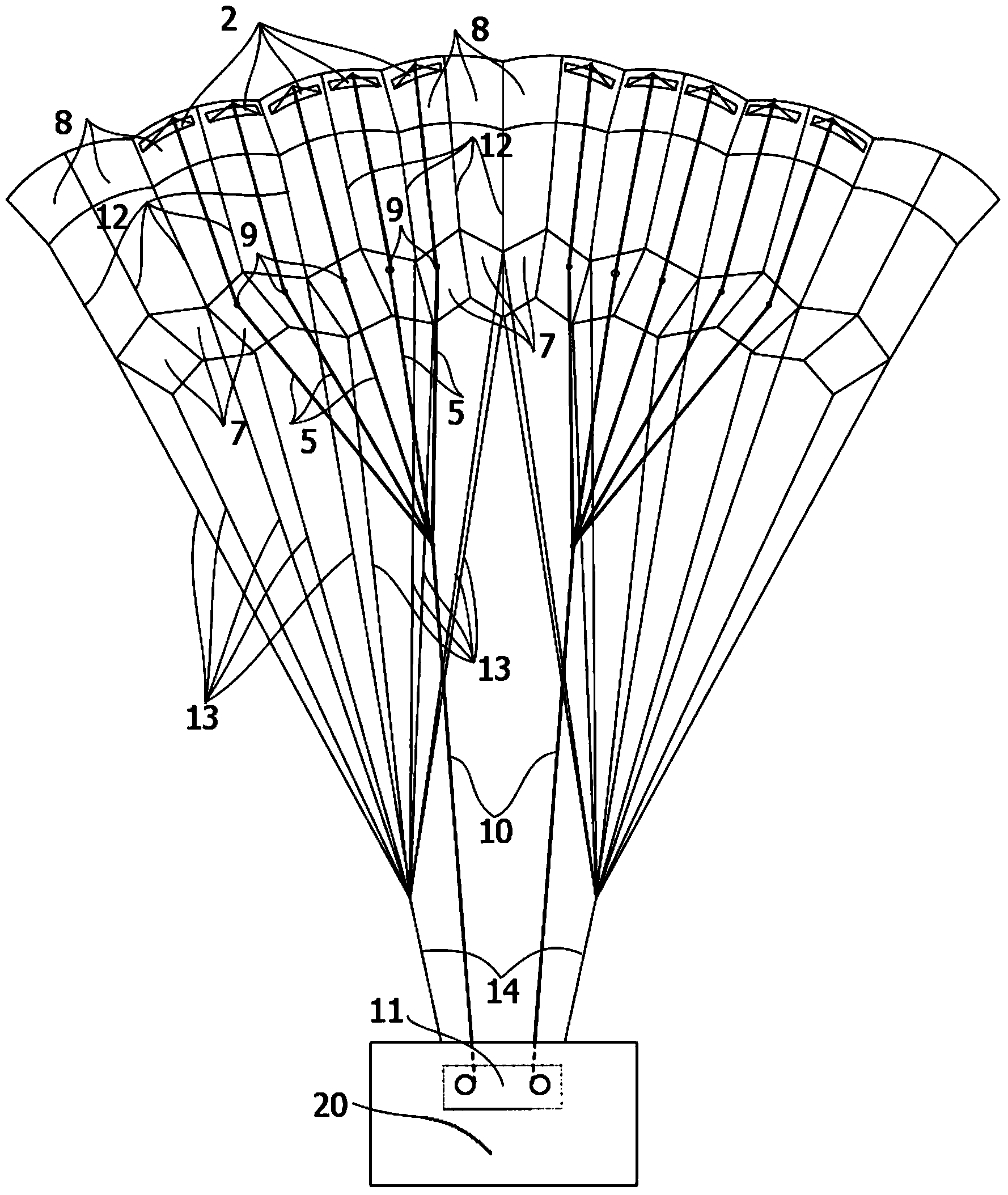

Novel parafoil and steering and control method thereof

InactiveCN103661955ASmall control forceHigh control precisionParachutesAerospace engineeringLower wing

The invention provides a novel parafoil and a steering and control method thereof. The parafoil comprises upper wing surfaces, lower wing surfaces, a plurality of wing ribs, two groups of parafoil ropes, two groups of steering ropes, two groups of straphangers and two steering straps. A plurality of flow guide holes are formed on two sides of each upper wing surface symmetrically, a flow guide vane is arranged on the inner side of each upper wing surface and at the position corresponding to each flow guide hole, a plurality of steering rope holes and the steering ropes penetrating the steering rope holes are arranged on two sides of each lower wing surface symmetrically, each flow guide vane is arranged between each upper wing surface and the corresponding lower wing surface, and each flow defector is connected with the corresponding steering rope. The steering ropes are stretched to drive the flow guide vanes to fold and unfold so as to control opening and closing of the flow guide holes, and directional steering and flared landing steering are realized. The novel parafoil has the advantages that aerodynamic performance of the parafoil is changed through the structures of the flow guide vanes, the flow guide holes and the steering ropes, weight of an existing steering mechanism is reduced greatly, steering force is low, the directional steering and the flared landing steering are realized simultaneously, and control accuracy is high.

Owner:AEROSPACE LIFE SUPPORT IND LTD

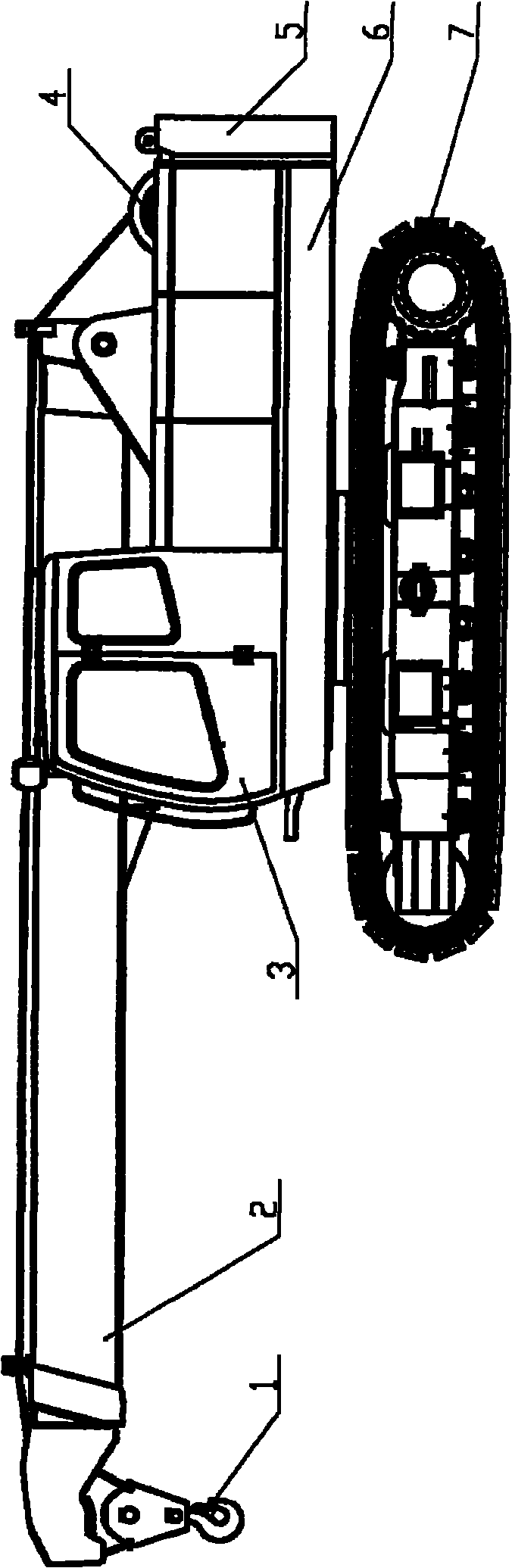

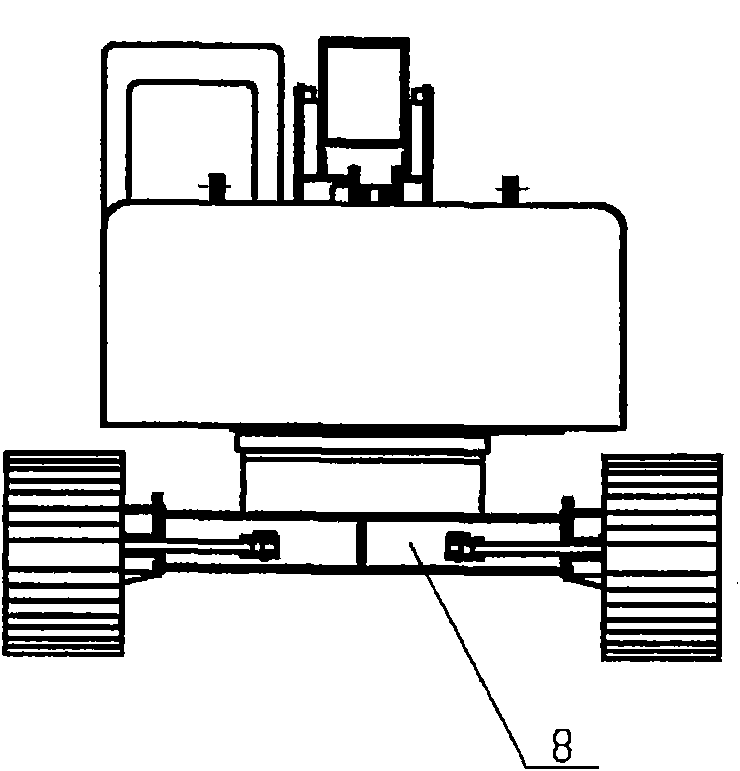

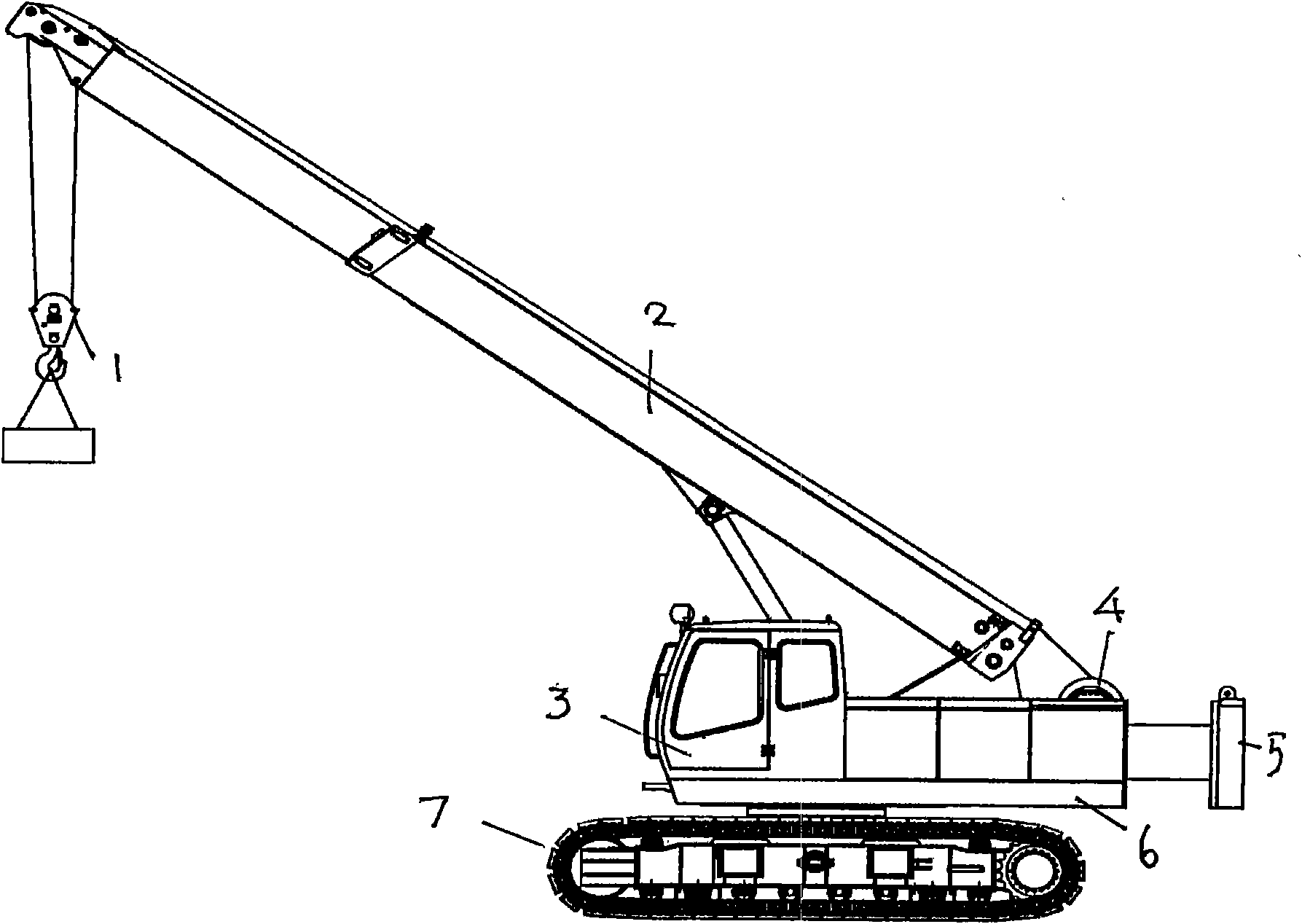

Novel lower chamber device

The invention relates to a novel lower chamber device. The lower part of the novel lower chamber device is provided with double crawler travel mechanisms. A frame is arranged between the double crawler travel mechanisms. The upper part of the frame is provided with a rotating platform. The rotating platform is provided with a cab. The rotating platform at the rear of the cab is assembly connected with the lower end of a telescopic suspension arm. The rotating platform is provided with a lifting mechanism. The lifting mechanism is matched with the telescopic suspension arm. The rotating platform is also provided with a telescopic counterweight mechanism. When the novel lower chamber device is used for operating under the cabin, two modes of complete counterweight extension and complete counterweight shrinkage can be realized, wherein the counterweight extends completely to improve the lifting performance; and the counterweight shrinks completely to improve conformability for the space.

