Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Shorten light-off time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

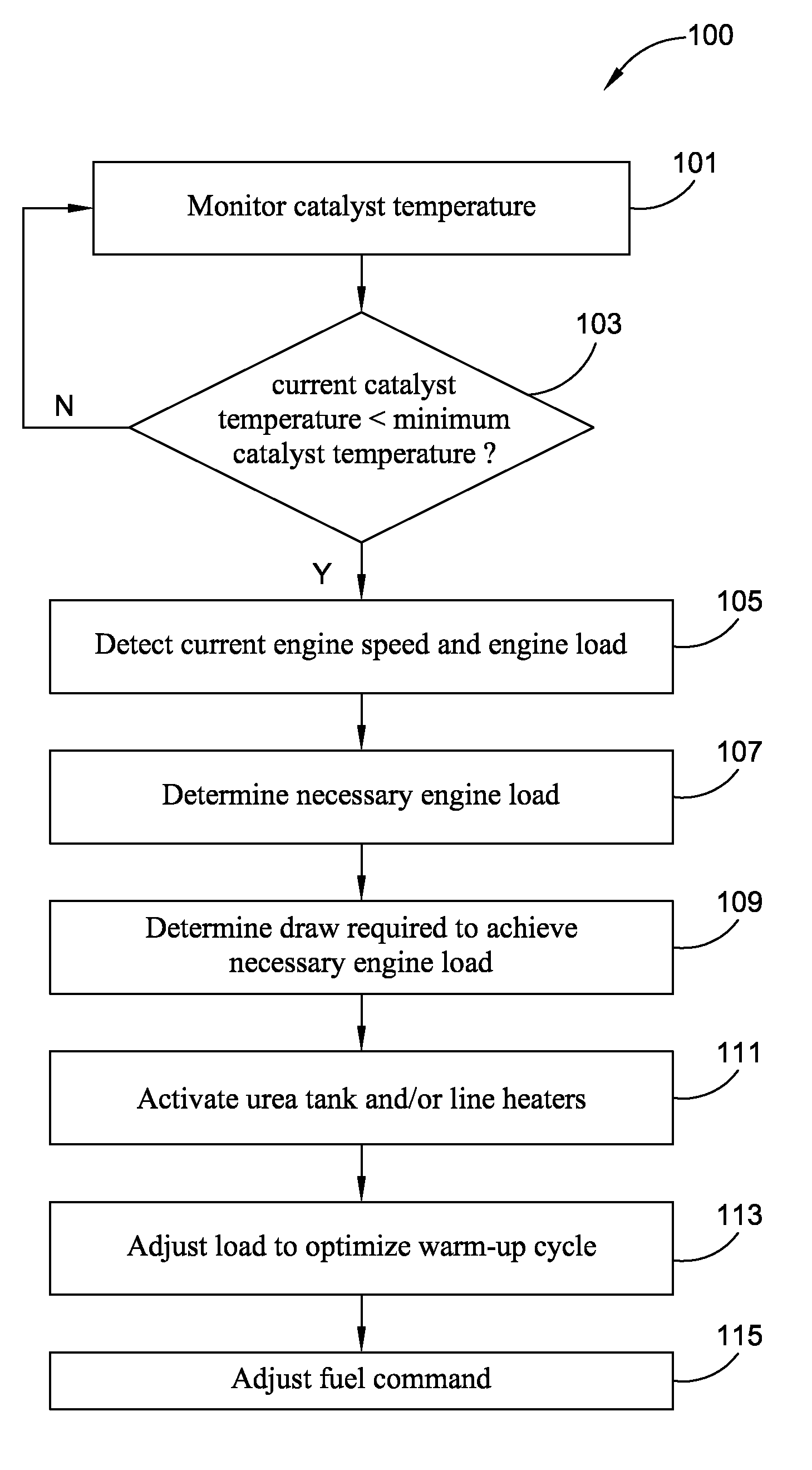

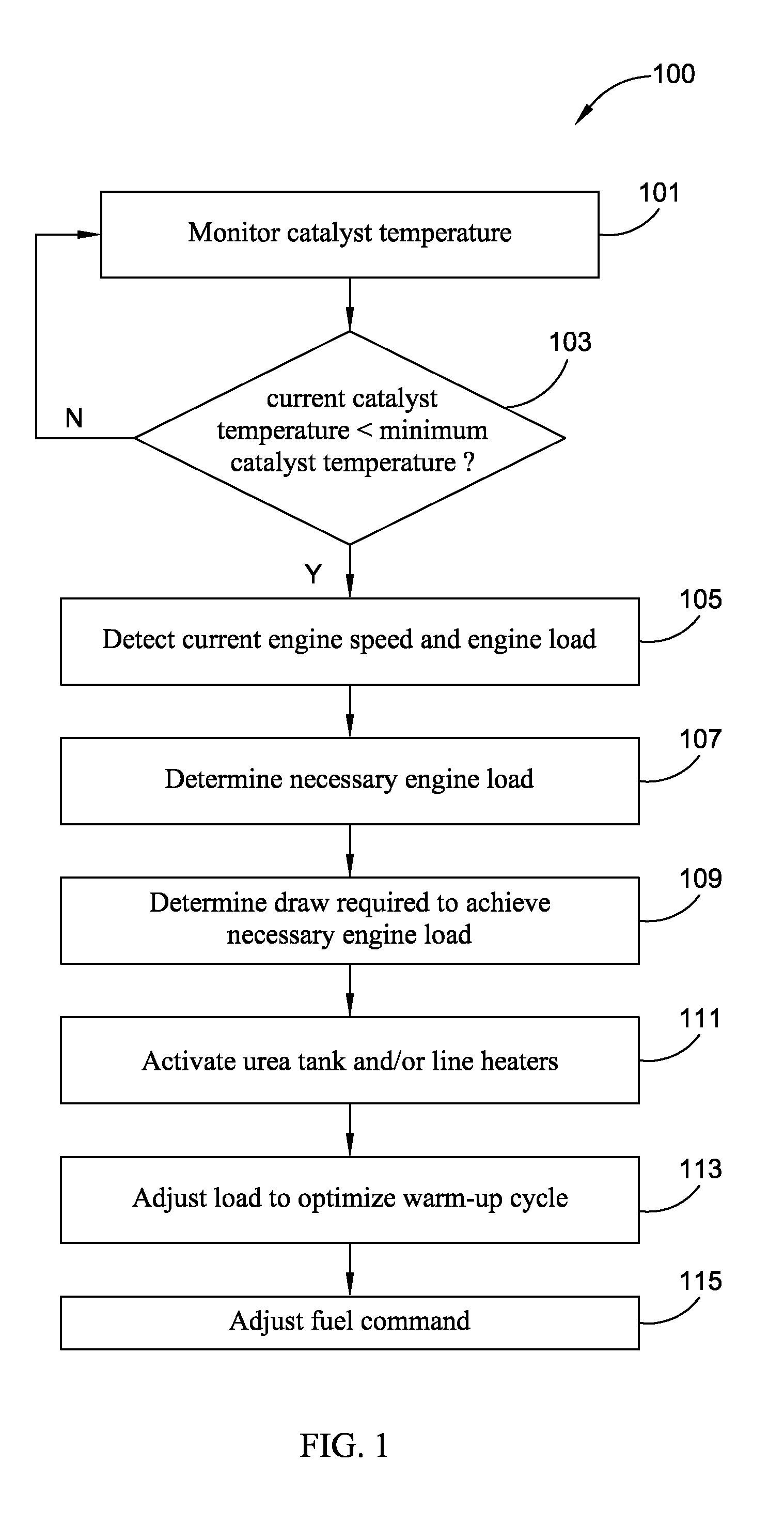

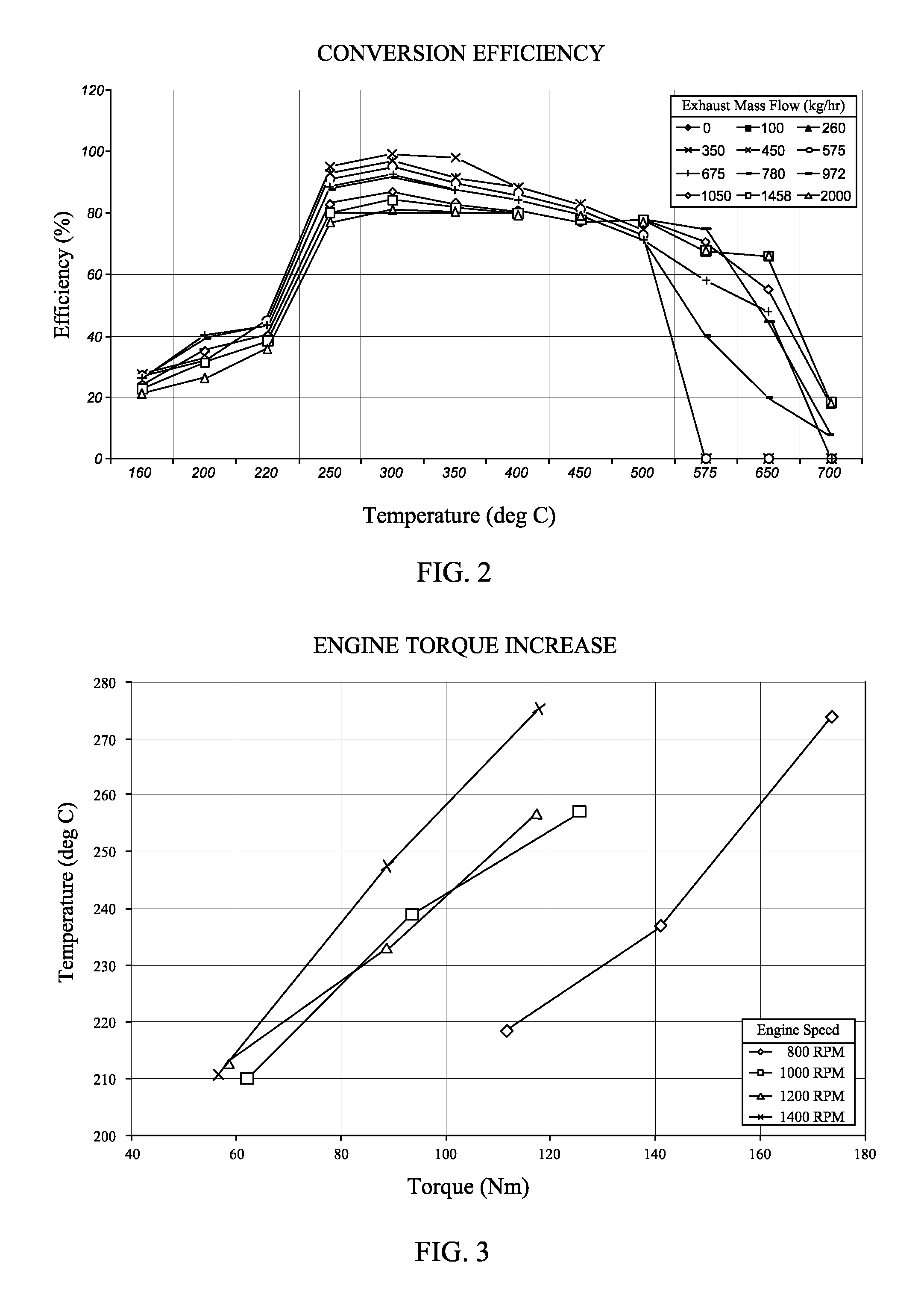

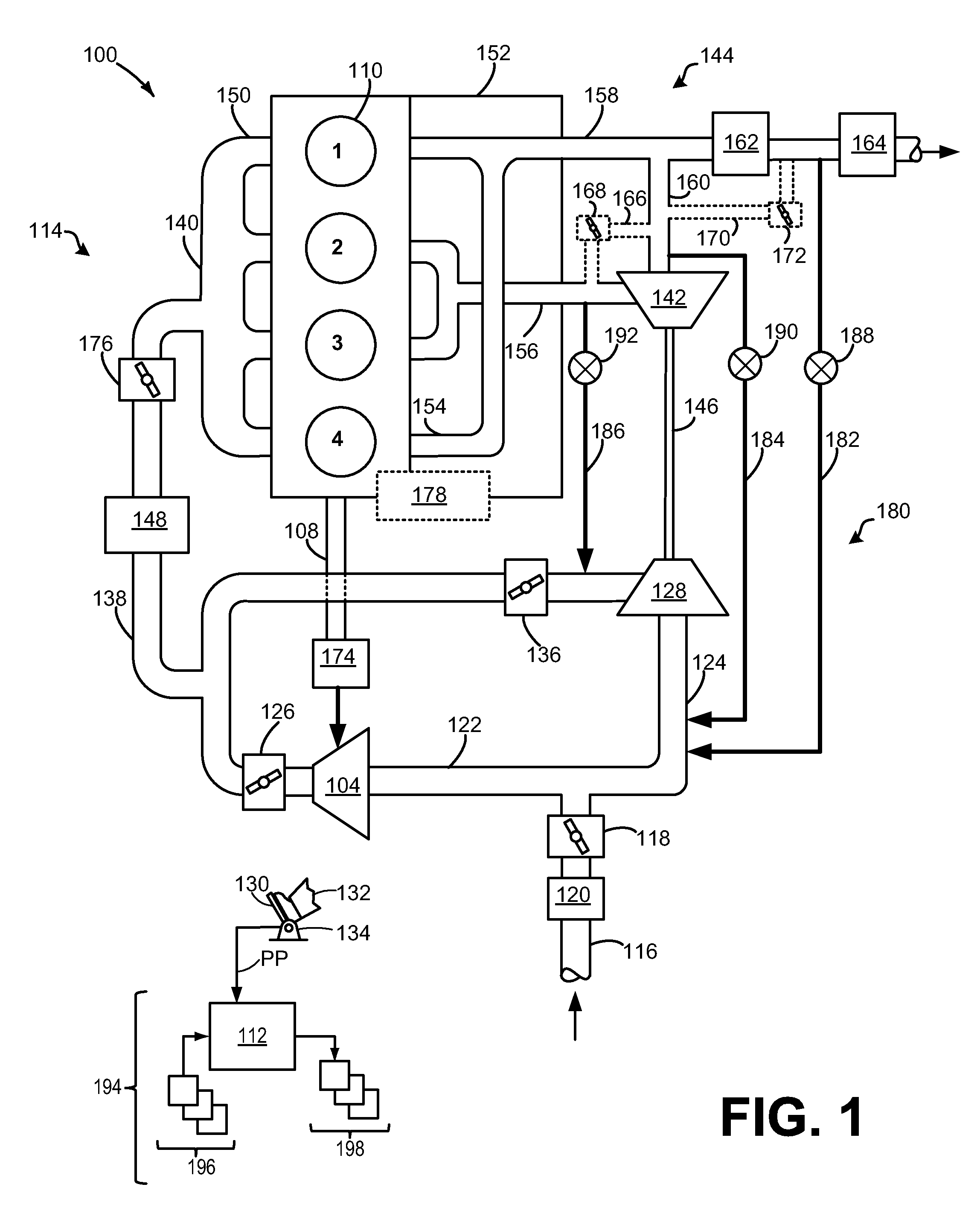

Cold-start engine loading for accelerated warming of exhaust aftertreatment system

InactiveUS20100122523A1Shorten light-off timeReduce nitrogen oxide emissionsInternal combustion piston enginesExhaust apparatusEngineeringLine heating

The methods of the present invention are adapted to adjust engine loading during catalyst warm up to accelerate heating of the exhaust aftertreatment system and thereby decrease catalyst light-off times. According to a preferred embodiment of the present invention, the method includes: monitoring the current catalyst temperature; determining if the current catalyst temperature is less than a predetermined minimum catalyst temperature; and, if the current catalyst temperature is less than the predetermined minimum catalyst temperature, increasing the current engine load. The current engine load is increased by activating a reducing agent tank heating device and / or a reducing agent line heating device.

