Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Saving concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

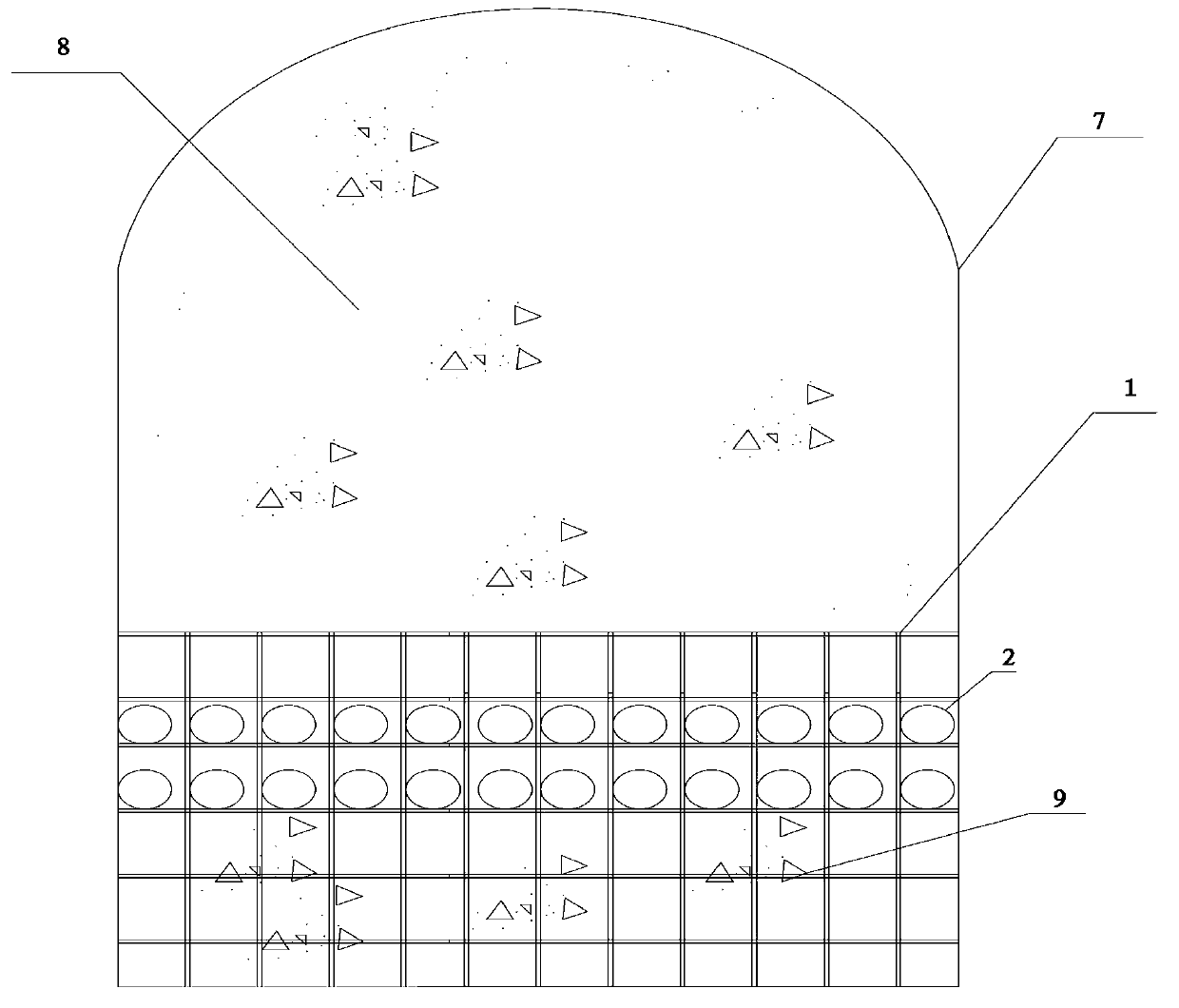

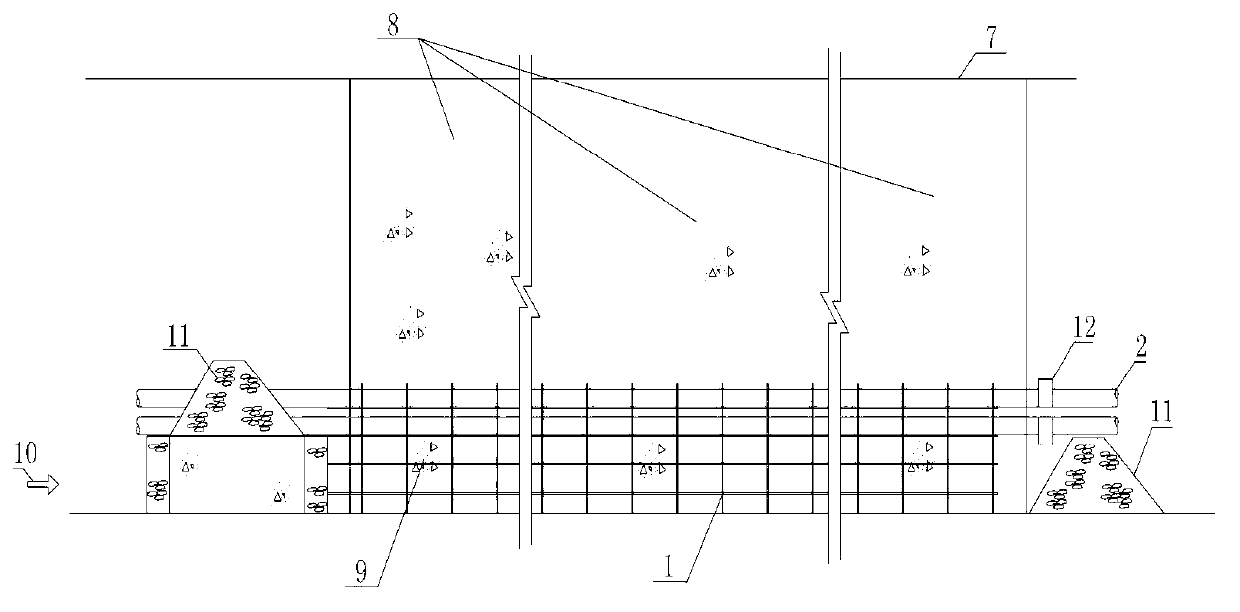

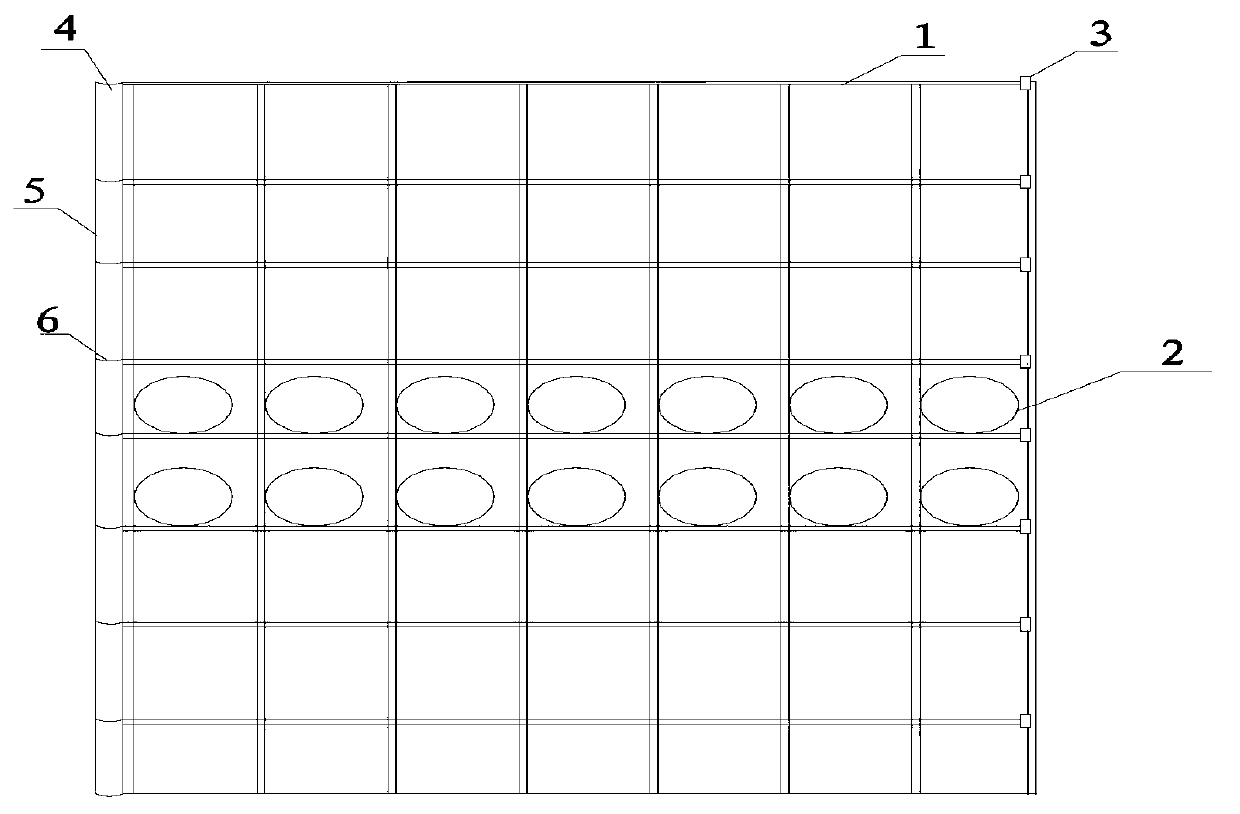

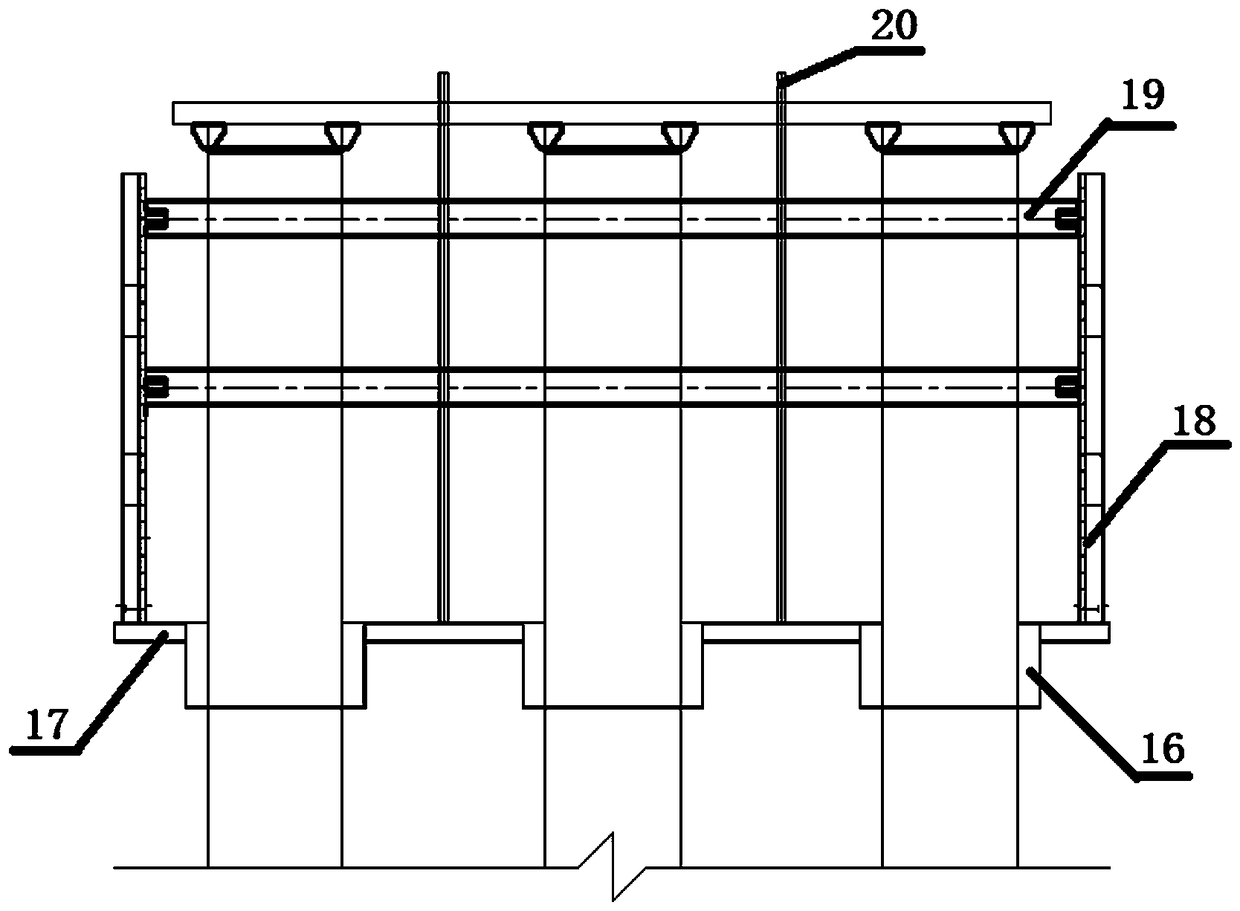

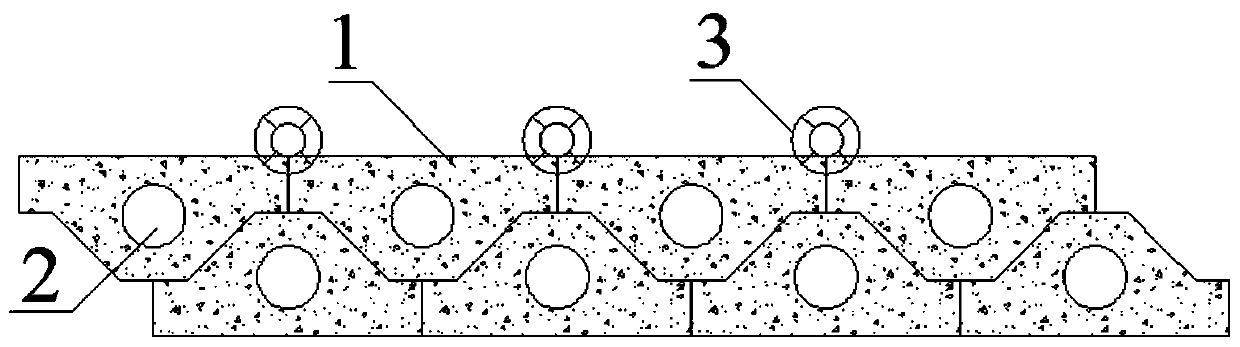

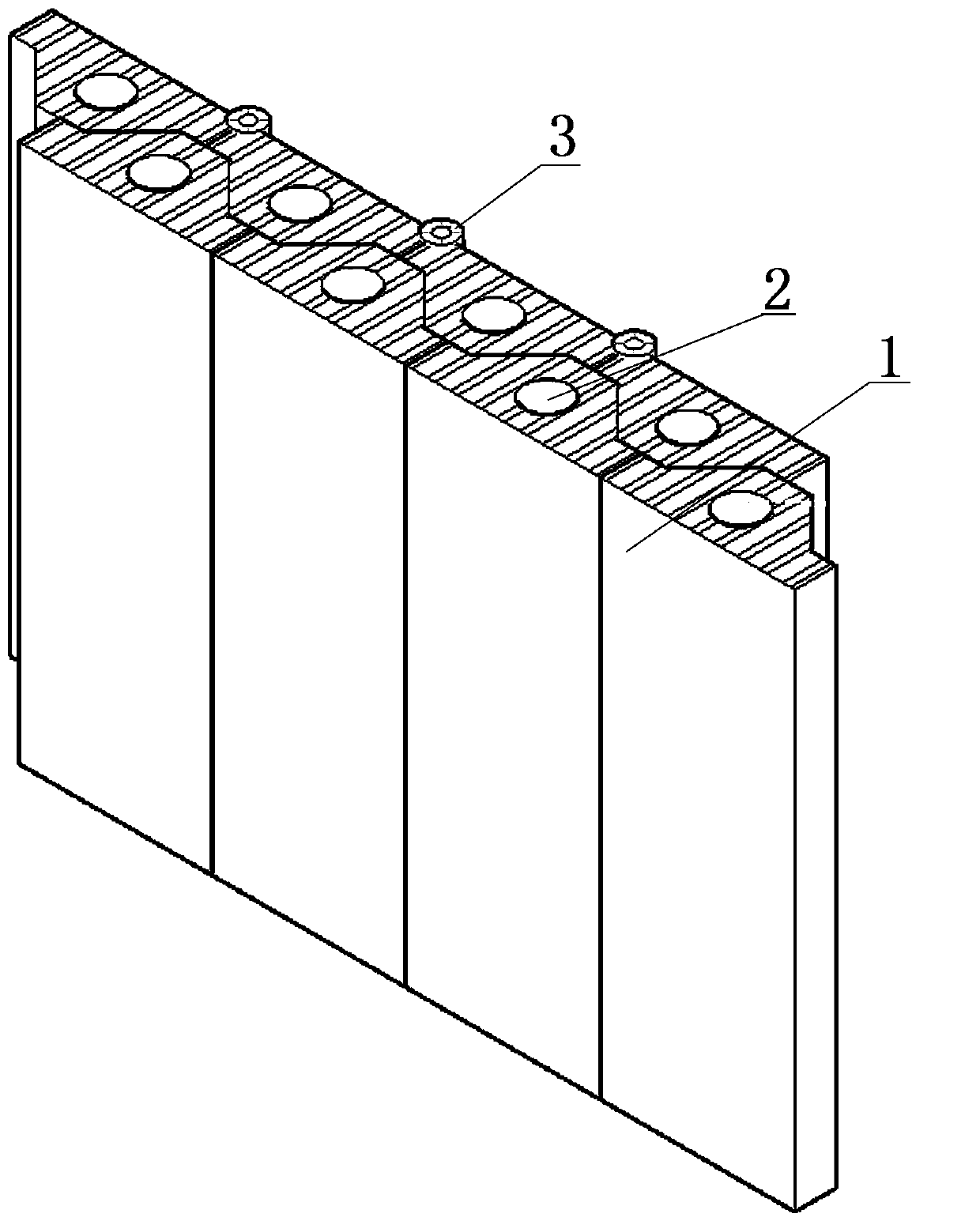

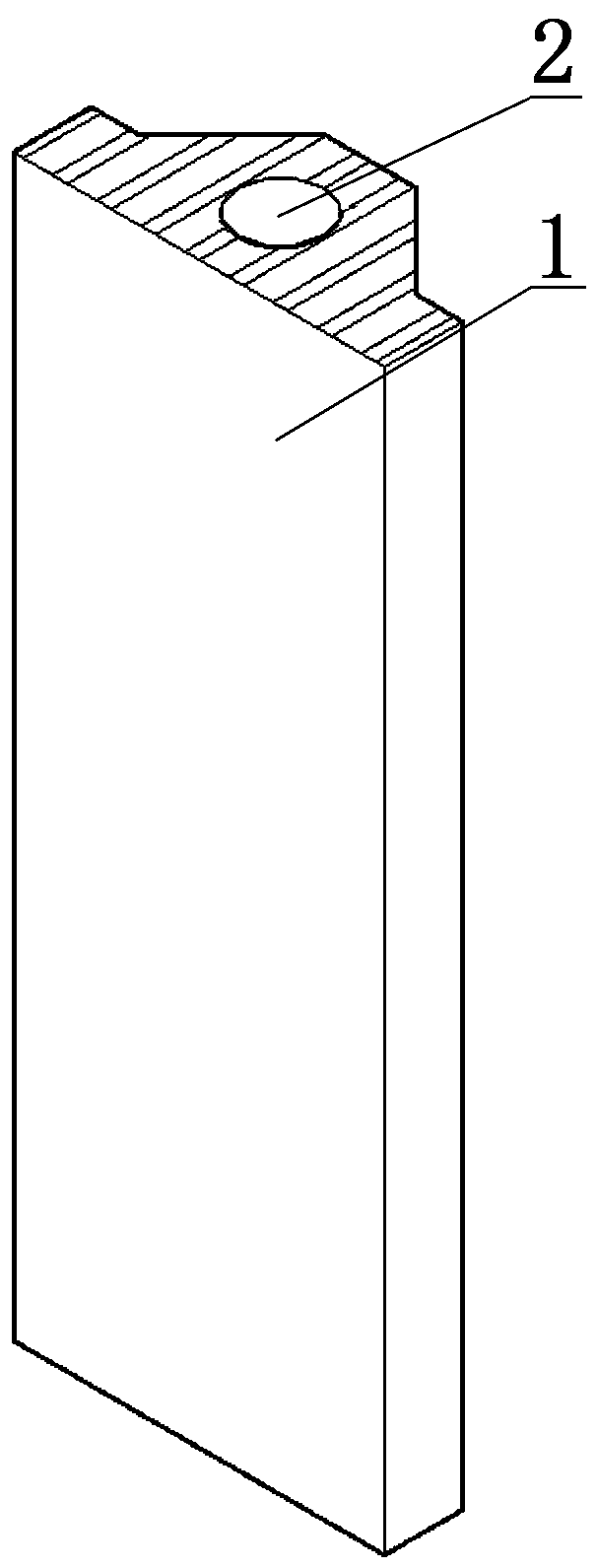

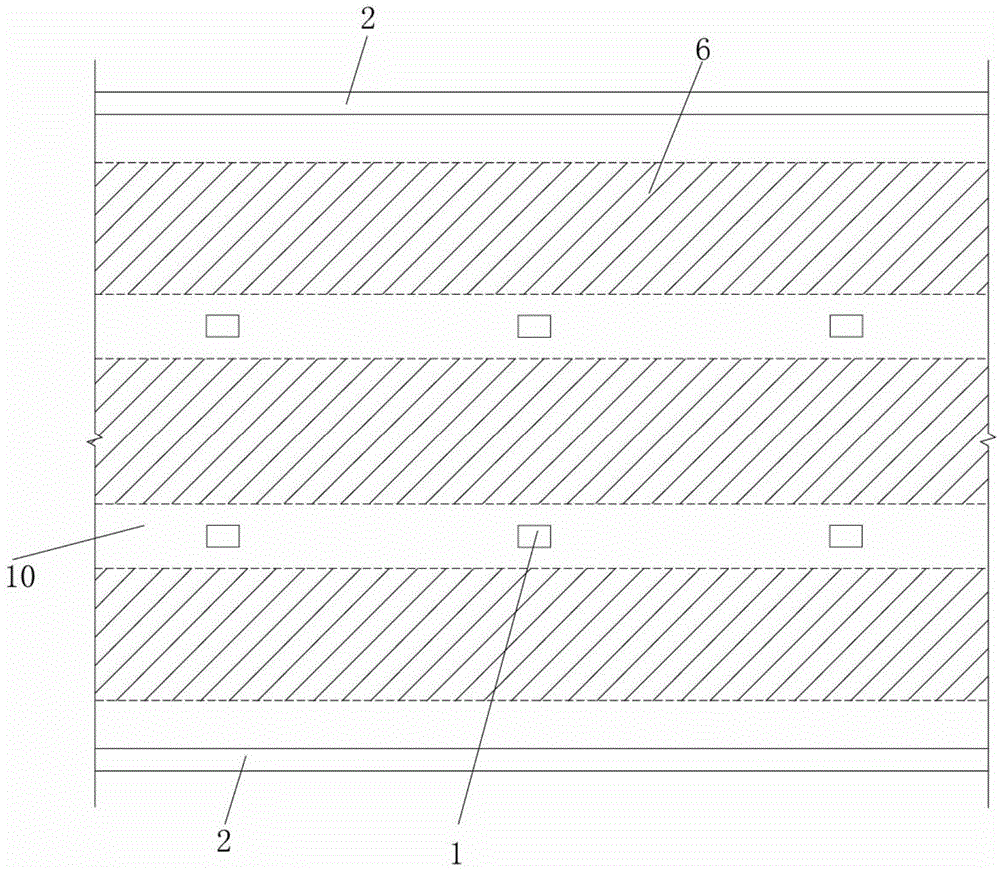

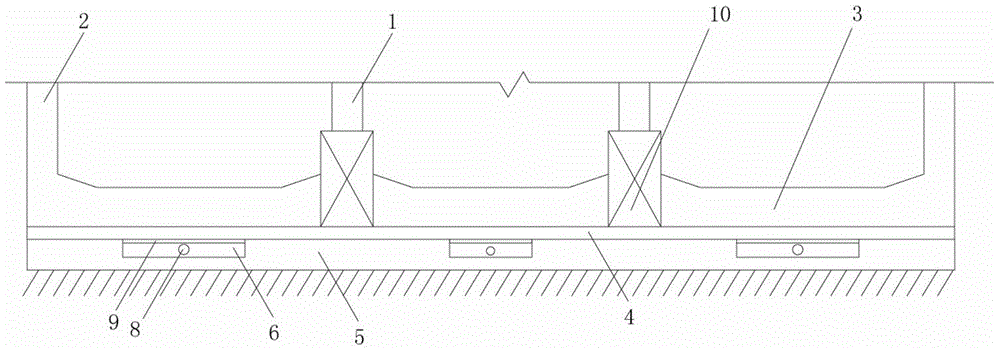