Owner:天津港第二港埠有限公司 +1

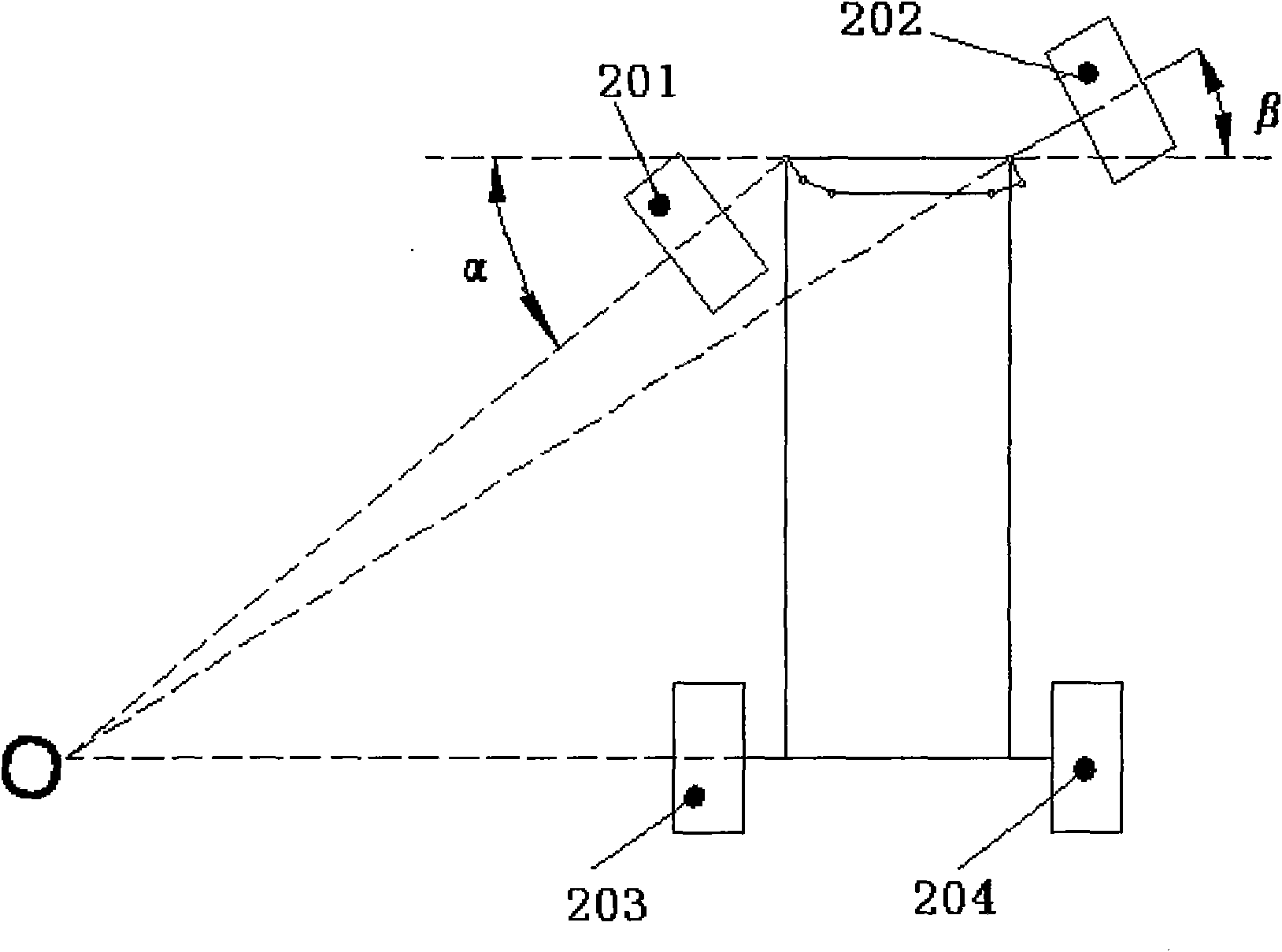

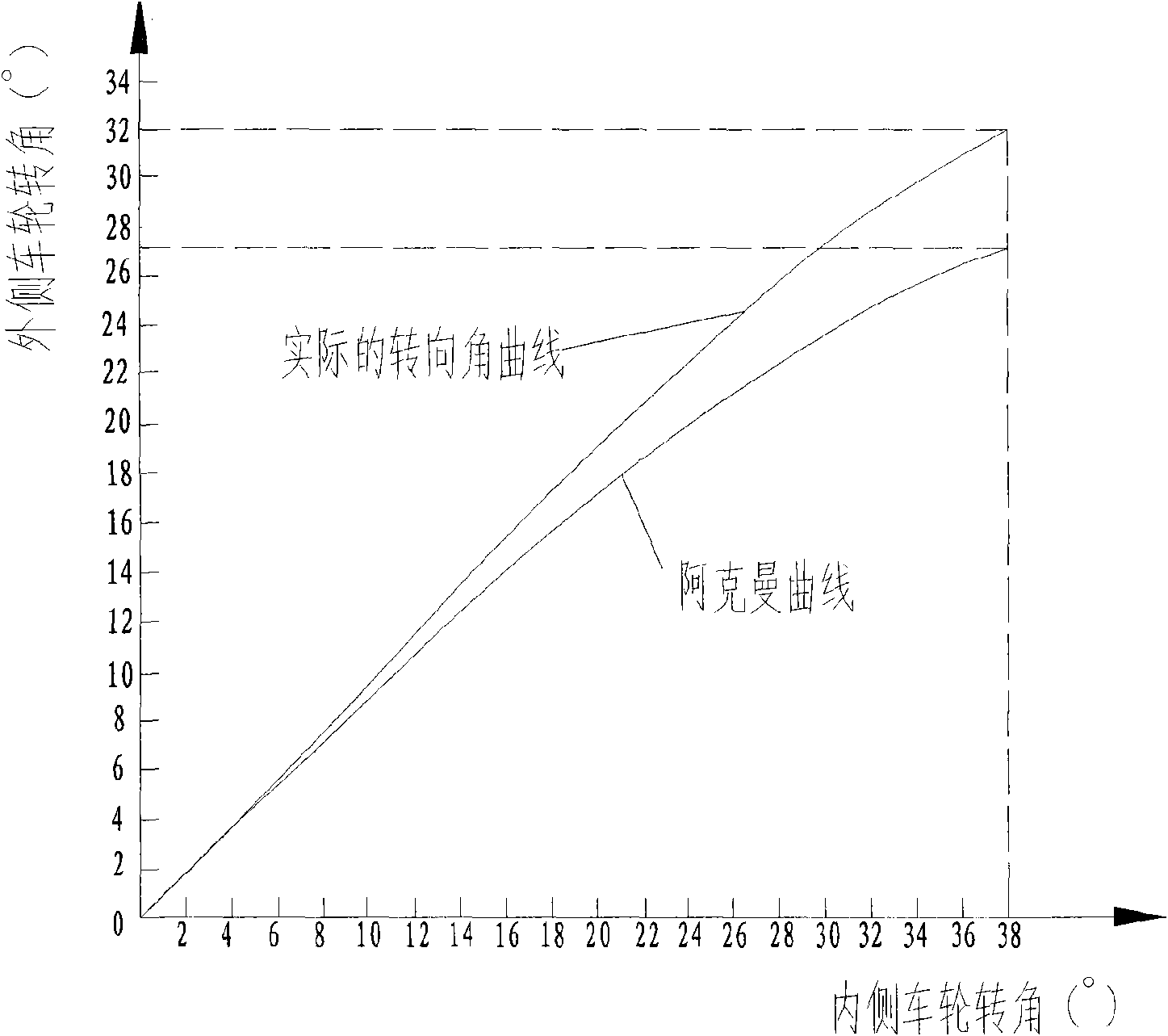

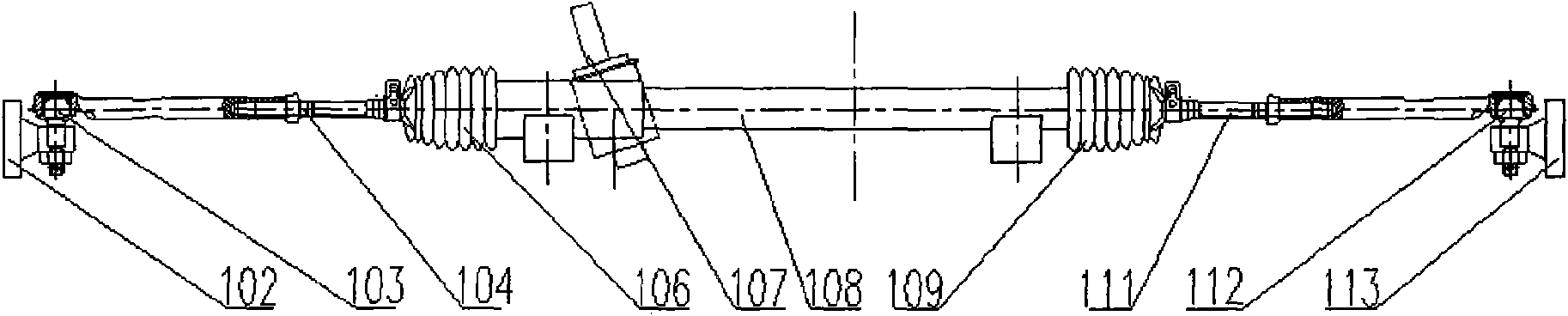

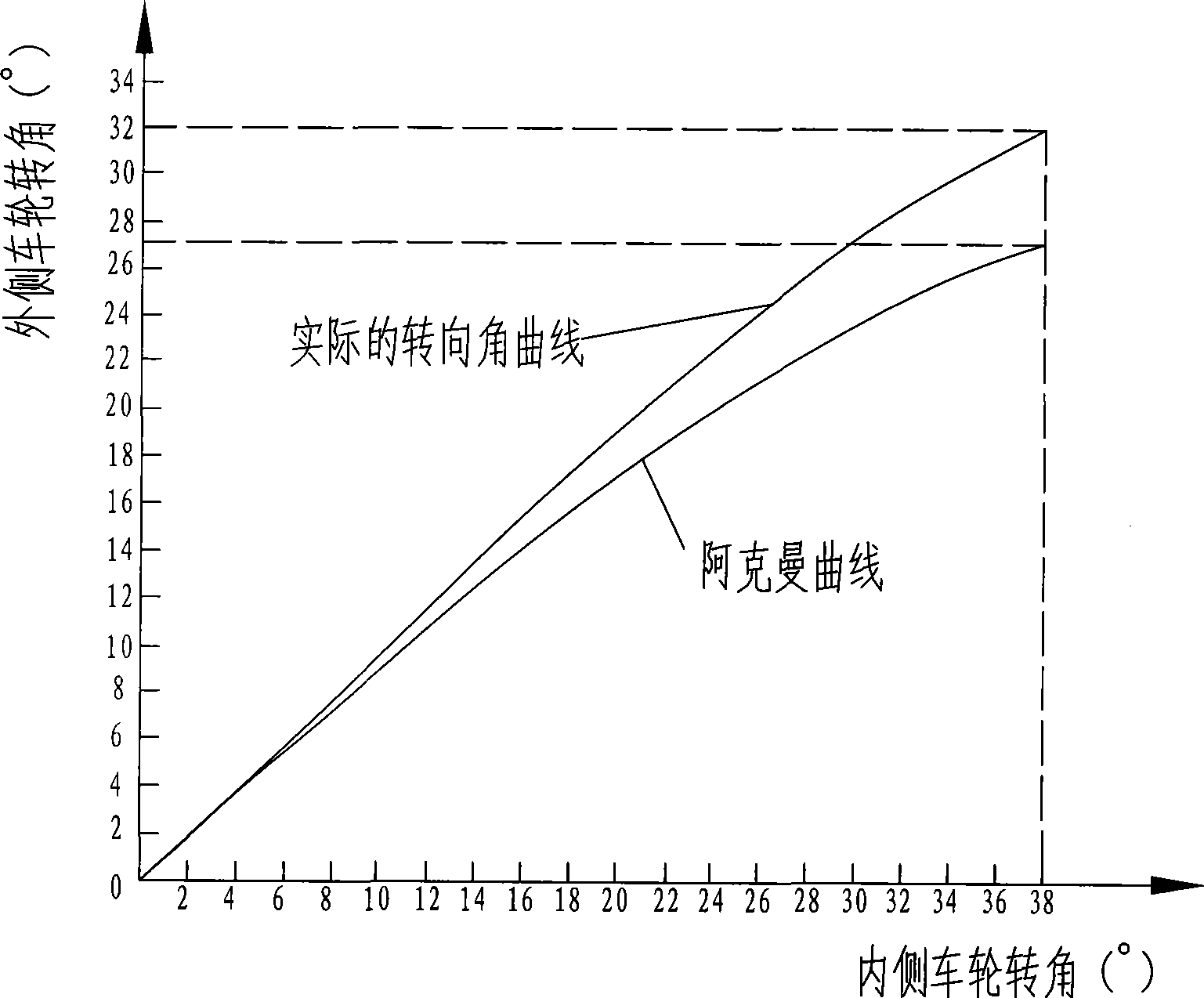

Vehicle steering gear

InactiveCN101549710AAvoid slidingReduce wearSteering linkagesMechanical steering gearsEngineeringCam

The invention discloses a vehicle steering gear, which comprises a left tie rod, a right tie rod, a steering shaft, a cylindrical cam, a left push rod and a right push rod; the inner wall of the cylindrical cam is formed with a left cam rolling groove and a right cam rolling groove; one end of the left push rod has a left push rod convexity matching with the left cam rolling groove; one end of the right push rod has a right push rod convexity matching with the right cam rolling groove. Since cam mechanism can realization any motion locus curve, so the left cam rolling groove and the right cam rolling groove can be designed to cause the motion locus of the push rod mechanisms in both the grooves to meet Ackermann's curve; thereby, the invention avoids slide phenomenon of wheel when vehicle turns, reduces tire abrasion, prolongs the service life of tire, can realize the transmission ratio variation function of the steering gear easily, and enable the vehicle to achieve better control performance.