Owner:GM GLOBAL TECH OPERATIONS LLC

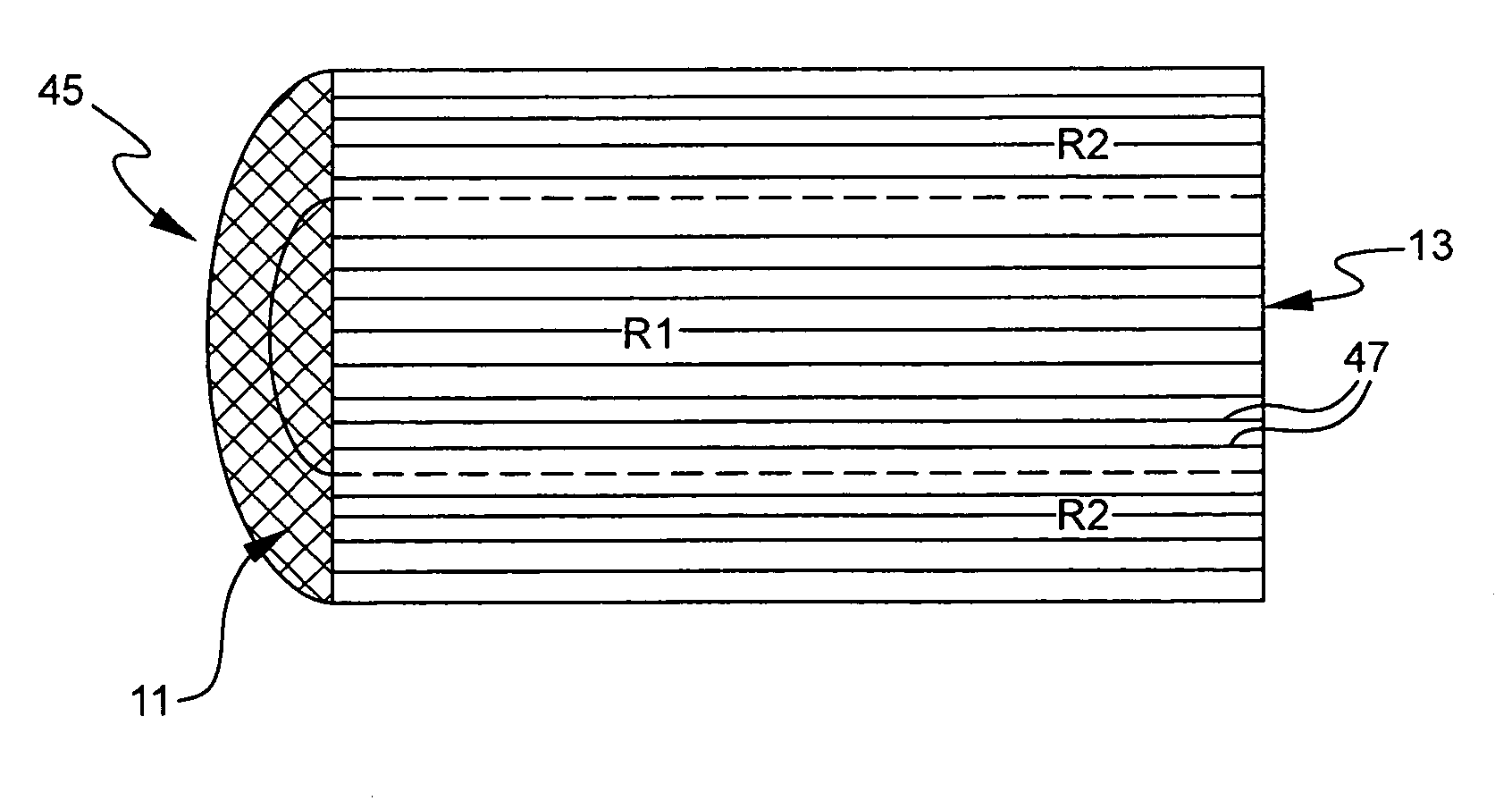

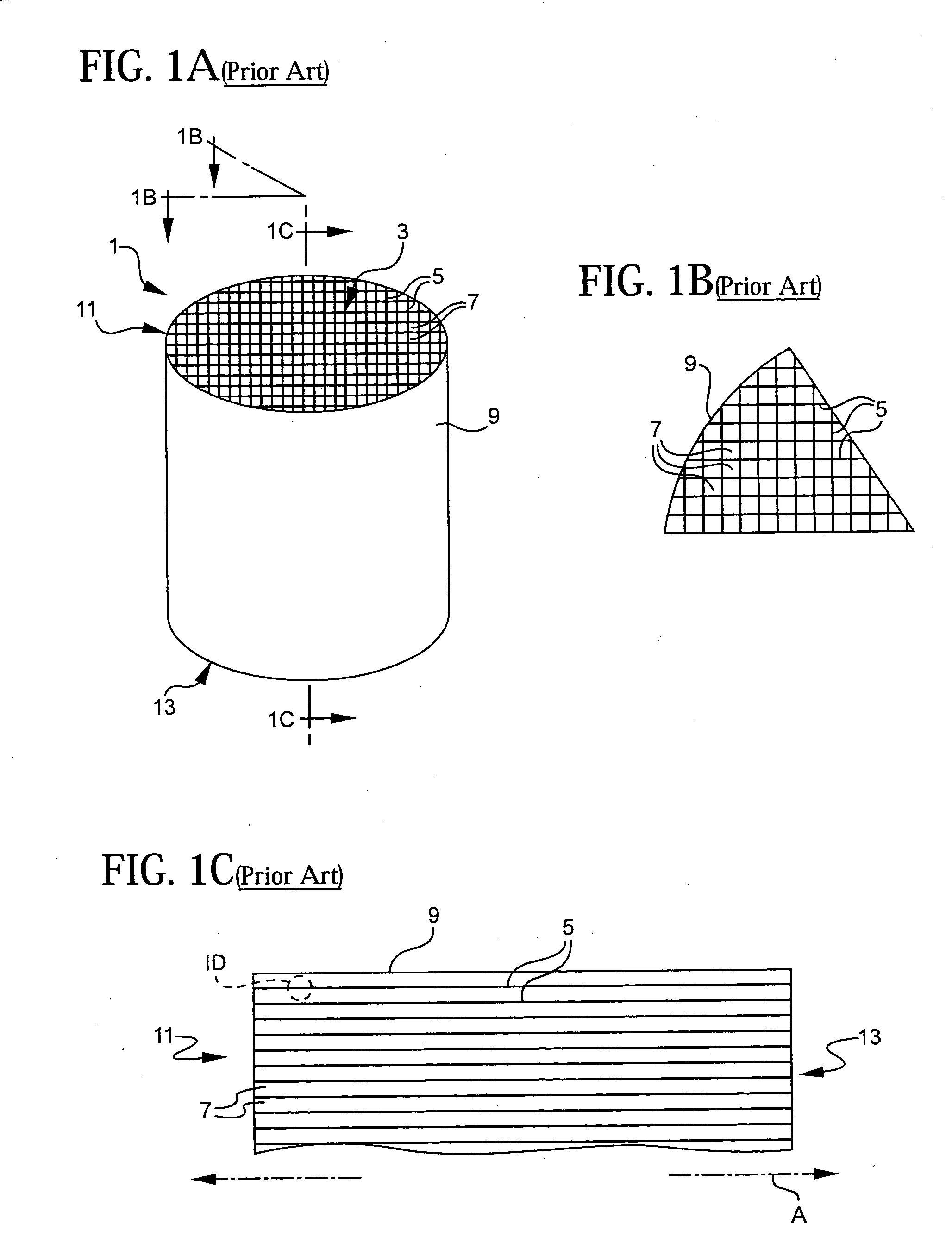

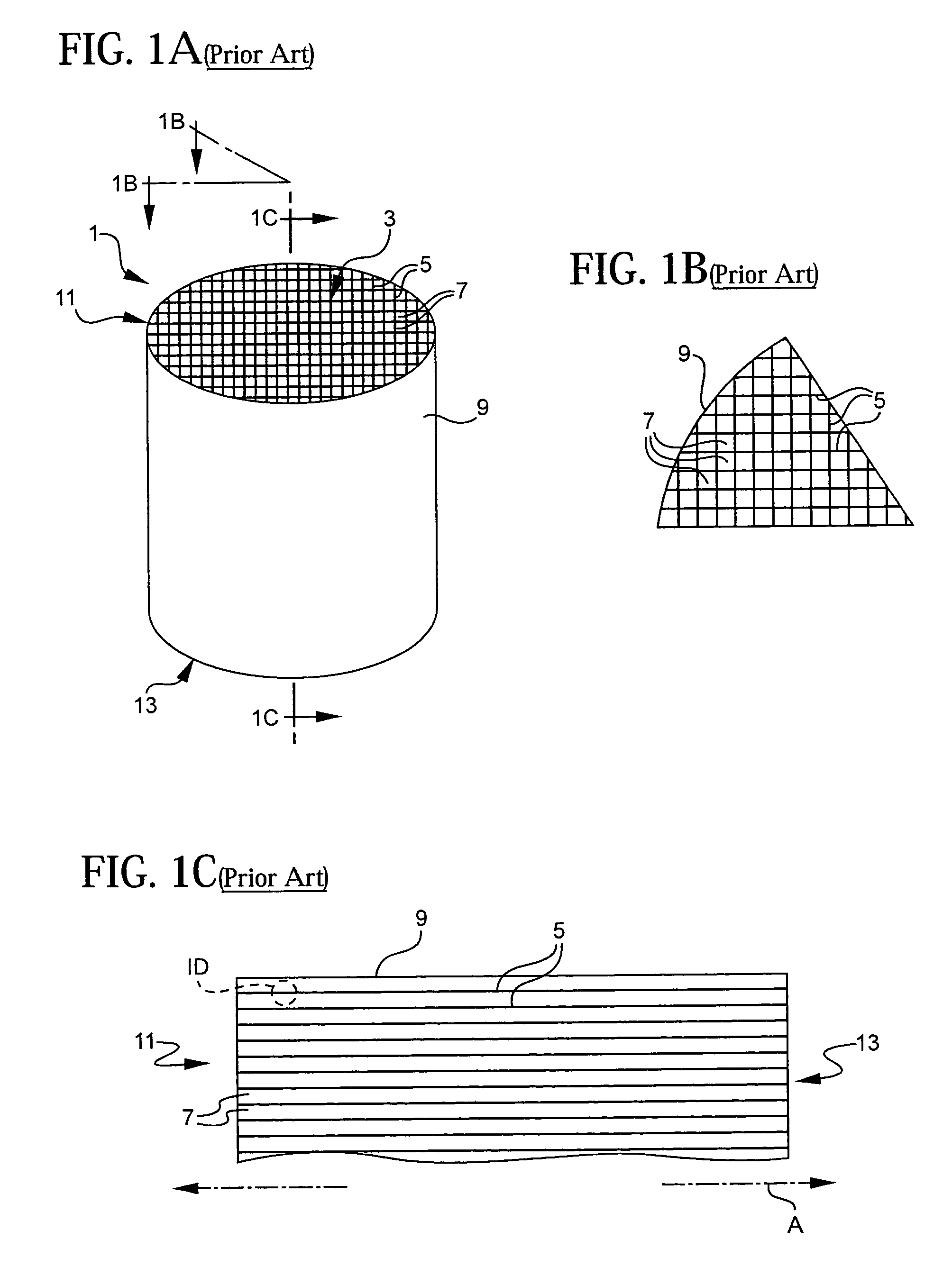

Catalytic flow-through fast light off ceramic substrate and method of manufacture

ActiveUS20070238256A1Quality improvementIncreasing the thicknessCombination devicesInternal combustion piston enginesFlow through cellCooling down

A fast light off flow-through ceramic substrate is provided that is particularly adapted for use as a catalytic converter. The substrate is formed from a body of ceramic material having axially opposing inlet and outlet ends for receiving and expelling the flow of automotive exhaust gas, respectively. The body contains a network of walls coated with a catalyst that define axially-oriented flow-through cell channels. The average thermal mass (ATM1) of a first axial region of the walls adjacent to the inlet end is at least 20% less than the average thermal mass (ATMTOT) of all of the walls. The lower average thermal mass of the walls in the first region advantageously shortens the light off time for the catalyst within the substrate to effectively neutralize automotive pollutants. The reduction of the average thermal mass in only the first axial region of the walls advantageously maintains the strength of the resulting body of ceramic material, and further increases the cool down time of the body.

Owner:CORNING INC

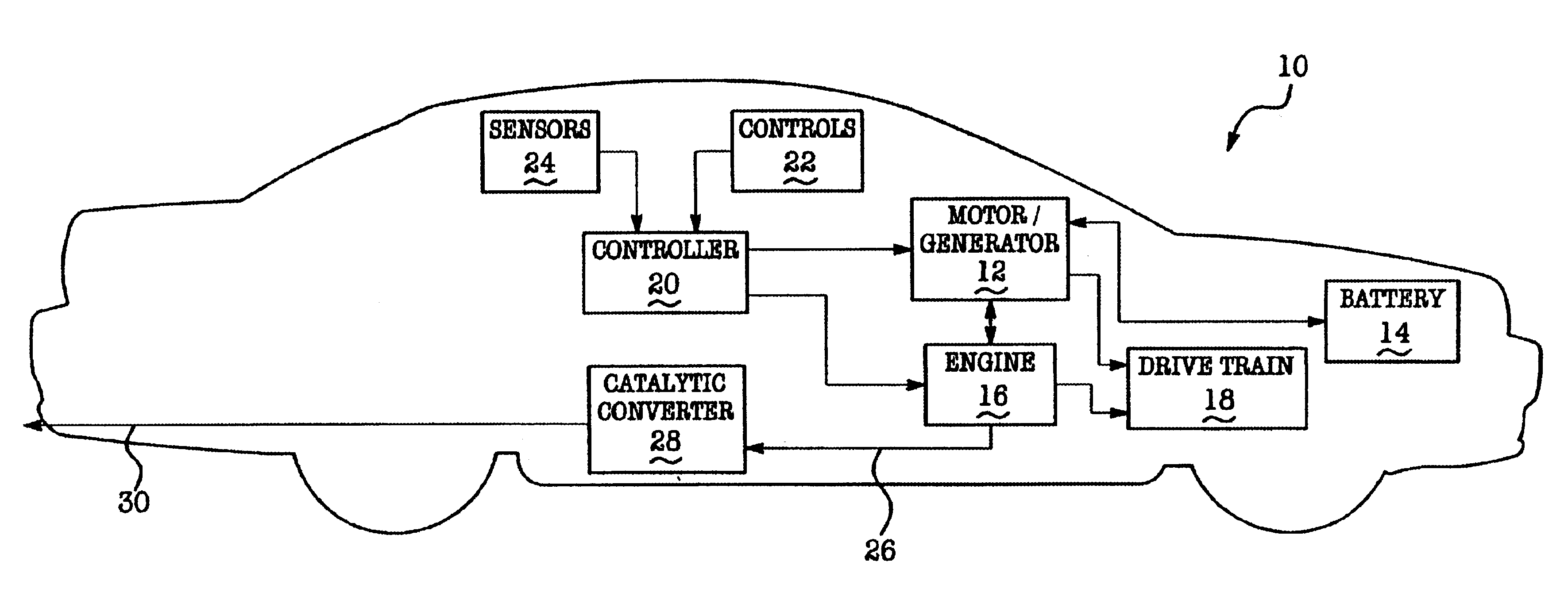

Method of operating a hybrid electric vehicle to reduce emissions

InactiveUS6856034B2Emission reductionReduce power outputElectrical controlInternal combustion piston enginesElectric vehicleElectric generator

A method of operating a hybrid electric vehicle 10 to reduce emissions. The method utilizes the vehicle's electric motor / generator 12 to generate a negative torque during cold-start conditions, effective to increase the load on the internal combustion engine 16, thereby reducing the light-off time of the catalytic converter 28. The method also reduces emissions by utilizing the vehicle's motor / generator 12 to provide a supplemental torque to engine 16 during transient events, thereby reducing the generated mass flow and amount of untreated emissions.

Owner:FORD GLOBAL TECH LLC

Catalytic flow-through fast light off ceramic substrate and method of manufacture

ActiveUS7722827B2Quality improvementIncreasing the thicknessCombination devicesInternal combustion piston enginesFlow through cellCooling down

A fast light off flow-through ceramic substrate is provided that is particularly adapted for use as a catalytic converter. The substrate is formed from a body of ceramic material having axially opposing inlet and outlet ends for receiving and expelling the flow of automotive exhaust gas, respectively. The body contains a network of walls coated with a catalyst that define axially-oriented flow-through cell channels. The average thermal mass (ATM1) of a first axial region of the walls adjacent to the inlet end is at least 20% less than the average thermal mass (ATMTOT) of all of the walls. The lower average thermal mass of the walls in the first region advantageously shortens the light off time for the catalyst within the substrate to effectively neutralize automotive pollutants. The reduction of the average thermal mass in only the first axial region of the walls advantageously maintains the strength of the resulting body of ceramic material, and further increases the cool down time of the body.

