Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Serve the purpose of protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

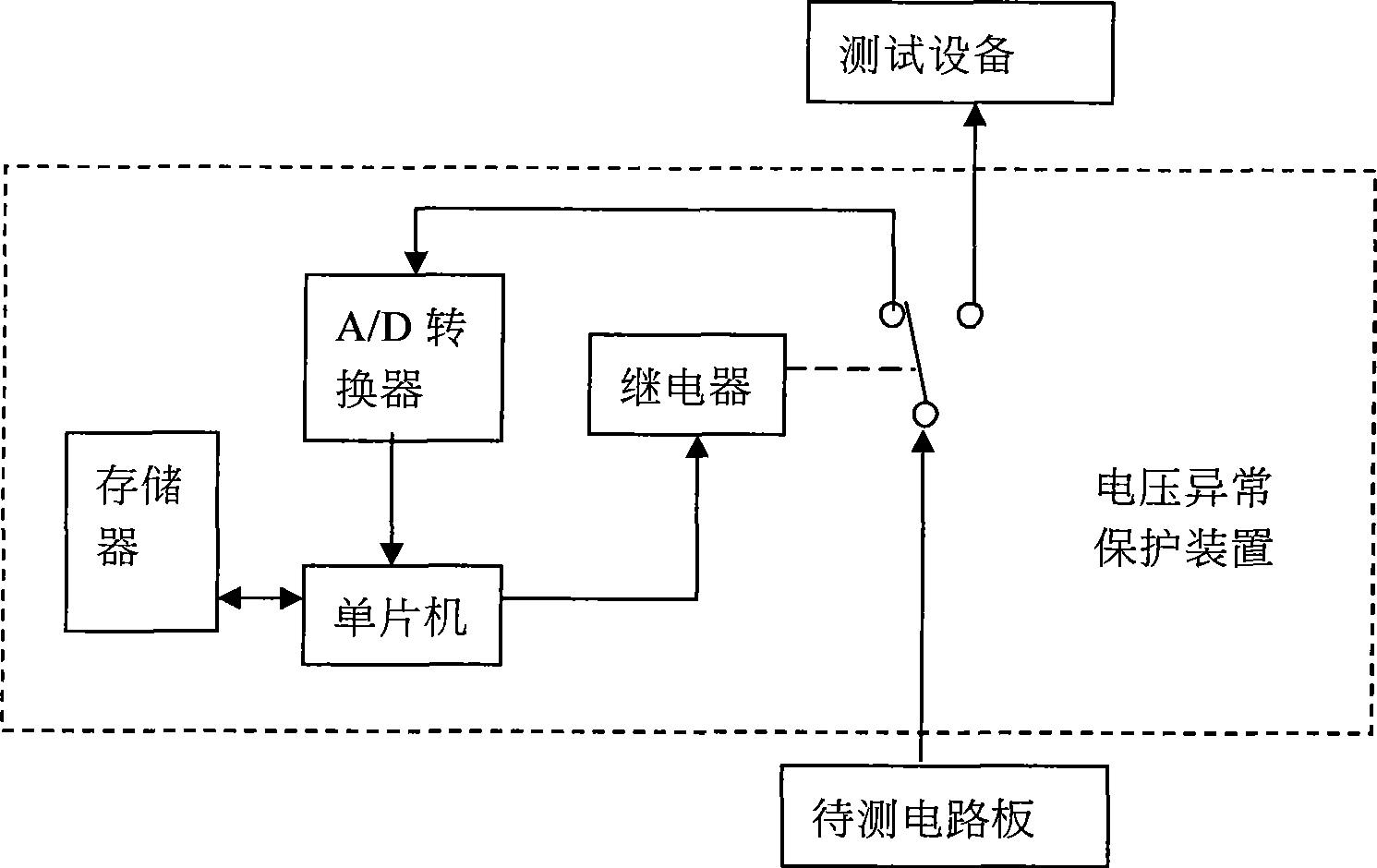

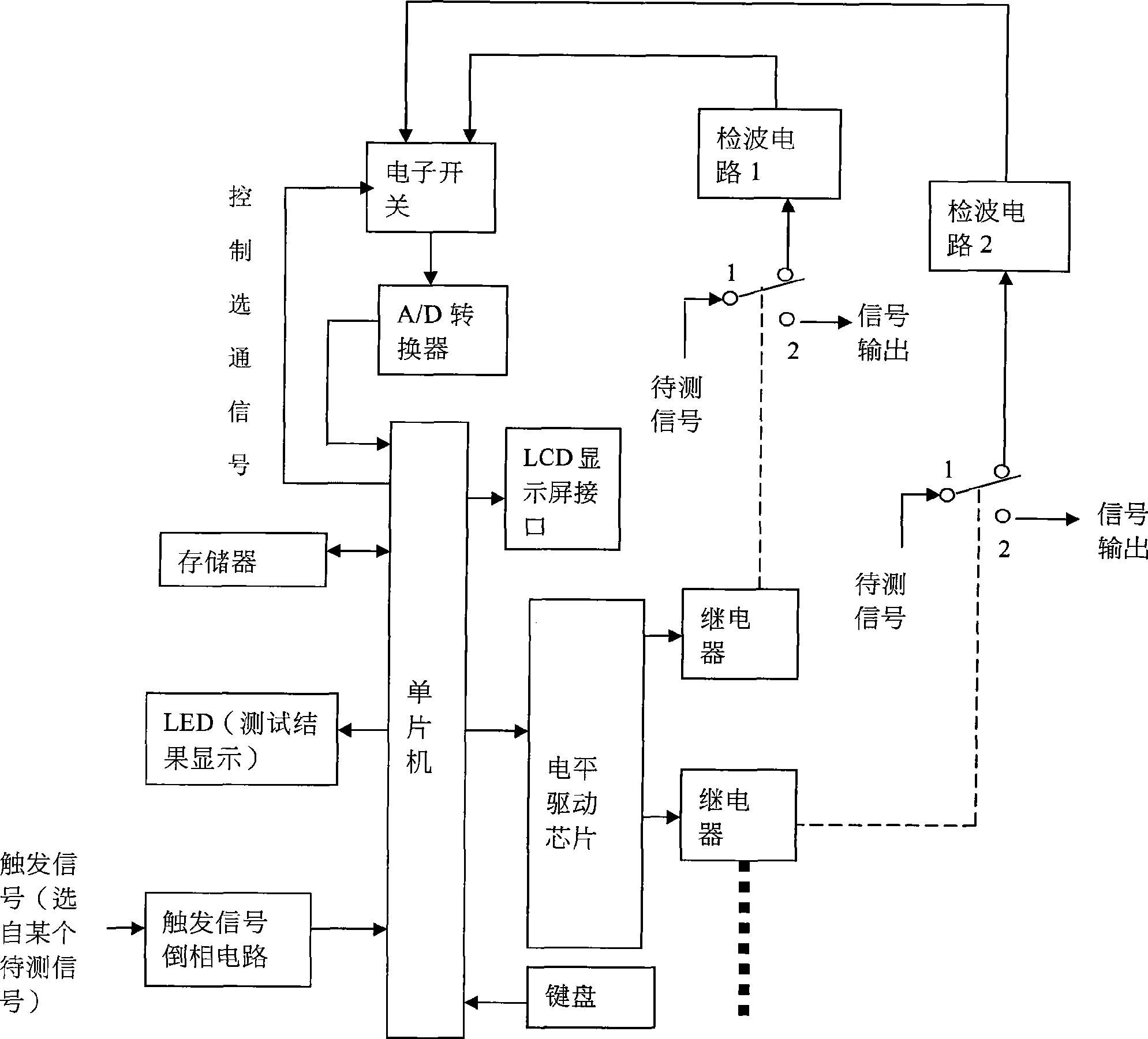

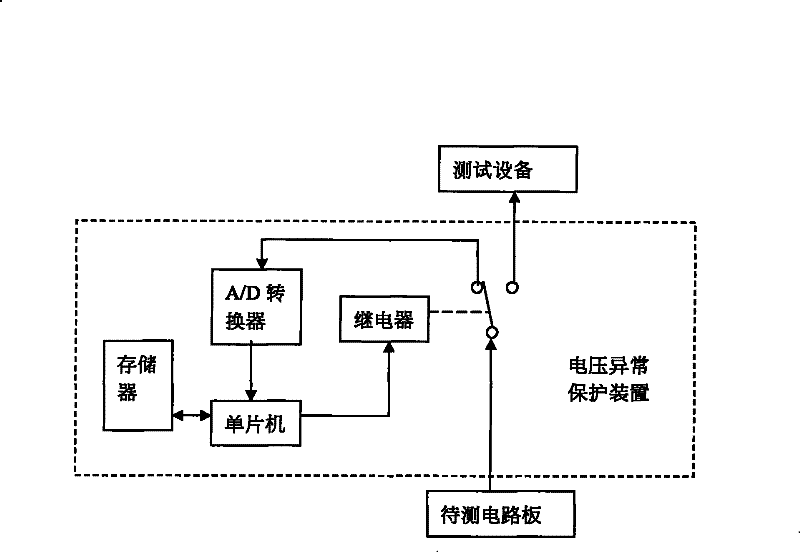

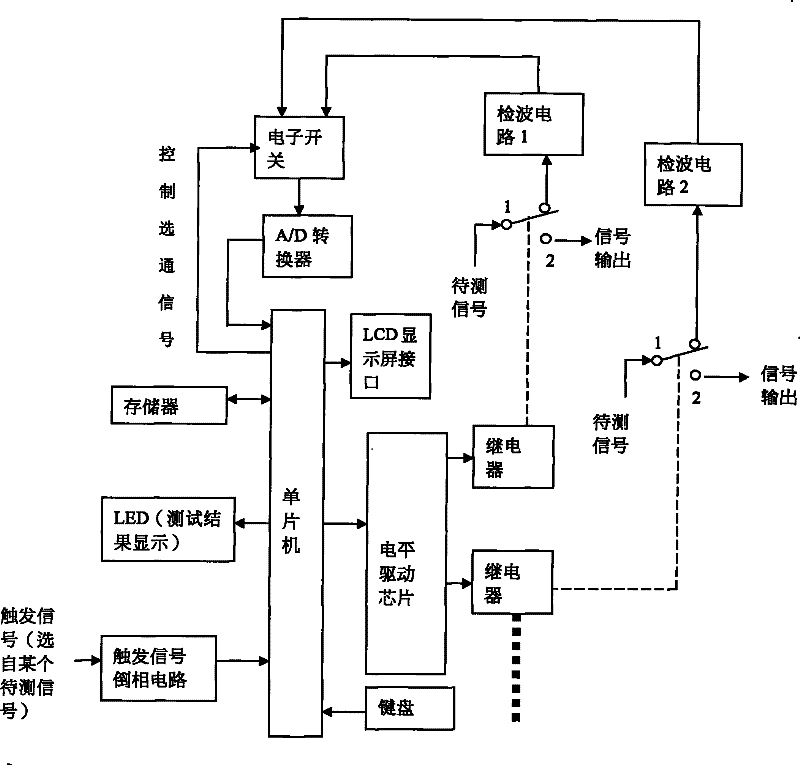

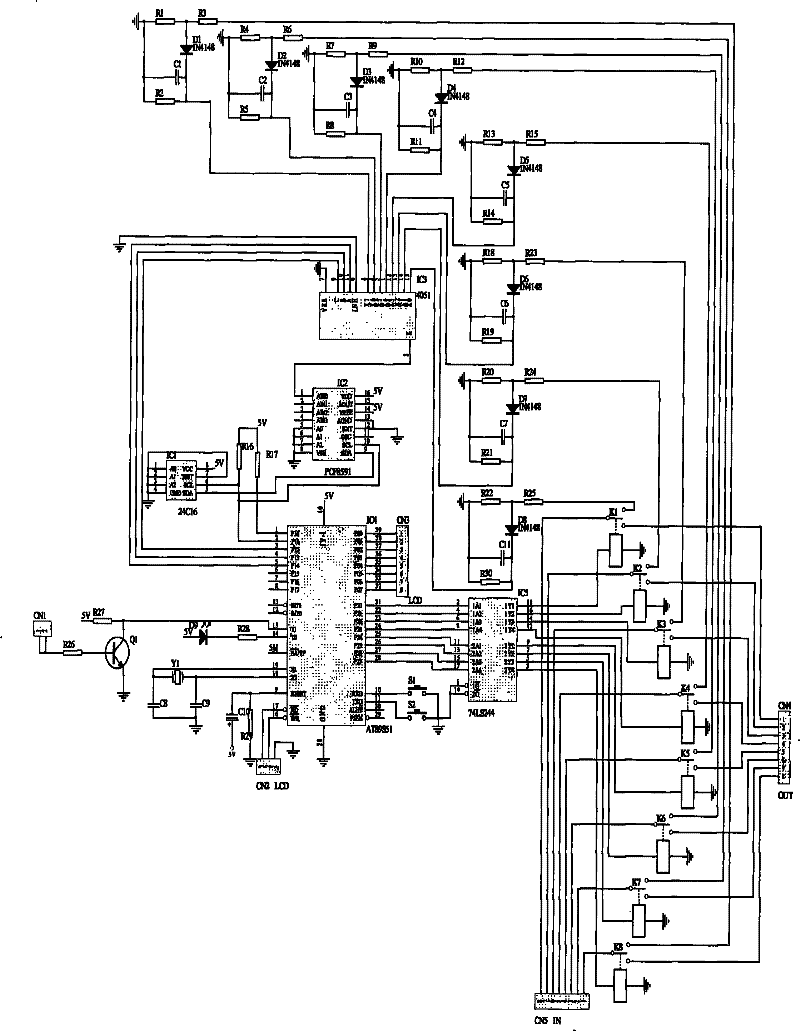

Electric voltage exception protection device used for circuit board test

InactiveCN101464473AAvoid failureAvoid damageElectrical measurement instrument detailsElectrical testingMicrocontrollerBuck converter

The invention discloses an abnormal voltage protection device in circuit board testing, which is connected between a circuit board to be tested and a test set, and comprises a relay, a singlechip, an A / D converter and a memorizer, wherein, the singlechip is connected with the relay; the A / D converter is connected between one contact point of the relay and the singlechip; the memorizer is connected with the singlechip and is used for storing a standard output voltage of the circuit board to be tested; and the other two contact points of the relay are respectively used for connecting the circuit board to be tested and the test set. Applied to the circuit board testing, the unusual voltage protection device serves the protection purpose reliably when the voltage output by the circuit board to be tested is abnormal, so as to avoid the failure of the test set; and the settings of the device is simple, the universality is good, and the device can be applied to the testing processes of the circuit boards in different types.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

Ecological protection system for highway cut slopes in bitter cold mountain area

InactiveCN110984193AAvoid slippery slope situationsServe the purpose of protectionExcavationsSteep slopeGabion

The invention relates to an ecological protection system for highway cut slopes in a severe cold mountain area. The ecological protection system comprises a fixed protection structure arranged on a slope and a movable protection structure arranged on the fixed protection structure. The fixed protection structure comprises a steplike concrete wall arranged on the slope and anchor rods anchored in the slope, a drainage ditch is formed between the lower end of the concrete wall and a roadbed, and the ends of the anchor rods stretch out from the surface of the concrete wall. The movable protectionstructure comprises gabion bands arranged along the step planes of the concrete wall, the stretching parts of the anchor rods are connected with the gabion bands, the vertical side faces of the concrete wall are provided with a plurality of ribs at intervals, each gabion band is composed of a plurality of gabions, and each gabion is embedded between two adjacent ribs. The protection system can beapplied to the terrain of high slopes and steep slopes in the mountain area and has high resistance to debris flows and ice and freezing failures.

Owner:河北水熠木丰工程技术有限责任公司

Forage feeding device for fishery breeding

ActiveCN110463642APromote fragmentationGuaranteed to passClimate change adaptationCuttersAnimal ForagingEngineering

The invention relates to the technical field of fishery breeding, and discloses a forage feeding device for fishery breeding. The device comprises a device main body; the upper end of the device mainbody is provided with a bearing frame; the upper end of the bearing frame is fixedly welded with a forage feeding groove; a pushing mechanism is arranged at the bottom of the inner wall of the foragefeeding groove; a limiting plate is mounted on one side of the pushing mechanism on the inner wall of the forage feeding groove; an extruding mechanism runs through the top of the forage feeding groove; a supporting mechanism is mounted on one side of the bearing frame on the upper end of the device main body; a feeding and conveying belt is arranged on the upper end of the supporting mechanism; aforage receiving frame is mounted below the forage feeding groove on the upper end of the feeding and conveying belt; a braking motor is mounted inside the bearing frame. The forage feeding device for fishery breeding can improve the use safety, and avoid the phenomenon that food intake is affected by excessive scramble of a fish school, and different sizes of forage can be obtained through crushing so as to meet the use requirements.