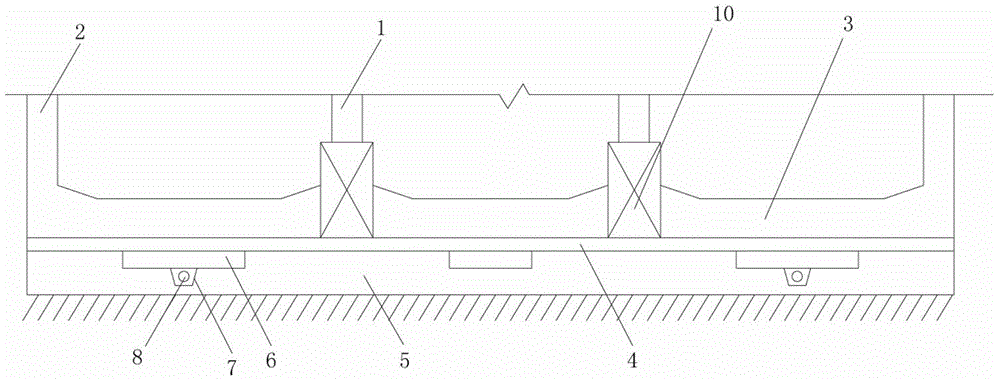

Airbag core mold component cast hollow floor construction method

InactiveCN105908887AMulti-building use spaceFlexible layoutFloorsBuilding material handlingSupporting systemSurface layer

The invention provides an airbag core mold component cast hollow floor construction method, and belongs to the field of construction methods. The airbag core mold component cast hollow floor construction method comprises the following steps: I, erecting a support system; II, paving bottom tendons and rib tendons; III, mounting a fixing device, wherein the fixing device is used for fixing airbag core mold components; IV, paving the airbag core mold components, and fixing the airbag core mold components through the fixing device; V, paving surface-layer reinforcing steel ribs; VI, casting concrete. By adopting the construction method, the self weight of floors can be reduced, the construction cost can be lowered, and the utilization rate of lands can be increased.