Owner:CORNING INC

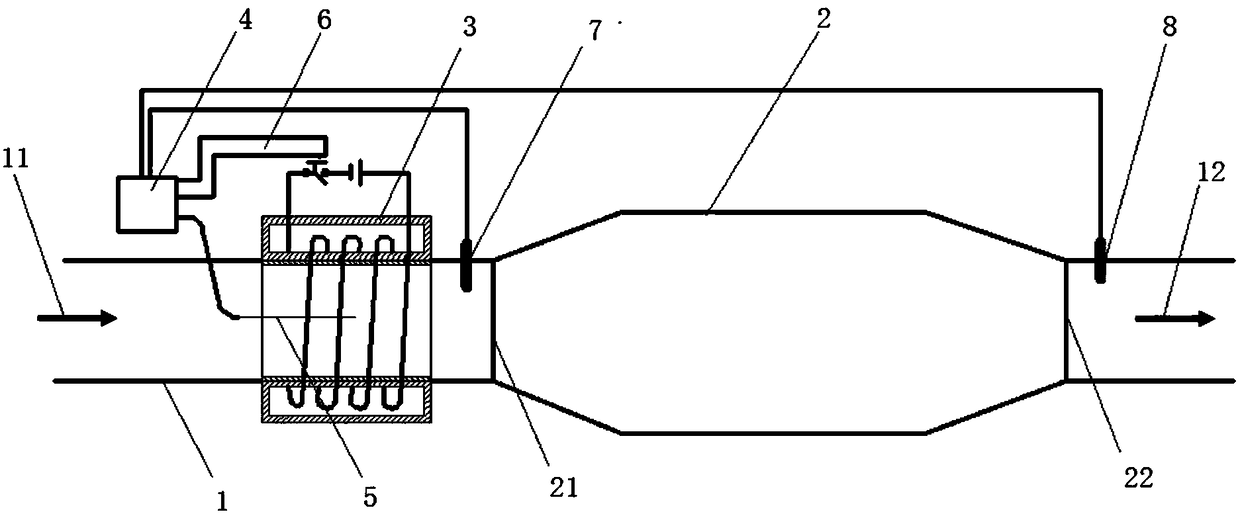

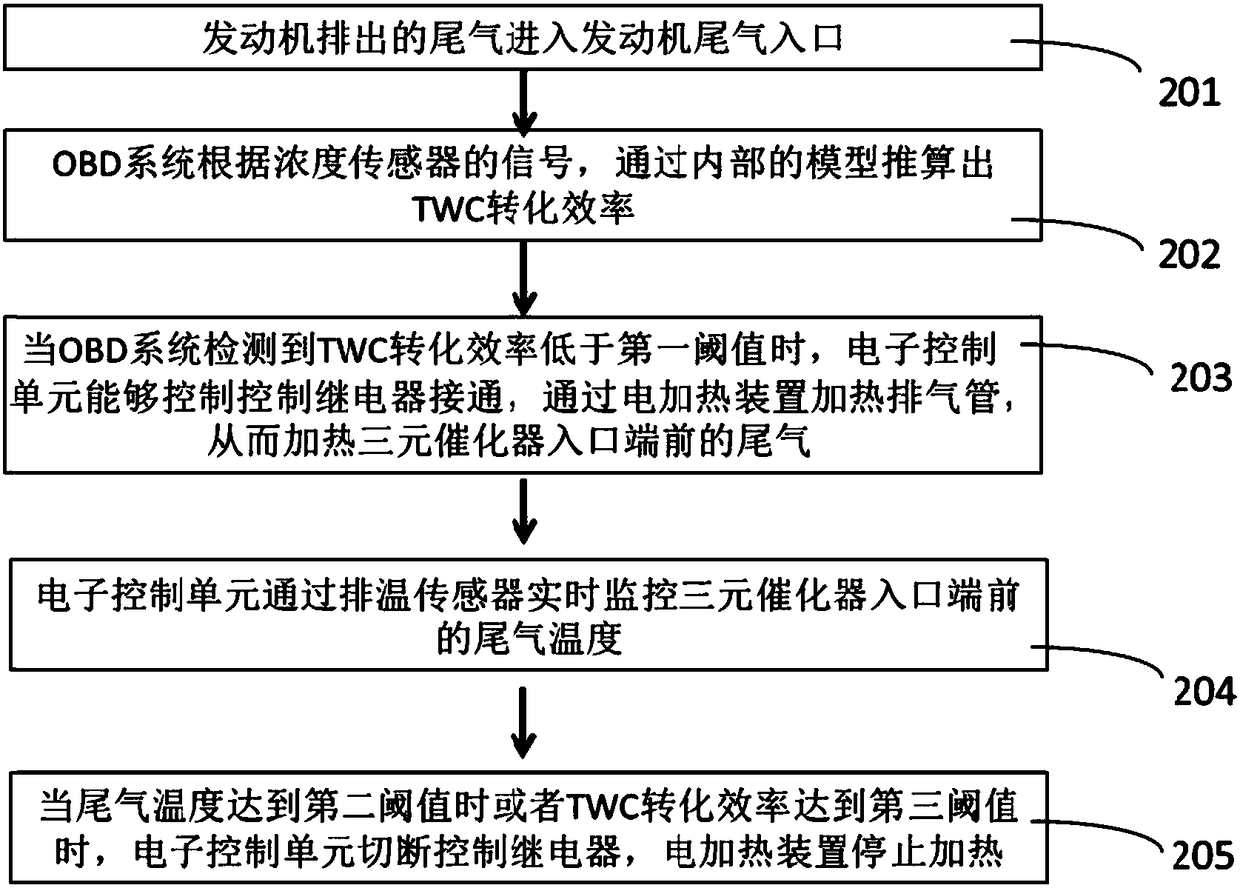

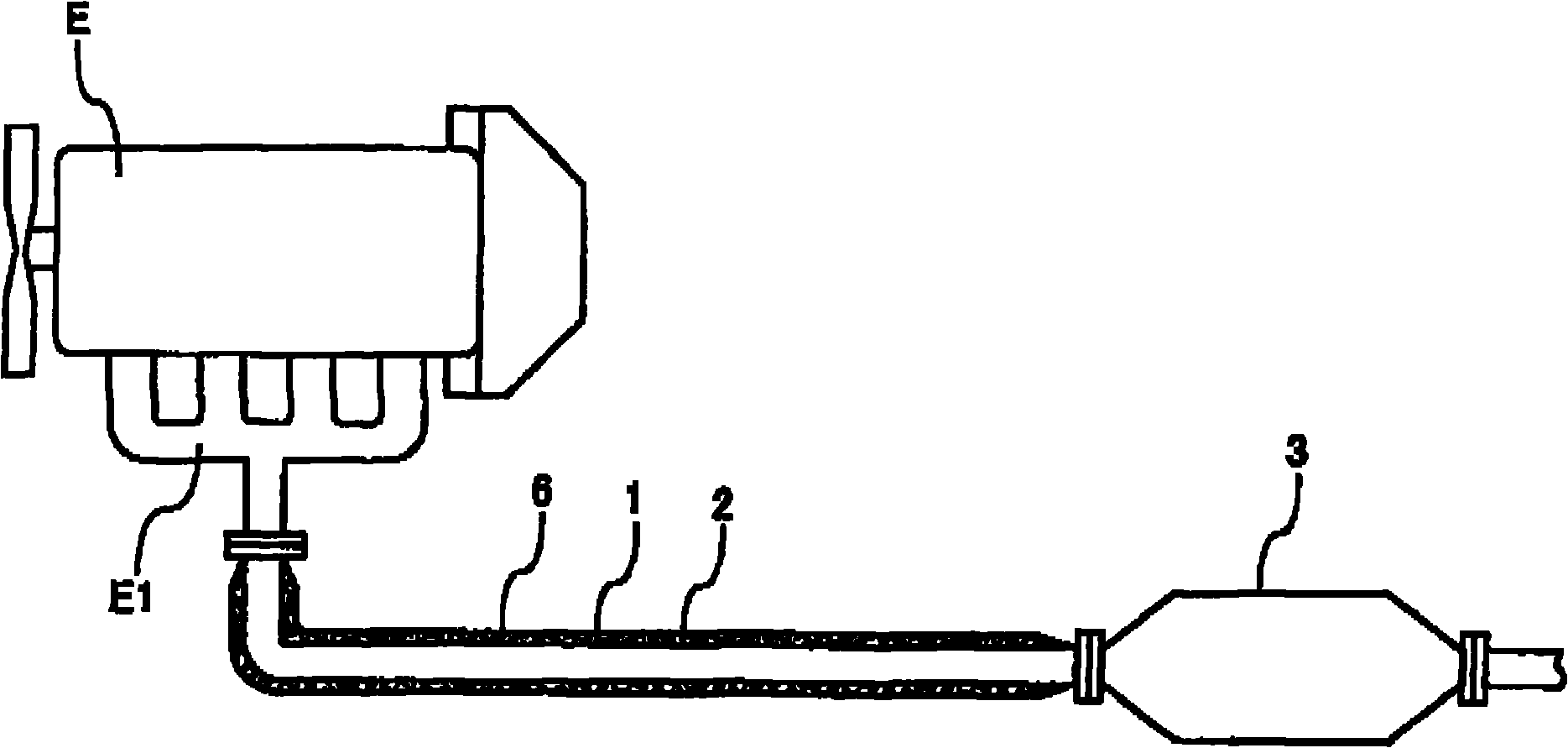

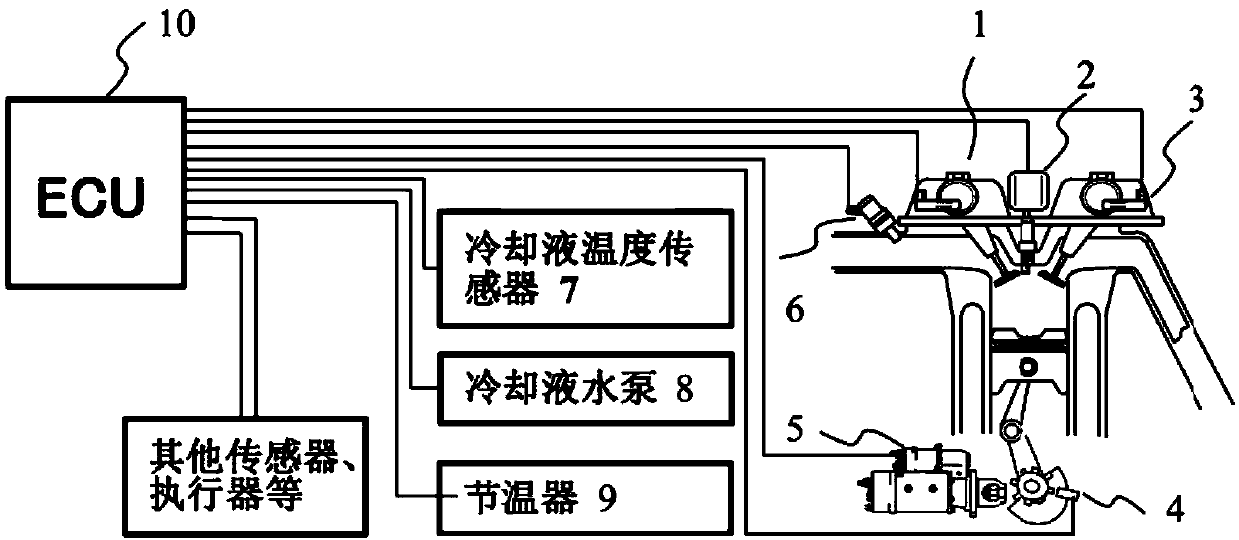

Device and method for controlling inlet temperature of three-way catalytic converter according to OBD monitoring efficiency

ActiveCN108590827ARaise the inlet temperatureShorten light-off timeInternal combustion piston enginesExhaust apparatusElectricityElectronic control system

The invention discloses a device and method for controlling the inlet temperature of a three-way catalytic converter according to OBD monitoring efficiency. The device comprises an exhaust pipe, a three-way catalytic converter, an electric heating device and an engine electronic control system, wherein the exhaust pipe comprises an engine exhaust gas inlet end; the inlet end of the three-way catalytic converter is connected with the engine exhaust gas inlet end; the electric heating device is arranged at the outer part of the exhaust pipe, distributed close to the inlet end of the three-way catalytic converter and used for heating exhaust gas before the inlet end of the three-way catalytic converter; and the engine electronic control system comprises an electronic control unit, an OBD system, an exhaust temperature sensor, a concentration sensor and a control relay, wherein the electronic control unit is separately electrically connected with the exhaust temperature sensor, the controlrelay and front and rear oxygen sensors, and the electronic control unit can control the working state of the electric heating device by controlling the connection and disconnection of the control relay. According to the device, the inlet temperature of the three-way catalytic converter can be raised in the cold starting and machine heating process of the engine, and the converting efficiency ofthe three-way catalytic converter is increased.

Owner:GUANGXI YUCHAI MASCH CO LTD

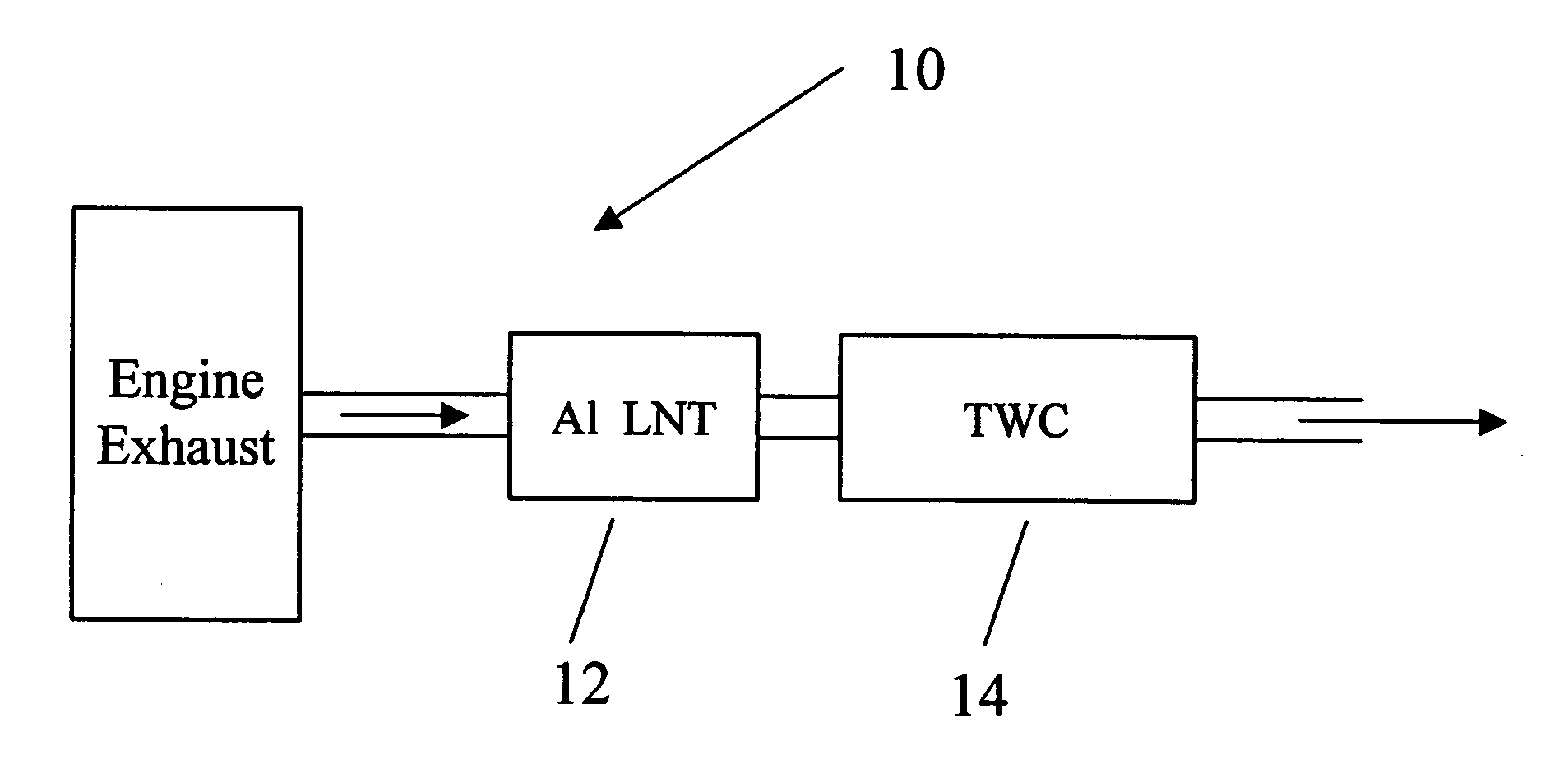

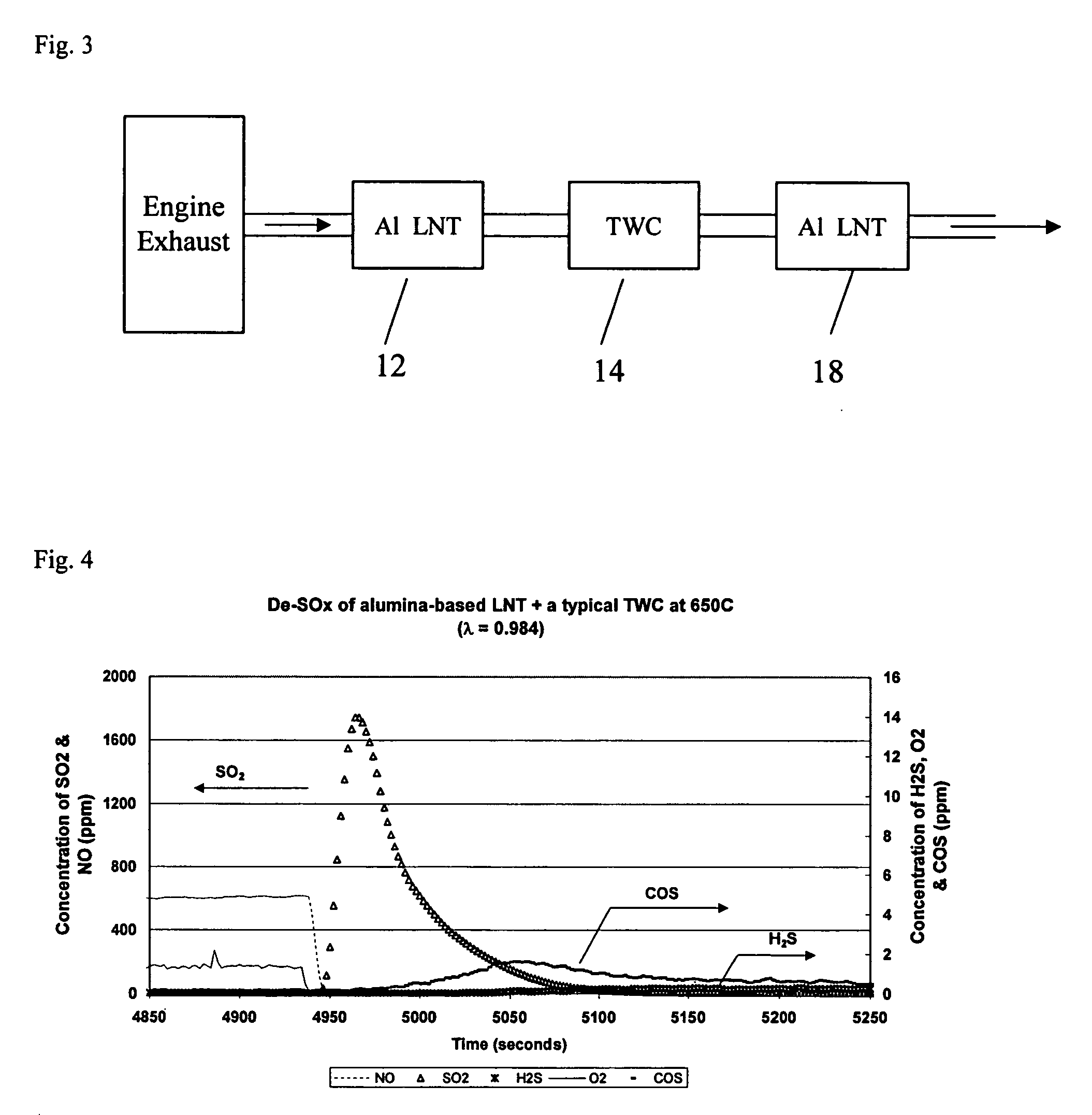

Alumina-based lean NOx trap system and method of use in dual-mode HCCI engines

InactiveUS20060168949A1Efficient desulfurizationEasy to useElectrical controlInternal combustion piston enginesDual modeAbsorbent material

An alumina-based lean NOx trap system for use in a HCCI engine exhaust is provided which includes at least one alumina-based lean NOx trap comprising a catalyst, an alumina NOx absorbent material, and optionally, from 0 to about 4 wt % of an alkaline earth metal oxide; and a conventional three-way catalyst. The lean NOx trap system substantially oxidizes HC and CO and converts at least a portion of NOx contained in the exhaust gas to N2 at a temperature between about 150° C. to about 250° C. in HCCI mode. The system also effectively removes HC, CO and NOx at high temperature when the engine is in SI mode (stoichiometric conditions). The alumina-based lean NOx trap in the system also undergoes efficient desulphurization and maintains its activity with extended use.