Owner:山东卓辰科技服务有限公司

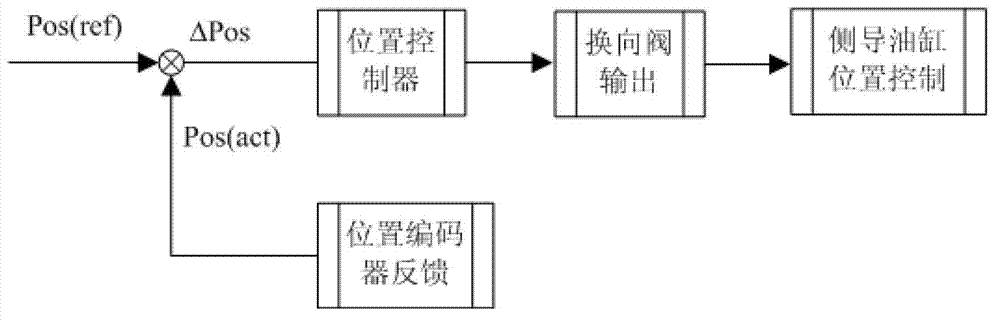

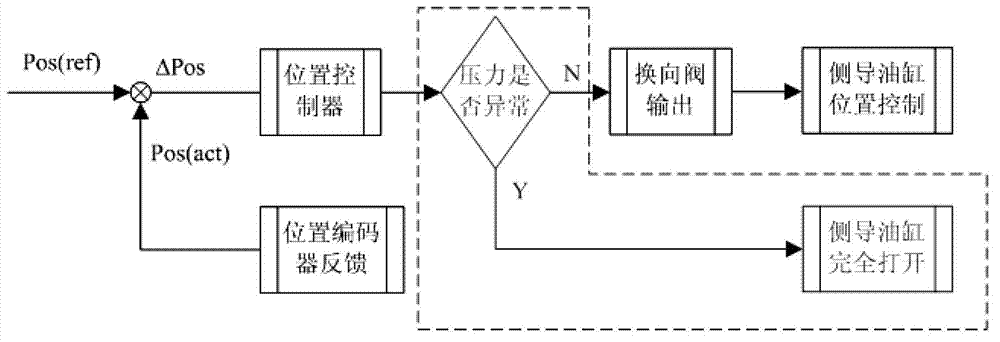

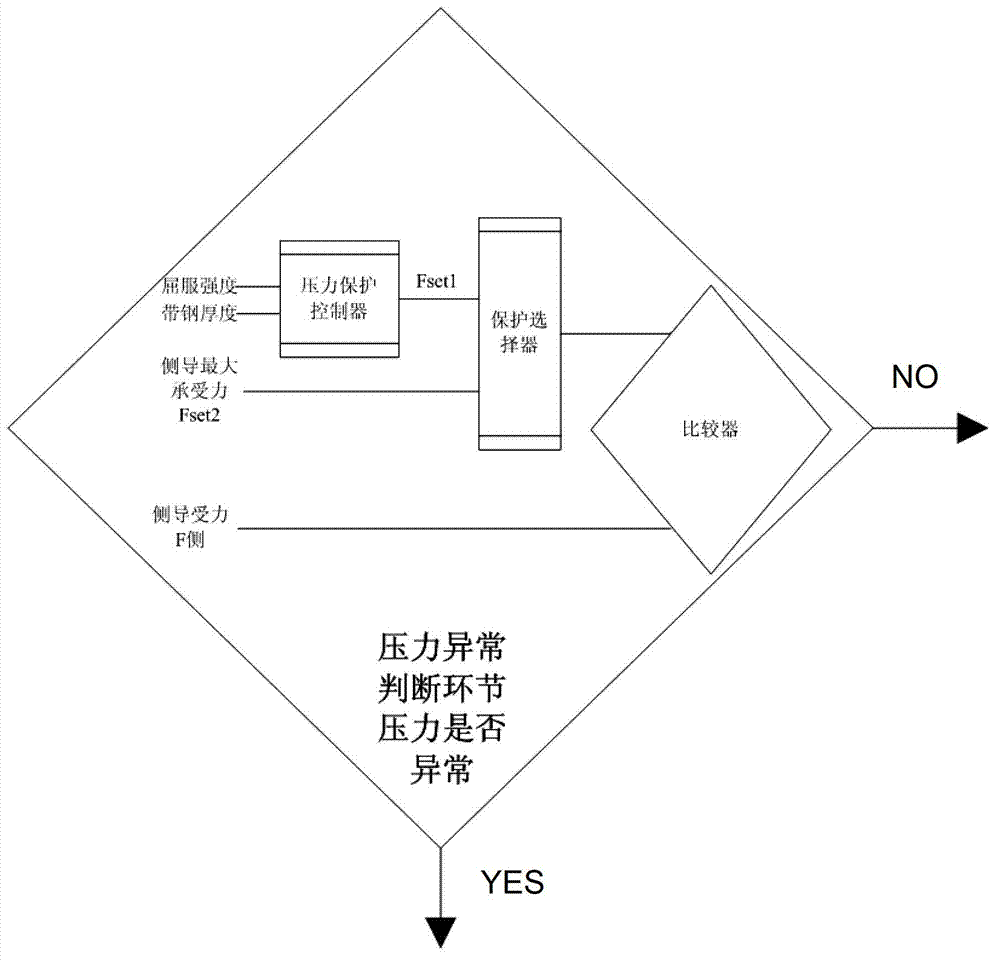

Side guide plate centring control device and control method

InactiveCN103926958AAvoid damageReduce edge damage defectsSimultaneous control of multiple variablesHydraulic cylinderSolenoid valve

The invention discloses a side guide plate centring control device which comprises a position controller and a position encoder of a side guide plate. The side guide plate centring control device further comprises a pressure protection controller, a protection selector, a pressure sensor and a comparer. The invention further discloses a side guide plate centring control method. Based on side guide short stroke and strip steel deformation pressure protection control and other technologies, protection clamping force is set according to different steel kinds and thicknesses, the protection function is started before strip steel is deformed or a side guide plate is damaged, the side guide plate is completely opened immediately, then a clamping steering solenoid valve coil signal is powered on to continue clamping the strip steel, therefore, through the reciprocating movement of the short stroke of a hydraulic cylinder, the strip steel side loss defect and side guide plate damage can be reduced, the aim of protection is achieved, and the function of beating the strip steel for centring can be achieved.

Owner:BAOSTEEL STAINLESS STEEL

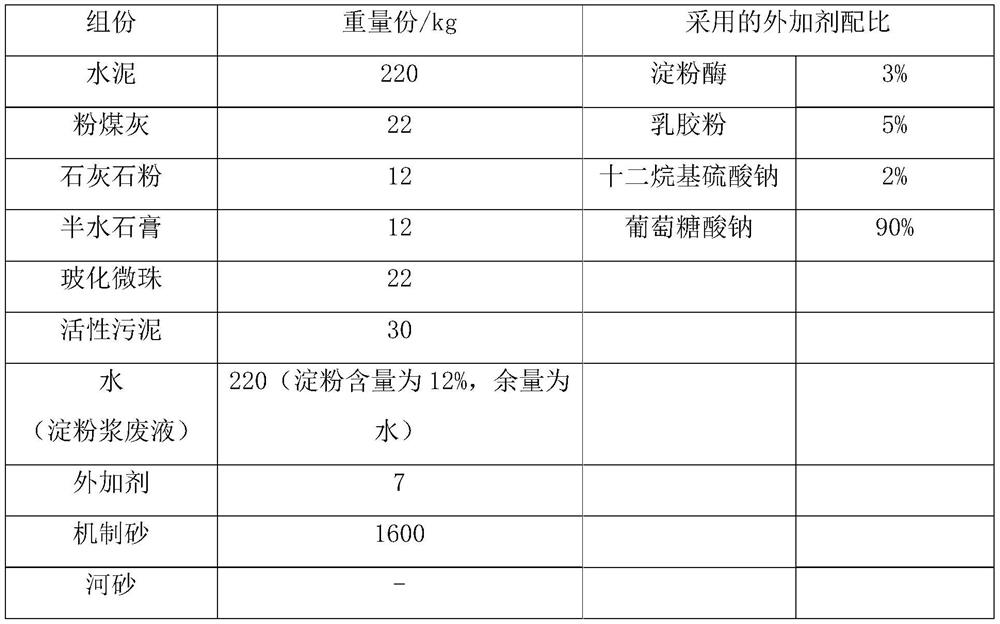

Full-machine-made sand wet-mixed mortar and processing method thereof

The invention provides full-machine-made sand wet-mixed mortar, which comprises the following components in parts by weight: 180-200 parts of cement, 18-22 parts of fly ash, 8-12 parts of limestone powder, 8-12 parts of semi-hydrated gypsum, 18-22 parts of vitrified micro beads, 180-220 parts of water, 3-7 parts of an additive, 20-30 parts of activated sludge and 1200-1600 parts of machine-made sand, wherein the water is from starch slurry waste liquid with the starch content of 8-12%, and the additive comprises 3% of amylase, 5% of latex powder, 2% of lauryl sodium sulfate and 90% of sodium gluconate. The invention further provides a processing method of the wet-mixed mortar, wherein starch production wastewater and activated sludge generated in urban life are utilized, so that secondarypollution of the starch industry and the activated sludge to the environment is avoided, and a large amount of waste materials can be consumed while the production cost is reduced. According to the invention, additives used in the production process are simple in component, can be purchased in the market, do not affect normal production of enterprises and can be popularized in wet-mixed mortar enterprises; and a full-machine-made sand formula is used, so that river ecology is not damaged.

Owner:重庆富普新材料有限公司 +1

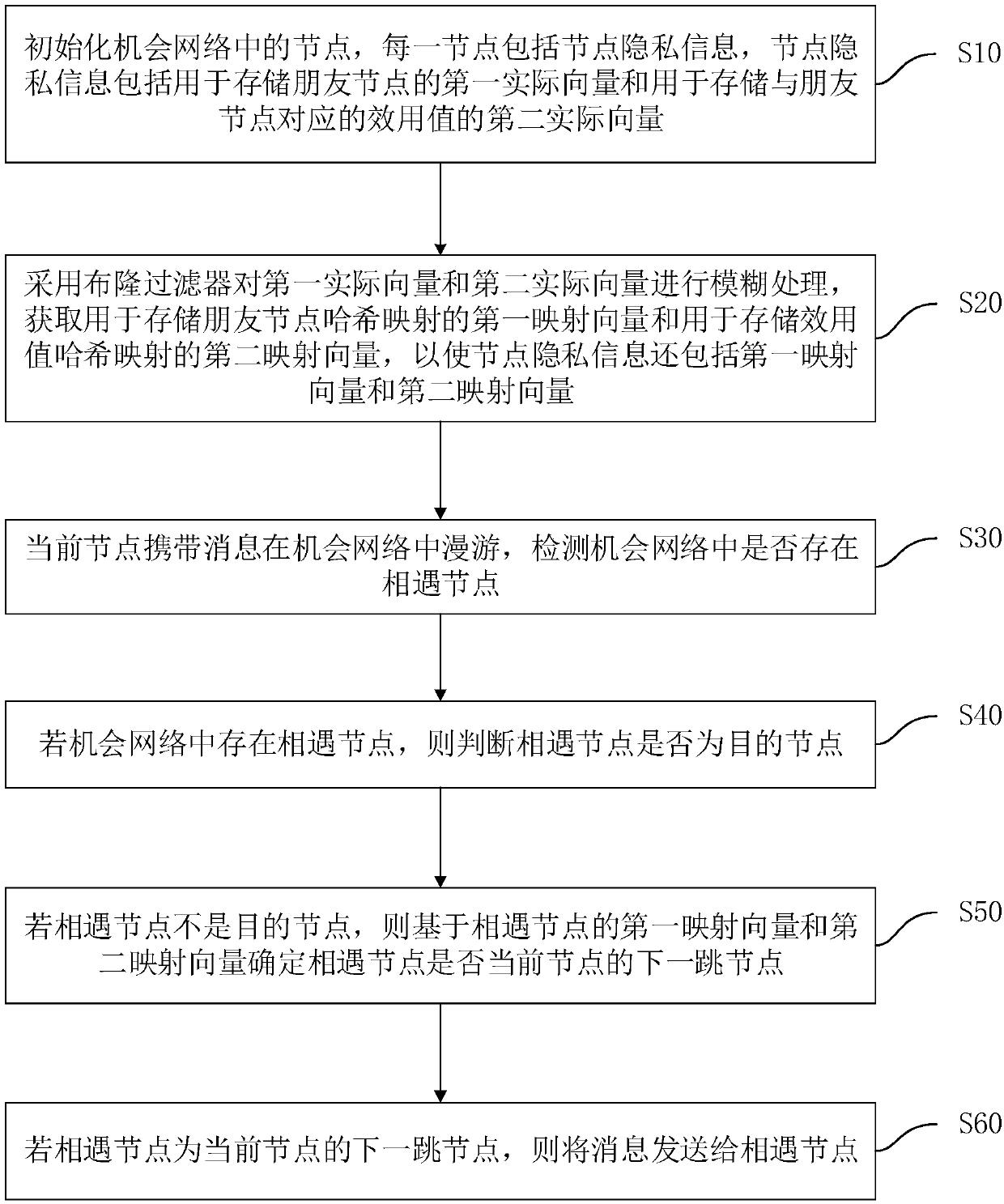

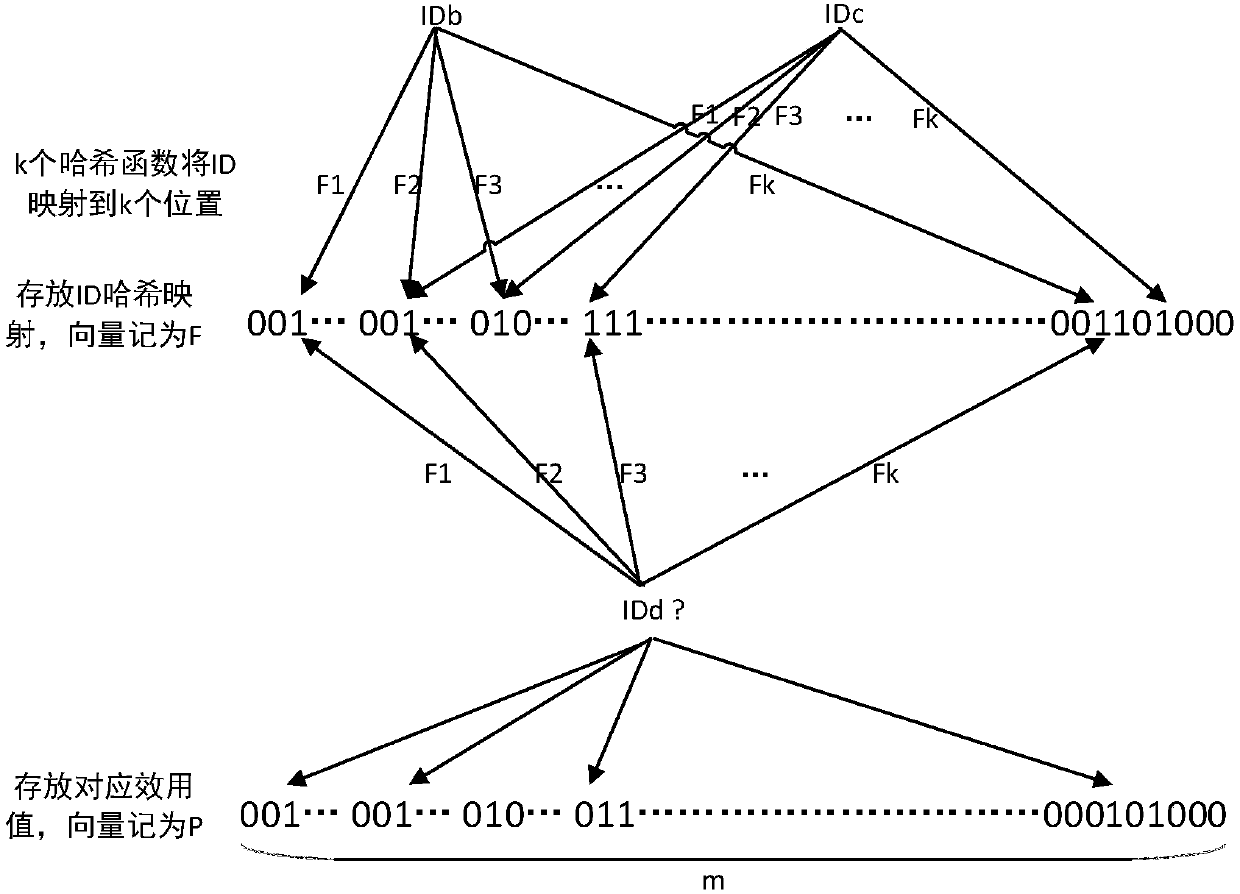

Privacy protection added routing method in opportunity network

ActiveCN107770771AServe the purpose of protectionIncrease success rateSecurity arrangementPrivacy protectionBloom filter

The invention discloses a privacy protection added routing method in an opportunity network. The method comprises the steps of initializing nodes in the opportunity network, wherein each node comprises node privacy information comprising a first actual vector used for storing friend nodes and a second actual vector used for storing utility values; using a Blond filter to perform fuzzy treatment onthe first actual vector and the second actual vector, and acquiring a first mapping vector and a second mapping vector; allowing the current node carrying a message to roam in the opportunity network, so as to detect whether a meeting node exists in the opportunity network; if the meeting node exists, judging whether the meeting node is a target node; if the meeting node is not the target node, determining whether the meeting node is the next hop node of the current node based on the first mapping vector and the second mapping vector of the meeting node; and if the meeting node is the next hop node, sending the message to the meeting node. According to the method, the purpose of protecting the privacy information of the node is achieved, and a success rate of message transmission is improved.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