Owner:SAIC MOTOR

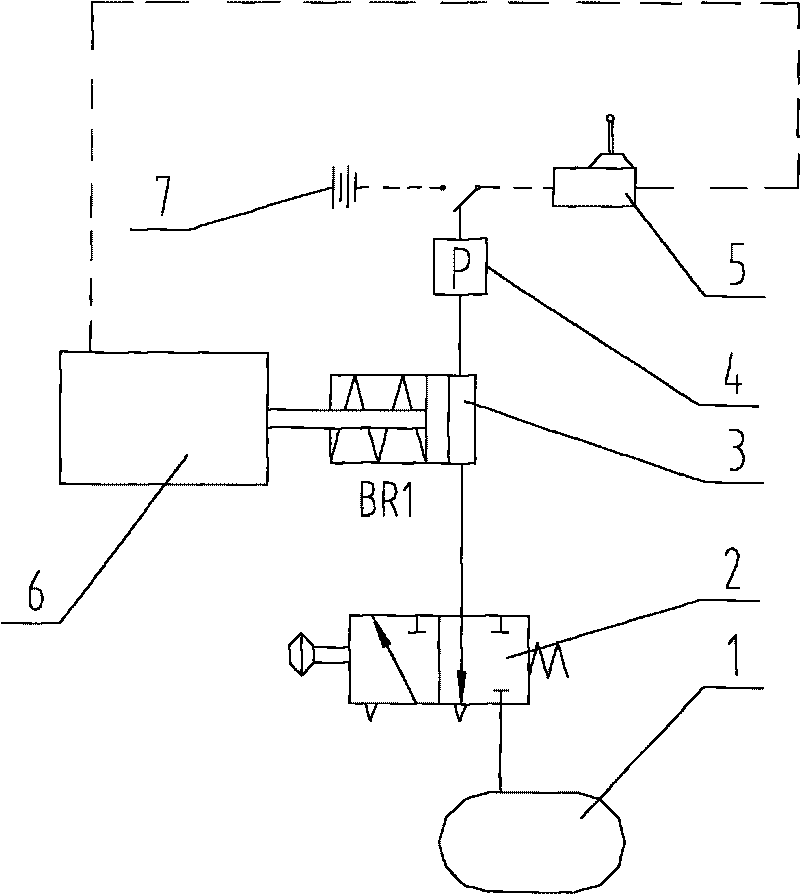

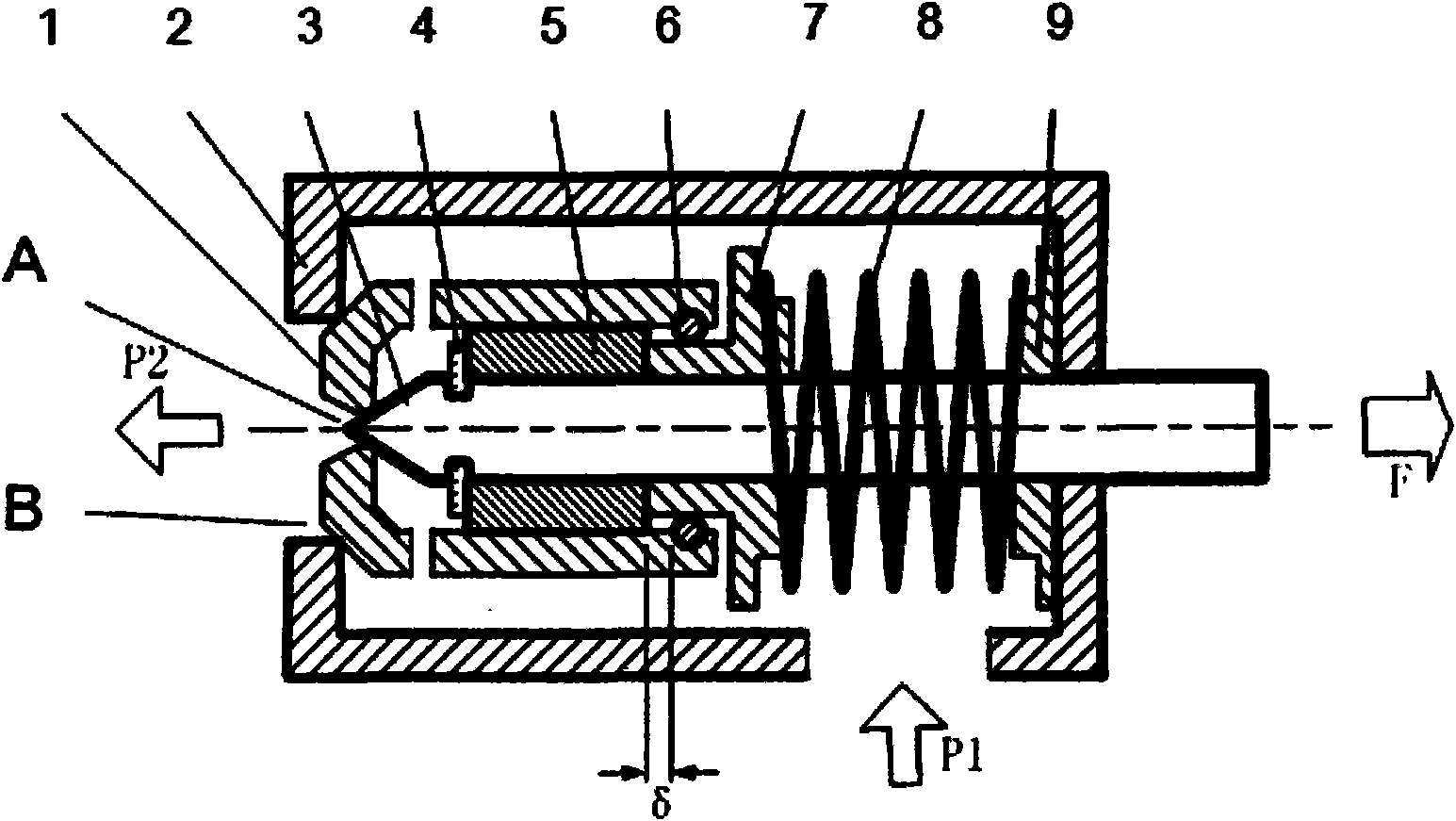

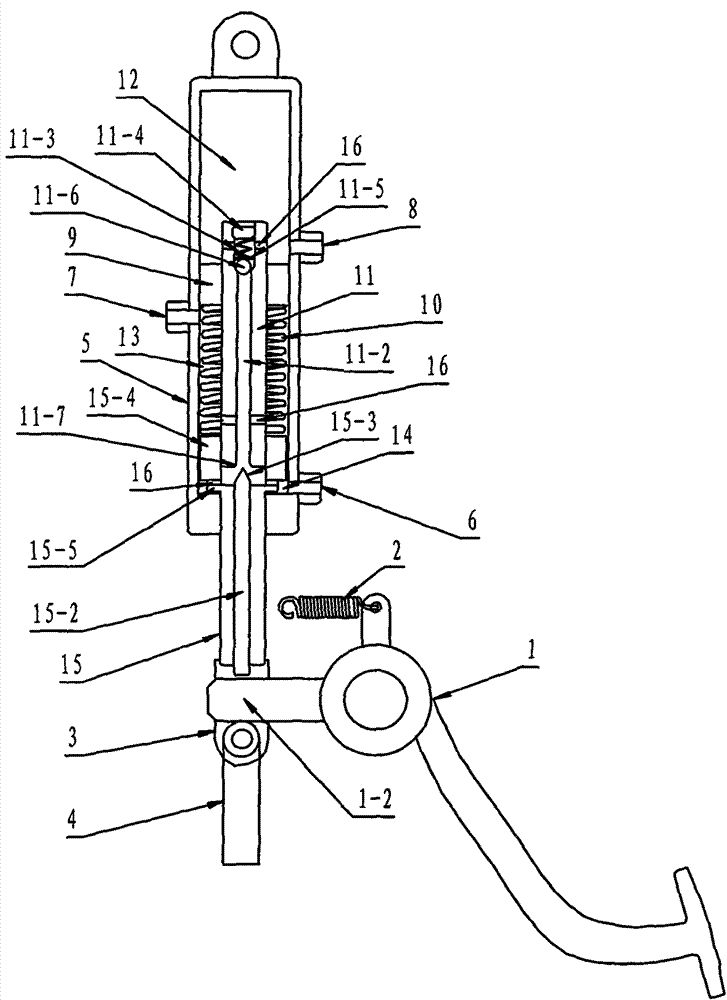

Brake system of mechanical single-drum road roller

InactiveCN101725105ASmall control forceApplication and release valvesRoads maintainenceParking brakePiston rod

The invention relates to a brake system of a mechanical single-drum road roller, which comprises an air storage tank (1), a brake control valve (2), a brake (3), a pressure switch (4) and a changeover governor (5) with a lock, wherein, the brake (3) comprises a cylinder (3.1) and a spring (3.2); the spring (3.2) is sheathed on a piston rod of the cylinder (3.1); the air storage tank (1) is connected with the brake control valve (2) which is connected with a rodless cavity of the cylinder (3.1) of the brake (3); the rodless cavity of the cylinder (3.1) of the brake (3) is connected with the pressure switch (4) which controls the power supply of the changeover governor (5) with a lock; and the pressure switch adopts normally open type pressure switch. The brake system of the invention utilizes an air-break brake principle to connect a pressure switch on a brake control valve or a brake cylinder, and realizes parking brake protection through controlling the changeover governor with a lock by the pressure switch. Only the parking brake is loosed, can the gear be put into gear for driving. The brake system has small operation force and safety and reliability.

