Multiway electro-hydraulic control valve adopting oil return differential pressure as pilot oil source

An electro-hydraulic control valve and pilot oil source technology, applied in the field of hydraulic machinery, can solve problems such as increased cost of hydraulic oil source, power loss, inconvenient installation and maintenance, etc., to reduce pipeline and oil source configuration, flow stability without interference , the effect of no loss of work flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

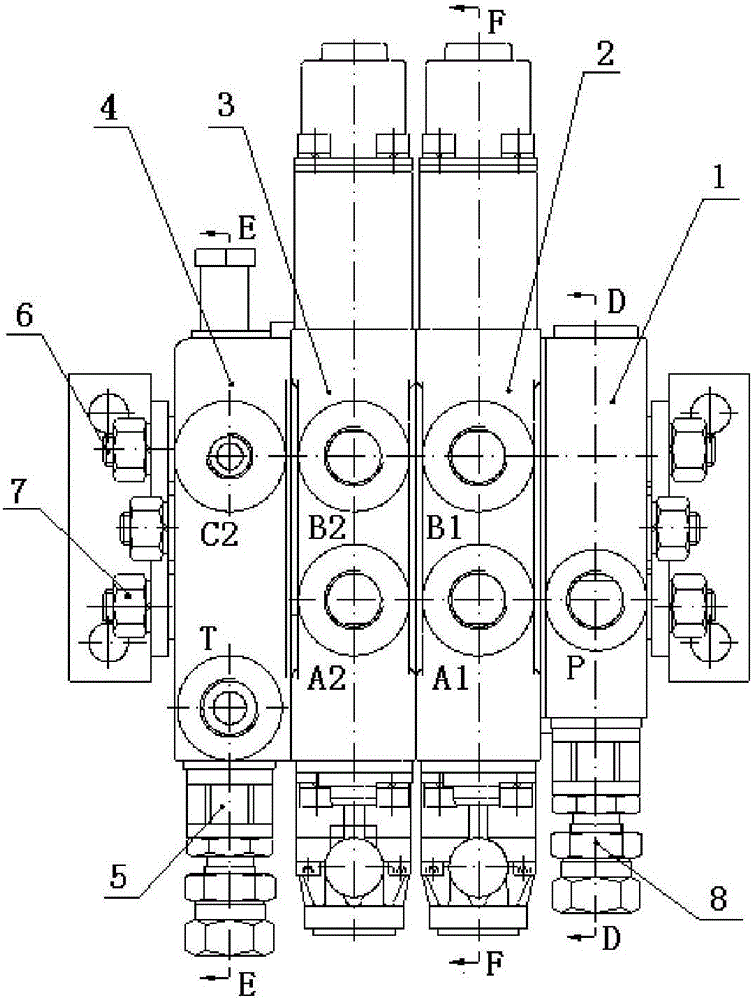

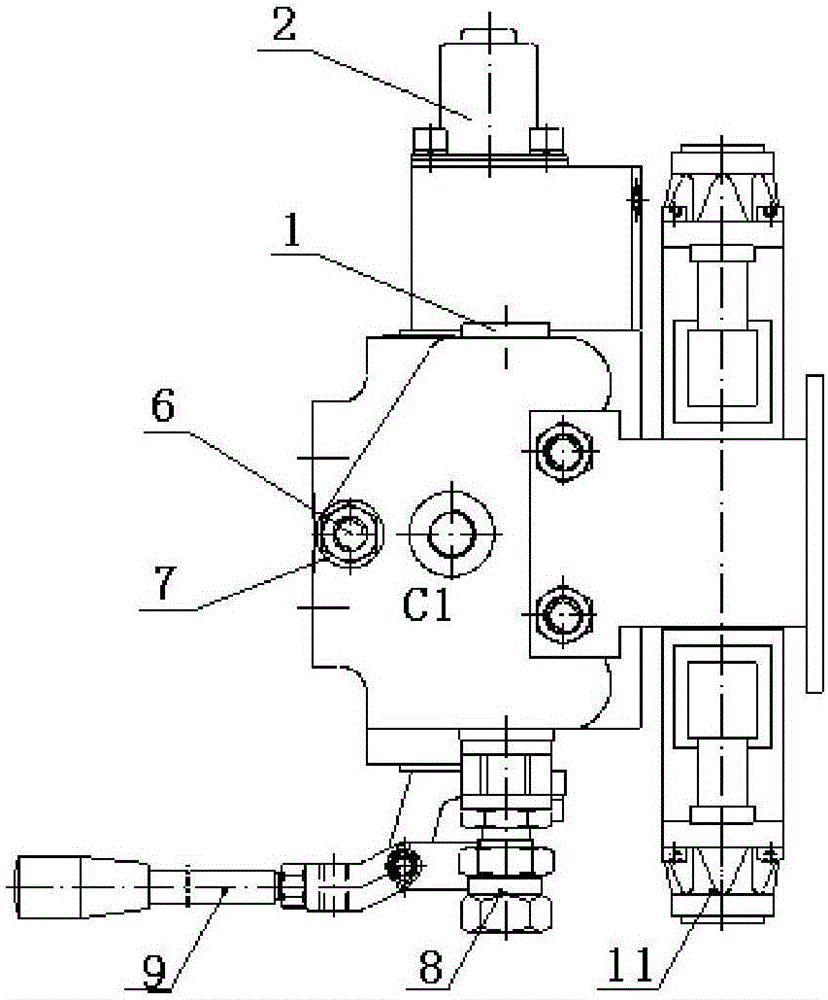

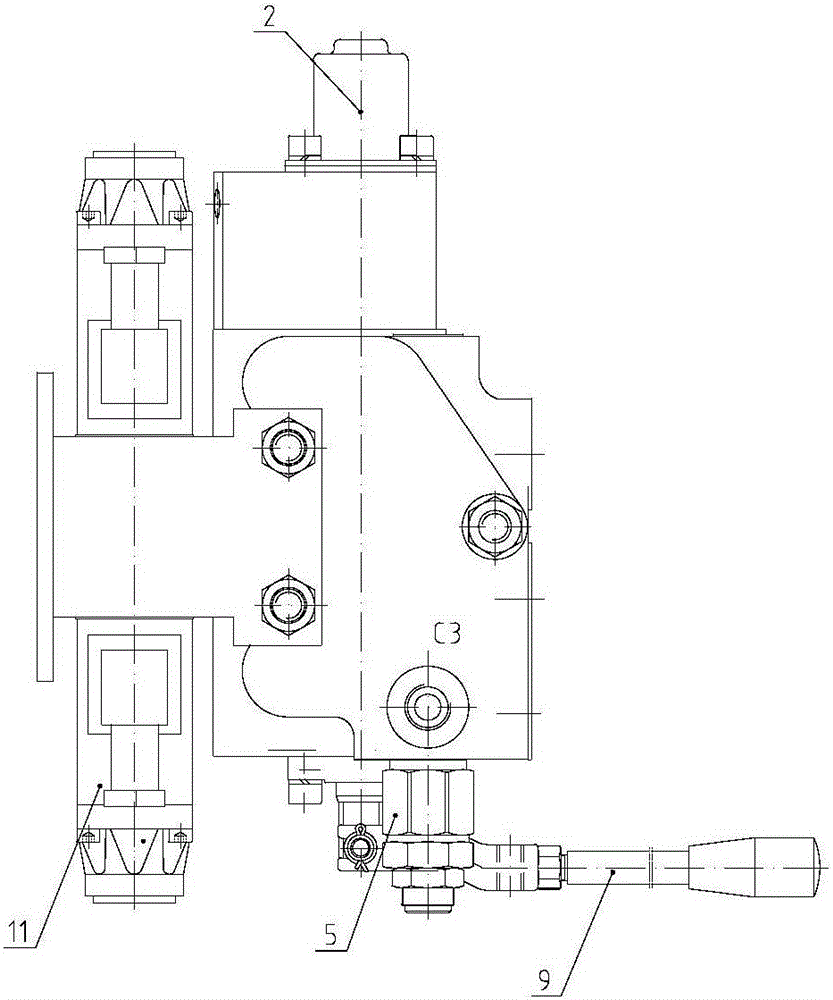

[0038] see Figure 1 to Figure 6The shown is a multi-channel electro-hydraulic control valve using oil return pressure difference as the pilot oil source, including oil inlet valve group 1, oil return pressure regulating valve group 4, oil inlet valve group and oil return pressure regulating valve group Between the multiple electro-hydraulic reversing valve groups, the oil inlet valve group, multiple electro-hydraulic reversing valve groups and oil return pressure regulating valve groups are connected as a whole through three double-ended screws 6 and three nuts 7; The valve bodies of the oil inlet valve group, a plurality of electro-hydraulic reversing valve groups and the oil return pressure regulating valve group are all provided with a common oil inlet passage 12, a neutral unloading passage 13 and a dual oil return passage 14; The oil inlet valve group 1 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com