Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

237results about How to "Simple and durable structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

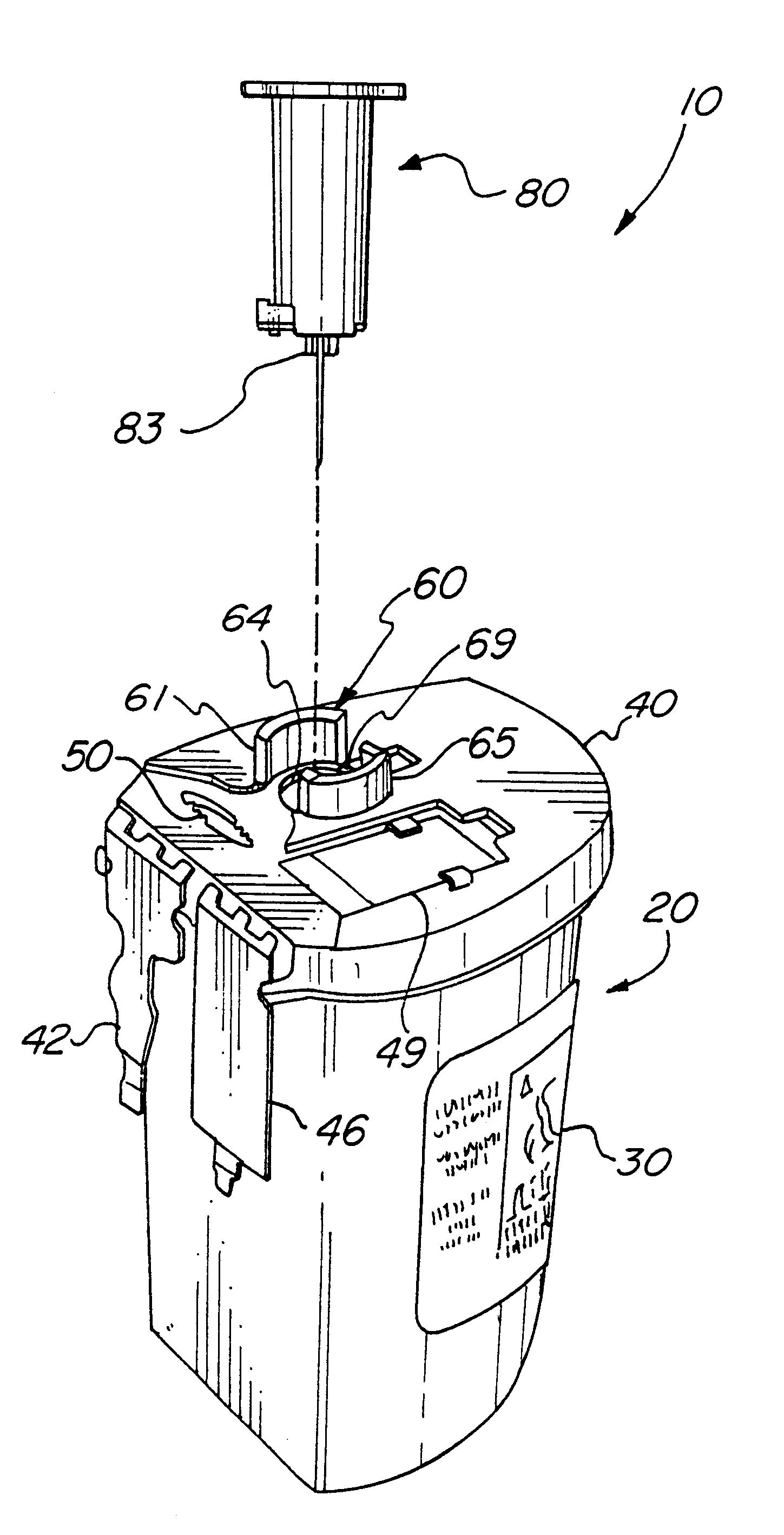

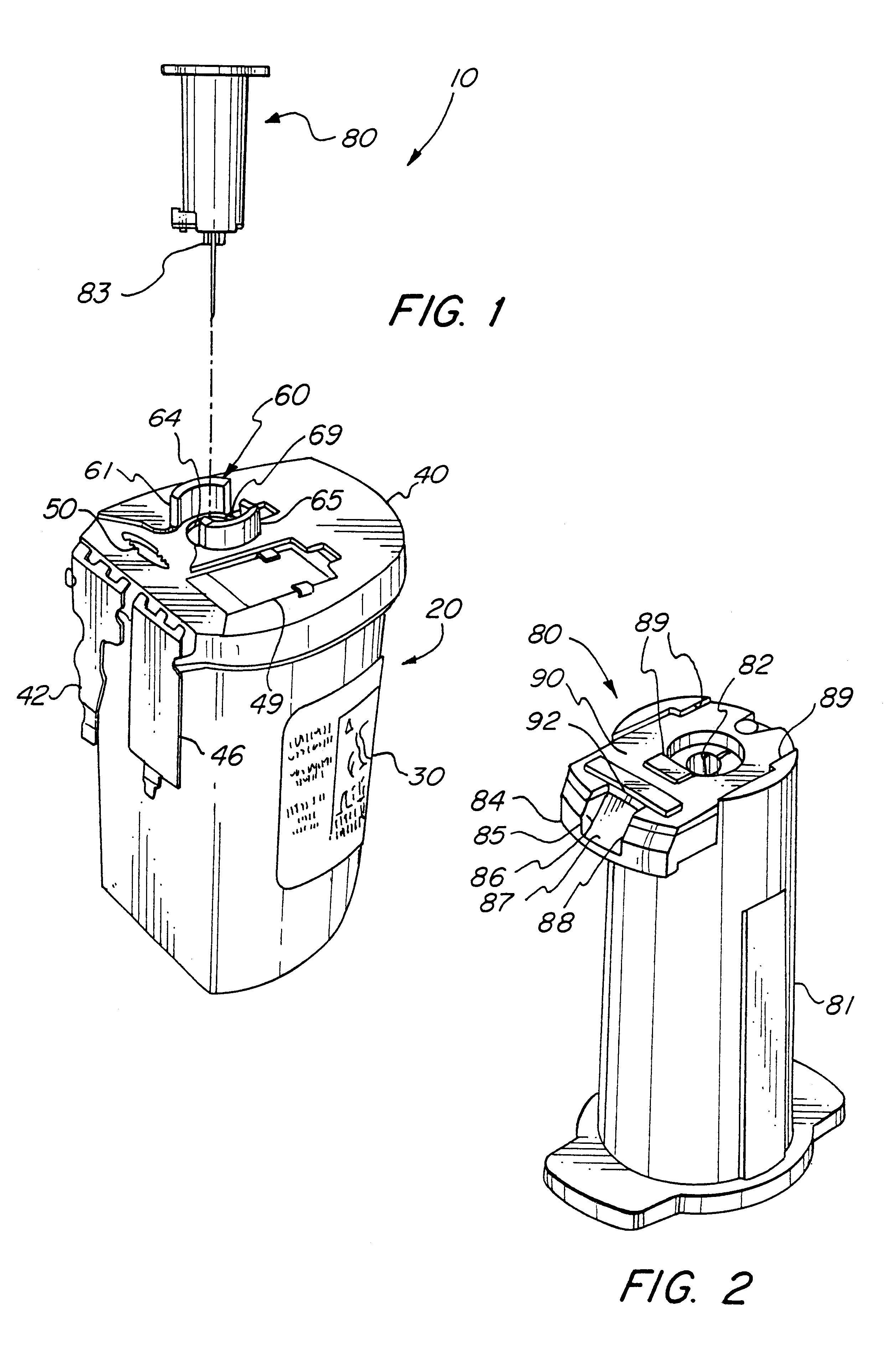

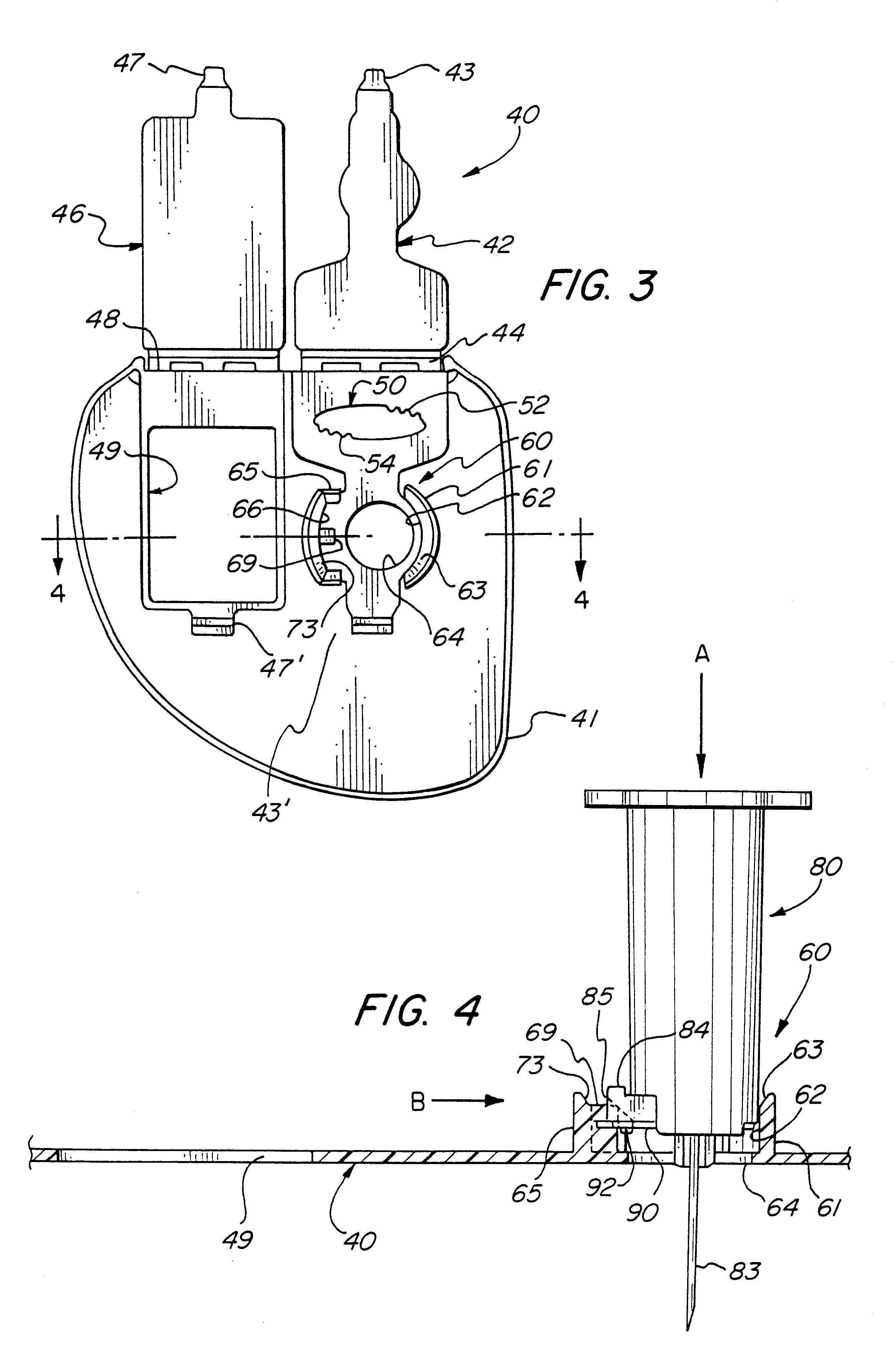

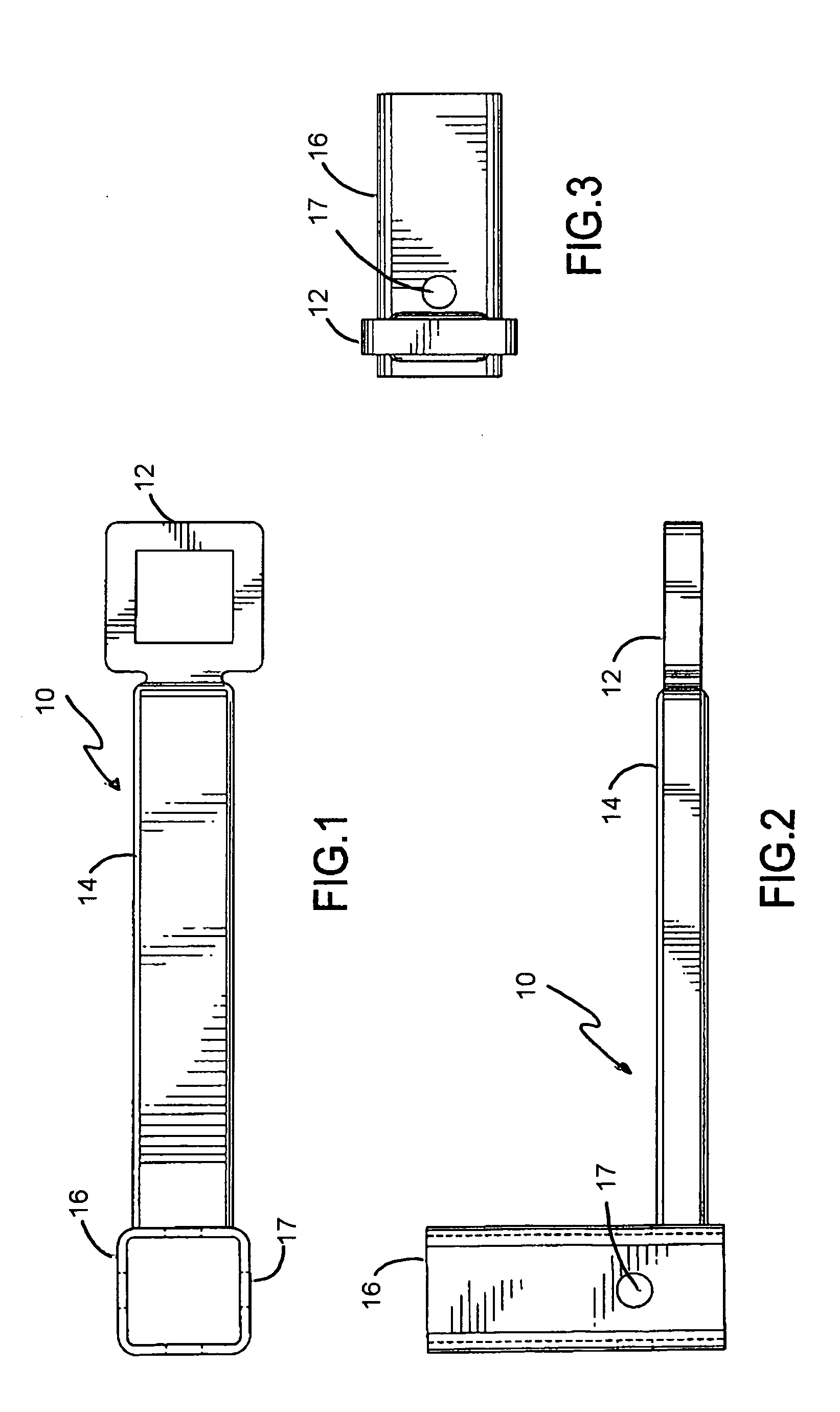

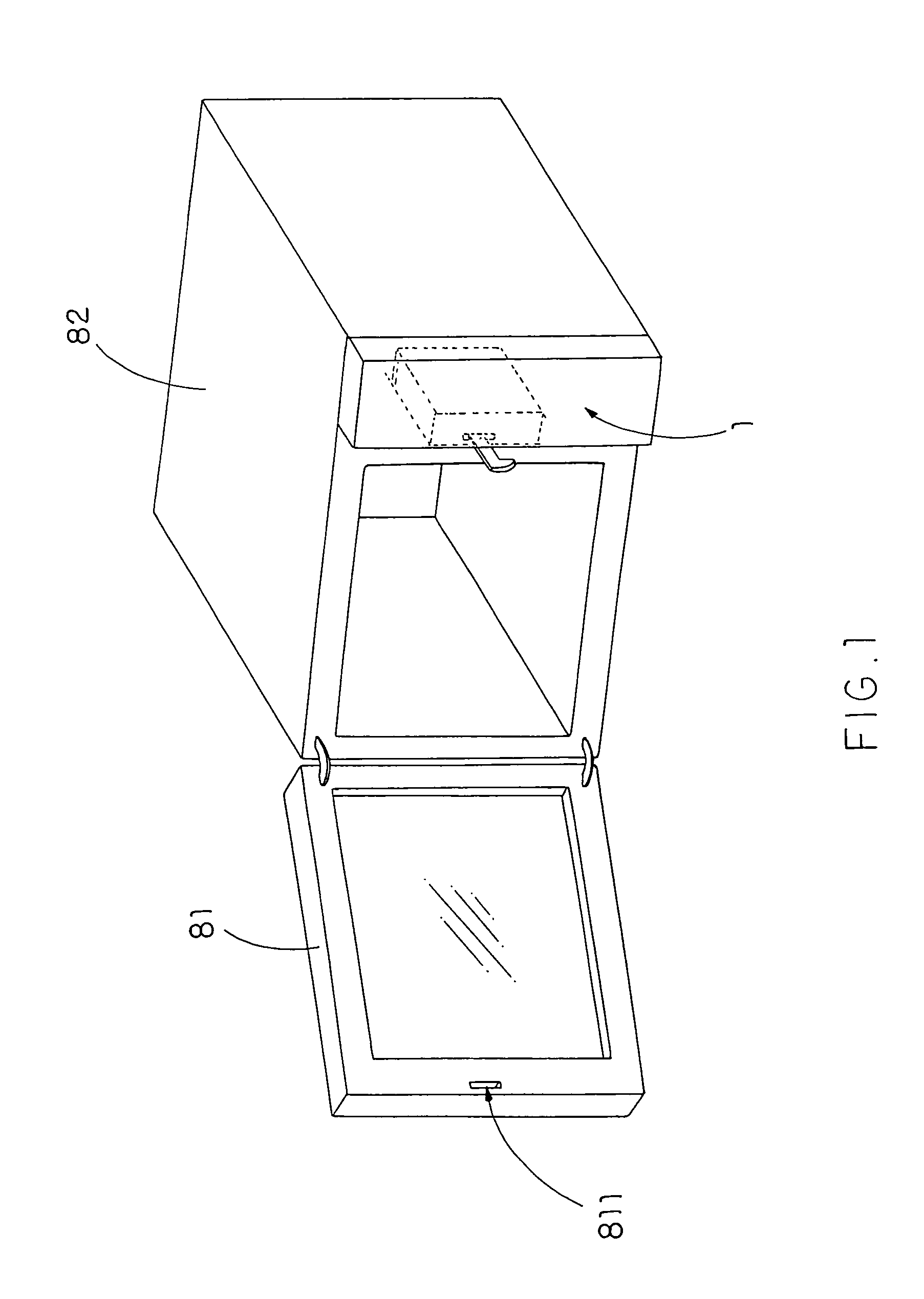

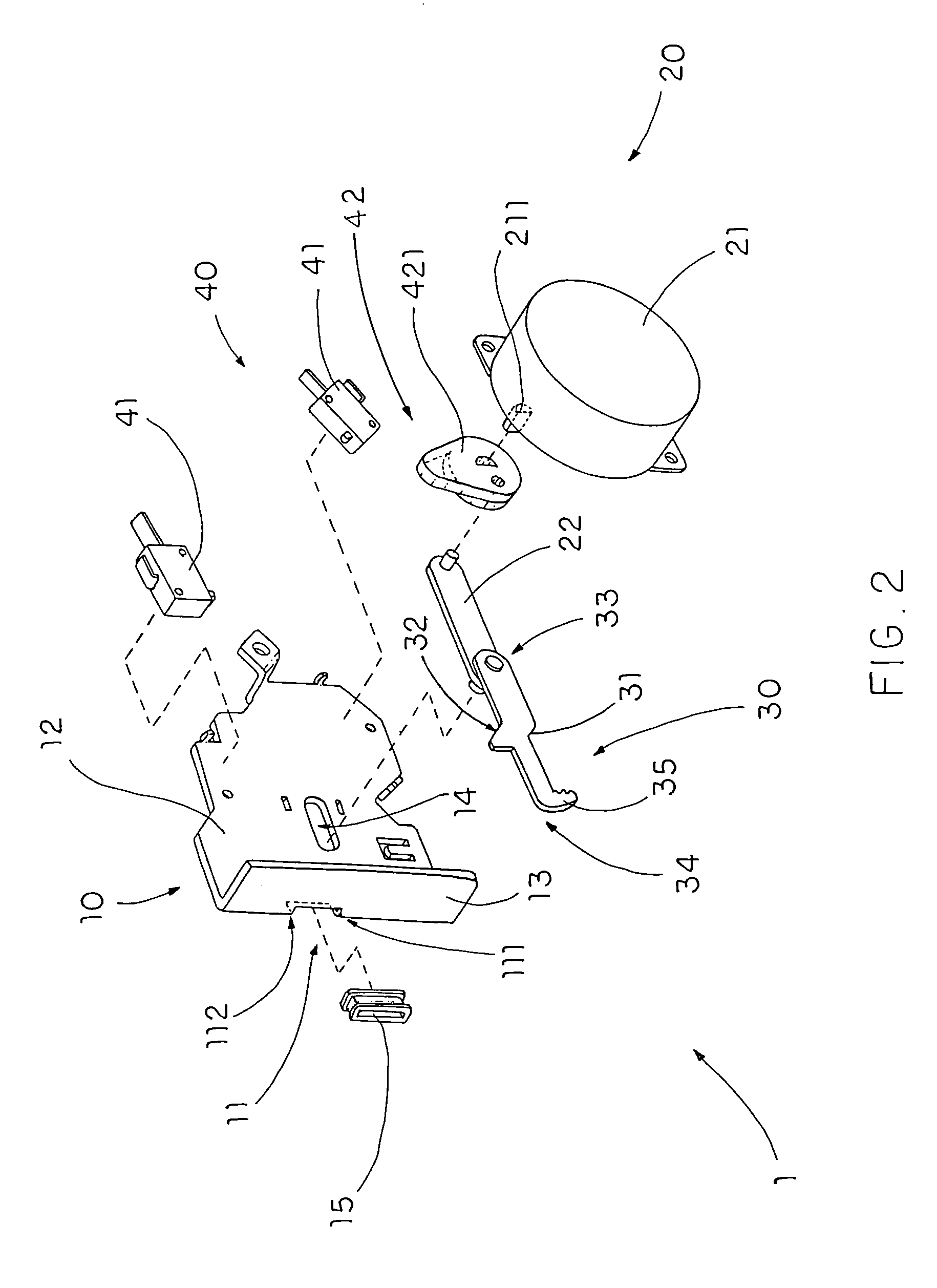

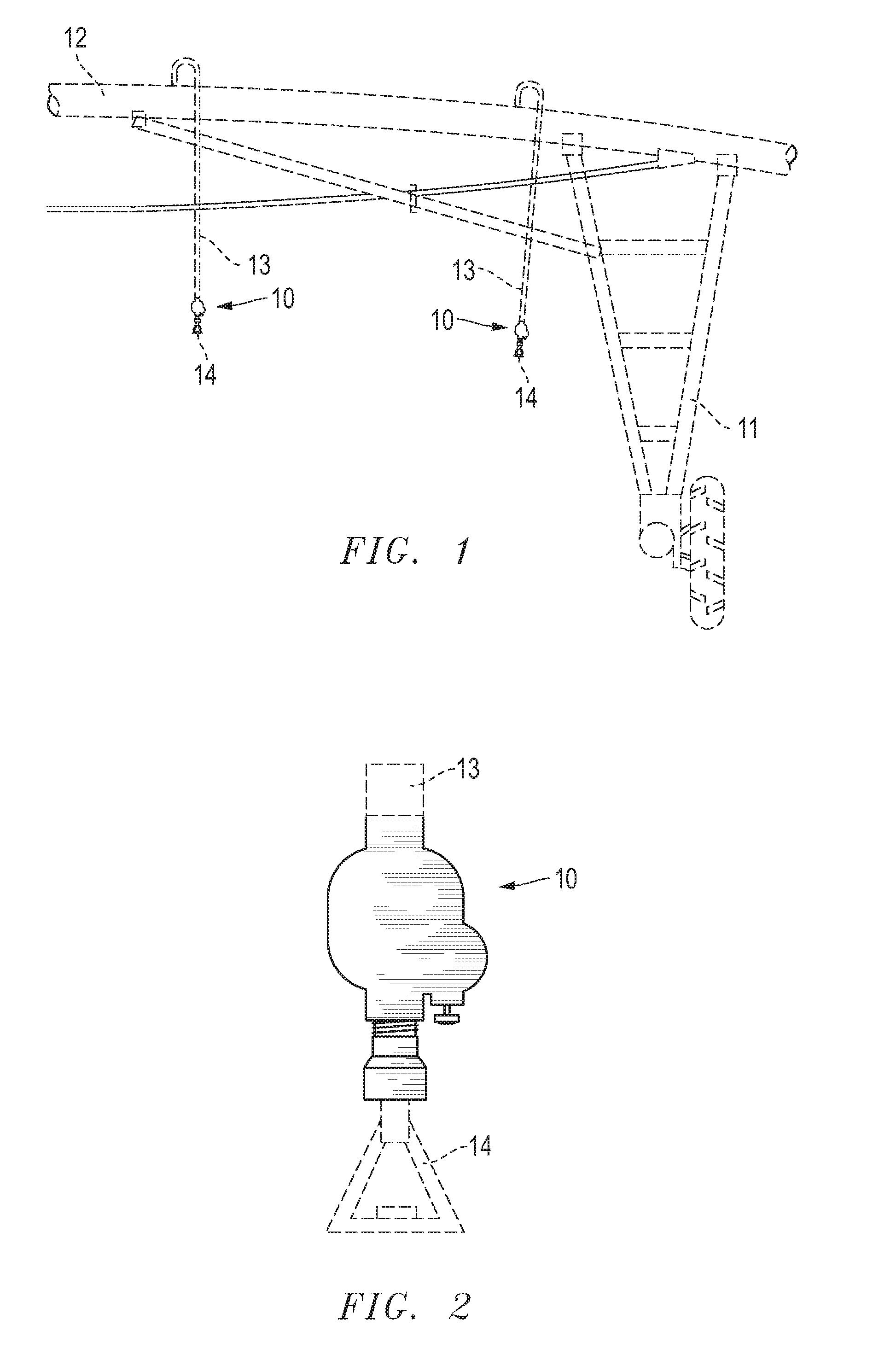

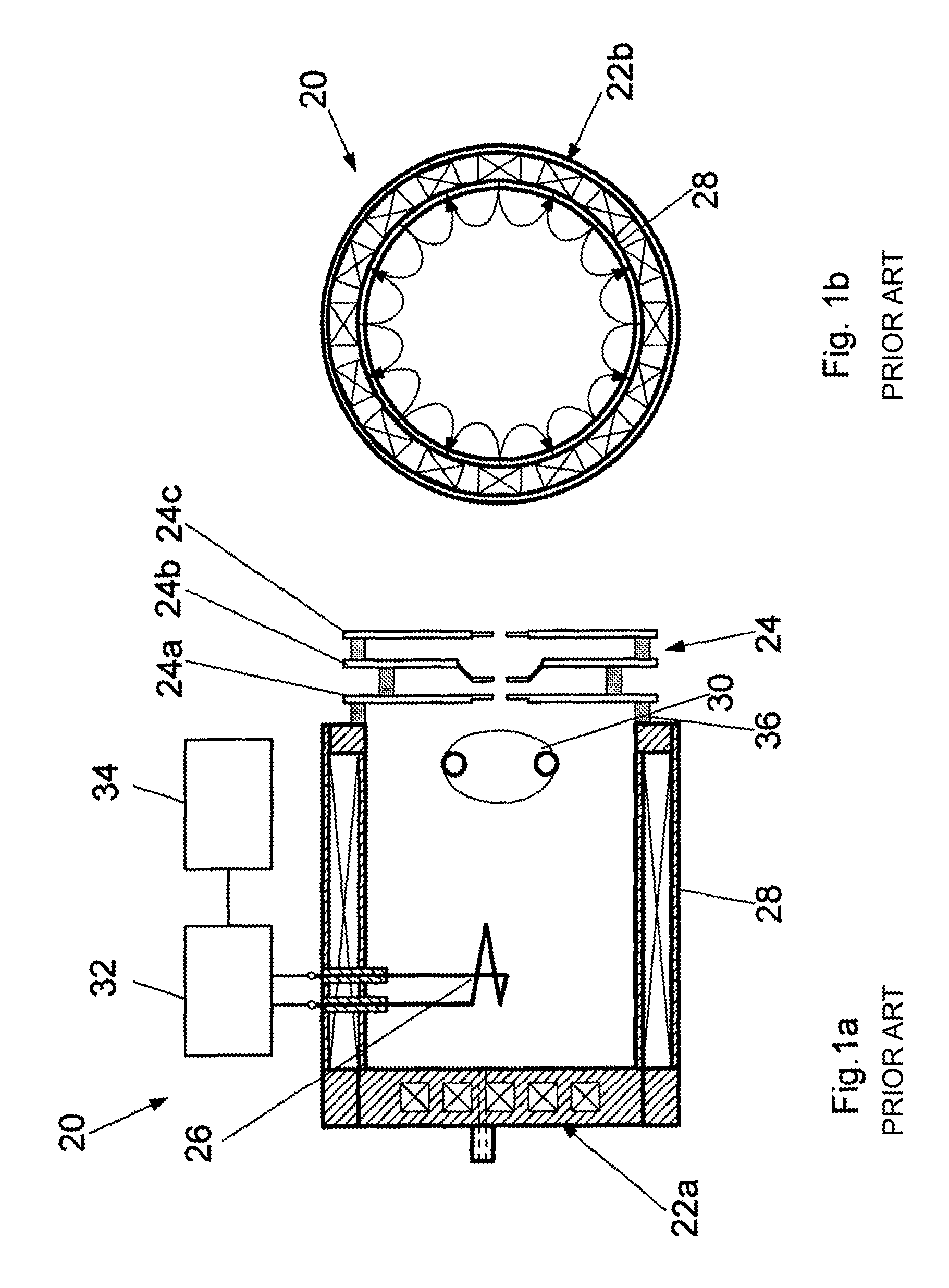

System for disposal of contaminated medical products

InactiveUS6247592B1Precise and reliable single-handedPrecise and reliable detachmentDispensing apparatusRefuse receptaclesMedical wasteMedical product

A disposed system for medical waste, and particularly sharp ended waste, includes a sharps receptacle and a companion needle holder. The needle holder has an actuation mechanism capable of detachably mounting an externally threaded hub of a needle assembly to the holder. The sharps receptacle has a top with an automatic release structure disposed thereon for engagement with the actuation mechanism of the needle holder. The automatic release structure cooperates with the actuation mechanism of the needle holder to automatically detach a mounted needle assembly from the holder into the sharps receptacle in response to placement of the holder into the automatic release structure.