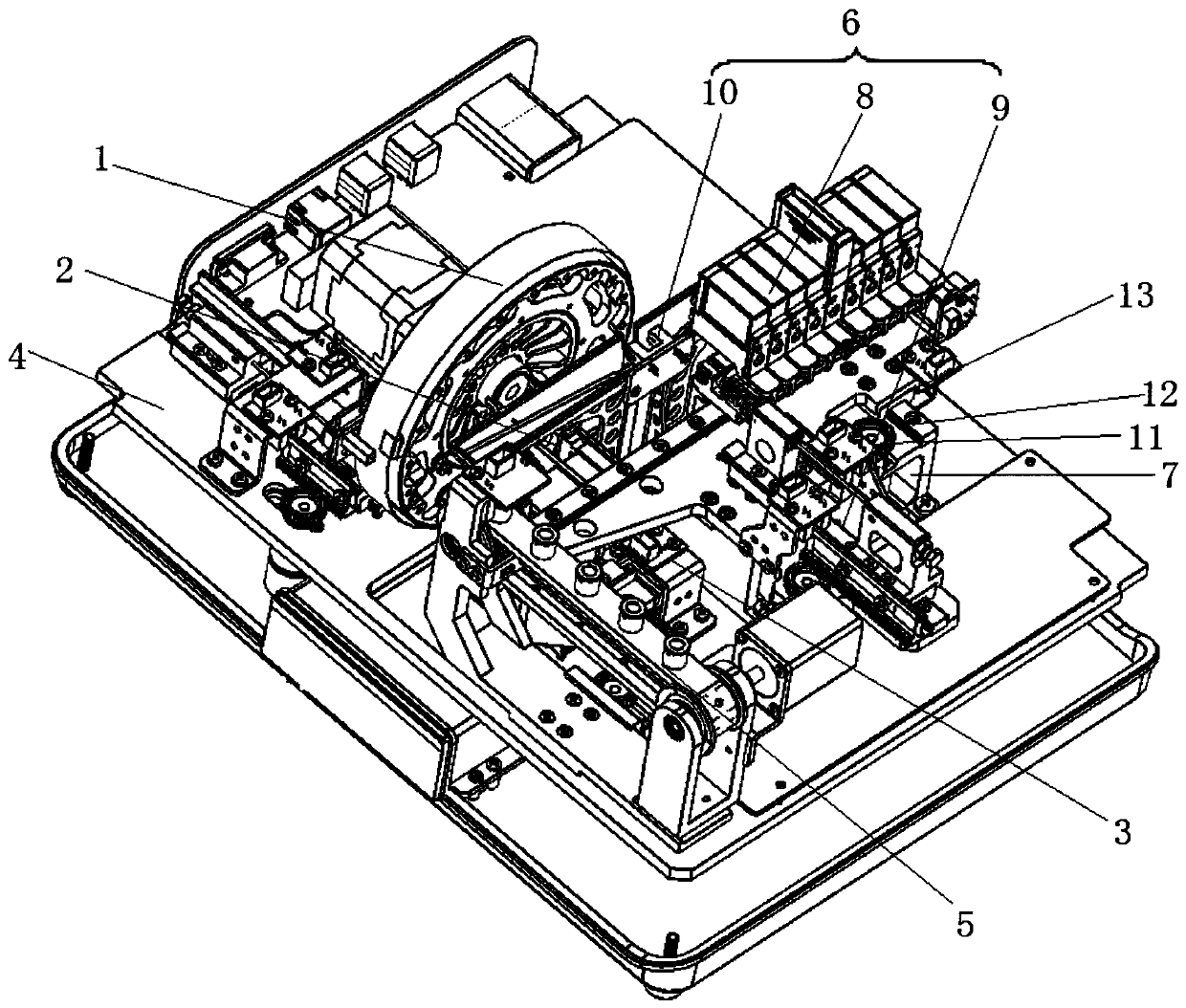

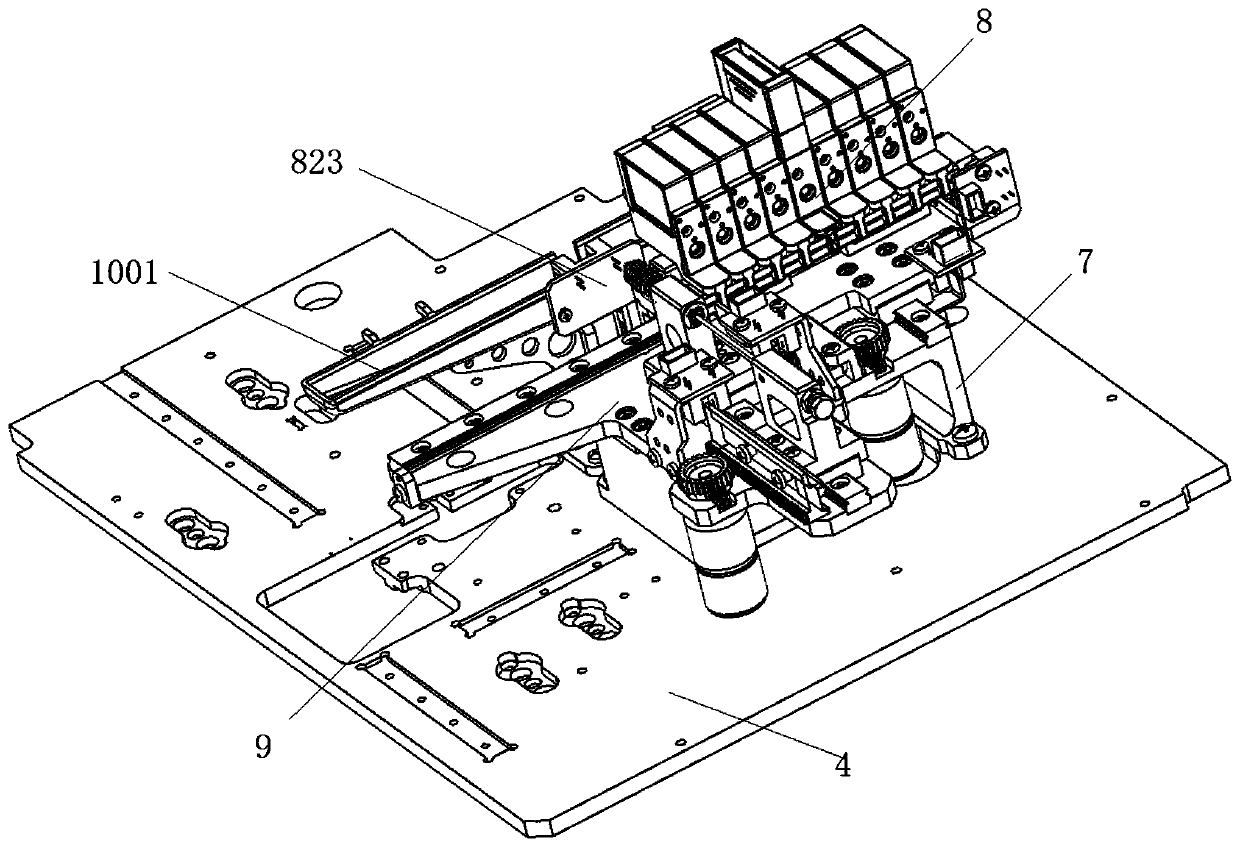

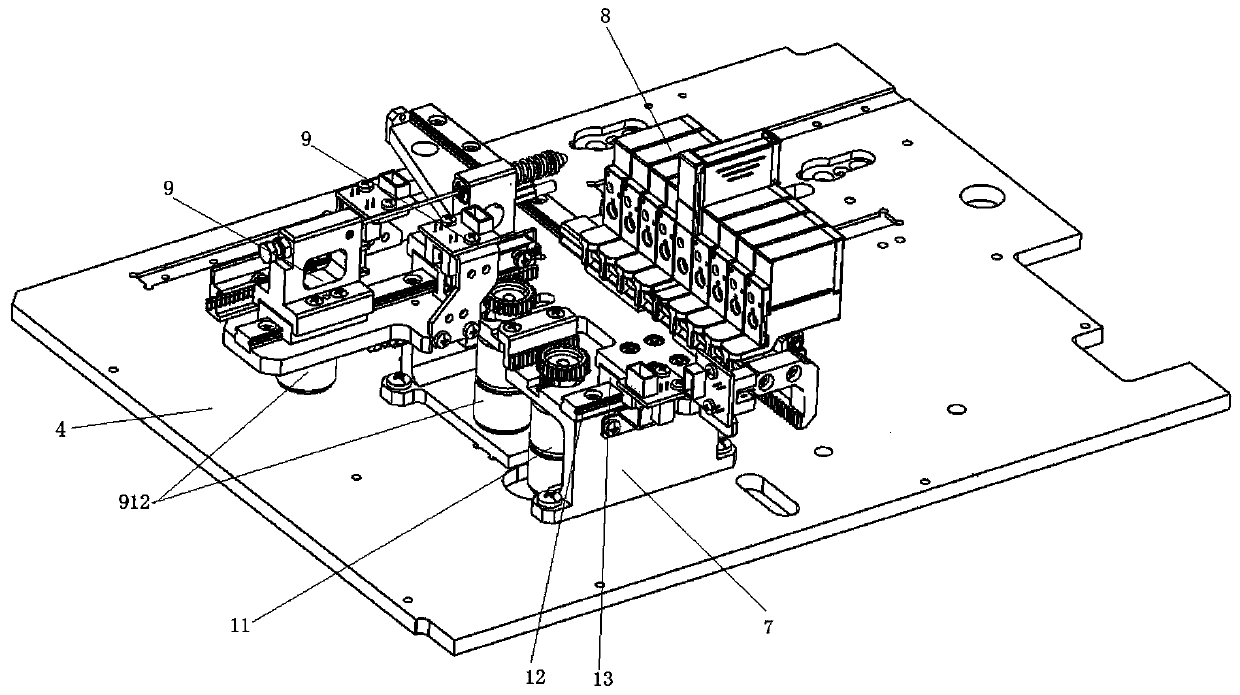

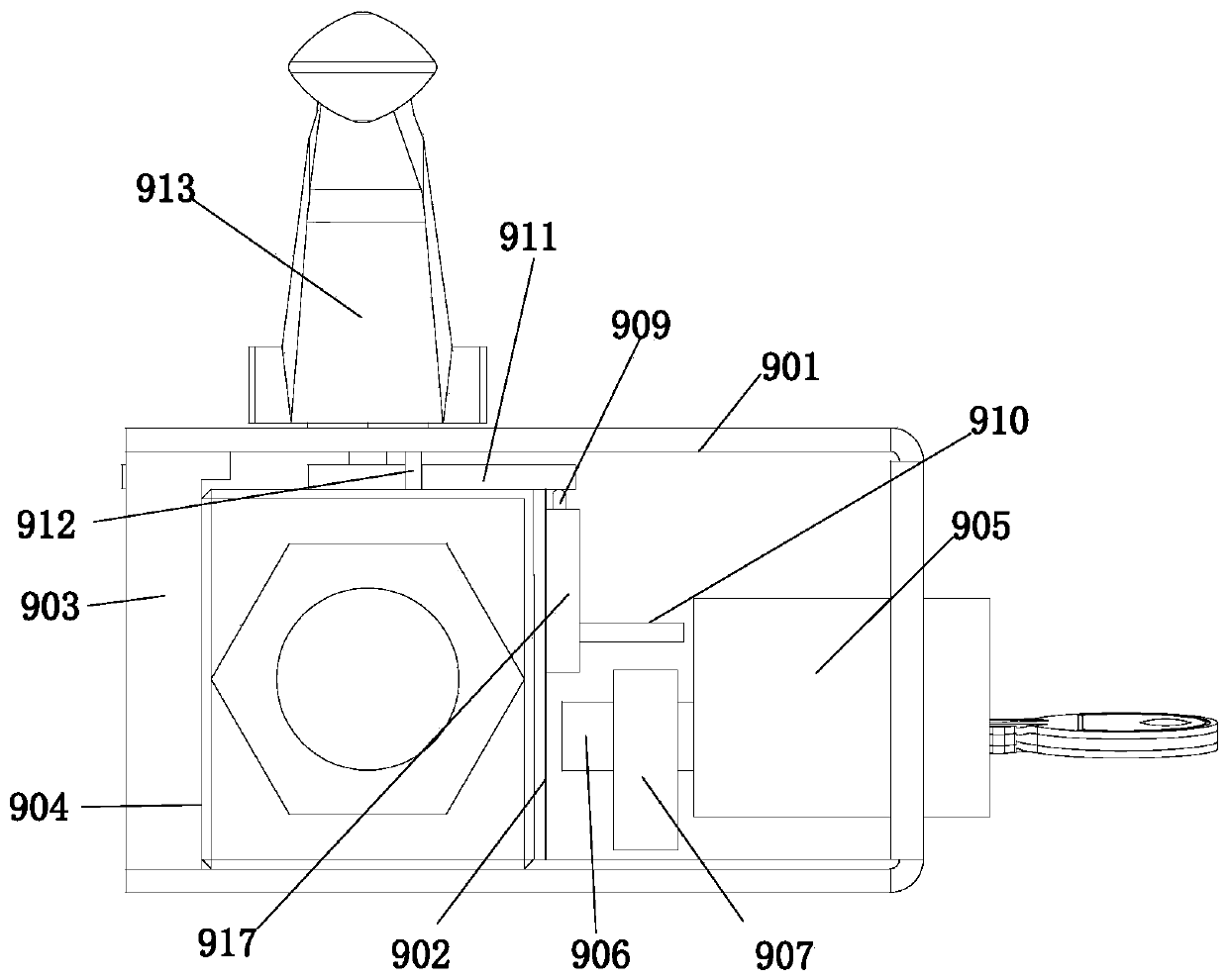

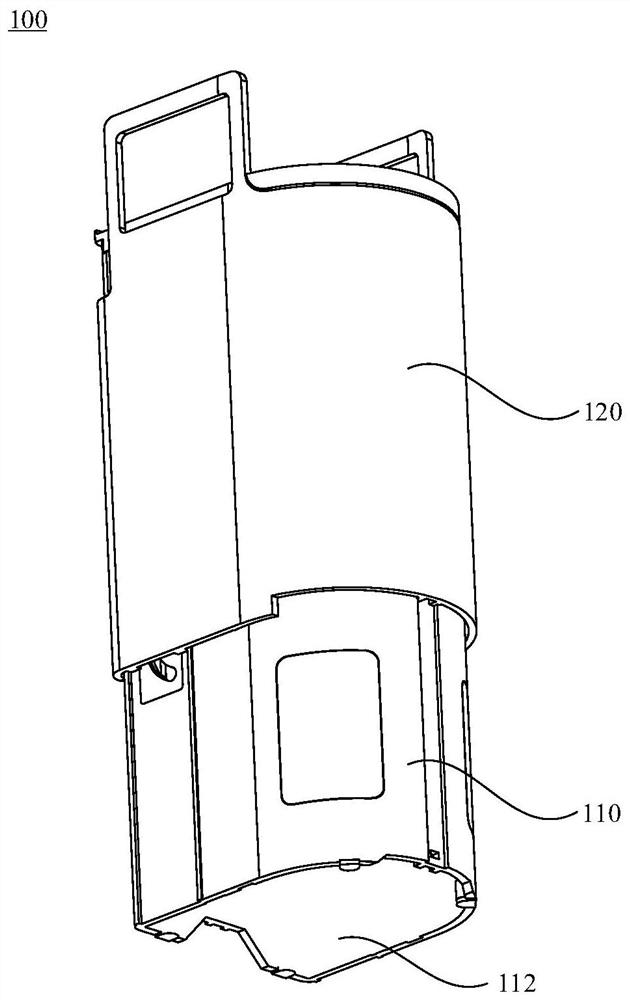

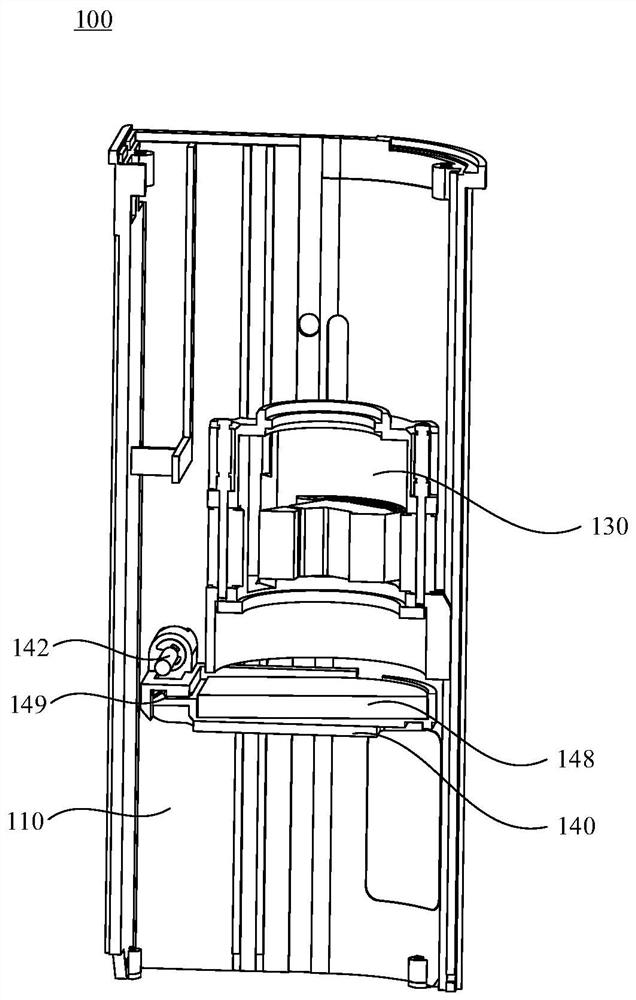

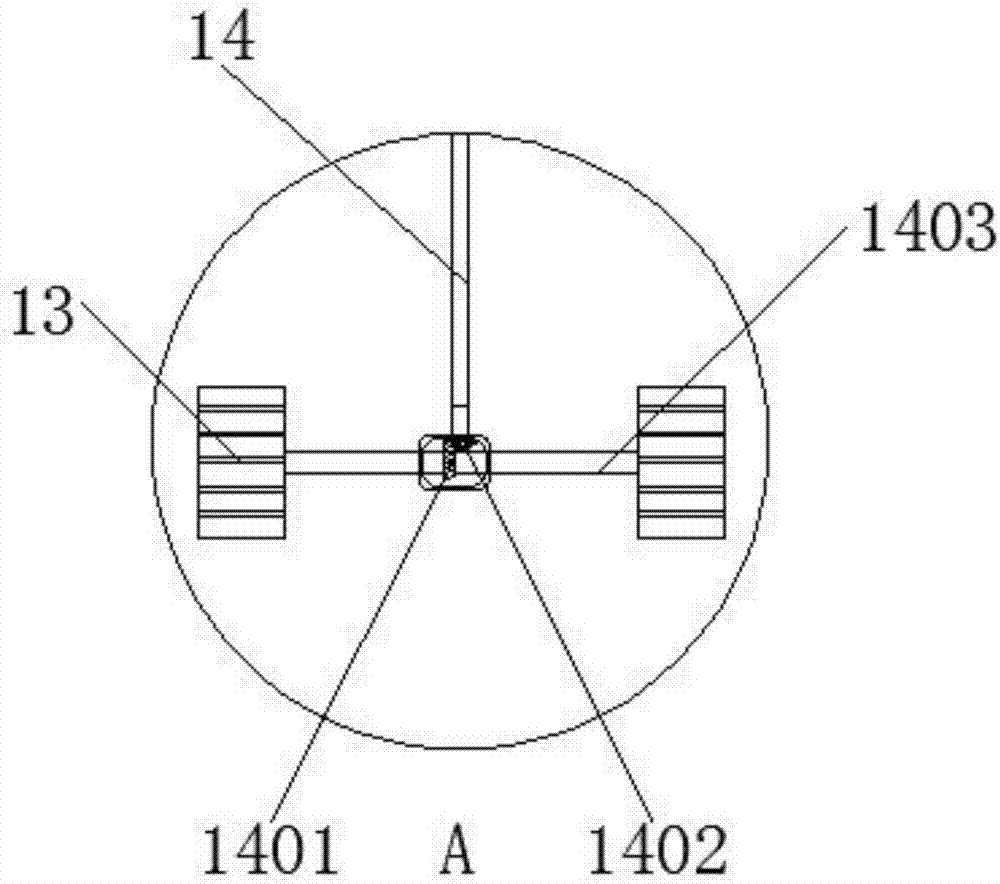

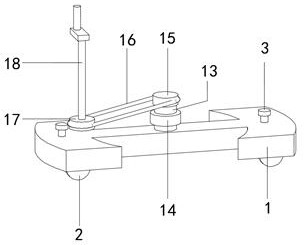

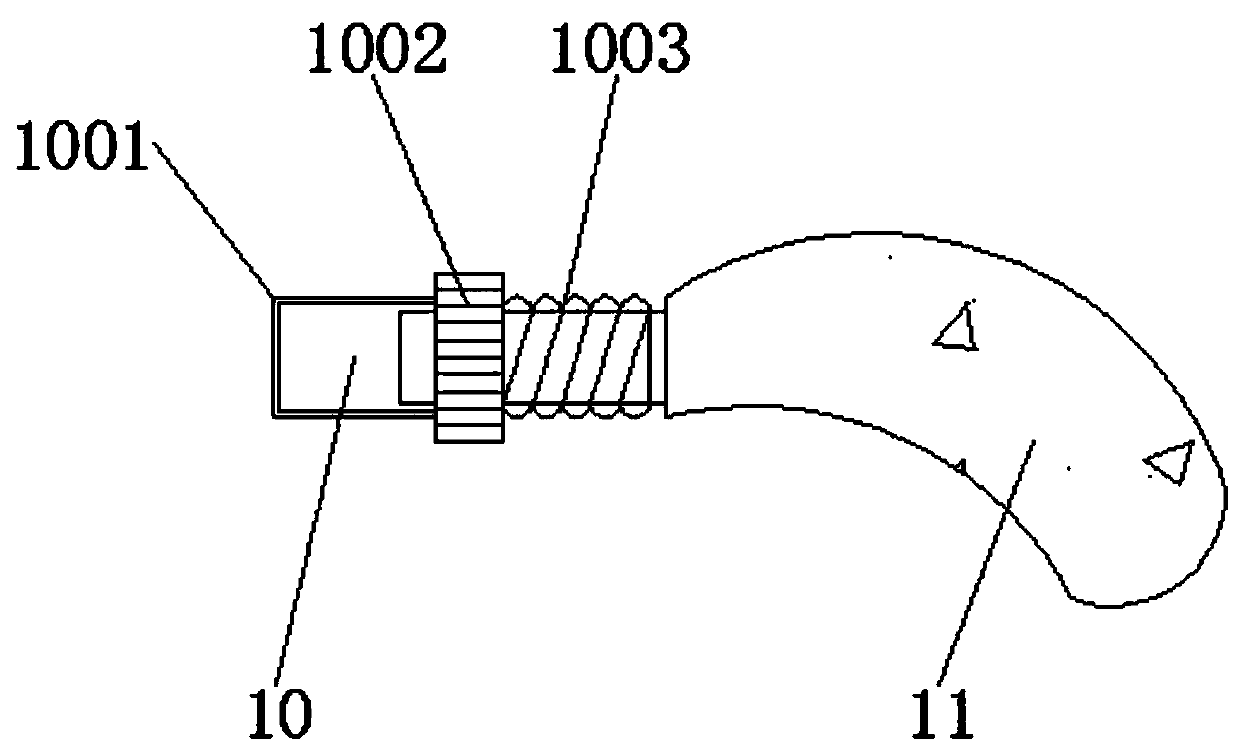

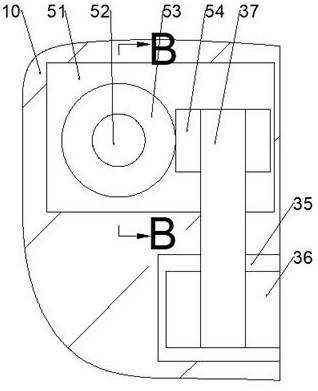

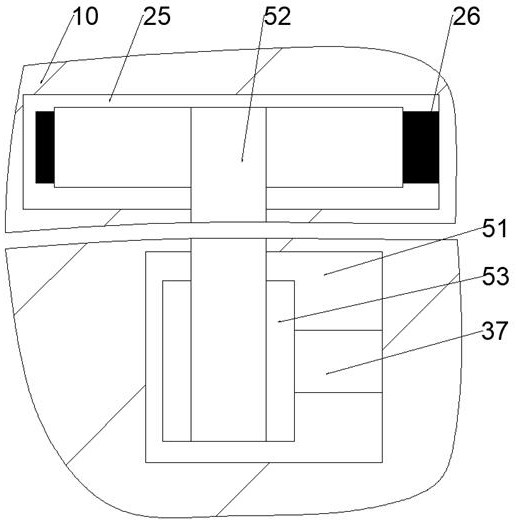

Material pushing and recycling system for chemiluminescence immunoassay analyzer

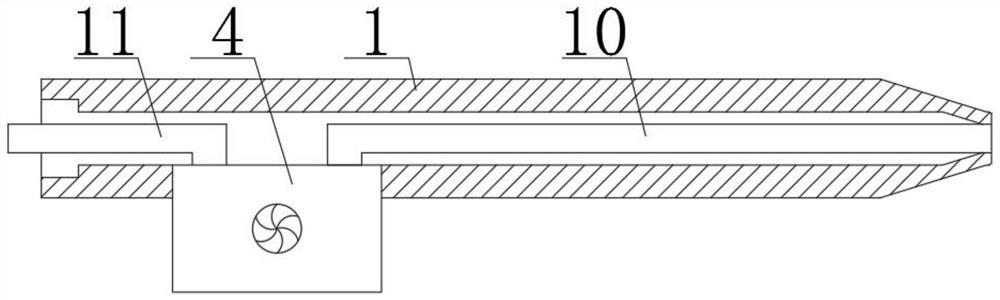

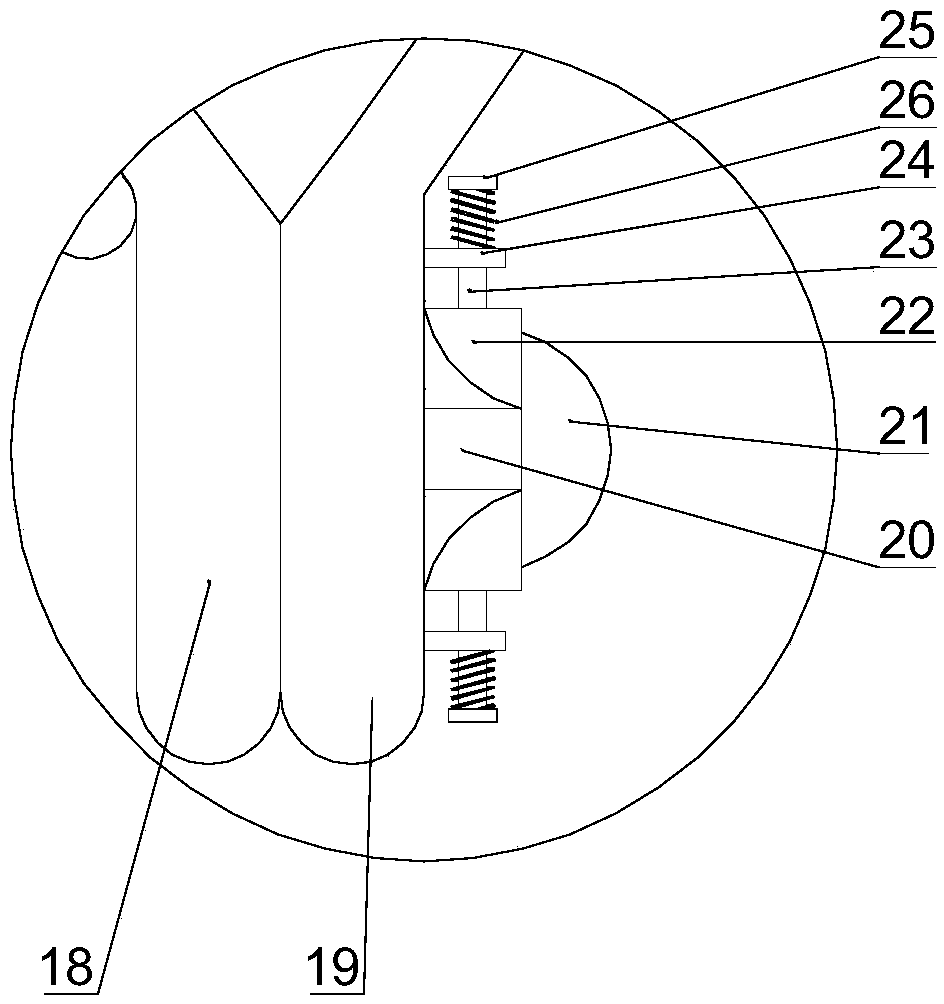

PendingCN111337480ALarge storage capacityLess componentsChemiluminescene/bioluminescenceBiological testingCapillary TubingProcess engineering

The invention discloses a material pushing and recycling system for a chemiluminescence immunoassay analyzer. The material pushing and recycling system comprises a fixed seat, a capillary tube pushingdevice, a storage device, a first driving device and a waste liquid recycling device, wherein the fixed seat and the waste liquid recycling device are used for being fixedly mounted on a bottom plateof the chemiluminescence immunoassay analyzer; the capillary tube pushing device is slidably mounted on the fixed seat; the first driving device is connected with the capillary tube pushing device and then can drive the capillary tube pushing device to move; the storage device is installed on the capillary tube pushing device in a sliding mode, the storage device can move on the capillary tube pushing device, the waste liquid recycling device is located below the storage device, and the waste liquid recycling device is communicated with a liquid collection box installed below a bottom plate of the chemiluminescence immunoassay analyzer. Waste liquid recycling, capillary tube push-out and reagent extrusion can be achieved, and the system has the advantages of being compact in structure andsmall in overall size.