Owner:柳工无锡路面机械有限公司

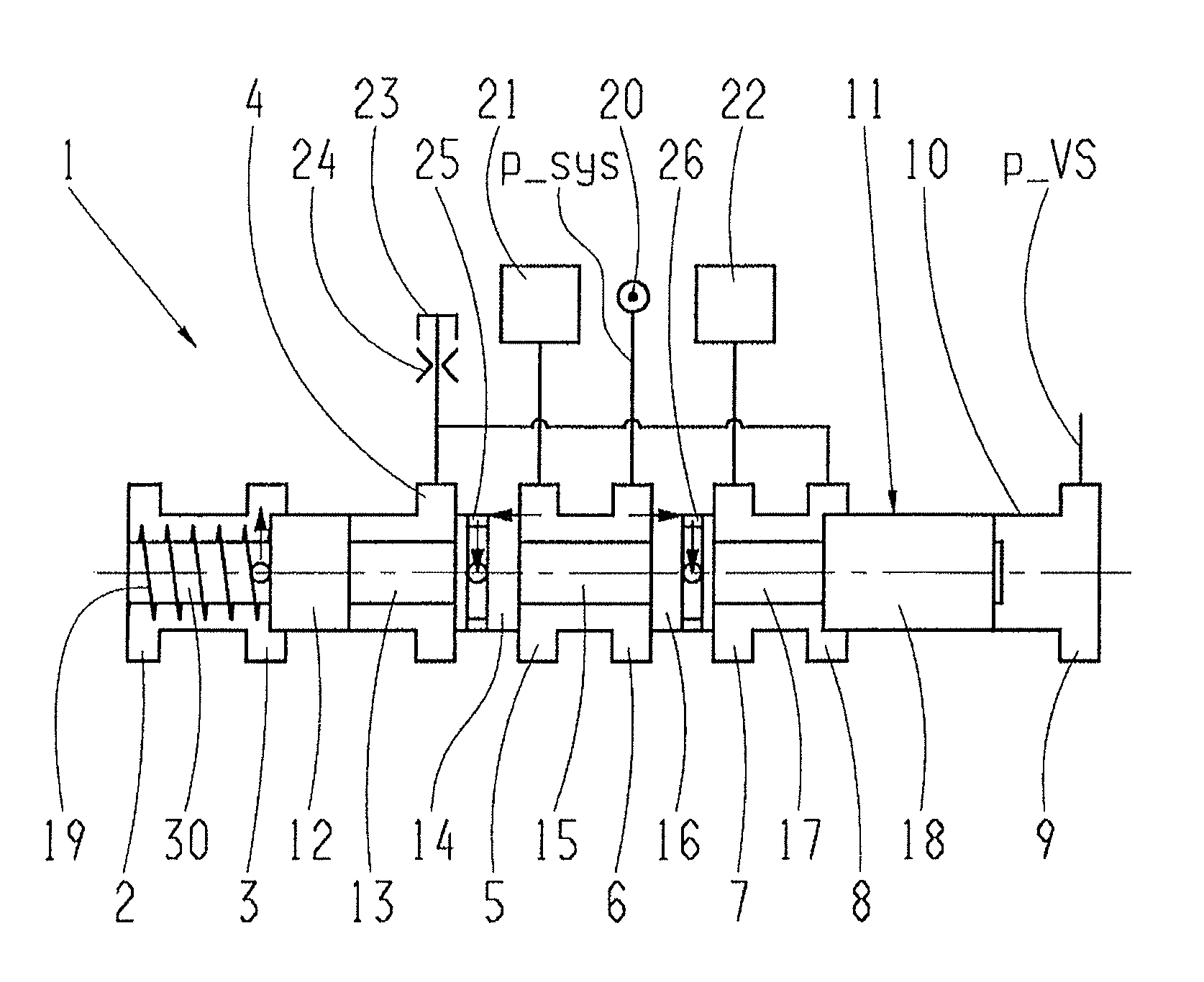

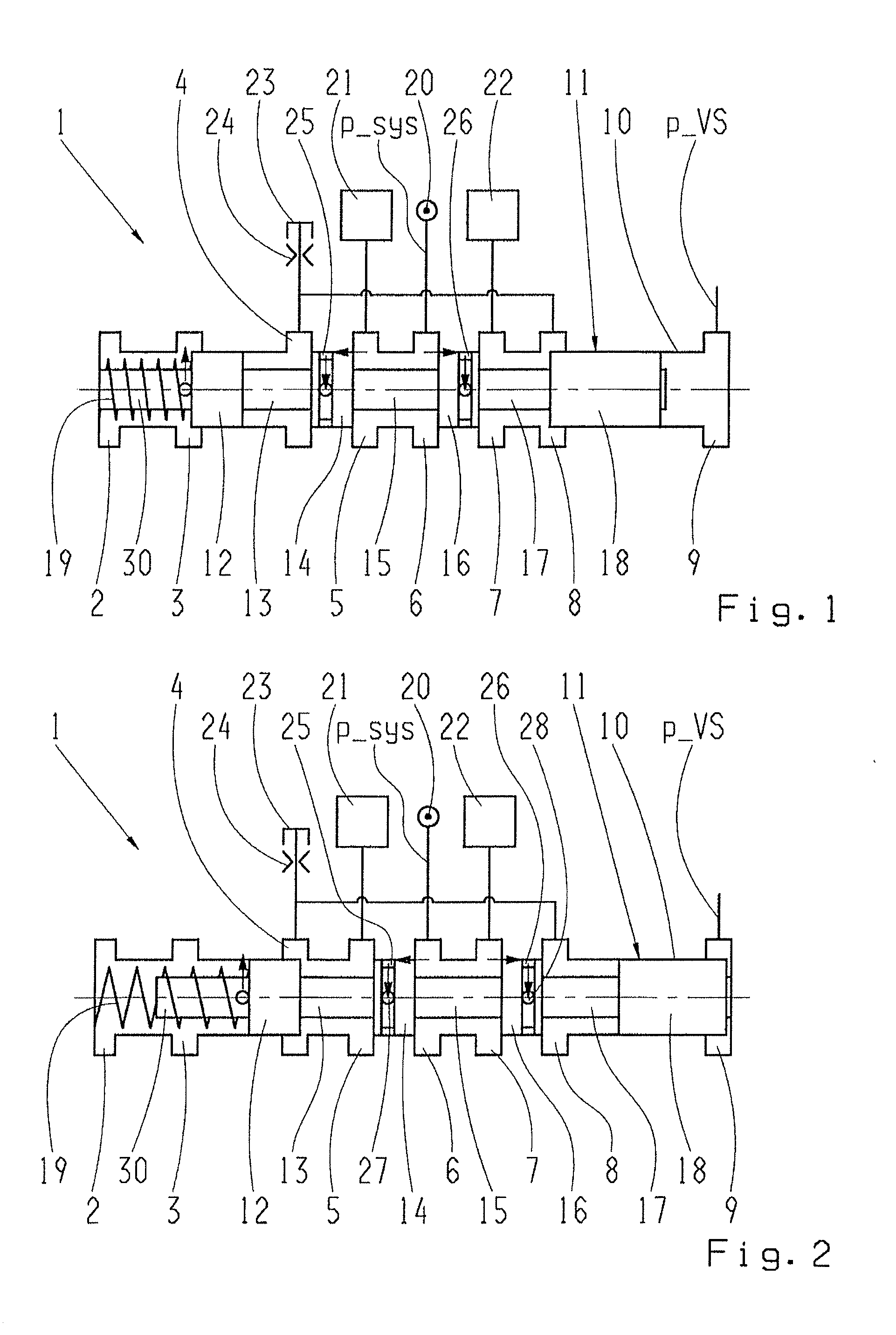

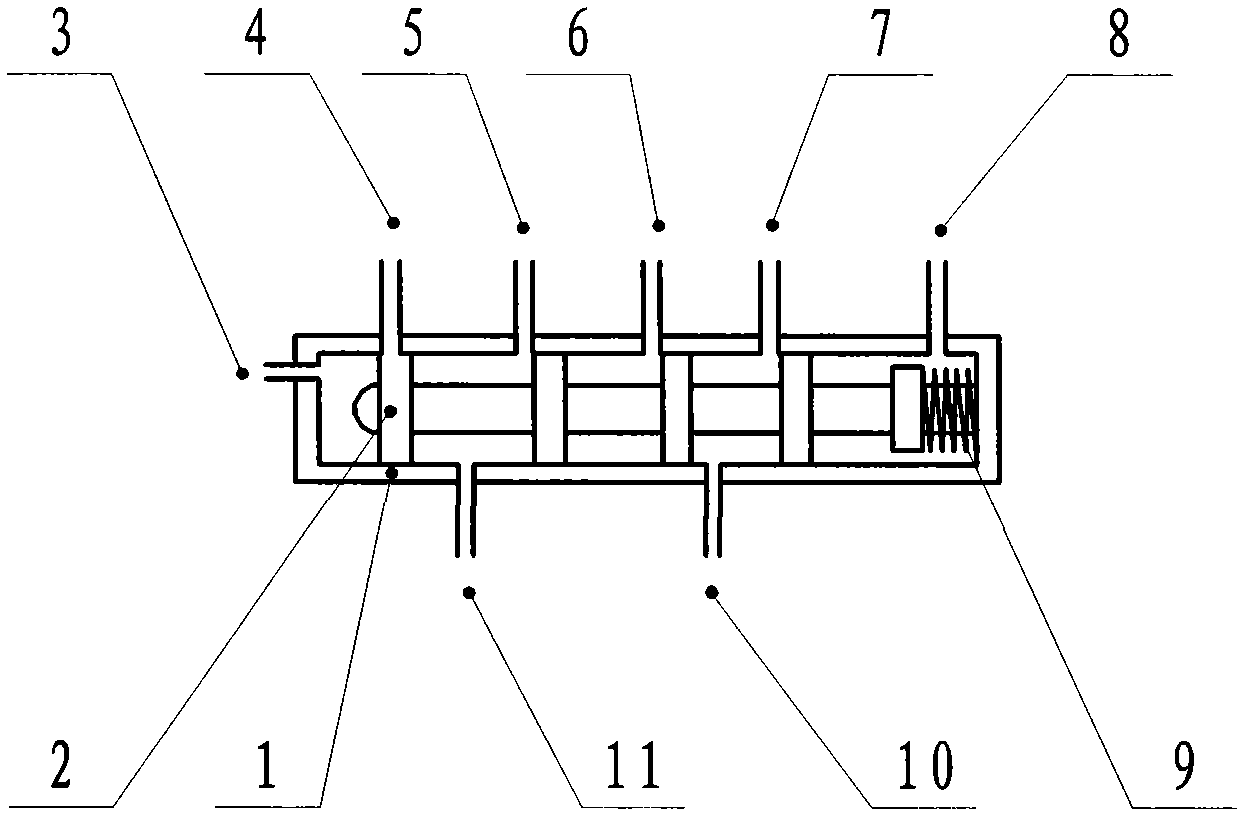

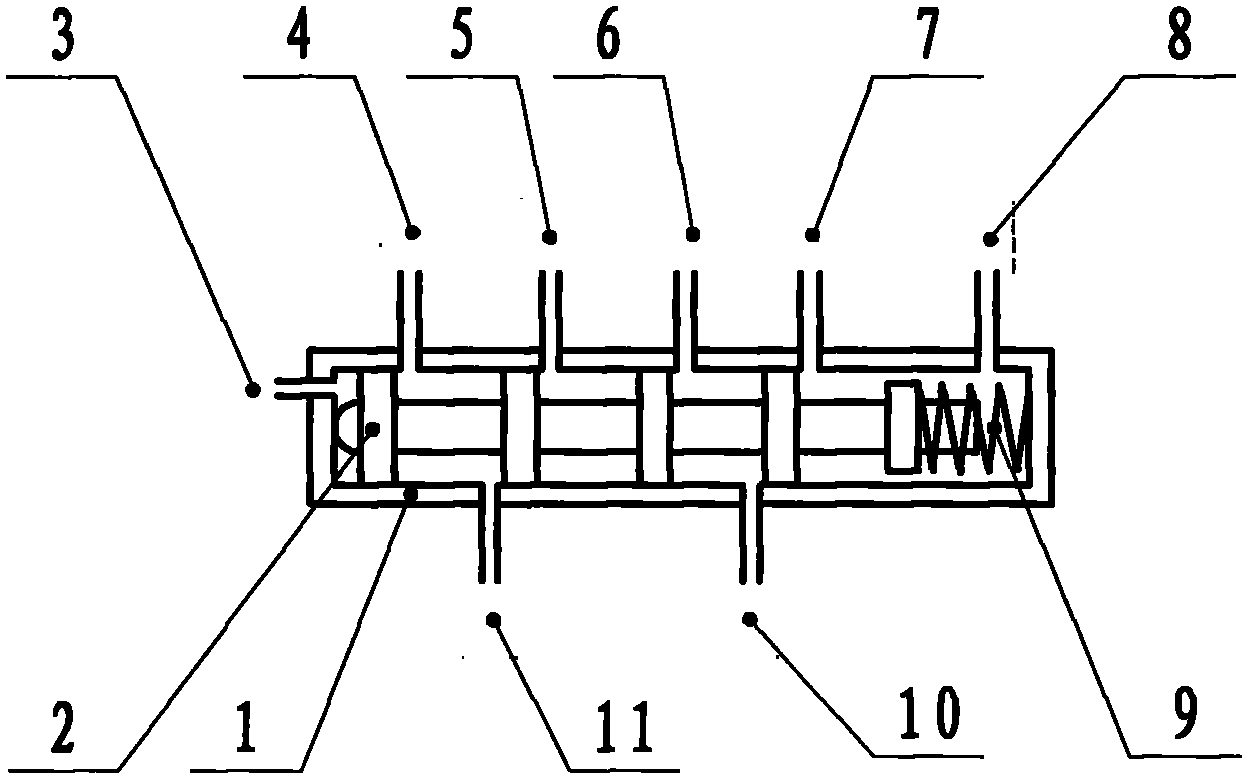

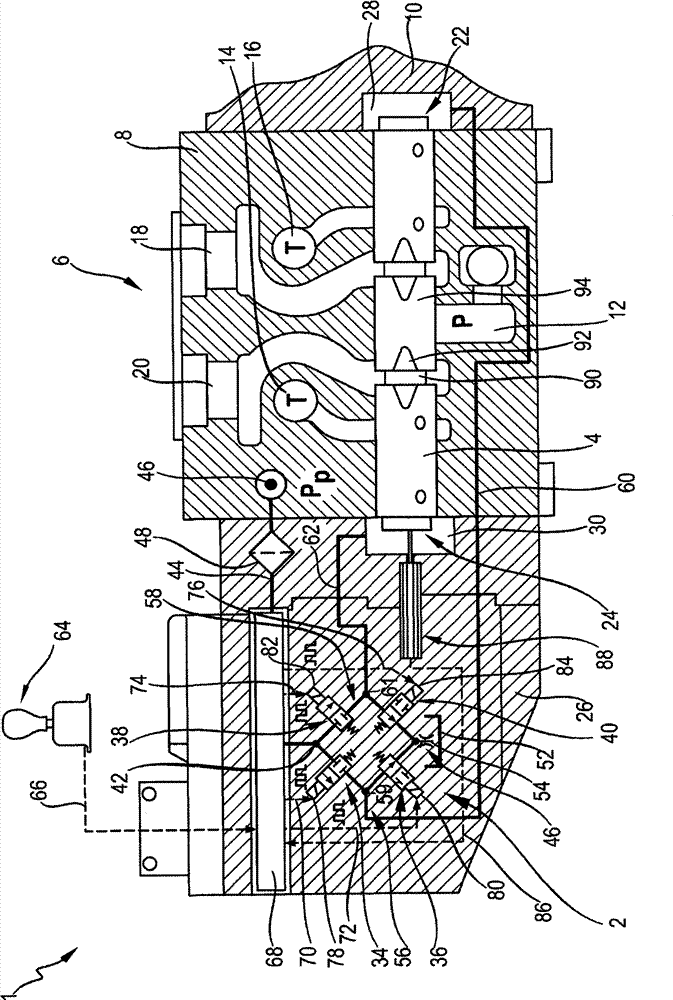

Valve device with a valve housing having multiple shift tongues

ActiveUS20130099147A1Small control forceCheck valvesMultiple way valvesEngineeringMechanical engineering

A valve device which comprises a valve housing having a plurality of shifting tongues and a valve slide that can move longitudinally in the valve housing. The valve slide is made with diameter sections which co-operate with the shifting tongues depending on an axial position of the valve slide. At least one of the diameter sections is made with at least one, at least approximately groove-like recess that extends in the circumferential direction of the valve slide. The groove-like recesses are functionally connected to an axial bore extending in the valve slide essentially in the axial direction, by way of at least one radial bore extending at least approximately in the radial direction in the valve slide.

Owner:ZF FRIEDRICHSHAFEN AG

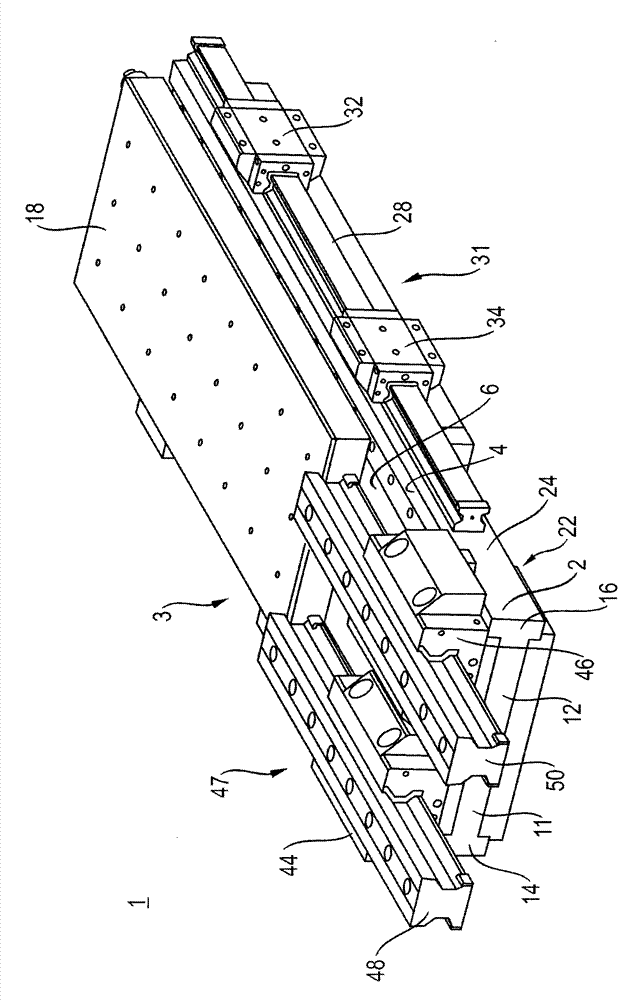

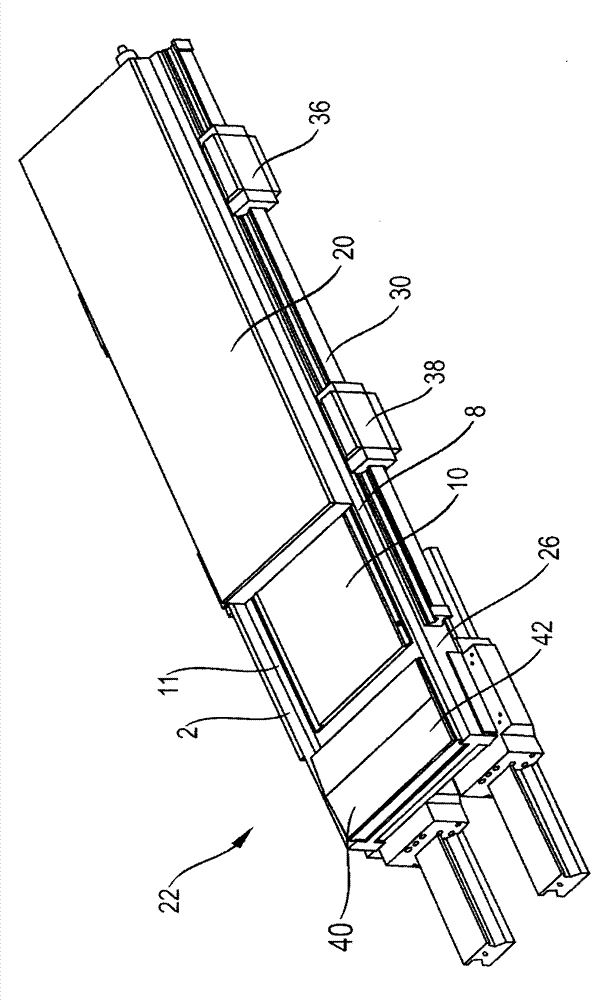

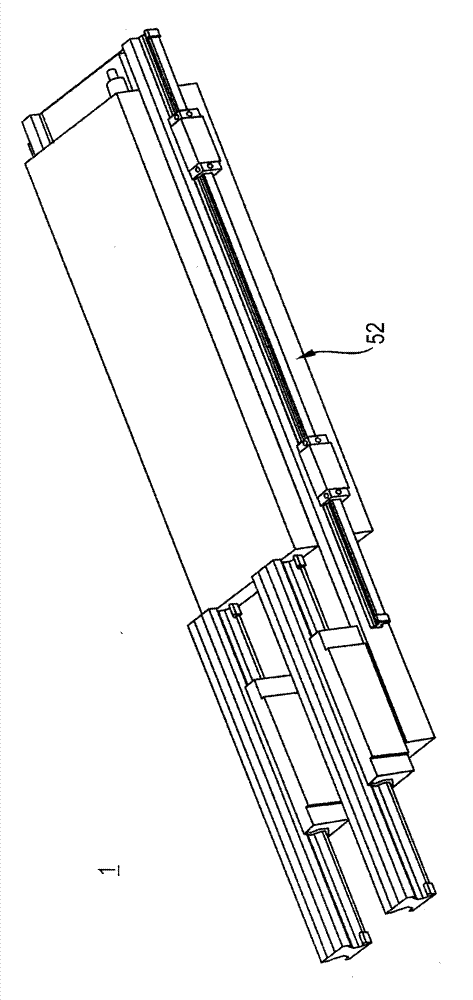

Linear Motor Assembly And Machine Tool With Linear Motor Assembly

InactiveCN104723154ALow costActive connectionFeeding apparatusLarge fixed membersEngineeringLinear motor

The present invention discloses a linear motor assembly used for a stepping machine tool. The linear motor assembly is provided with a linear motor with two secondary units which are arranged on a supporting plate of a sliding support, and each secondary unit is equipped with a primary unit. The supporting plate is sandwiched between the primary units, and the sliding support guides and supports movably along a longitudinal direction via at least one linear guide device. The sliding support can apply an operating force on a cutter at the end side, wherein the operating force is basically vertical with a longitudinal axis to play part.