Owner:ICU MEDICAL SALES +1

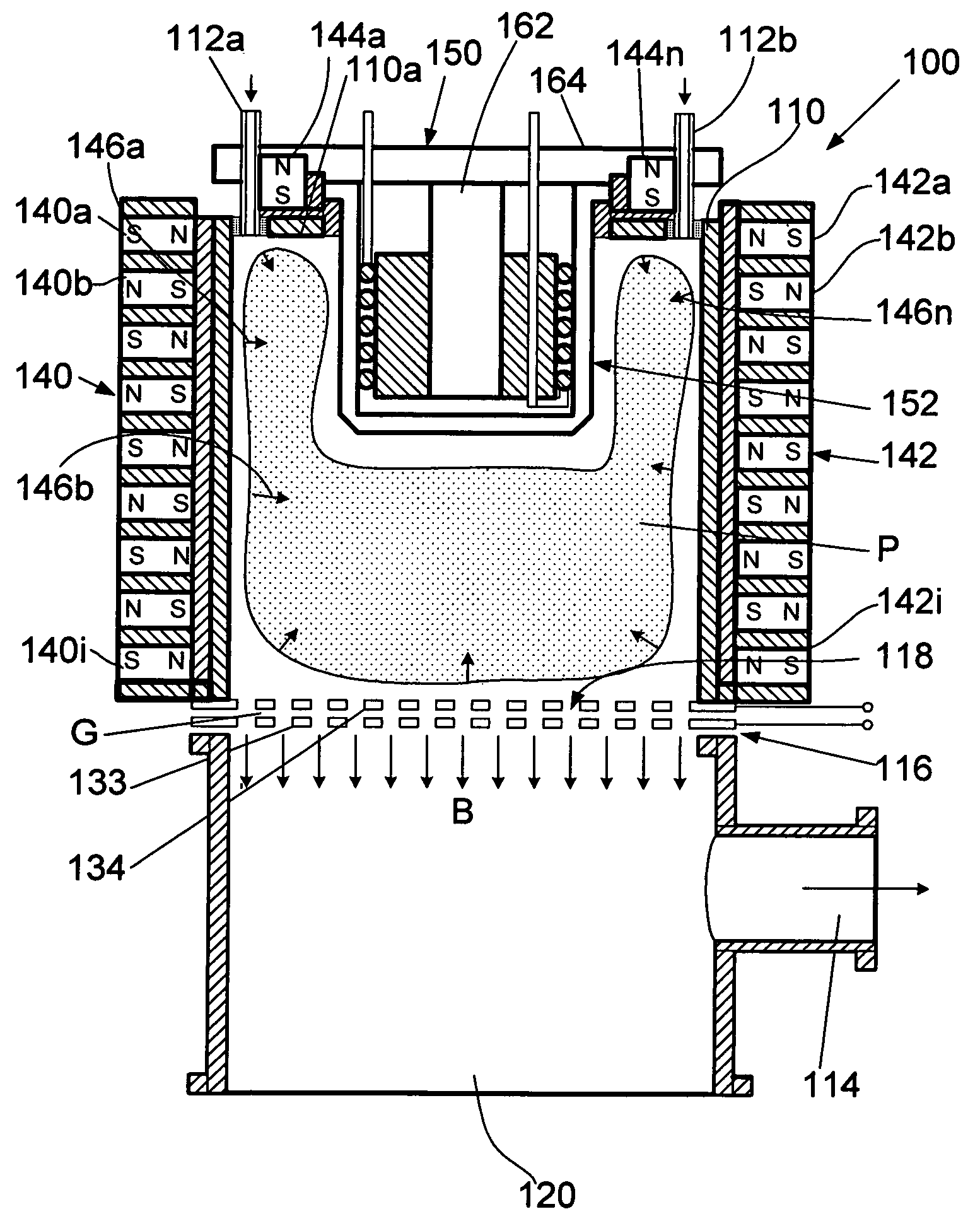

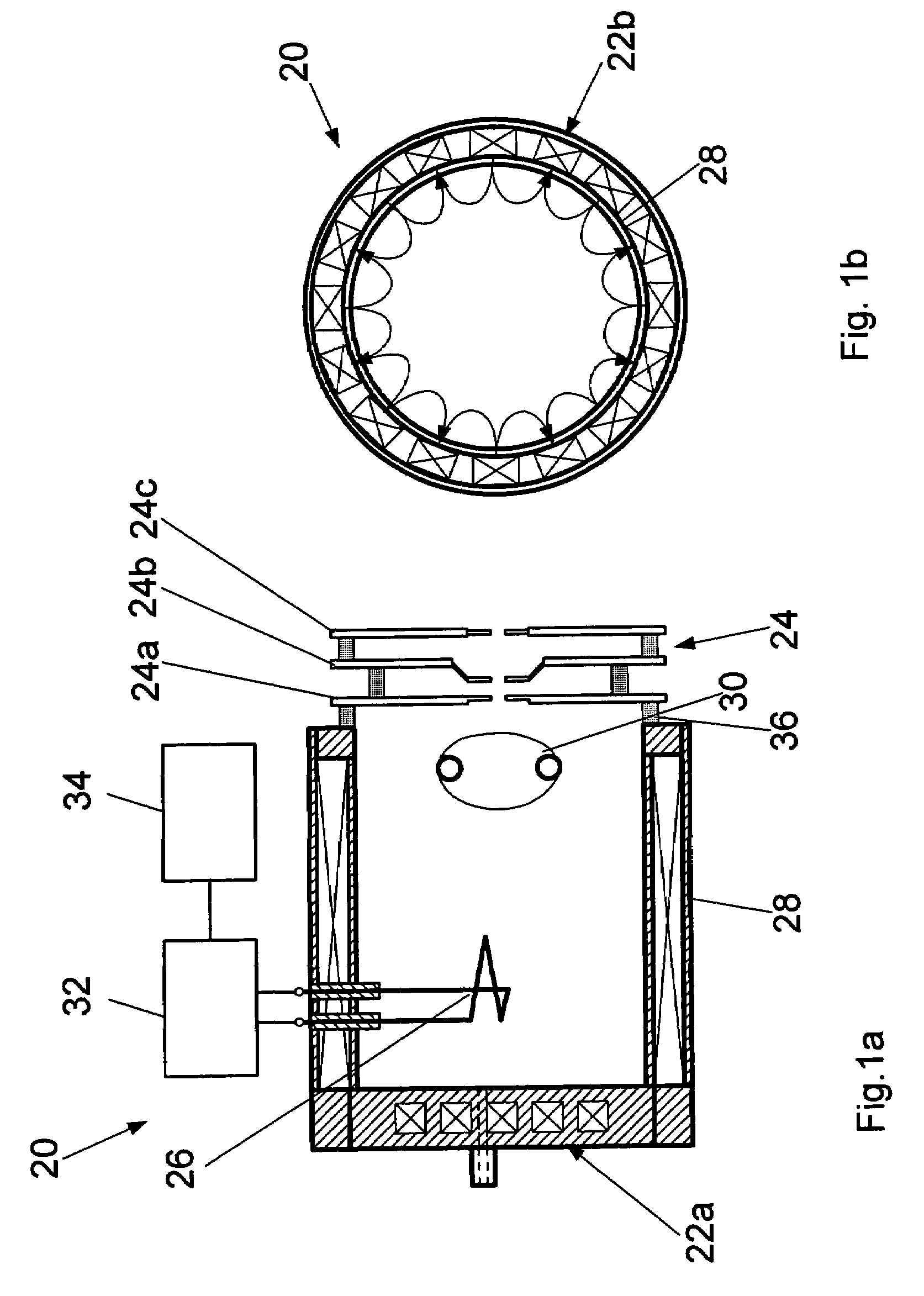

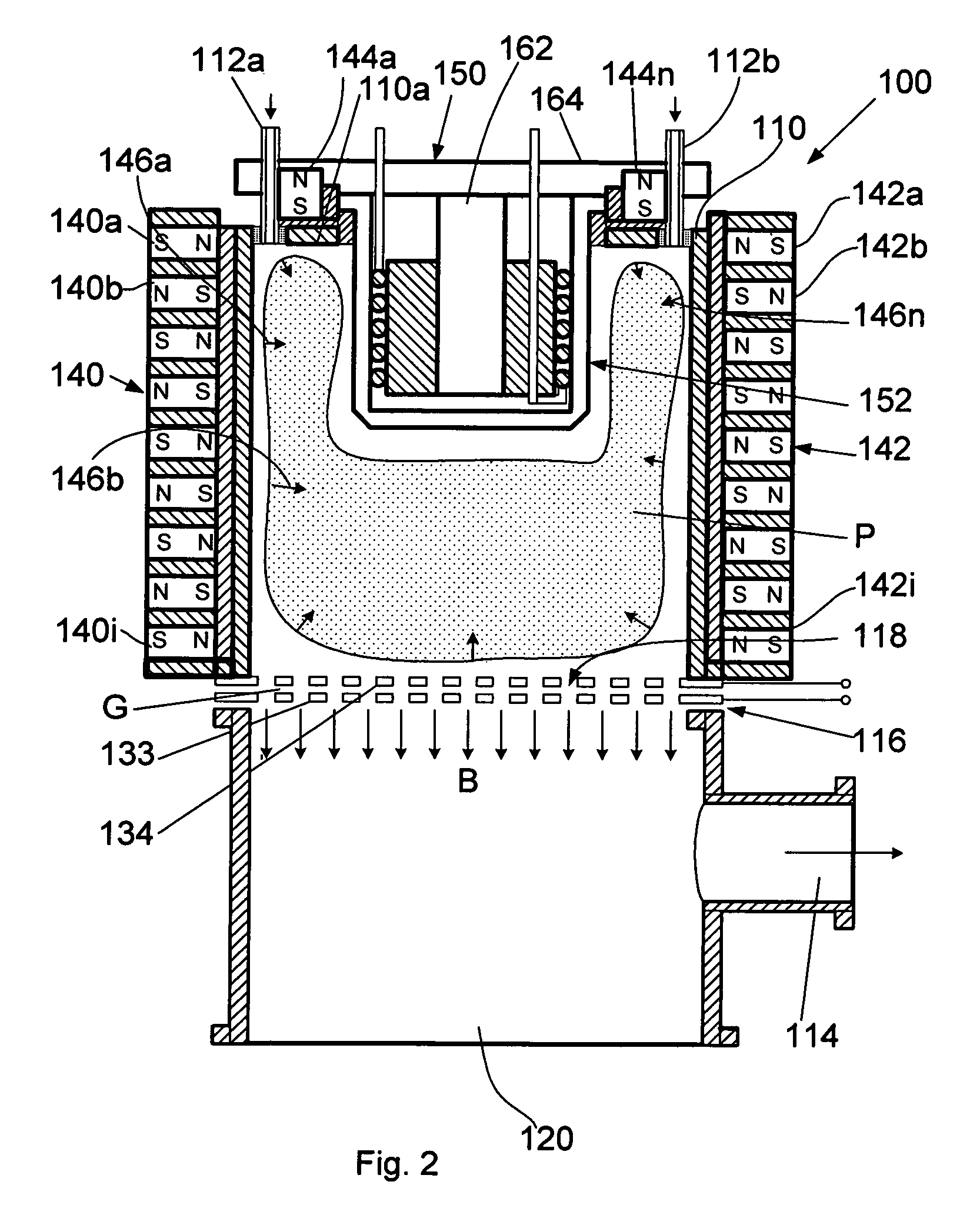

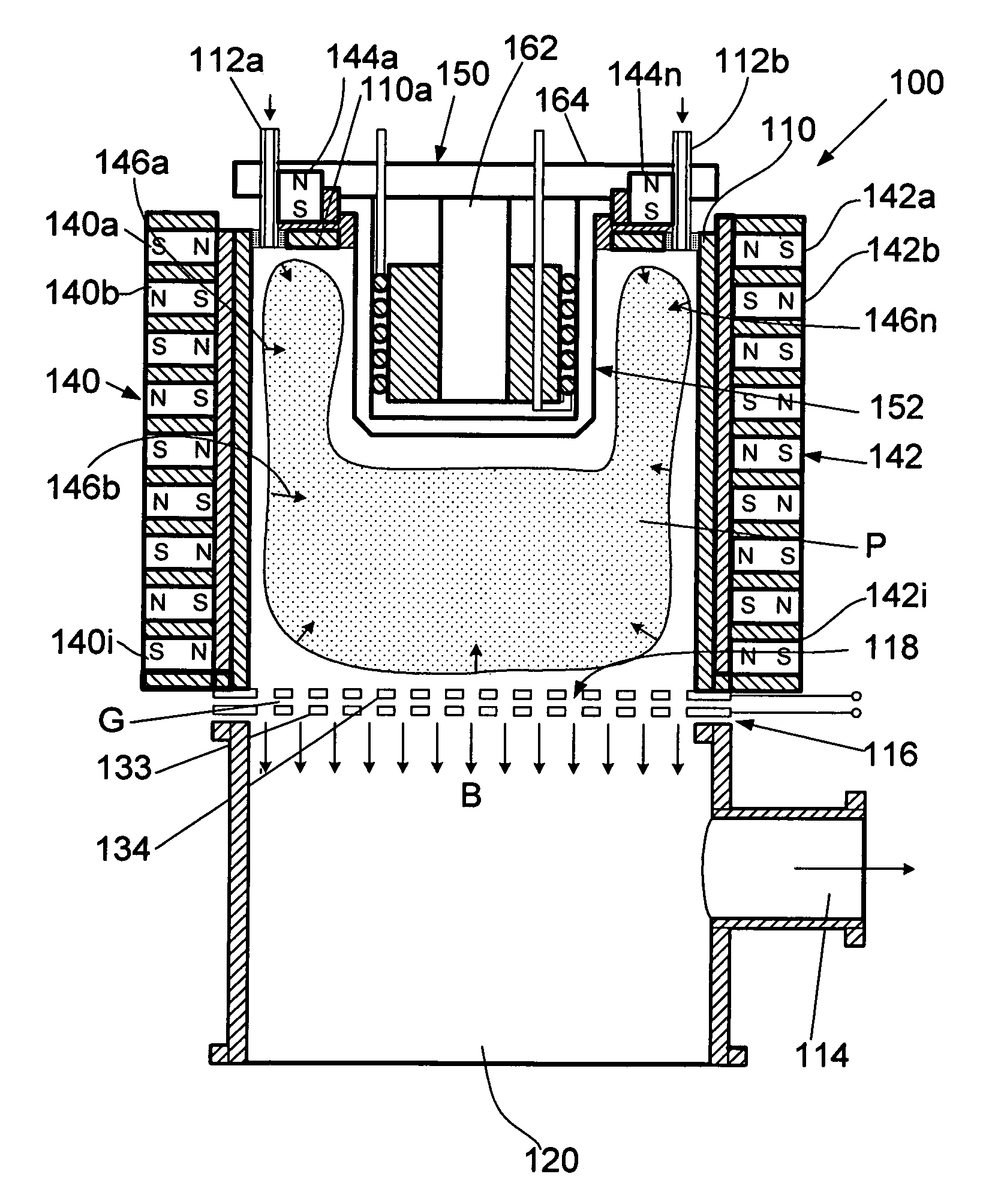

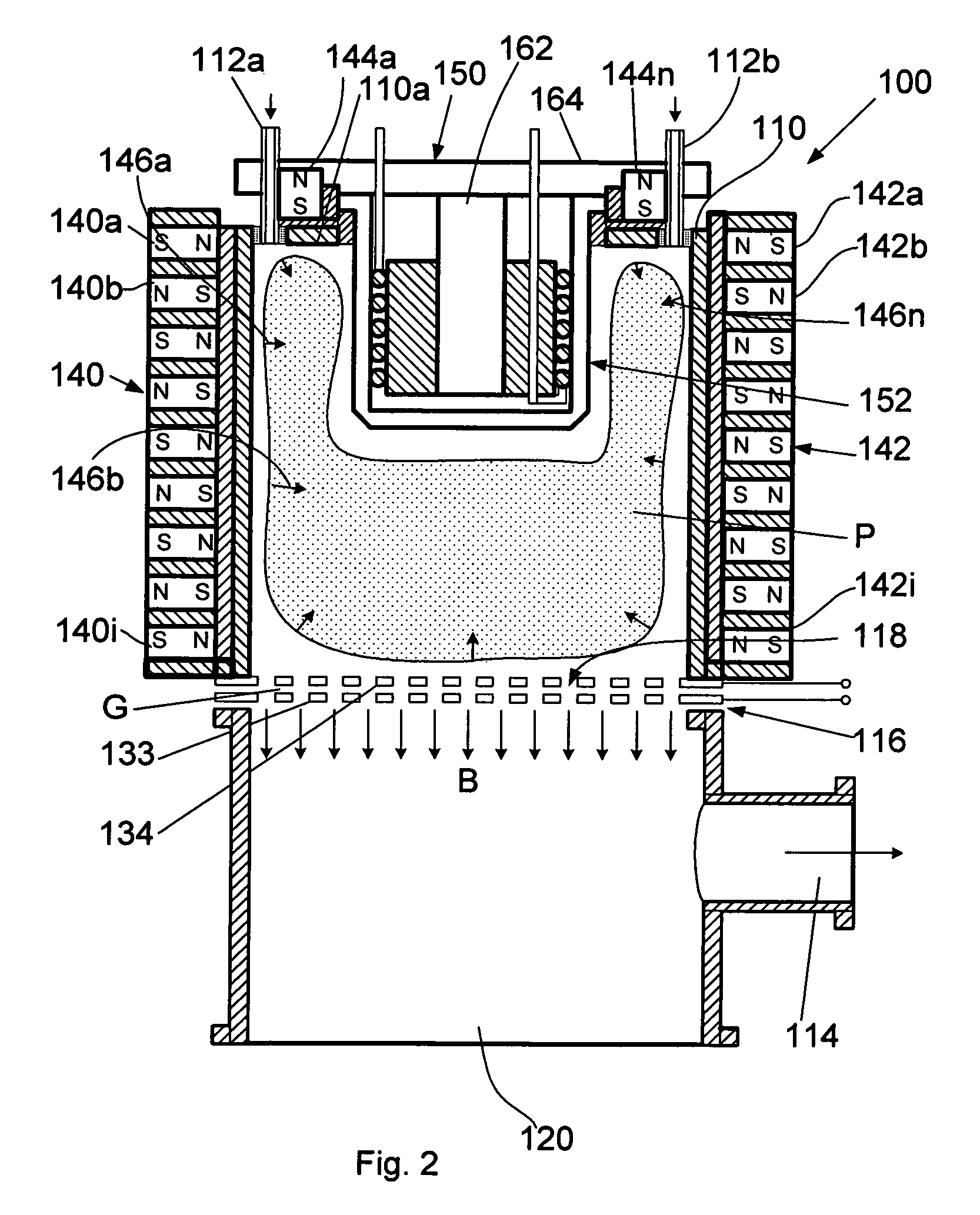

Ion-beam source

ActiveUS20090189083A1Enhanced couplingImprove efficiencyMaterial analysis by optical meansIon beam tubesElectrical conductorIon beam

An ion-beam source comprising: a plasma-generation unit for generating plasma and an ion-extraction unit for extraction and acceleration of ions from the aforementioned plasma, where the ion-extraction unit is made in the form of at least one grid under a negative potential. The plasma generating unit consists of a working chamber having a deeply immersed antenna cell. The cell contains a ferromagnetic core, a heat conductor with a heat sink, at least one inductive coil wound onto the ferromagnetic core, and a cap made from a dielectric material that sealingly covers the ferromagnetic core and the inductive coil.

Owner:GODYAK VALERY

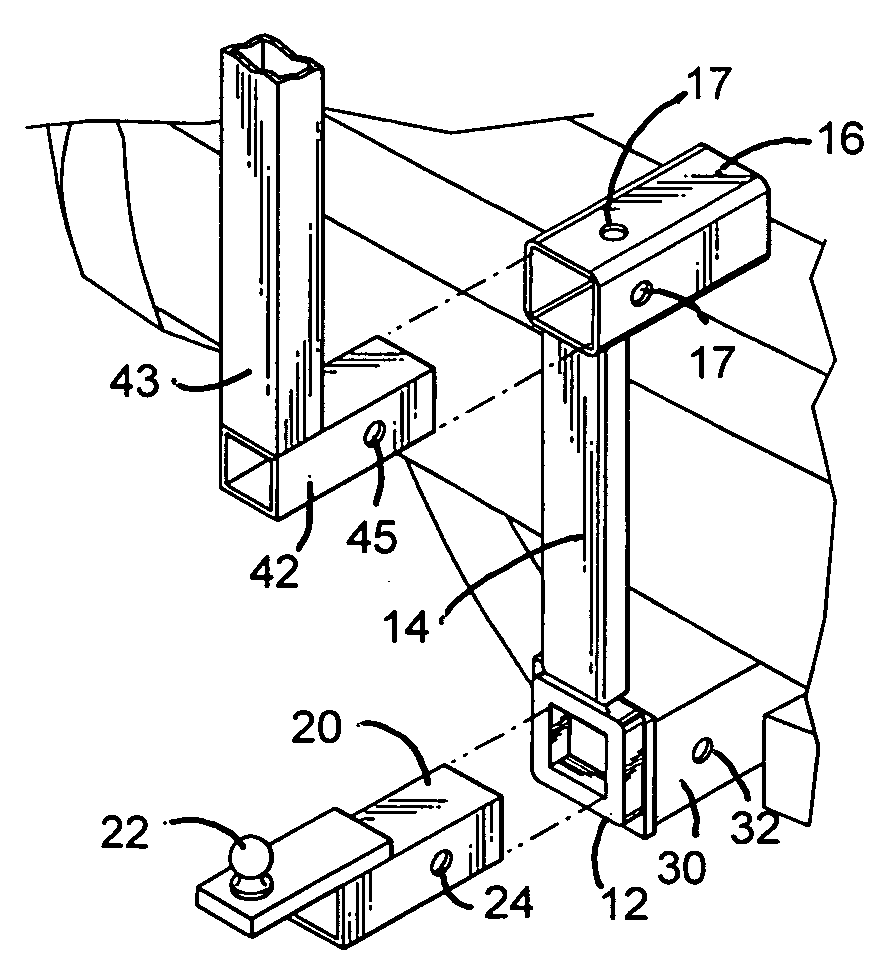

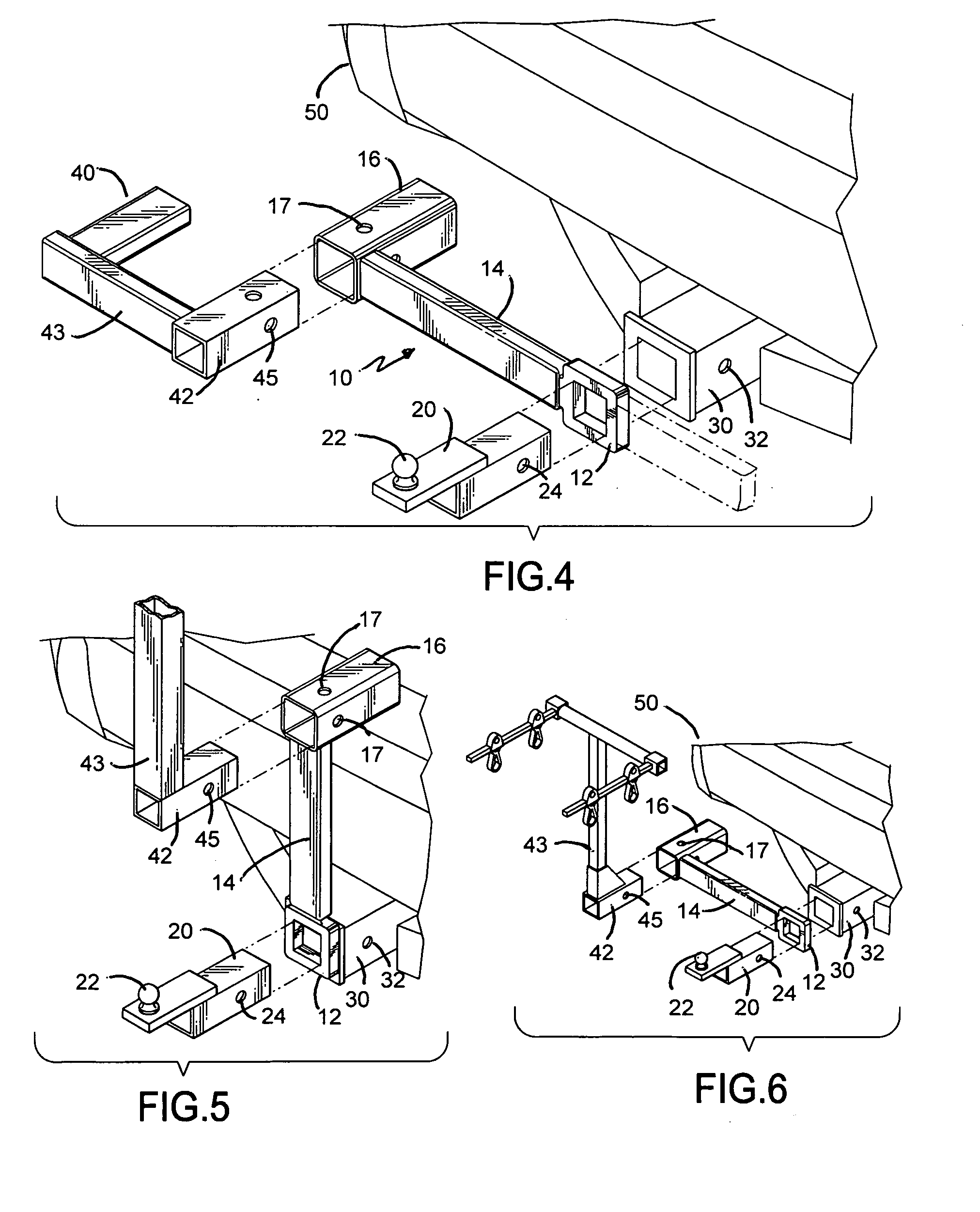

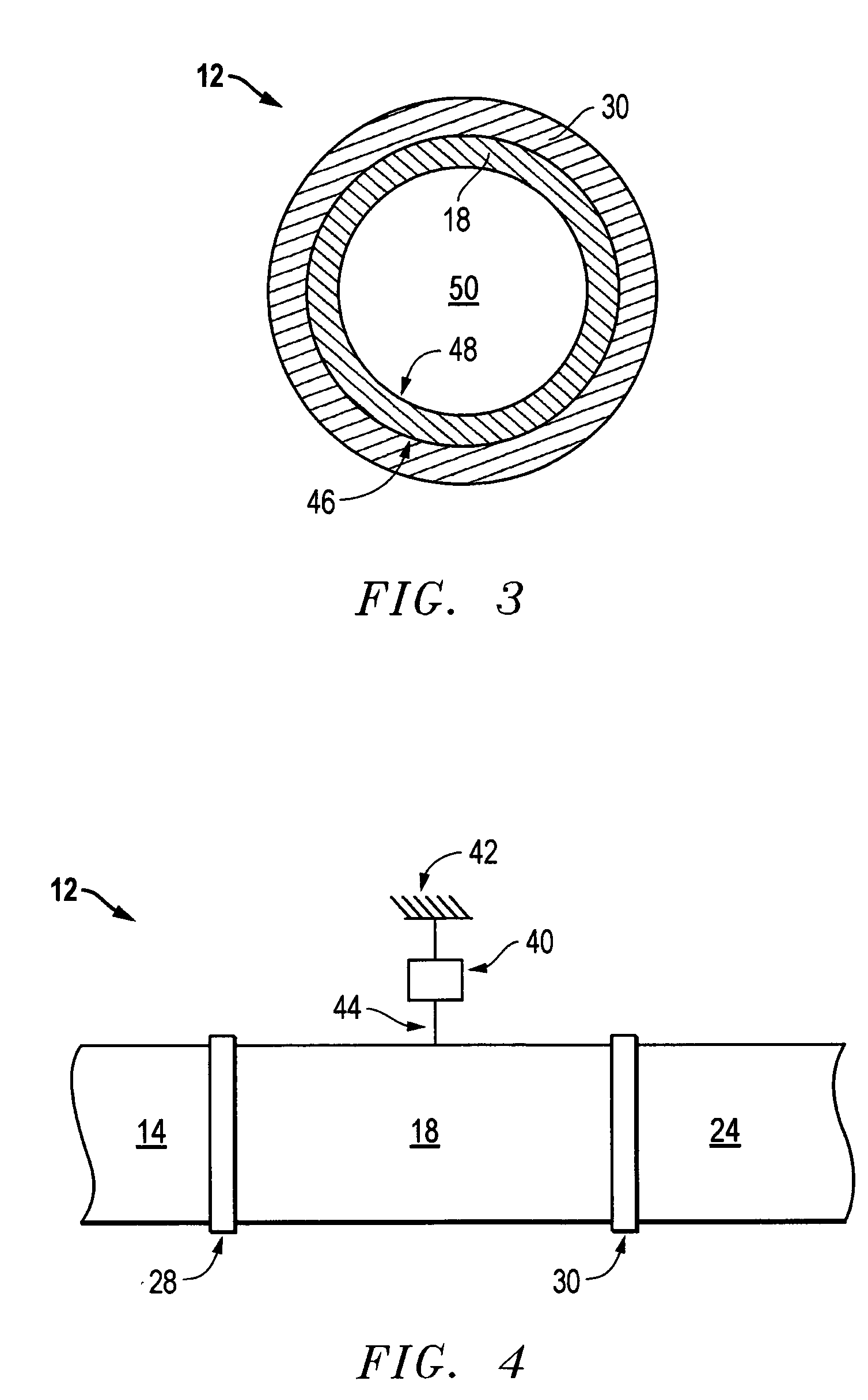

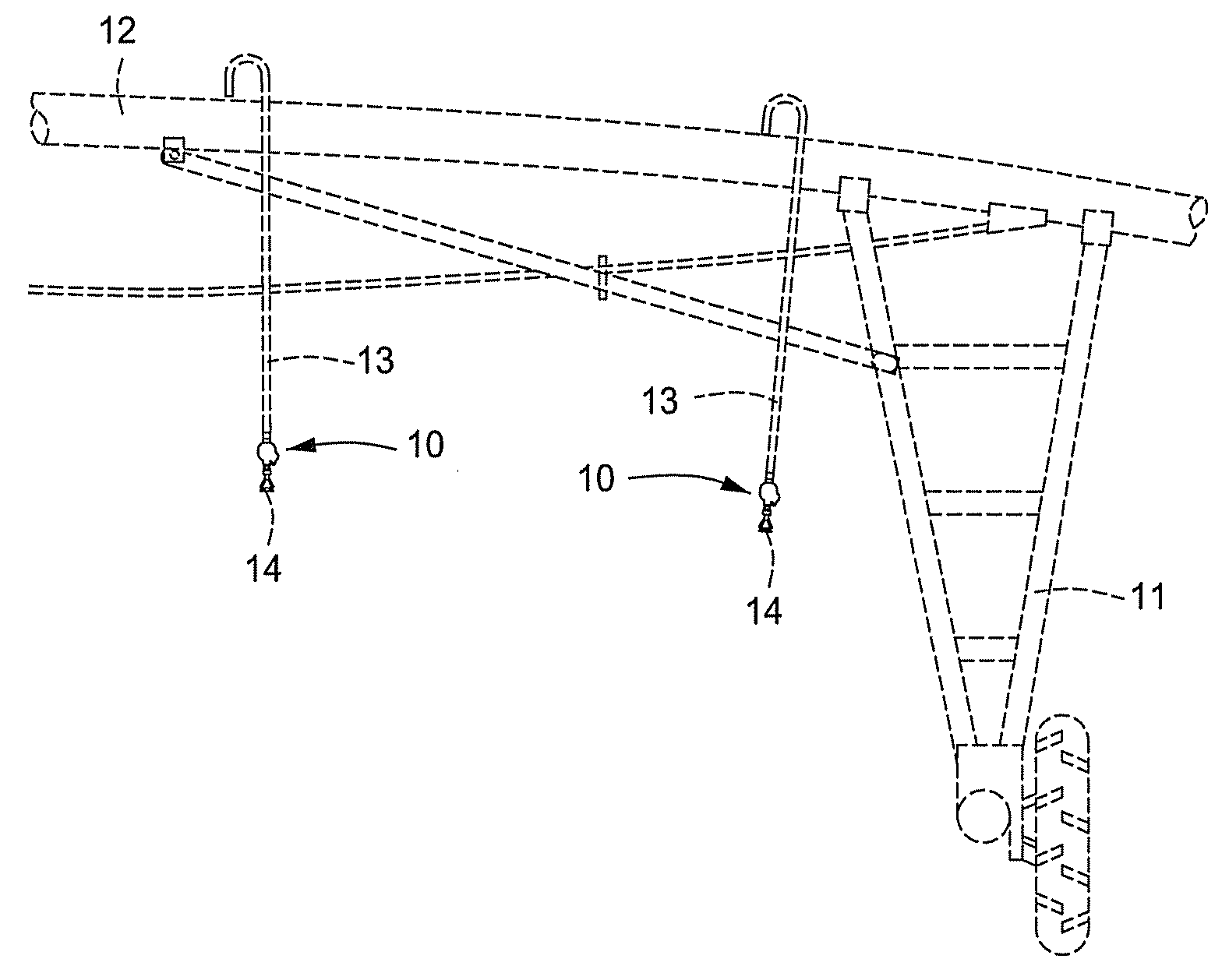

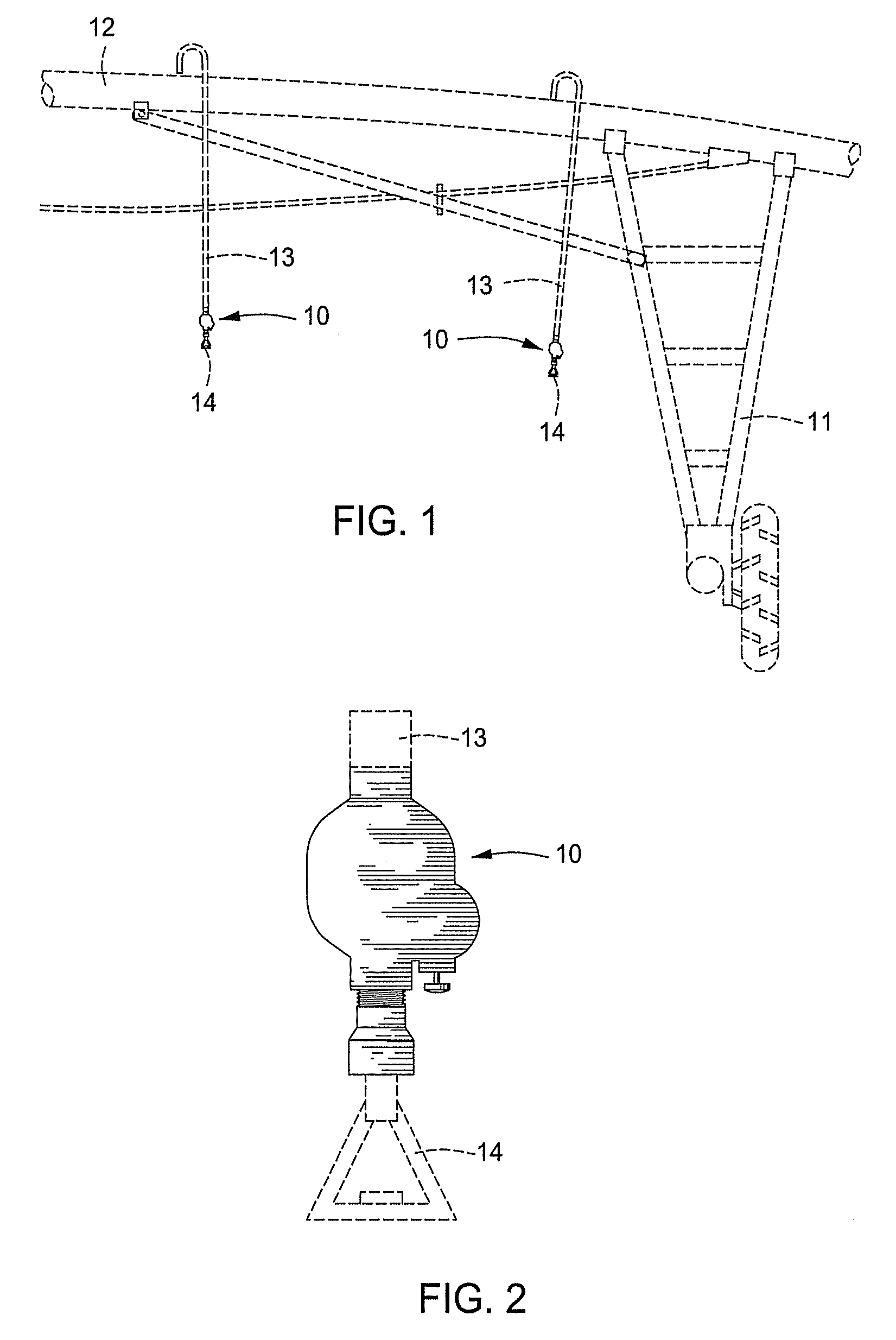

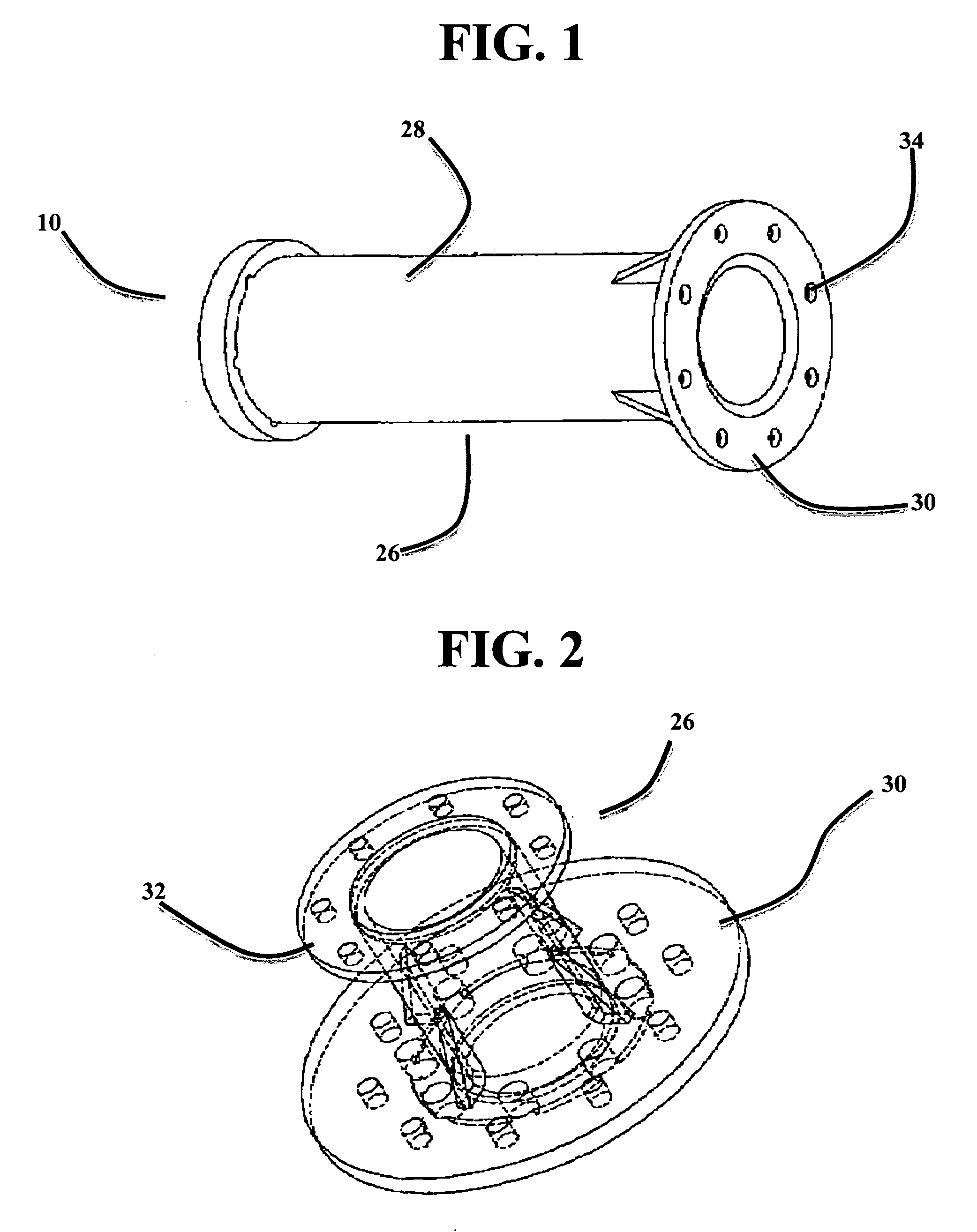

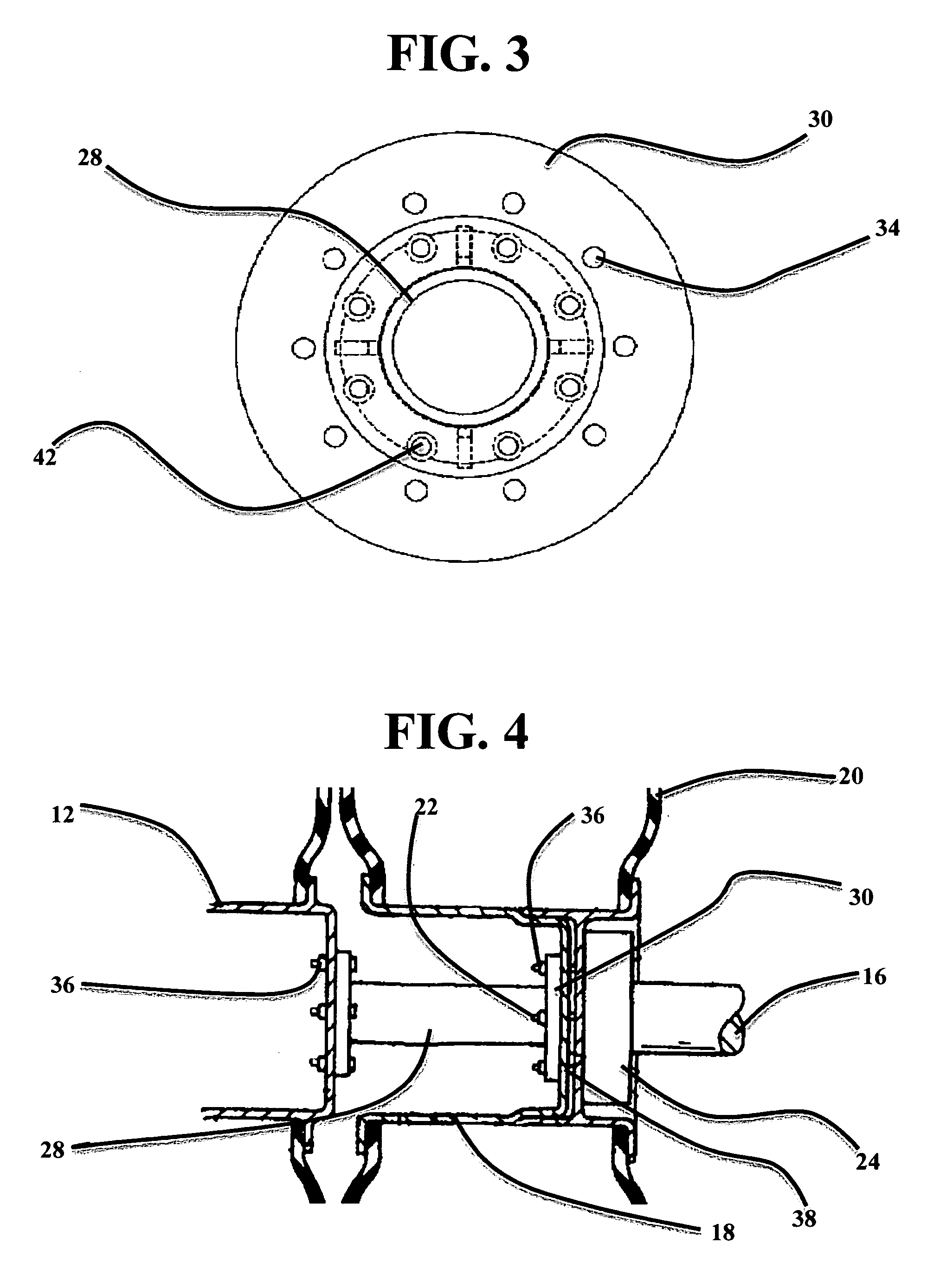

Trailer hitch accessory mounting receiver

InactiveUS20100294819A1Simple and durable structureSupplementary fittingsEngineeringElectrical and Electronics engineering

An accessory mounting receiver for trailer hitches is provided which includes a trailer hitch insert tube having lateral side walls. The side walls include cooperating aligned apertures for pinned connection to a trailer hitch receiver. An accessory mounting bar has proximal and a distal ends. An accessory receiver box is connected to the distal end of the mounting bar. The accessory receiver box has four side walls. At least two of the side walls each have cooperating diametrically opposed apertures for pinned connection to an accessory insert tube. A collar plate is connected to the proximal end of the mounting bar. The plate is slidably clearance fit for horizontal and vertical rotation of the accessory receiver about the trailer hitch insert tube.