Owner:CHONGQING DAOTONG BUILDING MATERIAL CO LTD

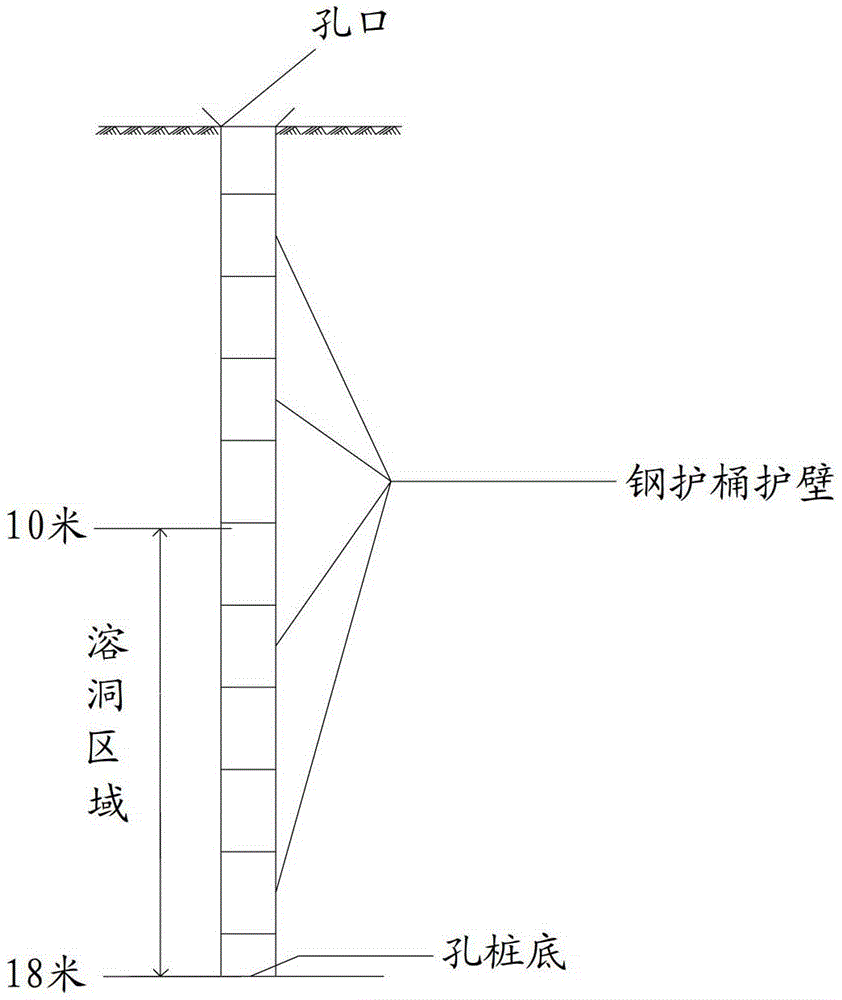

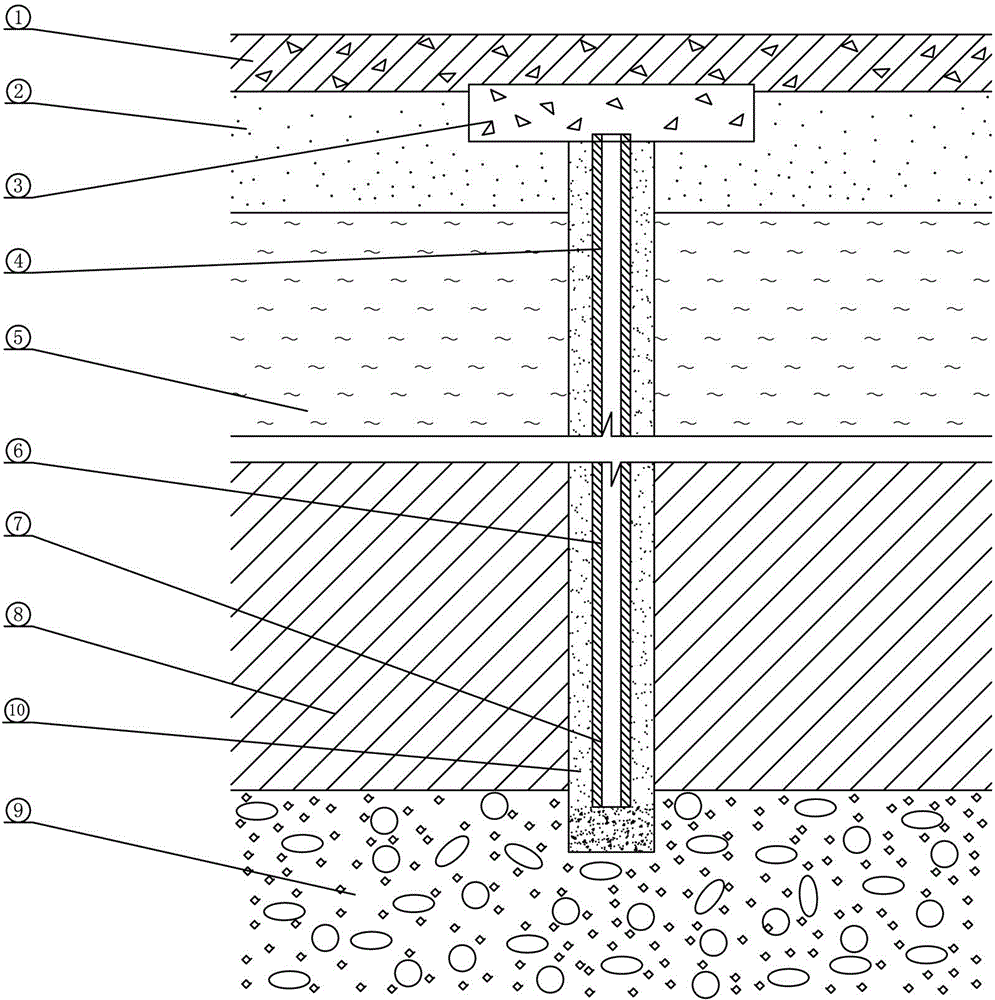

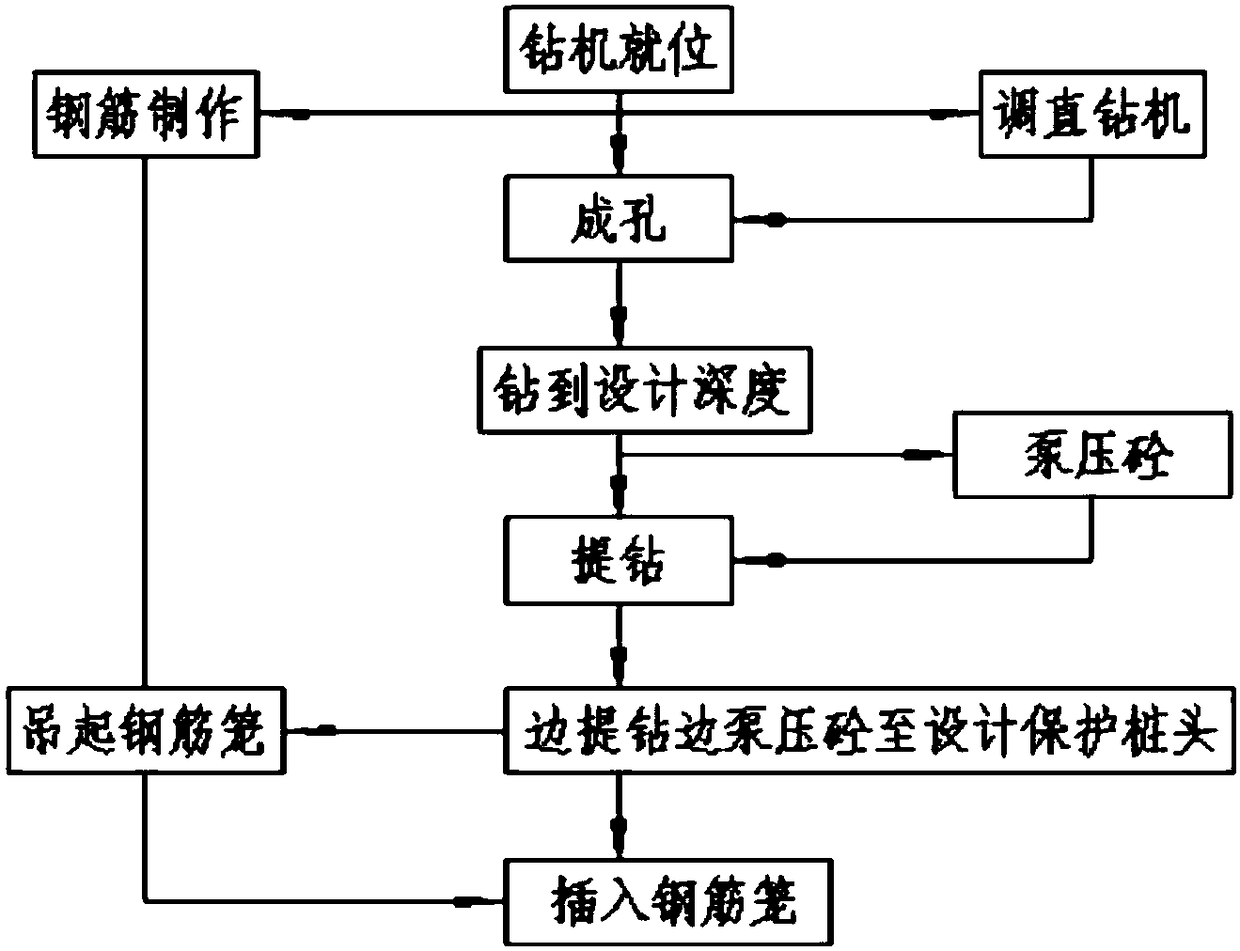

Mechanical hole forming technology applied to karst landform

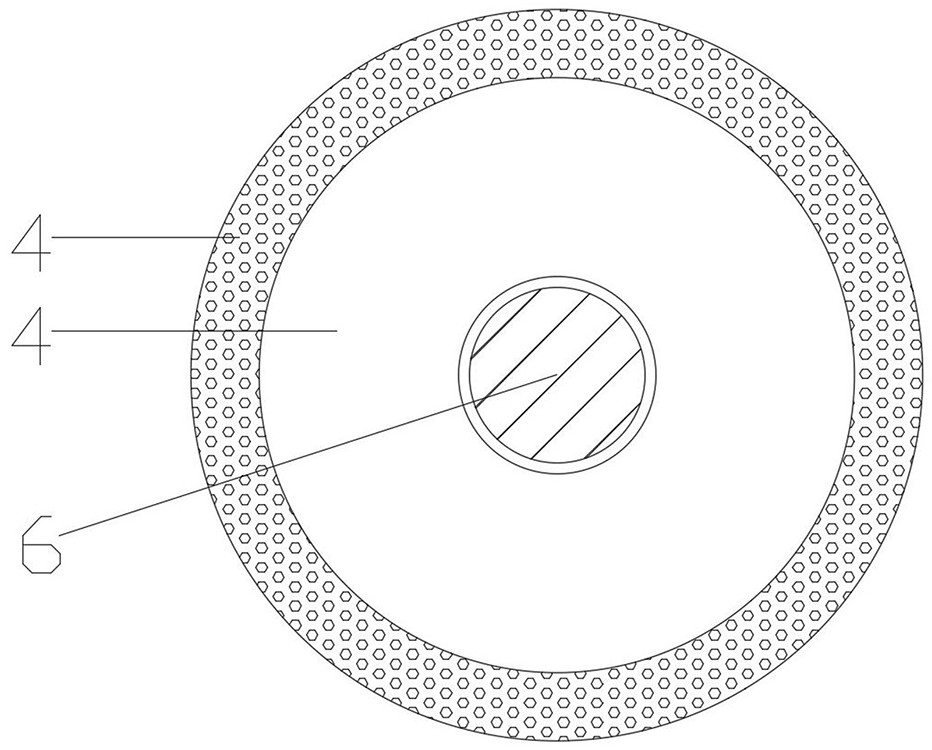

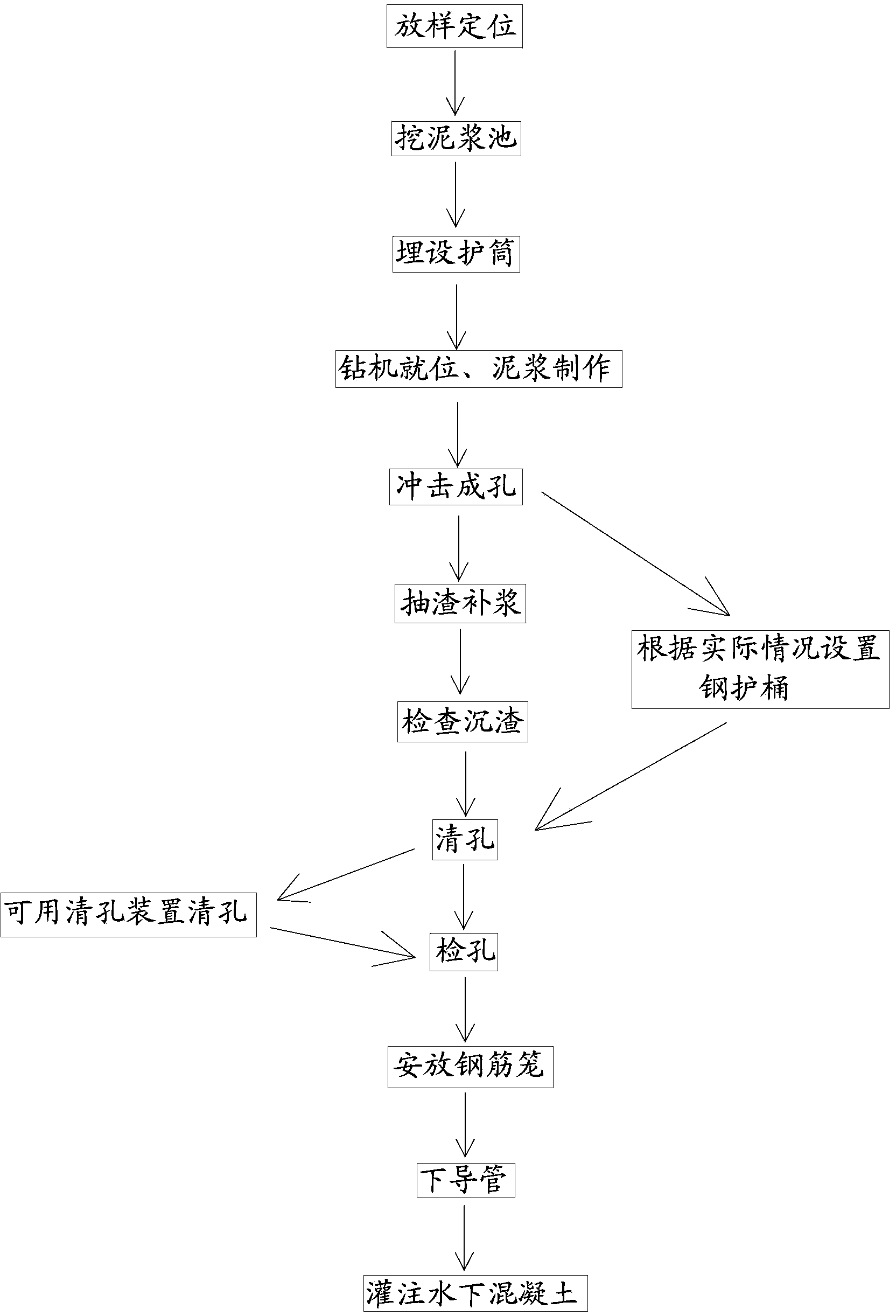

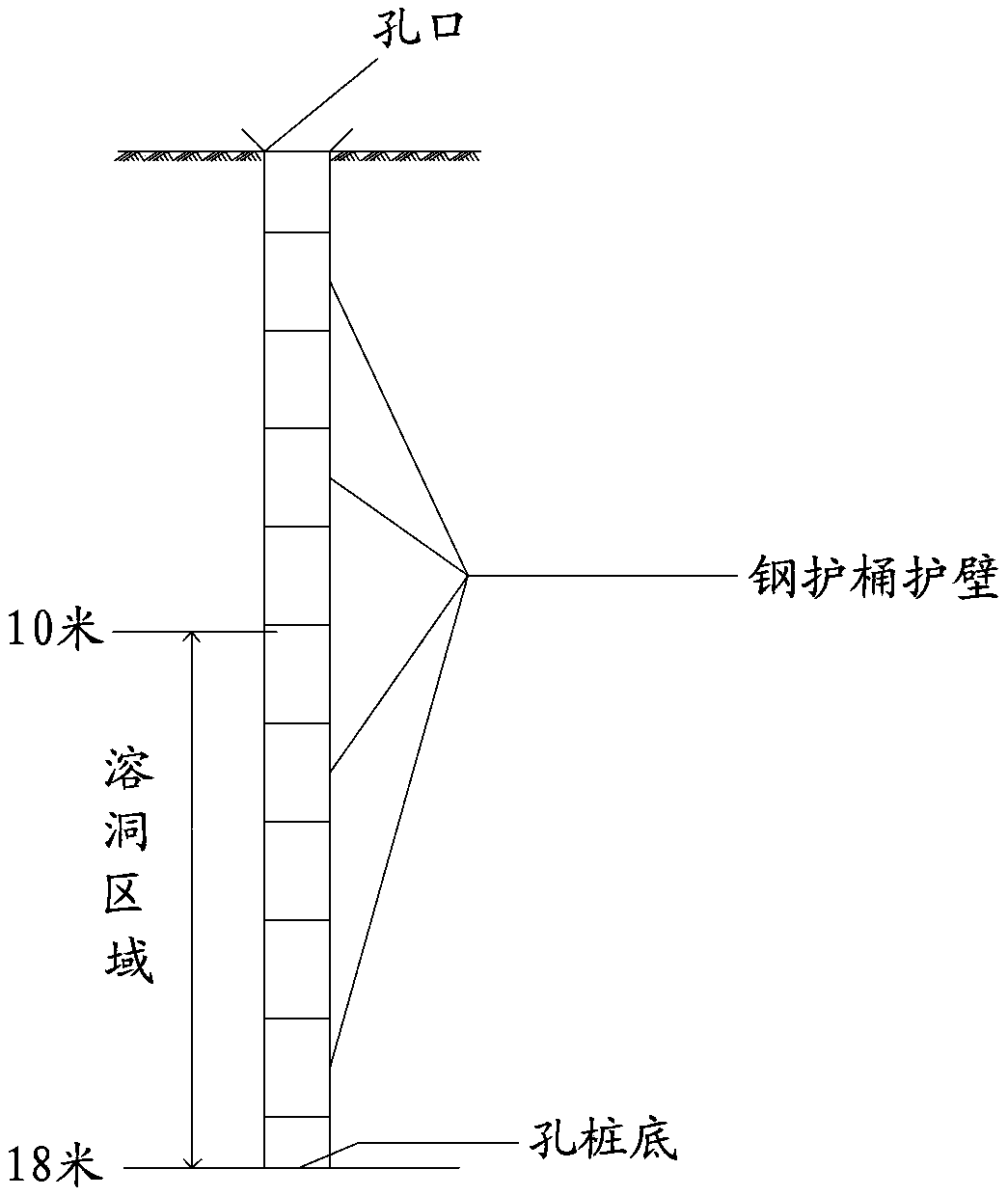

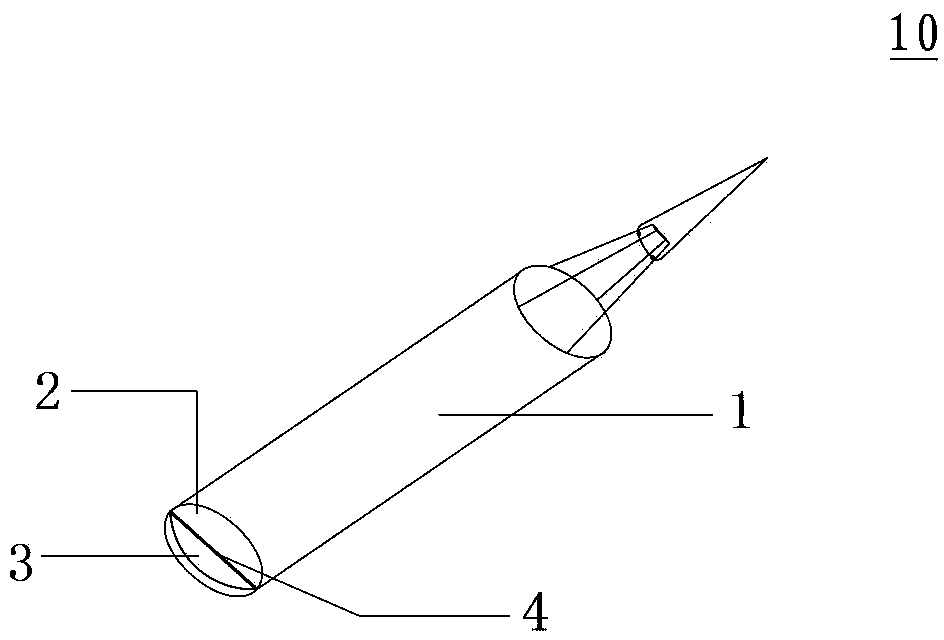

The invention relates to a mechanical hole forming technology applied to karst landform. The technology comprises the following steps of: laying off and positioning; digging a mud pit; burying a pile casing; arranging a drill in place and making mud; forming holes by using an impact machine, wherein when a karst cave is greater than or equal to 3m in depth during construction, a steel pile casing dado is arranged; pumping out sediment and supplementing mud; checking the sediment; clearing off the holes by using a home-made hole cleaning device; checking the holes; arranging a steel reinforcement cage; arranging guide pipes; and pouring underwater concrete. By the mechanical hole forming technology, the probability of occurrence of hole collapse, overfilling of concrete and the like can be lowered, karst cave areas can be effectively protected, the effect of saving concrete is achieved and the cost is further reduced; moreover, by the mechanical hole forming technology, a unit in charge of construction can be effectively helped to clear off sediment from the bottoms of holes, hole piles in collapsed holes can be cleared quickly, the specific depth of a hole pipe can be measured by construction workers.