Owner:ROBERT BOSCH GMBH

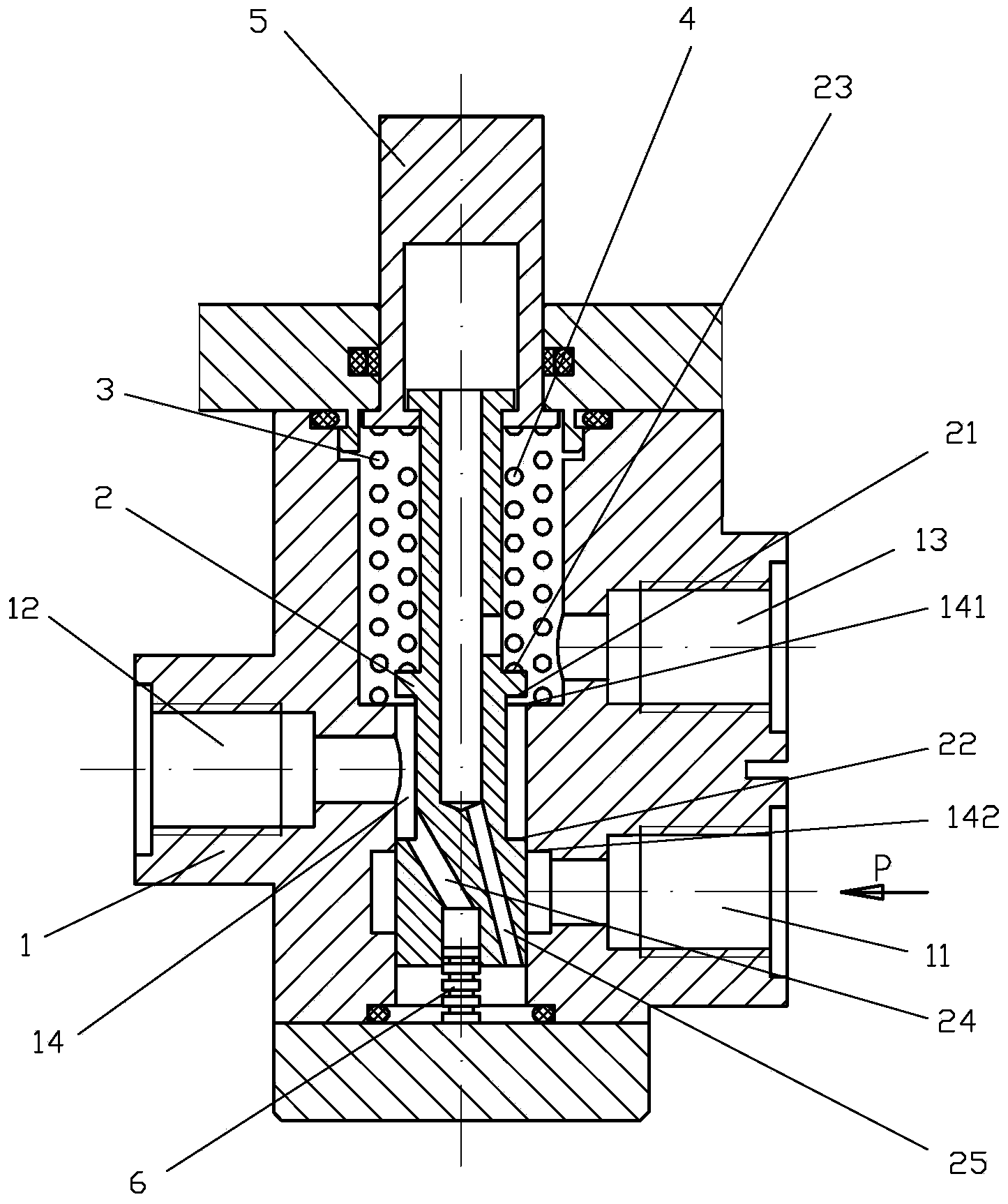

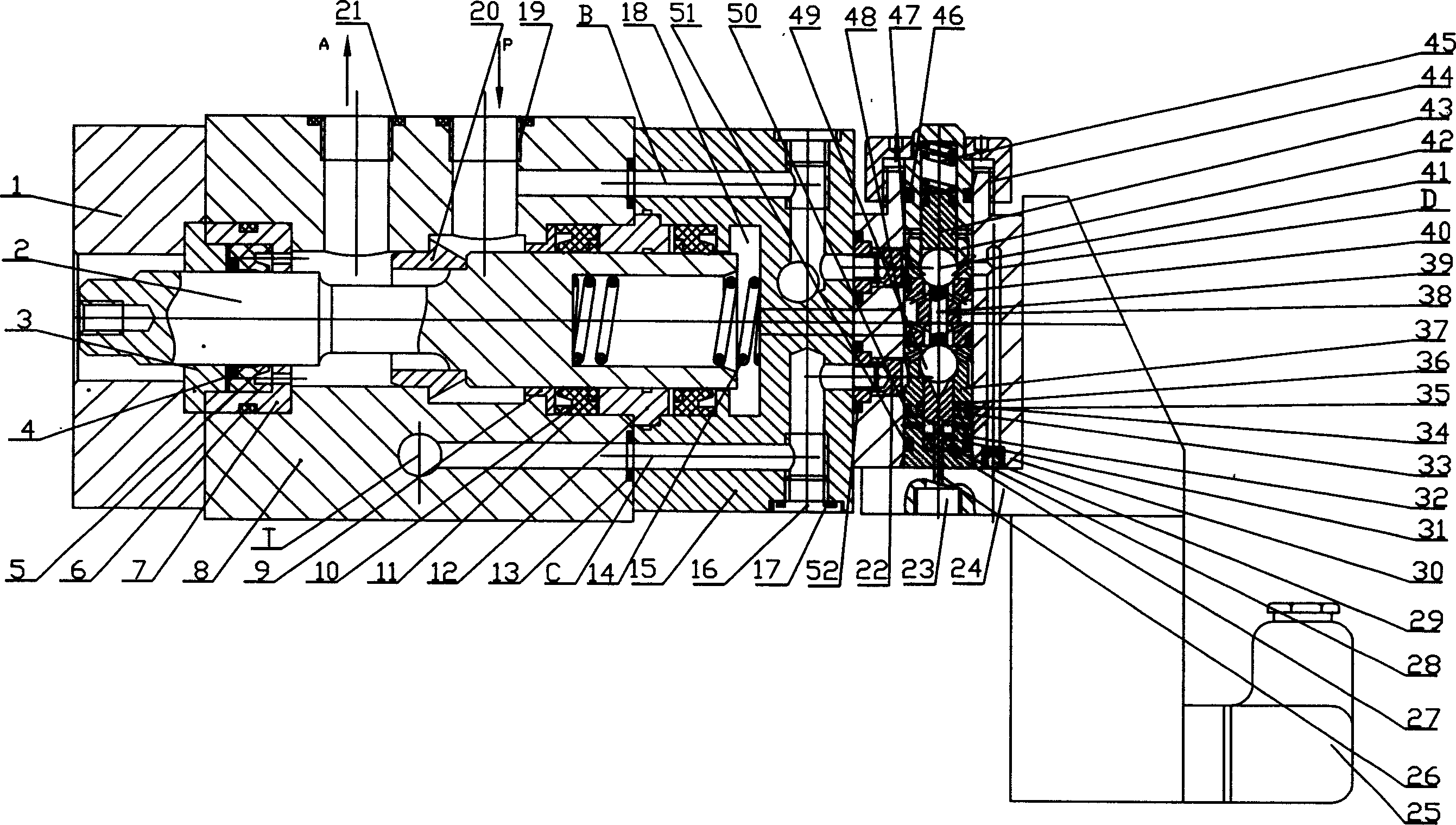

Pilot-operated high-pressure stop valve

InactiveCN101634367AExquisite structureReduce volumeOperating means/releasing devices for valvesFire rescueHand heldEngineering

The invention discloses a pilot-operated high-pressure stop valve structure. A pilot-operated valve bush is sleeved in a primary spool. A return spring generates a compression pressure for the pilot-operated spool through a spring seat, a guide sleeve and a check ring and also generates a compression pressure to the primary spool. When the pilot-operated high-pressure stop valve is opened, an operating force applied to the pilot-operated spool firstly opens the pilot-operated spool and then opens the primary spool under the actions of the check ring, the guide sleeve and a spring ring washer on the primary spool after the pilot-operated spool is opened to a designed opening travel. Because of simple structure, an adopted serial suit structure and few parts, the pilot-operated high-pressure stop valve structure is small in volume, light in weight, low in operating force and good in flux linearity and is particularly applied to hand-held high-flow high-pressure fire-fighting lances and spray pistols.

Owner:北京天龙万安科技发展有限公司

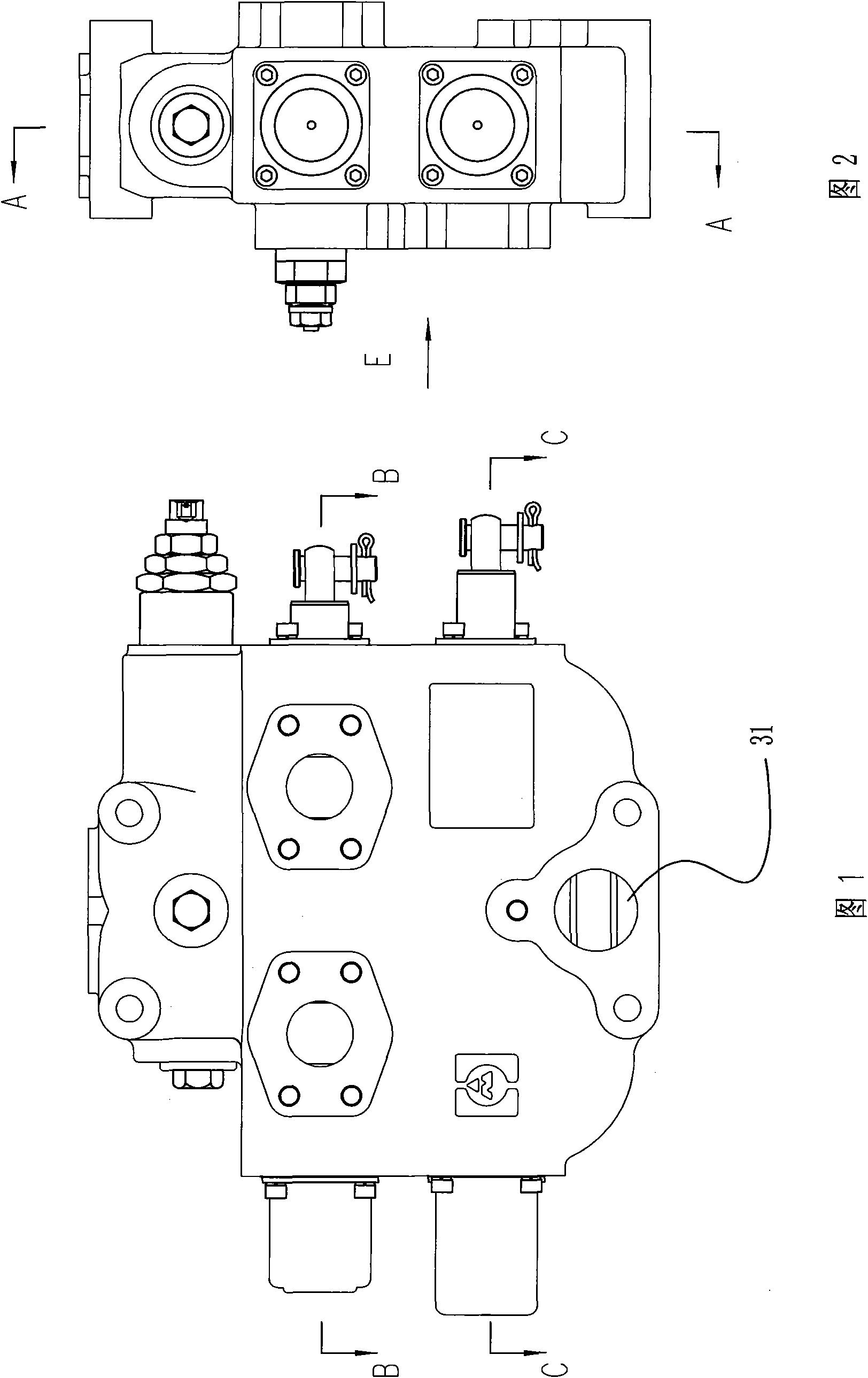

Multiway electro-hydraulic control valve adopting oil return differential pressure as pilot oil source

ActiveCN105971964AHighly integratedEasy to operateServomotor componentsRemote controlDifferential pressure

The invention relates to a multiway electro-hydraulic control valve adopting oil return differential pressure as a pilot oil source. The multiway electro-hydraulic control valve comprises an oil inflow valve group, an oil return pressure adjusting valve group, and multiple electro-hydraulic directional control valve groups arranged between the oil inflow valve group and the oil return pressure adjusting valve group. Common oil inflow channels, middle unloading channels and double-way oil return channels are arranged in valve bodies of the oil inflow valve group, the electro-hydraulic directional control valve groups and the oil return pressure adjusting valve group. The common oil inflow channels are communicated with the common oil return channels in parallel respectively. The middle unloading channels are of a series oil way structure. Pilot oil cylinders are arranged in end covers of the electro-hydraulic directional control valve groups. One end of a directional main valve element of each electro-hydraulic directional control valve group is connected with the corresponding pilot oil cylinder in a coaxially matched mode. Electromagnetic pilot valves are integrated on the electro-hydraulic directional control valve groups. Pilot pressure adjusting valves are arranged in the oil return channels of the oil return pressure adjusting valve group. 2-3 Mpa constant-value differential pressure is formed at the front ends and the rear ends of overflow ports of the pilot pressure adjusting valves. The safety guarantee requirements for remote control over hydraulic machines and safety guarantee for equipment or staff in an emergency can be met, and configuration of pipelines and the oil source is reduced.

Owner:泸州众大科技液压件有限公司

Automobile steering device

InactiveCN101417669ASmall steering sensitivityReduce abnormal wear and tearMechanical steering gearsSteering wheelCam

The invention discloses an automobile steering device which comprises a let steering pull rod, a right steering pull rod, a steering device shell body, a steering input shaft, a pinion, a left handspike, a right handspike and a cam, wherein, the center of the cam is provided with a ring gear whose center is rotatablely connected with the steering device shell body, and the periphery of the ring gear is provided with a left cam slot and a right cam slot. One end of the left handspike is provided with a left pin roll inserted in the left cam slot, and the other end of the handspike is hinged with the left steering pull rod; and one end of the right handspike is provided with a pin roll inserted in the right cam slot, and the other end of the handspike is hinged with the right steering pull rod. The invention makes use of a cam mechanism to cause rotation angles of the left steering wheel and the right steering wheel meet the Ackermann curve in real time, each wheel of the steering device carries out pure rolling movement when an automobile steers, and the abnormal abrasion is reduced when tyres steer, thus enhancing the life of the tyres greatly. The variable transmission ratio is realized, and the operation stability and the security are enhanced.