Owner:SPERA MICHAEL

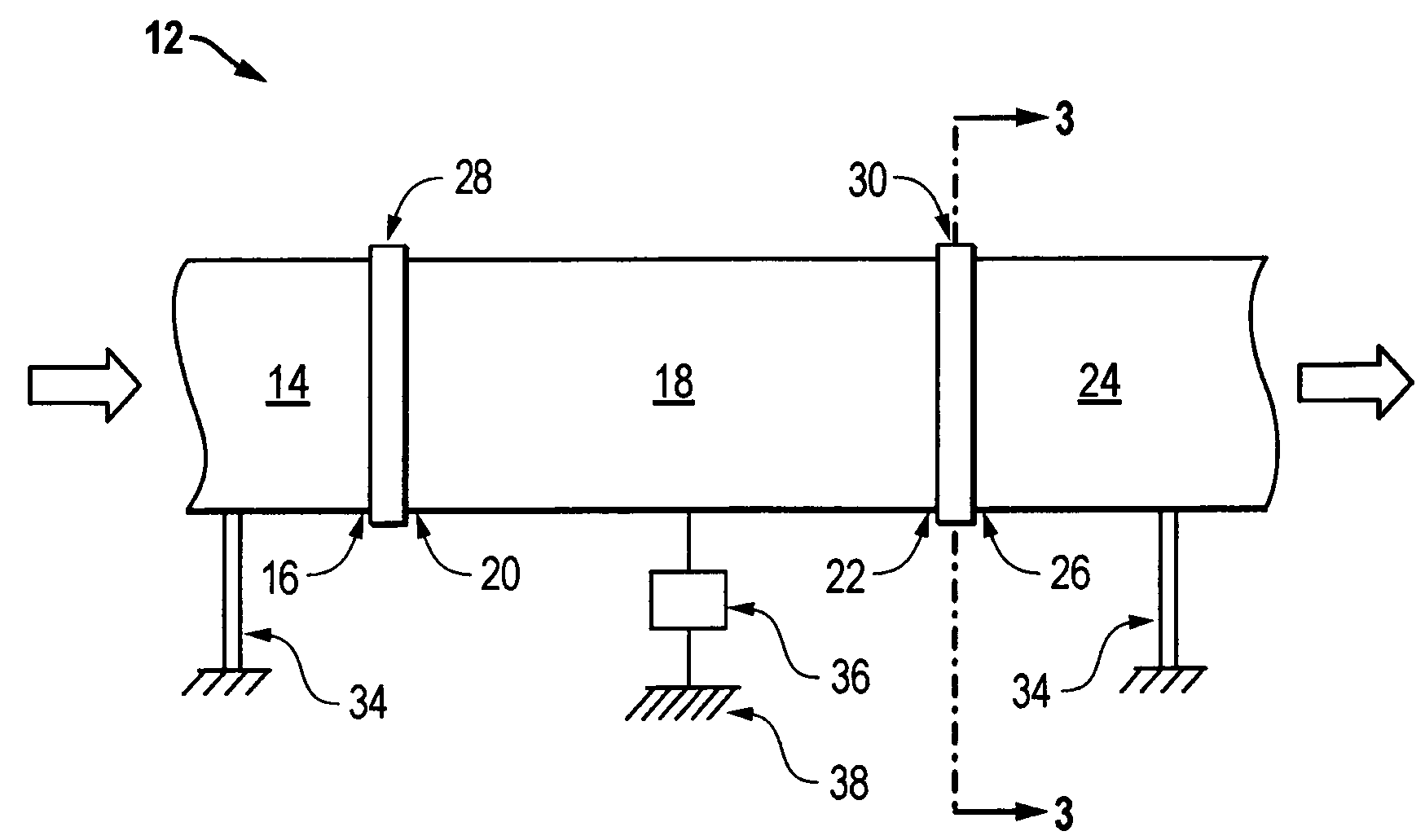

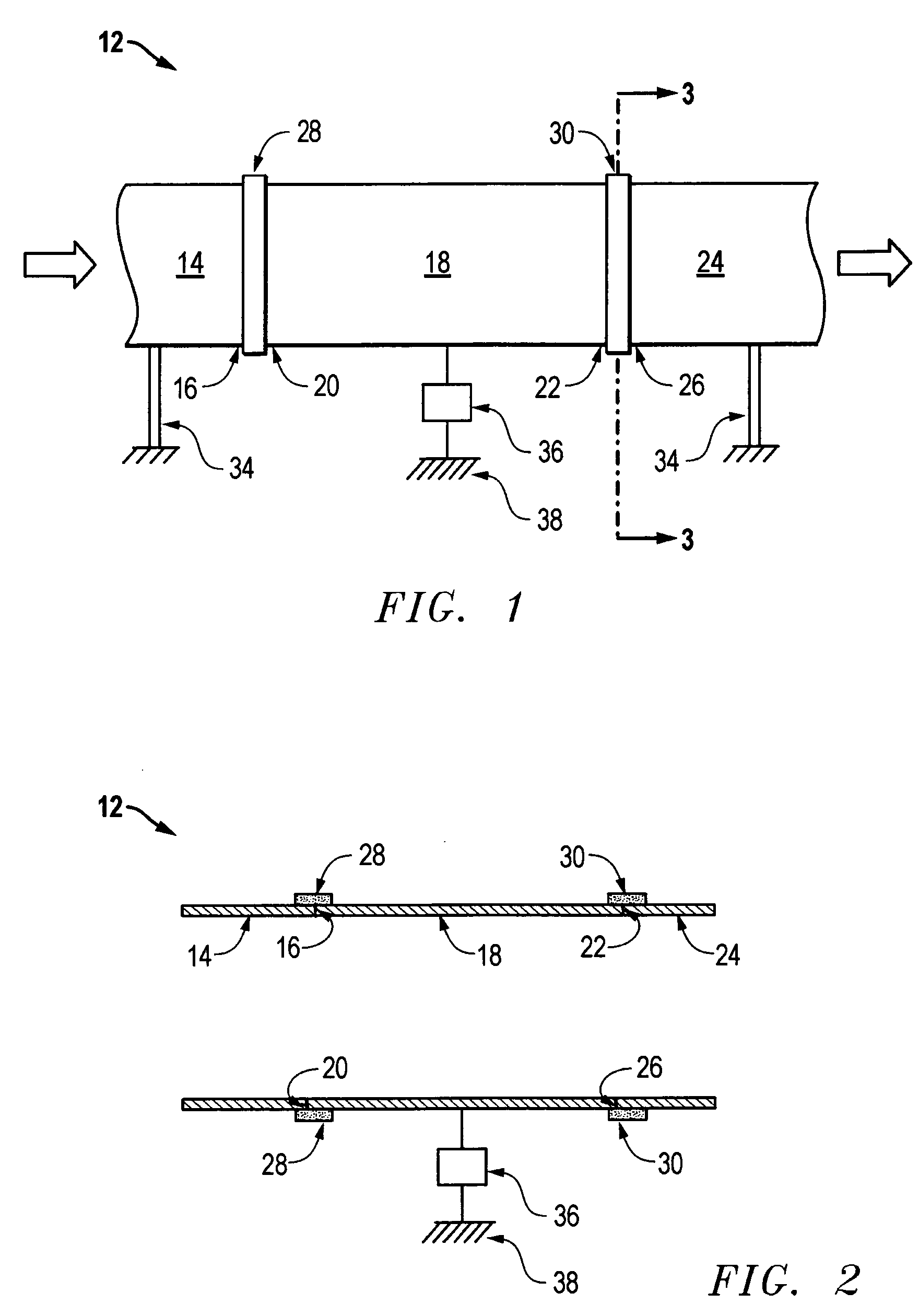

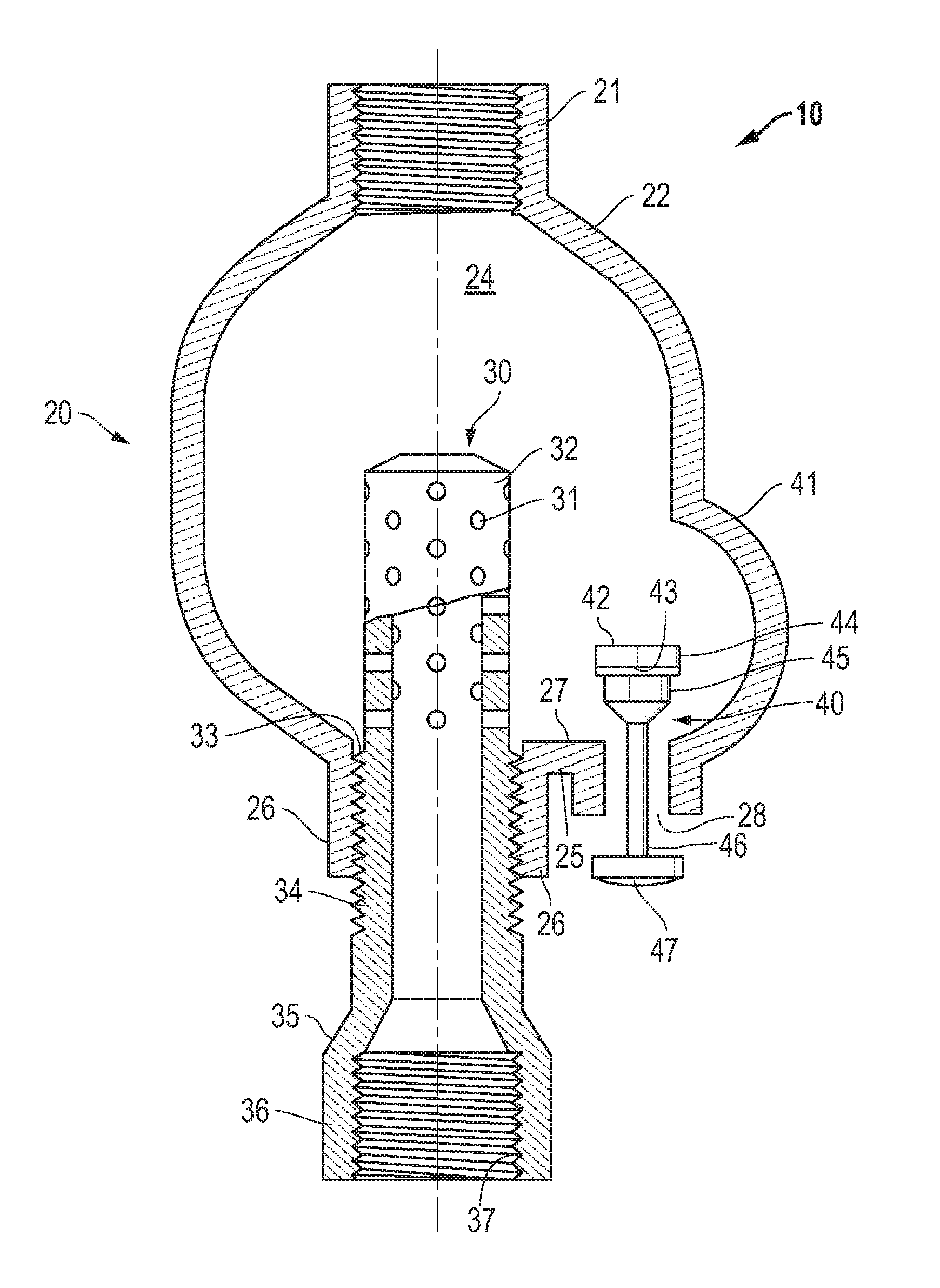

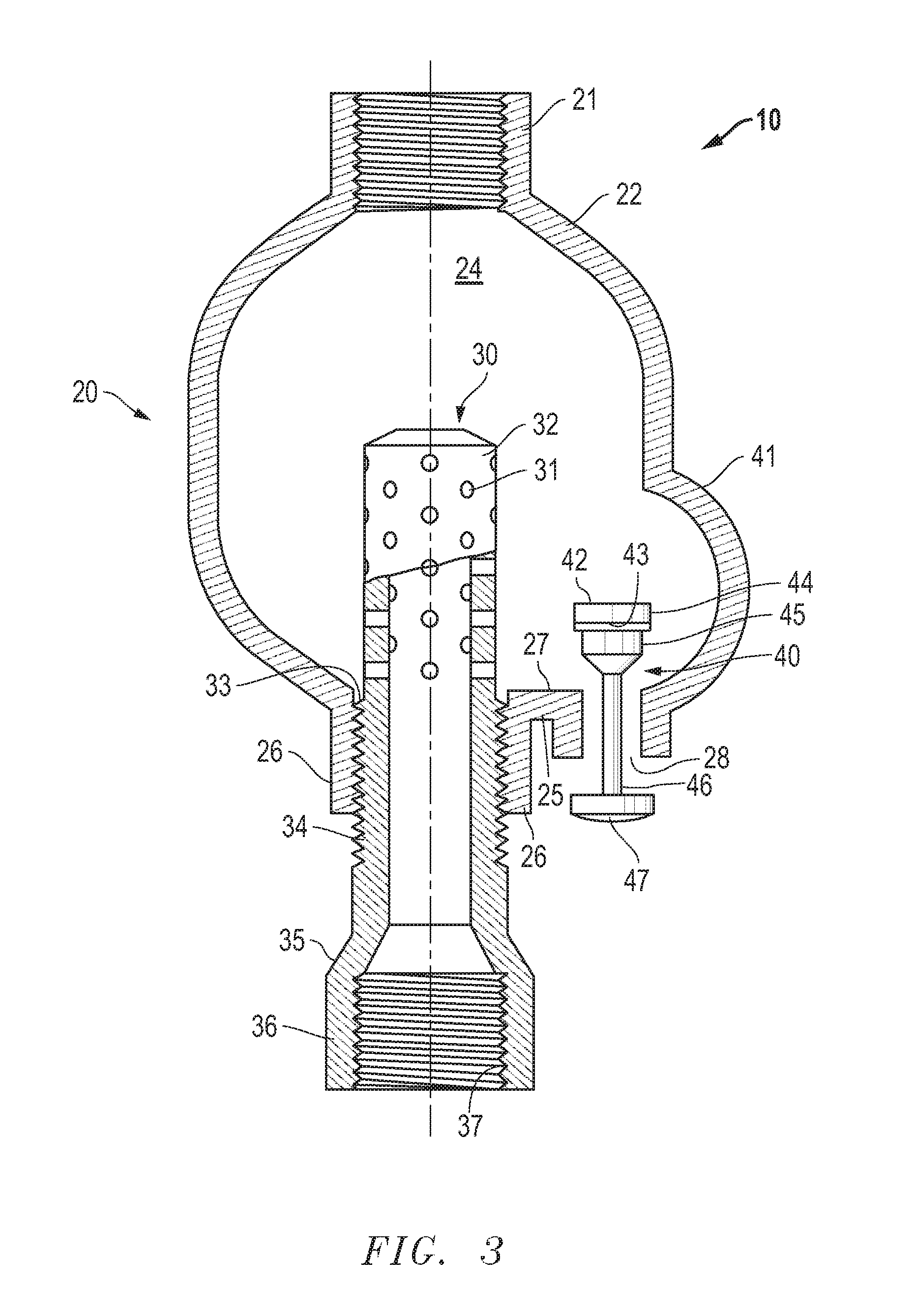

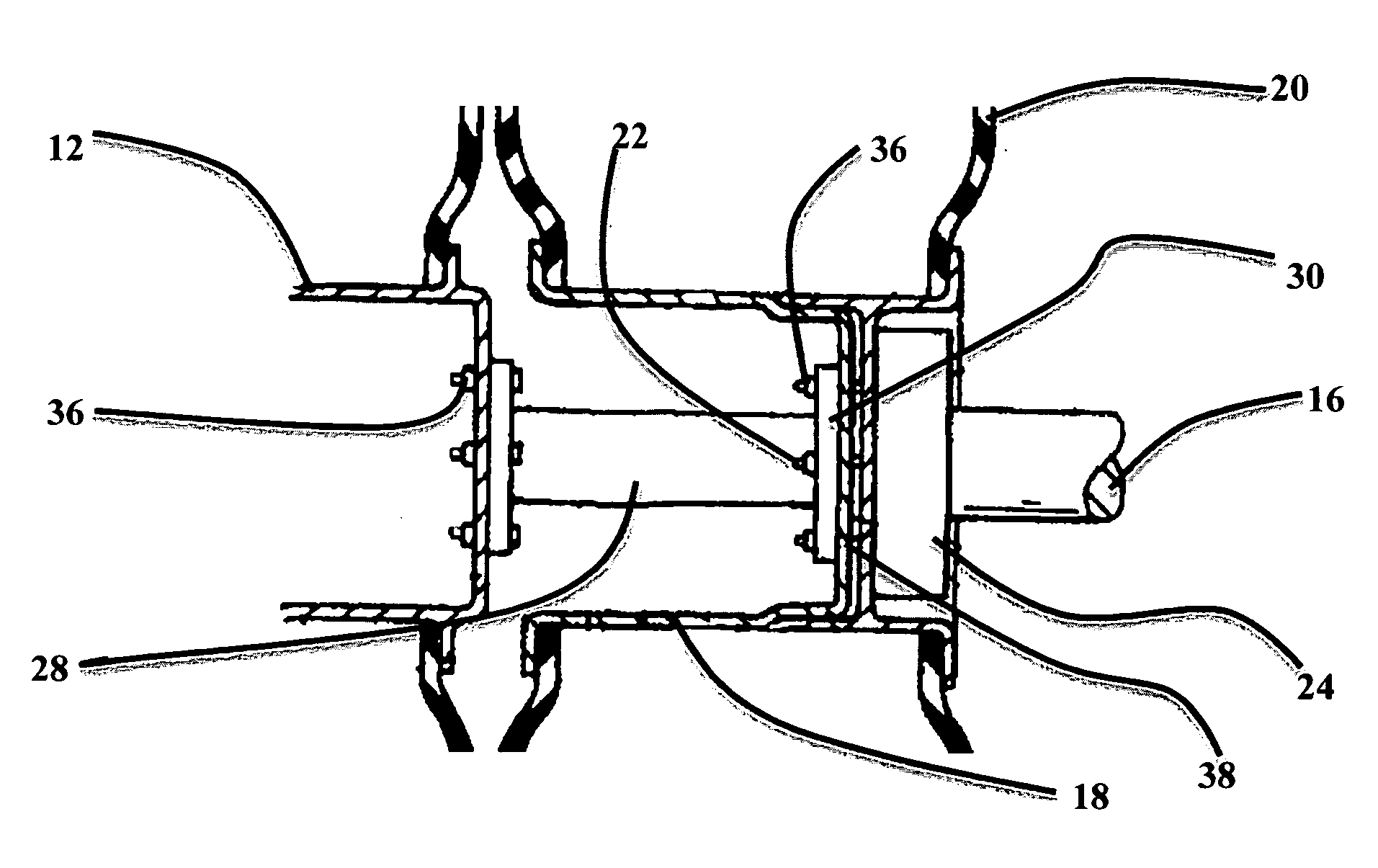

Density measuring apparatus containing a densimeter and a method of using the same in a pipeline

ActiveUS7290447B1Easy to calculateEasy to installTransportation and packagingMixer accessoriesRadial motionCoupling

A densimeter contains an inlet pipe section, a second pipe section joined to the downstream end of the inlet pipe section, and an outlet pipe section joined to the downstream end of the second pipe section. The inlet and outlet pipe sections are constrained by a support structure, while flexible couplings allow the second section of pipe to undergo a limited amount of radial motion relative to the adjacent pipe sections. The weight of the second pipe section is supported by a weight measuring unit, which continuously measures the weight of the second pipe section as fluid flows through the densimeter. One preferred embodiment of the invention uses the densimeter to measure the density of a proppant in a blender system for preparing fluid mixtures for fracturing and propping oil bearing geological formations.

Owner:BAKER HUGHES INC

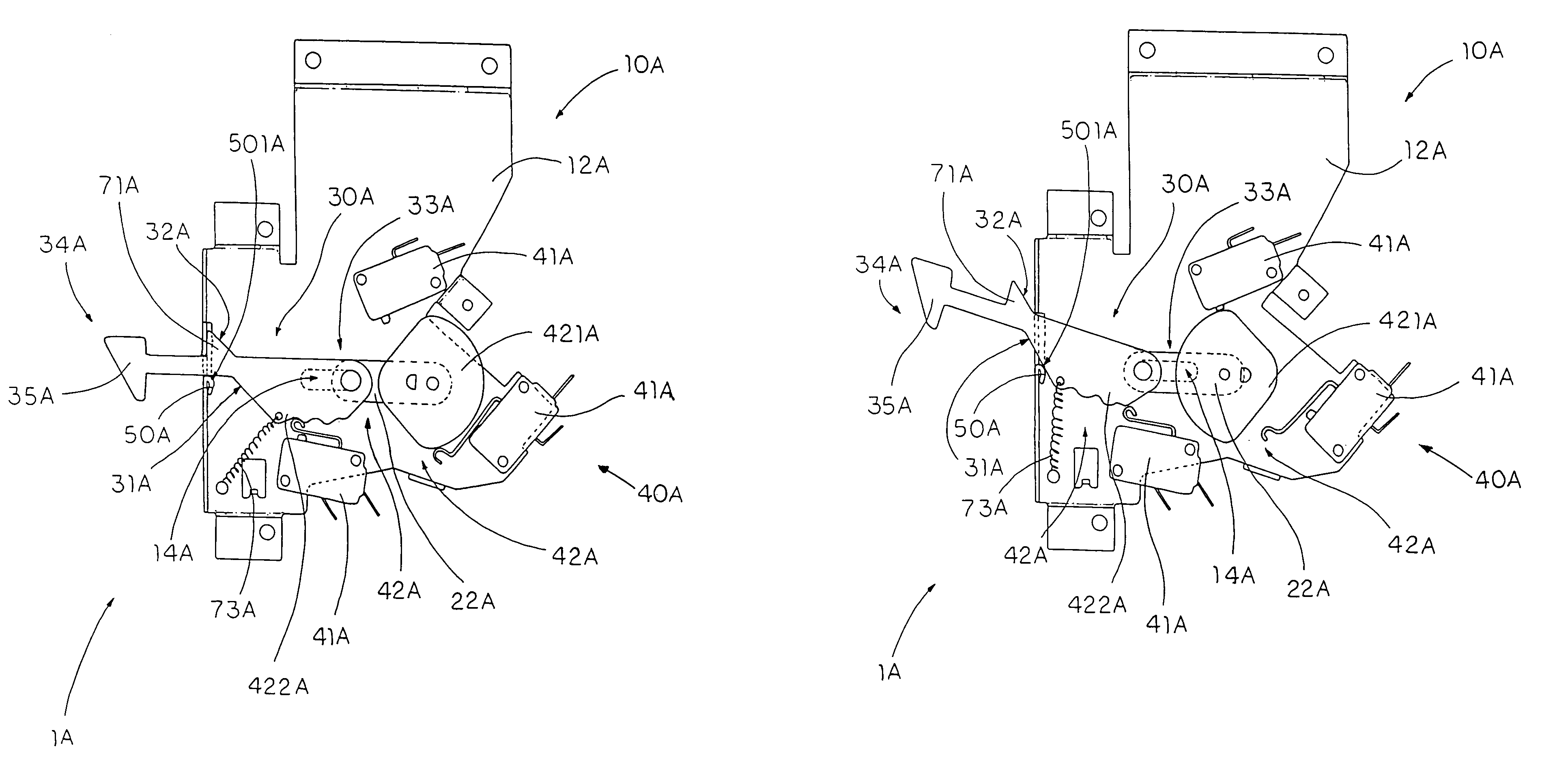

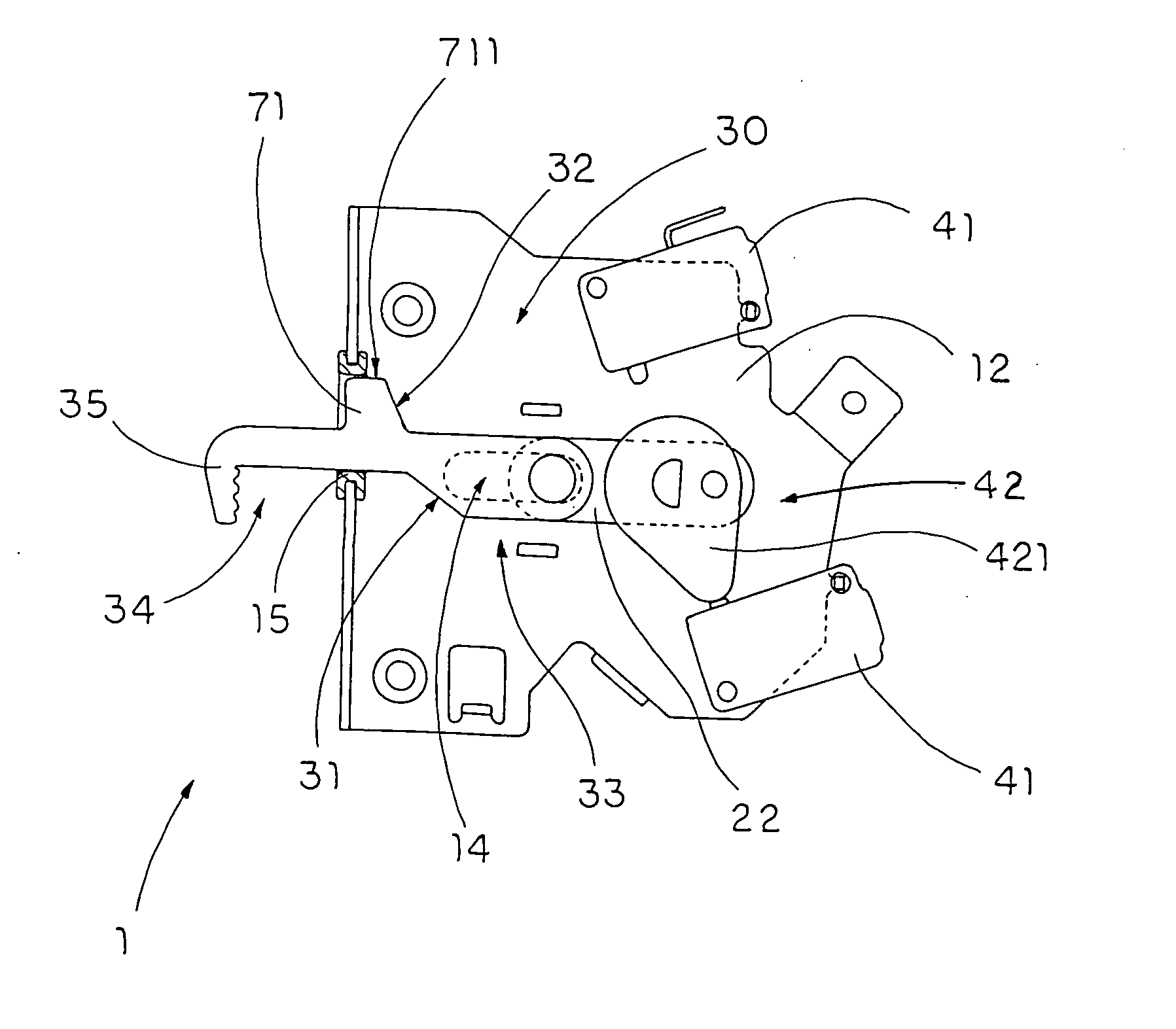

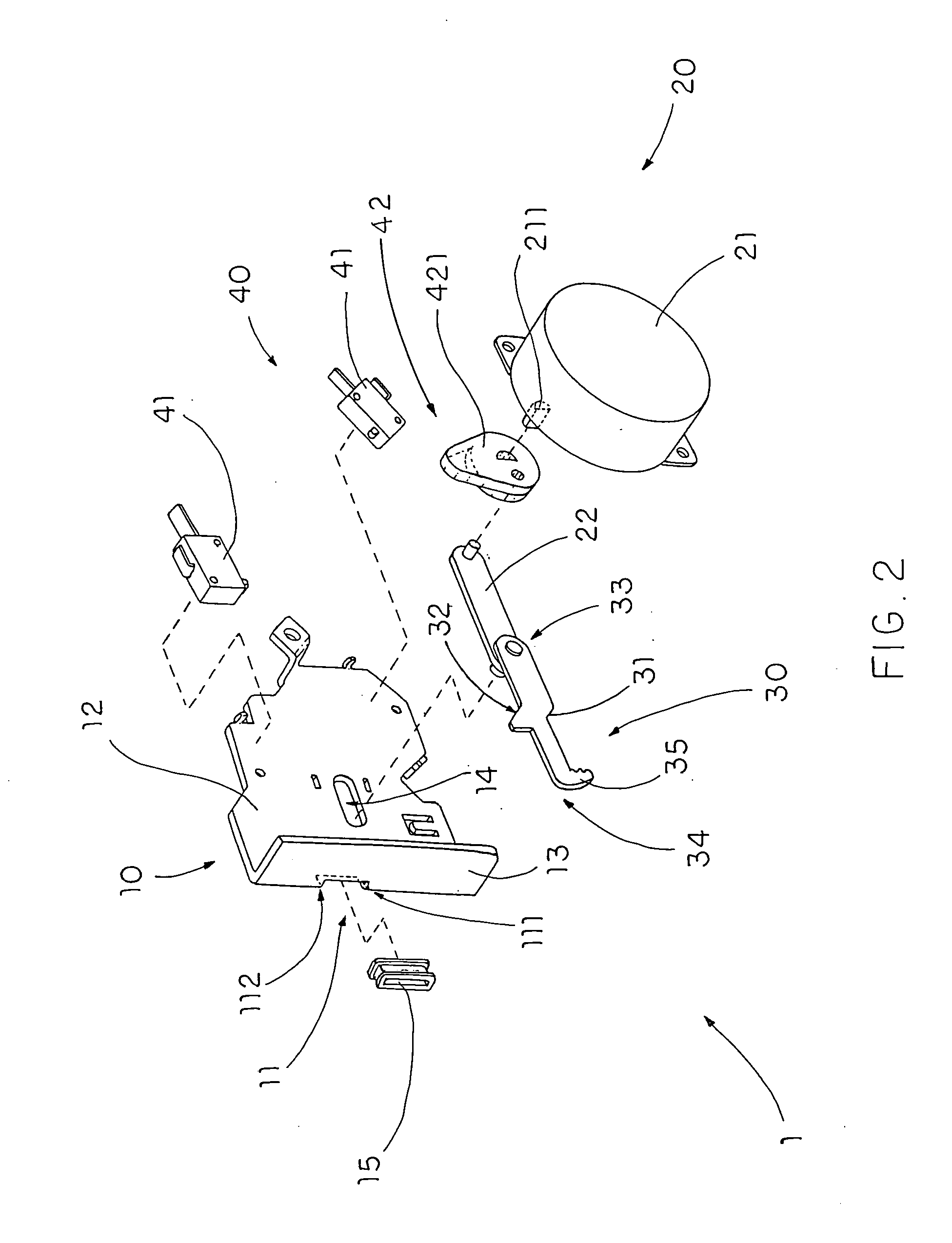

Powered latch assembly

ActiveUS7040674B2Simple structureHigh strengthDomestic stoves or rangesDoors for stoves/rangesCouplingElectric motor

A power latch assembly which includes a supporting frame adapted for mounting on a main housing, wherein the supporting frame has a locking slot and defines first and second slider ends thereof; a motor assembly including a power motor supported by the supporting base and adapted for being powered by the main housing, and a driving arm driven by the power motor in a linear movable manner; and a locking latch, defining a first guiding edge and a second guiding edge, having an inner coupling end coupling with the driving arm and an opposed latching end extended outwardly through the locking slot, wherein the driving arm drives the locking latch between a locking position and an unlocked position.

