Silk spraying device with micro controller

A microcontroller and spinner technology, applied in spinneret assemblies, textiles and papermaking, etc., can solve problems such as poor silk quality, uneven pressure and heat transfer, easy to block spinneret holes, etc., and achieve reliable quality , low maintenance cost, simple and durable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0023] The purpose of the present invention is to provide a spinneret with a microcontroller, the user can freely replace the nozzle head with different specifications and shapes according to the needs of customers or the needs of the process, the structure is simple and durable, and the maintenance cost is low.

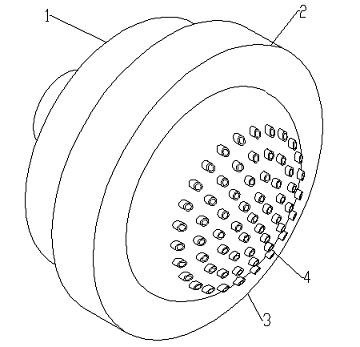

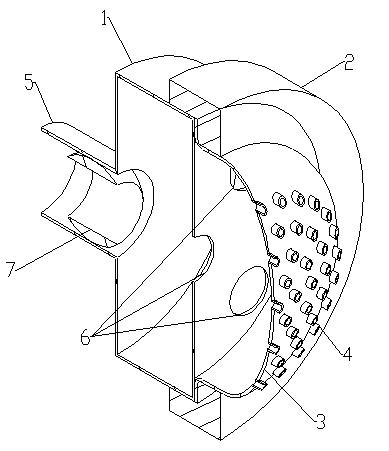

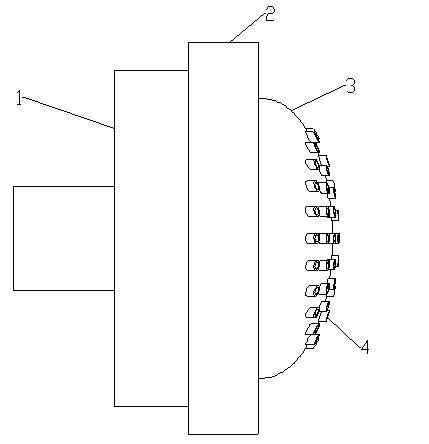

[0024] Such as figure 1 with figure 2 As shown, the spinneret with microcontroller of the present invention includes an injection part 1 for polymer injection, a spinneret 3 for spinning and an engaging part for connecting the injection part 1 and the spinneret 3 2. The left end of the injection part 1 contains a connecting pipe 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com