Owner:SAIC MOTOR

Hydraulic switch valve

ActiveCN102518614AReduce failure rateImprove dynamic performanceServomotor componentsFailure rateEngineering

The invention belongs to the filed of hydraulic pressure and relates to a hydraulic switch valve. The hydraulic switch valve comprises a switch valve core, a switch valve sleeve and a spring, wherein the switch valve sleeve is of a hollow structure; oil holes communicated with a left cavity and a right cavity of an action cylinder, and four servo control cavities and mechanical operation cavities, are formed in the side wall of the valve sleeve; the four servo control cavities and mechanical operation cavities are mutually separated at intervals; a control opening used for state switching and an oil return opening used for unloading are also formed in the switch valve sleeve; the switch valve core is arranged in the switch valve sleeve and has more than four convex shoulders; the width of the convex shoulders is more than the diameter of the oil holes; the distance between two convex shoulders corresponds to that between two oil holes in the side wall of the switch valve sleeve; and one end of the spring is sleeved on the end head of the switch valve core, and the other end of the spring props against the inner wall of the switch valve sleeve. The convex shoulders of the valve core are used for operating the control cavities to switch operation states of a hydraulic part and distribute flow, so switch interference is avoided, and the operation force is reduced, and the failure rate of the hydraulic part caused when the valve core is locked can be reduced.

Owner:JINCHENG NANJING ELECTROMECHANICAL HYDRAULIC PRESSURE ENG RES CENT AVIATION IND OF CHINA

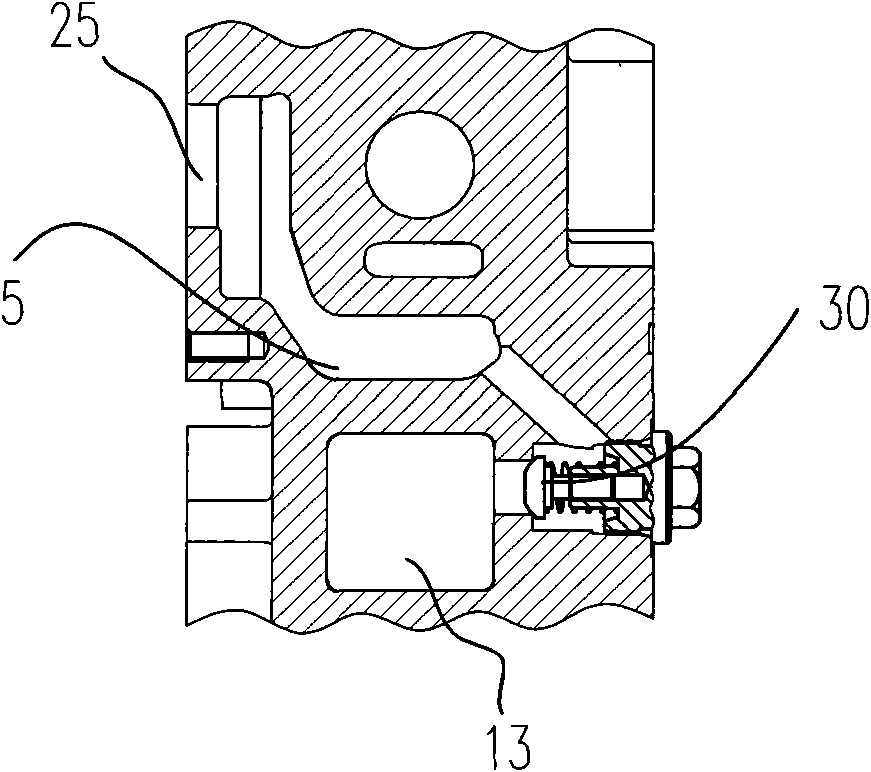

Hydraulic brake valve of feedback piston of valve core

InactiveCN103453178ASimple structureSmall control forceEqualizing valvesMultiple way valvesPistonEngineering

The invention discloses a hydraulic brake valve of a feedback piston of a valve core. The hydraulic brake valve comprises a valve body, the valve core, a return spring, a balance spring and a push rod, wherein the valve body is provided with an input port, an output port, an oil return port and a valve core cavity, the input port, the output port and the oil return port are respectively communicated through the valve core cavity, the valve core is connected to the valve core cavity in a sliding manner, and the push rod is movably connected to the upper end of the valve core; a feedback passage is arranged in the valve core, and the feedback channel is communicated between the output port of the valve body and the bottom end of the valve core cavity; the hydraulic brake valve further comprises the feedback piston, wherein the upper part of the feedback piston is contained in the feedback passage, and the bottom end face of the feedback piston is in contact with the bottom surface of the valve core cavity. According to the invention, through redesigning the structure of the feedback passage and adding the feedback piston, the hydraulic brake valve has the characteristics of high flow, low control force, stable output pressure and controllable size.

Owner:JIMEI UNIV

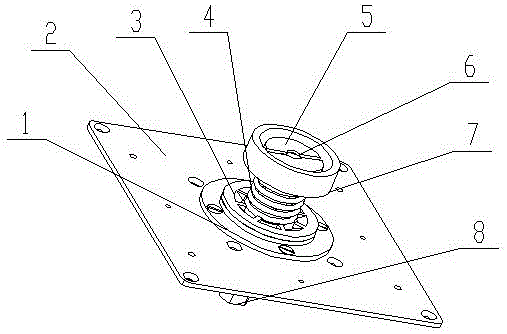

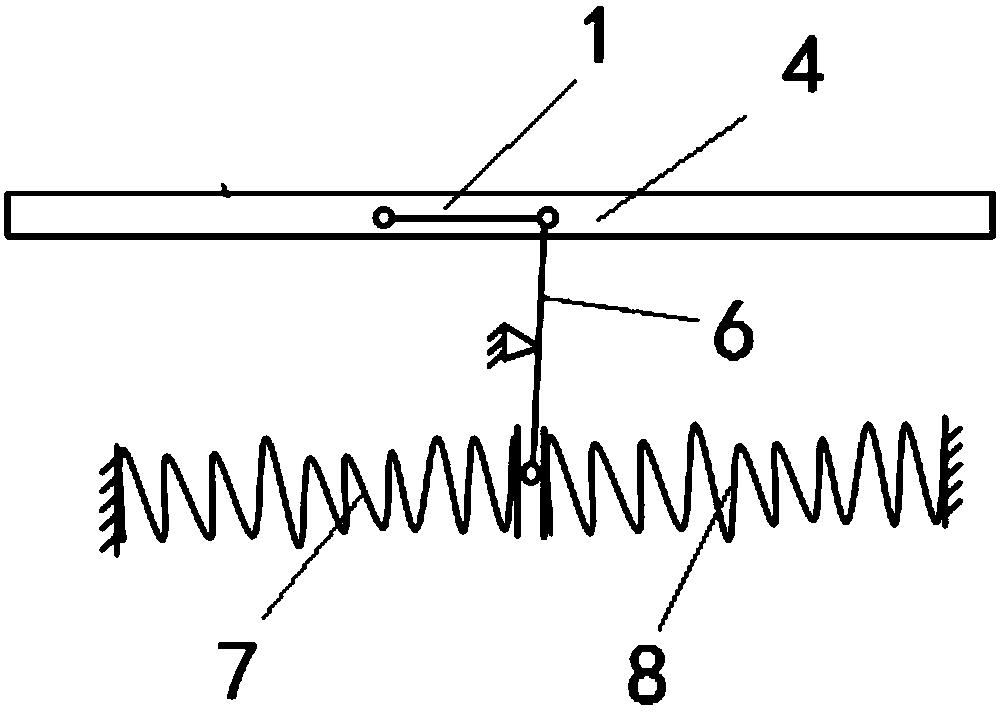

Automatic middle return mechanism

ActiveCN105936213AIncrease and decrease steering forceSmall control forceGearing controlControl devicesEngineeringGasket

The invention discloses an automatic middle return mechanism which comprises an installing panel (2), a locating bottom plate (1) and a center shaft (8). The automatic middle return mechanism is characterized in that the center shaft (8) is installed in the middle of the installing panel (2) in a penetrating mode, the locating bottom plate (1) is connected to the installing panel (2), a spring base (3) is connected to the upper portion of the locating bottom plate (1), a spring (4) is installed in the spring base (3), the center shaft (8) is sleeved with the spring (4), an adjusting nut (5) is installed on the upper portion of the spring (4), a fastening nut (7) is arranged outside the adjusting nut (5), the spring base (3) and the locating bottom plate (1) are matched in a spherical face mode, the locating bottom plate (1) is a concave spherical face, the spring base (3) is a convex spherical face, and an adjusting gasket (6) is installed on the adjusting nut (5). The automatic middle return mechanism is compact in structure, convenient to operate, reliable to carry, high in precision and suitable for use and popularization in automatic middle return.

Owner:GUIZHOU HUAYANG ELECTRICAL

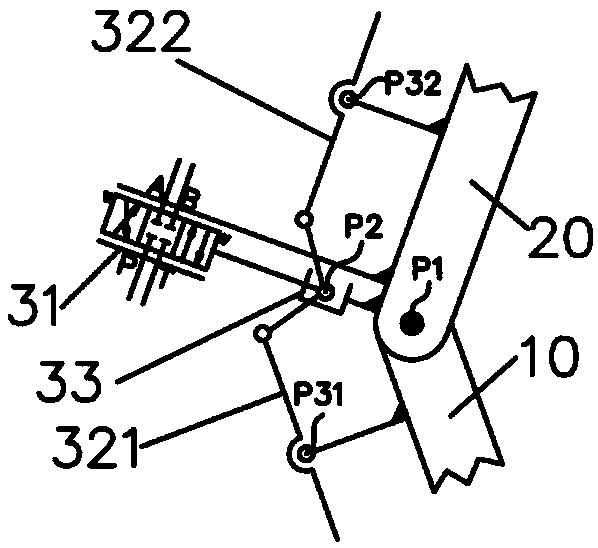

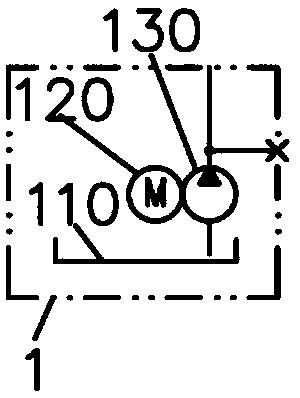

Valve-controlled hydraulic transmission system applied to exoskeleton robot

ActiveCN108518368AEasy to controlReliable controlProgramme-controlled manipulatorServomotor componentsLoop controlExoskeleton robot

The invention discloses a valve-controlled hydraulic transmission system applied to an exoskeleton robot. The valve-controlled hydraulic transmission system comprises a hydraulic oil source, a manualservo valve, an oil-filling one-way valve, an oil cylinder, a first mechanical arm and a second mechanical arm which is hinged to the first mechanical arm. The hydraulic oil source comprises a servo motor, a hydraulic pump and an oil tank; the servo motor drives the hydraulic pump; the hydraulic pump sucks oil from the oil tank to be supplied to the manual servo valve; the manual servo valve has mechanical position feedback to form closed-loop control; an oil outlet of the manual servo valve communicates with an oil inlet cavity of the oil cylinder and further communicates with the oil tank through the oil-filling one-way valve; and the manual servo valve comprises a reversing valve, a reversing control mechanism connected with the reversing valve, and a control mechanism travel limiting device. Under the joint cooperation effect of the manual servo valve, the oil-filling one-way valve and the oil cylinder, the control mode of the exoskeleton robot is simplified, the working reliability and safety are effectively improved, the working speed is increased while energy consumption is reduced, and the production and using cost is reduced.

Owner:GUIYANG HAIZHILI HYDRAULIC CO LTD

An operating method of a tractor clutch operating device with hydraulic power assist

ActiveCN104728309BEasy to controlIncreased torque reserve factorClutchesDriver/operatorPressure difference

Owner:LUOYANG WEILIN HYDRAULIC MACHINERY

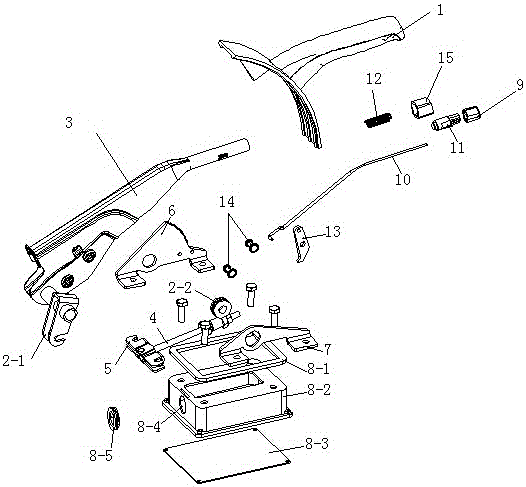

Parking brake control mechanism

PendingCN106671957ASimple structureIncrease leverage ratioHand actuated initiationsLocking mechanismEngineering

The invention discloses a parking brake control mechanism, which comprises a brake handle, a stay cable assembly and a brake handle locking mechanism, wherein one end of the brake handle is rotatably connected with a toothed plate seat through a rotating shaft, and a fan-shaped toothed plate is arranged on the toothed plate seat; the stay cable assembly is linked with the brake handle and includes a pull rod and a stay cable wiring board, one end of the pull rod is connected with the stay cable wiring board, and the other end of the pull rod is connected with a rotating shaft component on the rotating shaft; and the brake handle locking mechanism includes the toothed plate seat, a push rod, a push rod seat, a return spring and a button, one end of the push rod is provided with a pawl, the other end of the push rod is arranged in an inner hole at the end of the brake handle to be connected with the buttonthrough the return spring and the push rod seat, and the pawl is unlocked from the fan-shaped toothed plate. The parking brake control mechanism has the advantages that the technical structure is simple, the push rod is used as a pawl unlocking transfer device, reliability is good, durability is high, transmission efficiency is high, the stay cable wiring board is arranged under the car body floor for easy arrangement and after sales maintenance, and the button can be plated with chrome, so that the parking brake control mechanism can be beautifully shaped, and can be popularized on a large scale.

Owner:江西大乘汽车有限公司

Helicopter tail rotor flight control load compensation method

The invention discloses a helicopter tail rotor flight control load compensation method, and belongs to the technical field of helicopter flight control. The helicopter tail rotor flight control loadcompensation method comprises the following steps: Step I, firstly performing theoretical analysis on a tail rotor flight control system mechanism, thus obtaining a relation between an external load F1 and a tail rotor pitch; Step II, designing a load compensation device according to the relation between the external load F1 and the tail rotor pitch, wherein a force output by a load output elementis transmitted to a control line system to reduce a resultant force on the control line system; when a force transmitted from a force F2 output by the load output element to the operation line systemis zero, the corresponding external load F1 at the time is 0; when the external load F1 is 0, a force transmitted from the force F2 output by the load output element to the operation line system through a force transmission line system is matched with the external load F1, and the directions are opposite, so that the resultant force on the control system is reduced. According to the helicopter tail rotor flight control load compensation method, by the adjustment of a reference position, a control force can be further reduced.