Owner:HTI TECH & IND LLC

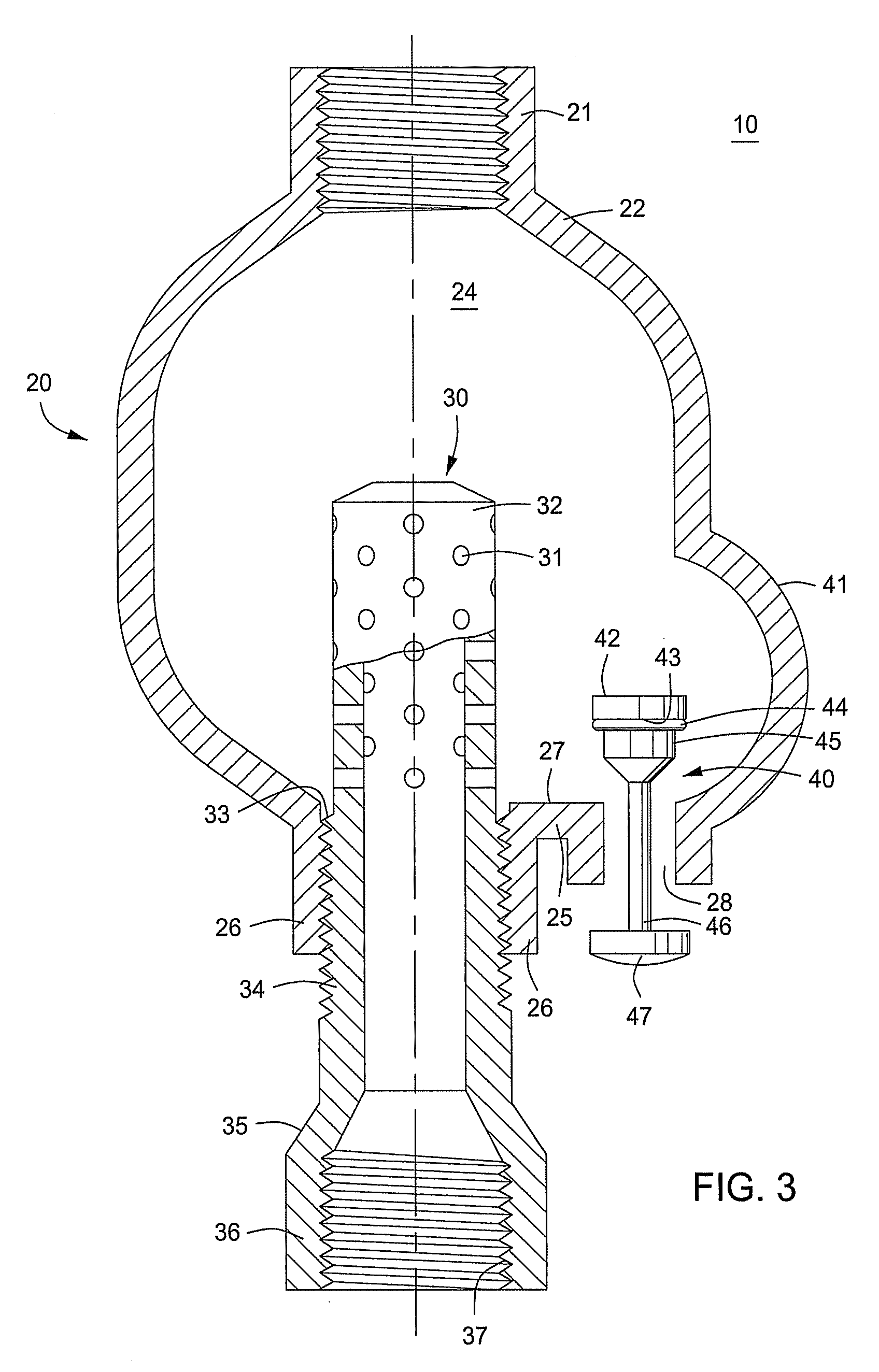

Filtration and cleaning system for sprinkler irrigation drop nozzles

ActiveUS20090294341A1Simple and durable structureEfficient and reliable in operationClimate change adaptationWatering devicesFiltrationReciprocating motion

A filter for use with overhead sprinkler irrigation systems is disclosed. The filter includes a body, a removable screen, and a manually-actuated plunger adjacent the screen. A water hammer table is partitioned in the body and located above the plunger. The plunger is positioned for reciprocal movement through a debris outlet between an open, debris-discharging position, and a closed filtering position. The plunger defaults to the closed filtering position by pressurized water flowing through the body. The water is simultaneously filtered through the screen and passes out a clean water outlet while debris accumulates within the body. The plunger may be manually retracted to the open, debris-discharging position at any time, whereby accumulated debris is flushed out of the body through the debris outlet by residual water flowing therethrough.

Owner:AMERICAN AGRI PRODS

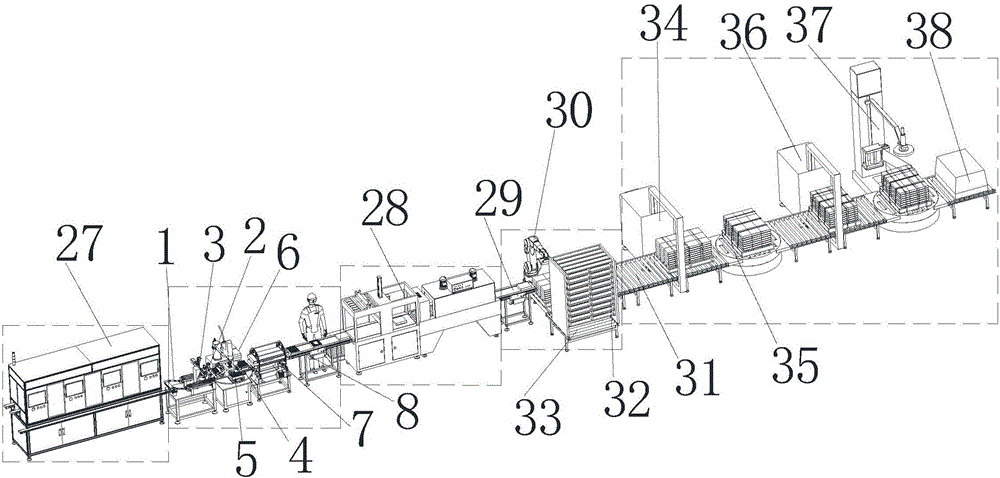

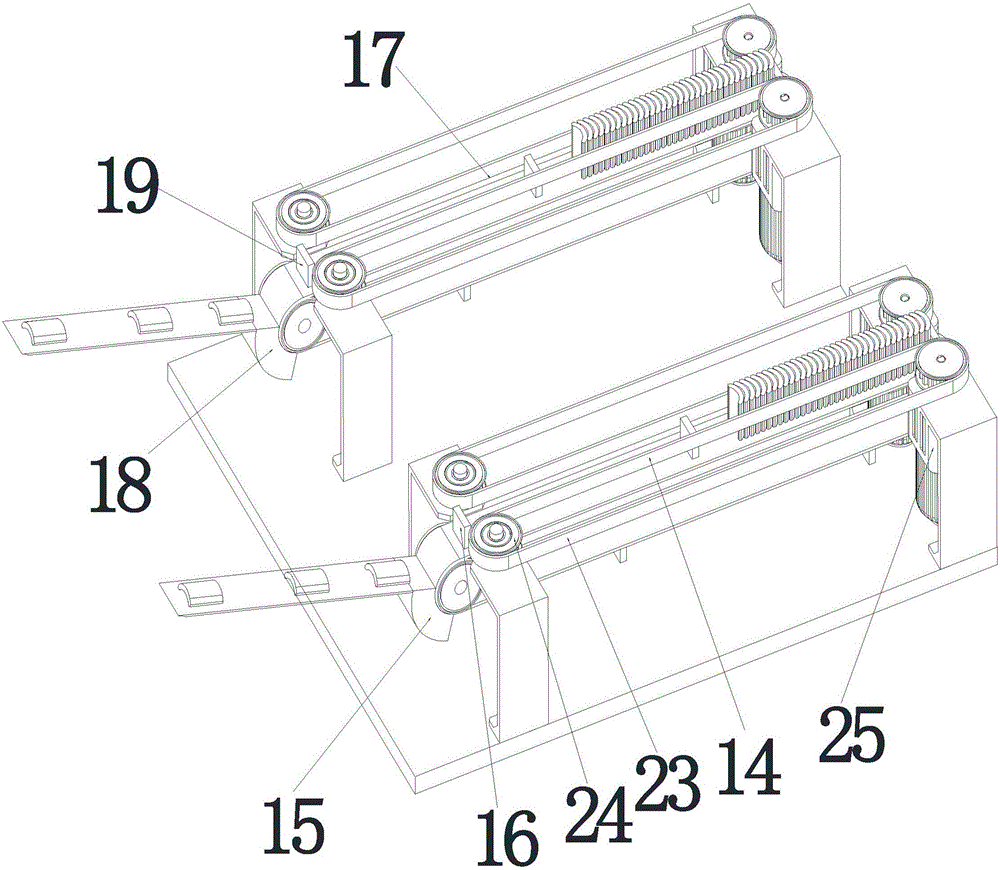

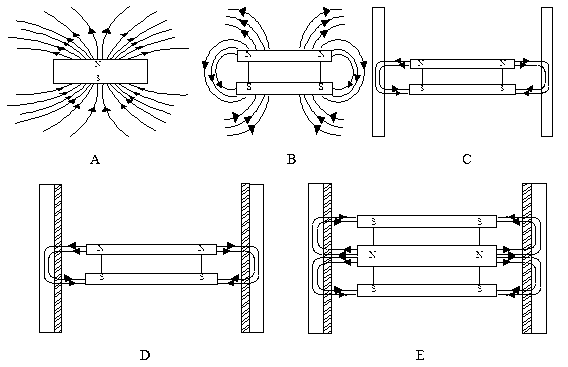

Automatic production line suitable for packaging magnetic shoes and realization method of automatic production line

ActiveCN105947293ASimple structureImprove product qualityWrappers shrinkageBinding material applicationProduction lineManipulator

The invention discloses an automatic production line suitable for packaging magnetic shoes. The automatic production line comprises automatic appearance detecting equipment, a controller, a magnetic shoe distributing device, a magnetic shoe finishing device, a transplanting and encasing manipulator, a magnetic shoe arranging device, a placement robot, a box body turnover device, a magnetic shoe full-box conveyor belt, a thermal shrinkage film sealing machine, a palletizing conveying belt, a palletizing robot and a binding / film winding system. The invention also discloses a realization method of the automatic production line suitable for packaging the magnetic shoes. The automatic production line and the realization method thereof disclosed by the invention have the characteristics of simple structure, good quality of products, high production efficiency, small production area, low production cost, time conservation, labor conservation and the like.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

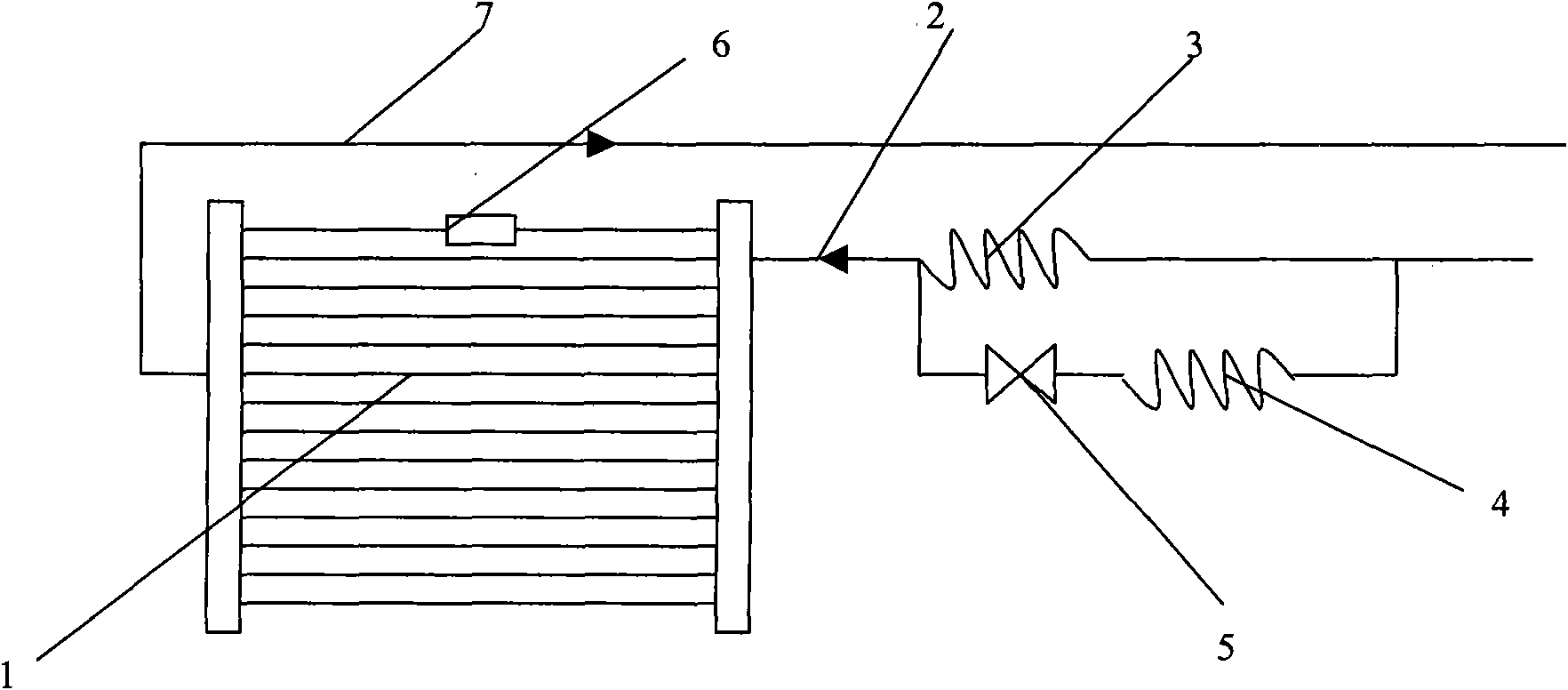

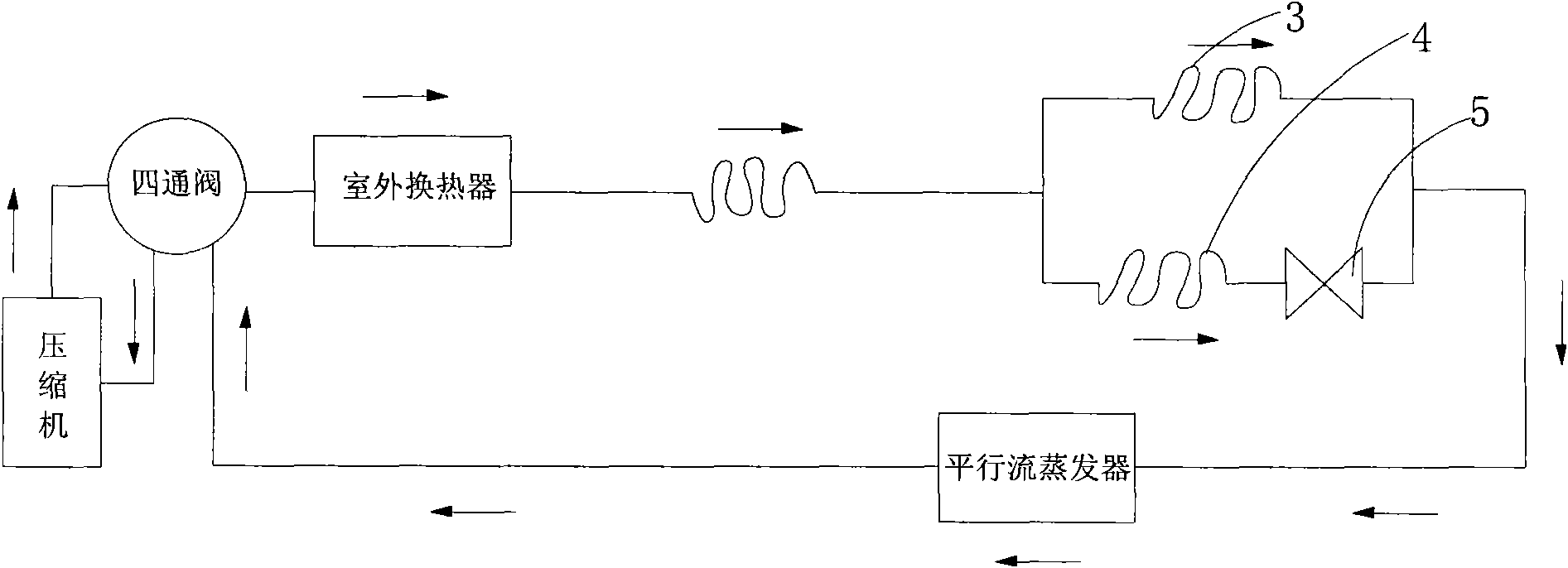

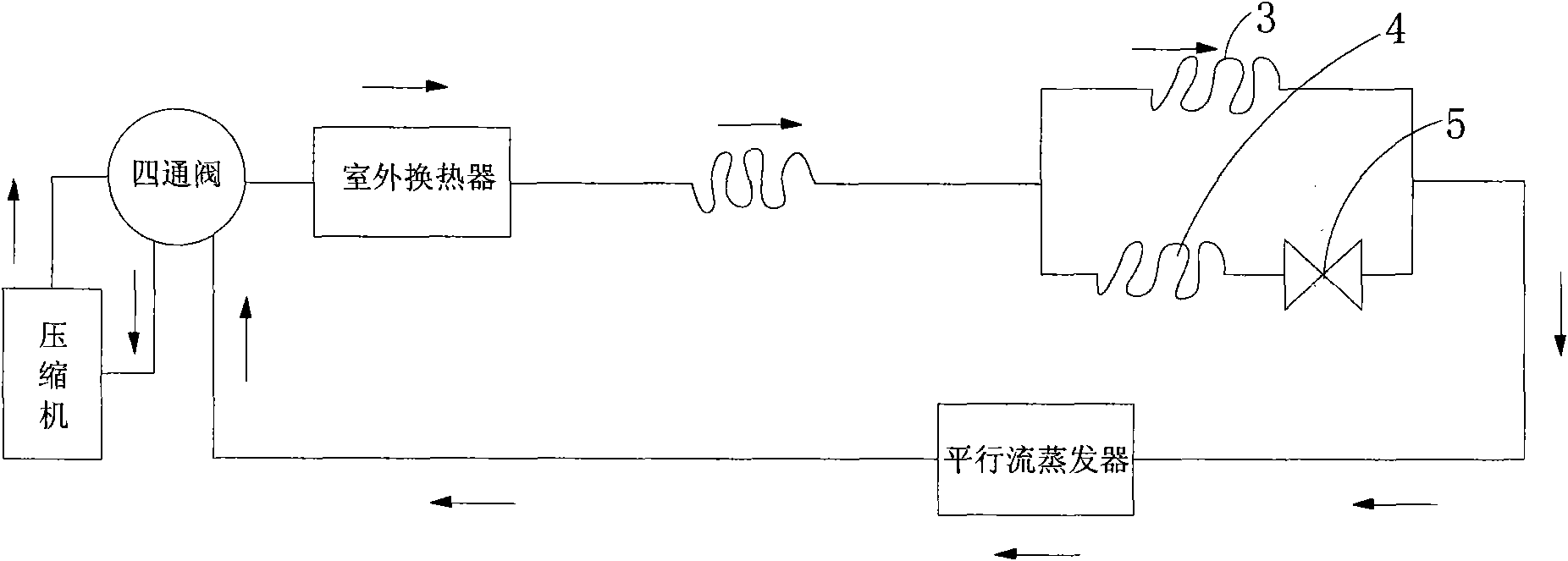

Parallel flow evaporator and anti-freezing method thereof

InactiveCN101644511ASimple and durable structureReduce frequent startupEvaporators/condensersRefrigeration safety arrangementAnti freezingMagnetic valve

The invention discloses a parallel flow evaporator and an anti-freezing method thereof. The method comprises multistage anti-freezing programs. During normal refrigeration of an air conditioner, when the primary surface temperature TA of the indoor parallel flow evaporator is less than or equal to 0 DEG C, the primary anti-freezing program is started, an electromagnetic valve is opened, and the evaporation temperature of the parallel flow evaporator is raised to defrost the evaporator; after the opening time TN of the electromagnetic valve achieves a set time Tn, the surface temperature TA of the indoor parallel flow evaporator is detected again; when the TA is more than or equal to a set temperature Ta of the indoor parallel flow evaporator, the primary anti-freezing program is finished, and the electromagnetic valve is closed; and when the TA is less than 0 DEG C, a secondary anti-freezing program is started, and a compressor of the air conditioner is closed. The parallel flow evaporator has a simple and durable structure; and the anti-freezing method can implement anti-freezing of the parallel flow evaporator more intelligently and friendlily, reduce frequent starting of the compressor in a refrigeration loop, and ensure the refrigeration effect of the air conditioner.

Owner:TCL CORPORATION

Marine folding tower

InactiveUS20090320738A1Less manual effortPromotes downward movementVessel partsFloating buildingsGas springEngineering

A system that will result in less physical effort in the lowering or raising of a marine folding tower, spotting station, driving station, fishing tower, or tuna tower. The system will be installed on a fishing boat, pleasure boat, or other marine vessel. The system comprises at least one gas spring, or hydraulic or electric ram or shock absorber of any size or style that attaches to both the upper frame assembly and lower frame assembly of the tower or other station.

Owner:BLUMBERG RYAN

Powered latch assembly

ActiveUS20050173932A1High strengthSimple structureDoors for stoves/rangesDomestic stoves or rangesCoupling

A power latch assembly which includes a supporting frame adapted for mounting on a main housing, wherein the supporting frame has a locking slot and defines first and second slider ends thereof; a motor assembly including a power motor supported by the supporting base and adapted for being powered by the main housing, and a driving arm driven by the power motor in a linear movable manner; and a locking latch, defining a first guiding edge and a second guiding edge, having an inner coupling end coupling with the driving arm and an opposed latching end extended outwardly through the locking slot, wherein the driving arm drives the locking latch between a locking position and an unlocked position.

Owner:HTI TECH & IND LLC

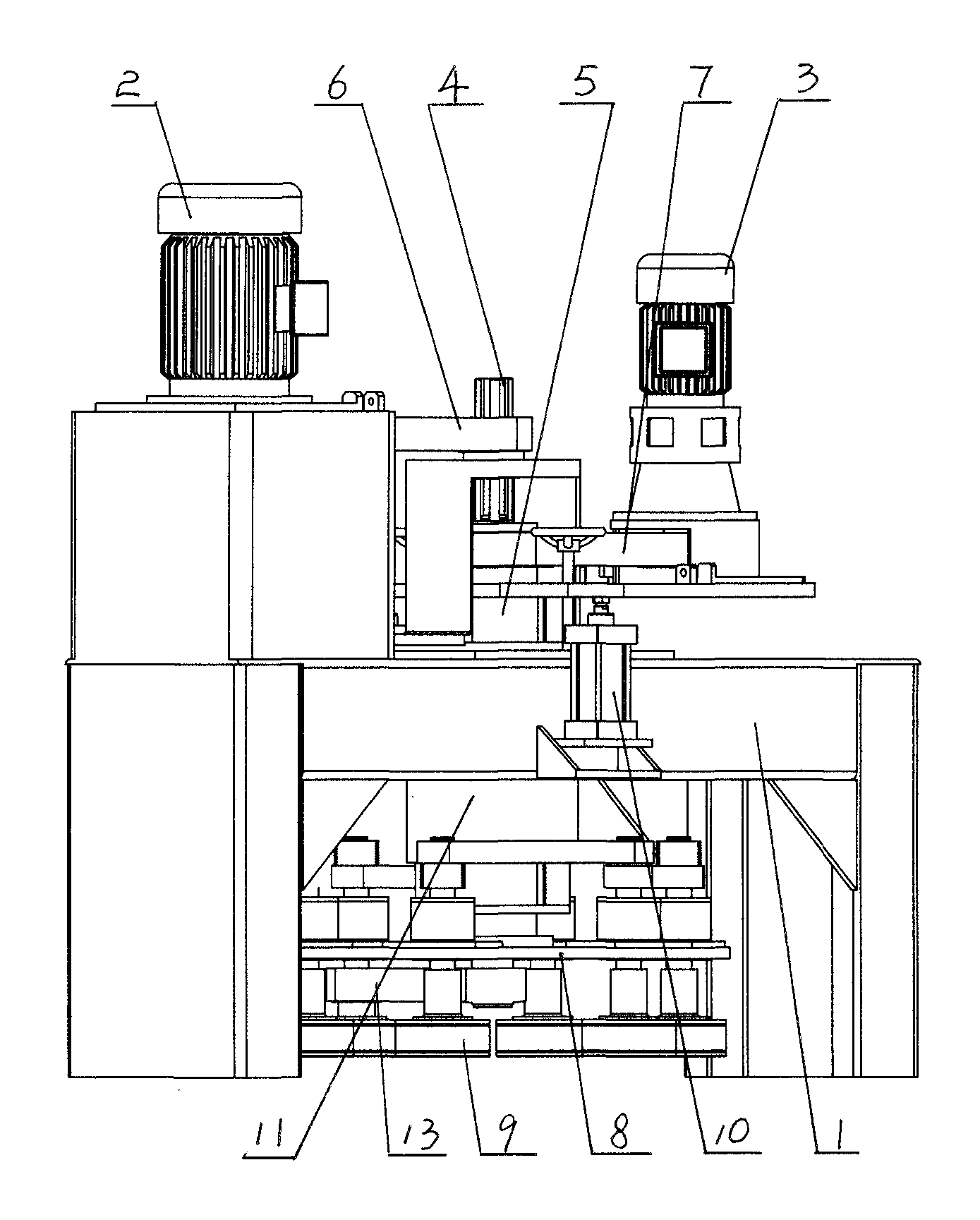

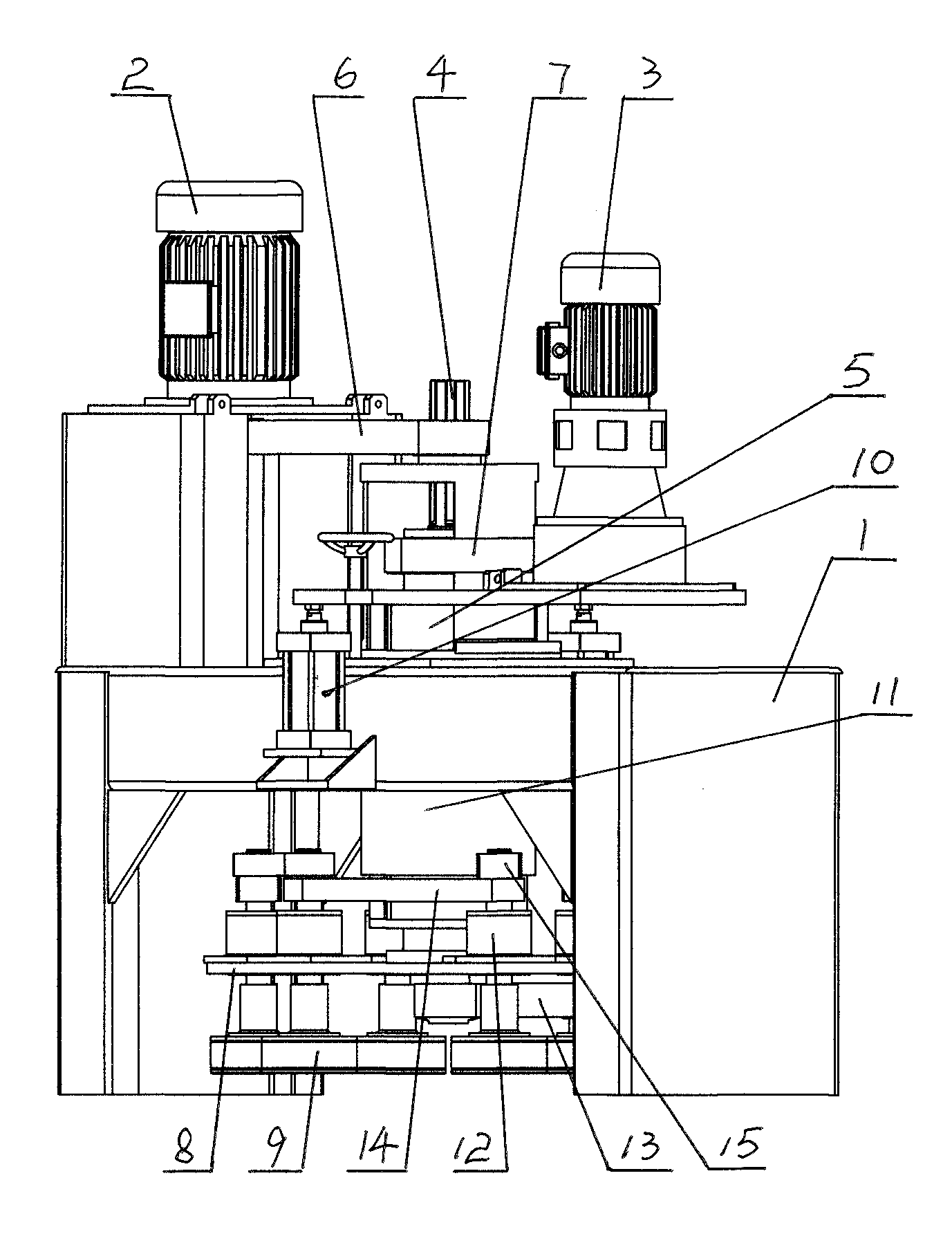

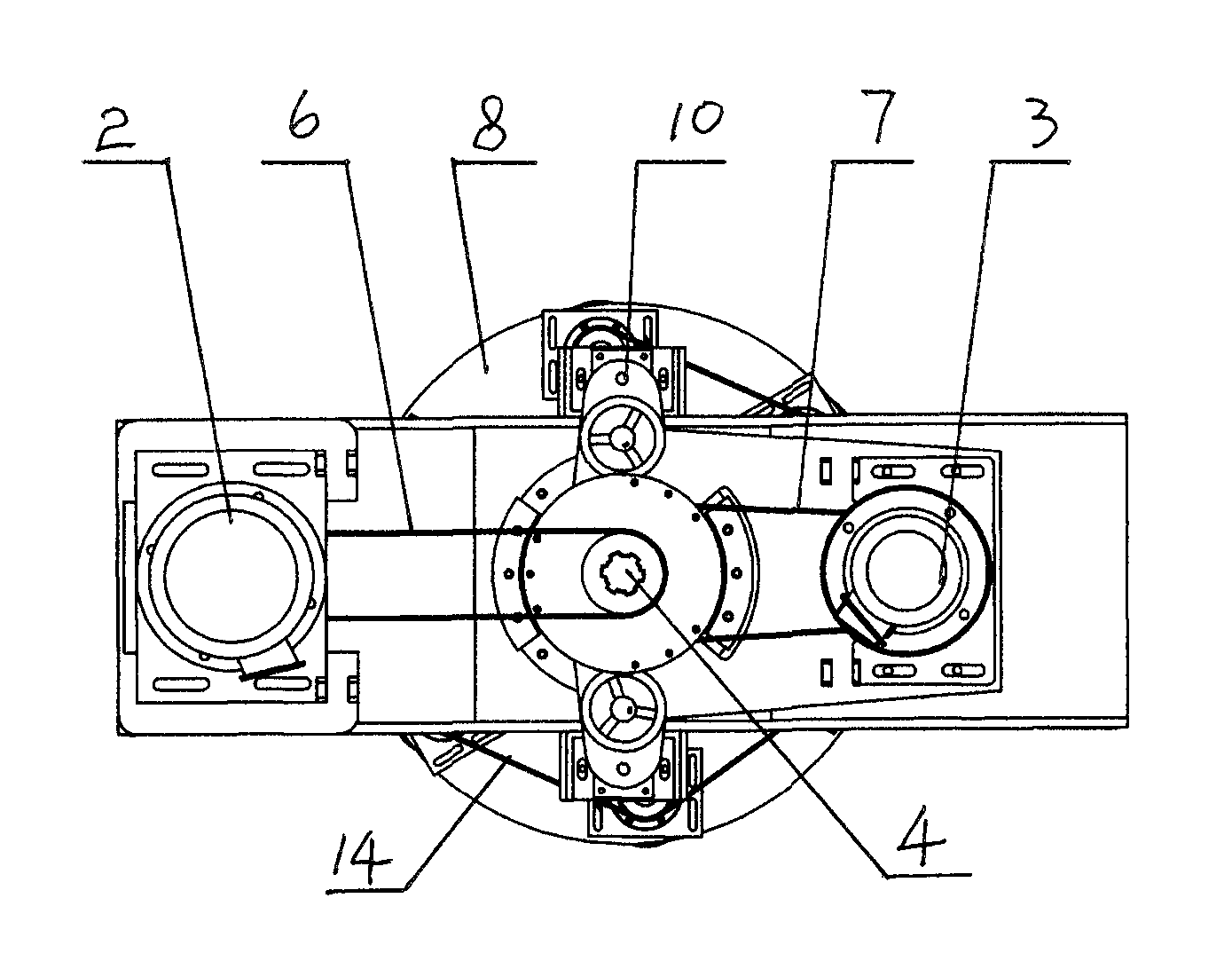

Antifouling polishing device for ceramic equipment

InactiveCN103252701AReduce in quantityCause secondary pollutionPolishing machinesCeramic shaping apparatusElectric machineryEngineering

The invention relates to an antifouling polishing device for ceramic equipment. The antifouling polishing device for the ceramic equipment comprises a rack, motors, rotary shafts, a rotary table and a plurality of grinding heads, wherein the motors are arranged on the rack, the rotary shafts are driven by the motors, the rotary table is arranged on the lower portion of the rack and is driven by the rotary shafts, and the grinding heads are arranged below the rotary table. The antifouling polishing device for the ceramic equipment is characterized in that the motors are divided into a main motor and an auxiliary motor, the rotary shafts are divided into a main shaft and an auxiliary shaft, the auxiliary shaft is sleeved outside the main shaft to form a concentric shaft structure with the two shafts rotating independently and respectively, the upper portion of the main shaft is driven by the main motor through a first belt and a first belt wheel, the auxiliary shaft is driven by the auxiliary motor through a second belt and a second belt wheel, the lower portion of the auxiliary shaft is in fixed connection and linkage with the rotary table through a shaft sleeve, the lower portion of the main shaft penetrates through the rotary table, and the lower end portion of the main shaft drives the grinding heads below the rotary table through a third belt and a third belt wheel. Through the mentioned design, energy consumption is low, an antifouling processing effect is good, producing and working efficiency is high, maintenance is convenient and fast, using cost is low, and the antifouling polishing device for the ceramic equipment can be widely applied to different kinds of ceramic machining equipment.

Owner:李汉超

Ion-beam source

ActiveUS7863582B2Generated reliablyImprove productivity and efficiencyMaterial analysis by optical meansIon beam tubesElectricityElectrical conductor

An ion-beam source comprising: a plasma-generation unit for generating plasma and an ion-extraction unit for extraction and acceleration of ions from the aforementioned plasma, where the ion-extraction unit is made in the form of at least one grid under a negative potential. The plasma generating unit consists of a working chamber having a deeply immersed antenna cell. The cell contains a ferromagnetic core, a heat conductor with a heat sink, at least one inductive coil wound onto the ferromagnetic core, and a cap made from a dielectric material that sealingly covers the ferromagnetic core and the inductive coil.

Owner:GODYAK VALERY

Filtration and cleaning system for sprinkler irrigation drop nozzles

ActiveUS20070241214A1Simple and durable structureEfficient and reliable in operationClimate change adaptationWatering devicesReciprocating motionFiltration

A filter for use with overhead sprinkler irrigation systems is disclosed. The filter includes a hollow cylindrical body, a removable screen, and a manually-actuated plunger adjacent the screen. The plunger is positioned for reciprocal movement through a debris outlet between an open, debris-discharging position, and a closed filtering position. The plunger defaults to the closed filtering position by pressurized water flowing through the body. The water is simultaneously filtered through the screen and passes out a clean water outlet while debris accumulates within the body. The plunger may be manually retracted to the open, debris-discharging position at any time, whereby accumulated debris is flushed out of the body through the debris outlet by residual water flowing therethrough.

