Pilot-operated high-pressure stop valve

A shut-off valve and pilot-operated technology, applied in the field of shut-off valves, can solve the problems of complex structure, high manual manipulation intensity, large volume and weight and difficult to popularize, and achieve the effect of smooth transition and guaranteed linear performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

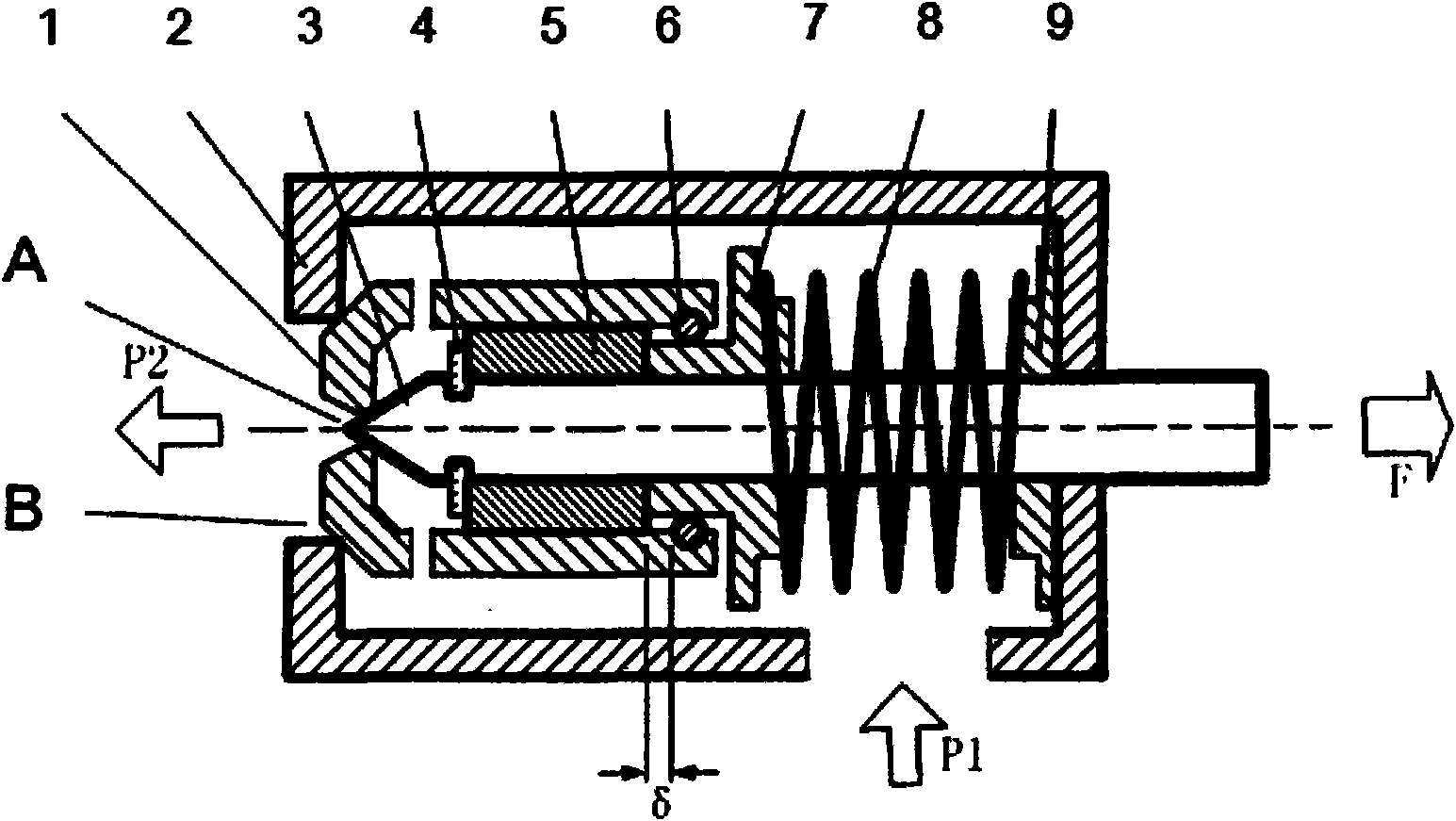

[0014] exist figure 1 Among them, the main spool 1 is pottery empty in the middle, and the pilot spool 3 is put into it to form the pilot valve opening A. At the same time, the retaining ring 4, the guide sleeve 5 and the spring retaining ring 6 are installed for transition and cooperation. The spring seat I 7 extends into the main spool 1 and contacts the guide sleeve 5, and the spring force of the return spring 8 acts on the pilot spool 3 through the retaining ring 4, and the pilot spool 3 is pressed against the main spool 1. These components are installed in the valve body 2, and the main valve core 1 and the valve body 2 form the main valve opening B. The distance δ between the guide sleeve 5 and the spring ring 6 is the opening stroke of the pilot valve. The external force acting on the rear end of the pilot spool is the opening control force F of the valve. P1 is the primary pressure of the fluid at the inlet of the valve, and P2 is the secondary pressure of the fluid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com