Owner:CHENGDU SEAMATY TECH

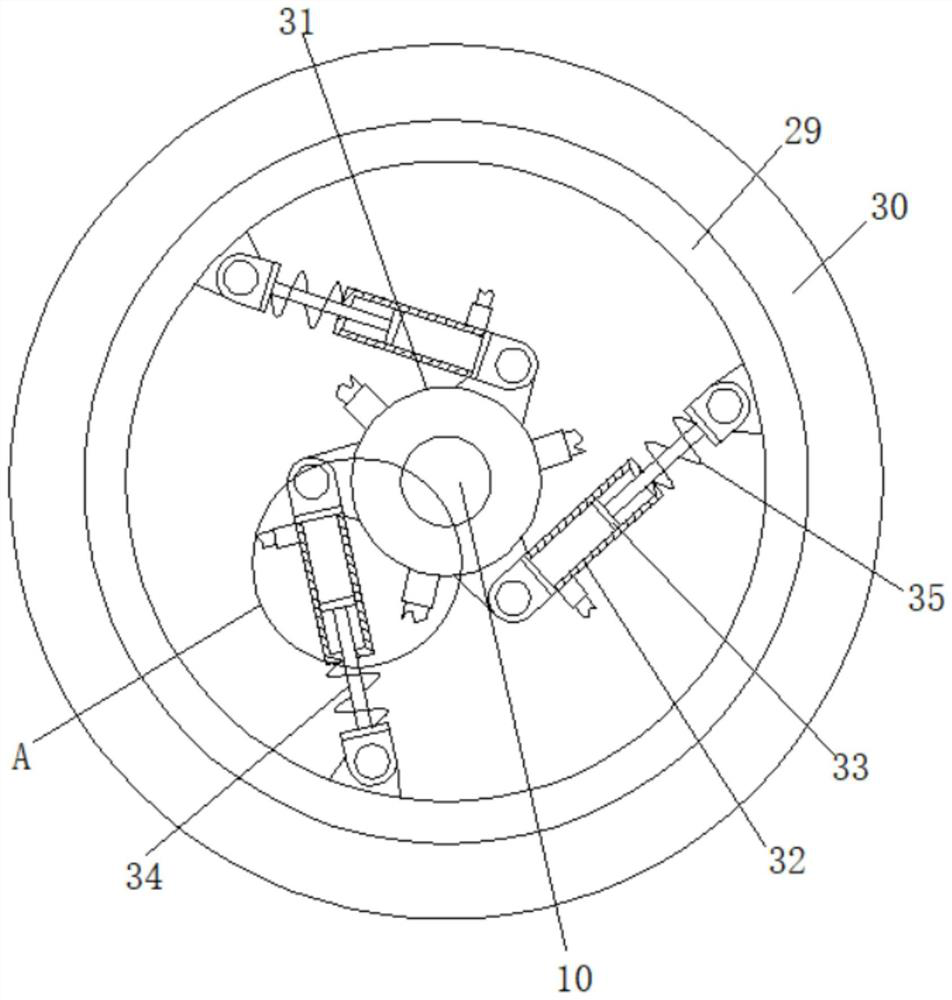

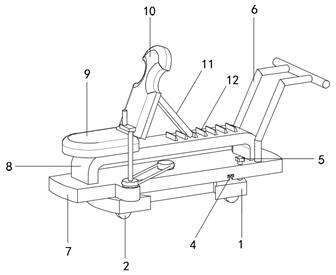

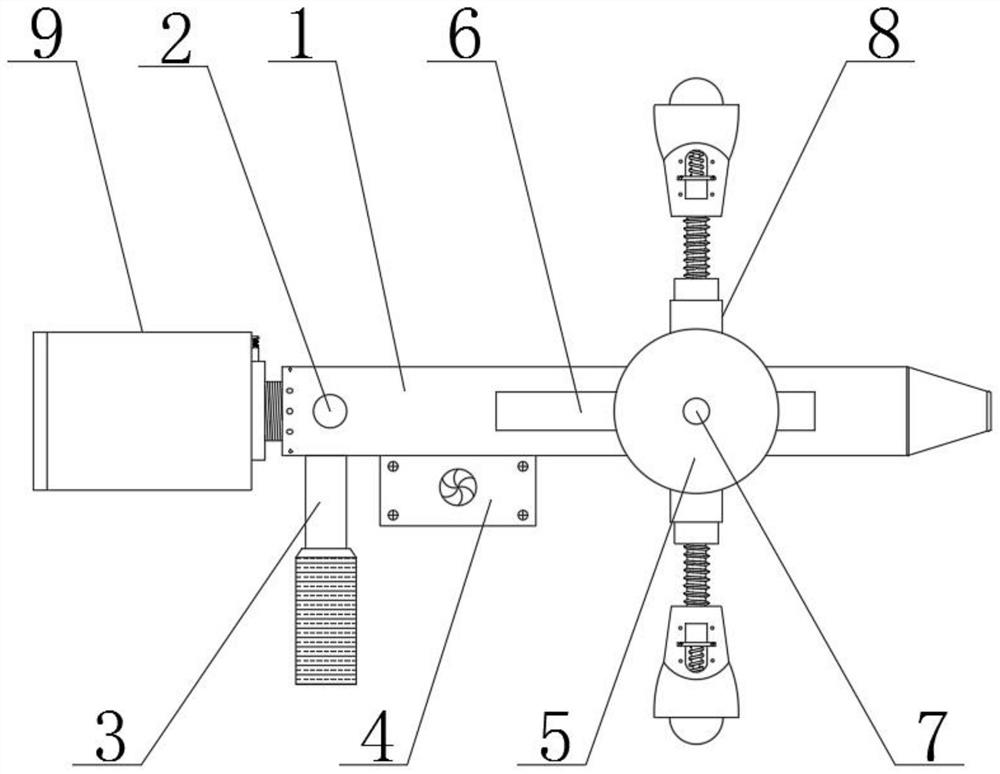

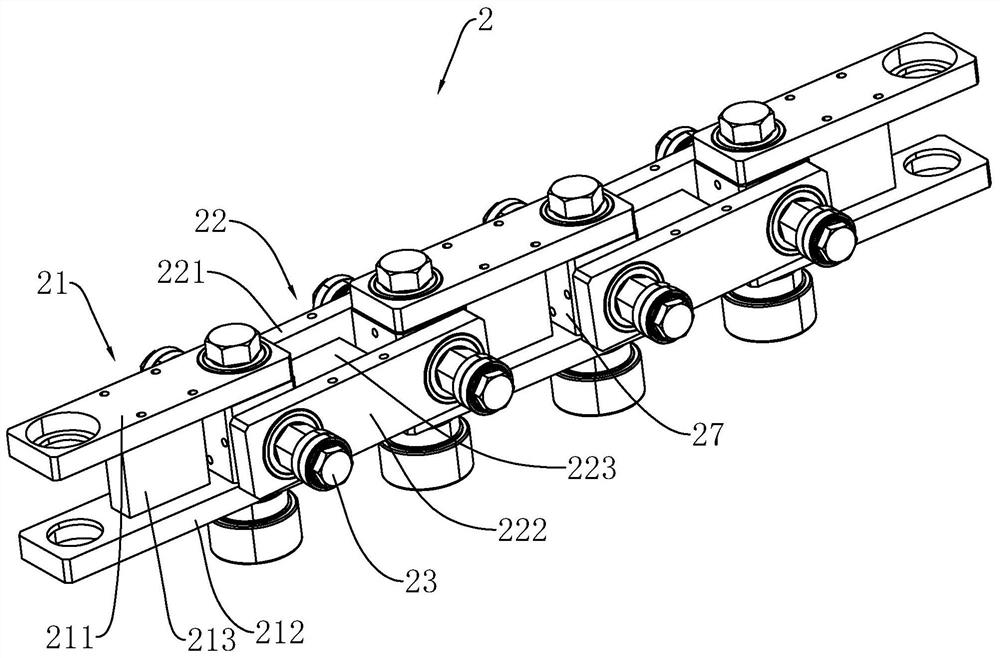

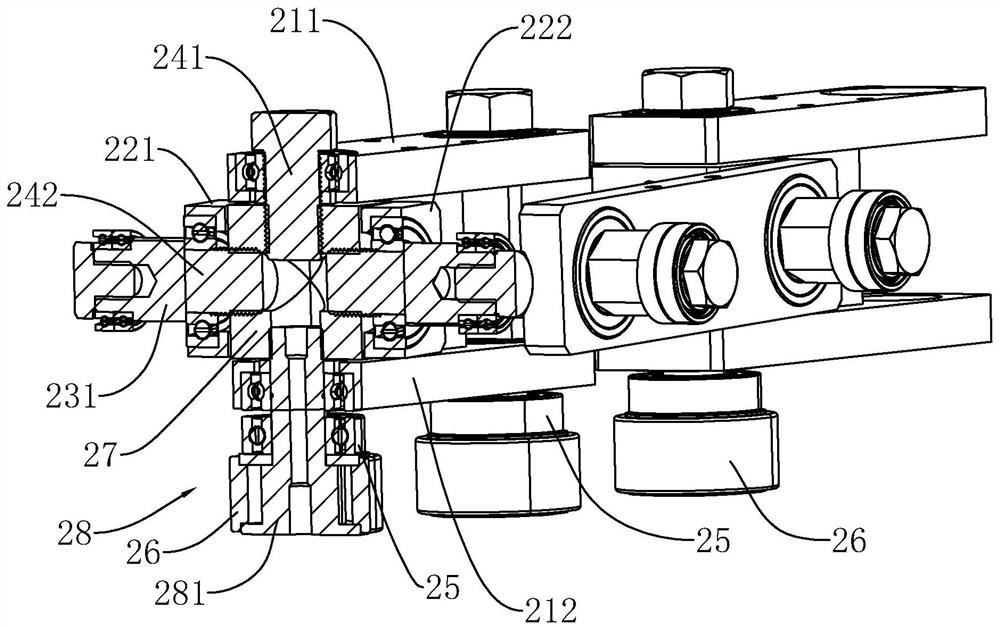

Multi-connecting-rod type tire clamping device carried on AGV and operation method of multi-connecting-rod type tire clamping device

The invention discloses a multi-connecting-rod type tire clamping device carried on an AGV and an operation method of the multi-connecting-rod type tire clamping device. The multi-connecting-rod typetire clamping device comprises two sets of opening-closing-type tire clamping mechanisms arranged symmetrically and used for synchronously clamping and lifting four wheels of an automobile; each set of opening-closing-type tire clamping mechanism comprises a ball lead screw mechanism used for providing driving force, and each ball lead screw mechanism is provided with a first nut sleeve structureand a second nut sleeve structure in a threaded transmission fit mode; and multi-connecting-rod mechanisms used for achieving opening-closing actions are hinged to the two ends of the first nut sleevestructures and the two ends of the second nut sleeve structures correspondingly, and the executing tail end of each multi-connecting-rod mechanism is connected with a clamping arm structure used forbeing matched with the outer walls of automobile tires for clamping. The two sets of tire clamping devices are symmetrically arranged on the AGV, clamping claws are opened and closed through an opening-closing mode, then the clamping claws are matched with the two sides of the automobile tires in a contact mode to clamp the automobile tires, thus the automobile is lifted away from the ground and carried and moved through the AGV conveniently, and automatic parking is achieved.

Owner:WUHAN ZHIXIANG ROBOT CO LTD

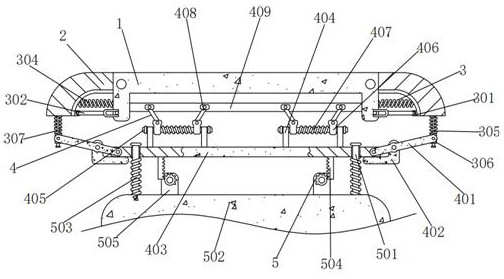

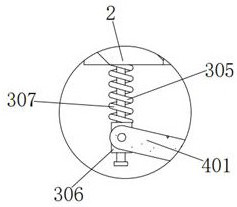

Bumper with shock absorption function for new energy automobile

ActiveCN111619494AWith shock absorption functionPlay a shock absorbing effectBumpersNew energyGear wheel

The present invention discloses a bumper with a damping function for a new energy automobile. The bumper comprises a bumper shell and arc-shaped plates, the left side and the right side of the bumpershell are movably connected with the arc-shaped plates through pin shafts, and elastic devices are installed on the inner sides of the left arc-shaped plate and the right arc-shaped plate. According to the bumper with the damping function for the new energy automobile, through mutual cooperation of a first vertical plate, a third spring, a second connecting rod, a second transverse plate and otherstructures, when the device is impacted, the damping effect can be achieved; through mutual cooperation of the arc-shaped plates, afirst spring, a second spring, a first connecting rod, an L-shaped plate and a first transverse plate, when the arc-shaped platesareimpacted in other directions, the impact force can be reduced through the elastic performance of the first spring and the second spring;and through mutual cooperation of structures such as afirst transverse plate, asecond vertical plate, a fourth spring, a toothed plate, a gear and the second vertical plate, the impact force borne bythe first transverse plate can be further weakened, and the practical performance is higher.

Owner:永康市能泽科技有限公司

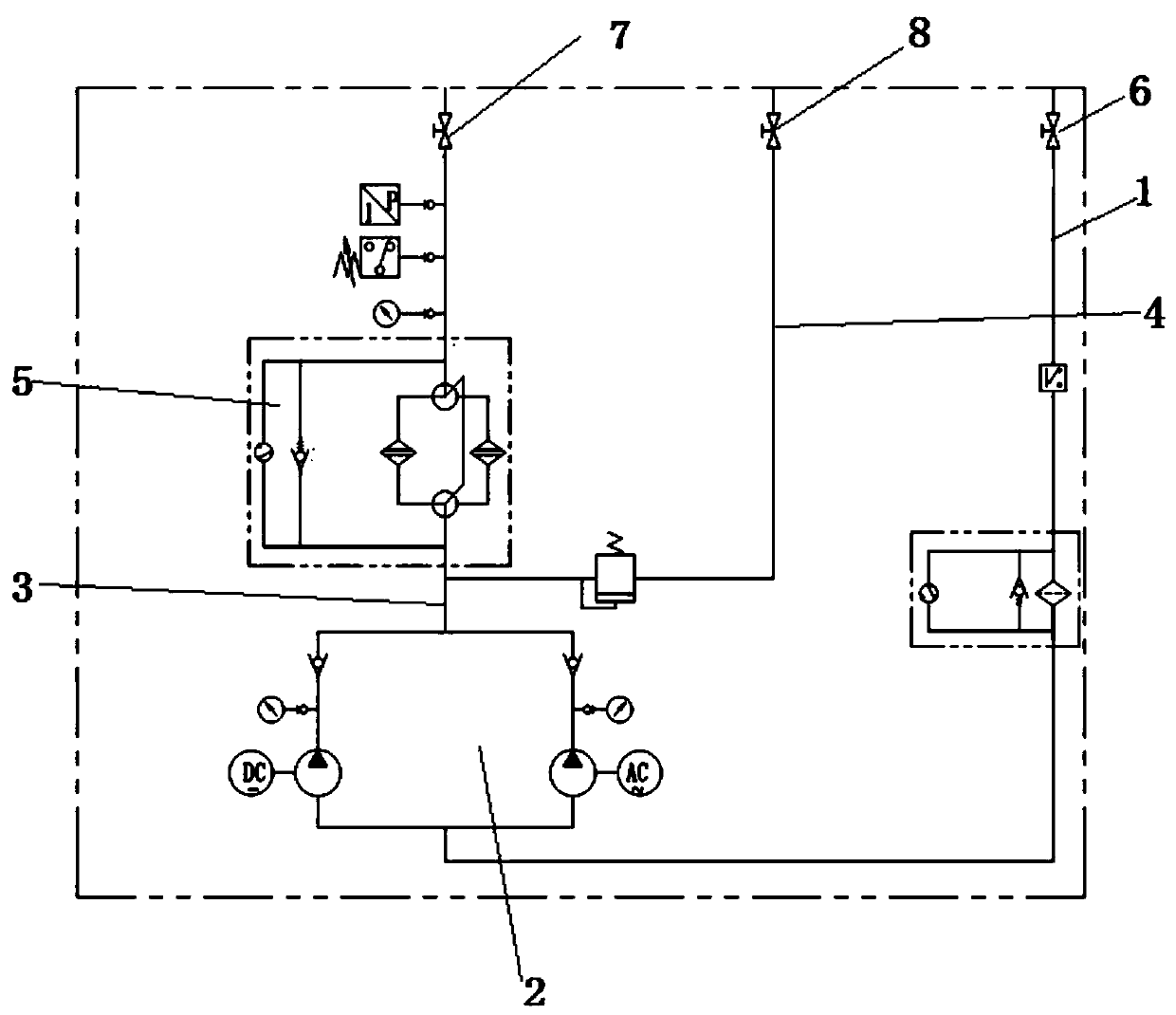

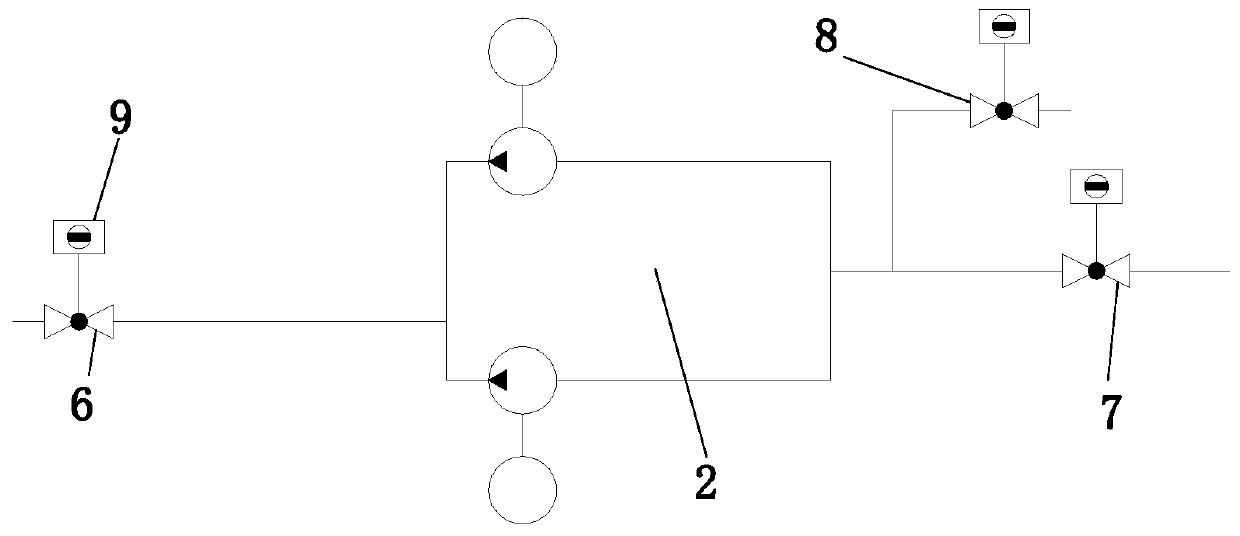

Anti-misoperation starting safe locking mechanism of high-oil-pressure jacking device

ActiveCN110425408AAvoid feverSimple structureHydro energy generationMachines/enginesOil pressureHigh pressure

The invention discloses an anti-misoperation starting safe locking mechanism of a high-oil-pressure jacking device. The anti-misoperation starting safe locking mechanism comprises an oil taking pipe,wherein the oil taking pipe is sequentially connected with a high-pressure oil pump and an oil supply pipe, the oil supply pipe is sequentially connected with an overflow pipe and a duplex filter, andthe overflow pipe is positioned between the duplex filter and the high-pressure oil pump; the anti-misoperation starting safe locking mechanism further comprises a control box, a starting control loop connected with the high-pressure oil pump is arranged inside the control box, an oil inlet valve is arranged at an inlet of the oil taking pipe, an outlet valve is arranged at an outlet of the oil supply pipe, and an overflow valve is arranged at an outlet end of the overflow pipe; a valve locking device is arranged on the oil inlet valve, the outlet valve and the overflow valve, a locking key is arranged on the valve locking device, and a starting switch and an electric locking device which are connected in series are arranged on the starting control loop. The anti-misoperation starting safe locking mechanism further comprises a key replacement box arranged on the side face of the control box, and the key replacement box is provided with a starting unlocking key. The anti-misoperation starting safe locking mechanism has the characteristics of being capable of protecting an oil pump of the high-pressure oil jacking device.

Owner:STATE GRID CORP OF CHINA +2

Bridge passage restriction device

The invention discloses a bridge passage restriction device. The bridge passage restriction device comprises a bridge deck; a middle column is built at the middle part of the bridge deck; edge columnsare built on the two sides of the bridge deck; arc edge plates are arranged on the external side surfaces of the edge columns; circular mounting cavities are formed between the edge plates and the edge columns; driving motors are mounted in the mounting cavities; reels sleeve output shafts of the driving motors; rotating pins are arranged at the top ends of the edge columns; supporting beams arepinned at the top ends of the edge columns through the rotating pins; connecting rods are welded at one ends, far away from the middle column, of the supporting beams; binding holes are formed in oneends, far away from the supporting beams, of the connecting rods; and a steel wire rope is bound on the binding holes. The bridge passage restriction device has the advantages that width restriction and height restriction effects can be simultaneously realized, the adjusting and mounting are more convenient, the passing of overhauling vehicles is made convenient, traffic congestion is reduced, andportal structures formed among the edge columns, the supporting beams and vertical columns are convenient for the passing of non-motor vehicles.