Owner:FORD GLOBAL TECH LLC

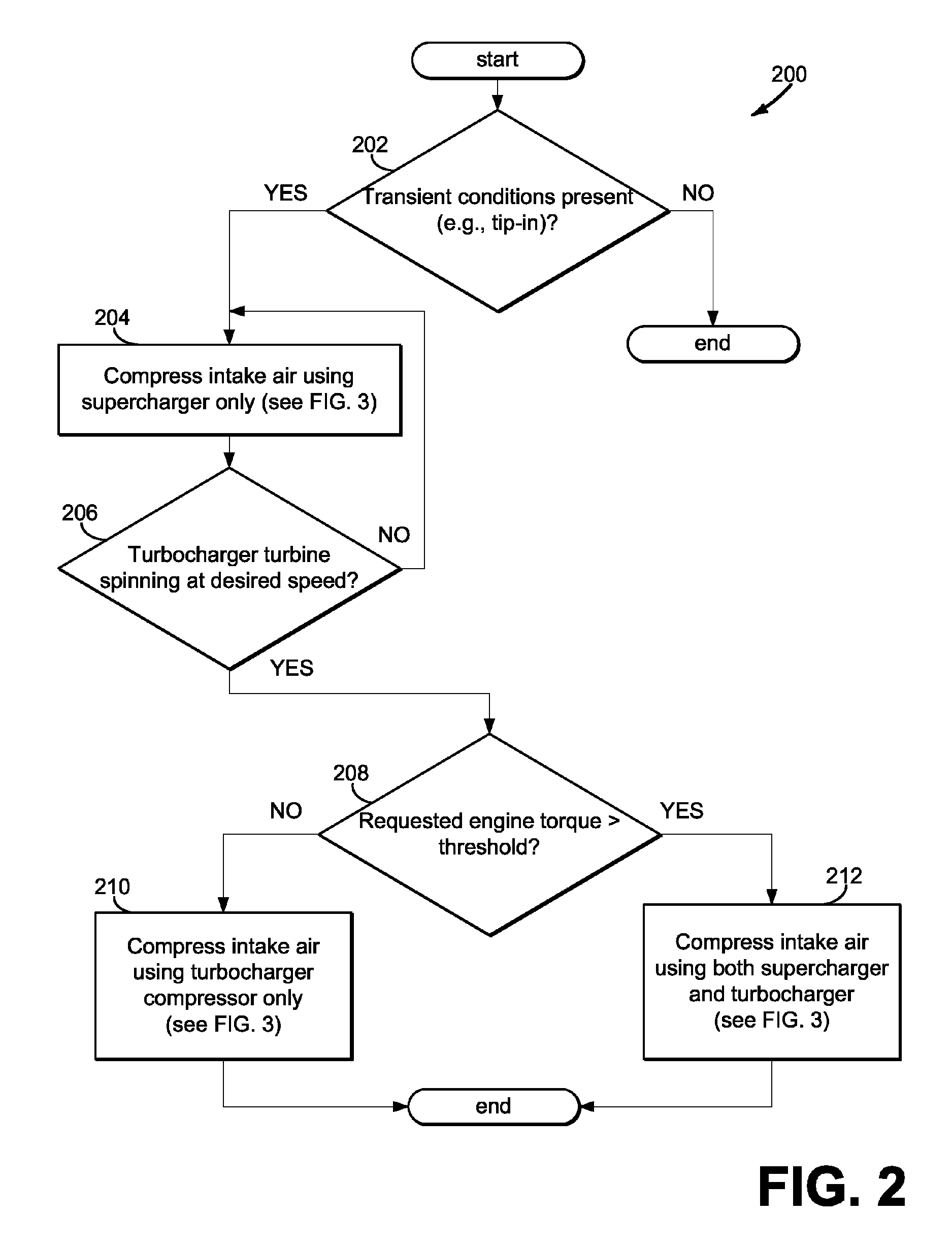

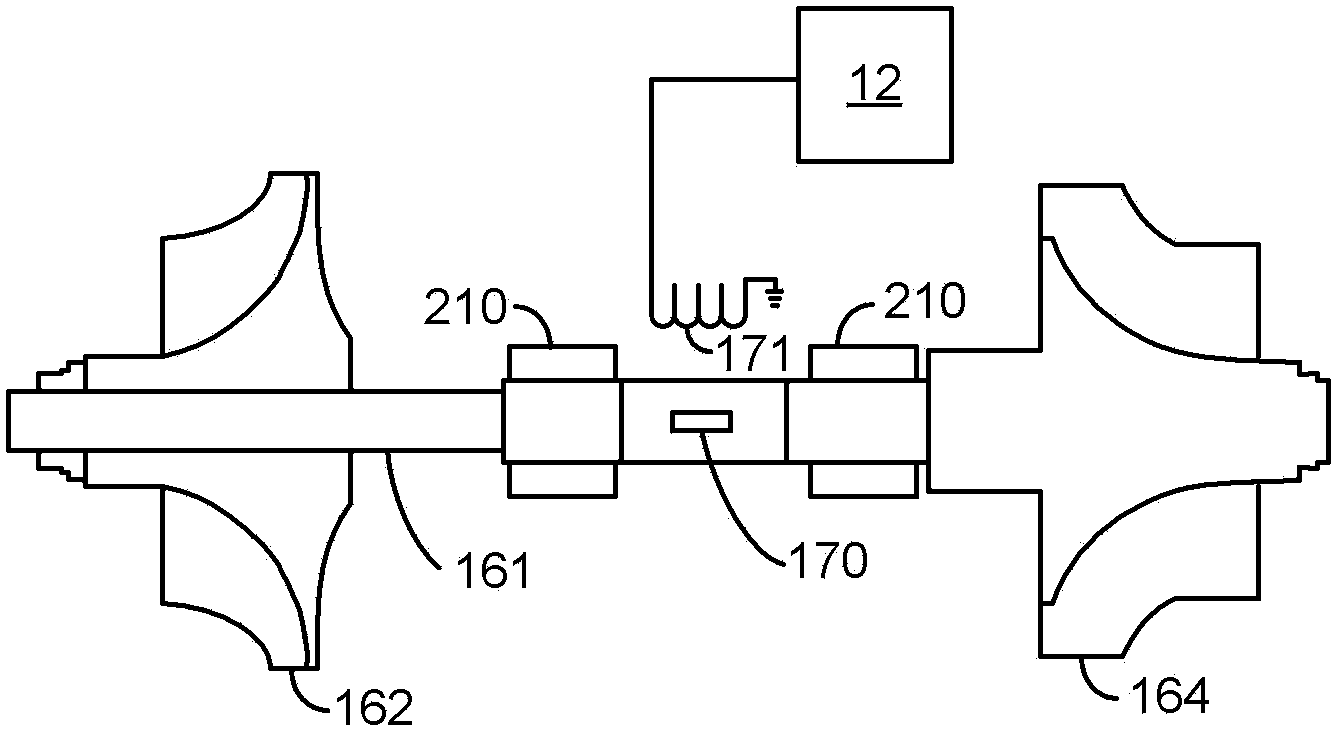

Twin independent boosted I4 engine

ActiveUS9157363B2Extended durationWork lessElectrical controlInternal combustion piston enginesTurbochargerCylinder block

Owner:FORD GLOBAL TECH LLC

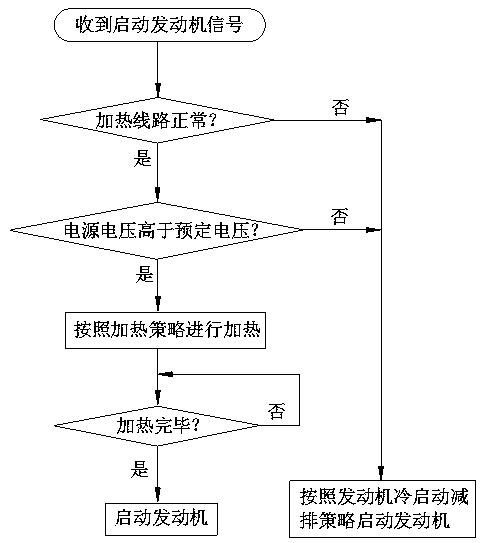

Control method for engine electric heating type catalytic converter

ActiveCN109611182AElectric heating improvementIncrease temperatureExhaust apparatusSilencing apparatusElectricityGas emissions

The invention provides a control method for an engine electric heating type catalytic converter. The control method is used for accelerating rapid ignition of a catalyst of a vehicle engine in a coldstart stage and a cold machine stage, so that reasonable and effective control over gas emission is achieved. The control method comprises the following steps that an engine control unit controls a power supply of the electric heating type catalytic converter to be on or off through a relay, and when electric heating is required, the engine control unit performs instrument checking according to the start and stop condition of the engine to control the electric heating time of the electric heating type catalytic converter. After receiving a signal for starting the engine, the engine control unit firstly determines either start this time is cold machine start or warm machine start, if the startup is cold machine start, the engine control unit checks a preset cold machine electric heating instrument based on the ambient temperature and outputs the corresponding time length of the electric heating of the catalytic converter; and if startup this time is warm machine startup, the engine control unit checks a warm machine electric heating instrument based on the engine down time and the ambient temperature and outputs the corresponding time length of electric heating of the catalytic converter.