Owner:中色十二冶金建设有限公司

Method for plugging diversion tunnel by cast-in-situ reinforced concrete without cutoff by gate and plugging reinforcing cage

ActiveCN103276705AEasy constructionLow costWater-power plantsHydro energy generationReinforced concreteEngineering

The invention discloses a method for plugging a diversion tunnel by cast-in-situ reinforced concrete without cutoff by a gate and a plugging reinforcing cage. The method for plugging the diversion tunnel by the case-in-situ reinforced concrete without cutoff by the gate and the plugging reinforcing cage have the advantages that the process of closing the gate for the diversion tunnel can be removed, the project amount of gate concrete is reduced, and meanwhile concrete plugging can be conducted in the process that normal stream diversion is achieved in the diversion tunnel. The plugging reinforcing cage is fixedly provided with a plurality of drain pipes, after a plurality of plugging reinforcing cages are assembled and combined, a cross sectional area is just the cross sectional area of the diversion tunnel, the plugging reinforcing cages are sequentially placed inside the diversion tunnel, or the diversion tunnel is divided into a plurality of areas to be respectively provided with mesh reinforcing frames with drain pipes in an erecting mode, concrete is sequentially poured, when the concrete strength reaches a design requirement, a gate of the drain pipes is closed, normal pouring is conducted to plug concrete on the back face of the gate, and the gate is poured in the concrete.

Owner:中国葛洲坝集团建设工程有限公司

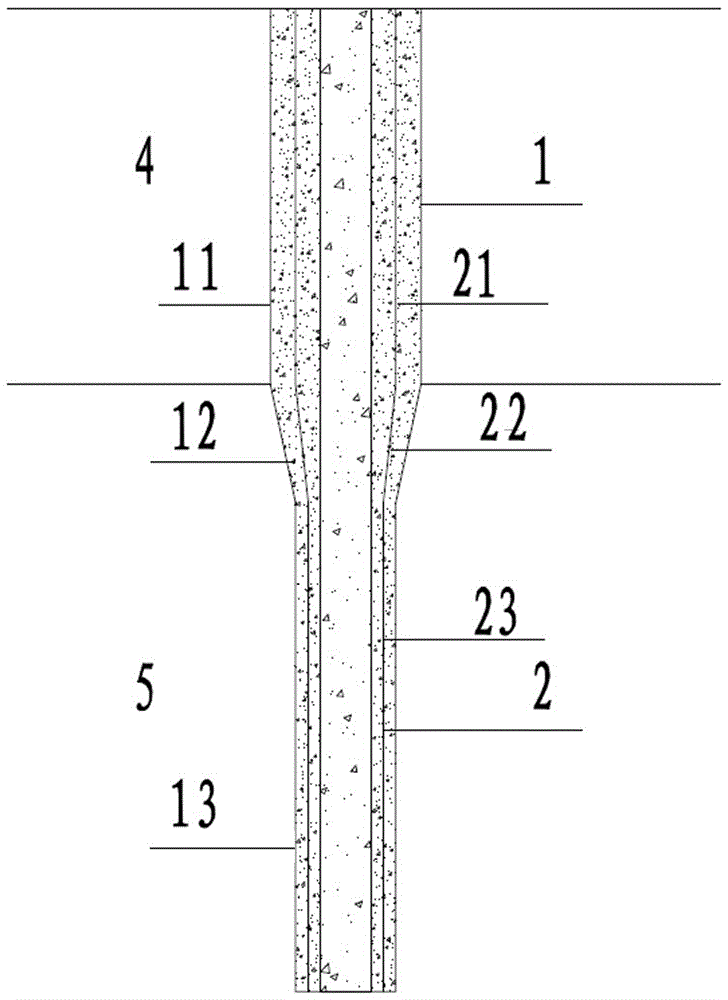

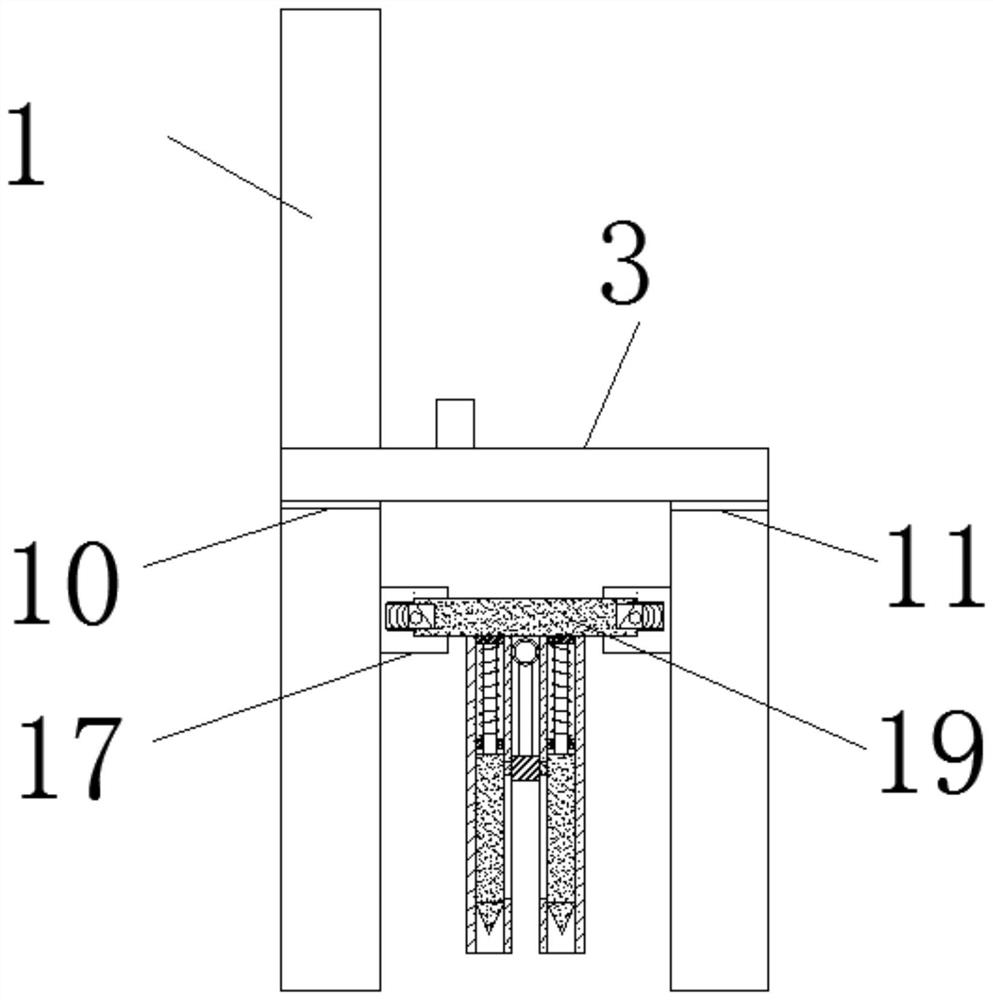

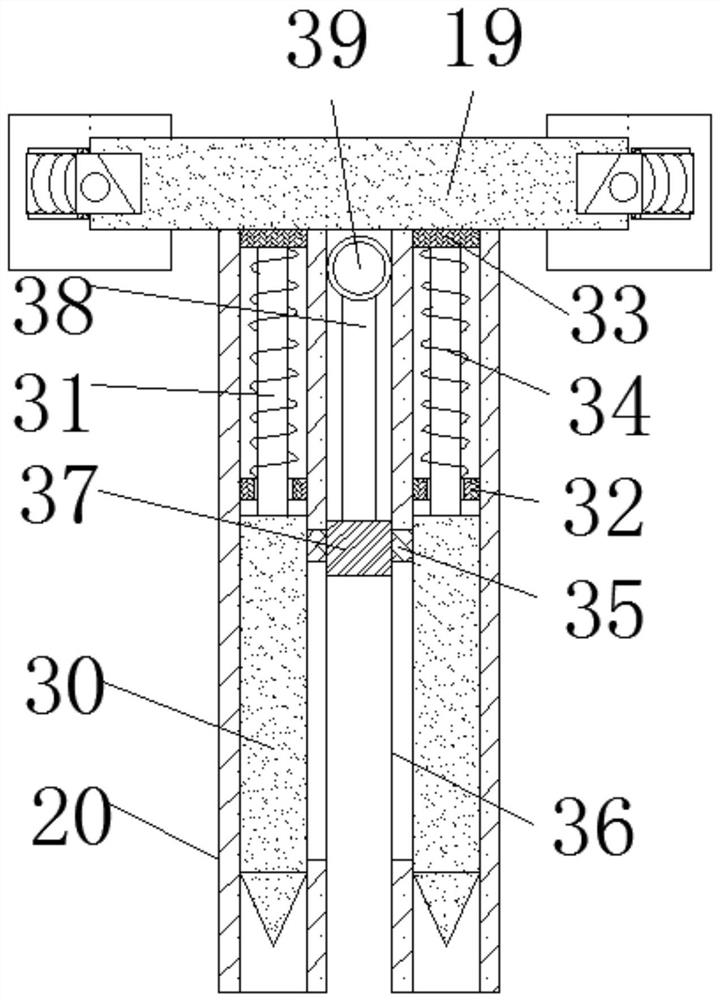

Construction method of composite pile

InactiveCN104153357AImprove bearing capacityNo mechanical damageBulkheads/pilesRigid coreStructural engineering