Owner:CHINA HELICOPTER RES & DEV INST

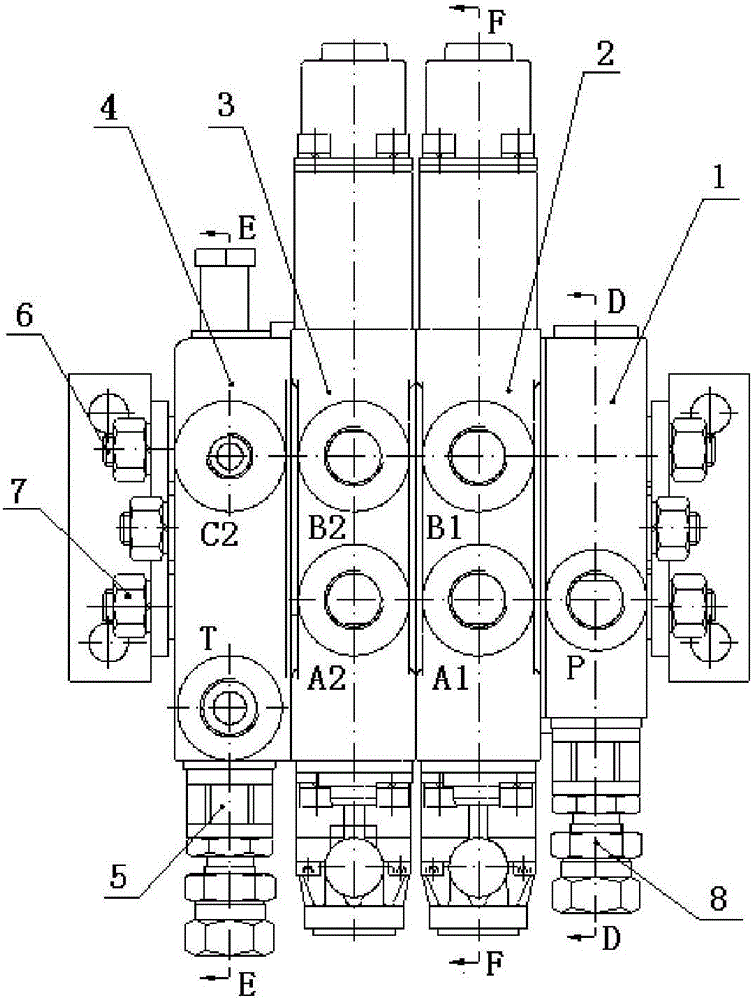

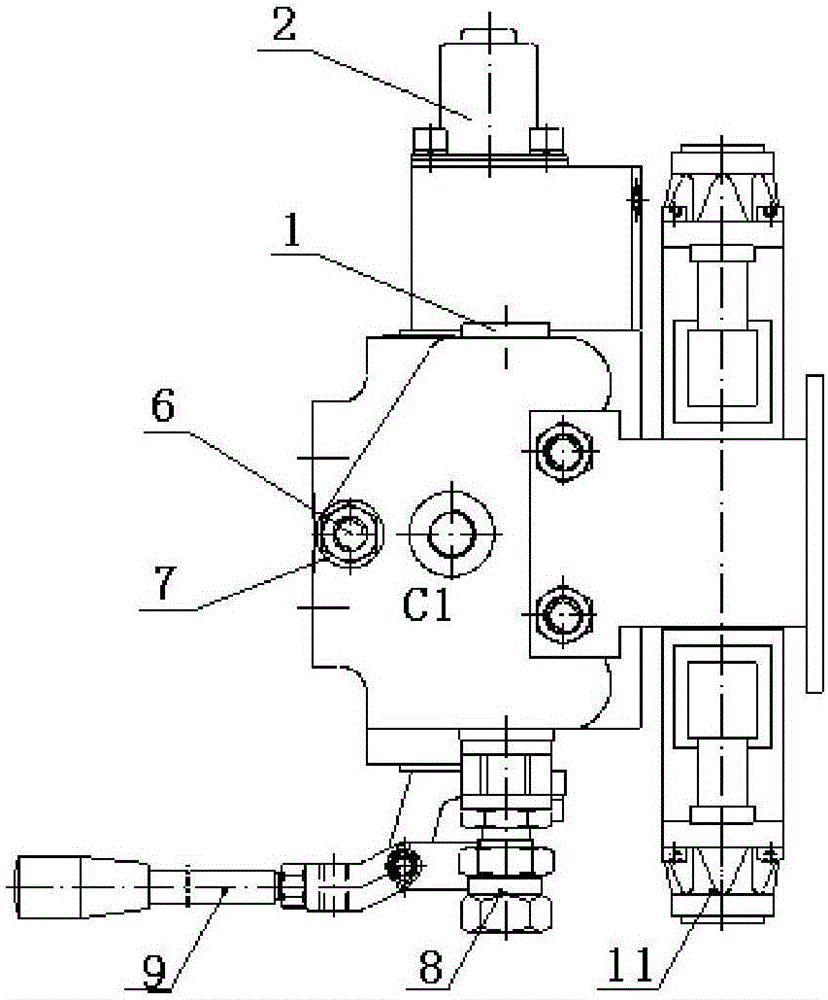

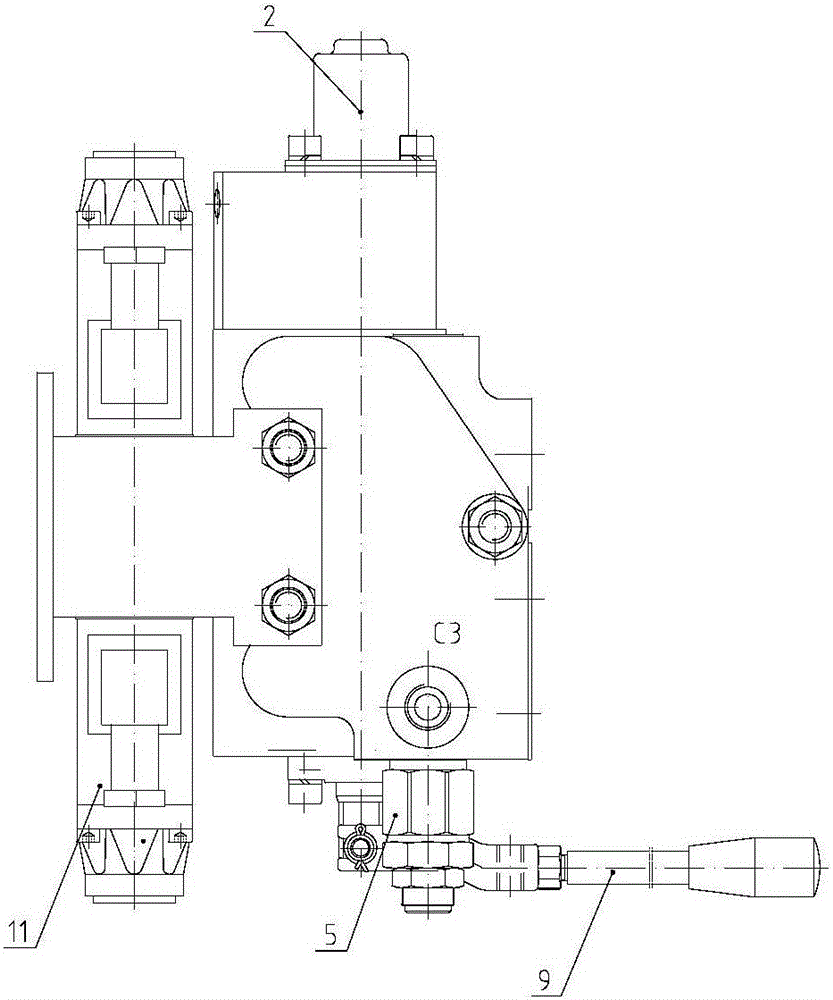

Integral manual multi-path reversing valve

InactiveCN101592171ASimple runner structureThe runner structure is simple and compactServomotor componentsMultiple way valvesSpool valveMulti path

The invention discloses an integral manual multi-path reversing valve. A three-position slide valve hole passes through a left oil return cavity, a four-position slide valve left oil inlet cavity, a three-position slide valve left oil inlet cavity, a three-position slide valve left oil outlet cavity, a middle oil return cavity, a three-position slide valve right oil outlet cavity, a three-position slide valve right oil inlet cavity, a four-position slide valve right oil inlet cavity and a right oil return cavity in turn from the left to right. A four-position slide valve hole passes through the left oil return cavity, the four-position slide valve left oil inlet cavity, a four-position slide valve left oil outlet cavity, the middle oil return cavity, a four-position slide valve right oil outlet cavity, the four-position slide valve right oil inlet cavity and the right oil return cavity in turn from the left to right. A flow passage in a valve body of the integral manual multi-path reversing valve has a simple structure and reasonable arrangement; and the integral manual multi-path reversing valve is convenient to process and manufacture and has low cost.

Owner:JINAN HYDRAULIC PUMP

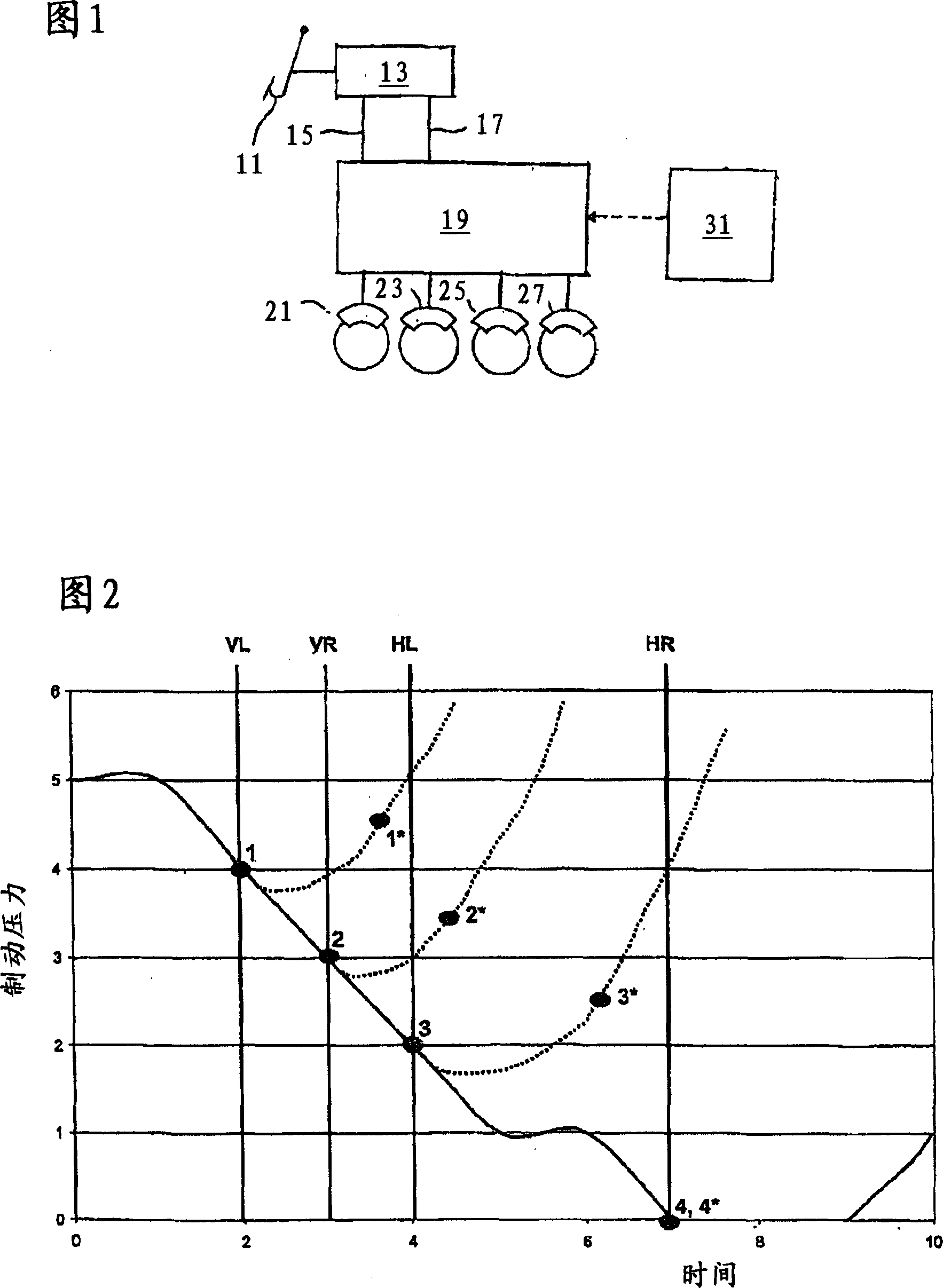

Device and methods for braking in a motor vehicle

InactiveCN1984804AReduce consumptionLow costNoise/vibration controlBraking systemsSlow speedBraking system

The invention relates to a braking system and a method for braking a motor vehicle. According to the invention, a braking system for a motor vehicle comprises at least one brake operating device for wheel brakes (21, 23, 25, 27), embodied as friction brakes. The braking system is characterised in that a controller (31) is provided, which on a braked transition from moving to standstill from a given slow speed and from standstill moving up to a given slow speed, the wheel brakes are operated at differing times or at differing times with increasing braking force, or released at different times, or operated with reducing braking force.