Owner:CHERY AUTOMOBILE CO LTD

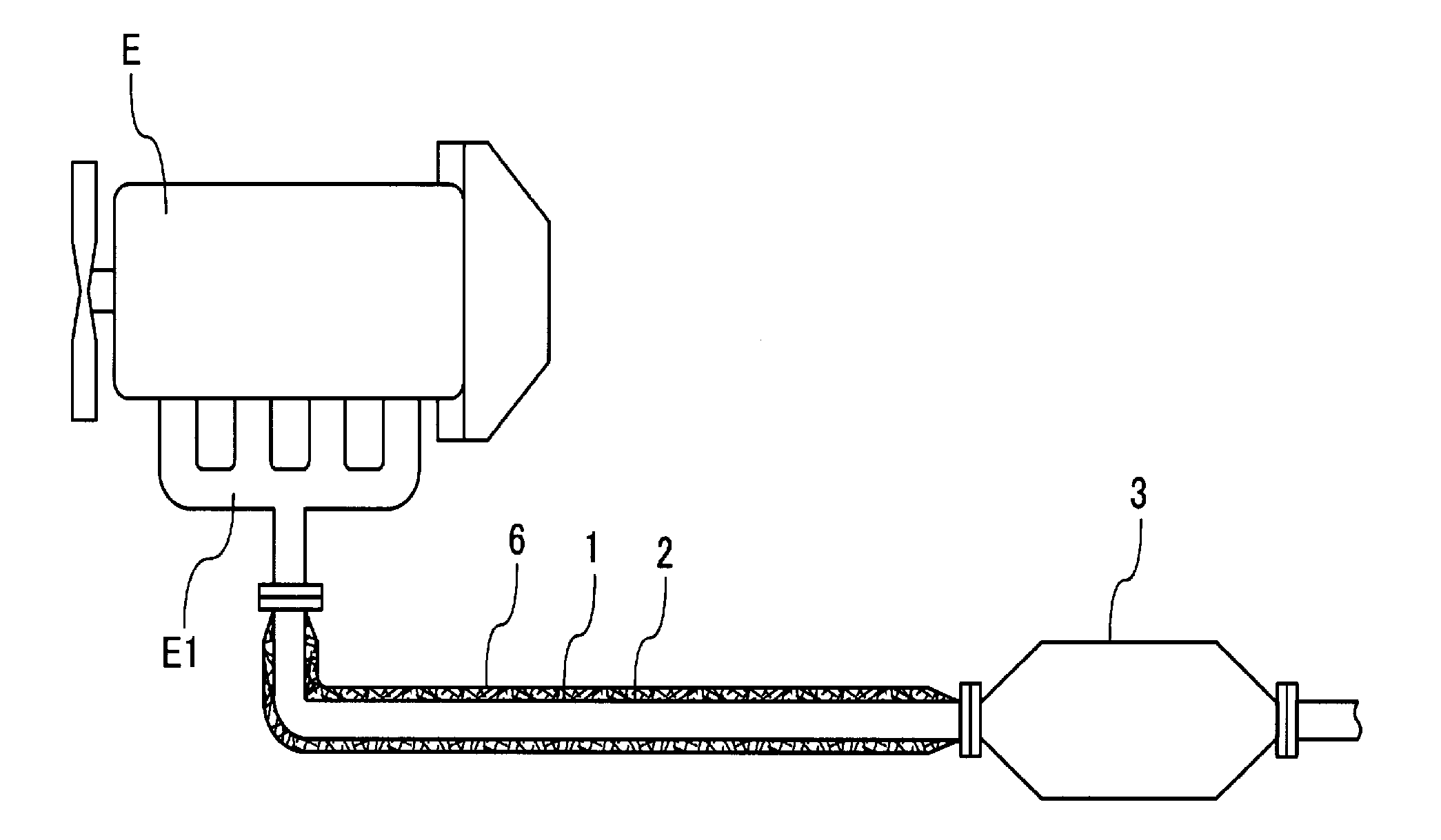

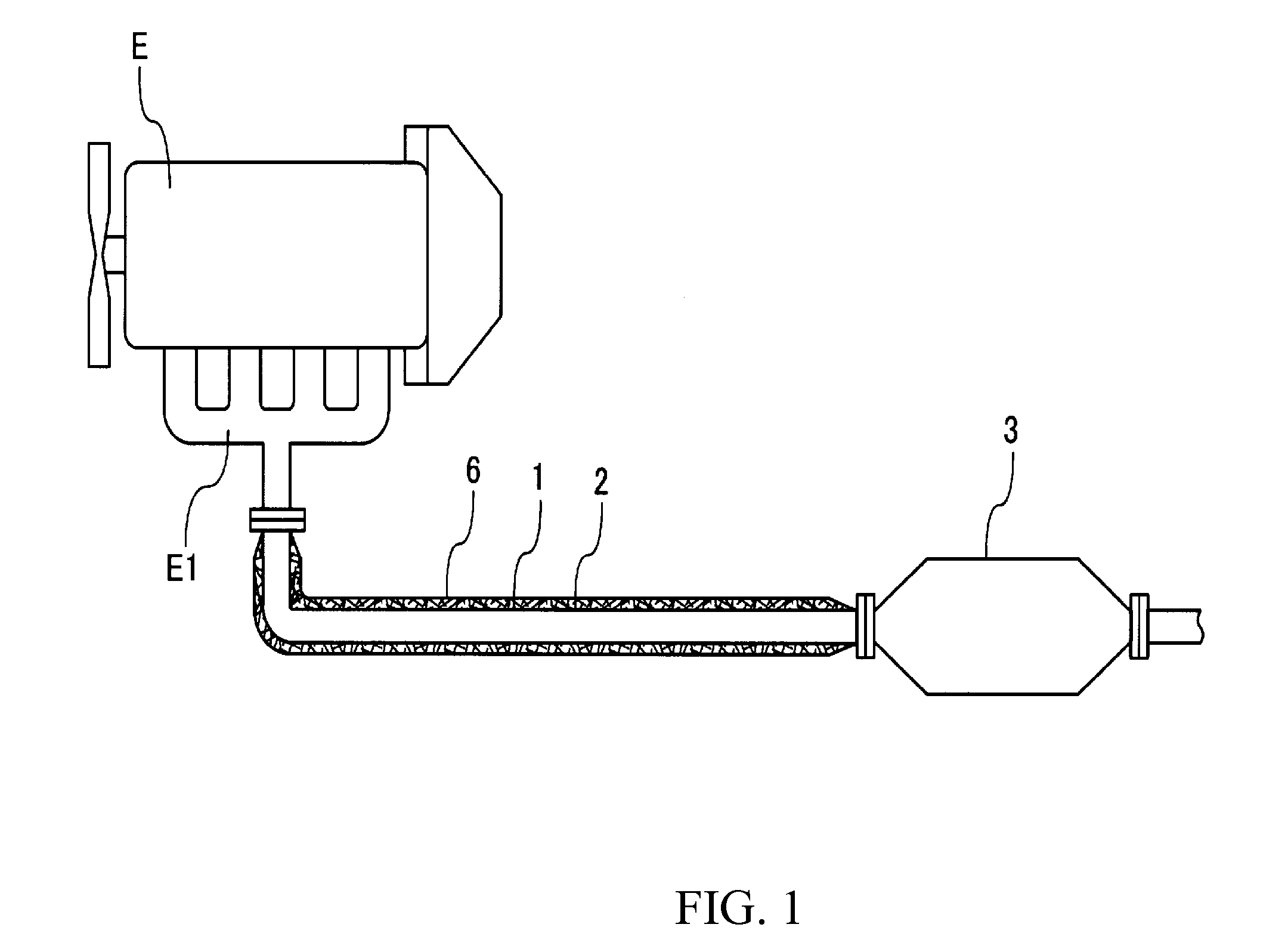

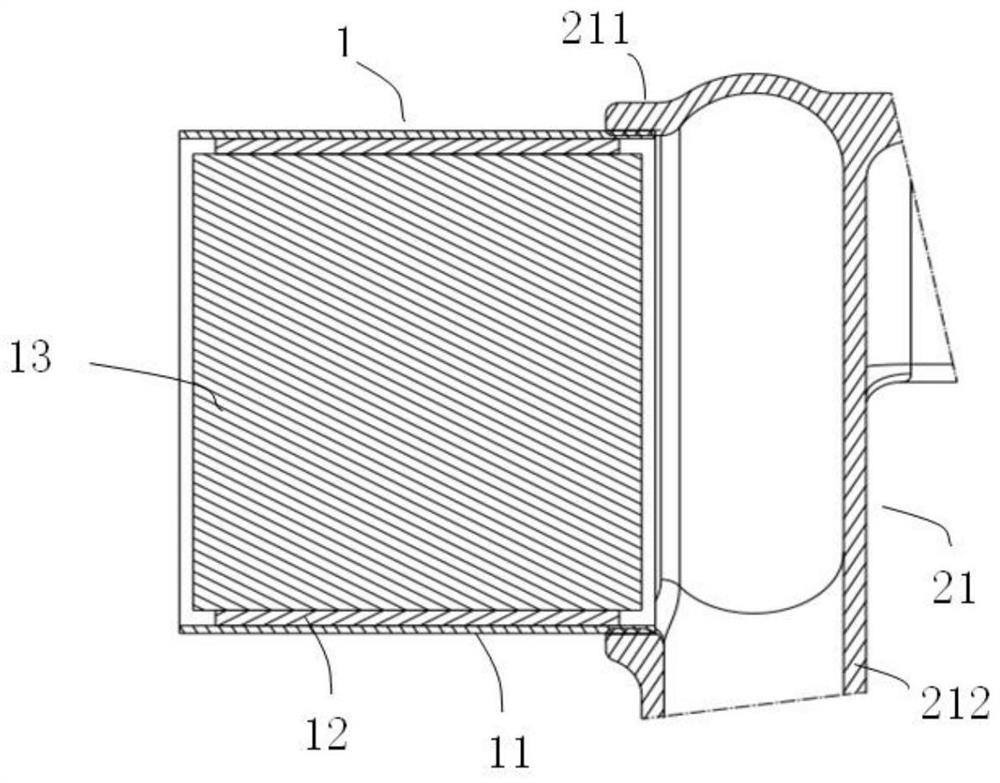

Heat insulator for a vehicle exhaust pipe and methods for manufacturing the same

ActiveCN102042068AShorten light-off timeGood heat insulationSilencing apparatusMachines/enginesMetal foilHeat resistance

Owner:NAKAGAWA SANGYO

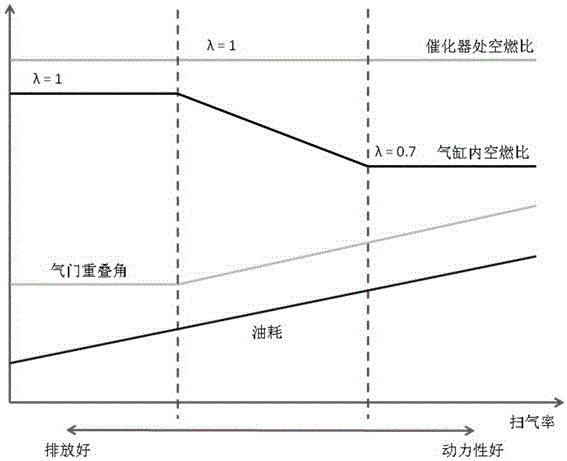

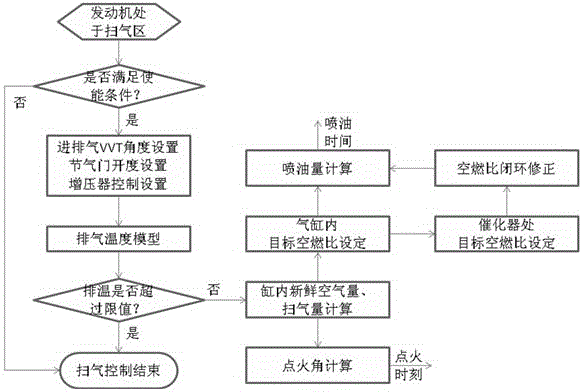

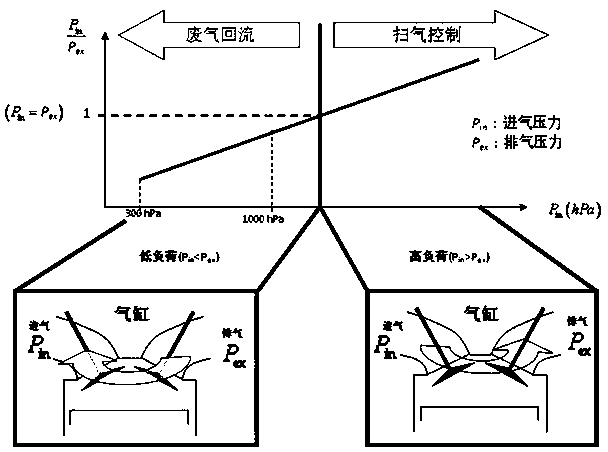

Scavenging control method of homogeneous turbocharged direct injection gasoline engine

ActiveCN106285965AIncrease combustion torqueIncrease output powerInternal combustion piston enginesOutput powerVariable valve timingEngineering

The invention relates to a scavenging control method of a homogeneous turbocharged direct injection gasoline engine. The scavenging control method is characterized by including the following specific control steps that in a low-revolution-speed large-load area of the homogeneous turbocharged direct injection gasoline engine, the intake and exhaust variable valve timing (VVT) angle is controlled, and residual gas remaining in a cylinder is reduced; the purpose of controlling the scavenging amount is achieved by controlling the overlapping angle of the intake VVT opening angle and the exhaust VVT closing angle; weak scavenging or strong scavenging can be selected through a precise gas amount and fuel amount control system in a scavenging area according to the central temperature of a catalytic converter, and the fuel injection quantity is calculated according to the quantity, calculated through a model, of fresh air in the cylinder and the target value of the air-fuel ratio in the cylinder; before the temperature of the catalytic converter reaches an ignition temperature, a weak scavenging mode is adopted by the system, the temperature of the catalytic converter can be quickly increased, and the ignition time of the catalytic converter is shortened; and after the temperature of the catalytic converter exceeds the ignition temperature, a strong scavenging mode is adopted by the system, an exhaust-temperature low supercharger can work for a long time, and compared with the weak scavenging mode, the higher torque and the higher power output can be provided. By means of the method, the temperature of the catalytic converter can be quickly increased through after-burning; during strong scavenging, the fuel injection quantity can be calculated through the model, the air-fuel ratio in the cylinder is made to be 1, the exhaust temperature is lower than that of the weak scavenging mode, and long-time work can be achieved; and the combustion torque and output power can be increased through both the weak scavenging mode and the strong scavenging mode.

Owner:CHINA FIRST AUTOMOBILE

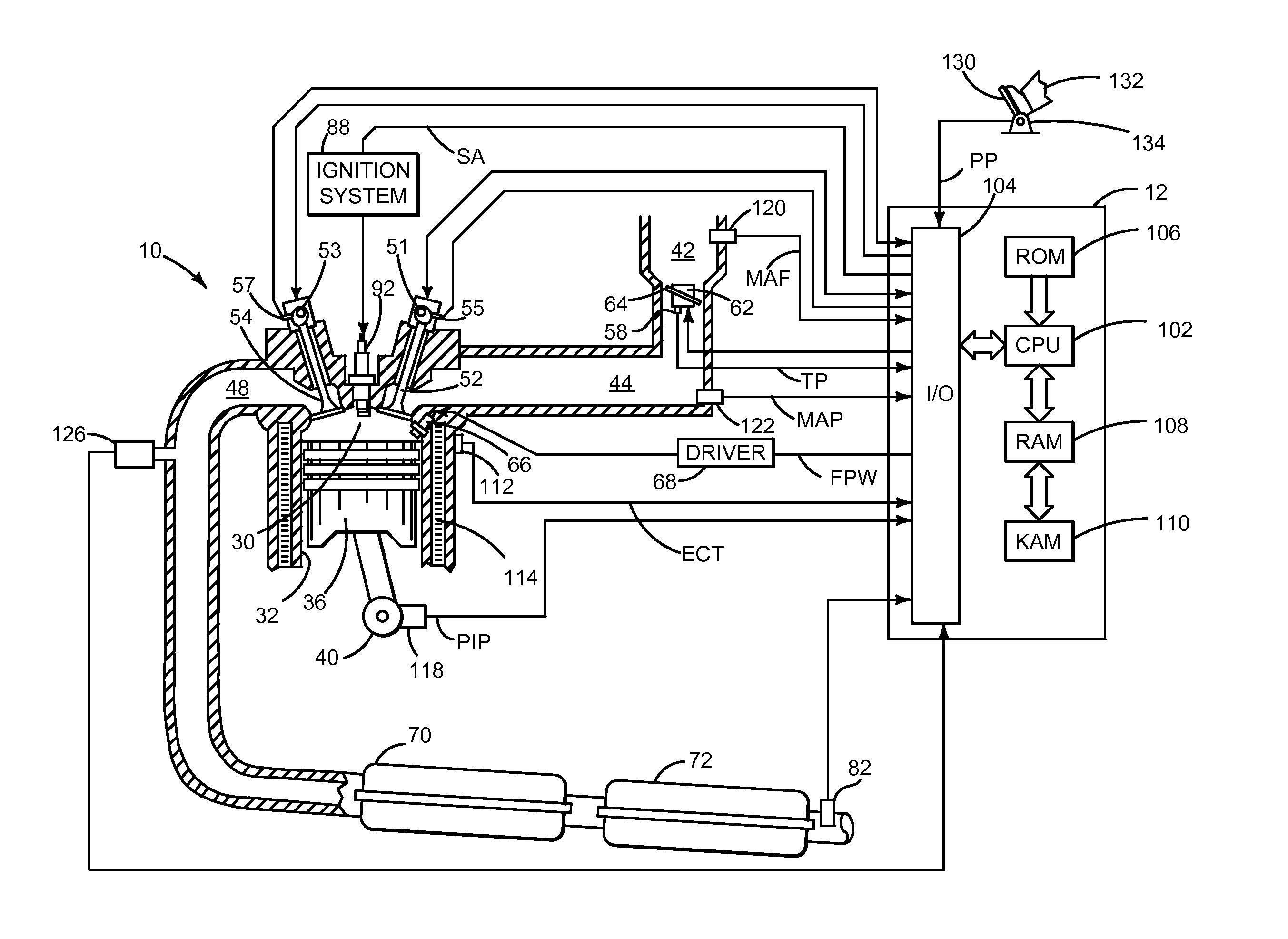

Method for Adjusting Engine Air-Fuel Ratio

ActiveUS20110213547A1Emission reductionImprove efficiencyElectrical controlExhaust apparatusOxygen sensorControl theory

A method for adjusting an air-fuel ratio of an engine is disclosed. In one example, the engine air-fuel ratio is adjusted in response to a duty cycle and frequency of a post catalyst oxygen sensor. The method may improve catalyst efficiency.

Owner:FORD GLOBAL TECH LLC

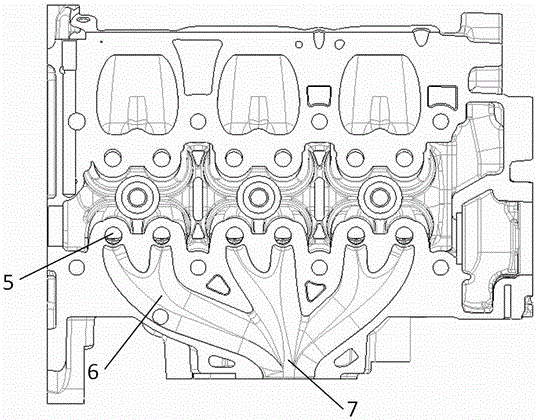

Integrated-designed engine cylinder cover

ActiveCN106368846AReduce exhaust temperatureImprove fuel economyCylinder headsExhaust gas recirculationIntegrated designOil consumption

The invention provides an integrated-designed engine cylinder cover. The engine cylinder cover integrates an exhaust manifold, an EGR cooling device and a secondary air channel device simultaneously. The exhaust manifold is integrated on the exhaust side of the engine cylinder cover. A gas inlet of the EGR cooling device is integrated on the exhaust manifold. A gas outlet of the EGR cooling device is integrated on the gas inlet side of the engine cylinder cover. The secondary air channel device is integrated on the exhaust manifold. The engine cylinder cover is installed as a whole, too many exhaust manifolds, external type EGR cooling devices, external type secondary air channel devices and other parts do not to be installed, through the highly integrated engine cylinder cover, the number and weight of parts of the complete machine are reduced, oil consumption and discharge performance of an engine is also improved significantly, meanwhile, the design of the complete machine is more compact, and the cost of the complete machine has more advantages.

Owner:CHERY AUTOMOBILE CO LTD

Heat insulator suitable for a vehicle exhaust pipe

InactiveUS20110088805A1Excellent thermal insulation propertyLight off time be reduceSilencing apparatusMachines/enginesMetal foilEngineering

A heat insulator is wound around an outer periphery of a vehicle exhaust pipe. The heat insulator comprises a deformable sheet-shaped heat insulating material hermetically encased in a reduced pressure state in a bag member comprised of heat-resistant metal foil.

Owner:NAKAGAWA SANGYO

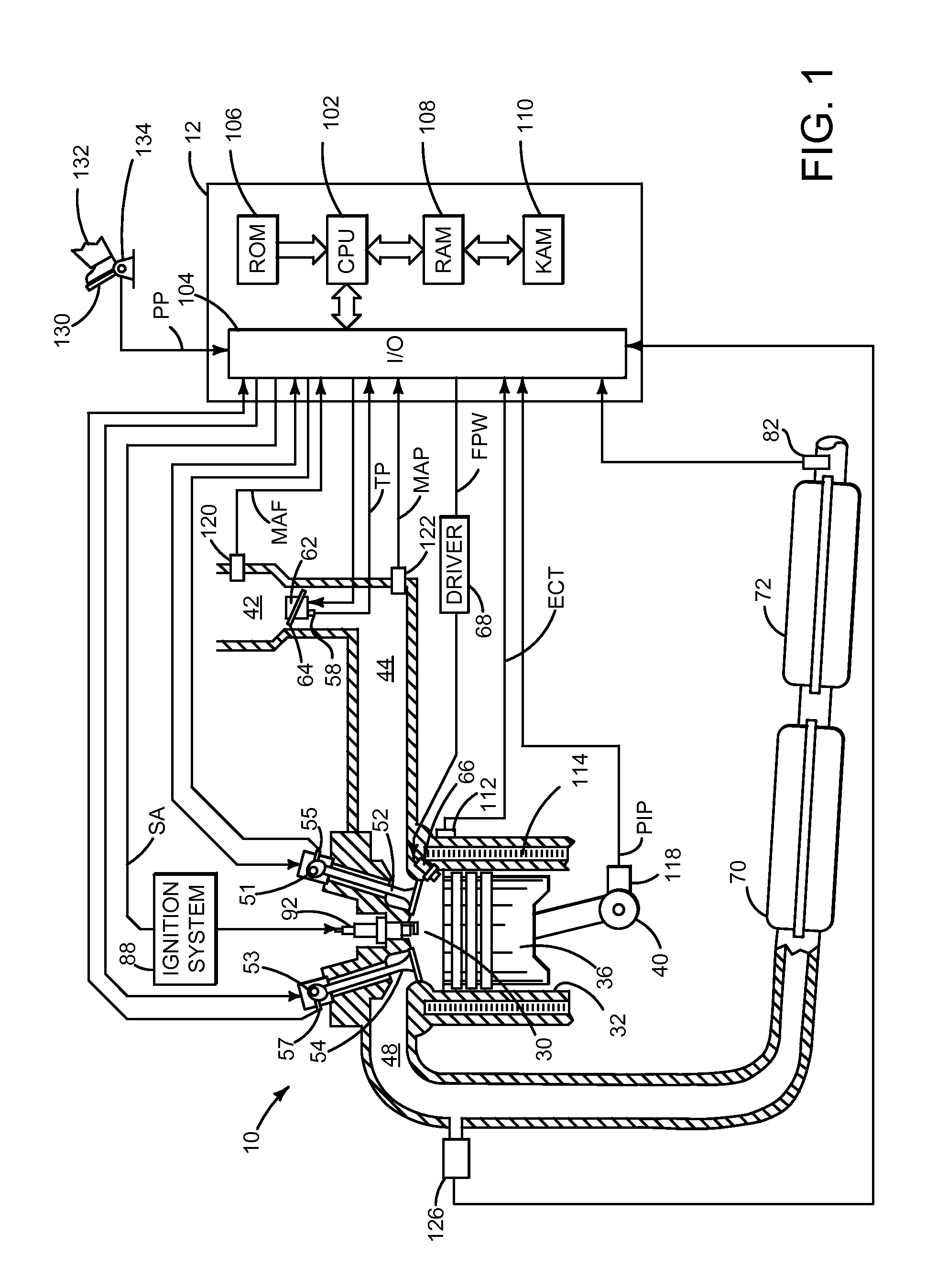

Method and system for operating an engine turbocharger

ActiveCN103670675AEmission reductionShorten light-off timeHybrid vehiclesElectrical controlTurbochargerAutomotive engineering

A system and method for operating an engine turbocharger is described. In one example, the turbocharger is rotated in different directions in response to operating conditions. The system and method may reduce engine emissions.

