Side guide plate centring control device and control method

A technology of a control device and a control method, applied in non-electric variable control, control/regulation system, and simultaneous control of multiple variables, etc., can solve problems such as reducing corporate profits, overflowing edges, and not considering side guide devices, etc. Steel edge damage defects, the effect of reducing side guide damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

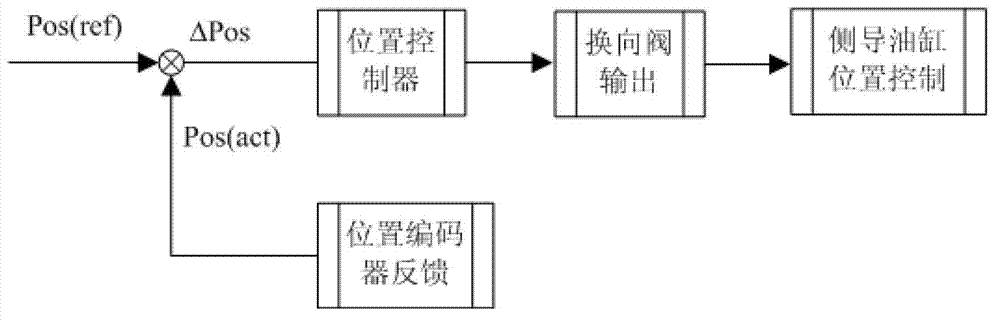

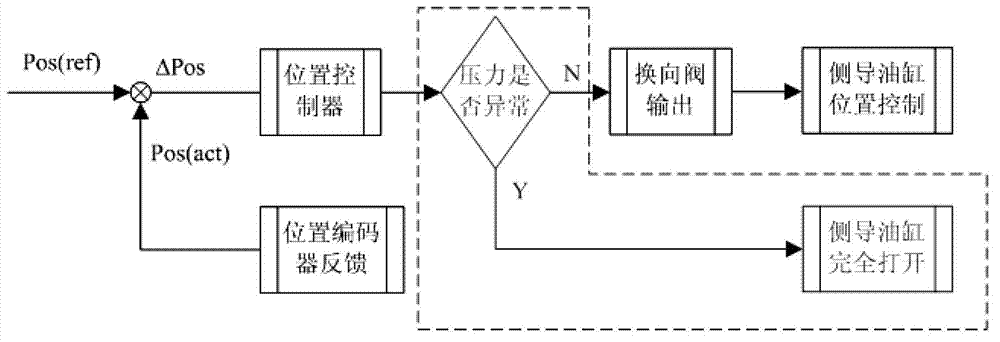

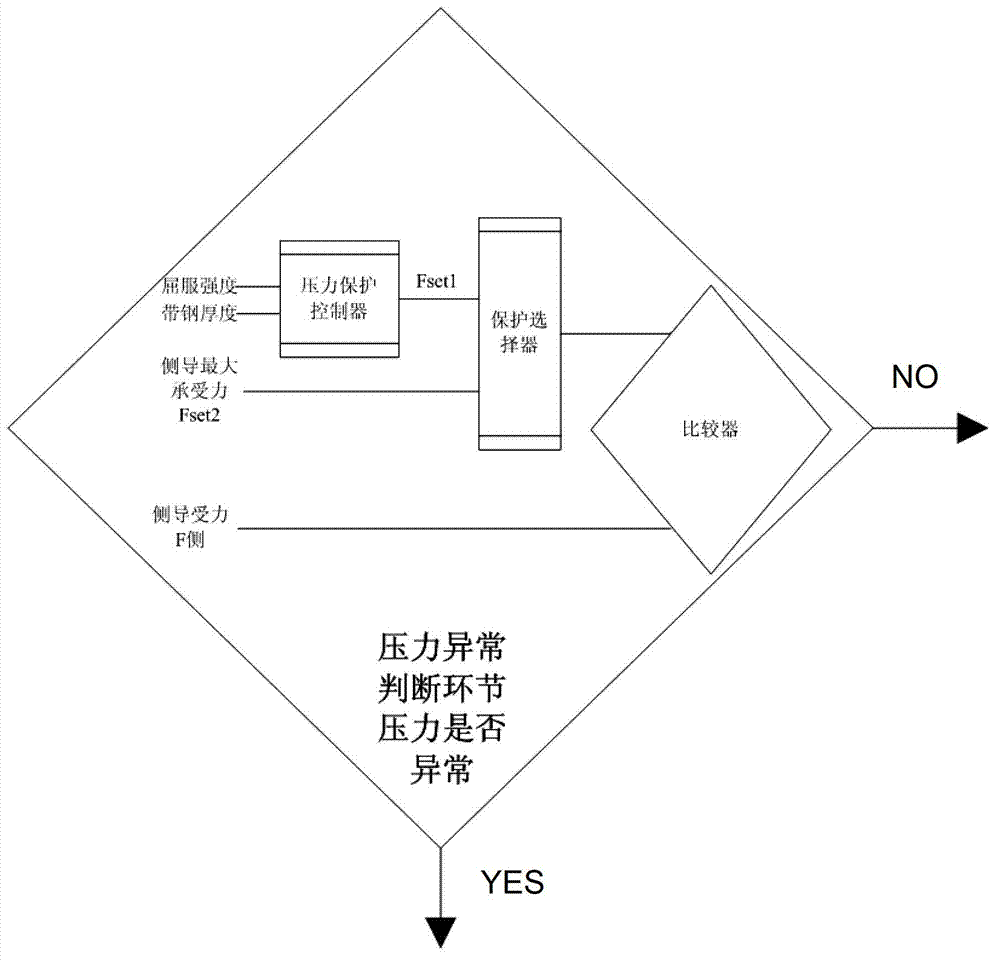

[0024] Please combine Figure 2 ~ Figure 3 As shown, the centering control device of the side guide plate of the present invention also includes a position controller and a position encoder of the side guide plate, wherein the position controller generates the position setting value of the side guide clamping according to the strip width and control requirements, And compared with the position feedback value generated by the position encoder detecting the side guide stroke, the position controller sends a side oil guide cylinder position control signal; the difference is that the control device of the present invention also includes a pressure protection controller, a protection selector , a pressure sensor and a comparator, wherein the pressure protection controller includes a pressure algorithm whose input is the yield stren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com