A construction method of a composite pile comprises the steps of (1), sinking a steel sleeve into the center soil layer of a pile position in a vibrating mode or a hammering mode or a static pressure mode, wherein the diameter of the steel sleeve is larger than the diameter of a core pile by 10-80 cm, and the maximum length of the steel sleeve is 40 m; (2), taking out soil bodies in the steel sleeve or below the steel sleeve by a certain depth through a long auger or a rotary drilling rig or a grab bucket; (3), spraying cement paste and gas to the soil layer at the lower portion of the steel sleeve through a speed-variable agitator, agitating the soil and the cement paste to form uniform pasty cement soil at the same time and agitating the soil within the range of 1-3 meters at the pile tip repeatedly, wherein the number of times of vertical agitation is not smaller than 4; (4), implanting the rigid core pile into the steel sleeve in an inserting mode or a vibrating mode, wherein the pasty cement soil overflows and fills the portion between the rigid core pile and the steel sleeve in the implanting process of the rigid core pile, pulling out the steel sleeve before initial setting of the cement soil, and forming the composite pile after the pasty cement soil is hardened. According to the construction method, in the pile implanting process, mud discharging and soil squeezing effects are avoided.

Owner:骆嘉成 +2

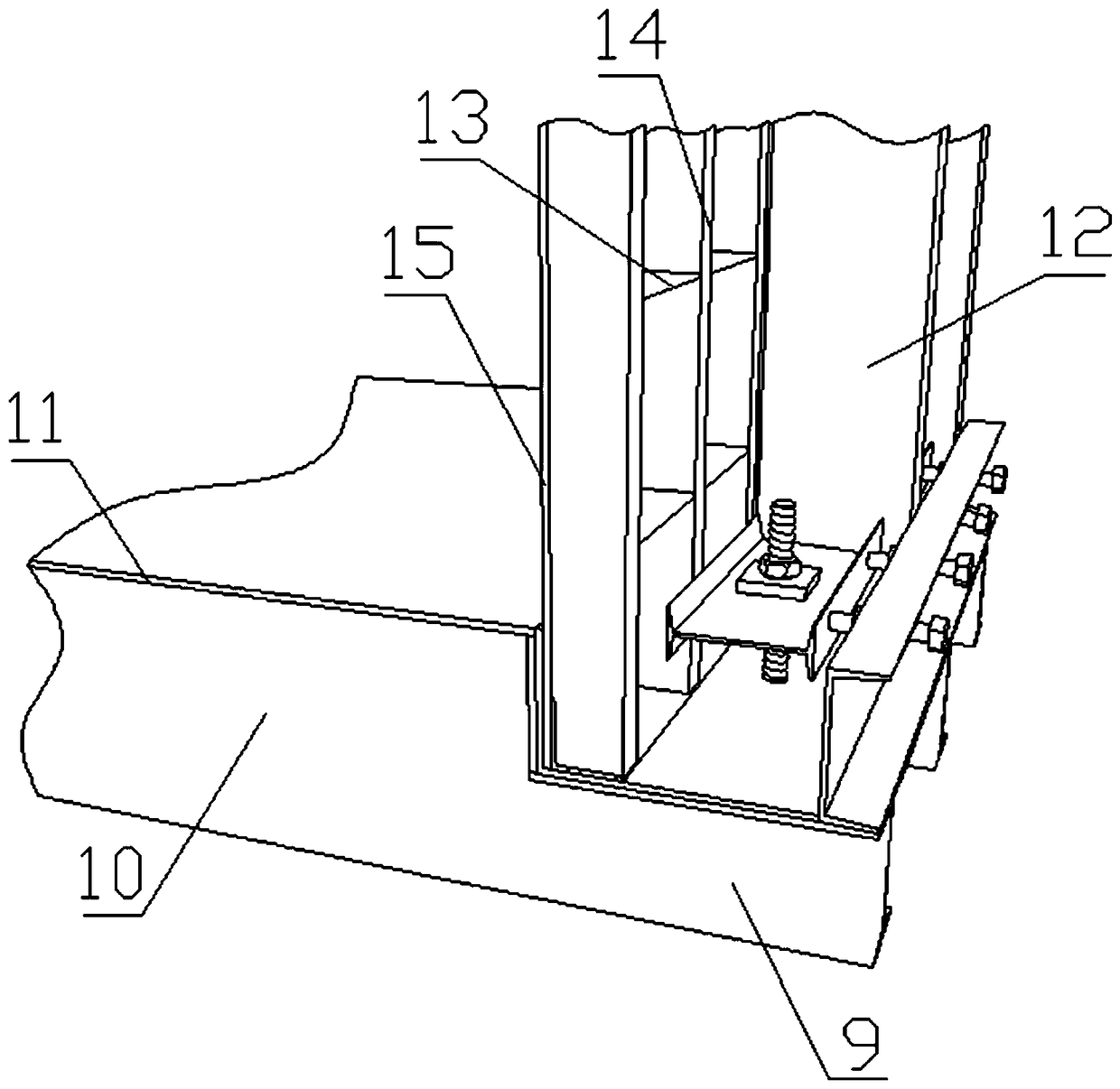

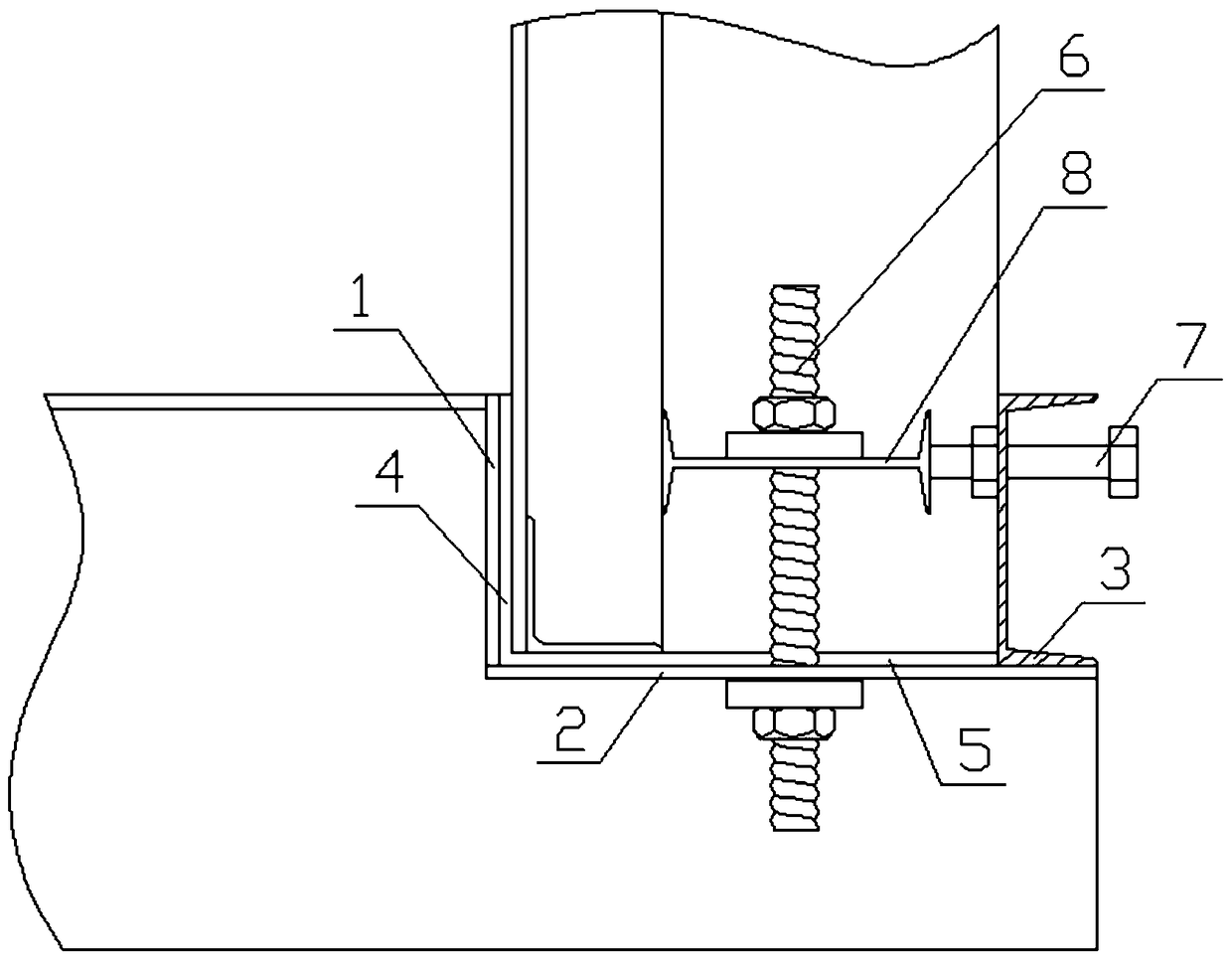

Steel suspension box side plate and base plate connection device without top seal concrete and construction method thereof

PendingCN108643207ASaving concreteReduce construction costsFoundation engineeringEngineeringRear quarter