Owner:FORD GLOBAL TECH LLC

Method for adjusting engine air-fuel ratio

ActiveUS8165787B2Emission reductionImprove efficiencyElectrical controlExhaust apparatusOxygen sensorEngineering

A method for adjusting an air-fuel ratio of an engine is disclosed. In one example, the engine air-fuel ratio is adjusted in response to a duty cycle and frequency of a post catalyst oxygen sensor. The method may improve catalyst efficiency.

Owner:FORD GLOBAL TECH LLC

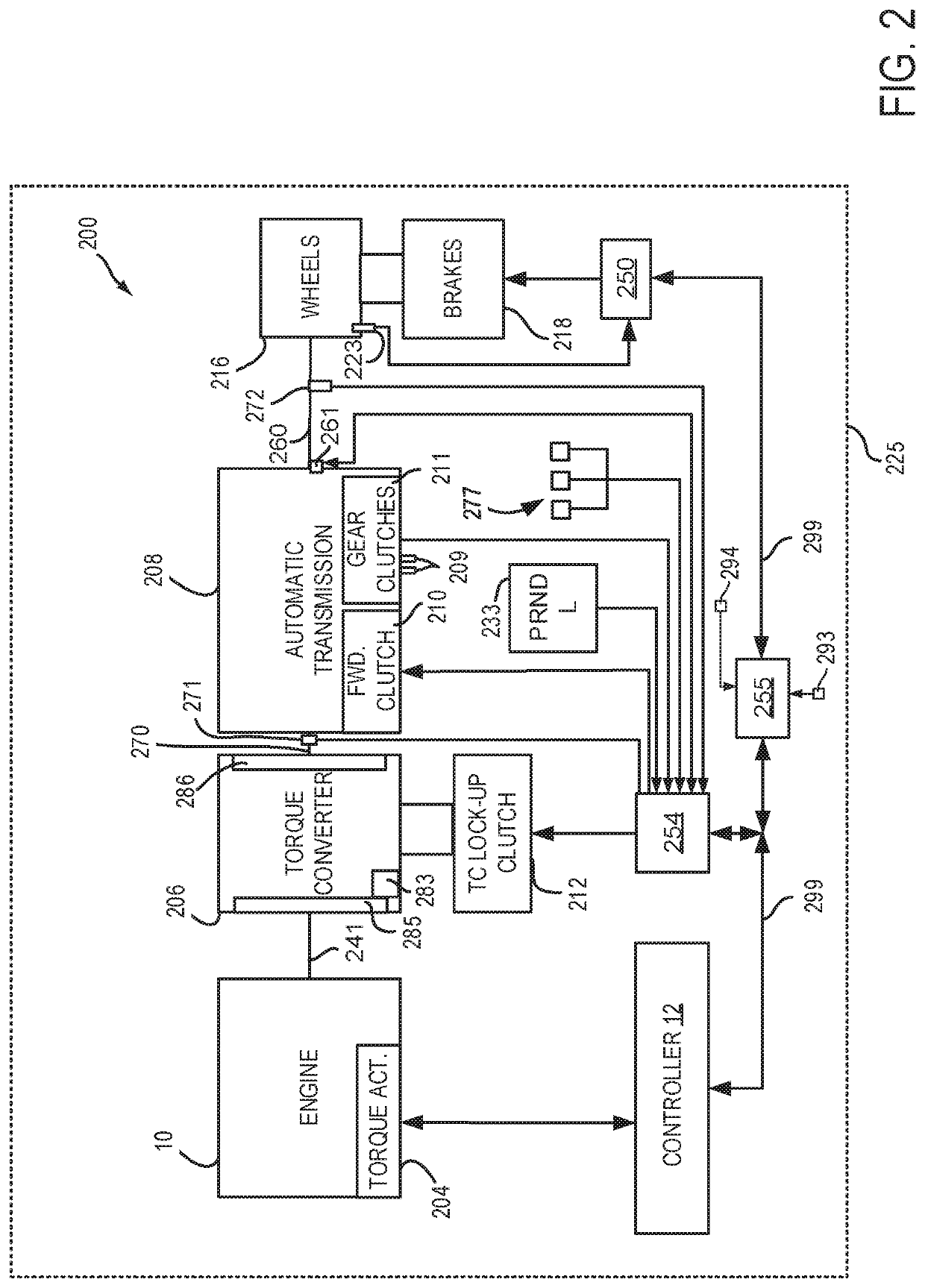

System and method for increasing catalyst temperature

ActiveUS10836397B1Low efficiencyImprove efficiencyInternal combustion piston enginesGearing controlClutchVariator

Systems and methods for operating an engine and a transmission to reduce a catalyst light off time are disclosed. In one example, clutches of a transmission are operated to provide a desired load to the engine so that engine combustion stability may be improved while supplying heat to a catalyst so that the catalyst light off time may be reduced.

Owner:FORD GLOBAL TECH LLC

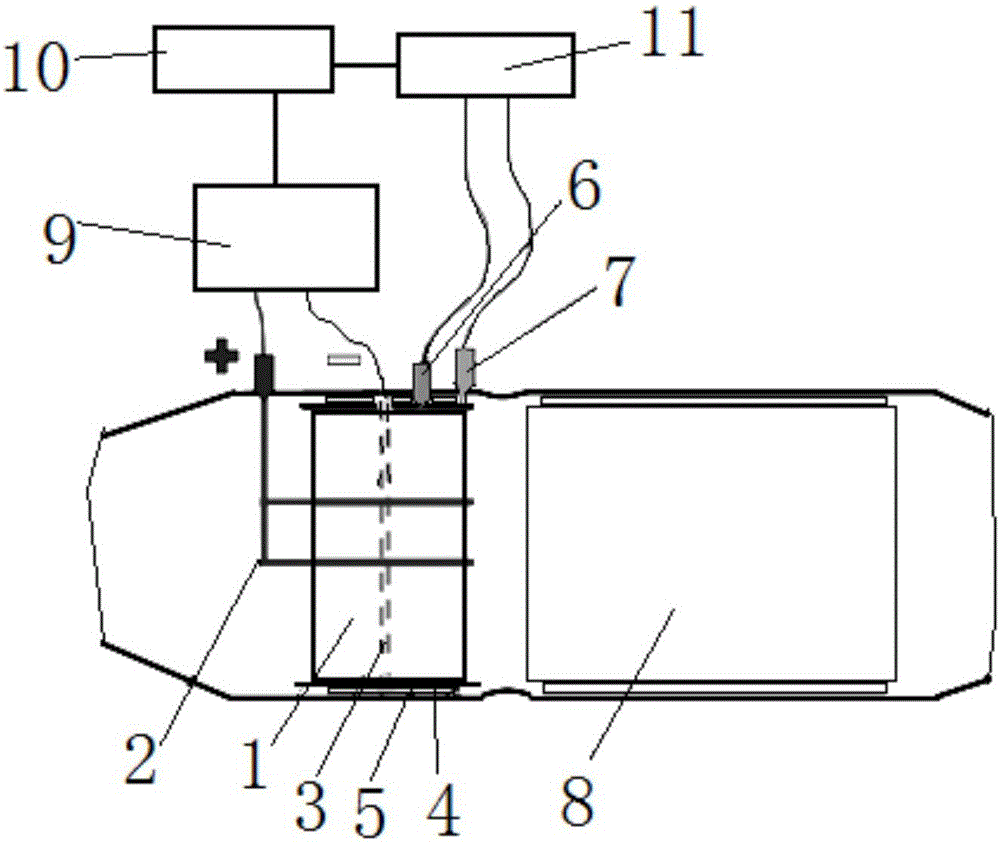

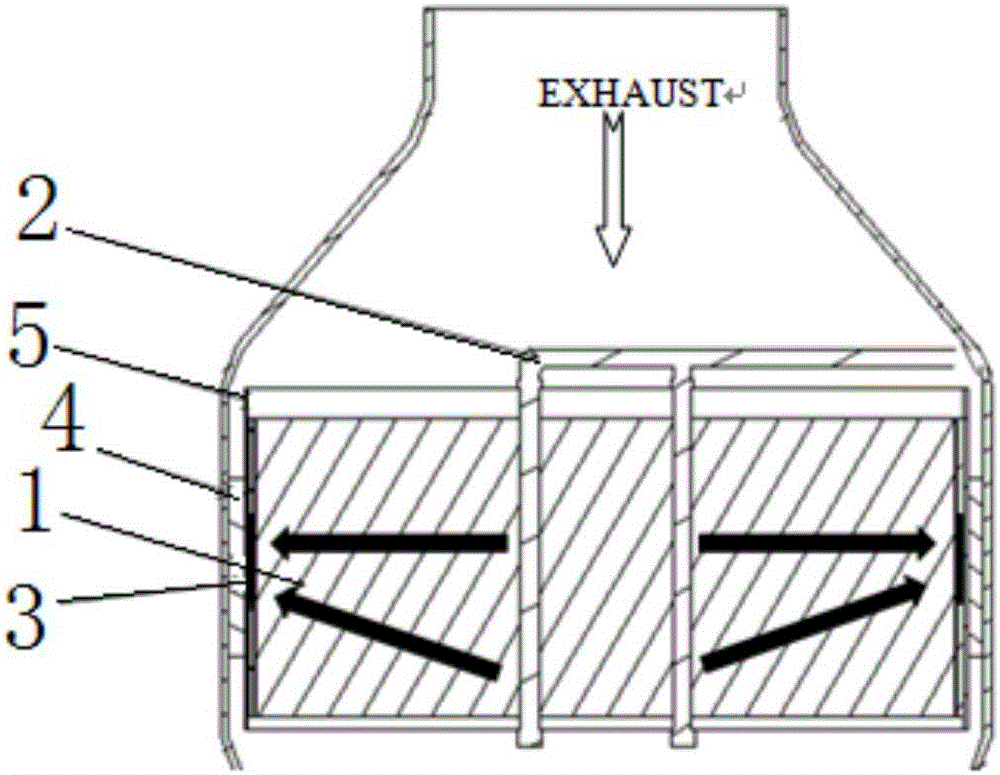

Electric heating type catalytic converter and heating control method thereof

ActiveCN106321201AShorten light-off timeEmission reductionInternal combustion piston enginesExhaust apparatusElectricityEngineering

The invention discloses an electric heating type catalytic converter which comprises a shell. The electric heating type catalytic converter is characterized in that a metal carrier is arranged in the shell and provided with a positive electrode and a negative electrode which are connected with a power source; a temperature sensor is arranged on the outer surface of the metal carrier, and an insulation structure for wrapping the side of the metal carrier and the temperature sensor is arranged on the outer portion of the metal carrier; an electric leakage inductor is arranged on the outer wall of the shell; and the power source, the temperature sensor and the electric leakage inductor are all connected with an ECU. The electric heating type catalytic converter achieves the function of promoting a catalyst to be fast ignited through electric heating during cold start of a vehicle, the ignition time of the catalyst is greatly shortened, and whole vehicle discharge is greatly reduced.

Owner:CHERY AUTOMOBILE CO LTD

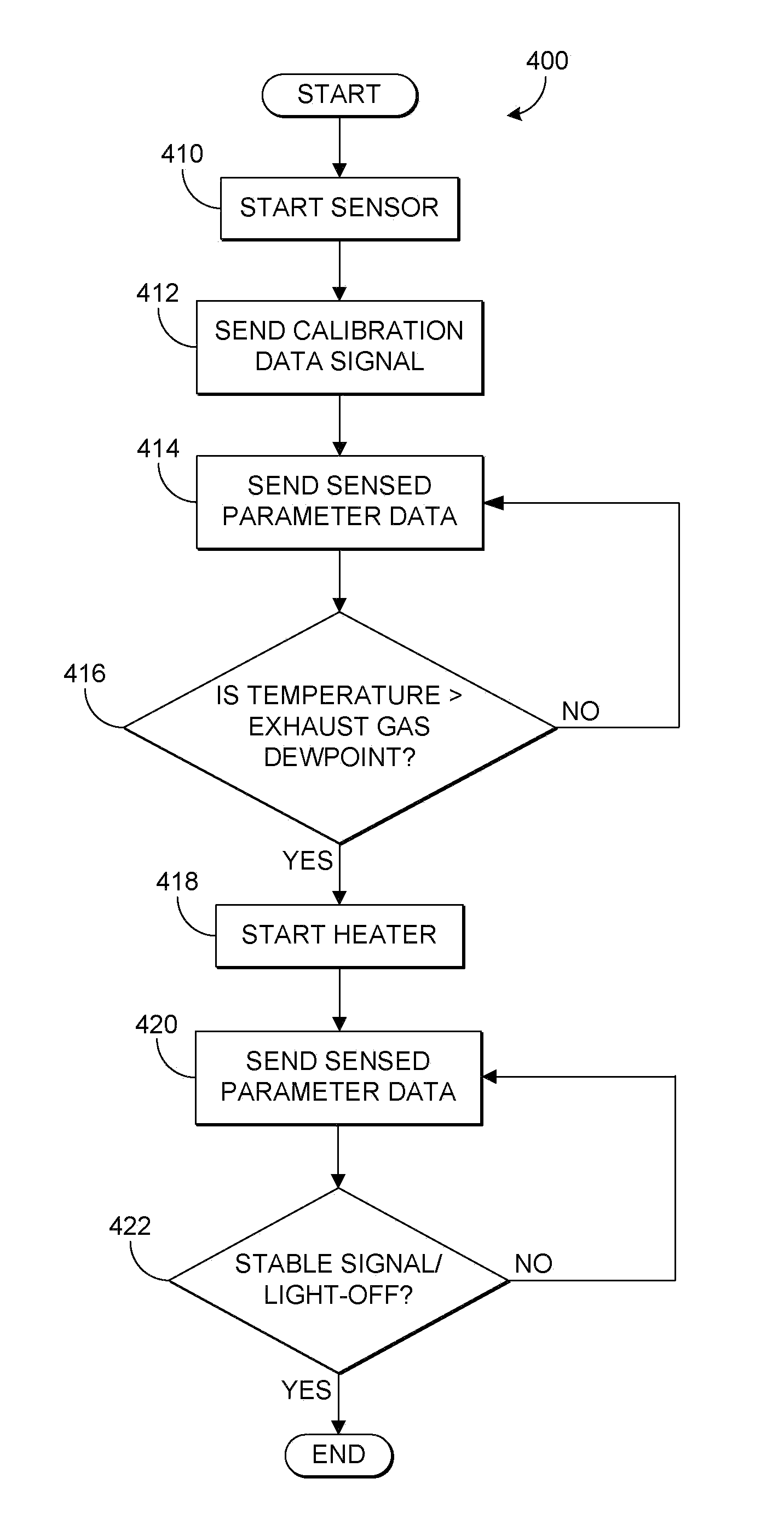

Smart vehicle sensor

ActiveUS8370017B2Accurate inductionImproved vehicle diagnosticsVehicle testingElectrical controlMotorized vehicleSmart vehicle

Owner:FORD GLOBAL TECH LLC

Exhaust treatment apparatus and method

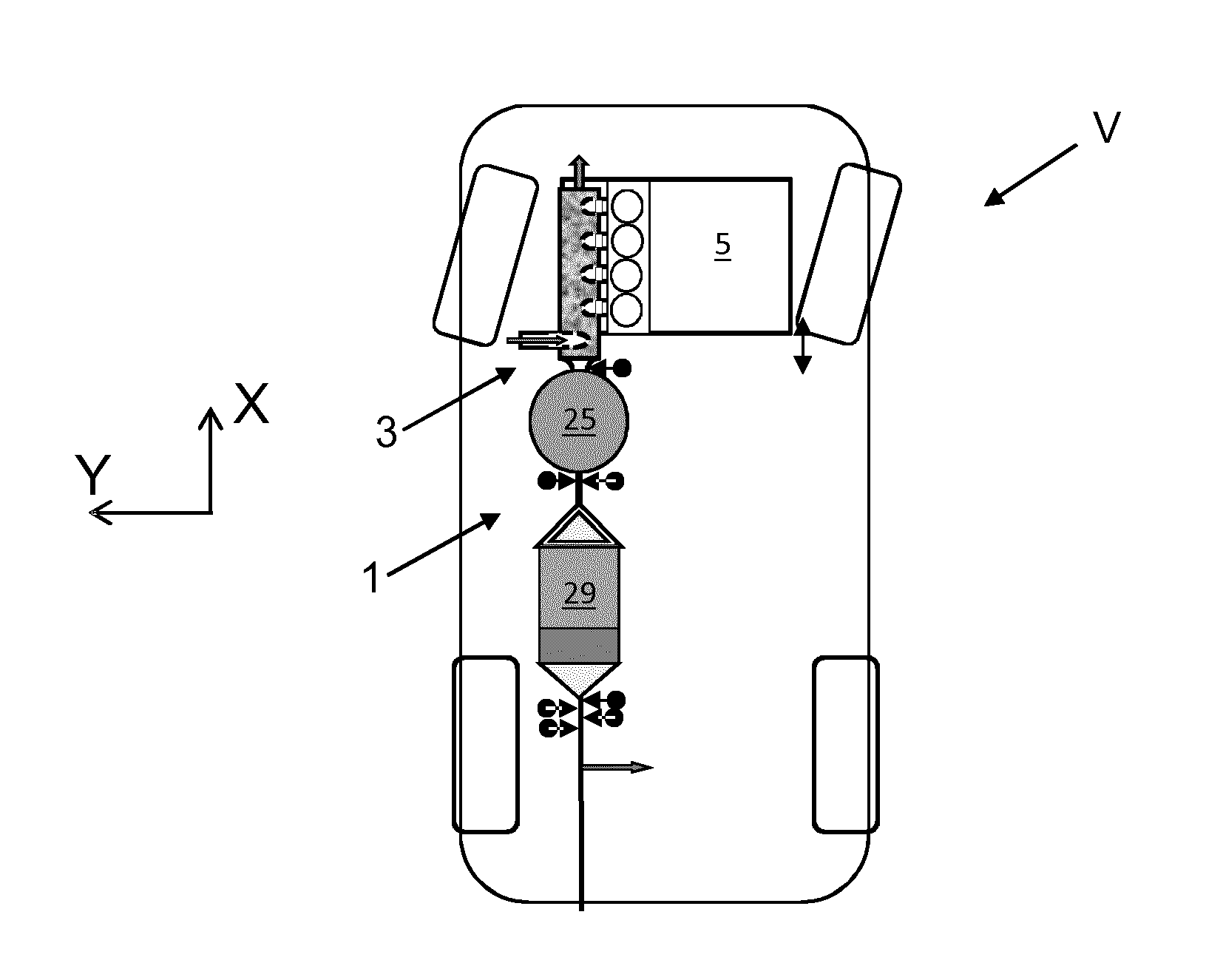

InactiveUS20160230629A1Shorten light-off timeWell mixedInternal combustion piston enginesExhaust apparatusTurbochargerEngineering

The present invention relates to an exhaust treatment apparatus (1) for an internal combustion engine (5). The apparatus includes a catalyst chamber (15) containing a catalyst (35). One or more exhaust gas inlets (11 A-D) are provided for supplying exhaust gases from the internal combustion engine (5) to the catalyst chamber (C). An exhaust gas outlet (21) for supplying exhaust gases from the catalyst chamber to a turbocharger (25). An injection nozzle (19) is provided for introducing a reductant (23) into the exhaust gases between the catalyst (15) and the turbocharger (25). The reductant (23) and the exhaust gases can undergo mixing as they pass through the turbocharger (25). The catalyst (15) can have a three-dimensional open structure to facilitate the flow of exhaust gases. The invention also relates to a method of treating exhaust gases from an internal combustion engine (5).