Owner:BAYERISCHE MOTOREN WERKE AG

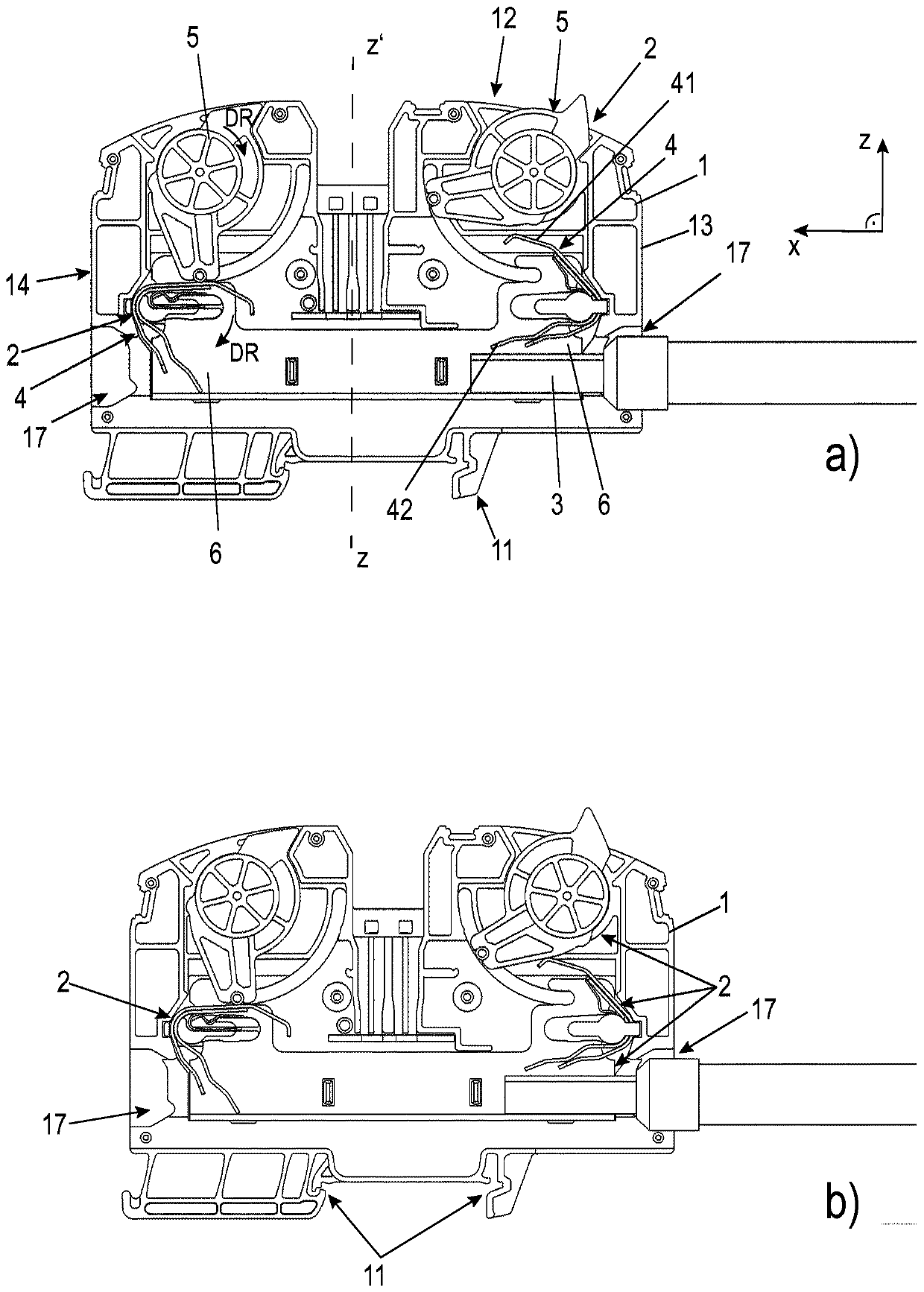

Connection device for connecting a conductor end

ActiveCN111386631AGood fit requirementsSmall control forceElectric connection structural associationsClamped/spring connectionsElectrical conductorClassical mechanics

Connection device for connecting a conductor end (3), which has a housing (1) and, in the housing (1), a busbar section (6), a clamping spring arrangement (4) and a rotary lever arrangement (5), wherein the clamping spring arrangement (4) can be rotated, with the aid of the rotary lever arrangement (5), from an open position into a contact position in which the conductor end (3) is contacted, wherein the rotary lever arrangement (5) and the clamping spring arrangement (4) have the same direction of rotation (DR) upon rotation from the open position into the contact position.

Owner:WEIDMULLER INTERFACE GMBH & CO KG

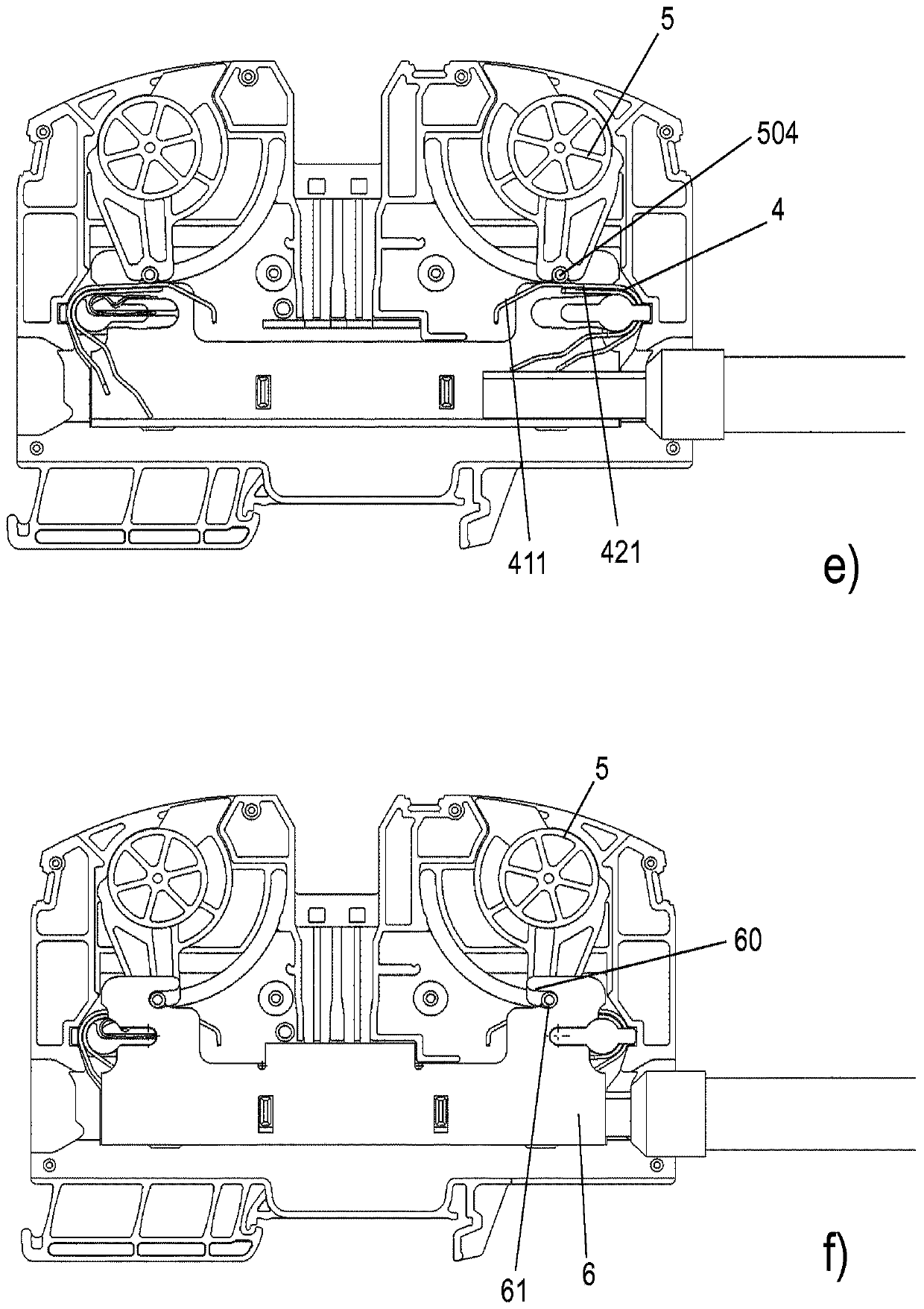

Connection device for connecting conductor end

ActiveCN111466057AReliable contactReliable disengagementElectric connection structural associationsClamped/spring connectionsElectrical conductorClassical mechanics

Connection device for connecting a conductor end (3), which has a housing (1) and, in the housing (1), a busbar portion (6), a clamping spring arrangement (4) and a rotary lever arrangement (5), wherein the clamping spring arrangement (4) can be rotated, with the aid of the rotary lever arrangement (5), from an open position into a contact position in which the conductor end (3) is contacted, wherein the rotary lever arrangement (5) has a rotary lever element (50) which is mounted in the housing (1) so as to be rotatable in or on a preferably central portion (500) and which has the axis of rotation (D2), and wherein the rotary lever element (50) has an eccentric portion (502) which has a control cam (503) along which the clamping spring arrangement (4) slides during a movement into the endcontact position, wherein the eccentric portion (502) engages by way of a guide means, such as by way of a projection or a pin (504) inserted therein or the like, into a slotted link (18) of the housing (1), and wherein a clamping and / or latching means are or is formed on the eccentric portion (502), and wherein the slotted link (18) of the housing (1) is aligned with a slotted link (60) in the busbar portion (6), in which the fixing position for the clamping and / or latching means is formed.

Owner:WEIDMULLER INTERFACE GMBH & CO KG

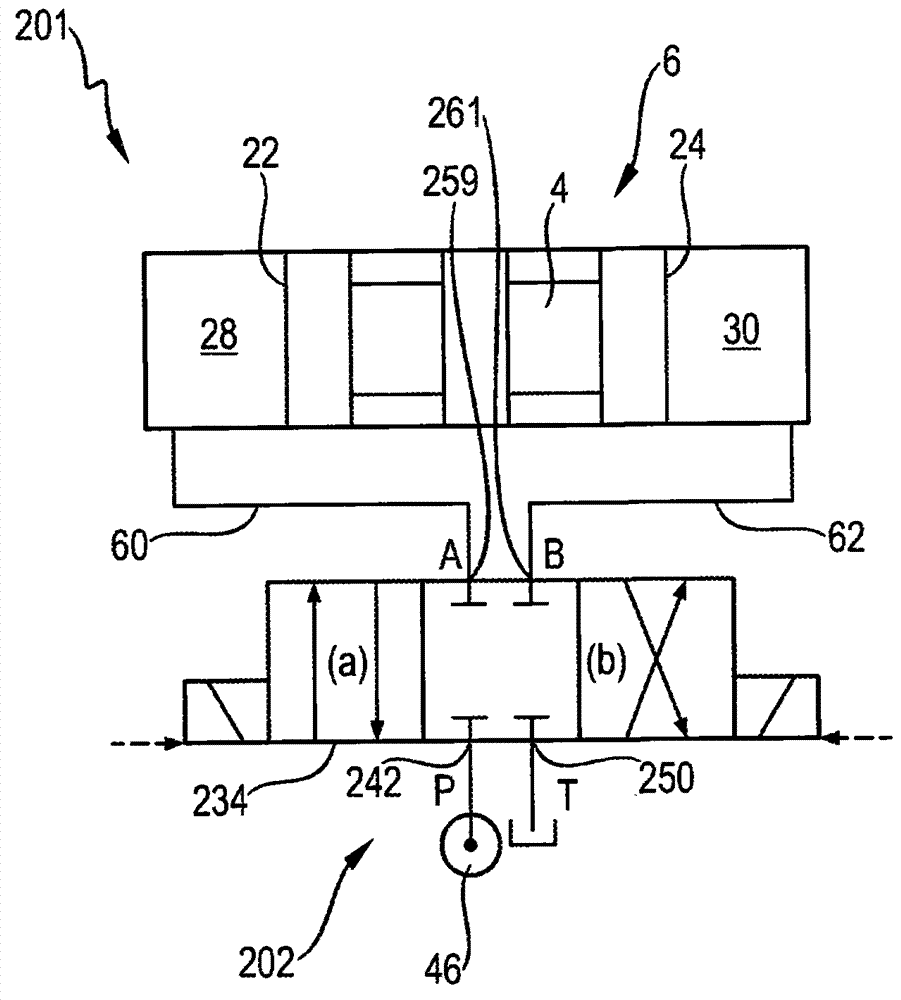

Hydraulic pilot valve arrangement and hydraulic valve arrangement having the same

InactiveCN103321978ABacklog controlSmall control forceServomotor componentsServomotorsEngineeringPulse width modulated

The invention relates to a hydraulic pilot valve arrangement and a hydraulic valve arrangement having the same. The hydraulic pilot valve arrangement for pilot-controlling a valve includes at least one pilot valve configured to be activated electromagnetically in a pulse-width-modulated fashion. The pilot valve is configured to be activated ballistically or inversely ballistically. The hydraulic valve arrangement including the hydraulic pilot valve arrangement also has a valve configured to be pilot-controlled by the pilot valve arrangement.

Owner:ROBERT BOSCH GMBH

Integral manual multiple-way valve

InactiveCN101498375ASmall diameterFully integratedOperating means/releasing devices for valvesServomotor componentsCheck valveSafety valve

The invention provides a technical scheme for integrated manual multi-way valves, characterized in that a double-functional relief valve is provided with left and right double-functional relief valves of a three-position slide valve, and a check valve is provided with a left check valve and a right check valve of the other three-position slide valve, wherein the left double-functional relief valve of the three-position slide valve is coaxially and fixedly connected to the left check valve of the other three-position slide valve, the right double-functional relief valve of the three-position slide valve is coaxially and fixedly connected to the right check valve of the other three-position slide valve, and the left and right double-functional relief valves are distributed on the upper ends of the three-position slide valves on the two sides of an upper oil inlet cavity, the axes of the left and right double-functional relief valves of the three-position slide valve are parallel with the axes of the other three-position slide valve and a four-position slide valve, the relief valve is parallel with the axis of one three-position slide valves and is positioned between the other three-position slide valve and the four-position slide valve, a check valve of the four-position slide valve is parallel with the axis of the three-position slide valves and is positioned between the other three-position slide valve and the four-position slide valve, and the three-position and four-position slide valves are provided with middle grooves thereof respectively.

Owner:徐福刚

Leakless plane type pure water electrohydraulic change valve

InactiveCN1587720ASmall control forceCommutation is reliableOperating means/releasing devices for valvesServomotor componentsElectro hydraulicEngineering

The invention discloses a kind of no leakage and pure water flat electro-hydraulic directional control valve. A king valve cover is in the heart of the king valve and flat king valve core compacted by a spring lies in the cavity of axial of the king valve body; on the upper of king valve body there is a water inlet and a water outlet connected by the king valve's channel; in the king valve there is a sensitive cavity connected with electromagnetic ball valve by tunnels; a valve port damper installed at the valve entrance of electromagnetic ball valve matches with the sensitive cavity of king valve in order to control the flow velocity of fluid and reduce directional strike at the same time diverting fast. The invention adopt flat king valve core set on the packing force of the king valve cover and increase dramatically valve covers, adopt direct seal to realize zero leakage; divert fast and steadily through matching the sensitive cavity of king valve with the damper at the entrance of the electromagnetic ball valve; not change the structure of the king valve and only change structural form of electromagnetic ball valve in order to have different functions and fit to work under conditions of middle and high pressure water medium.

Owner:ZHEJIANG UNIV

Fuel injector and method for the manufacture and/or assembly of a nozzle needle assembly

InactiveCN102782302AReduce loadSuitable for manufacturingMachines/enginesSpecial fuel injection apparatusPistonElectricity

The invention relates to a fuel injector for a fuel injection system, in particular a common rail injection system, having a nozzle body (1) and having an injector body (2), wherein in the nozzle body (1) there is formed a high-pressure bore (3) for accommodating a nozzle needle (4) which can perform a stroke movement and by means of the stroke movement of which at least one injection opening (5) can be opened up or closed off, and wherein in the injector body (2) there is formed a low-pressure chamber (6) for accommodating a piezoelectric actuator (7), which low-pressure chamber can be or is hydraulically coupled via a coupling device (8) to the nozzle needle (4) in such a way that the nozzle needle (3) assumes the closed position thereof when the piezoelectric actuator (7) is electrically discharged. According to the invention, the coupling device (8) comprises a first and a second disk-shaped coupler body (9, 10) with in each case one cylinder bore (11, 12) for accommodating in each case one coupler piston (15, 16) which delimits a coupler chamber (13, 14). The invention also relates to a method for the manufacture and / or assembly of a nozzle needle assembly for a fuel injector.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com