Roof bars for a motor vehicle

A technology for motor vehicles and vehicle roofs, applied in vehicle parts, additional accessories, transportation and packaging, etc., can solve the problem of not providing tolerance compensation, and achieve the effect of reliable and durable clamping, easy one-hand manipulation, and reliable locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

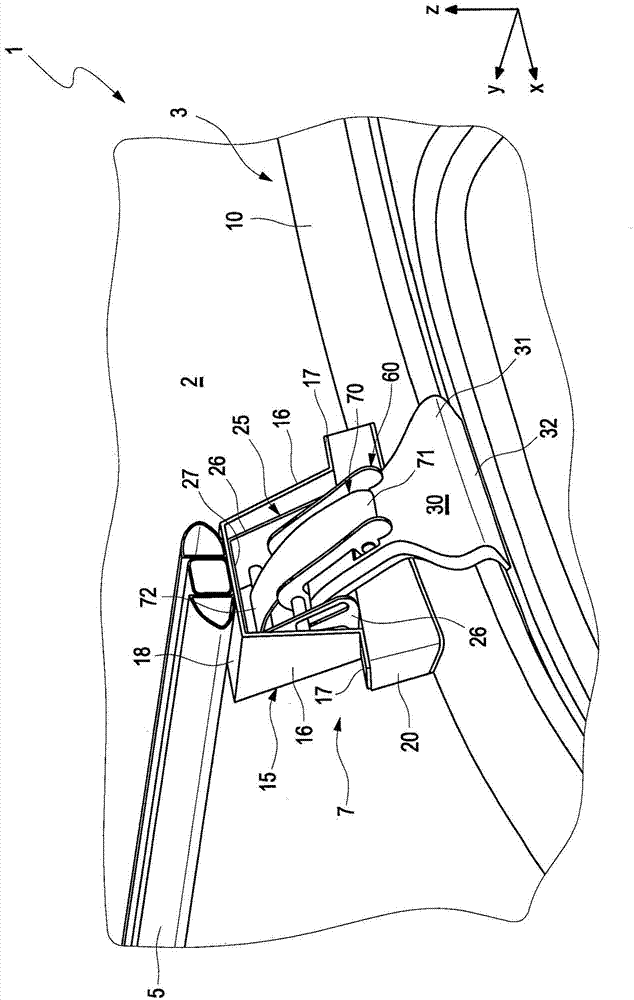

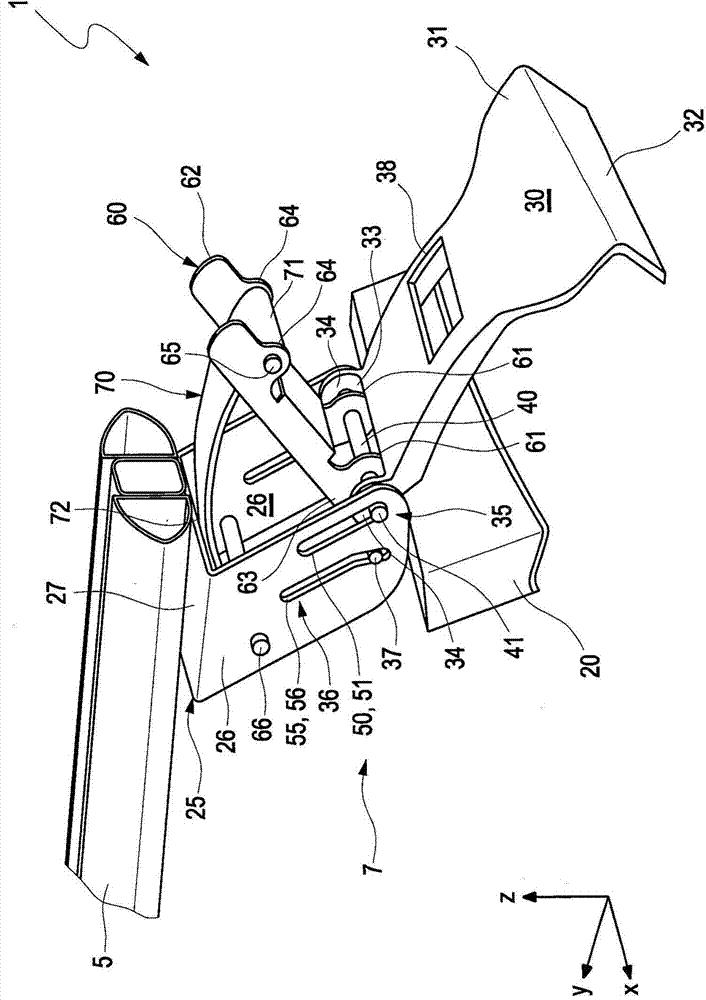

[0024] figure 1 A roof base cross member 1 for a motor vehicle is shown in a locked state, which is mounted on a vehicle roof 2 and is known for receiving loads or luggage, such as skis or the like. For this purpose, usually two roof base cross members 1 are fastened to the vehicle roof 2 , one facing the front of the vehicle and one facing the rear of the vehicle.

[0025] Each roof base cross member 1 has a Figures 1 to 4 The top beam element 5 which is only partially shown in the figure is designed as a hollow profile in the illustrated embodiment. The roof member 5 is attached to the side wall longitudinal members 10 or to the side wall frame of the body 3 via two opposing support structures 7 on the roof 2 . To this end, the supporting structures 7 each have a first outer U-shaped profile element 15 with two legs 16 each with a foot 17 and a connecting element 18 . The U-shape of the first profiled element 15 is formed by two legs 16 and a first connecting element 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com