Integral manual multi-path reversing valve

A multi-way reversing valve, integrated technology, applied in the direction of multi-way valves, fluid pressure actuators, valve devices, etc., can solve the problems of high processing and manufacturing costs, complex flow channel structure, etc., and achieve low cost and smooth flow channel. The effect of simple structure and reduced processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

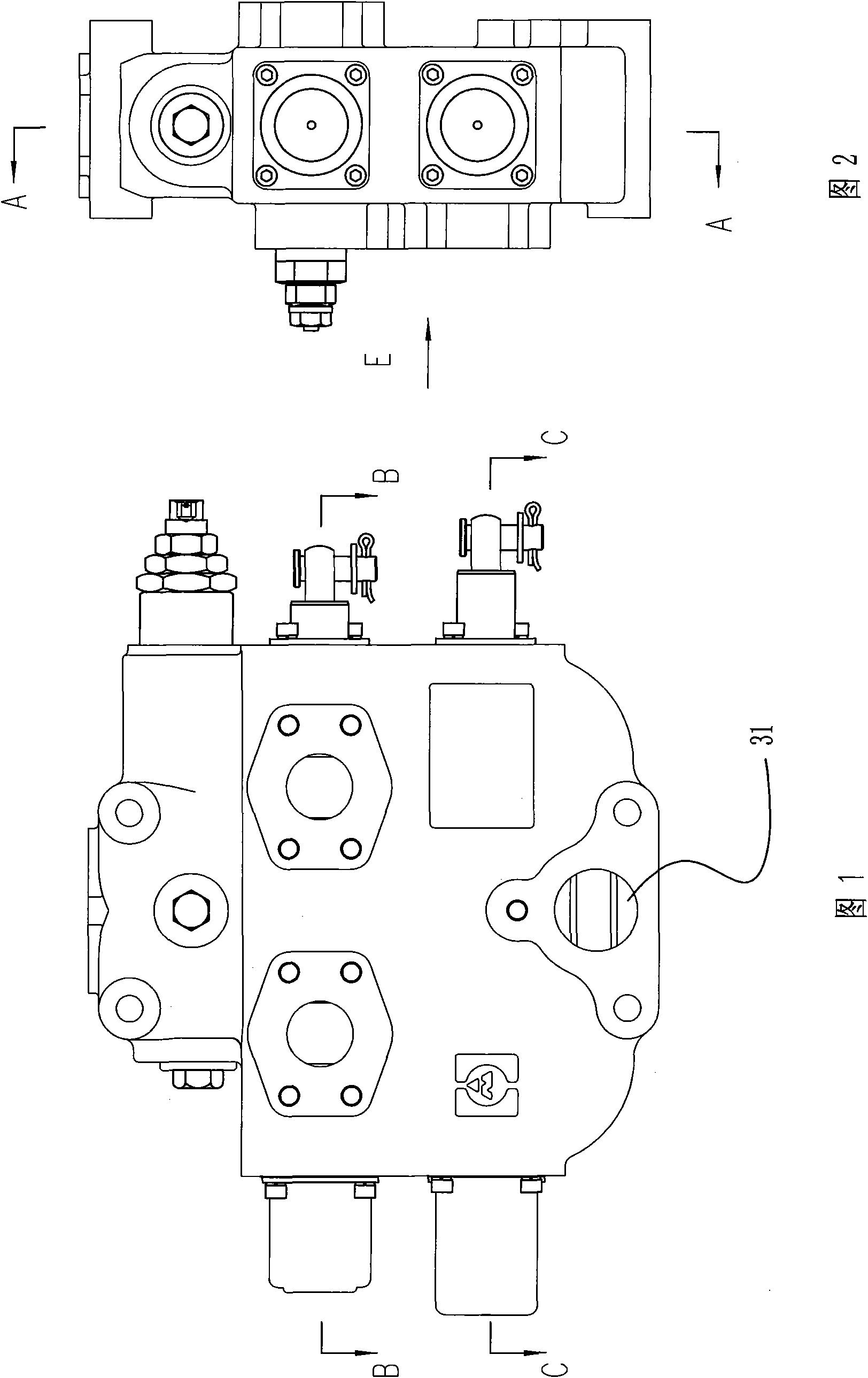

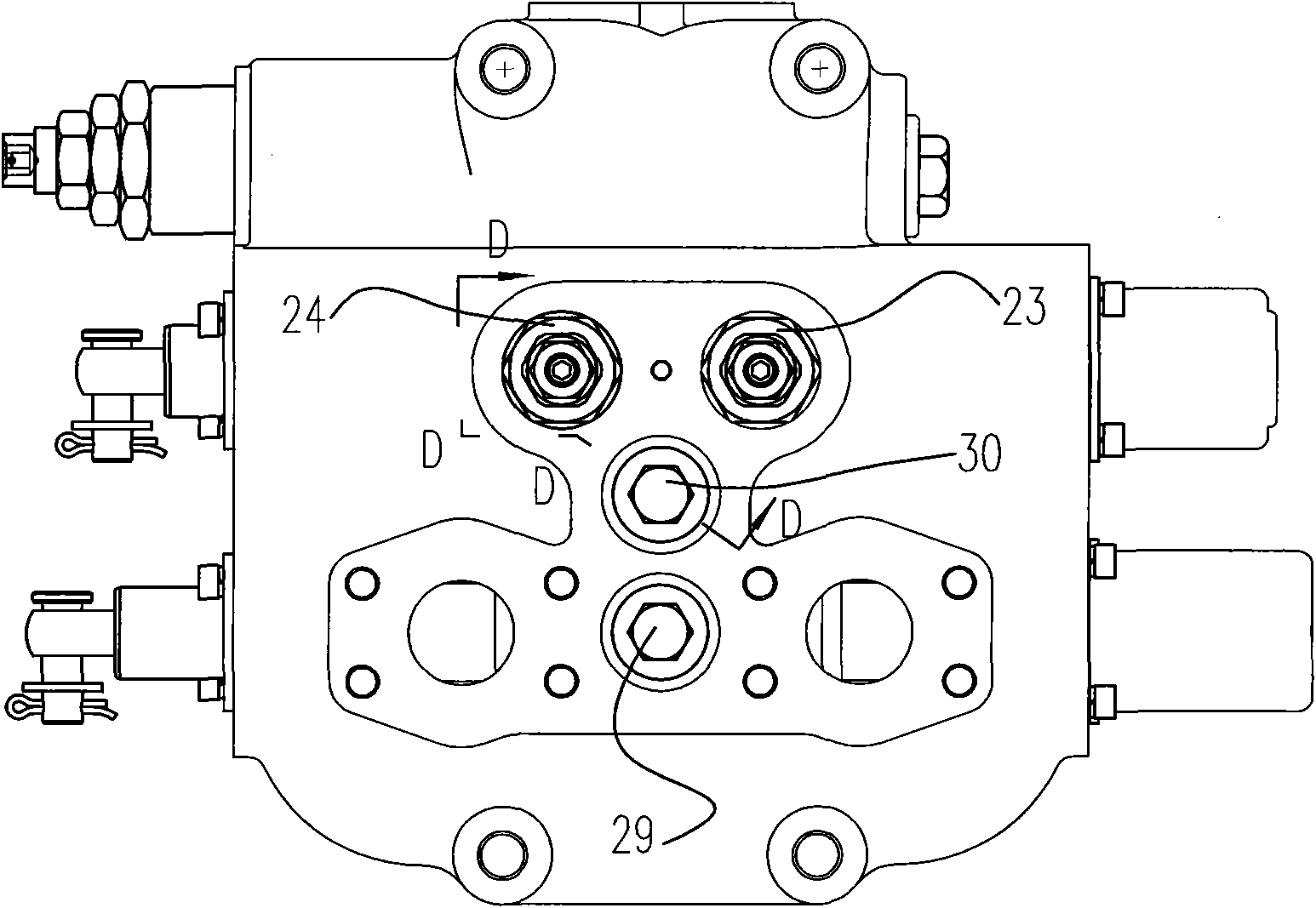

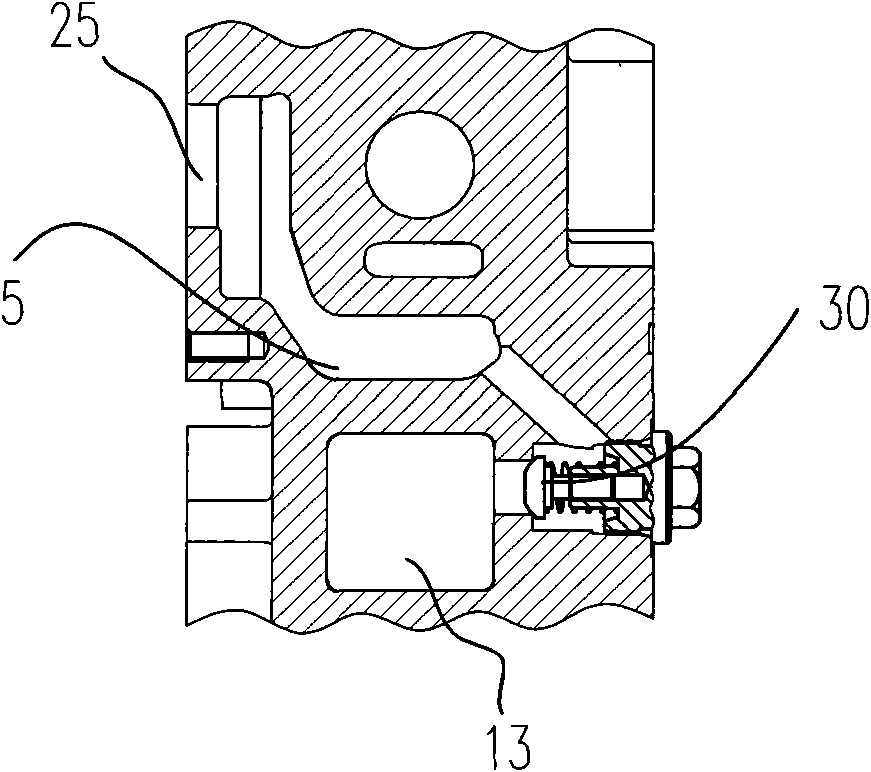

[0022] Such as Figure 1-Figure 7 A specific embodiment is shown, which includes valve body 1, right check valve 4, safety valve 8, three-position slide valve 10, four-position slide valve 11, four-position slide valve positioning mechanism 16, three-position slide valve positioning mechanism Resetting mechanism 18, left one-way valve 22, left overload valve 23, right overload valve 24, four-position spool oil supply valve 29 and three-position spool valve oil supply valve 30.

[0023] Valve body 1 is provided with oil inlet 2, three-position spool valve right oil outlet 25, three-position spool valve left oil outlet 26, four-position spool valve right oil outlet 27, four-position spool valve left oil outlet 28 And oil return port 31. In the valve body 1, there are oil inlet chamber 3, three-position spool valve right oil outlet chamber 5, three-position spool valve right oil inlet chamber 6, right oil return chamber 7, four-position spool valve right oil inlet chamber 9, fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com