Double-layer circular-tube type axial-force eddy current damper

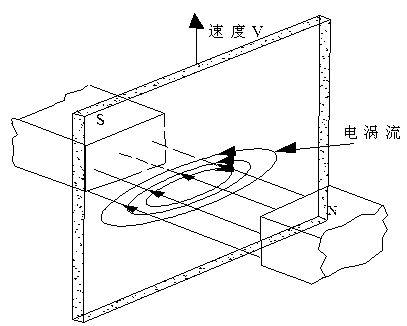

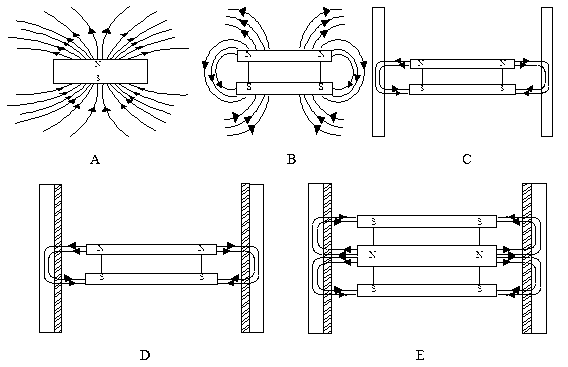

A technology of eddy current damping and round tube type, which is applied in the direction of magnetic spring, spring/shock absorber, spring, etc., to achieve the effect of simplified structure, large damping force and energy dissipation effect, and elimination of unfavorable constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

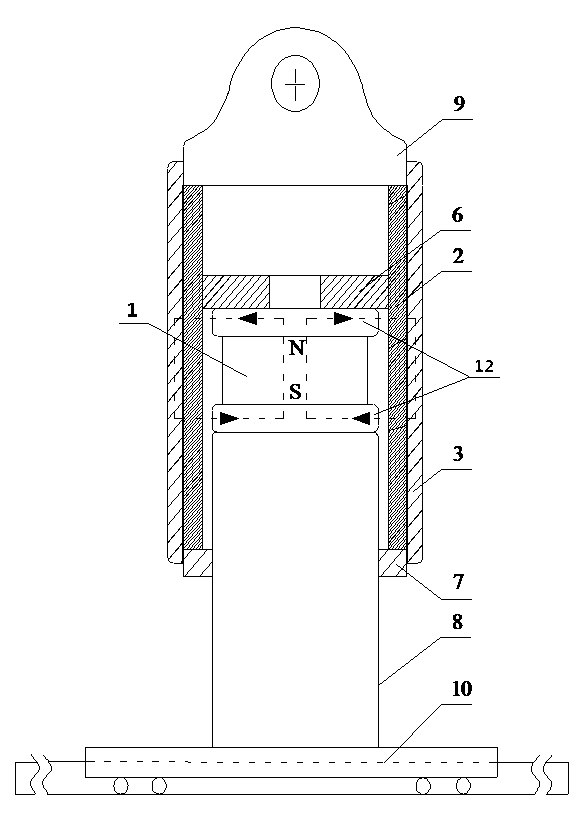

[0034] The basic structure of the present invention is: a double-layer cylindrical axial force-current eddy current damper, which includes an upper whole and a lower whole; the upper whole includes an inner circular tube 2, an outer circular tube 3 and a connecting piece 9, wherein The inner tube 2 and the outer tube 3 are nested to form a double-layered tube, and the upper end of the inner tube 2 is connected to the bottom of the connector 9; the lower part includes a circular magnet 1, a circular magnetic pole plate 12, a circular support The column 8 and the support 10, the upper and lower ends of the circular magnet 1 are fixedly covered with a circular magnetic pole plate 12 with an area larger than the circular magnet 1 and not in contact with the inner tube 2, and the circular magnetic pole plate 12 at the lower end is fixed on the circular support The top of the column 8, the support 10 and the bottom of the circular support column 8 are connected; a guide structure is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com