An operating method of a tractor clutch operating device with hydraulic power assist

A technology of clutch control and hydraulic power assist, applied in the direction of clutch, mechanical equipment, etc., can solve the problems of limited space for enlarged clutch friction plates, heavy clutch pedal operating force, and reduced tractor operating comfort, and achieves novel design ideas and improved Operational comfort and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

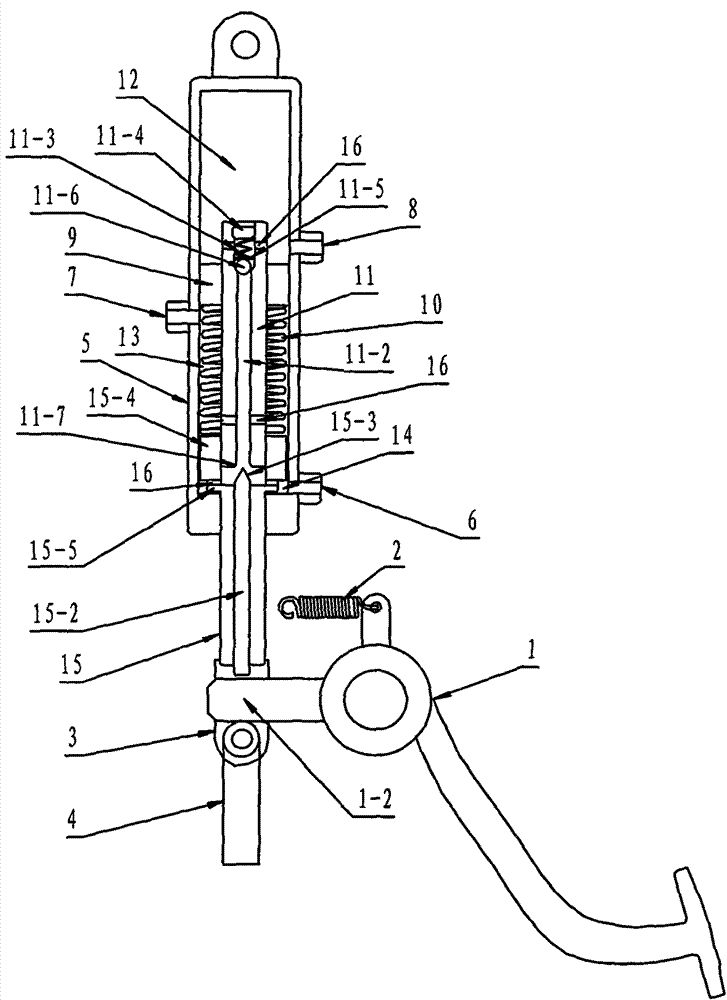

[0017] The clutch pedal 1 is connected with the fixed bracket of the cab through the return spring 2, the top plate 1-2 of the clutch pedal 1 is arranged in the U-shaped connecting fork 3, and the U-shaped opening of the connecting fork 3 is connected with the clutch pull rod 4 through the connecting pin, and connected The middle part of the fork 3 is connected with the piston rod 15 of the booster cylinder 5; the booster cylinder 5 is provided with an oil inlet 6, an oil outlet 7, and an oil return port 8 from bottom to top, between the oil inlet 6 and the output port of the steering constant flow pump Install the hose, install the hose between the oil outlet 7 and the oil inlet of the hydraulic steering gear, install the hose between the oil return port 8 and the oil inlet of the steering constant flow pump oil tank, set the lifting lug above the power cylinder 5, and set the power cylinder Blocking block 9 is set in the middle of 5, oil return cavity 12 is formed above block...

Embodiment 2

[0019] When the clutch pedal 1 is not stepped on, the throttle valve 15-2 is in the open state, and the hydraulic oil in the steering constant flow pump enters the lower chamber 14 through the oil inlet 6, and flows into the piston from the oil hole 16 of the connecting block 15-5. 15-4, it enters the oil passage 11-2 of the valve stem 11 upwards, enters the upper cavity 13 through the oil holes 16 on both sides below the valve stem 11, flows into the hydraulic steering gear through the oil outlet 7, and the oil that flows into the oil inlet 6 Pressure is less than 3 MPa, and the oil pressure of upper chamber 13 and lower chamber 14 in the booster cylinder 5 is equal, so that the pressure in the booster cylinder 5 remains balanced.

Embodiment 3

[0021]During normal use, step on the clutch pedal 1, the top plate 1-2 of the clutch pedal 1 pushes up the throttle valve 15-2 in the piston rod 15, the throttle valve 15-2 is in a semi-closed state, and the throttle valve 15-2 The conical head 15-3 enters the bell mouth 11-7 of the valve stem 11 upwards, the oil pressure entering the oil inlet 6 is 3-10 MPa, and the hydraulic oil in the piston 15-4 enters the oil passage 11- 2 decreases, the flow flowing into the upper chamber 13 decreases, so that the oil pressure in the lower chamber 14 increases, pushing the piston 15-4 to move upward along the inner wall of the booster cylinder 5, and the piston 15-4 drives the piston rod 15 to move upward , the piston rod 15 drives the clutch rod 4 through the connecting fork 3 to generate an upward pulling force; the throttle valve 15-2 moves up and down to control the flow flowing into the oil passage 11-2 to generate different thrusts, and the conical head 15-3 is close to the bell mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com