Automatic production line suitable for packaging magnetic shoes and realization method of automatic production line

An automatic production line and magnetic tile technology, applied in packaging, wrapping paper, shrinkage of wrapping paper, etc., can solve the problems of increased production cost, low production efficiency, and excessive floor space, and achieve simple and durable structure, improved production efficiency, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

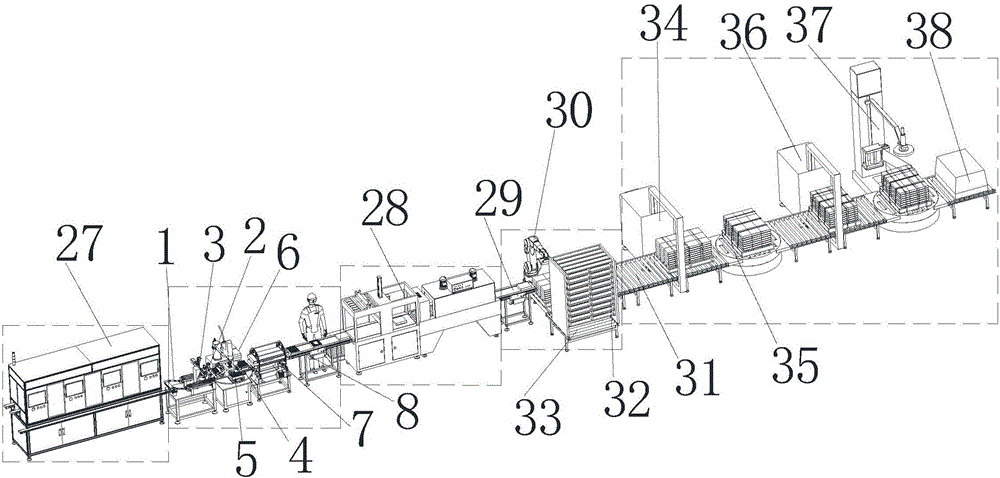

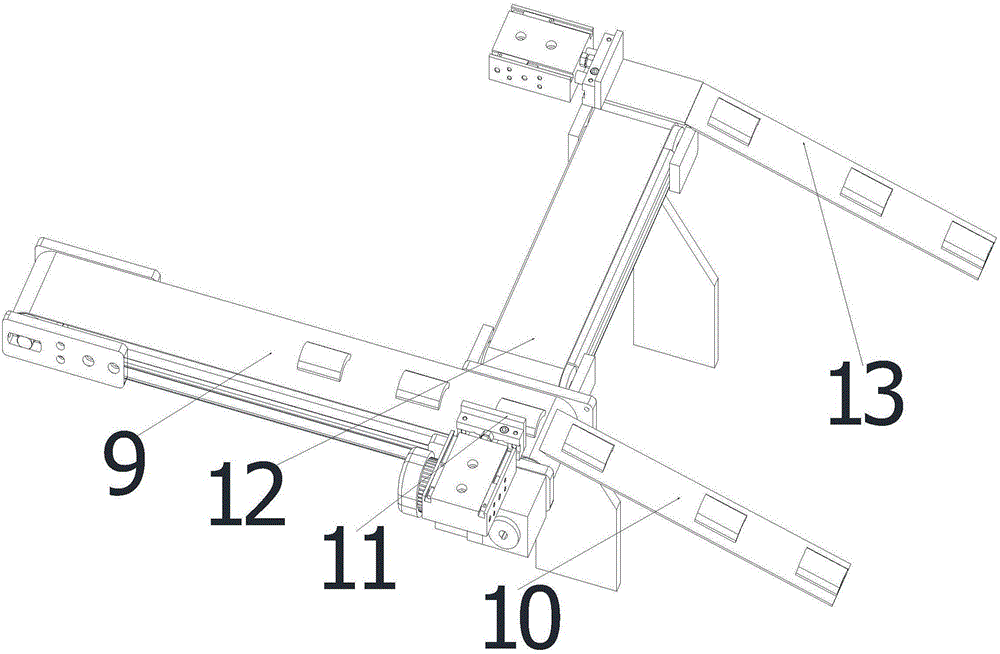

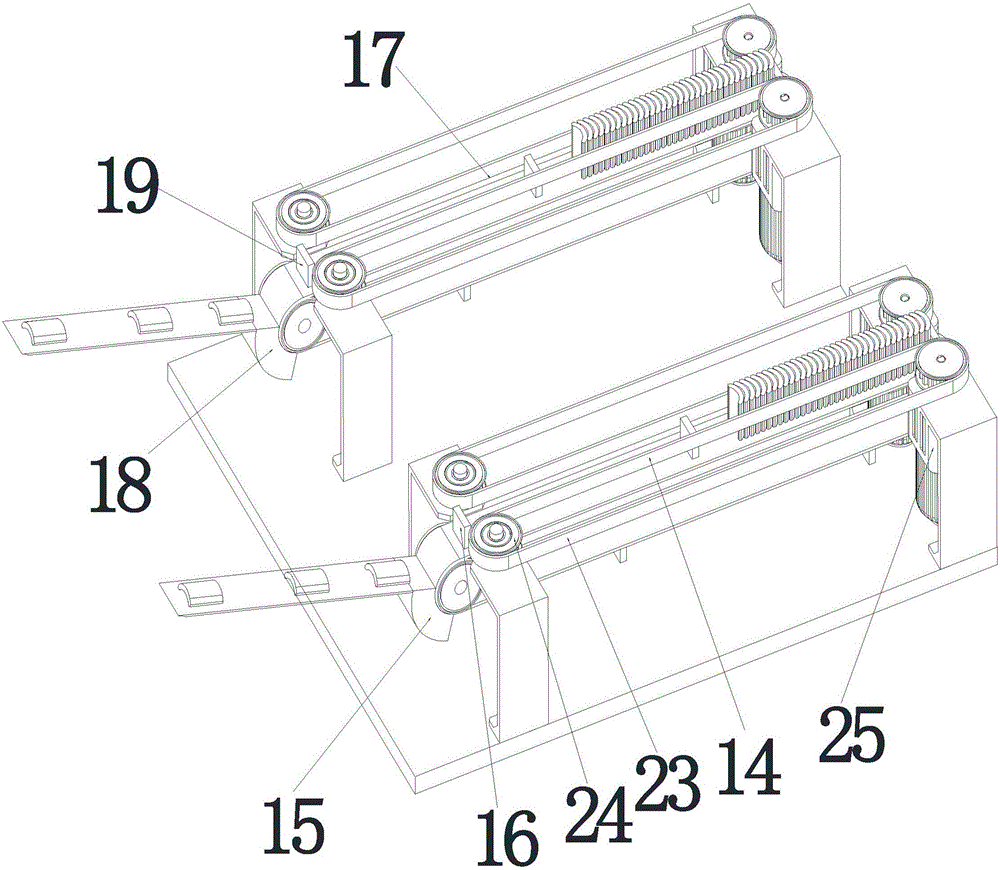

[0056] Such as Figure 1-8 As shown, an automatic production line suitable for magnetic tile packaging includes automatic appearance detection equipment, the automatic appearance detection equipment is connected to the magnetic tile shunting device, the magnetic tile shunting device is connected to the magnetic tile sorting device, and a moving device is arranged above the magnetic tile sorting device. Planting box manipulator, the transplanting boxing manipulator in this embodiment is a single-axis module, the manufacturer is SMC, the model is LEFS32A-500, LEYG16MA-100 and LEJS63S2A-500, to achieve linkage, the outlet end of the magnetic tile finishing device is set There is a magnetic tile arrangement device, and a placement robot is installed on the side of the magnetic tile arrangement device. The placement robot in this embodiment is a four-axis robot, the manufacturer is Yamaha, and the model is YK800X200. The side of the placement robot is a crate supply mechanism. This ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com