Owner:AMERICAN AGRI PRODS

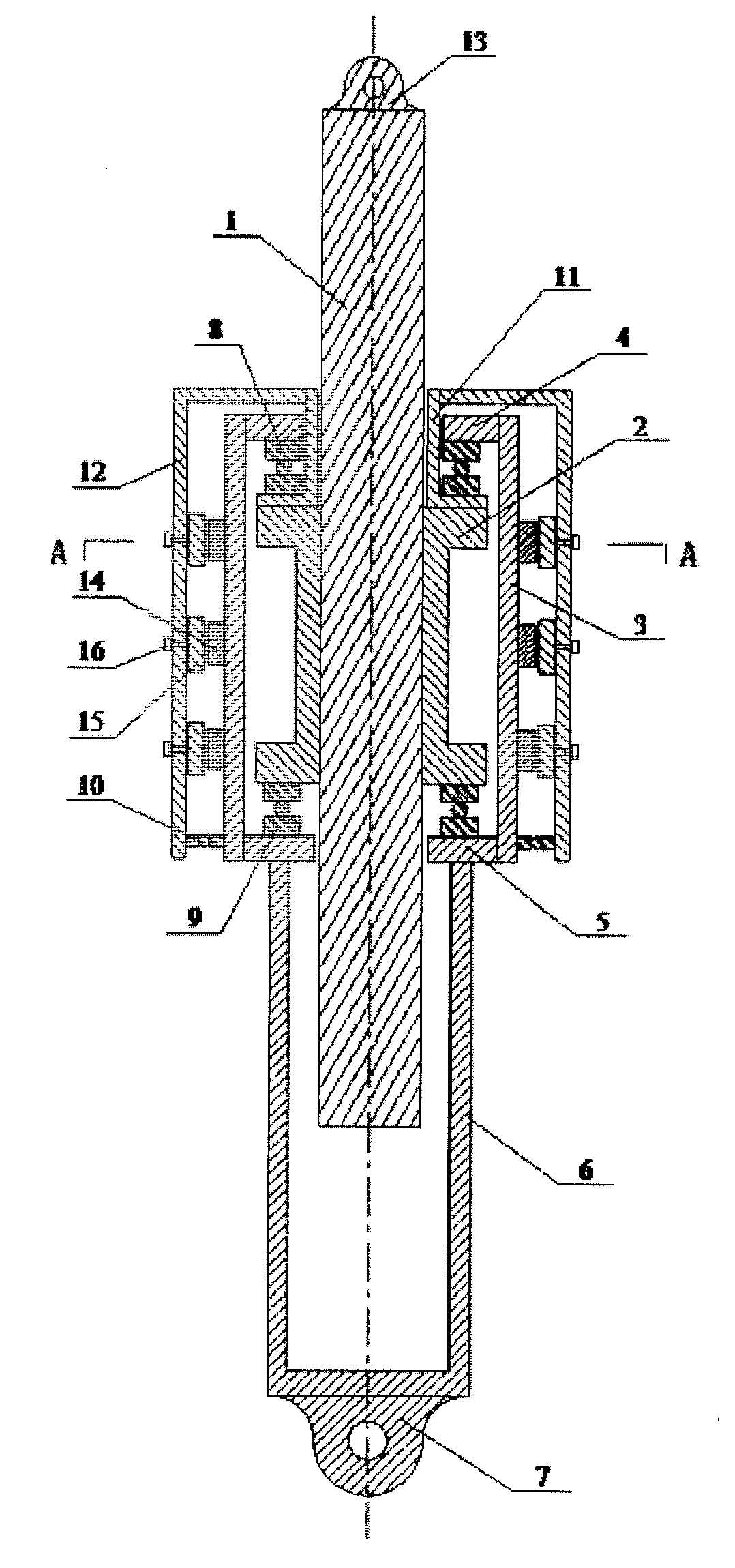

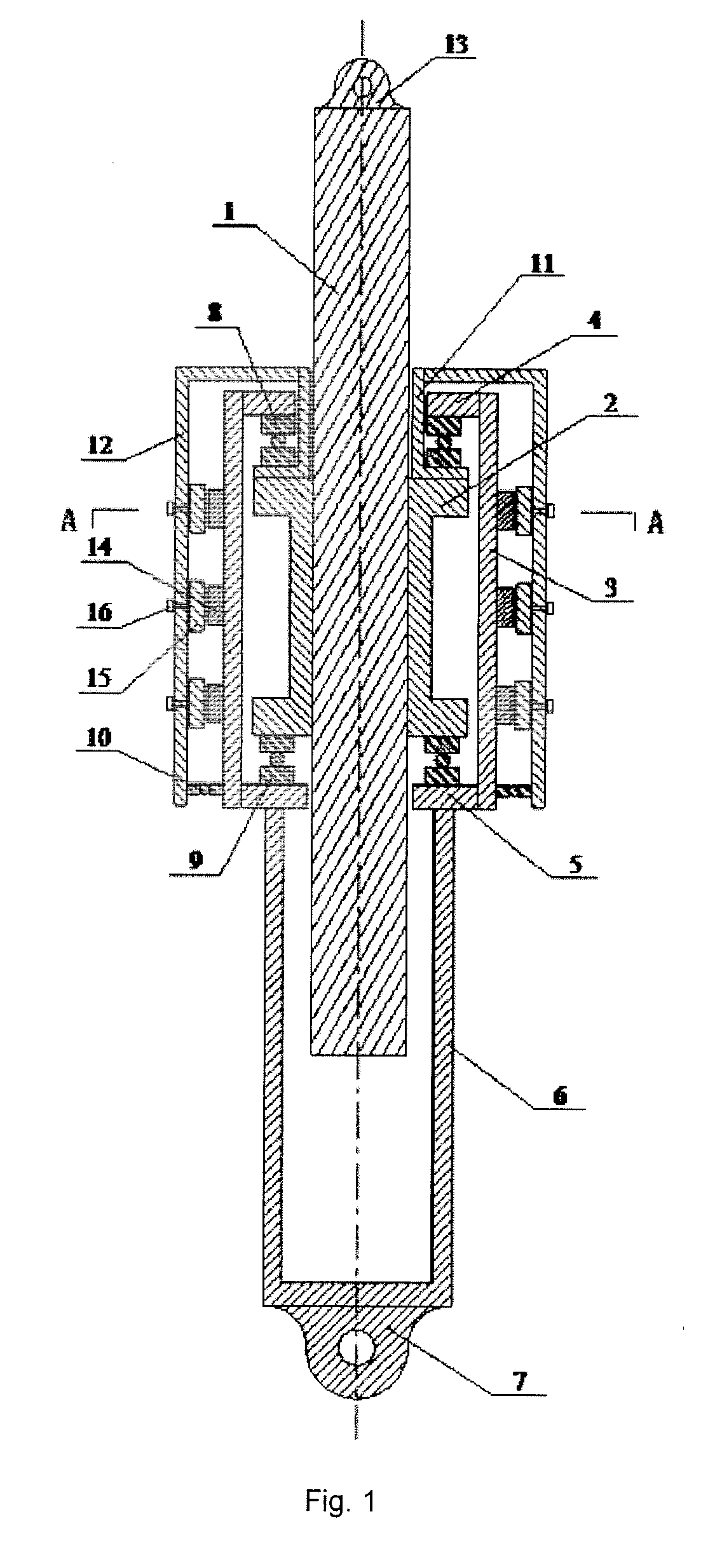

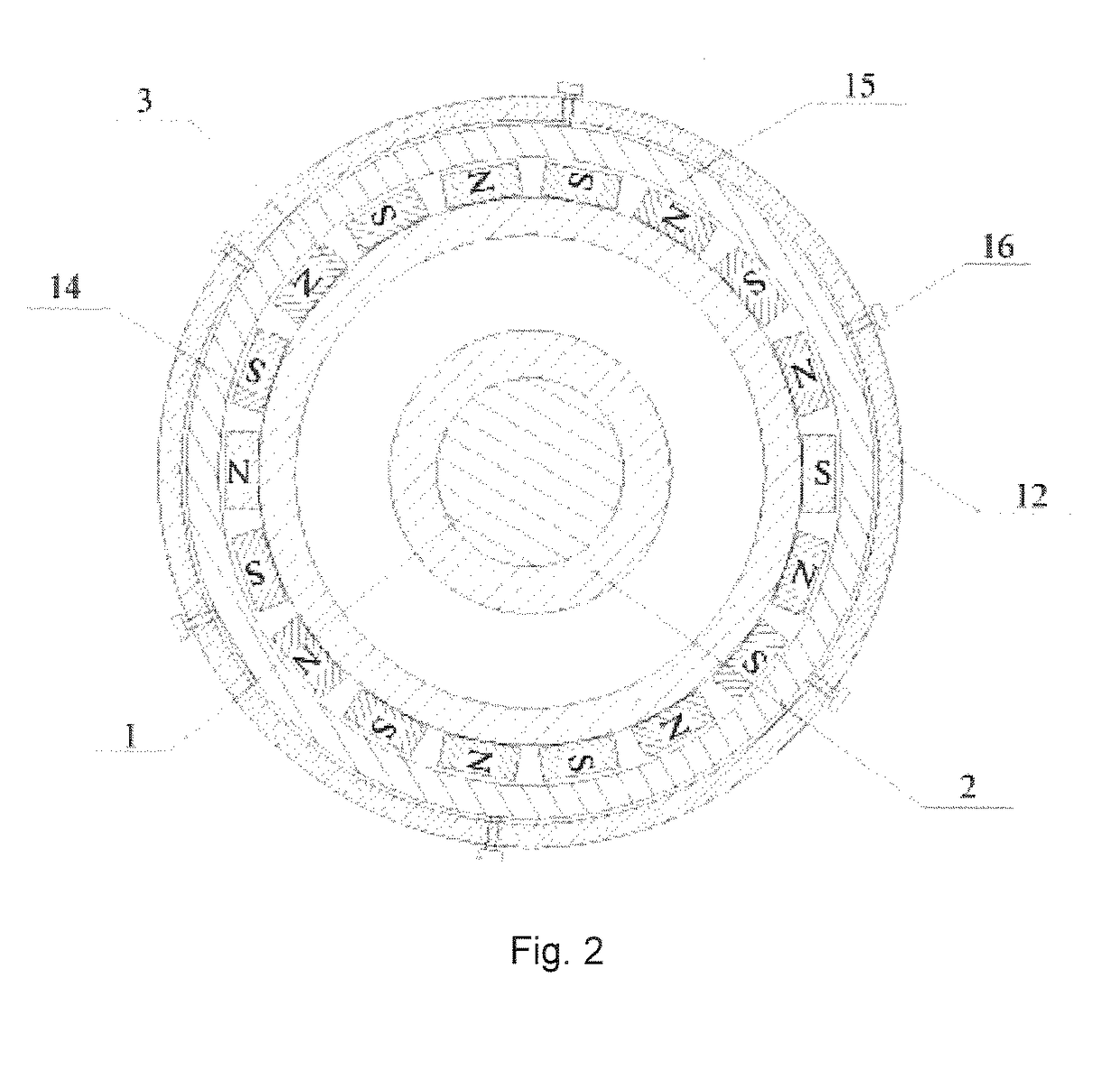

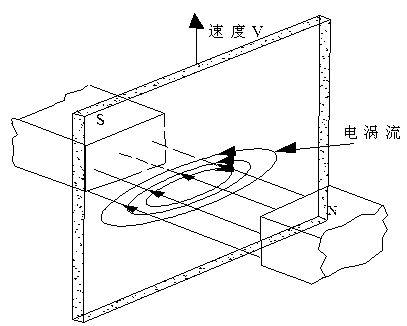

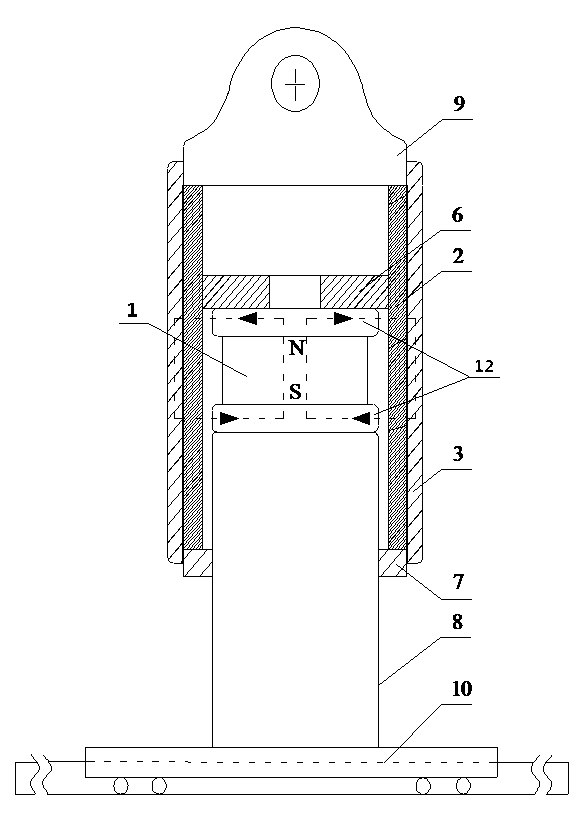

Outer cup rotary axial eddy current damper

ActiveUS20170294828A1Easy to controlNegative stiffness effectVibration dampersGearingDamping factorEngineering

A large-size axial eddy current damper manufactured by use of screw drive comprises a drive assembly and an eddy current damping generator; the drive assembly comprises a screw drive pair, and a stator and a rotor respectively made of magnetic conductive materials; the screw drive pair comprises a screw rod and a nut sleeved on the screw rod; the screw rod sequentially penetrates through central holes of upper and lower flanges of the stator; the nut is within the stator; the rotor comprises an outer rotor and an inner rotor having the bottom provided with a lower connecting flange; one or more eddy current damping generators are arranged between the stator and the outer rotor. Problems of having difficulty in manufacturing axial dampers with a large damping coefficient and simulating anti-vibration dampers with a speed index of less than 1, by use of eddy current damping, can be solved simultaneously.

Owner:HUNAN XIAOZHEN ENG TECH CO LTD

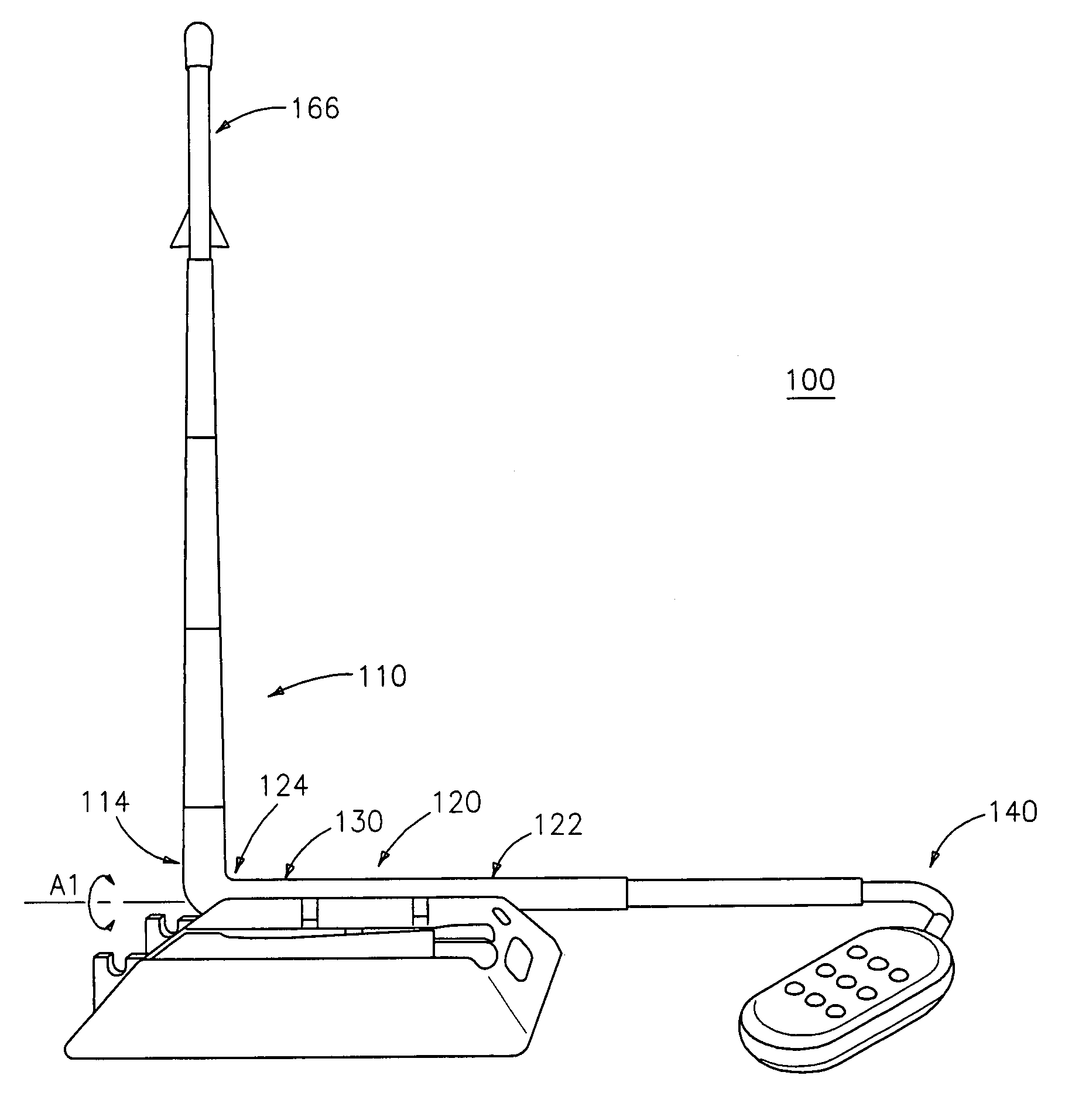

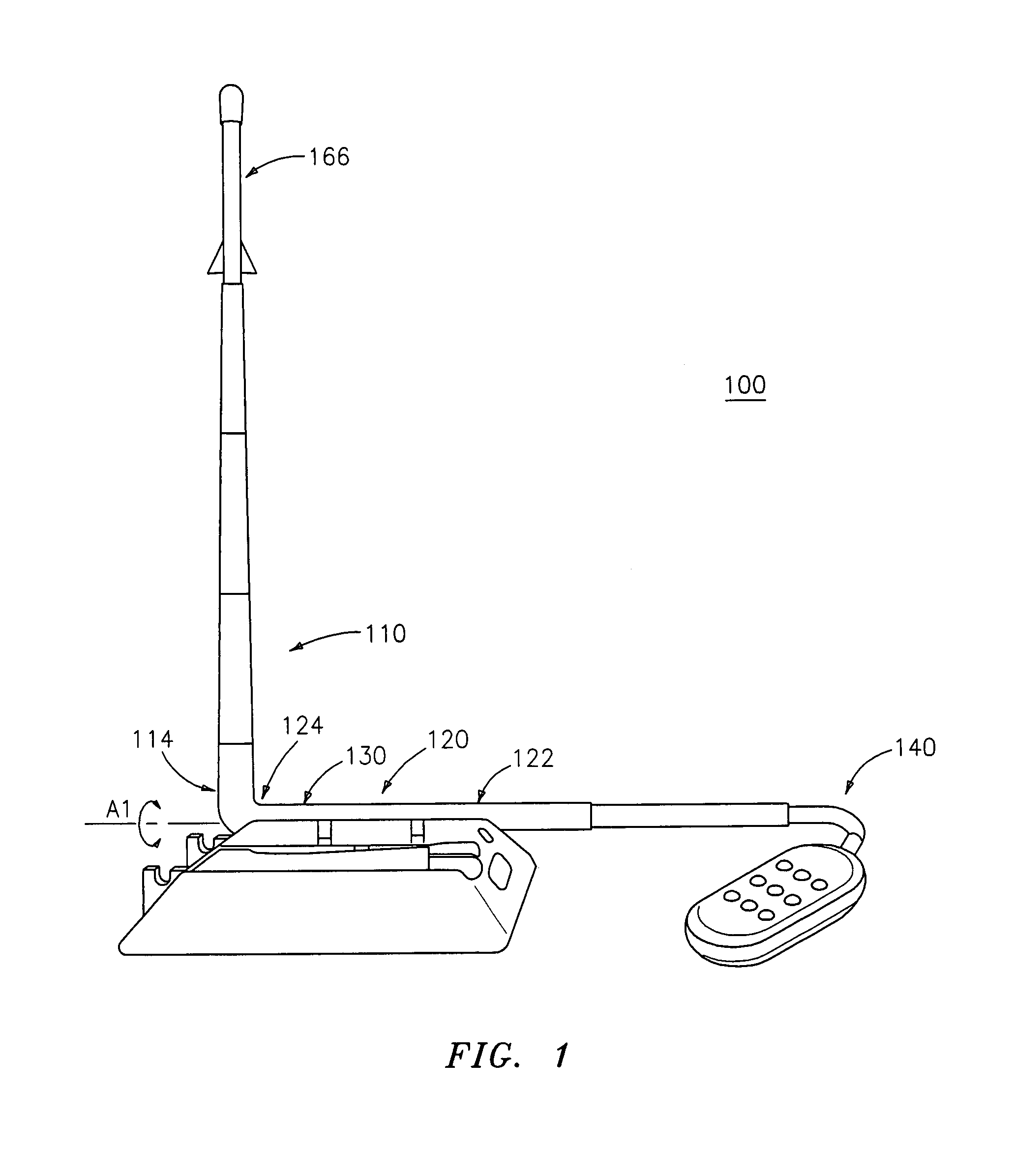

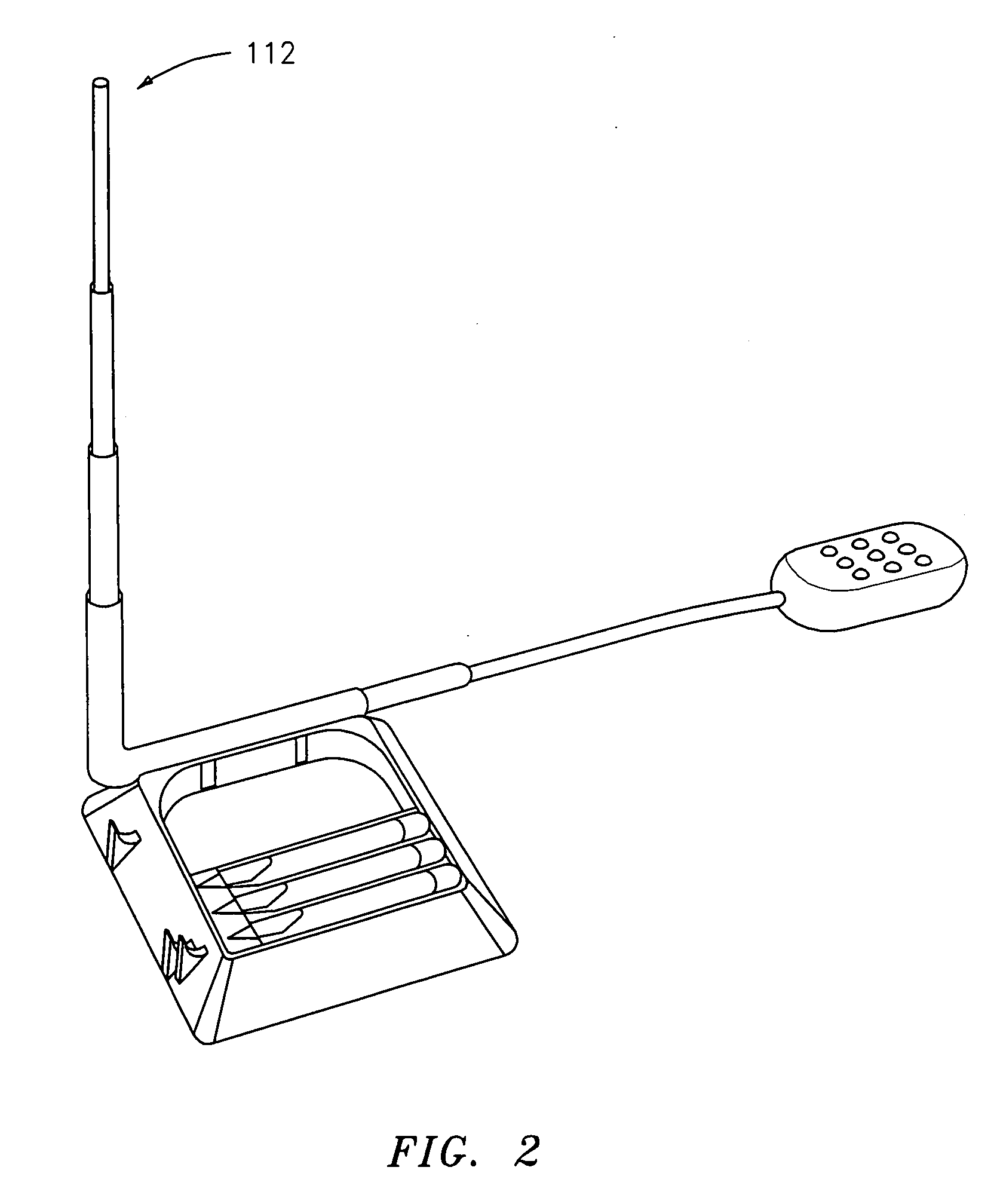

Toy rocket launch pad with directional safety valve

ActiveUS6926579B2Efficient and cost-effectiveSimple and durable structureRocket launchersCompressed gas gunsRocket launchPerpendicular direction

Disclosed herein is an apparatus and method for launching a toy rocket that includes rotating a launch tube about an axis that is parallel with a connecting tube, which is rotatably connected to the launch tube; extending the launch tube in a perpendicular direction; progressively closing a safety valve by rotating the launch tube toward a vertical position, relative to a launch pad assembly; loading the toy rocket onto a distal end of the extended launch tube; and rapidly compressing a bellows in communication with the launch tube.

Owner:RAPPAPORT MARK

Double-layer circular-tube type axial-force eddy current damper

The invention discloses a double-layer circular-tube type axial-force eddy current damper, which consists of an eddy current damping system, a guiding system and a connecting system, wherein the eddy current damping system is composed of a circular magnet and a double-layer circular tube, the double-layer circular tube comprises an outer circular tube made of strong magnetic-conducting material and an inner circular tube made of strong electricity-conducting magnetic-isolating material through nesting; the guiding system consists of a guiding ring, an inner guiding shaft and a hollow round support column, has inner-layer and outer-layer guiding functions, and also can have one guiding function according to the condition; and the connecting system is composed of a connecting block at the upper end of the double-layer circular tube and a support base at the lower end of the circular magnet. With the adoption of the specific double-layer circular tube design, the damper is only provided with one group of circular magnets on the inner side of an electric conductor tube, all magnetic-force lines can vertically cut the circular tube in the electric conductor and cannot be distributed outside the double-layer circular tube, and achieves the purposes of improving the eddy current efficiency and shielding the magnetic field outwards.

Owner:湖南省潇振工程科技有限公司 +1

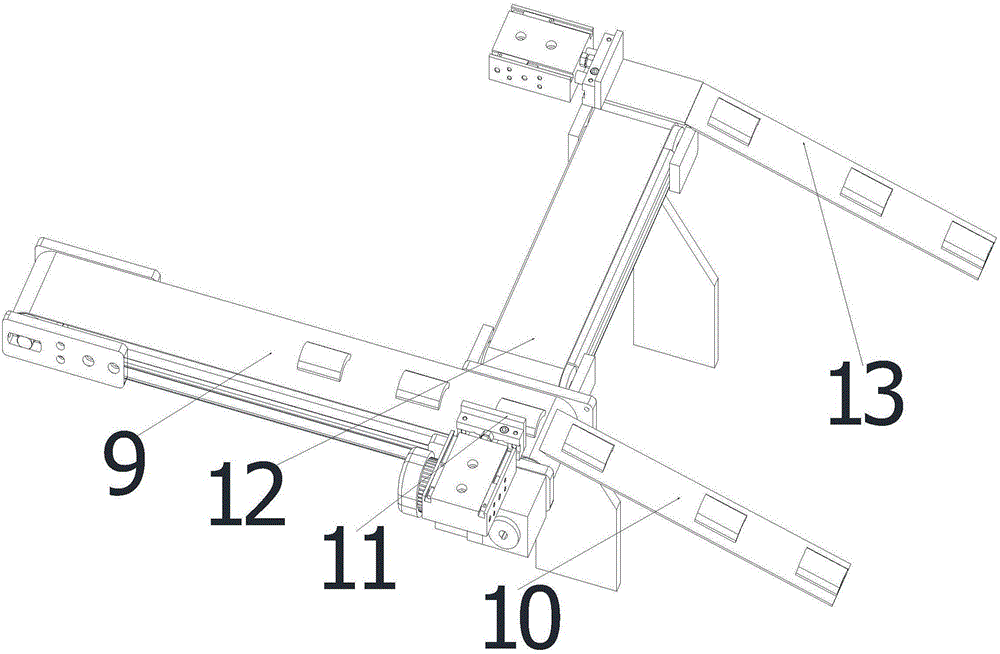

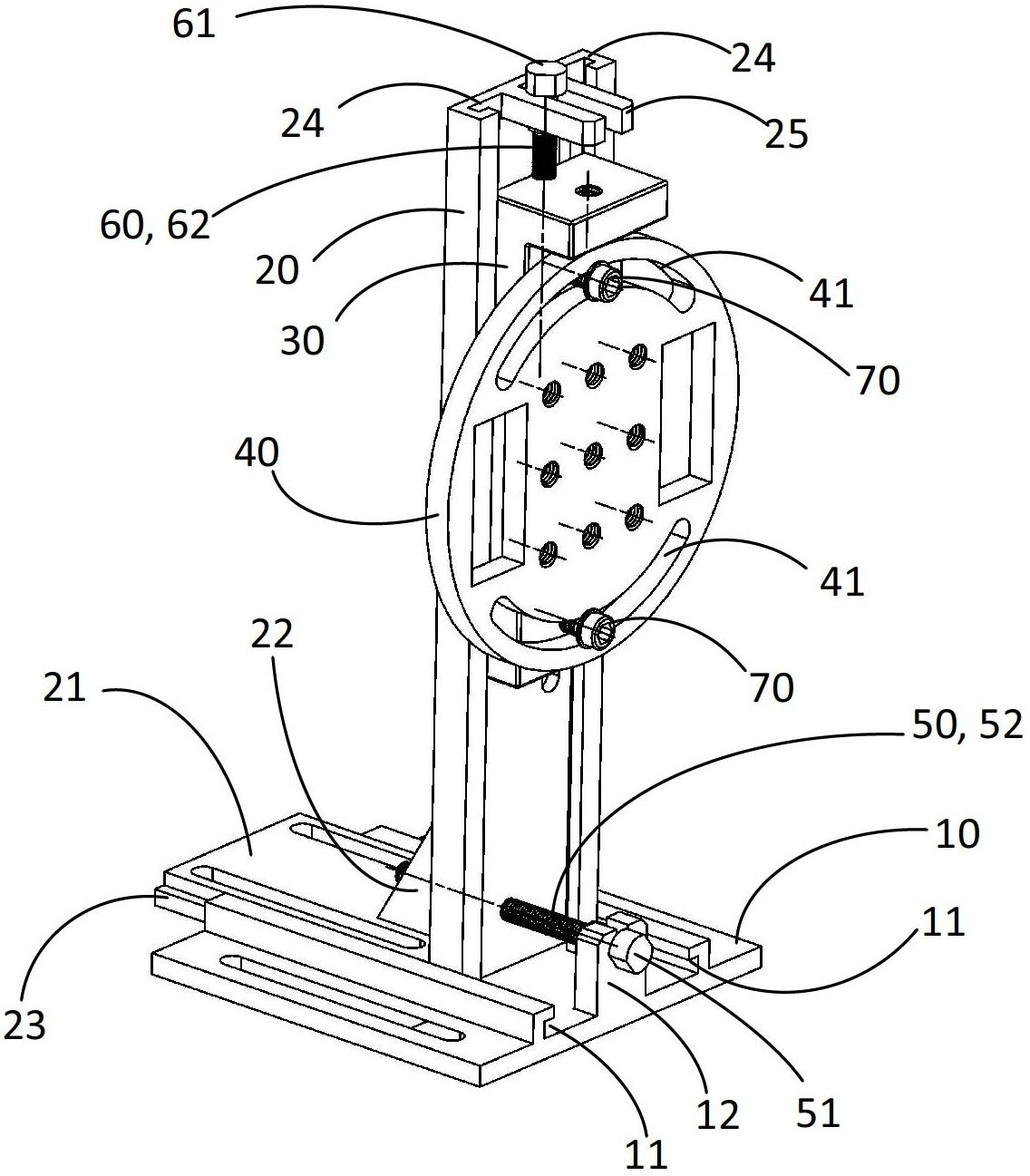

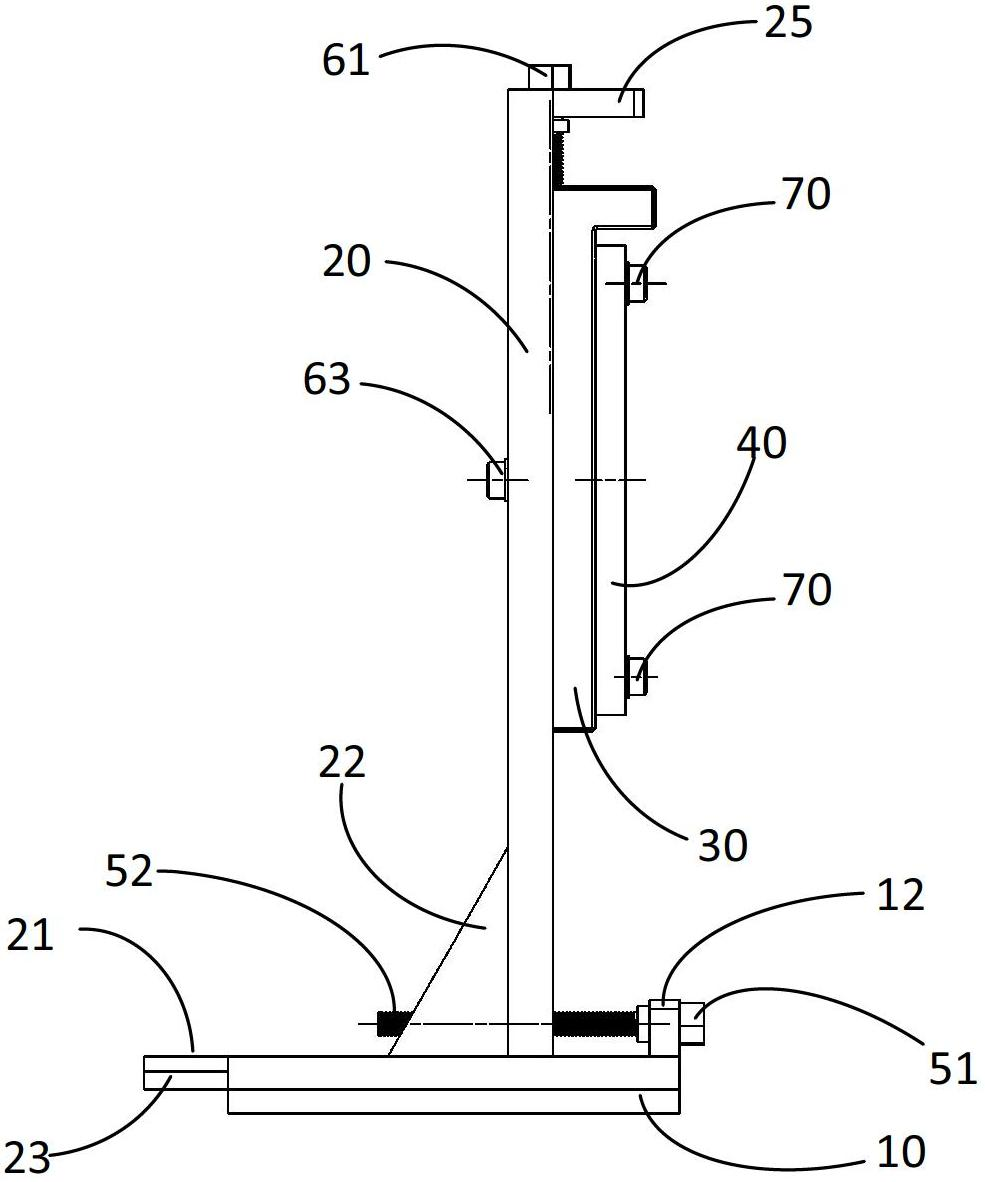

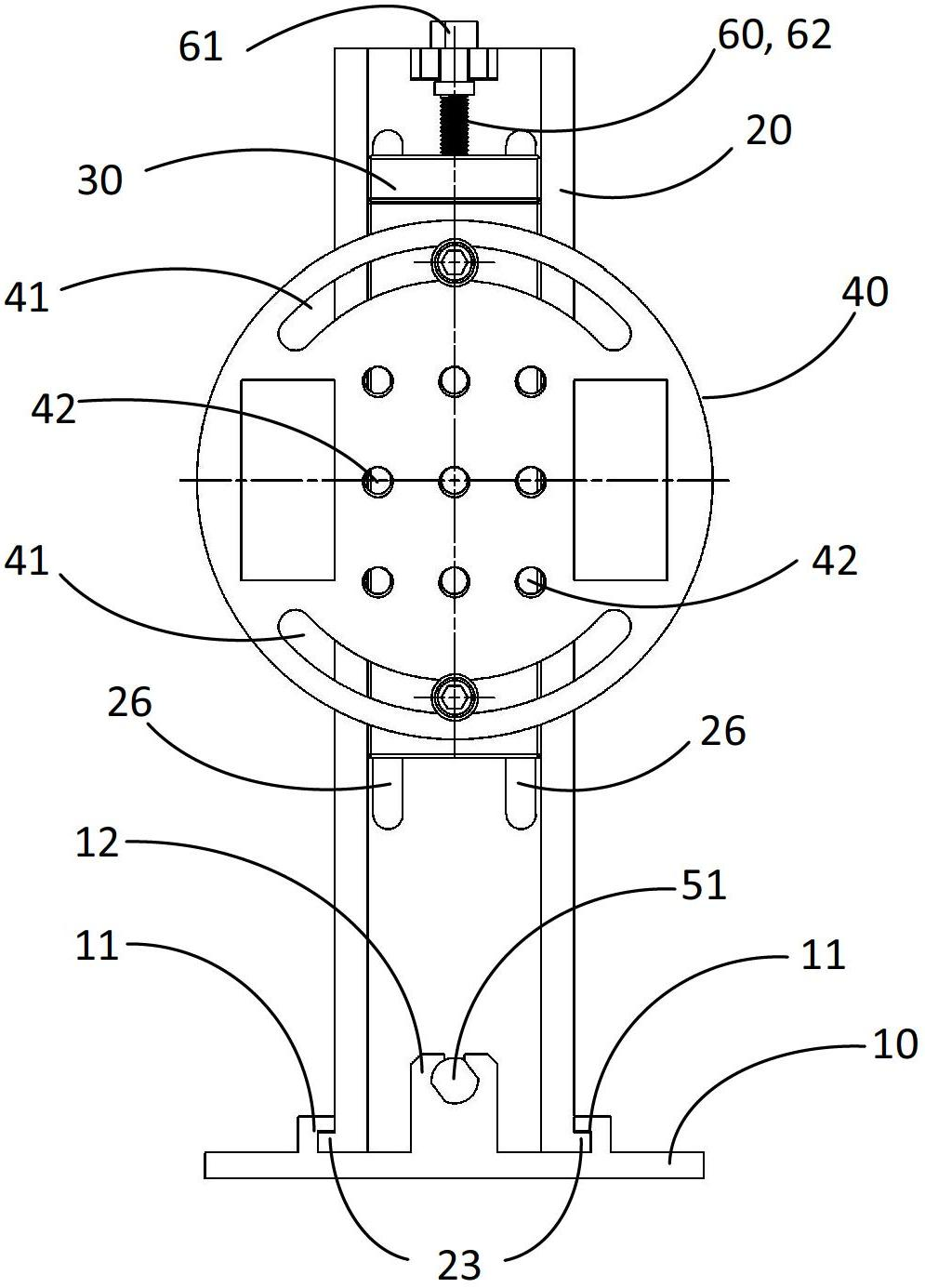

Multi-dimensional adjustable test mounting rack

ActiveCN102692325AFlexible installationLow costVehicle testingMachine part testingVertical planeTest sample