Owner:JAGUAR LAND ROVER LTD

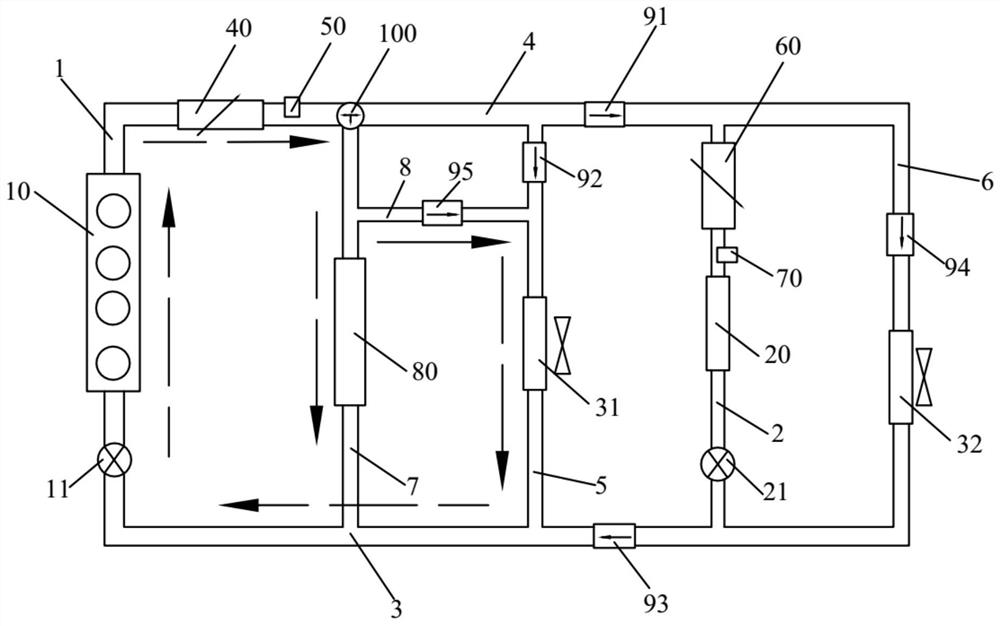

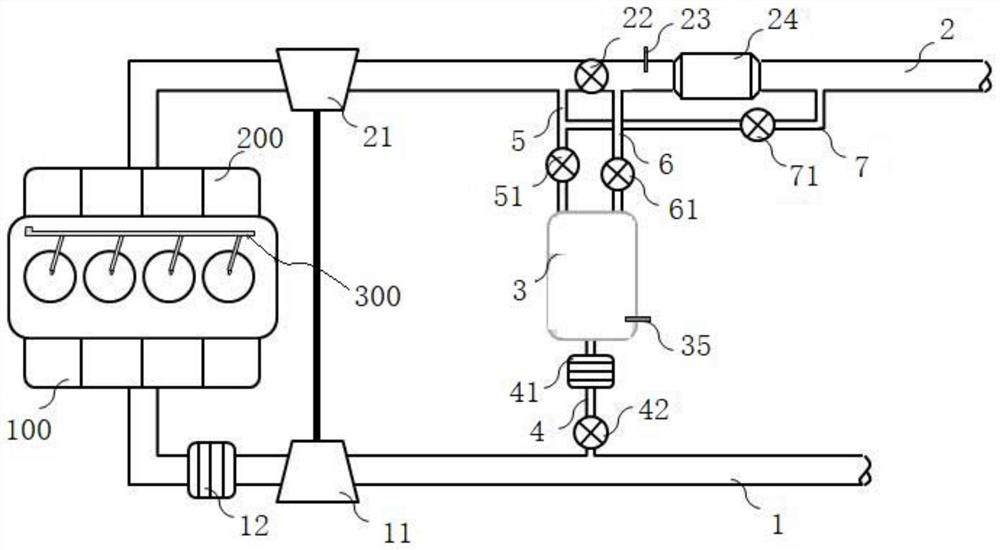

Exhaust treatment system

ActiveCN104405482AShorten light-off timeAdvance working hoursInternal combustion piston enginesExhaust apparatusExhaust fumesInjector

The invention discloses an exhaust treatment system. Air is leaded into an exhaust pipe through an air compressor and an ejector, is mixed with waste gas in the exhaust pipe, and flows to a catalytic converter. The exhaust treatment system can adjust the temperature of the waste gas in the exhaust pipe and the excess air coefficient to satisfy optimal chemical reaction conditions of the catalytic converter; meanwhile, when an engine is started, a high-concentration fuel generates a large quantity of HC and CO; and the HC and CO are mixed with the leaded-in air in the catalytic converter for burning to heat the catalytic converter, so that the temperature of the catalytic converter quickly rises, the burning rising time of the catalytic converter is shortened, the working time is ahead of time, and the problem of injurant increment caused by the starting of the engine is reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Cooling liquid preheating and waste heat recovery device and vehicle

ActiveCN111765029AShorten warm-up timeImprove the lubrication effectLiquid coolingAir-treating devicesProcess engineeringWater jacket

The invention relates to the technical field of vehicles, and discloses a cooling liquid preheating and waste heat recovery device and a vehicle. The cooling liquid preheating and waste heat recoverydevice comprises a first pipeline, a second pipeline, a connecting pipeline, a heating pipeline and a first waste heat recovery pipeline, wherein an engine water jacket is arranged on the first pipeline; cooling liquid in the engine water jacket is used for cooling an engine; an exhaust pipe water jacket is arranged on the second pipeline; the cooling liquid in the exhaust pipe water jacket is used for cooling an exhaust pipe; the connecting pipeline is used for connecting one end of the first pipeline and one end of the second pipeline; the heating pipeline is connected to the other end of the first pipeline and the other end of the second pipeline; the heating pipeline is capable of selectively heating the cooling liquid in the heating pipeline; the first waste heat recovery pipeline respectively communicates with the connecting pipeline and the heating pipeline; a first heat exchanger is arranged on the first waste heat recovery pipeline; and the first heat exchanger is connected toan automobile heating system.

Owner:CHINA FIRST AUTOMOBILE

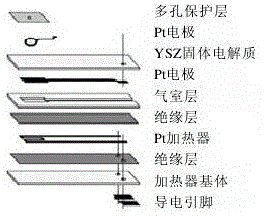

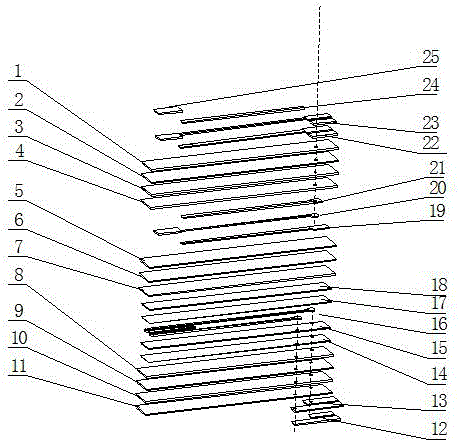

Novel chip type potentiometric automobile oxygen sensor and preparation method thereof

PendingCN106706743ACompact structureReduce volumeMaterial analysis by electric/magnetic meansPunchingOxygen sensor

The invention relates to a novel chip type potentiometric automobile oxygen sensor. The sensor comprises a protective layer, a signal layer and a heating layer, which are sequentially superposed, wherein the signal layer comprises seven layers of tape casting substrates which are sequentially laminated, the protective layer, an upper reactive electrode insulating layer, an outer reactive electrode and a lower reactive electrode insulating layer are sequentially arranged on the upper surface of the first layer of tape casting substrate from top to bottom, and an upper reference reactive electrode insulating layer, a reference reactive electrode and a lower reference reactive electrode insulating layer are sequentially arranged on the lower surface of the fourth layer of tape casting substrate from top to bottom; the heating layer comprises fourth layers of tape casting substrates which are sequentially laminated, and a heating electrode and a heating electrode pin are respectively arranged on the upper surface of the uppermost layer of tape casting substrate and the lower surface of the lowermost layer of tape casting substrate. The sensor is prepared by preparation of multiple kinds of tape casting slurry, tape casting forming, edge removal slitting, punching, printing, superposition, vacuum sealing molding, hot isostatic pressing, slitting and sintering. The oxygen sensor has the advantages of being more stable in performance and higher in production consistency.

Owner:莱鼎电子材料科技有限公司

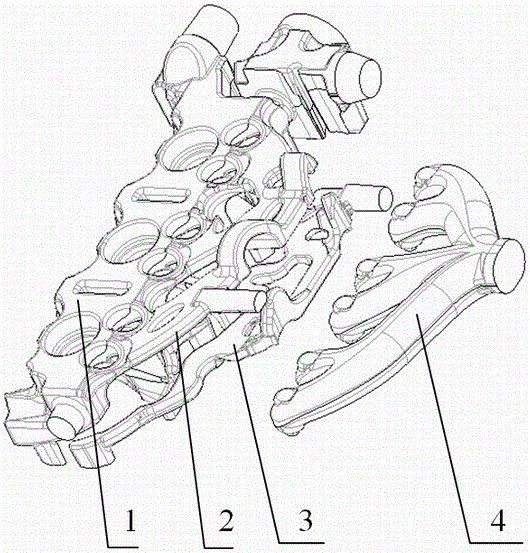

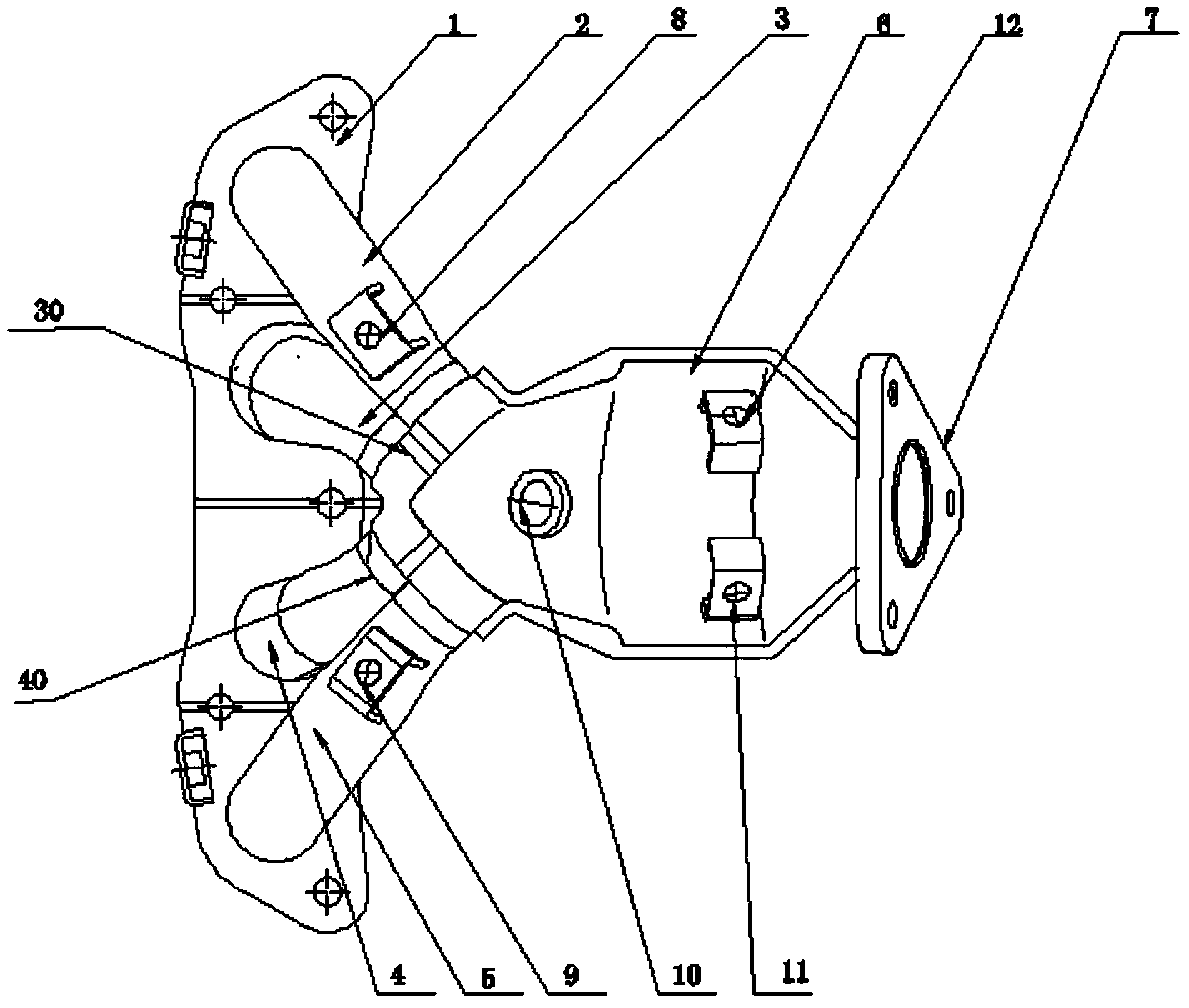

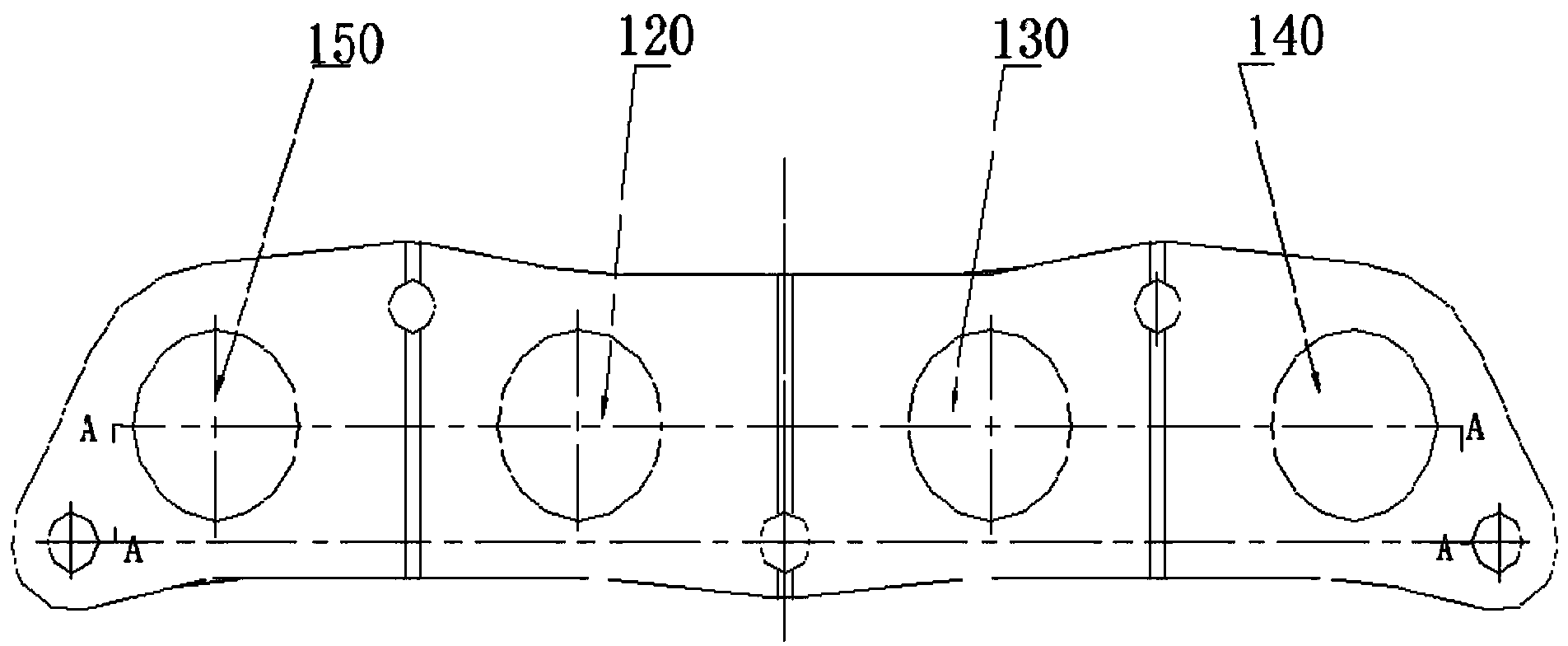

Manifold assembly with three-way catalyst

InactiveCN103967576AShorten light-off timeIncrease working temperatureExhaust apparatusSilencing apparatusThermal deformationWorking temperature

The invention provides a manifold assembly with a three-way catalyst. The manifold assembly comprises air inlet flanges of a thermal deformation resistant groove, four exhaust manifolds, a catalyst body and an air outlet flange. The front faces of the air inlet flanges are directly connected with an engine, the back faces of the air inlet flanges are connected with the air inlet ends of the four exhaust manifolds respectively, and the other ends of two exhaust manifolds are made to be in D shapes to be jointed through pipe end forming and are connected with the catalyst body; the other ends of the other two exhaust manifolds are made to be in D shapes to be jointed through pipe end forming and are connected with the catalyst body, and the catalyst body is directly connected with the air outlet flange. The ignition time of the catalyst is shortened, and work temperature is improved.

