Hydraulic switch valve

A conversion valve and hydraulic technology, applied in the hydraulic field, can solve the problems of increasing the failure rate of valve core stuck, increasing the failure rate of hydraulic system, etc., and achieve the effect of avoiding conversion interference, improving dynamic performance and reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

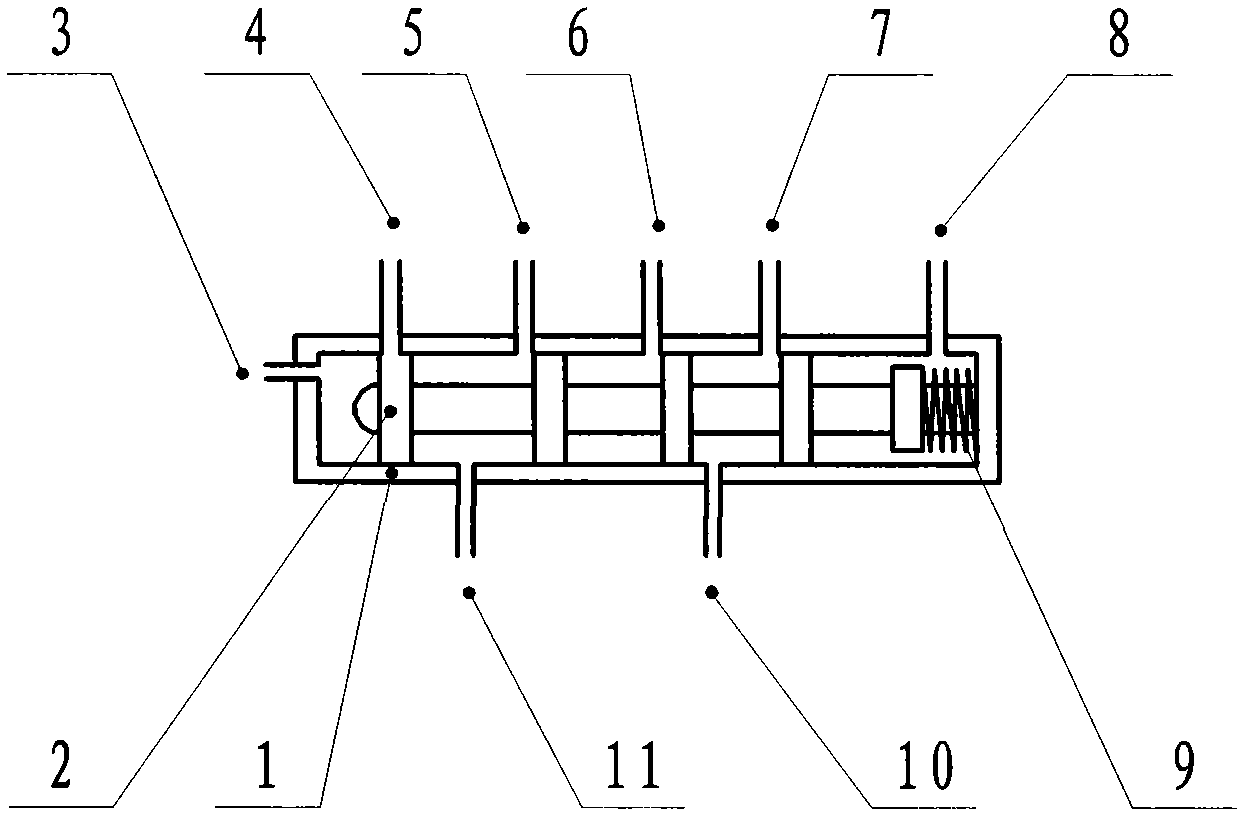

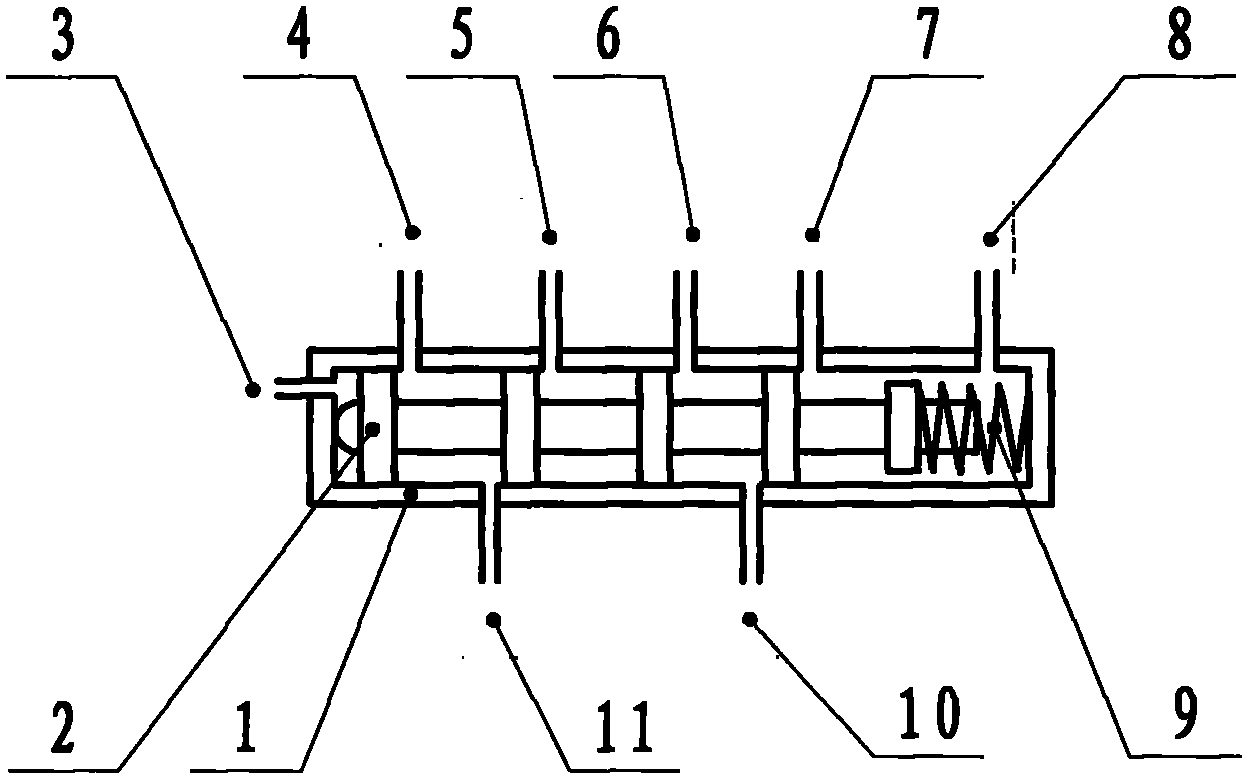

[0013] In order to better illustrate the present invention, it will be described in detail below in conjunction with the accompanying drawings.

[0014] The hydraulic switching valve includes a switching valve core 1, a switching valve sleeve 2 and a spring 3. The switching valve sleeve is a hollow structure, and the side wall of the valve sleeve is provided with oil holes connected with the left and right cavities of the actuator and four servo control cavities and mechanical control cavities spaced apart from each other. At the same time, the switching valve sleeve is also provided with a control port for state switching and an oil return port for load relief, wherein the control port and the oil return port are located at both ends of the switching valve sleeve, and can be arranged on the side of the switching valve sleeve. end or side. Among them, the servo control cavity and the mechanical control cavity close to the control cavity are the left control channel, the servo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com