The invention discloses a multi-dimensional adjustable test mounting rack, which is used for mounting a test sample of an automobile part. The multi-dimensional adjustable testing mounting rack includes a base extending along the horizontal direction, a vertical plate extending along the vertical direction, a vertical sliding block and a test sample mounting disc, wherein the vertical plate is arranged on the base and can slide horizontally along the base; the vertical sliding block is arranged on the vertical plate and can slide vertically along the vertical plate; and further, the test sample mounting disc is used for mounting the test sample of the part, is arranged on the vertical sliding block and can rotate in the vertical plane relative to the vertical sliding block. Through the ingenious design, the multi-dimensional adjustable test mounting rack realizes adjustment in horizontal, vertical and rotational movements through the least components, has simple structure and low cost, is highly durable, and is easy to manufacture. And moreover, the multi-dimensional adjustable test mounting rack disclosed by the invention is flexible to mount and convenient to operate, and can be suitable for test installation of various automobile components.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

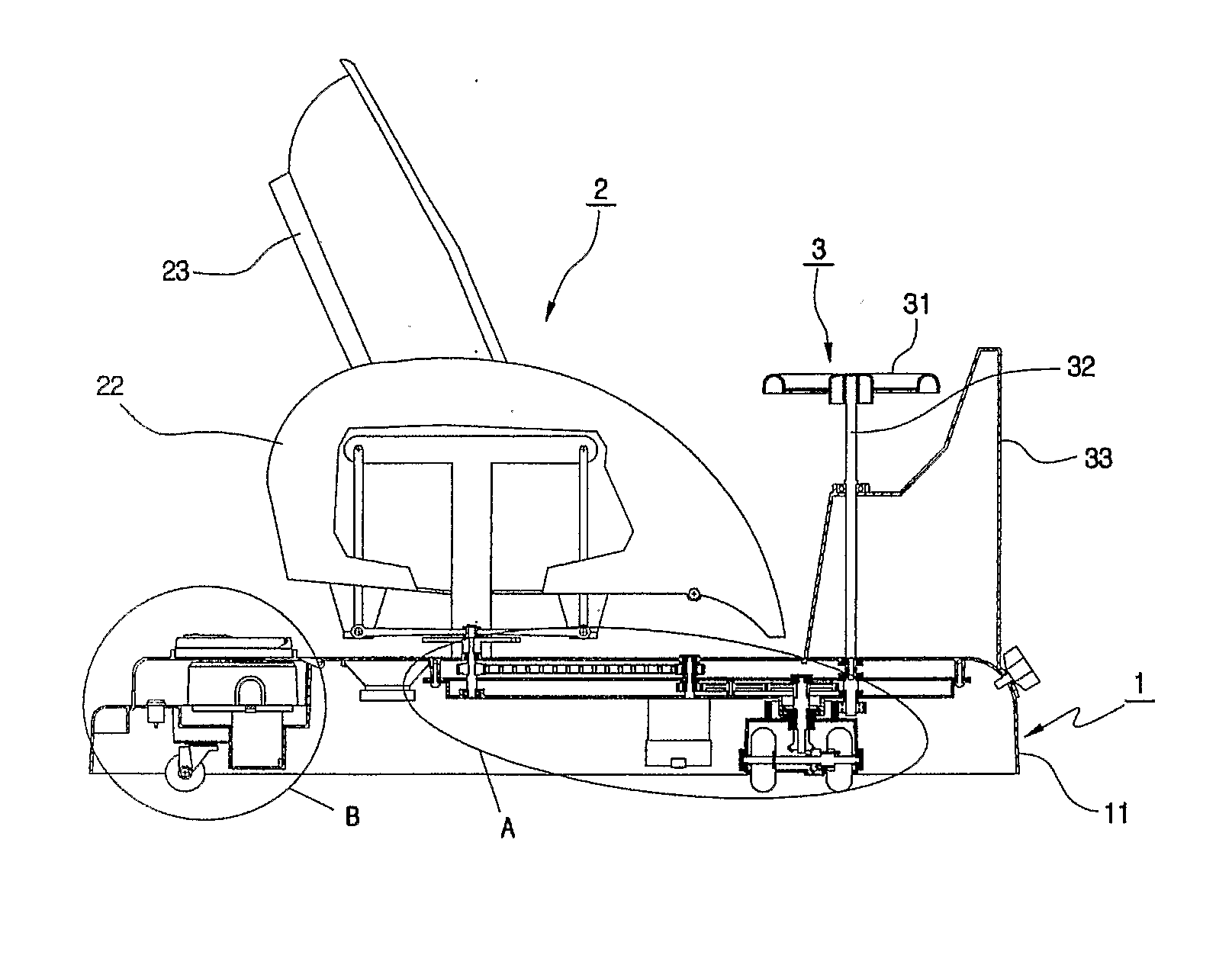

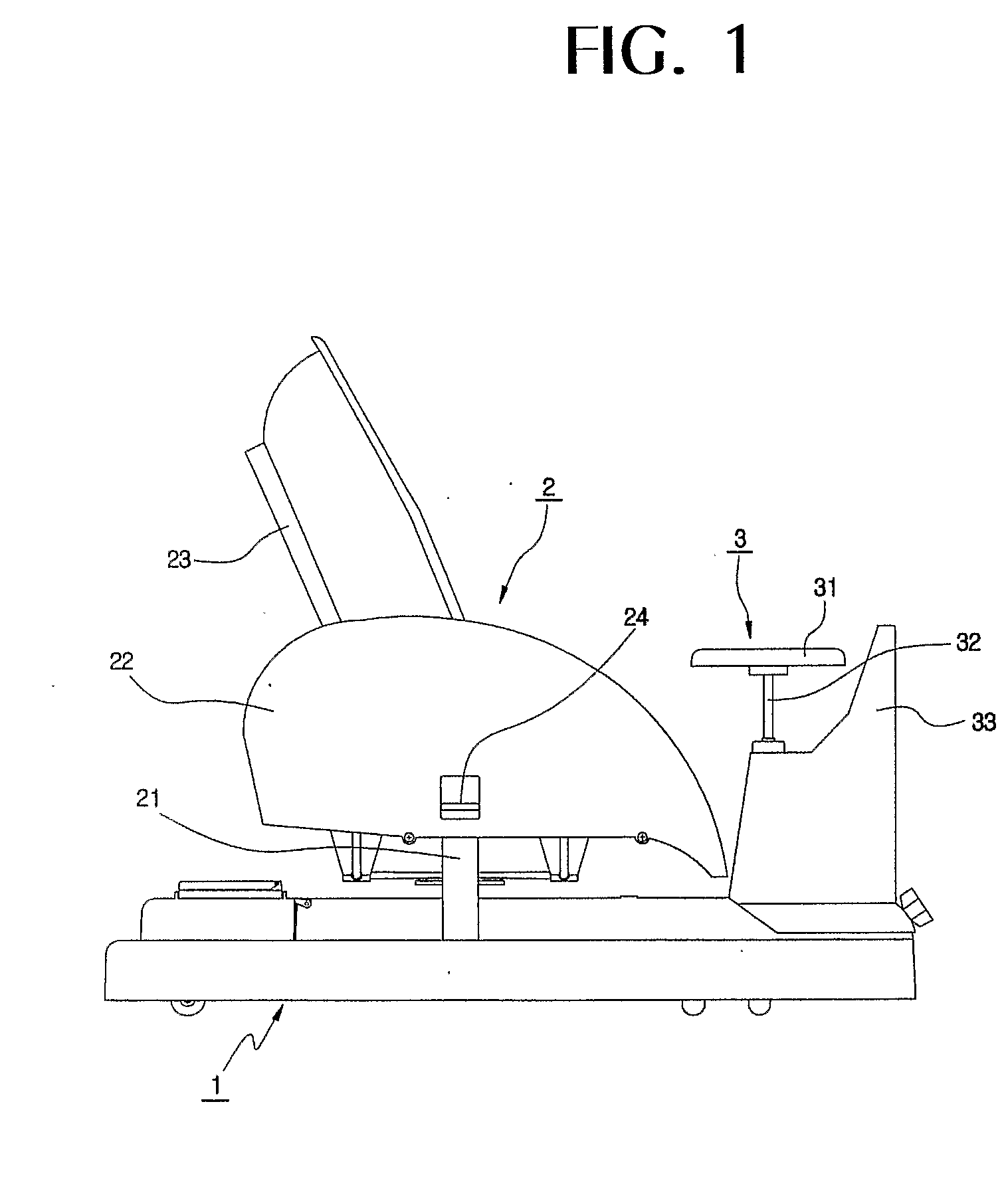

Multifunctional electric-powered infant car with cradle function

InactiveUS20070175678A1Reduce the burden onAvoid polluting the environmentCarriage/perambulator accessoriesCradleDrive wheelDrive motor

Owner:BAE MYUNG SOON

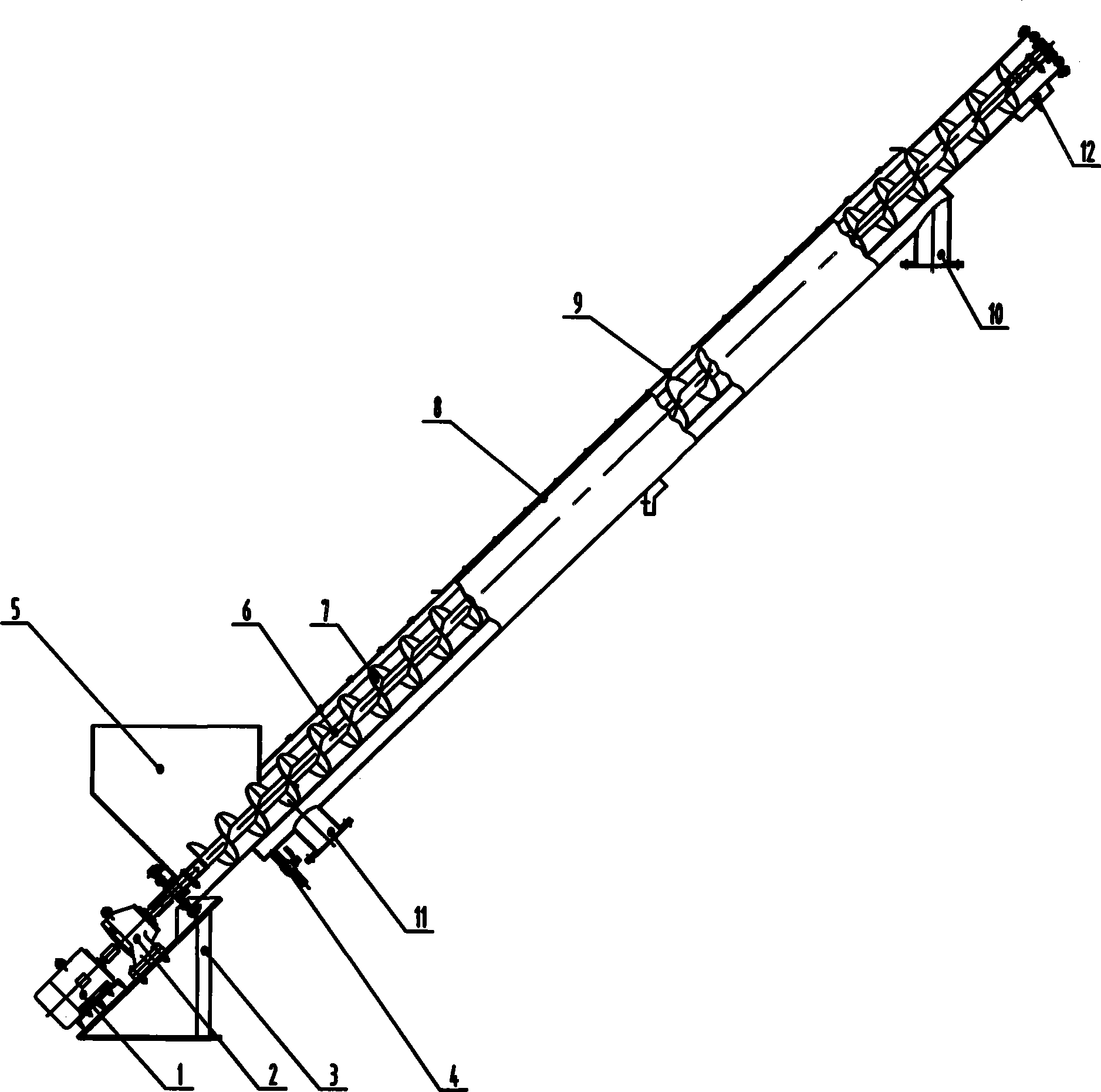

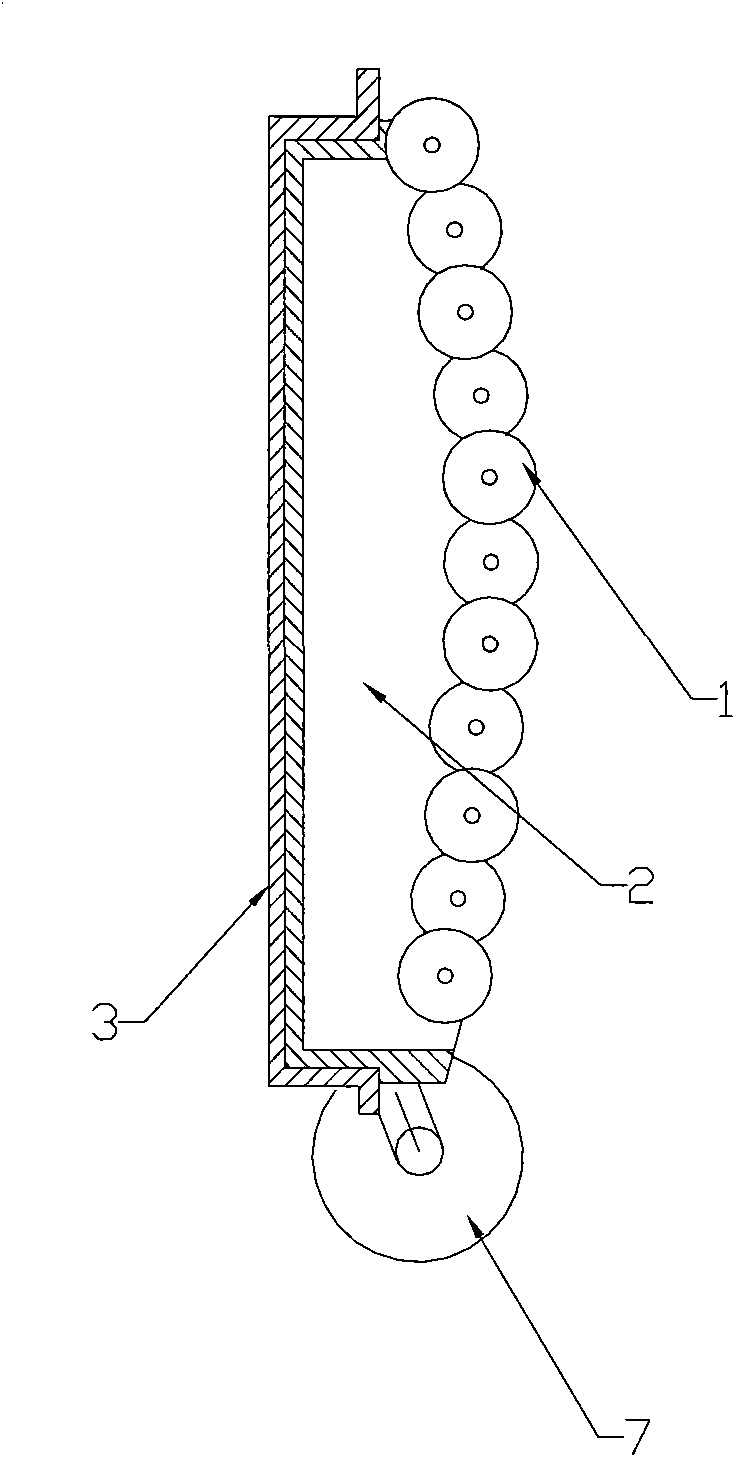

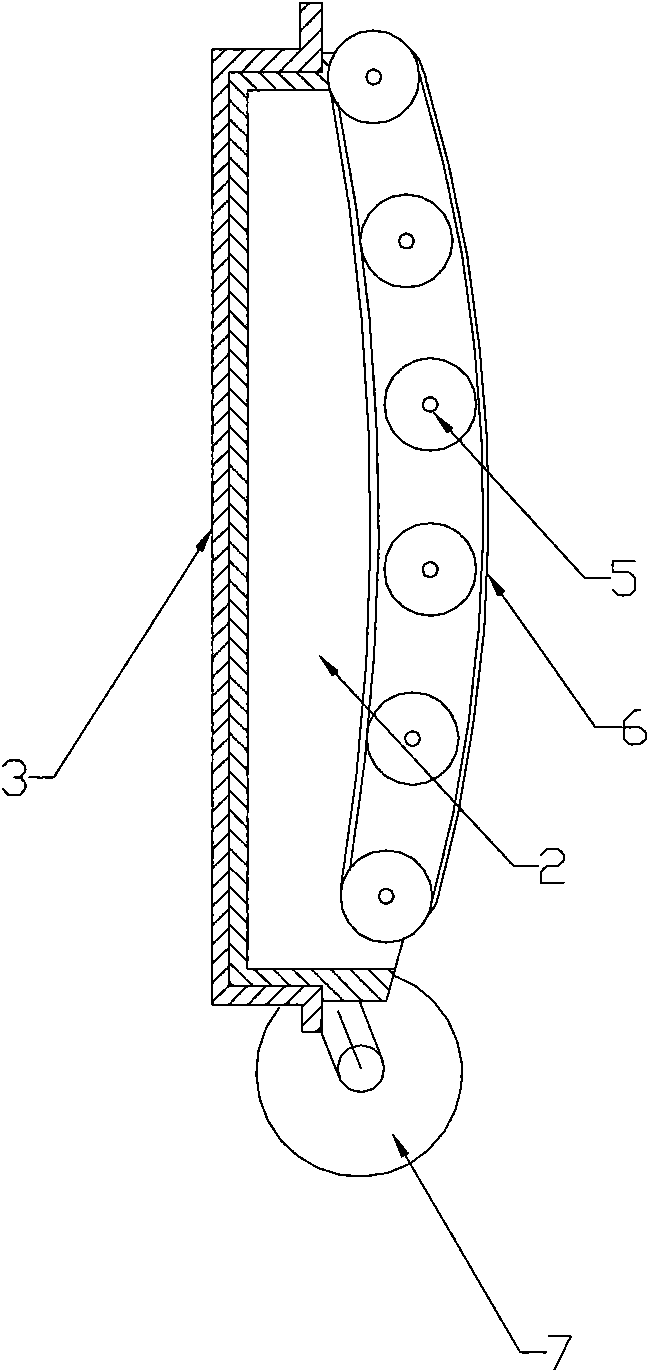

Helical feeder

Owner:SHENGLI OIL FIELD SHENGLI POWER MACHINERY GRP

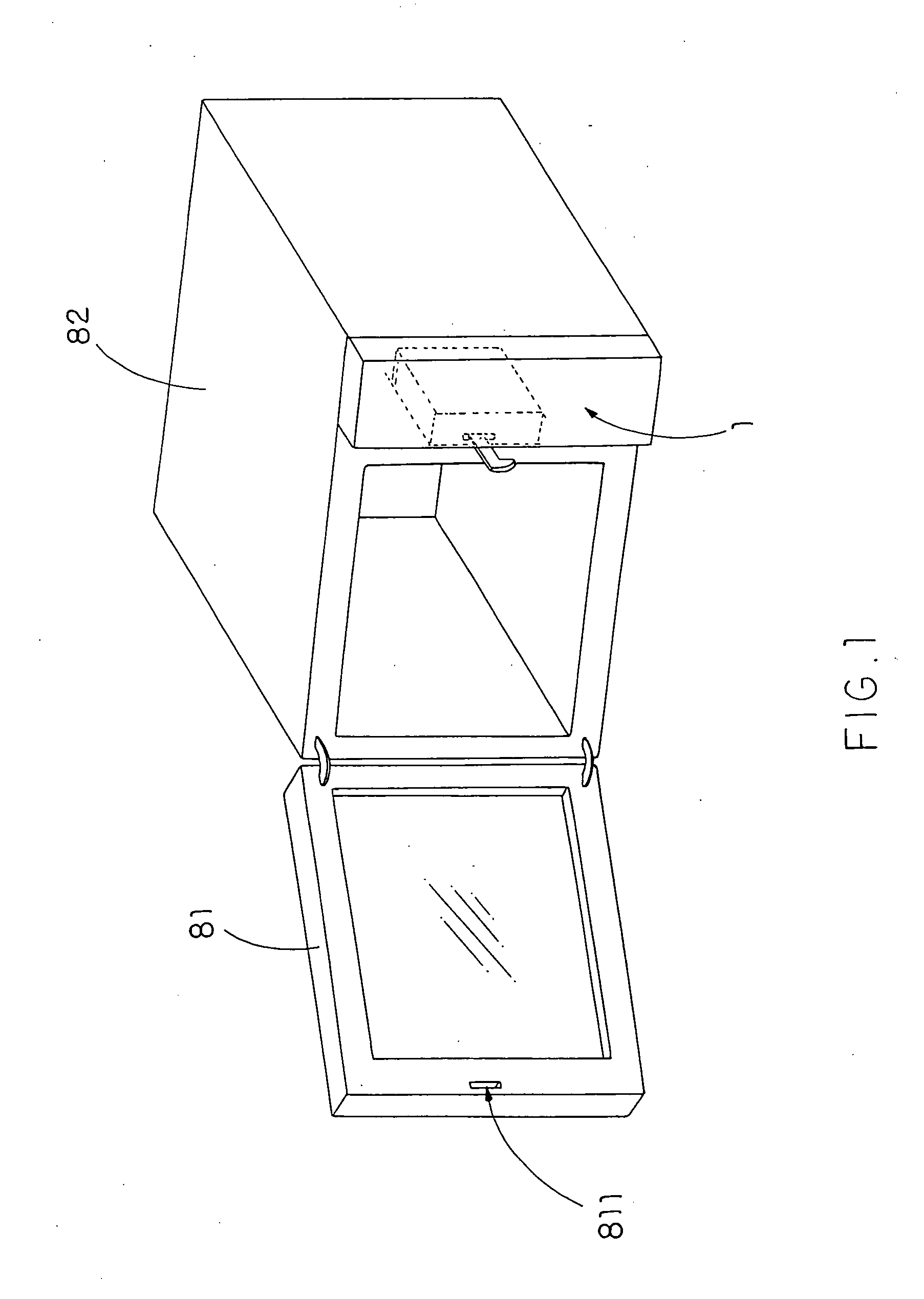

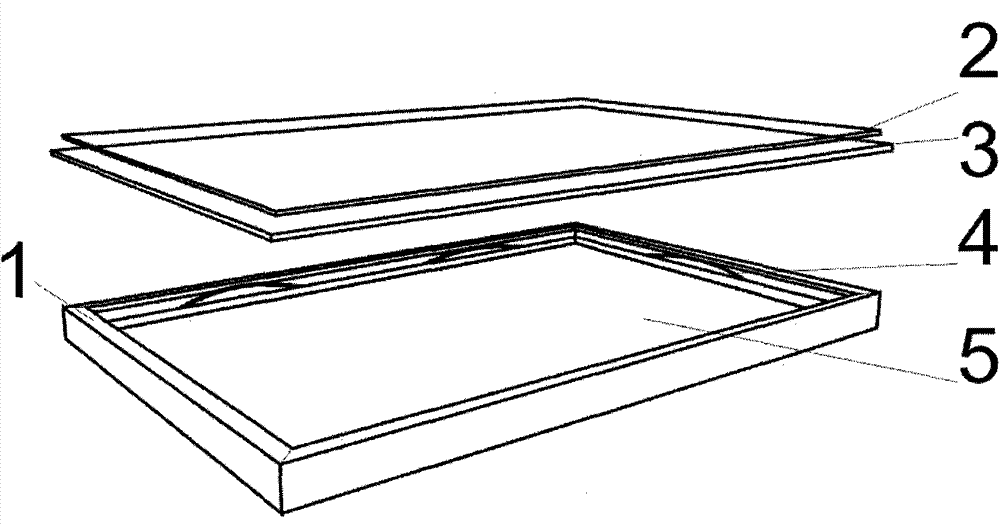

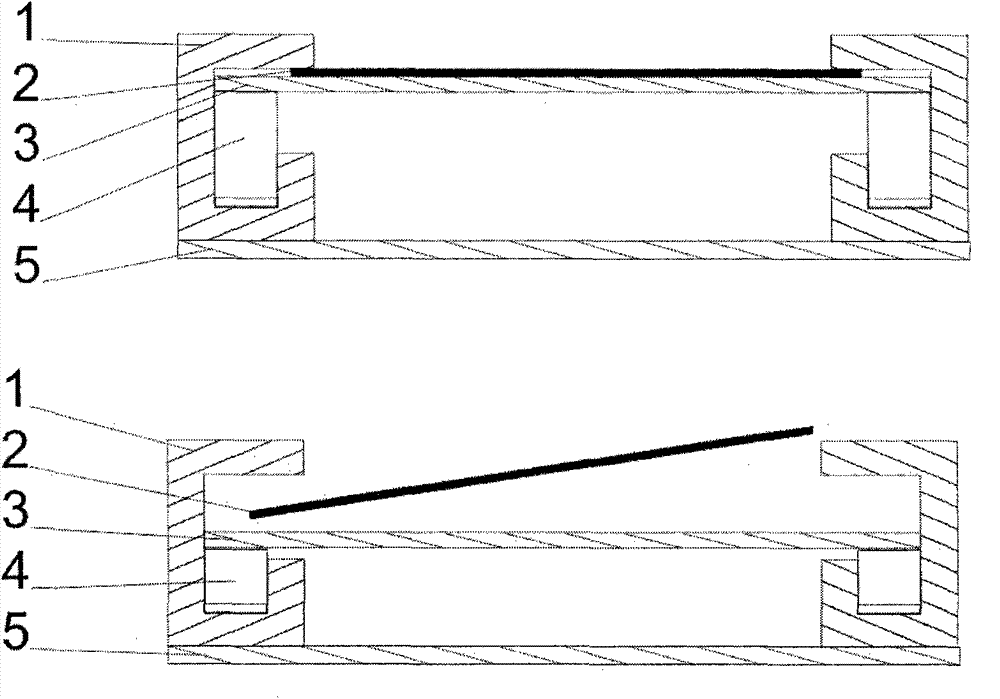

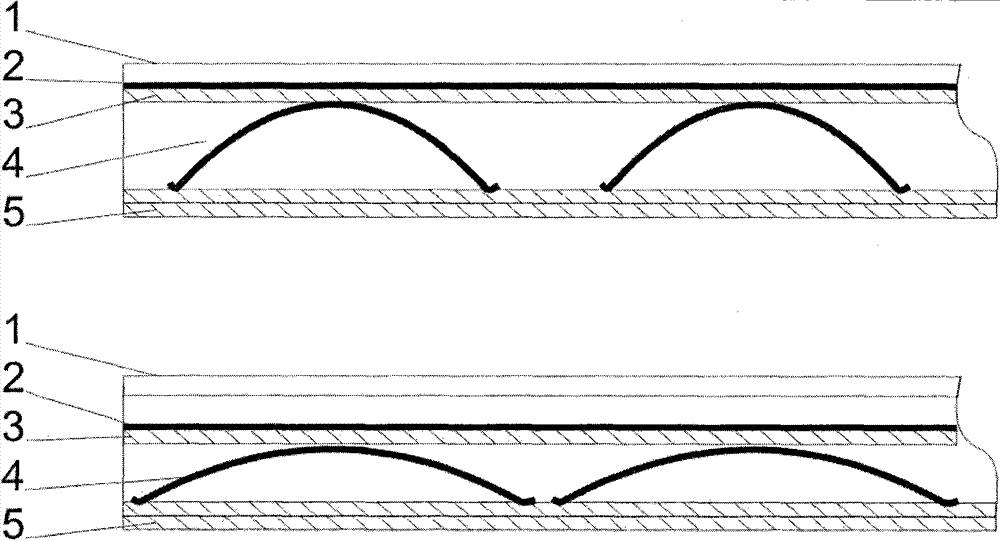

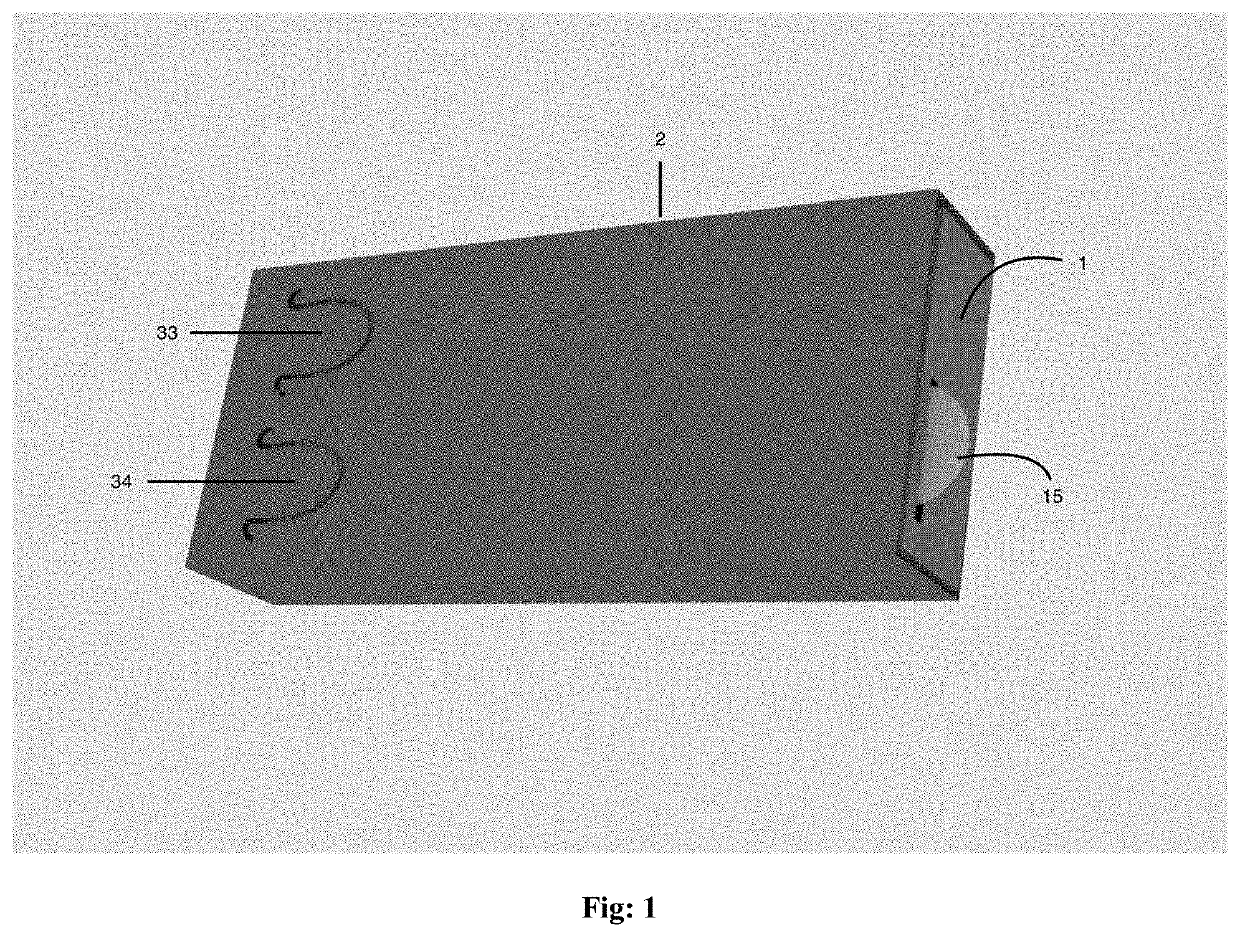

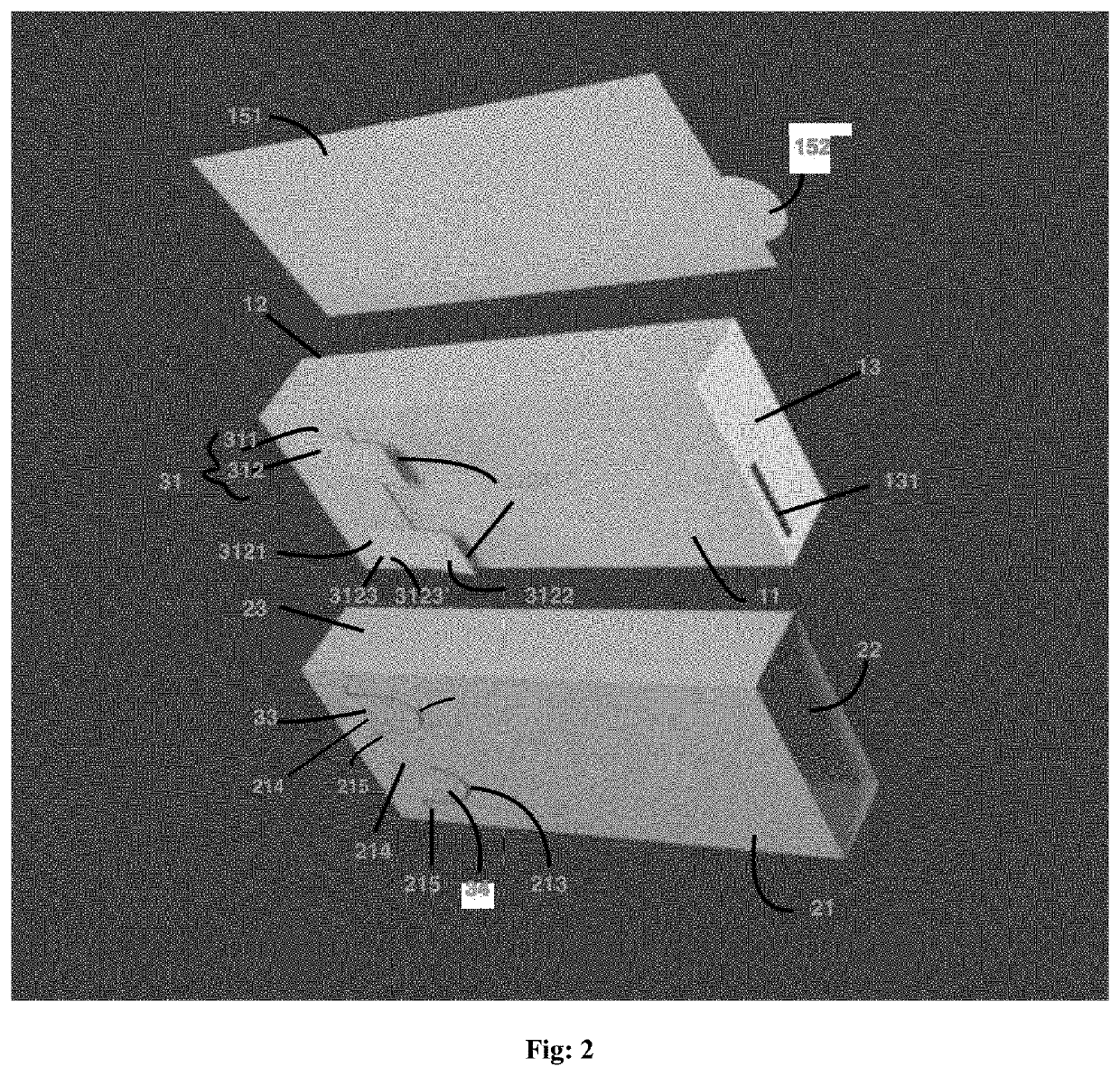

Picture frame with pictures easy to replace

InactiveCN103479142AEasy to replaceExcellent designPicture framesDomestic mirrorsComputer graphics (images)Light source

The invention provides a picture frame with pictures easy to replace. The picture frame is applied to a lamp box, an advertising board, a frame, a photo frame and the like with the pictures needing to be replaced. A spring, an elastic piece, a single spraying structure and a matching side frame structure are arranged in the picture frame in a hidden mode, and therefore the picture frame and the pictures can be clamped and loosened through the elastic force. The pictures can be clamped or loosened by pressing or loosening the pictures from the outside of the picture frame, and can be replaced. Any structural member and screw can not be seen from the outside of the picture frame. The picture frame is simple and durable in structure, low in manufacturing cost and beneficial for secondary appearance design. The internal structure is simple. When the picture frame is applied to the lamp box, shadows can not be caused as the picture frame does not shield the portion between a light source of the lamp box and the pictures. Moreover, the traditional picture replacing mode which is tedious and damages the appearance can be replaced, and the picture frame is easy to use.