Owner:CENXI DONGZHENG POWER TECH DEV

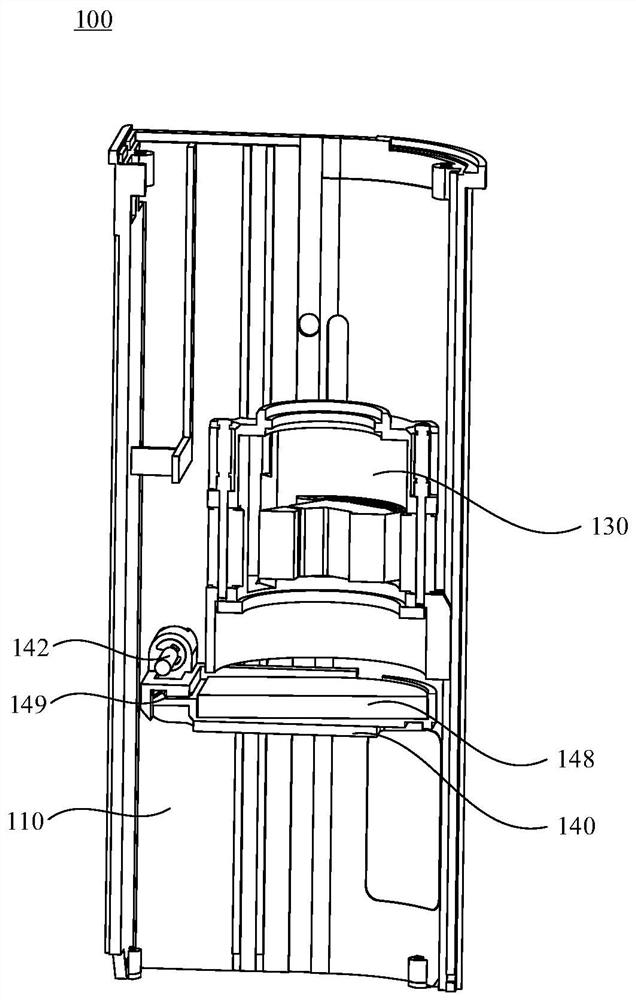

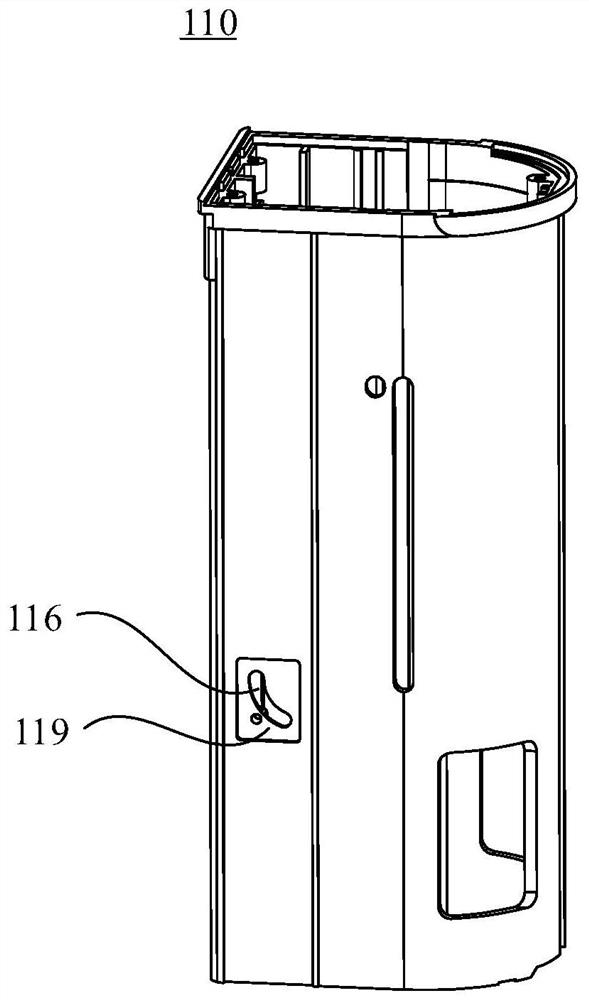

CT scanner convenient to transfer and using method thereof

InactiveCN112205995AServe the purpose of protectionPlay a protective effectNon-rotating vibration suppressionCastorsMedical equipmentMedicine

The invention relates to the field of CT scanners, in particular to a CT scanner convenient to transfer and a using method thereof. The CT scanner comprises a frame, wherein four supporting legs are arranged on the frame, a supporting plate used for fixing medical equipment is arranged on the supporting legs, each supporting leg comprises a walking mechanism, a longitudinal damping mechanism is arranged on each walking mechanism, a transverse damping mechanism is arranged on each longitudinal damping mechanism, and each walking mechanism is in transmission connection with the corresponding longitudinal damping mechanism and can also be in transmission connection with the corresponding transverse damping mechanism. According to the CT scanner convenient to transfer and the using method thereof, vibration impact generated on the ground is damped and buffered through the walking mechanisms, vibration impact transmitted by the walking mechanisms is buffered through the longitudinal dampingmechanisms, and the transverse damping mechanisms are started through the walking mechanisms to increase the transverse moving resistance of the supporting plate when large vibration impact is encountered, and the CT scanner can be protected in the transferring process.

Owner:张侠

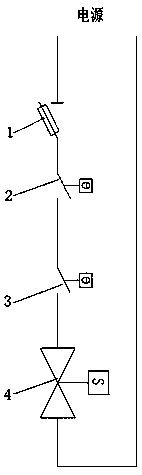

Automatic sprinkling control system and control method thereof

InactiveCN110617557AEasy to controlControl won'tMechanical apparatusSpace heating and ventilation safety systemsWater sourceControl system

The invention discloses an automatic sprinkling control system. The automatic sprinkling control system comprises a fuse protector and an electromagnetic valve, and further comprises an environment temperature switch and an exhaust gas temperature switch which are set in a normally open mode, wherein the electromagnetic valve is connected in a sprinkling system in a series connection mode, and thefuse protector, the electromagnetic valve, the environment temperature switch and the exhaust gas temperature switch are connected together in a series connection mode. The invention further discloses a control method of the automatic sprinkling control system. The control method of the automatic sprinkling control system achieves connection and disconnection of an electric circuit by simultaneously closing the environment temperature switch and the exhaust gas temperature switch, can guarantee that the sprinkling system cannot perform sprinkling under a halt state, avoids waste of water sources, and can guarantee accuracy of control and improve control accuracy by using exhaust gas temperature and environment temperature as reference.

Owner:YIMIKANG TECH GRP CO LTD

Ink reclaiming mechanism and seal device

ActiveCN113478991AServe the purpose of protectionRealize automatic ink returnStampingEngineeringStructural engineering

The invention provides an ink reclaiming mechanism and a seal device, and relates to the technical field of seals. The ink reclaiming mechanism comprises a support and a sleeve arranged on the support in a sliding and sleeving mannere, a seal installing clamp used for clamping a seal is arranged in the support, the seal installing clamp is fixedly connected with the sleeve, and a seal area is formed at one end of the support. The orthographic projection of the seal face of the seal clamped by the seal installing clamp is located in the seal area, a protective cover used for abutting against and covering the seal face of the seal is further arranged in the support, and the protective cover is rotationally connected with the support and the sleeve through a fulcrum shaft. The sleeve is pushed to slide in the direction close to the seal area, the protective cover rotates along with the fulcrum shaft to be exposed out of the seal face of the seal, and the seal linearly moves to the seal area of the support to conduct seal operation. The seal can be pressed and sealed, the seal face of the seal is covered in a non-seal state, the seal surface of the seal is protected, and the compactness of the structure is improved.

Owner:江苏群杰物联科技有限公司

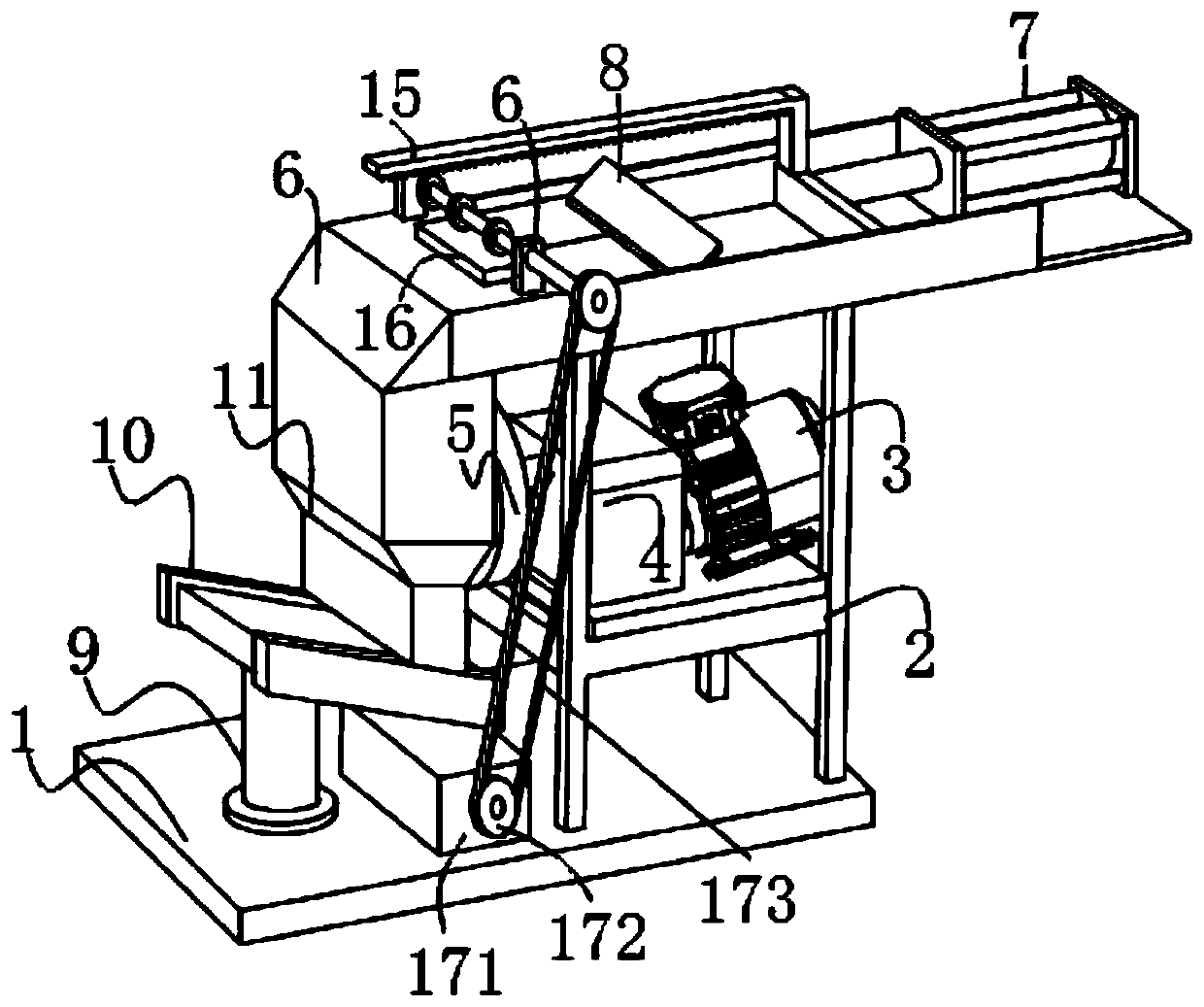

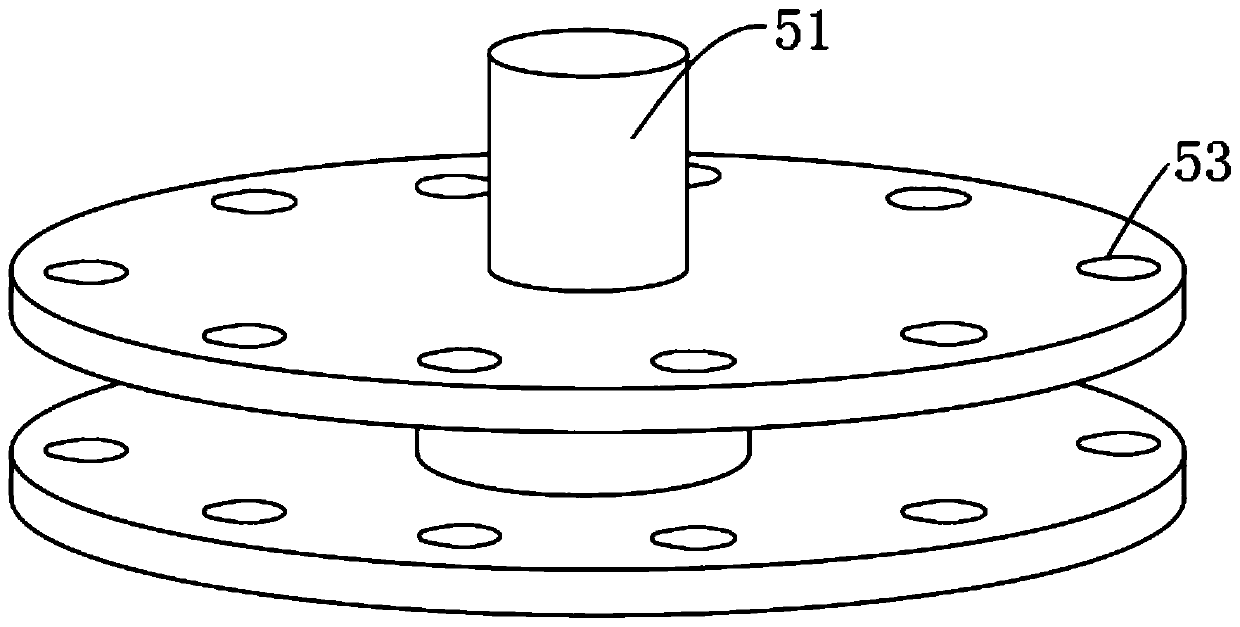

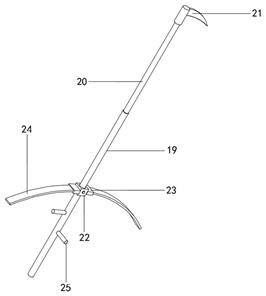

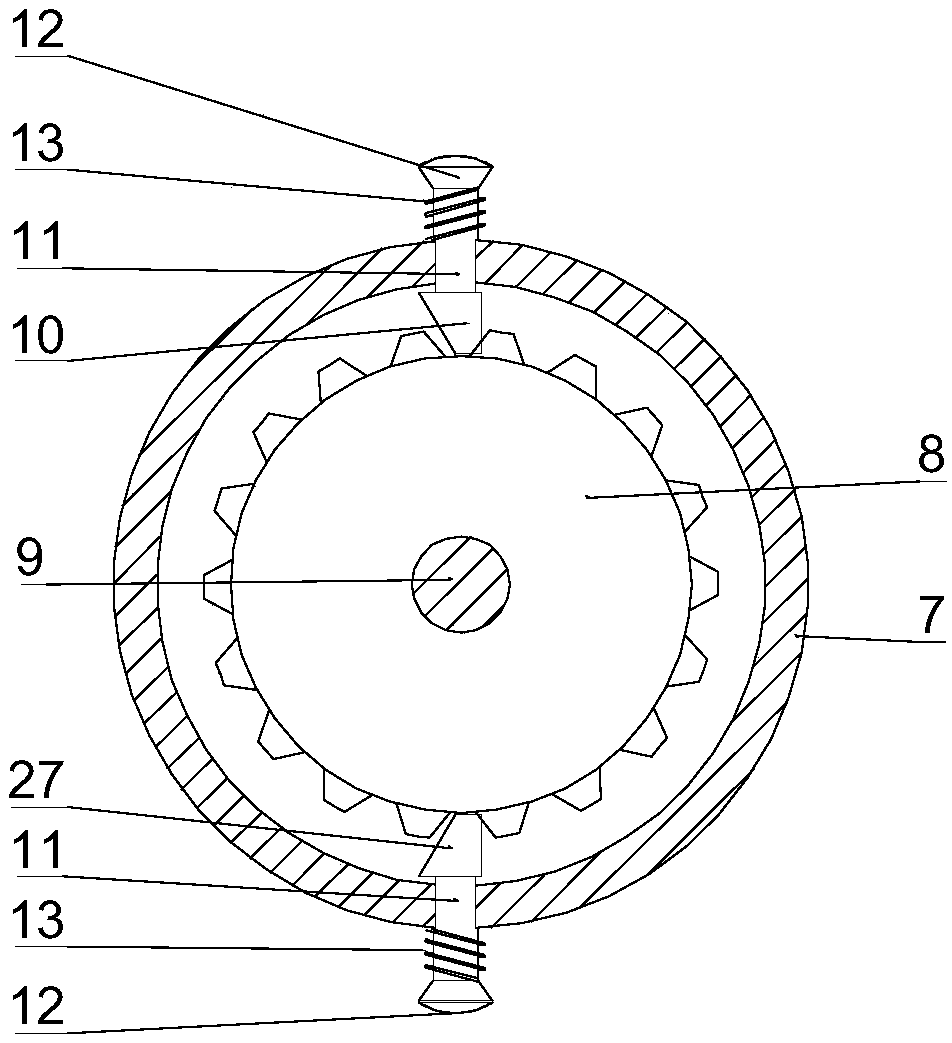

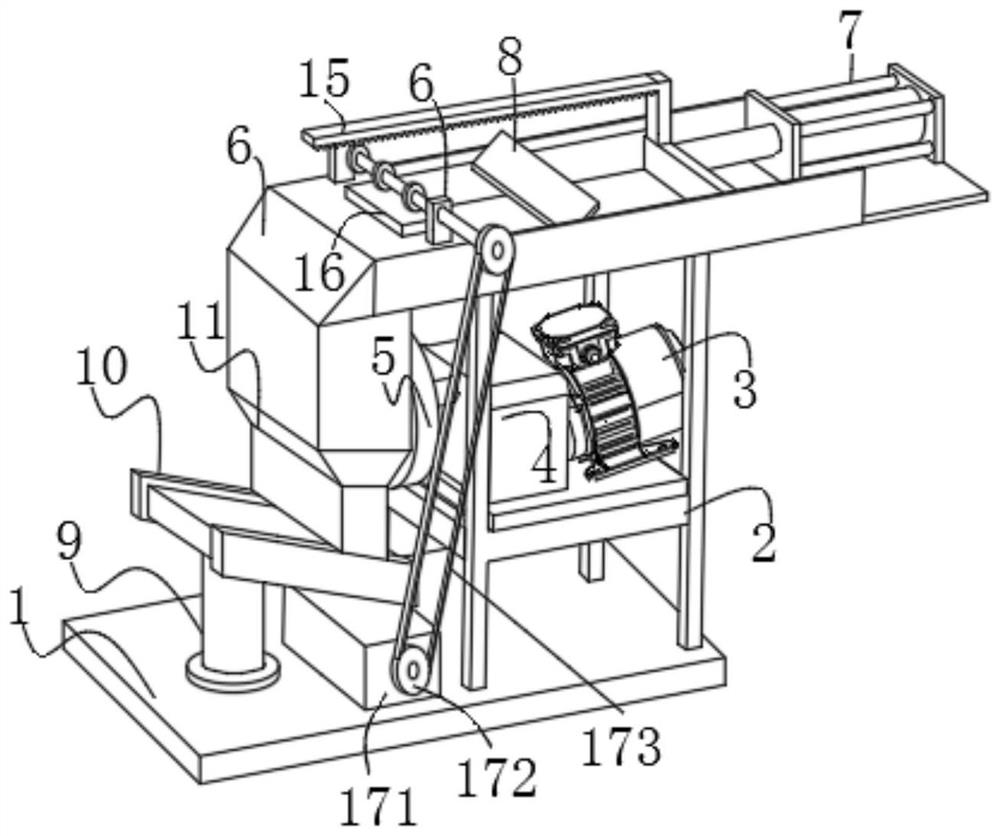

Novel micro-tillage machine for agricultural machine

ActiveCN107258114AAdjustable distanceConvenient distanceTilling equipmentsDrive wheelTransmission belt

The invention discloses a novel micro-tillage machine for an agricultural machine. The novel micro-tillage machine comprises an engine base and a bearing, wherein a diesel engine is mounted at the upper end of the engine base; a speed reducer is mounted at the right side of the diesel engine; a transverse transmission rod is mounted between the diesel engine and the speed reducer; a mounting disc is fixed at the outer side of a rotating wheel; the outer side of the mounting disc is connected with a rotary blade through a regulating mechanism; a caterpillar track is arranged below the engine base; a driving wheel and a driven wheel are mounted at left and right sides in the caterpillar track respectively; the left side of the driving wheel is connected with a transmission mechanism through a second transmission belt; the upper end of the transmission mechanism is connected with the diesel engine; the caterpillar track is internally provided with a buffering mechanism; the buffering mechanism is located between the driven wheel and the driving wheel; and a handle is fixed at the left side of the engine base. The novel micro-tillage machine for the agricultural machine, disclosed by the invention, is provided with the regulating mechanism and the distance of the rotary blade can be conveniently regulated; and the distance, exceeding the rotating wheel, of the rotary blade can be conveniently controlled so that the distance, entering the ground, of the machine can be regulated.