Owner:无锡红湖消声器有限公司

exhaust treatment system

ActiveCN104405482BOptimal chemical reaction conditionsShorten light-off timeInternal combustion piston enginesExhaust apparatusHigh concentrationChemical reaction

The invention discloses an exhaust treatment system. Air is leaded into an exhaust pipe through an air compressor and an ejector, is mixed with waste gas in the exhaust pipe, and flows to a catalytic converter. The exhaust treatment system can adjust the temperature of the waste gas in the exhaust pipe and the excess air coefficient to satisfy optimal chemical reaction conditions of the catalytic converter; meanwhile, when an engine is started, a high-concentration fuel generates a large quantity of HC and CO; and the HC and CO are mixed with the leaded-in air in the catalytic converter for burning to heat the catalytic converter, so that the temperature of the catalytic converter quickly rises, the burning rising time of the catalytic converter is shortened, the working time is ahead of time, and the problem of injurant increment caused by the starting of the engine is reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

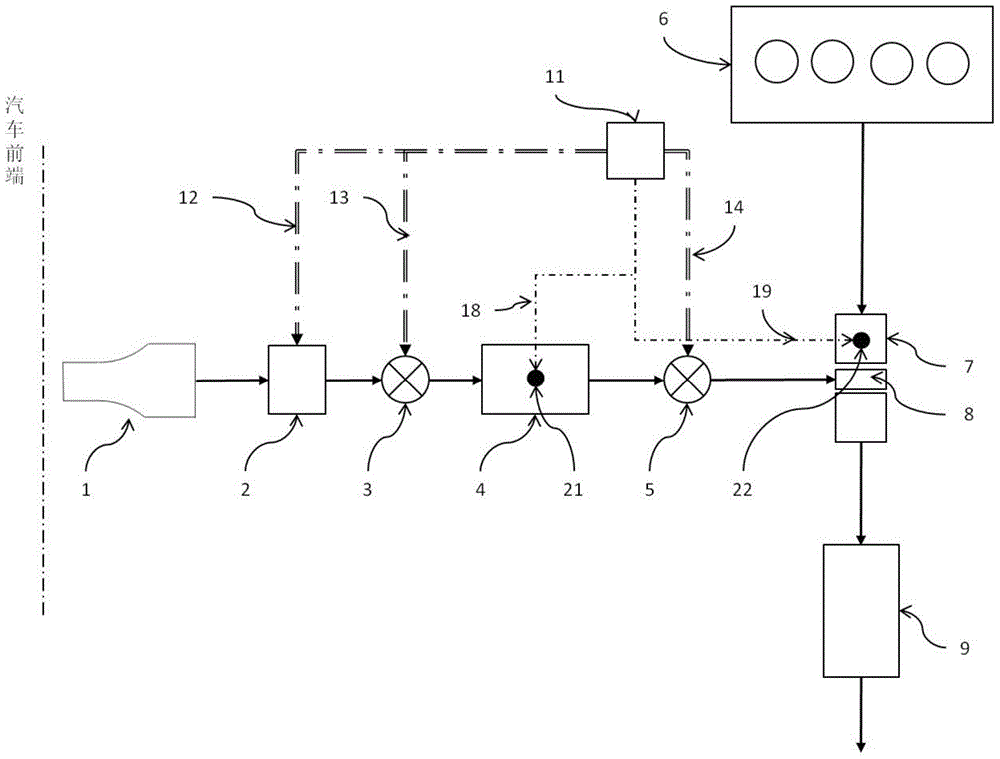

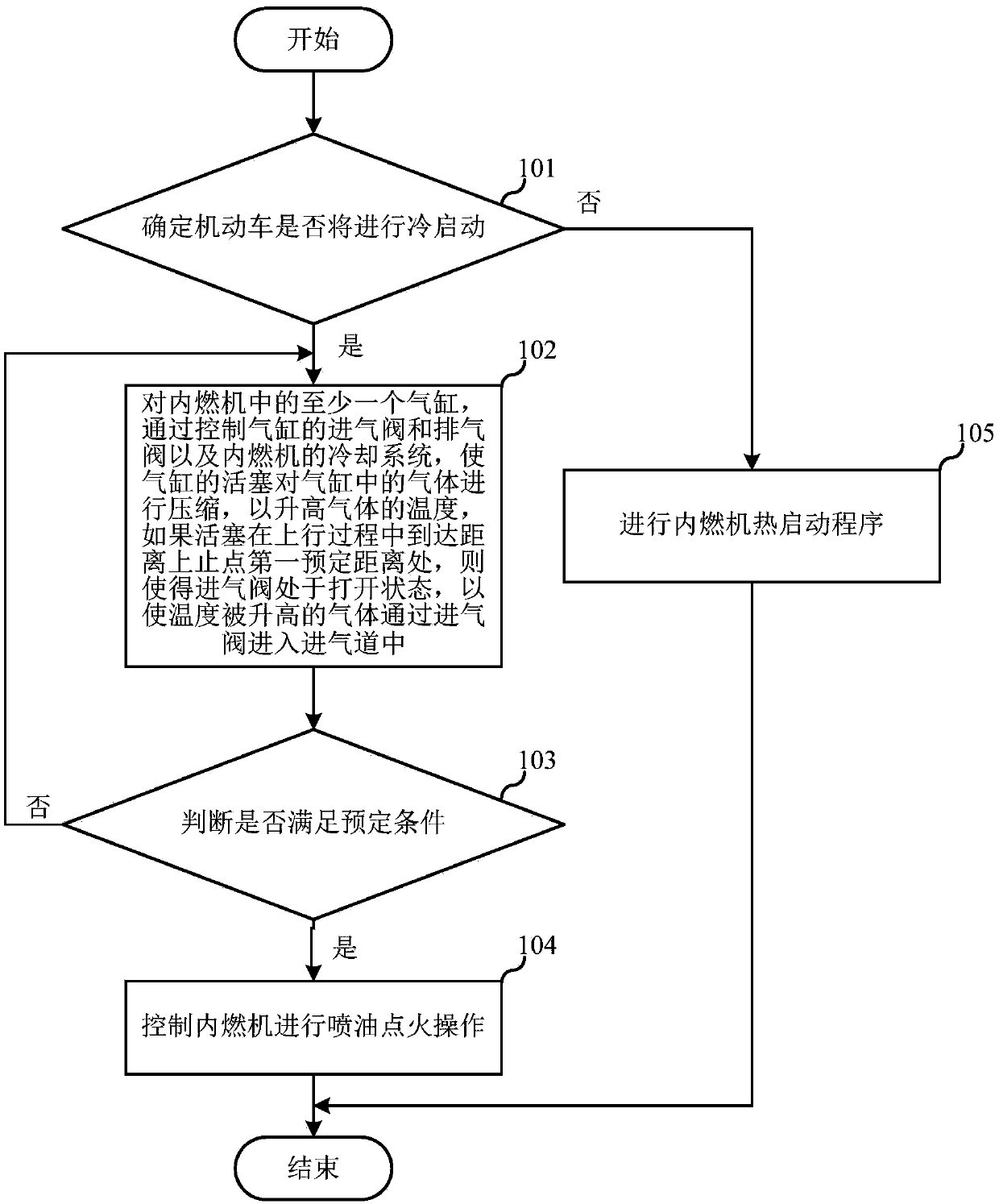

Cold start method, device and equipment of motor vehicle, and storage medium thereof

ActiveCN110469410AAchieve heatingSpeed up evaporationEngine controllersMachines/enginesCombustion systemExhaust valve

The invention relates to the field of motor vehicles, and discloses a cold start method, device and equipment of a motor vehicle, and a storage medium thereof. The cold start method of the motor vehicle comprises the steps of executing the following operation to at least one cylinder in an internal combustion engine of the motor vehicle repeatedly till the preset conditions are met if determiningthat the motor vehicle is subjected to cold start; compressing gas in the cylinder through a piston of the cylinder via control over an intake valve and an exhaust valve of the cylinder and a coolingsystem of the internal combustion engine, so that the gas temperature is increased; enabling the intake valve to be in the open state and accordingly enabling the heated gas to enter an air inlet waythrough the intake valve if the piston reaches the position with the first preset distance from the top dead center in the uplink process; and controlling the internal combustion engine to perform fuel injection ignition operation. According to the cold start method, through control over the cooling system and intake and exhaust systems, heating of parts and components of a combustion system is achieved, so that fuel evaporation is promoted effectively, and hydrocarbon emissions in the cold start process are reduced.

Owner:日立安斯泰莫汽车系统(中国)有限公司

Exhaust gas recirculation system

InactiveCN111894765AShorten light-off timeIncrease the differential pressureExhaust gas recirculationMachines/enginesExhaust fumesEngineering

The invention provides an exhaust gas recirculation system. The exhaust gas recirculation system comprises an engine cylinder, an exhaust manifold, a catalyst, a cooler, a supercharger, an air channeland an intake manifold, the supercharger comprises a turbine and a turbine press, the catalyst comprises a first-stage carrier and a second-stage carrier which are separated from each other, the intake end of the catalyst is connected to the turbine, a part, located between the first-stage carrier and the second-stage carrier, of the catalyst is connected to the intake end of the cooler, the airoutlet end of the cooler and the air channel are connected to the intake end of the turbine press, and the air outlet end of the turbine press is connected to the intake manifold through an intake pipeline. Due to the fact that the catalyst comprises the first-stage carrier and the second-stage carrier which are separated from each other, the middle of the first-stage carrier and the middle of thesecond-stage carrier are connected to the intake end of the cooler, an exhaust gas lead-in point of the cooler is located between the first-stage carrier and the second-stage carrier, the exhaust gaspressure at the position is large, and therefore the pressure difference between the lead-in point and the lead-out point of the cooler can be improved, and the exhaust gas recirculation rate is further improved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Supercharger, exhaust aftertreatment system and control method thereof

PendingCN113982743AShorten light-off timeEmission reductionInternal combustion piston enginesExhaust apparatusExhaust gas emissionsExhaust fumes

The invention provides a supercharger, an exhaust aftertreatment system and a control method thereof. The supercharger comprises a volute and a turbine, wherein the volute is provided with an air inlet and an air outlet, and the turbine is arranged in the volute. The supercharger further comprises an auxiliary catalyst, and the auxiliary catalyst is installed at the position, between the air inlet and the turbine, in the volute. The auxiliary catalyst is arranged in the volute of the supercharger, and the auxiliary catalyst is arranged at the position close to the air inlet of the volute, so that a carrier of the auxiliary catalyst is completely surrounded by exhaust gas. In addition, the distance between the air inlet of the volute and the exhaust port of the engine is short, so that the ignition time of the auxiliary catalyst is effectively shortened, and the exhaust emission of the vehicle is effectively reduced.

Owner:NINGBO GEELY ROYAL ENGINE COMPONENTS +2

Scavenging Control Method of Homogeneous Supercharged Direct Injection Gasoline Engine

ActiveCN106285965BIncrease output powerEasy dischargeInternal combustion piston enginesOutput powerVariable valve timingControl system

The invention relates to a scavenging control method of a homogeneous turbocharged direct injection gasoline engine. The scavenging control method is characterized by including the following specific control steps that in a low-revolution-speed large-load area of the homogeneous turbocharged direct injection gasoline engine, the intake and exhaust variable valve timing (VVT) angle is controlled, and residual gas remaining in a cylinder is reduced; the purpose of controlling the scavenging amount is achieved by controlling the overlapping angle of the intake VVT opening angle and the exhaust VVT closing angle; weak scavenging or strong scavenging can be selected through a precise gas amount and fuel amount control system in a scavenging area according to the central temperature of a catalytic converter, and the fuel injection quantity is calculated according to the quantity, calculated through a model, of fresh air in the cylinder and the target value of the air-fuel ratio in the cylinder; before the temperature of the catalytic converter reaches an ignition temperature, a weak scavenging mode is adopted by the system, the temperature of the catalytic converter can be quickly increased, and the ignition time of the catalytic converter is shortened; and after the temperature of the catalytic converter exceeds the ignition temperature, a strong scavenging mode is adopted by the system, an exhaust-temperature low supercharger can work for a long time, and compared with the weak scavenging mode, the higher torque and the higher power output can be provided. By means of the method, the temperature of the catalytic converter can be quickly increased through after-burning; during strong scavenging, the fuel injection quantity can be calculated through the model, the air-fuel ratio in the cylinder is made to be 1, the exhaust temperature is lower than that of the weak scavenging mode, and long-time work can be achieved; and the combustion torque and output power can be increased through both the weak scavenging mode and the strong scavenging mode.

Owner:CHINA FIRST AUTOMOBILE

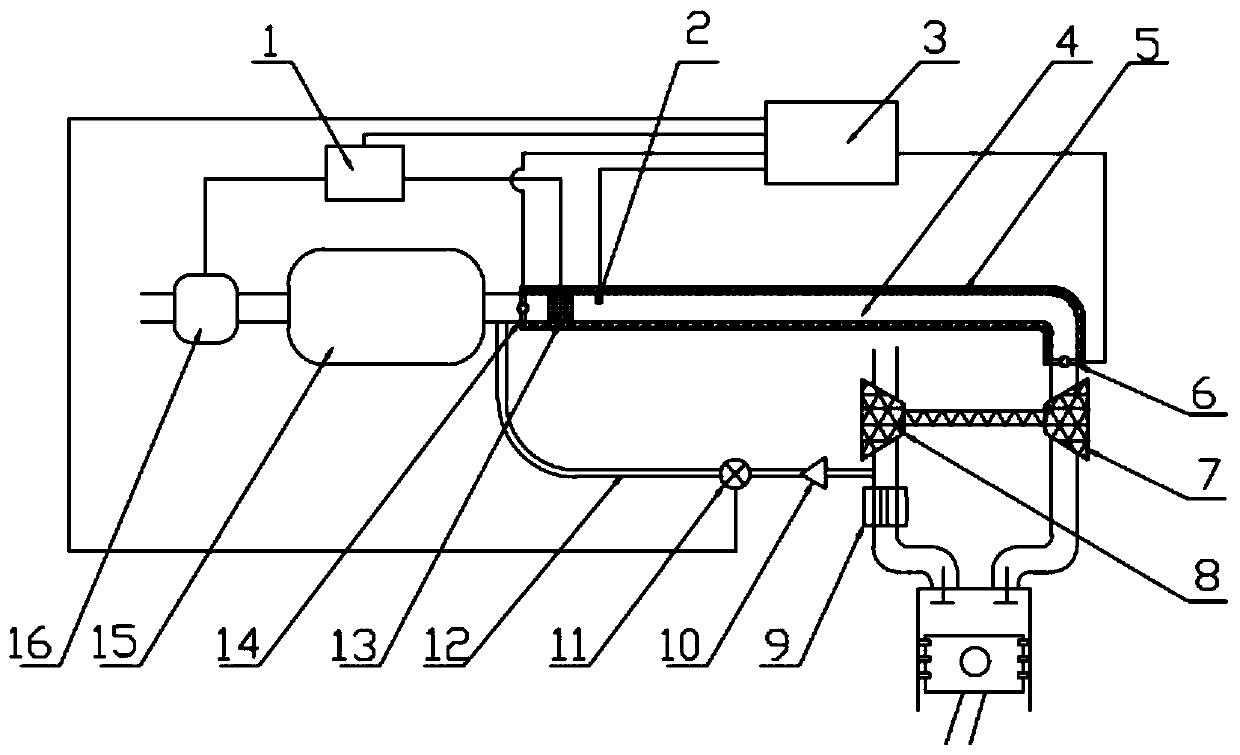

A kind of engine system and control method

ActiveCN111237102BIncrease temperatureShorten light-off timeInternal combustion piston enginesExhaust apparatusThermal insulationControl theory

The invention relates to the field of automobile power, and discloses an engine system and a control method. The engine system includes an intake pipeline, an exhaust pipeline and an insulated gas storage tank. The insulated gas storage tank is provided with a first communication port, a second communication port and a third communication port, and the first communication port passes through the first connecting pipe. connected to the intake pipeline upstream of the compressor, the second communication port is connected to the exhaust pipeline between the turbine and the exhaust regulating valve through the second connection pipeline, and the third communication port is connected to the exhaust pipeline through the third connection pipeline. On the exhaust line between the gas regulating valve and the temperature sensor. The invention introduces the low-temperature exhaust gas in front of the three-way catalytic converter into the thermal insulation gas storage tank when the engine is cold started, and can be used as a low-pressure EGR while reducing emissions, reducing fuel consumption, and refilling the three-way catalytic converter stored before the last stop. The high-temperature, low-emission gas is exported to the three-way catalytic converter, the temperature of the three-way catalytic converter is increased, the light-off time is shortened, and the cold start emission is reduced.

Owner:CHINA FIRST AUTOMOBILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com