Owner:林健

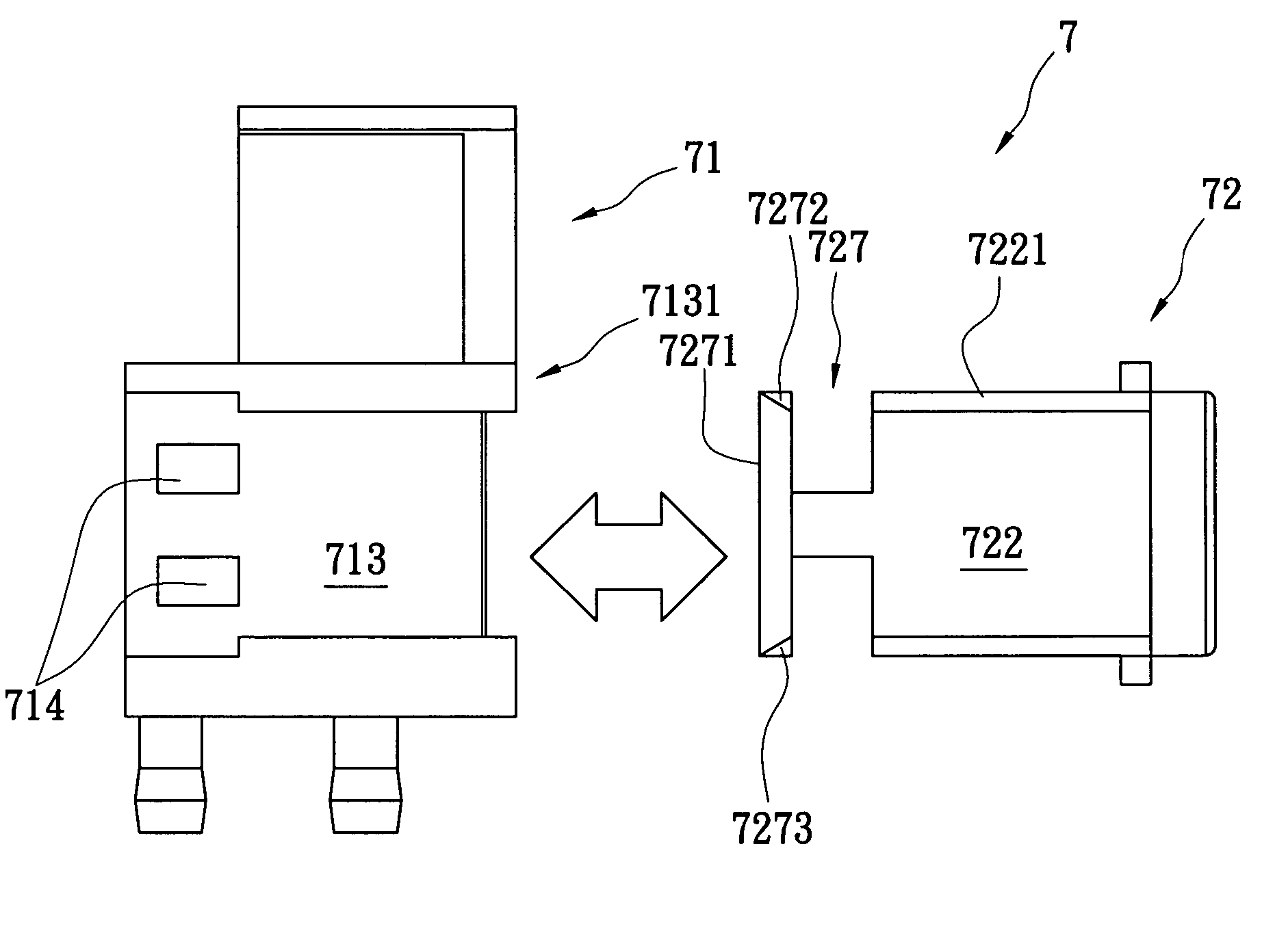

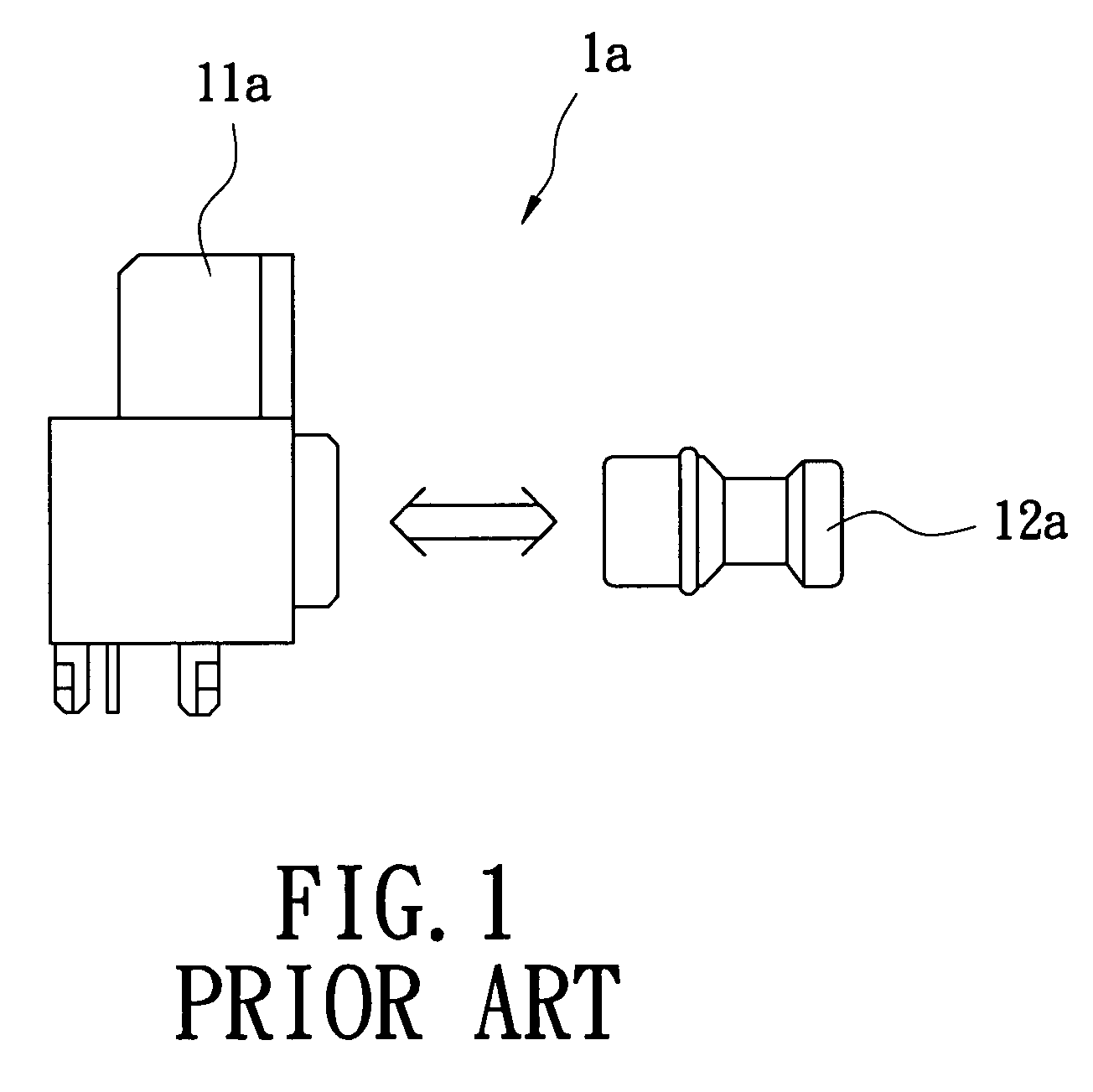

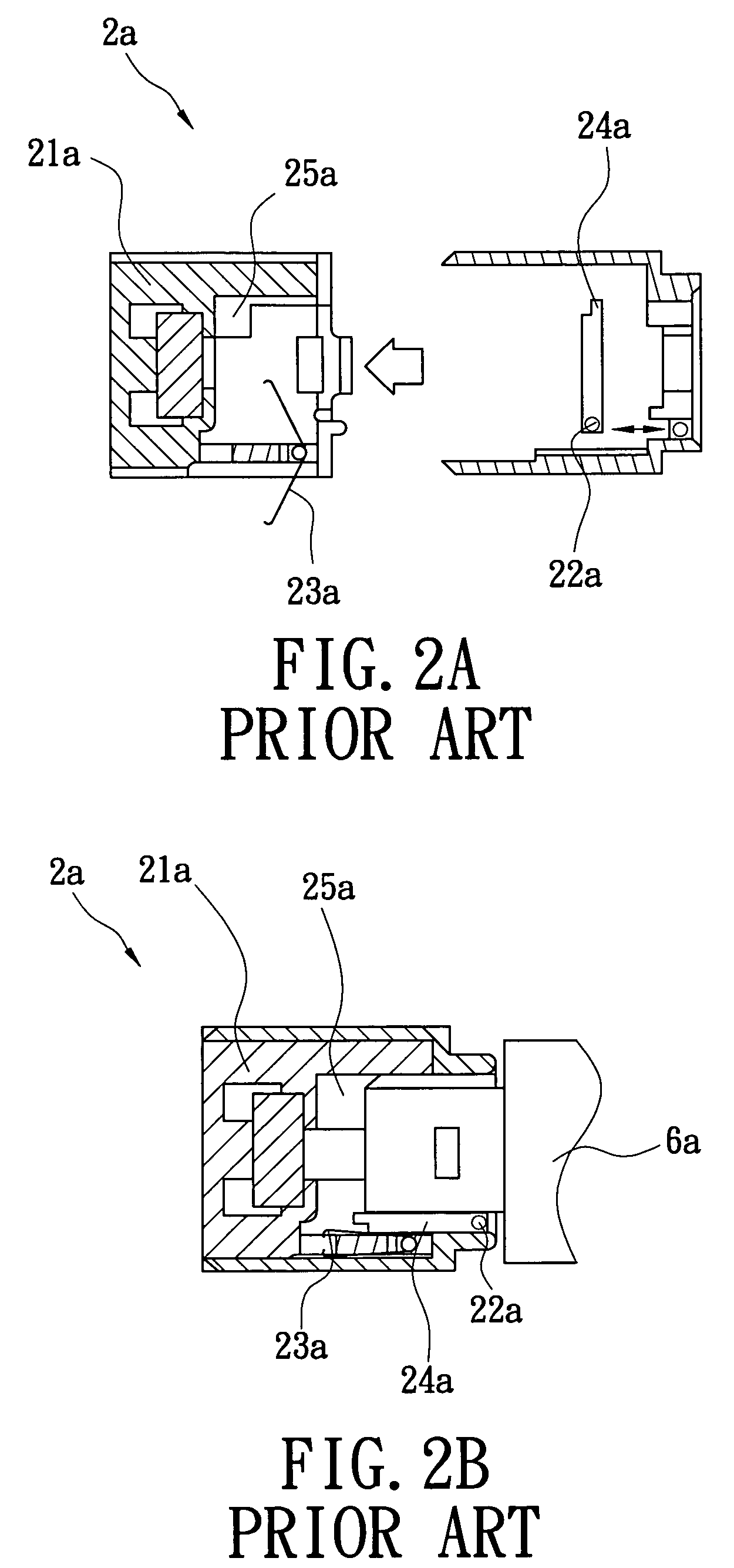

Fiber optical connector

InactiveUS6988836B2Simple and durable structurePrevent the choking hazard for childrenCoupling light guidesFiberEngineering

An optical fiber connector for mating with an optical fiber coupling has a housing and a U-shaped portion assembled to the housing. The housing has two clamping grooves respectively formed on upper and lower edges of each opposite lateral outer surface thereof. The U-shaped portion includes a socket frame and two side plates extending from the socket frame. The socket frame includes a shutter downwardly extending from an upper front edge thereof and made integrally in one piece. Each of the side plates has two engaging faces respectively retained in the clamping grooves and arranged on upper and lower edges thereof.

Owner:LITE ON TECH CORP

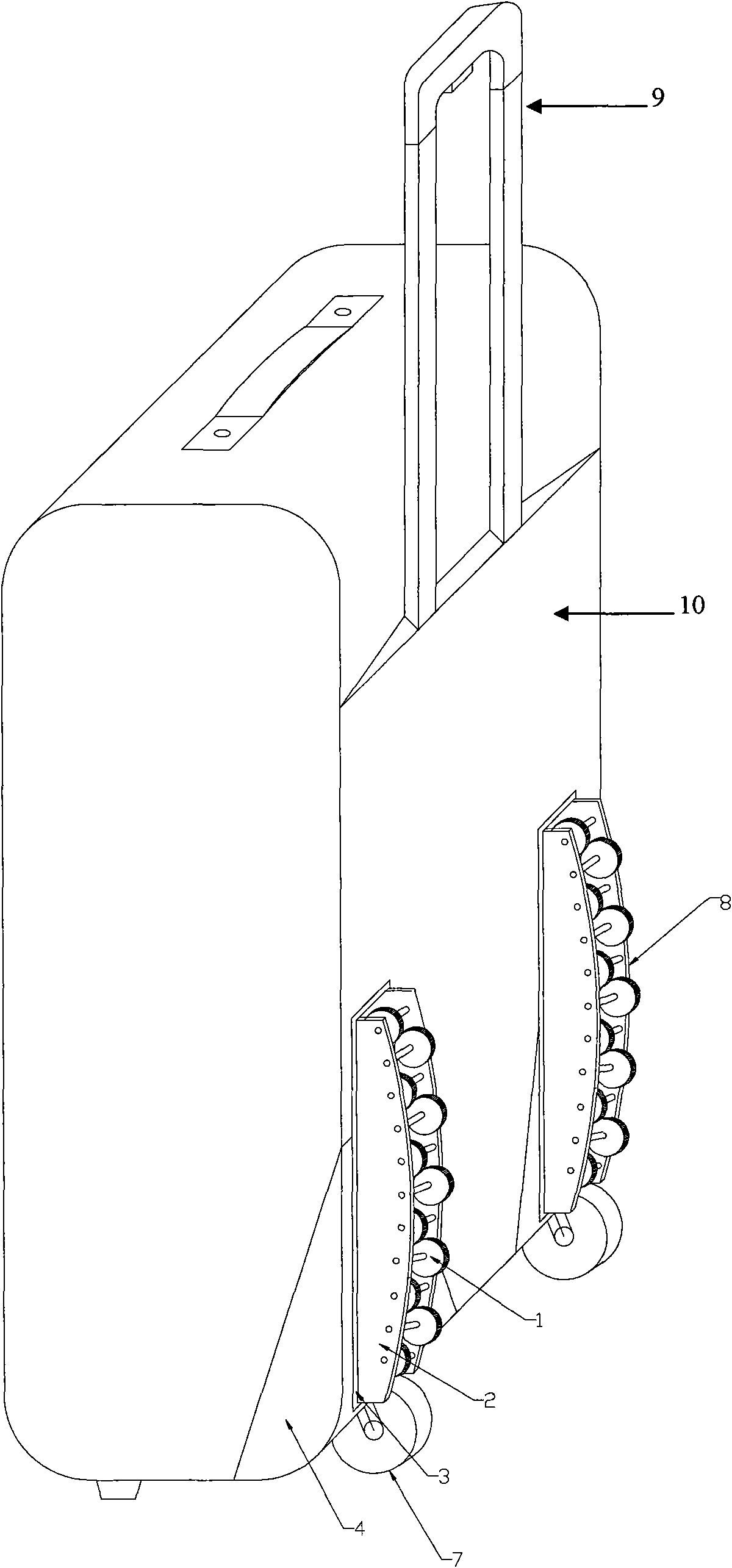

Travel suitcase with stairs-climbing mechanisms with sliding wheels

InactiveCN101579165ADrag and save effortSimple and durable structureLuggageOther accessoriesEngineeringStair climbing

The invention relates to the technical field of articles for daily use, in particular to a hand-pulling type travel suitcase, which is provided with a plurality of stairs-climbing mechanisms with sliding wheels; the stairs-climbing mechanisms are matched with landing wheels; each stairs-climbing mechanism comprises a sliding wheel part and a concave seat part with fixed protective covers; the sliding wheel part is provided with a wheel-arranging box; and the box surface of the convex seat part is provided with fixed protective covers for wrapping part of box corners or angle edges. The hand-pulling type travel suitcase not only can travel on flat ground, but also can travel smoothly in the environments with rugged ground of stairs, steps, slopes and the like, has simple and durable structure, beautiful appearance and convenient assembly, also can have the function of reducing vibration, and can be adjusted according to the conditions of ground environment so as to lead a user to drag the travel suitcase more relaxedly with less effort.

Owner:阮红菊

Double Button Safety Match Box

InactiveUS20200262618A1More conciseMore durableTobacco devicesRemovable lids/coversSoftware engineeringMechanical engineering

Owner:NELSON ANDREW

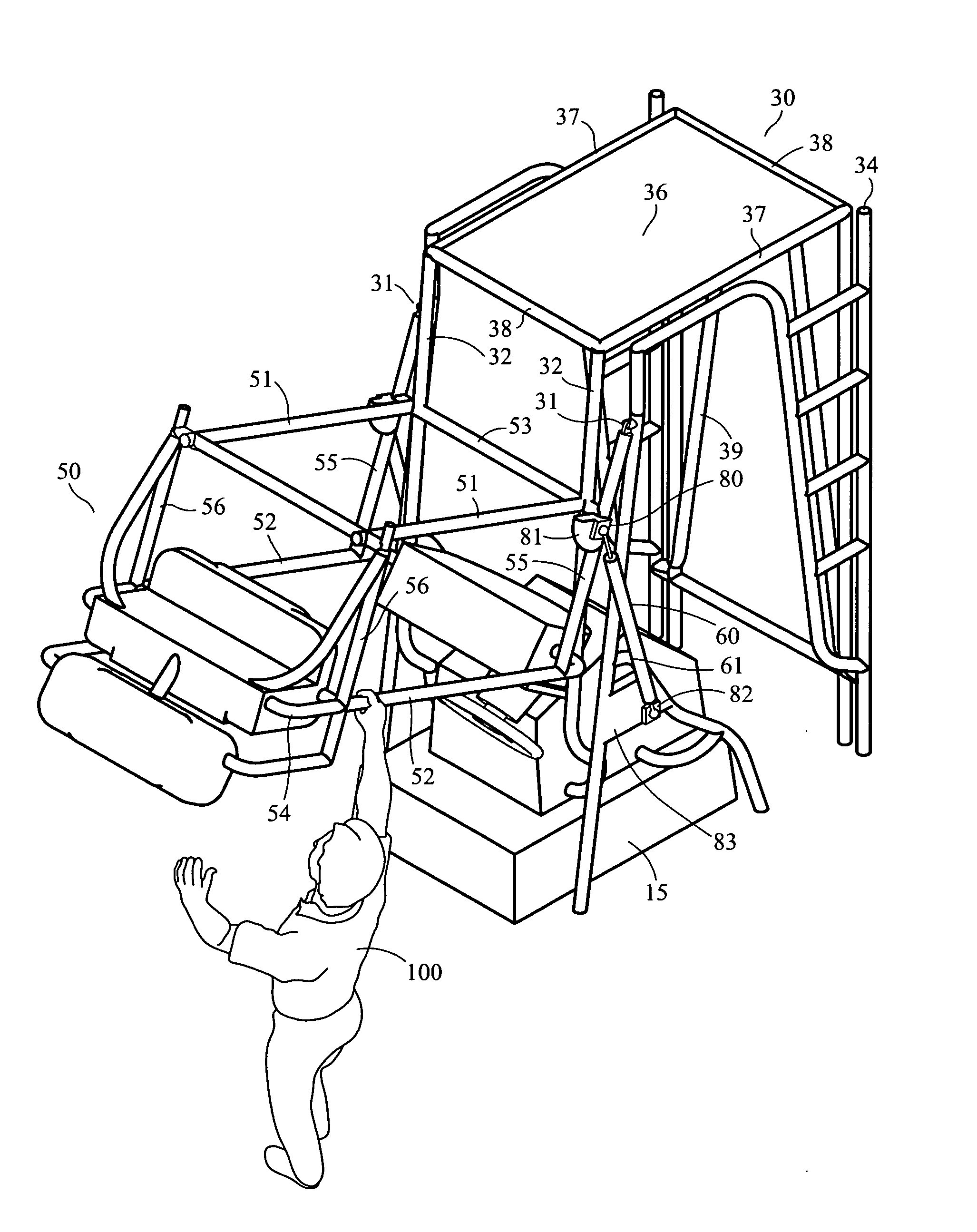

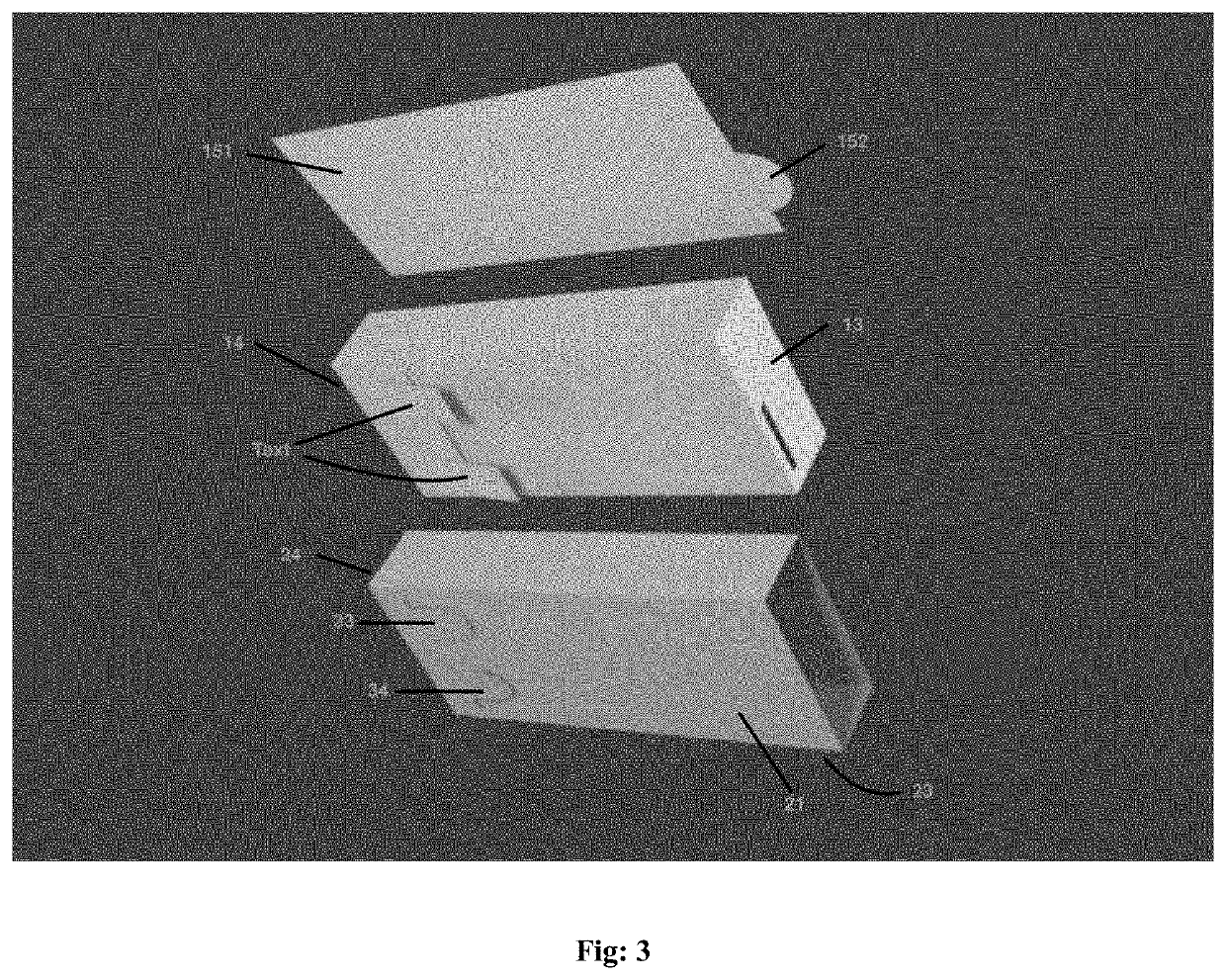

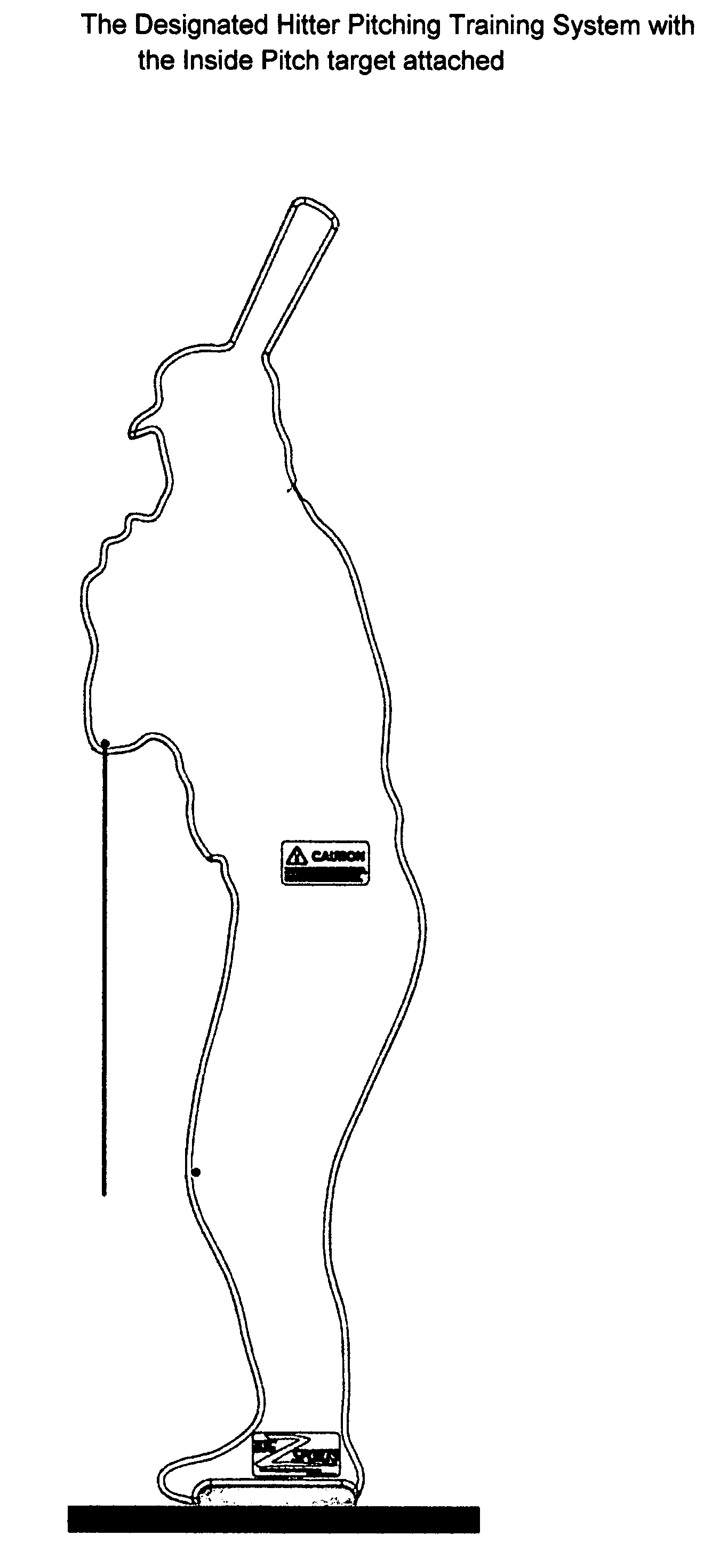

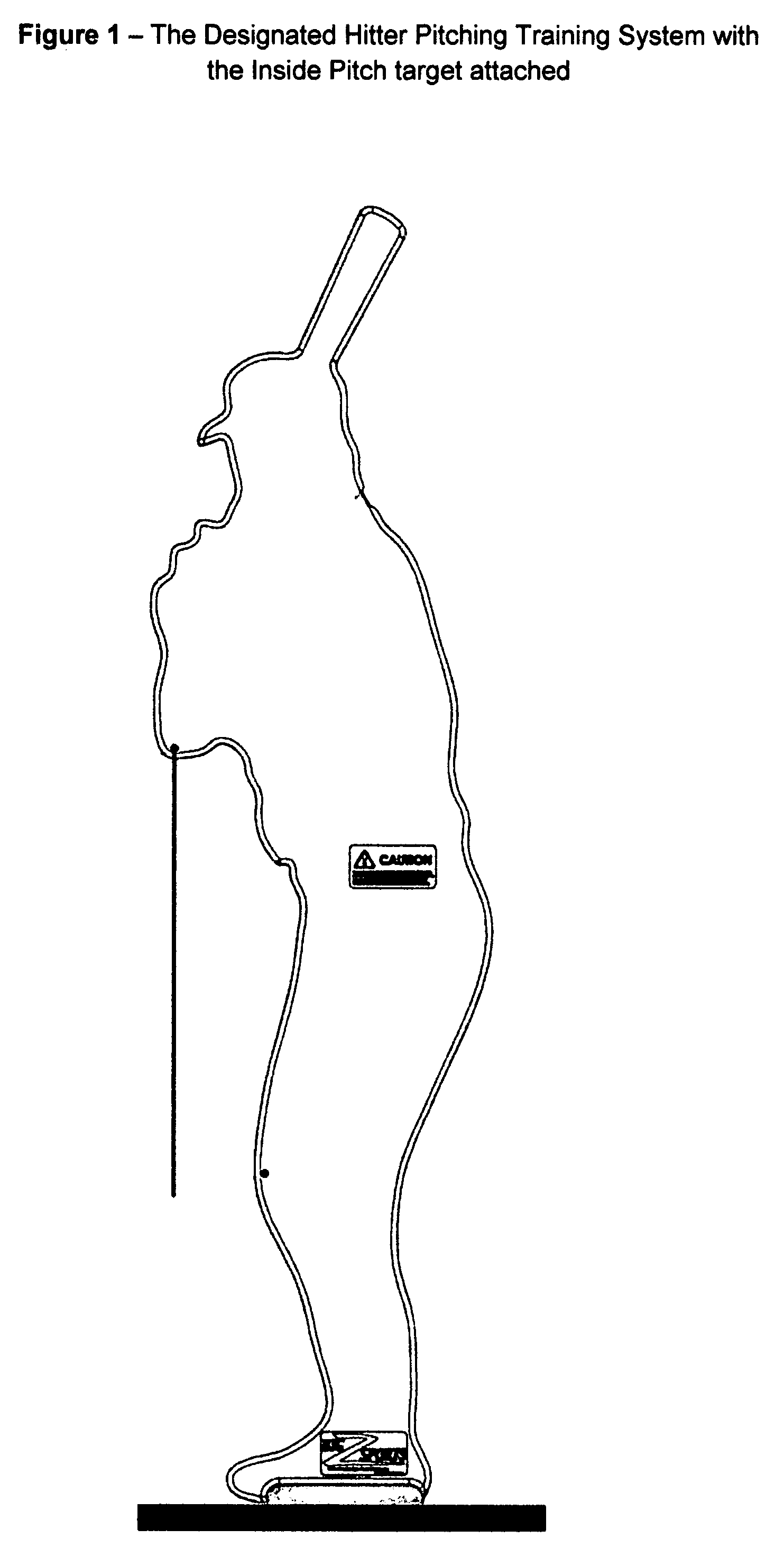

Designated hitter pitching training system (The DH)

InactiveUS20080194360A1Simpler and durable in constructionUniversally usableSport apparatusSkill setsEngineering

The Designated Hitter Pitching Training System (DH) is a silhouette figure of a batter that stands in the batter's box during bullpen sessions for baseball and fastpitch softball pitchers of all ages and skill levels. Constructed of durable polyethylene, the DH comes in three sizes: the Pro (6′2″), Varsity (5′8″) and Youth (5′2″). The DH provides a more realistic, game-like way for pitchers to practice and will improve a pitcher's ability to more consistently throw their pitches in the strike zone, as well as pitch more accurately and confidently to the inside part of the plate with the Inside Pitch Target. All of this will combine to improve game performance. The DH can also be used by pitchers and catchers as part of their practice activities such as throwing to bases, bunt defense, pitchouts, and intentional walks.