Owner:池州市勇攀智岩机电有限公司

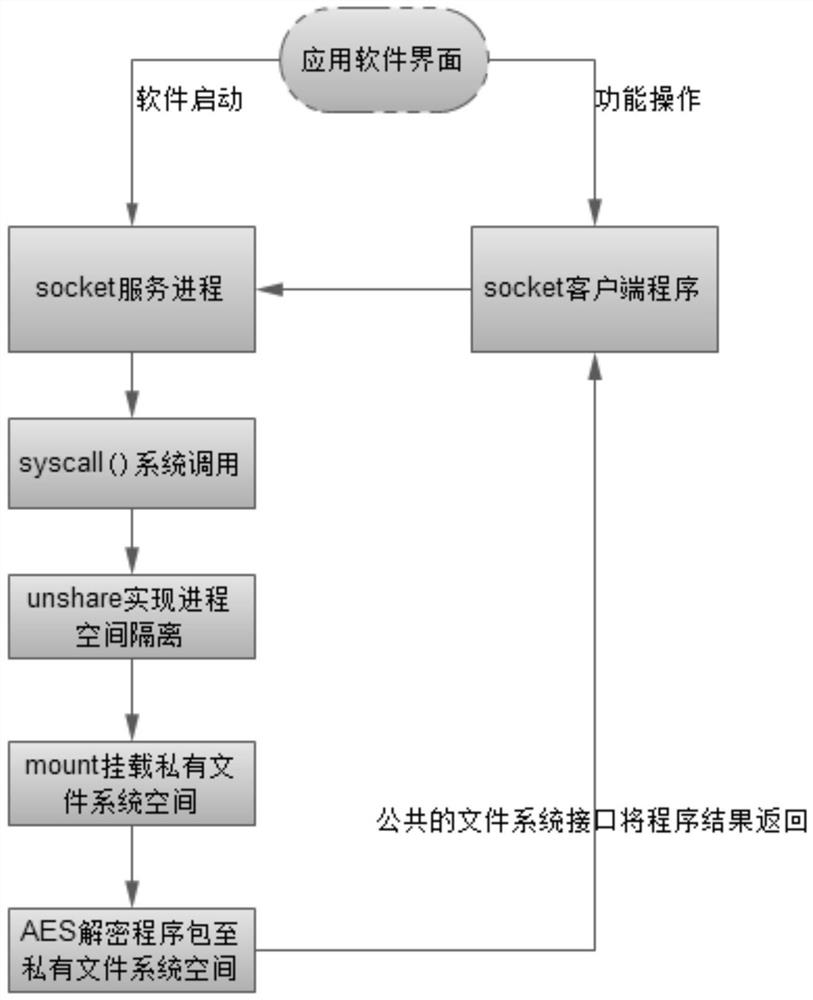

Method and system for protecting software source codes based on Linux kernel calling

PendingCN112084490AAchieve isolationServe the purpose of protectionDigital data protectionPlatform integrity maintainanceFile systemSoftware engineering

The invention provides a method and system for protecting software source codes based on Linux kernel calling. The method for protecting the software source code based on Linux kernel calling comprises the following steps that S1, adding a system calling number into a Linux kernel, and providing a system calling interface for application layer software; S2, when application layer software is started, creating a process private file system in a kernel space through a Namespace-related API (Application Program Interface) by calling a SysCall-like system; and S3, loading the program file encrypted by AES in the private file system, wherein only the current process is visible, and other processes cannot access the file in the private file system even if the other processes have Root permission. The method and system for protecting the software source code based on Linux kernel calling have the advantages of being safe and reliable.

Owner:南京烽火星空通信发展有限公司

Multi-face pad printing machine capable of achieving multi-machine splicing

PendingCN114103414AAvoid pollutionGuaranteed stabilityRotary pressesPrinting press partsWorkmanshipProcess engineering

The multi-face pad printing machine comprises a bottom box, the top of the bottom box is fixedly connected with an outer cover, the top of an inner cavity of the outer cover is fixedly connected with a pad printing machine main machine, the bottom of the inner cavity of the outer cover is fixedly connected with a turnover type workbench, and the left side of the inner cavity of the outer cover is fixedly connected with a transverse walking type oil cup. The top of the left side of the bottom box is fixedly connected with a supporting table, and the top of the supporting table is fixedly connected with a joint manipulator. Through cooperative use of the bottom box, the outer cover, the pad printing machine main machine, the overturning type workbench, the transverse walking type oil cup, the supporting table, the joint mechanical arm, the waste gas treatment device and the cover plate, the environment-friendly problems that a traditional pad printing machine cannot achieve the overturning function and waste gas generated by solvent volatilization cannot be well recycled and filtered can be effectively solved; the pad printing machine can be turned over to print on different surfaces, multi-machine splicing can be carried out according to the pad printing process requirements to carry out multi-pass printing, manual participation is not needed in the whole process, and high automation of production is achieved.

Owner:太仓维高模塑有限公司

Electric voltage exception protection device used for circuit board test

InactiveCN101464473BAvoid failureAvoid damageElectrical measurement instrument detailsElectrical testingMicrocontrollerBuck converter

The invention discloses an abnormal voltage protection device in circuit board testing, which is connected between a circuit board to be tested and a test set, and comprises a relay, a singlechip, an A / D converter and a memorizer, wherein, the singlechip is connected with the relay; the A / D converter is connected between one contact point of the relay and the singlechip; the memorizer is connected with the singlechip and is used for storing a standard output voltage of the circuit board to be tested; and the other two contact points of the relay are respectively used for connecting the circuit board to be tested and the test set. Applied to the circuit board testing, the unusual voltage protection device serves the protection purpose reliably when the voltage output by the circuit board to be tested is abnormal, so as to avoid the failure of the test set; and the settings of the device is simple, the universality is good, and the device can be applied to the testing processes of the circuit boards in different types.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

Comfortable seat for municipal garden trimming

InactiveCN112166861AEasy to controlReduce work intensityCuttersCutting implementsAgricultural engineeringCushion

The invention discloses a comfortable seat for municipal garden trimming, and aims to solve the problems of inconvenience in control, high working intensity and low working efficiency due to the factthat a worker generally holds a long rod with the front end fixedly provided with a sickle for operation in an existing conventional municipal garden trimming mode and the operation mode completely depends on human body support. The following scheme is provided, and the seat comprises a base, a bottom plate and a top plate. The outer wall of the top of the bottom plate is fixedly connected with the top plate through bolts, a cushion is fixed to one side of the outer wall of the top of the top plate through screws, and a back cushion is connected to the outer wall of one side of the cushion through a hinge. A second fluted disc is driven by rotating a rocker, a first fluted disc is driven to rotate through transmission of a chain, then a gear is made to rotate, the gear is engaged with a tooth opening in the center of the bottom plate to enable the bottom plate to rotate, a sliding block slides on the inner wall of an arc-shaped sliding rail, and the trimming direction can be effectively adjusted in time during operation; and control is convenient, working intensity is reduced, and working efficiency is improved.

Owner:陆燕

A kind of ink return mechanism and seal device

ActiveCN113478991BServe the purpose of protectionRealize automatic ink returnStampingStructural engineeringMechanical engineering

The application provides an ink return mechanism and a seal device, which relate to the technical field of seals. The ink return mechanism includes a bracket and a sleeve slidably sleeved on the bracket, a stamping clamp for holding a stamp is arranged in the bracket, and the stamping clamp is fixedly connected with the sleeve, the A stamping area is formed at one end of the bracket; the orthographic projection of the stamp surface clamped by the stamping fixture is located in the stamping region, and the bracket is also provided with a seal surface for abutting and covering the stamp surface The protective cover is rotatably connected to the bracket and the sleeve through a support shaft; push the sleeve to slide in the direction close to the seal area, and the protective cover is exposed as the support shaft rotates On the seal face, the seal moves linearly to the stamping area of the bracket for stamping operation. It can press the seal and seal the seal face in the non-sealed state, protect the seal face, and improve the compactness of the structure.

Owner:江苏群杰物联科技有限公司

Tiller for agricultural machinery

ActiveCN107258114BAdjustable distanceConvenient distanceTilling equipmentsDrive wheelAgricultural engineering

The invention discloses a novel micro-tillage machine for an agricultural machine. The novel micro-tillage machine comprises an engine base and a bearing, wherein a diesel engine is mounted at the upper end of the engine base; a speed reducer is mounted at the right side of the diesel engine; a transverse transmission rod is mounted between the diesel engine and the speed reducer; a mounting disc is fixed at the outer side of a rotating wheel; the outer side of the mounting disc is connected with a rotary blade through a regulating mechanism; a caterpillar track is arranged below the engine base; a driving wheel and a driven wheel are mounted at left and right sides in the caterpillar track respectively; the left side of the driving wheel is connected with a transmission mechanism through a second transmission belt; the upper end of the transmission mechanism is connected with the diesel engine; the caterpillar track is internally provided with a buffering mechanism; the buffering mechanism is located between the driven wheel and the driving wheel; and a handle is fixed at the left side of the engine base. The novel micro-tillage machine for the agricultural machine, disclosed by the invention, is provided with the regulating mechanism and the distance of the rotary blade can be conveniently regulated; and the distance, exceeding the rotating wheel, of the rotary blade can be conveniently controlled so that the distance, entering the ground, of the machine can be regulated.

Owner:池州市勇攀智岩机电有限公司

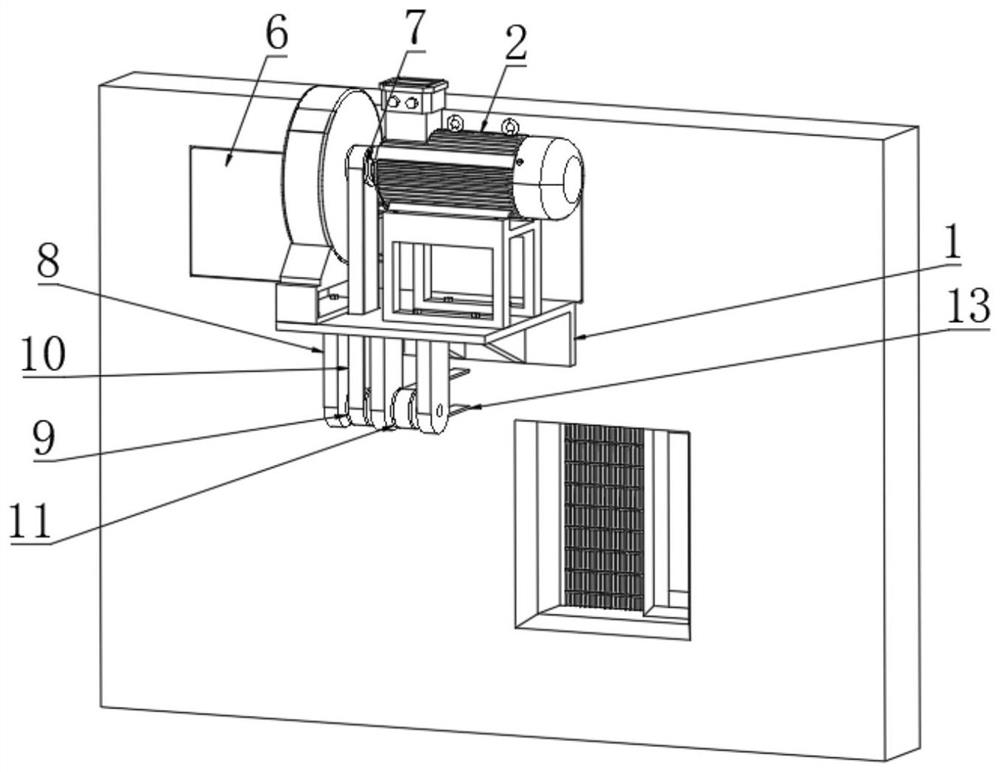

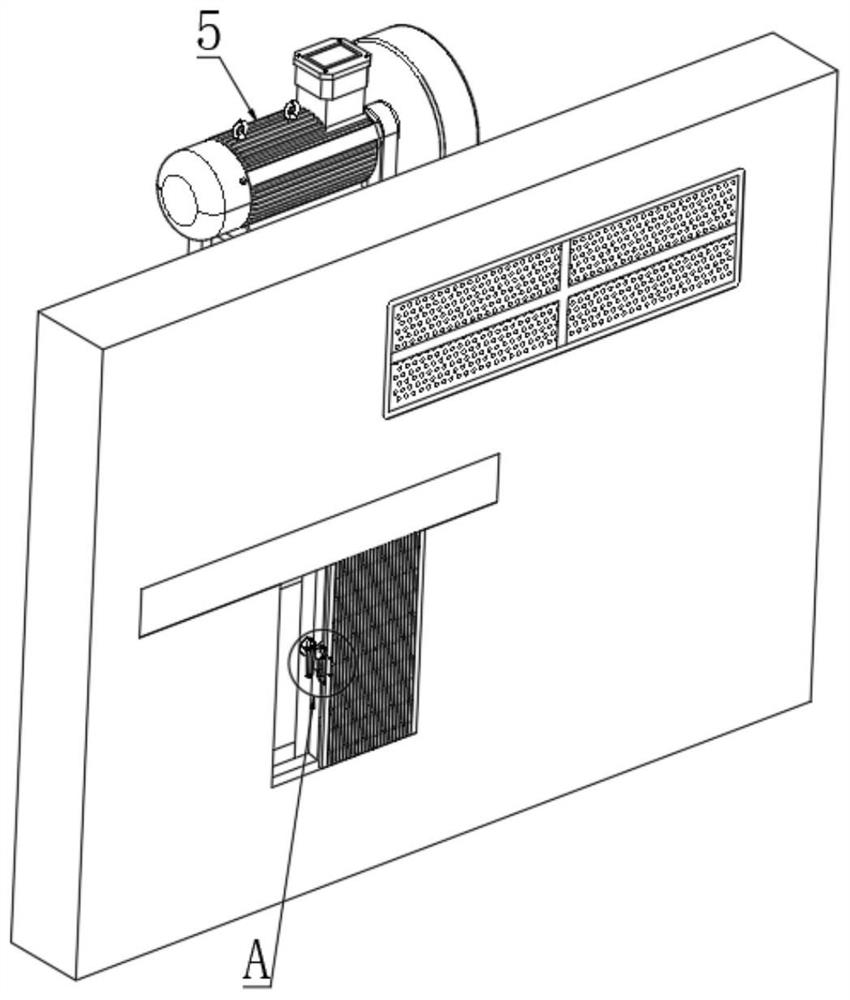

Building structure with good ventilation performance and using method thereof

ActiveCN114737845AAchieve the purpose of exchangeAvoid enteringInsect protectionEfficient regulation technologiesArchitectural engineeringStructural engineering

The invention provides a building structure with good ventilation performance and a using method thereof, and belongs to the technical field of building structures. Comprising a wall body, a through hole is formed in the wall body, and a window frame is installed in the through hole. The ventilation unit, the cleaning unit and the clamping unit are arranged, the ventilation unit ventilates the interior of the building structure, meanwhile, the ventilation unit drives the glass window to be opened, air in the building is led out, the purpose of air exchange between the interior and the exterior of the building is achieved, and the ventilation efficiency is further improved; the inner side and the outer side of the glass window are automatically cleaned through the cleaning unit, a manual cleaning mode is replaced, use is convenient, meanwhile, in the glass window opening process, through cooperation of the clamping unit, the glass window drives the screen window to be automatically opened, a manual opening mode is replaced, in the ventilation process, through protection of the screen window, outside mosquitoes are prevented from entering, and the ventilation effect is good. And the comfort during ventilation is further improved.

Owner:伽师县振鑫建筑安装有限责任公司

Wall gap cleaning protection device for historic building repair

ActiveCN113818710AAvoid secondary damageWill not affect healthBuilding repairsBrickArchitectural engineering

The invention relates to the technical field of historic building repair, in particular to a wall gap cleaning protection device for historic building repair. The wall gap cleaning protection device comprises a treatment shell and a switch button; the left end surface of the treatment shell is fixedly connected with a collecting device; the left side of the front end surface of the treatment shell is fixedly connected with the switch button; the right sides of the front and rear end surfaces of the treatment shell are both provided with sliding grooves; sliding shafts are arranged in the sliding grooves; the other ends of the sliding shafts are fixedly connected with sliding balls; the upper end faces and the lower end faces of the sliding balls are fixedly connected with supporting mechanisms; the supporting mechanisms comprise threaded cylinders and rotating rings; and one ends of the threaded cylinders are fixedly connected with the sliding balls. According to the wall gap cleaning protection device, by arranging the switch button, a dust collection air pump, the sliding grooves and the sliding shafts, bricks above and below are supported through the supporting mechanisms, then dust in the bricks is sucked out through the dust collection air pump, gaps of different depths can be cleaned, and the supporting mechanisms can achieve the effects of supporting the bricks above, preventing the bricks from falling off and achieving the protection purpose.