Owner:ZAWROTNY STEVEN CRAIG +1

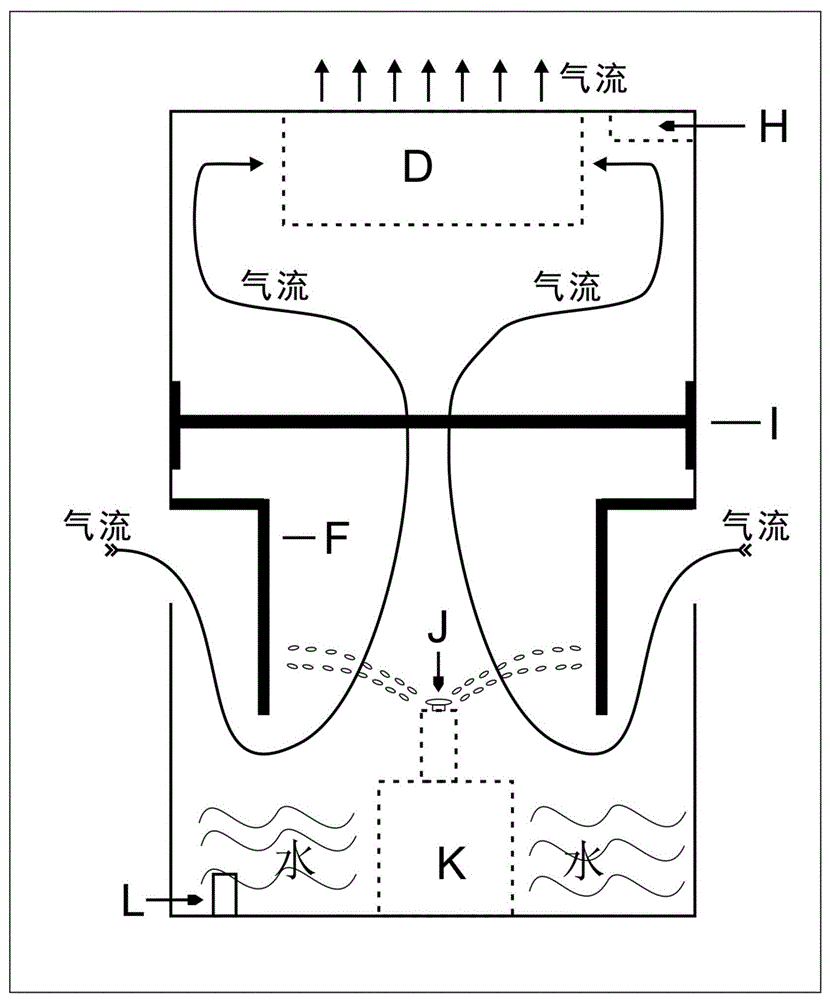

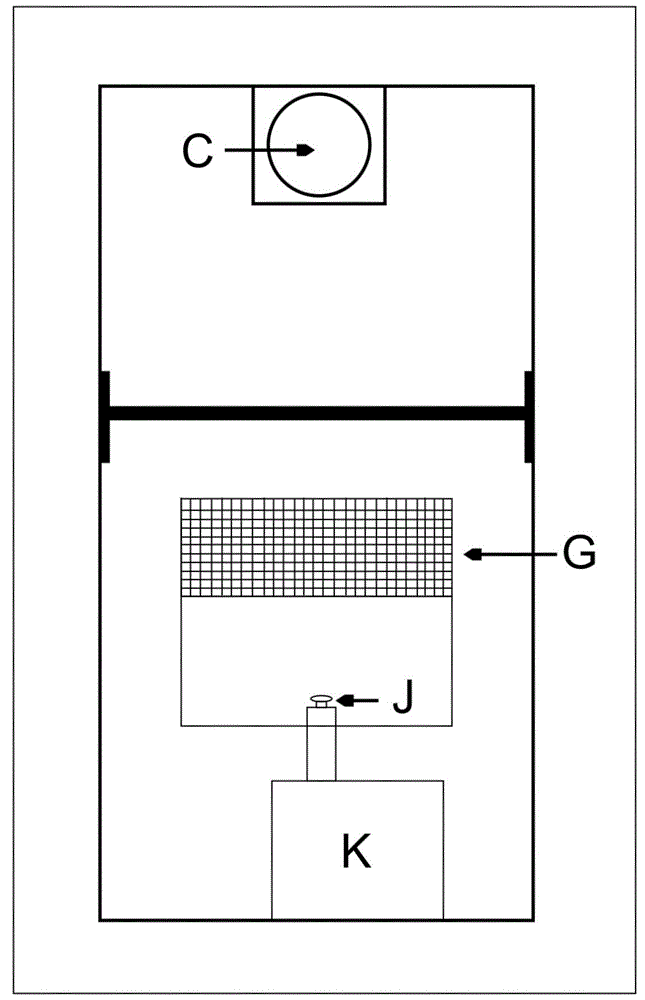

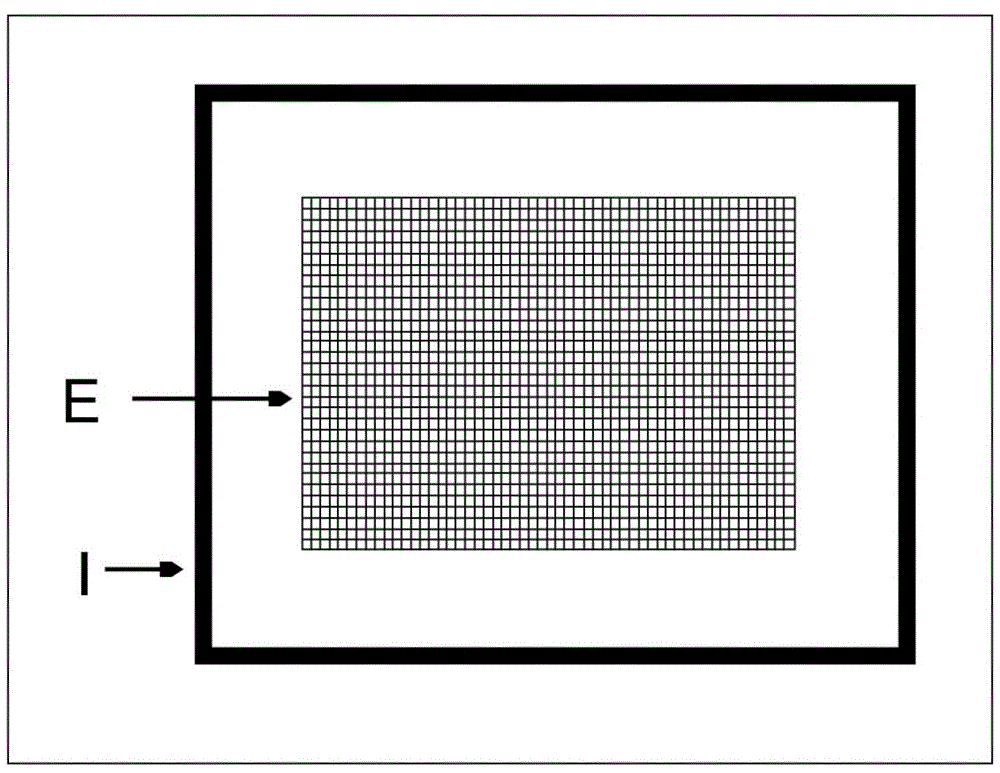

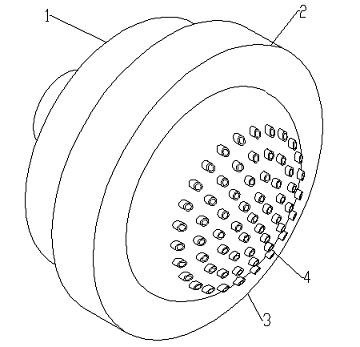

Air purifier

PendingCN106839118ASimple and durable structureMechanical apparatusSpace heating and ventilation safety systemsAir volumeProduct gas

The invention provides an air purifier and solves the problem of reduced purifying efficiency due to long-term use and the problem about air disinfection in the technical field of air purification. The air purifier is characterized in that the structure is simple, the air purifying efficiency cannot be affected after long-term use and various bacteria in air can be killed by adding a disinfecting solution, a switch (B) in an attached drawing 4 and a blast volume controller are rotated to the position 1 or 2 and rotated to send signals to a circuit board (H), a turbo-blower (D) and a water pump (K) are started simultaneously for operation by the circuit board (H), the water pump (K) conveys water to a sprinkler head (J), and water is sprayed to outside of a diversion trench. The turbo-blower (D) exhausts air in a box to an air outlet (A). Specifically, the air flows into an air diversion trench (F) from an air inlet fly net (G) in an attached drawing 2, is cleaned by the sprinkler head (J), flows through a water spray blocking net (E) in an attached drawing 3, enters a turbo-blower air inlet (C) and is exhausted from the air outlet (A).

Owner:陈志文

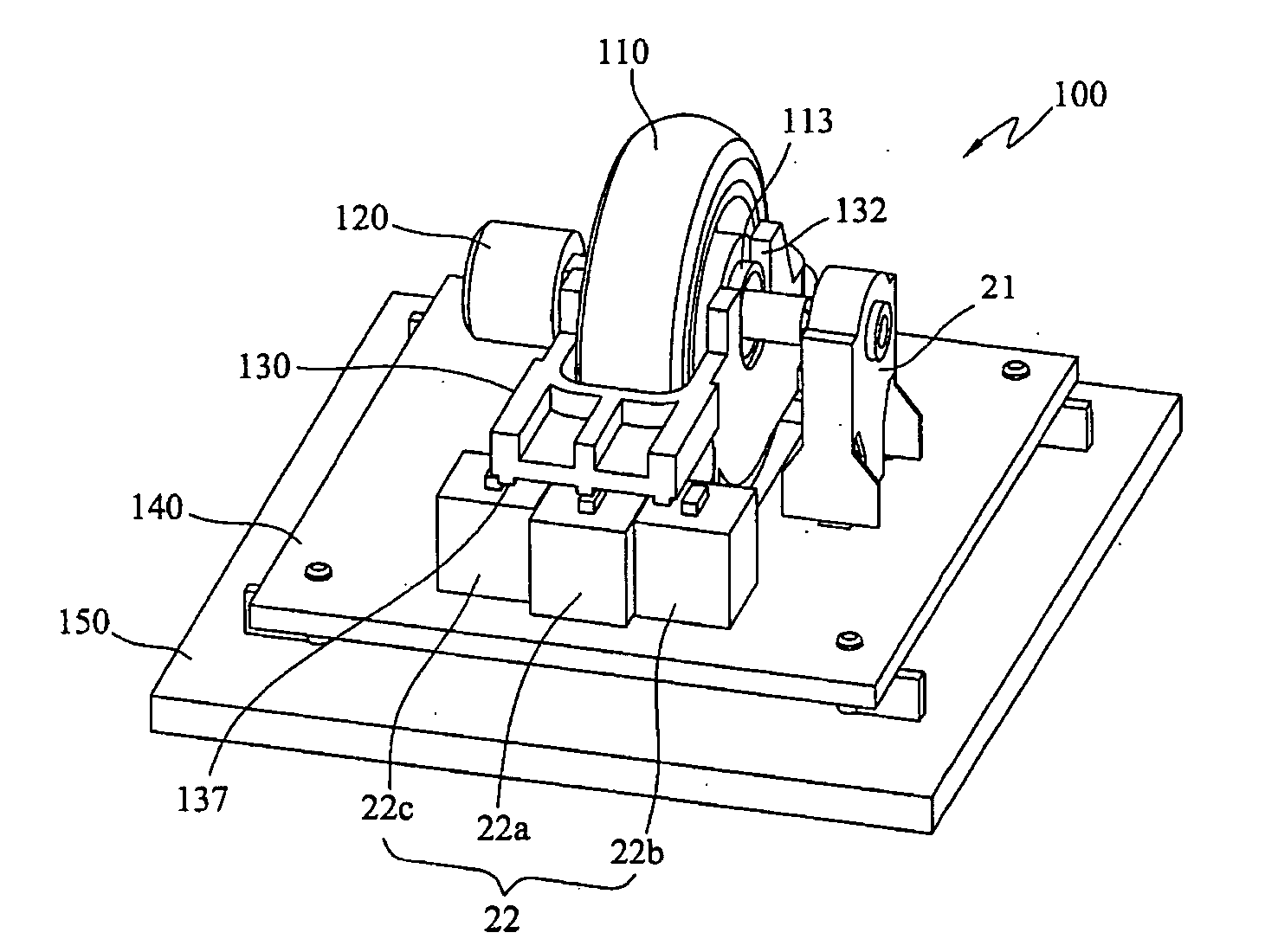

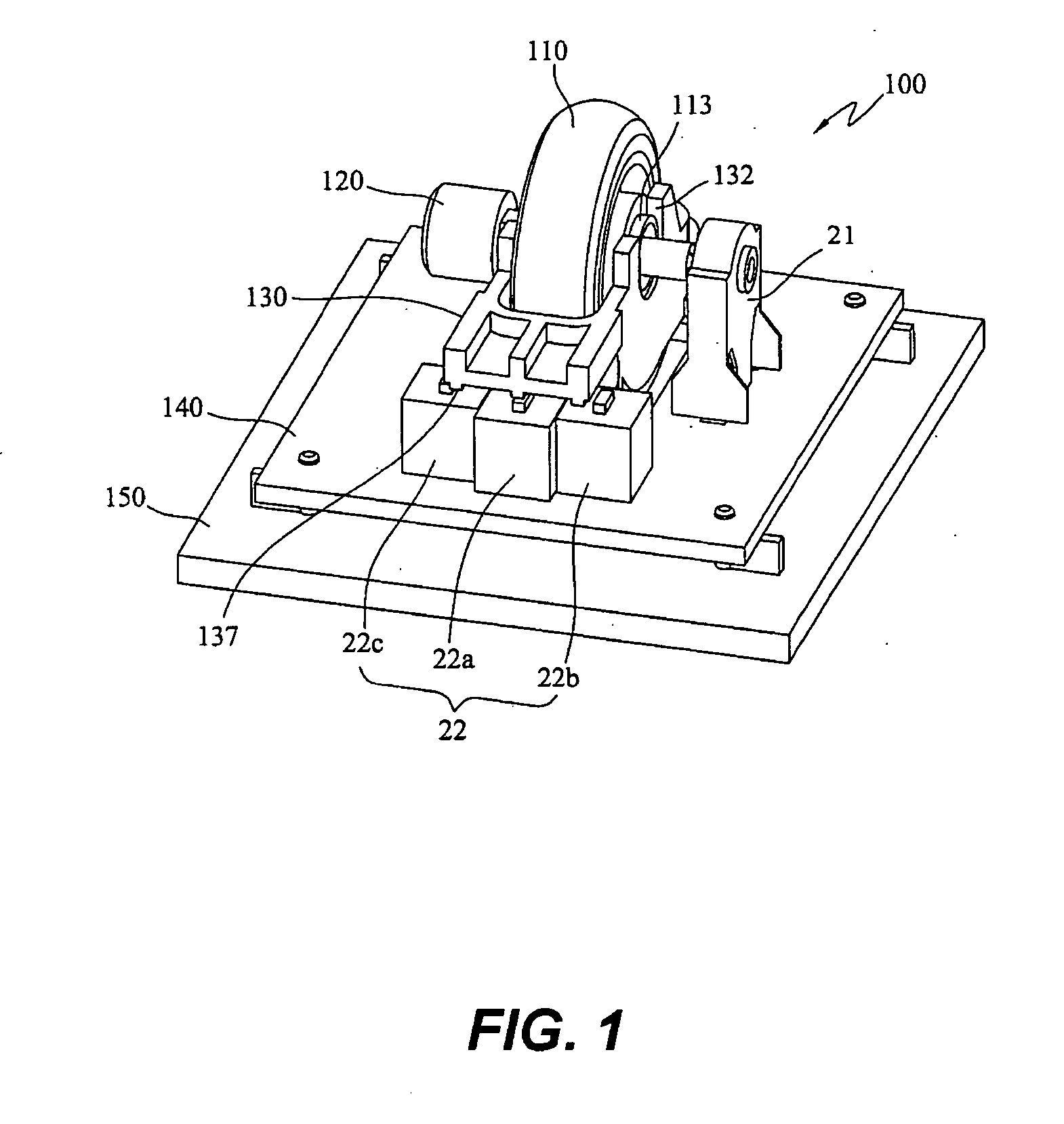

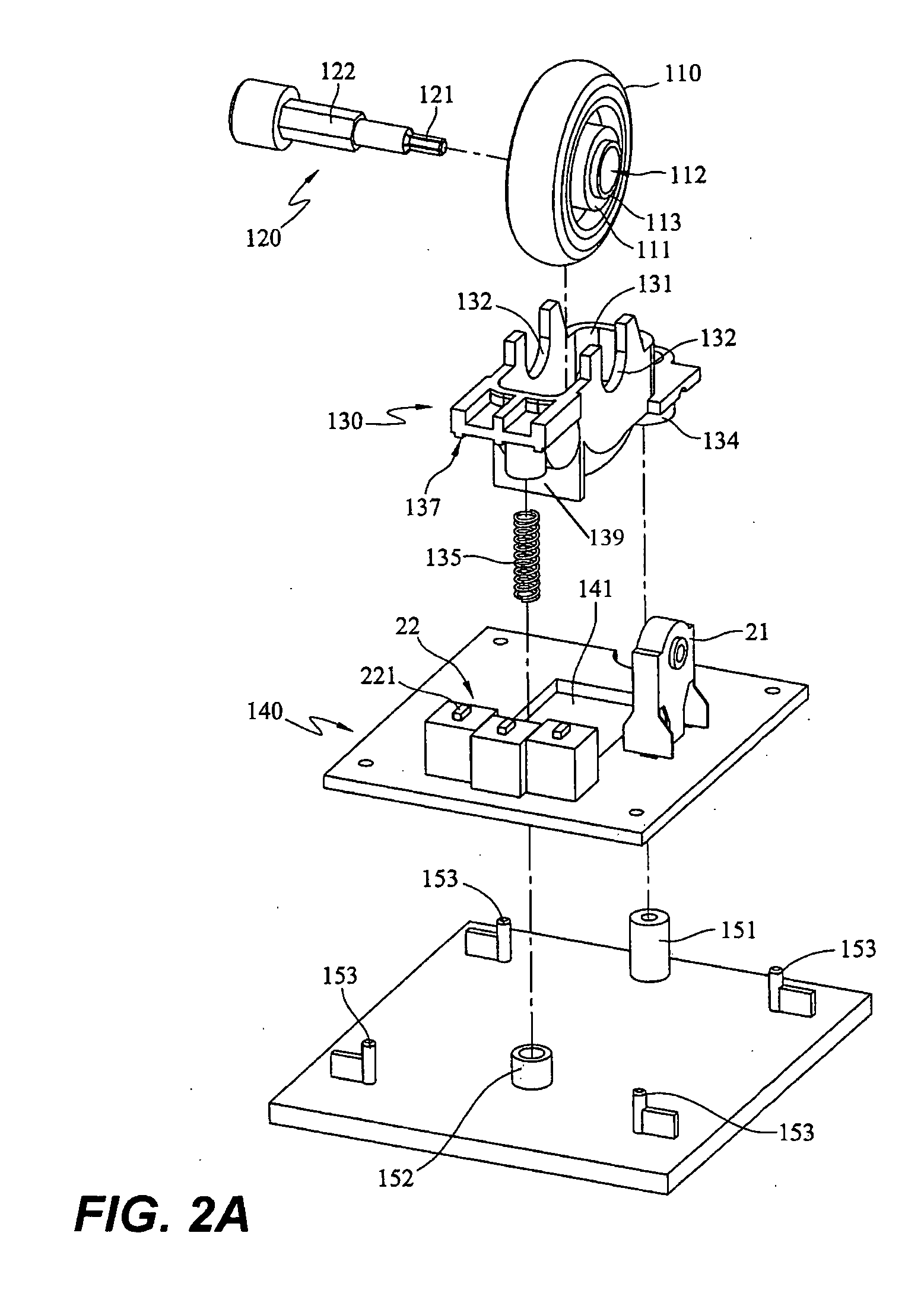

Roller mechanism for multiple directions control

InactiveUS20070097075A1Simple and durable structureLow costManual control with multiple controlled membersCathode-ray tube indicatorsControl signalCoupling

The present invention relates to a roller mechanism for generating a plurality of control signals, for example to scroll an image on a computer display in multiple directions. The roller mechanism has a carriage, and a roller rotatable within the carrier. The roller can drive an encoding unit to output the control signal. The carriage has a coupling portion, and the coupling portion is pivoted to a bottom support. Thus the roller and the carriage are turnable relative to the coupling portion in a fan-shaped movement while the roller is also being rotated within the carriage.

Owner:KYE SYST CORP

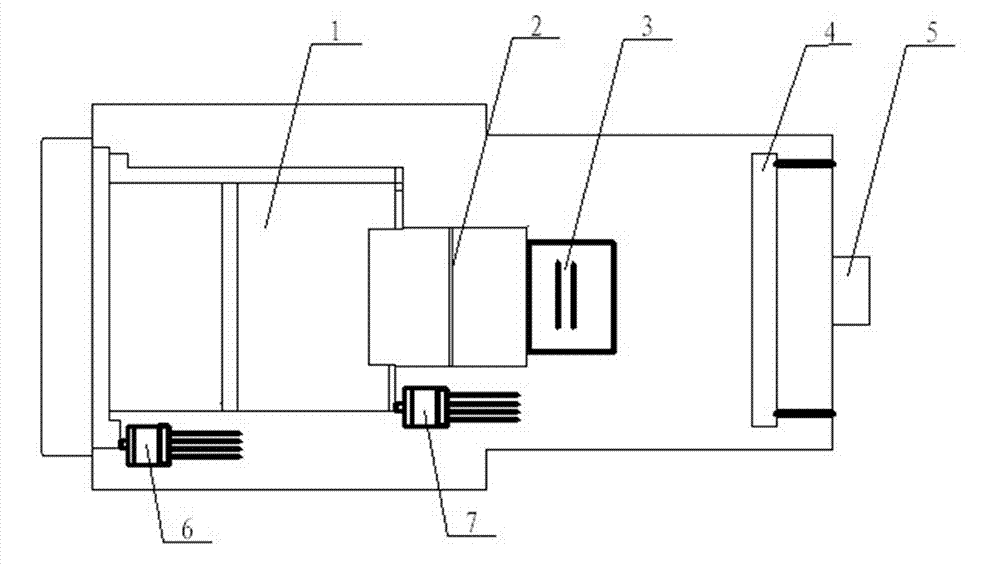

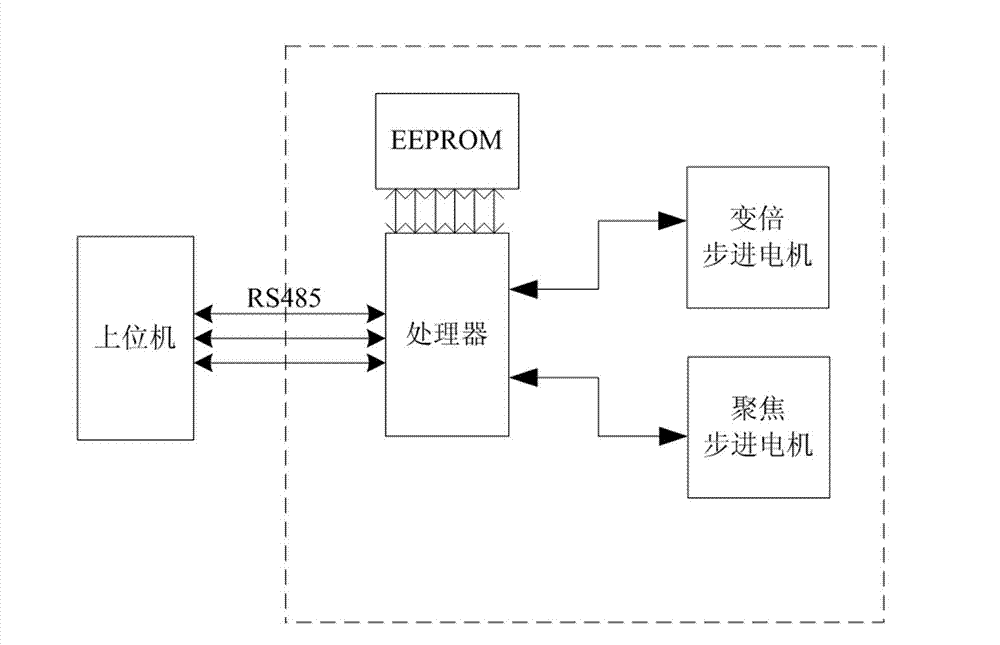

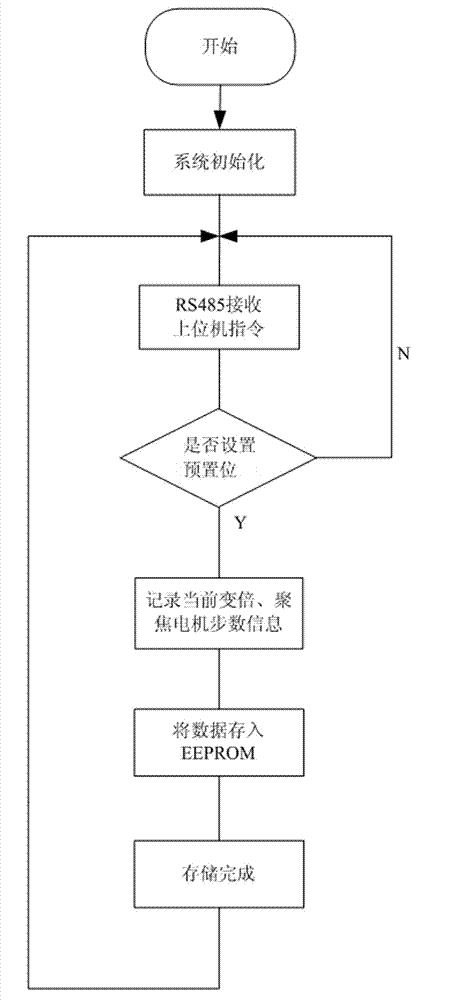

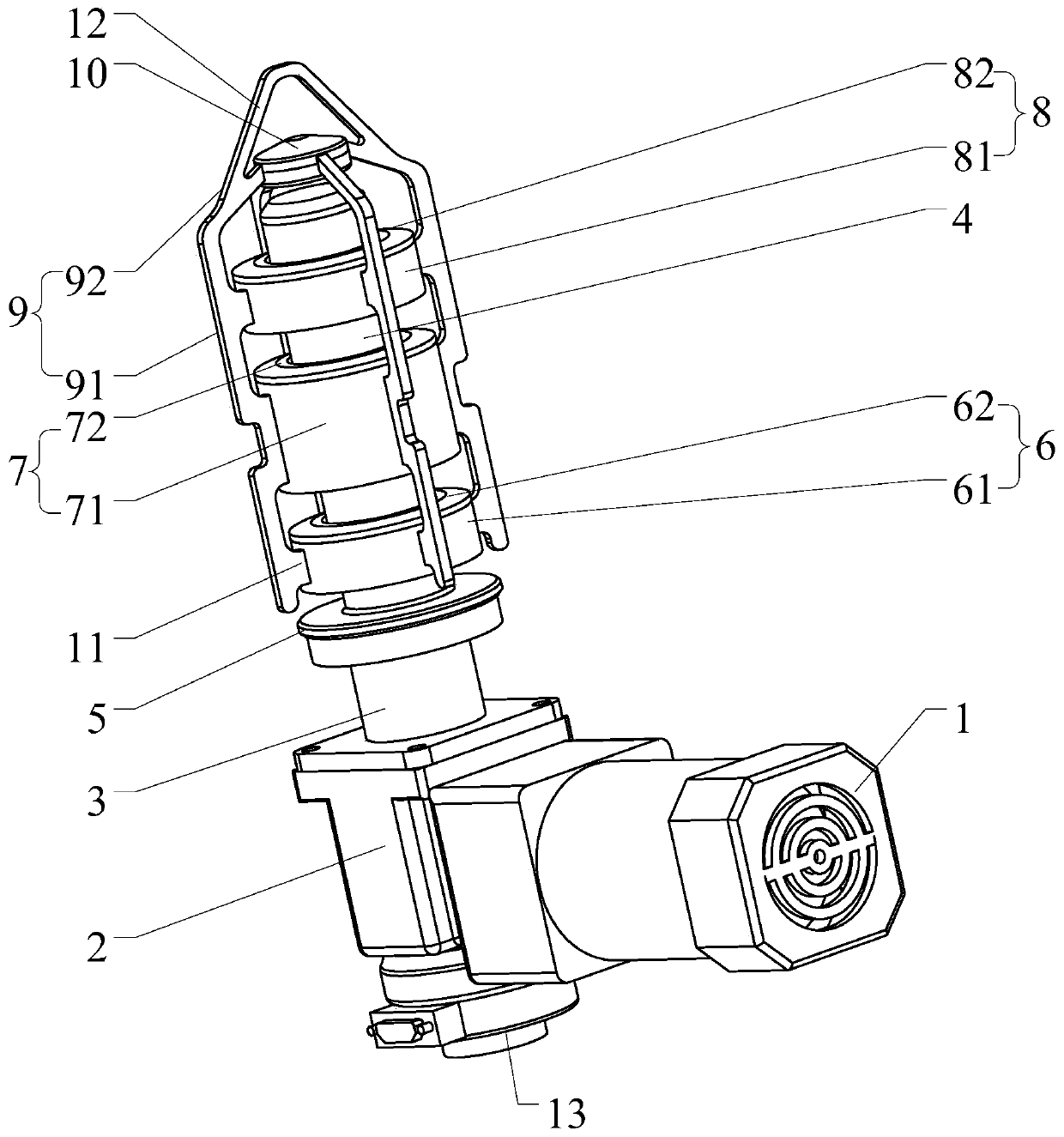

Infrared thermal imaging instrument and method capable of implementing presetting function based on stepping motor

ActiveCN102967375AImprove efficiencyGuaranteed imaging effectRadiation pyrometryPhysicsControl circuit

The invention discloses an infrared thermal imaging instrument capable of implementing a presetting function based on a stepping motor. The infrared thermal imaging instrument comprises an imaging zooming lens group, an imaging focusing lens group, a thermal imaging detector assembly and a control circuit board, and is characterized in that the control circuit board respectively drives the imaging zooming lens group and the imaging focusing lens group to work through a zooming stepping motor assembly and a focusing stepping motor assembly. A method comprises the following steps of: mounting the thermal imaging instrument; initializing the thermal imaging instrument; manually zooming and focusing; reading zooming and focusing information; and storing the information. A preset position calling method comprises the steps of judging a scene to be monitored, calling the information, adjusting the thermal imaging instrument, and acquiring a clear image. By the infrared thermal imaging instrument and method, the clear image is acquired at first time, and the zooming and focusing information at the moment is stored; during cruise monitoring, the clear image in the specific scene can be acquired by calling the zooming and focusing information stored before; and manual adjustment is not needed, and thus the efficiency is higher.

Owner:山东神戎电子股份有限公司

Shaft-sleeve-free full-suspension magnetic stirrer

ActiveCN111013469AExtended service lifeImprove mix qualityTransportation and packagingMixersPhysicsMagnetic stirrer

The invention relates to a shaft-sleeve-free full-suspension magnetic stirrer, which comprises a driving device, a speed reducer and an inner driving shaft, the outer portion of the inner driving shaft is sequentially sleeved with a rack and a sealing sleeve from bottom to top, and the sealing sleeve is connected with the rack through a welding chassis; a lower magnetic suspension sleeve, a driving magnetic cylinder and an upper magnetic suspension sleeve are sequentially arranged outside the sealing sleeve from bottom to top in a sleeving manner, stirring blades are arranged outside the uppermagnetic suspension sleeve, the driving magnetic cylinder and the lower magnetic suspension sleeve, and the upper ends of the stirring blades are fixed to a magnetic suspension positioning sleeve atthe top end of the inner driving shaft; lower magnetic rings with opposite polarities are respectively arranged on the inner walls of the lower inner magnetic suspension sleeve and the lower outer magnetic suspension sleeve; upper magnetic rings with opposite polarities are respectively arranged on the inner walls of the upper inner magnetic suspension sleeve and the upper outer magnetic suspension sleeve; and magnets are arranged on the inner walls of the inner driving magnetic cylinder and the outer driving magnetic cylinder. The problem that liquid medicine is polluted by abrasive dust generated by magnetic stirring of the shaft sleeve is solved, the structure is simple and durable, the service life of the stirrer is prolonged, and the liquid medicine stirring quality is improved.

Owner:河北奥格流体设备有限公司

Planter dual wheel mounting device

InactiveUS20130234496A1Improving planter 's tractionReduce soil compactionRimsSpoked wheelsEngineeringMechanical engineering

A device for mounting an additional wheel on an agricultural planter to provide a dual wheel assembly. Said device comprising a generally cylindrical member with radially projecting flanged portions at each end thereof, a plurality of apertures extending through the flanged portion at one end of said cylindrical member and positioned to receive the wheel mounting studs of a planter's wheel hub, and a plurality of externally threaded shafts projecting outwardly from the flanged portion at the opposite end of said cylindrical member and positioned to mate with the mounting apertures of the auxiliary planter wheel being added.

Owner:LEADING EDGE INDS

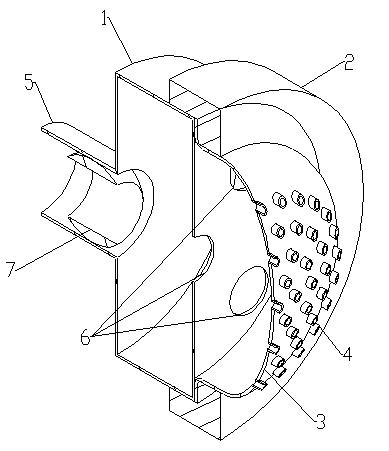

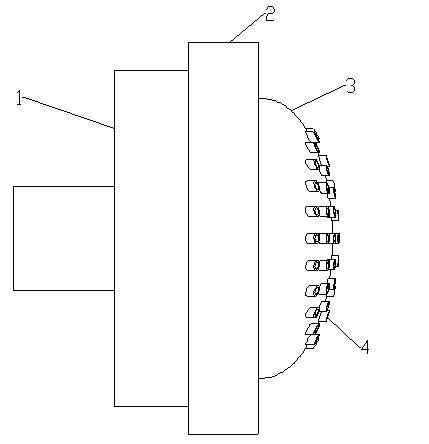

Silk spraying device with micro controller

InactiveCN102367592ASimple and durable structureReduce maintenance costsSpinnerette packsFiberMoisture sensor

The invention discloses a silk spraying device with a micro controller, which comprises a filling part (1) used for polymer filling, a silk spraying part (3) used for silk spraying and a middle engaging part (2), wherein the left end of the filling part (1) comprises a connecting pipe (5), a humidity sensor is also arranged inside the filling part (1), a ball valve (7) is arranged on the connecting pipe (5), the ball valve (7) is controlled by the micro controller, the micro controller is connected with the humidity sensor arranged in the filling part (1), the right end of the filling part (1) comprises a plurality of filling holes (6), the middle engaging part (2) is arranged at the connecting part of the filling part (1) and the silk spraying part (3), the filling part (1) is connected with the middle engaging part (2) through screw threads, and the silk spraying part (3) is engaged with the middle engaging part (2). The silk spraying device with the micro controller has the advantages that the structure is simple and durable, the maintenance cost is low, the quality is reliable, and different requirements of fiber knitting in knitting industry can be met.

Owner:WENXING TEXTILE SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com