Owner:新疆喀建建设工程有限公司

Rapid mounting structure wide in application range and used for information communication equipment

InactiveCN108679392AEasy to moveEasy to adjust the horizontal positionStands/trestlesEngineeringSurface plate

The invention discloses a rapid mounting structure wide in application range and used for information communication equipment, and relates to the technical field of the information communication equipment. A sleeve is convenient to move by releasing a first puller bolt, so that the horizontal position of the information communication equipment installed between an arc panel and a convex panel is convenient to adjust; a corresponding pulling handle is pulled open and is rotated and adjusted when the information communication equipment installed between the arc panel and the convex panel needs to be rotated and inclined in a certain direction, and when an upper wedge block and a lower wedge block are clamped between two teeth of a gear, the position of the information communication equipmentis fixed, the inclination angle is convenient to adjust, and the signal direction is convenient to adjust accordingly; after the information communication equipment is put into the arc panel and theconvex panel, a hemisphere is directly limited by the plane side of a limiting block, and the mounting efficiency is improved; a fixing block is pulled open and the plane of the limiting block is disengaged from the hemisphere when the information communication equipment needs to be taken out, and operation is easy and rapid.

Owner:佛山博发智能科技有限公司

A kind of forage feeding device for fish farming

ActiveCN110463642BPromote fragmentationGuaranteed to passClimate change adaptationCuttersEngineeringZoology

The invention relates to the technical field of fish farming, and discloses a forage feeding device for fish farming, comprising a device main body, the upper end of the device main body is provided with a bearing frame, and the upper end of the bearing frame is fixedly welded with a feeding trough, The bottom of the inner wall of the discharge trough is provided with a push mechanism, and a limiting plate is installed on one side of the push mechanism on the inner wall of the discharge trough, and an extruding mechanism is installed through the top of the discharge trough, and the main body of the device One side of the carrier frame at the upper end is equipped with a support mechanism, the upper end of the support mechanism is provided with a feeding conveyor belt, and a material receiving frame is installed below the discharge chute at the upper end of the feeding conveyor belt, and the inside of the carrier frame is installed With brake motor. The forage feeding device for fish farming can improve the safety of use, avoid the phenomenon that the fish school affects eating due to excessive grabbing, and can crush forage of different sizes to meet the use requirements.

Owner:山东卓辰科技服务有限公司

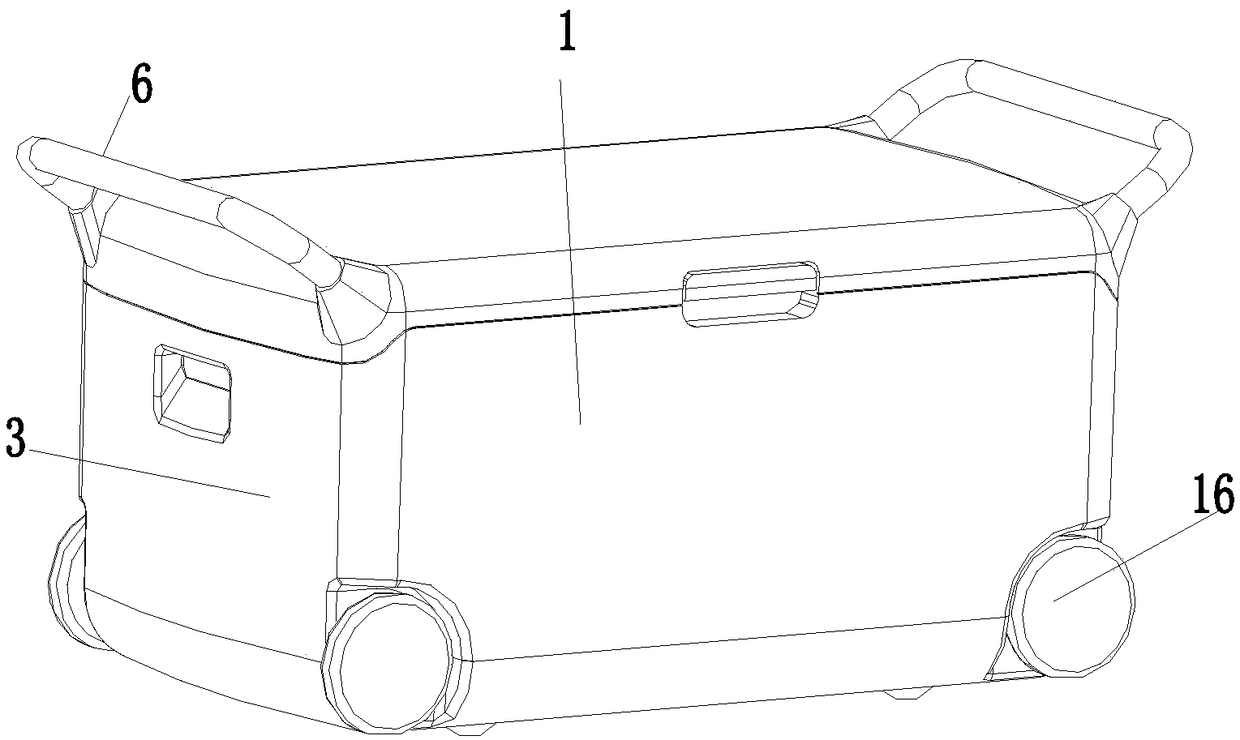

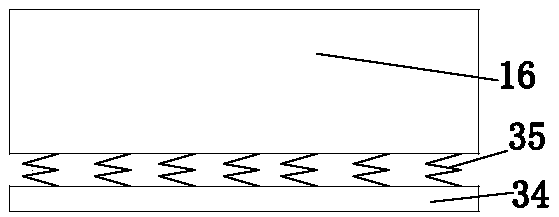

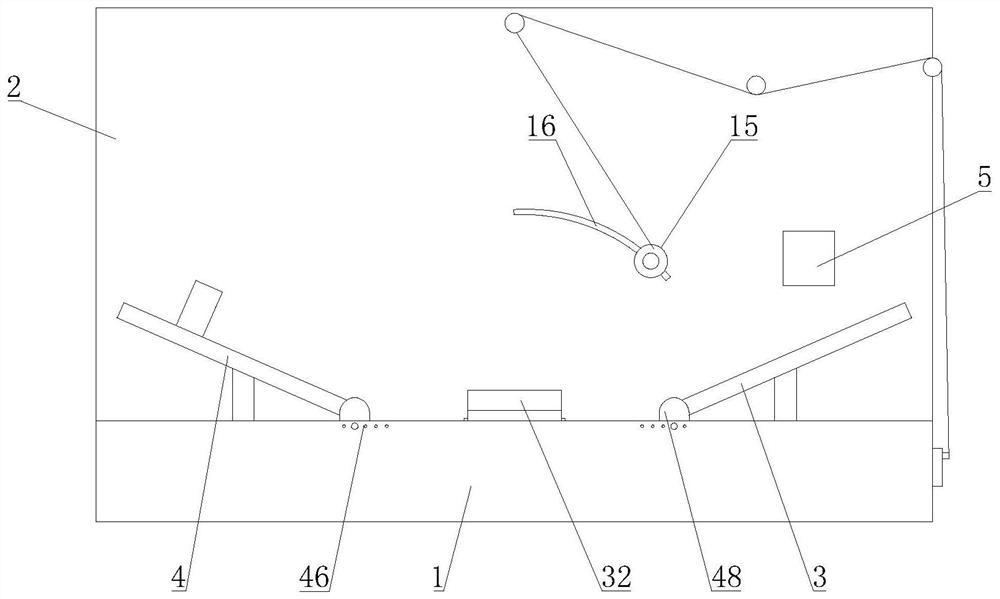

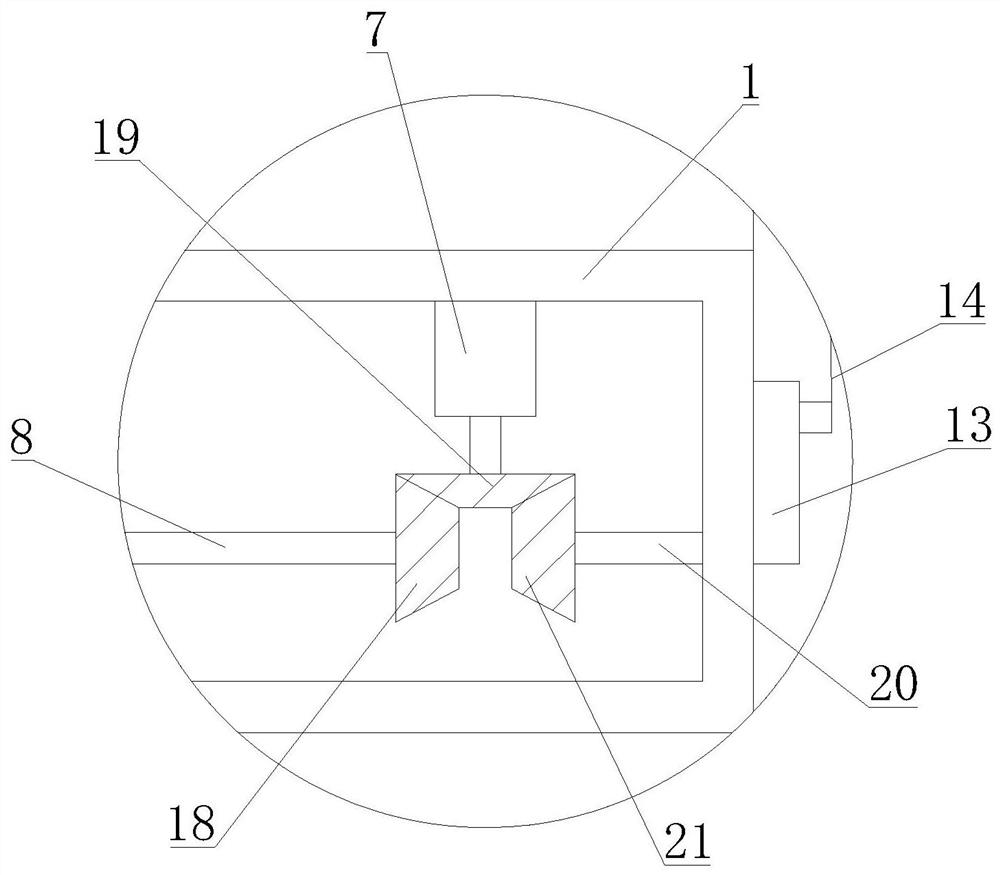

Multifunctional vehicle-mounted refrigerator

PendingCN109307395AEasy to carrySimple structureVehicle arrangementsLighting and heating apparatusInductive chargingEngineering

The invention discloses a multifunctional vehicle-mounted refrigerator. The multifunctional vehicle-mounted refrigerator comprises a box body, the box body is internally provided with a refrigerationcavity and a refrigeration system, the side wall of the box body is provided with a wireless charging base, two ends of the box body are provided with moving mechanisms, the moving mechanisms are externally provided with shells, and the upper ends of the shells are provided with handles. The multifunctional vehicle-mounted refrigerator has the characteristics of being convenient to carry and diversified in function.

Owner:浙江云格电器股份有限公司

Multifunctional postpartum rectus abdominis training device

A multifunctional postpartum rectus abdominis training device relates to the field of postpartum rehabilitation and comprises a training table, a mounting frame, an upper limb supporting plate, a lower limb supporting plate, a controller and an elastic positioning belt; the mounting frame is arranged on the rear side of the training table; the upper limb supporting plate and the lower limb supporting plate are rotationally arranged at the two ends of the training table and rotate oppositely; the elastic positioning belt is arranged between the upper limb supporting plate and the lower limb supporting plate; a training assembly is further included, which is arranged on the training table and the mounting frame. The first sliding part and the second sliding part are arranged, so that the distance between the upper limb supporting plate and the lower limb supporting plate is matched with the height of a patient; besides, the training assembly is arranged to provide support for the upper limbs, the lower limbs and the arms of the patient, the extrusion track is stabilized, and the training difficulty is reduced; and a massage positioning assembly is arranged to fix and massage the lower limbs of the patient; moreover, the rectus abdominis massage assembly is arranged to adjust the distance between two sets of second massage rollers, and rectus abdominis is heated, pressed and relaxed through a massage head, so that rectus abdominis folding is accelerated.

Owner:深圳德佳智联科技有限公司

An electrical cabinet device for flood control and dehumidification

ActiveCN112512256BControl the opening and closing timingServe the purpose of protectionCasings/cabinets/drawers detailsElectric switchesTransmission beltElectric machinery

The invention relates to the related field of electrical cabinets, and discloses a flood control and dehumidification electrical cabinet device, which includes a main box body, a motor is arranged in the main box body, a fan wheel transmission chamber is arranged on the lower side of the motor, and a fan wheel transmission chamber is arranged on the lower side of the fan wheel transmission chamber. Clutch chamber, the left and right sides of the clutch chamber are provided with fan pulley chambers arranged symmetrically with the clutch chamber as the center, the clutch transmission chamber is provided on the lower side of the clutch chamber, and two The left and right symmetrical clutch transmission belt senses the rise of the external water potential through the descending distance of the hydraulic pressure block, and under the drive of the clutch pull rope, it affects the meshing relationship between the clutch slider and the power-off friction block cavity, so as to indirectly affect the flood control. The opening and closing relationship between the plate and the flood control cooling chamber, so as to control the opening and closing timing of the flood control device, and when the external water potential is too high, the hydraulic pressure block will drive the movement of the power-off slider, thereby driving the movement of the power-off friction block , so as to achieve the purpose of disconnecting the main power switch to protect the power supply.

Owner:上海日盛电气有限公司

Conveying equipment

The invention relates to conveying equipment, and relates to the technical field of material conveying. The conveying equipment comprises a supporting frame. A driving device is arranged on the supporting frame and comprises a conveying chain and a driving mechanism. The driving mechanism comprises a driving gear and a driven gear. The conveying chain sleeves the driving gear and the driven gear and meshes with the driving gear and the driven gear. The conveying chain comprises a plurality of connecting pieces and a plurality of steering assemblies. Each steering assembly comprises a connecting frame and steering blocks. The steering blocks are rotationally connected with the connecting frames, and the connecting pieces are rotationally connected with the steering blocks. The rotating axis of rotational connection between the steering blocks and the connecting frames is perpendicular to the rotating axis of rotational connection between the connecting pieces and the steering blocks. A guide groove is further formed in the supporting frame, and guide pieces are further arranged on the conveying chain and extend into the guide groove. The conveying equipment has the advantage of being capable of achieving arc conveying of materials.

Owner:江苏泗阳协力轻工机械有限公司

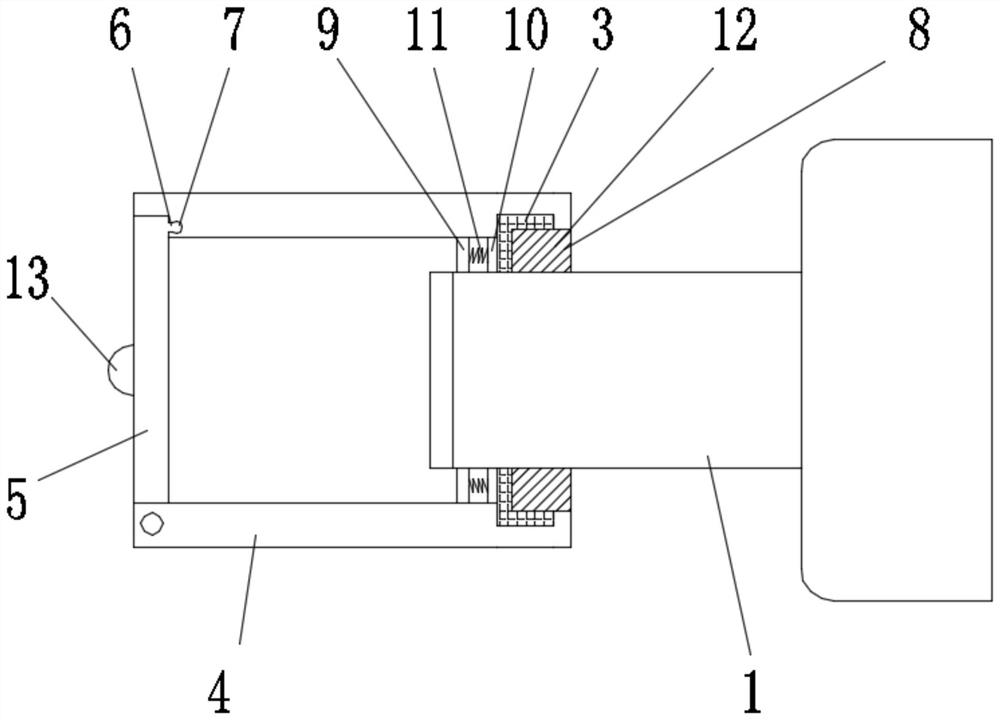

Protection device for CCD (Charge Coupled Device) digital high-definition camera

PendingCN114859630AServe the purpose of protectionQuick fixCamera body detailsEngineeringMechanical engineering

A CCD digital high-definition camera protection device disclosed by the present invention comprises a camera body, a sliding groove, a buckle plate, a sleeve, a door cover, a buckle column, a buckle groove and a sliding buckling device, the sliding groove is located in the camera body, the buckle plate is arranged on the camera body, the sleeve is sleeved on the camera body, the door cover is hinged to the end portion of the sleeve, and the buckle column is arranged on the buckle groove. The buckling column is arranged on the door cover, the buckling groove is formed in the sleeve, the door cover can be inserted into the buckling groove, and the sliding buckling device is arranged in the sleeve. The invention belongs to the technical field of cameras, and particularly relates to a lengthened protection device for a CCD (Charge Coupled Device) digital high-definition camera, which is convenient to install.

Owner:HUANENG YINGKOU THERMAL POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com