Owner:GUANGXI ROAD CONSTR ENG GRP CO LTD

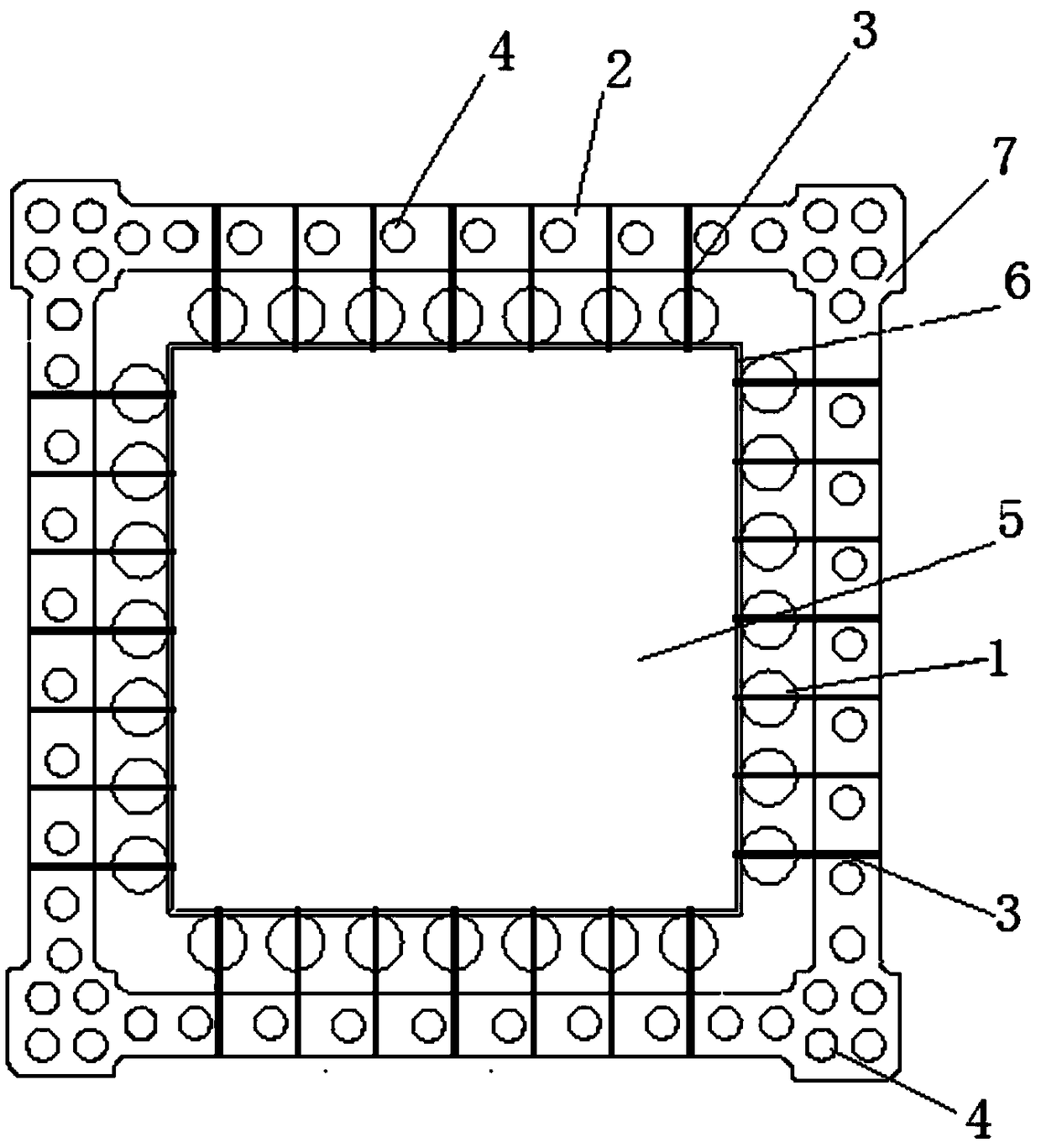

Special-shaped precast pile zipper type supporting structure and construction method thereof

PendingCN111173004AReduce land useLow costExcavationsBulkheads/pilesPre stressArchitectural engineering

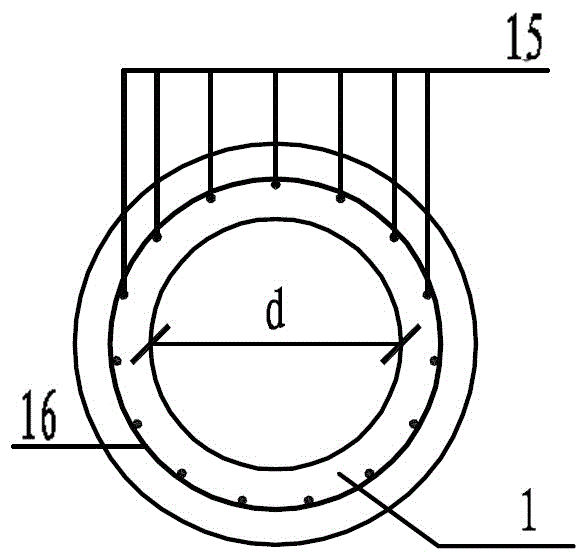

The invention discloses a special-shaped precast pile zipper type supporting structure and a construction method thereof. A special-shaped precast pile comprises a special-shaped pile end plate and aspecial-shaped pile body, the special-shaped precast pile body is made of a concrete material and applies prestress, a reinforcement cage is arranged in the pile body, a pile web is in a hollow circular shape, and the special-shaped precast pile is in an irregular short T shape. The construction method comprises the steps that the special-shaped precast piles are symmetrically constructed in a staggered mode on site; the two staggered special-shaped precast piles are tightly buckled to form a chain type supporting structure; after buckling construction of the special-shaped precast piles is finished, small-diameter high-pressure jet grouting mixing pile construction is carried out at the joint of the two parallel special-shaped precast piles, and a high-pressure jet grouting mixing water stop body is formed to block a gap formed by the parallel special-shaped precast piles; and concrete crown beams are arranged at the tops of the special-shaped precast piles. The supporting structure is particularly suitable for a construction environment with a narrow site, the use amount of concrete and water-stop mixing pile cement is saved, meanwhile, the integrity and the lateral deformation resistance of the foundation pit supporting structure can be enhanced, and economic and environmental benefits are remarkable.

Owner:南京市测绘勘察研究院股份有限公司

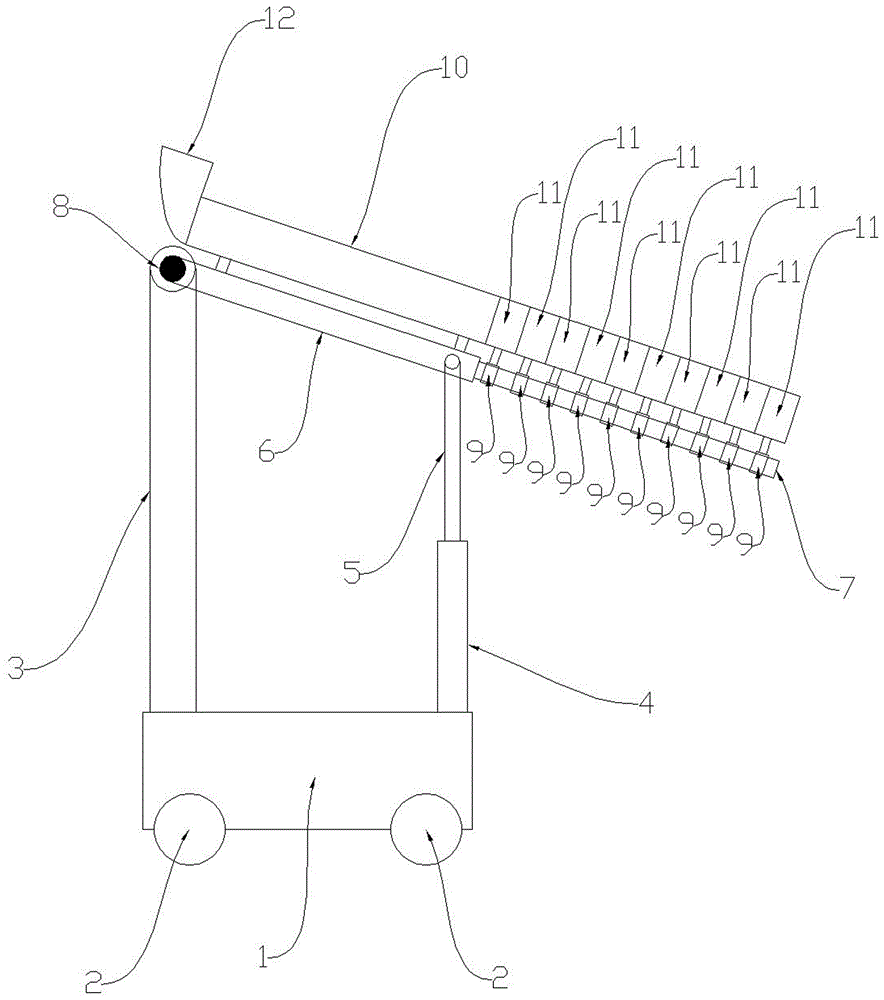

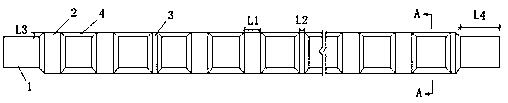

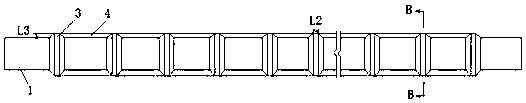

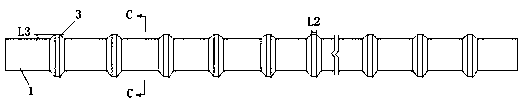

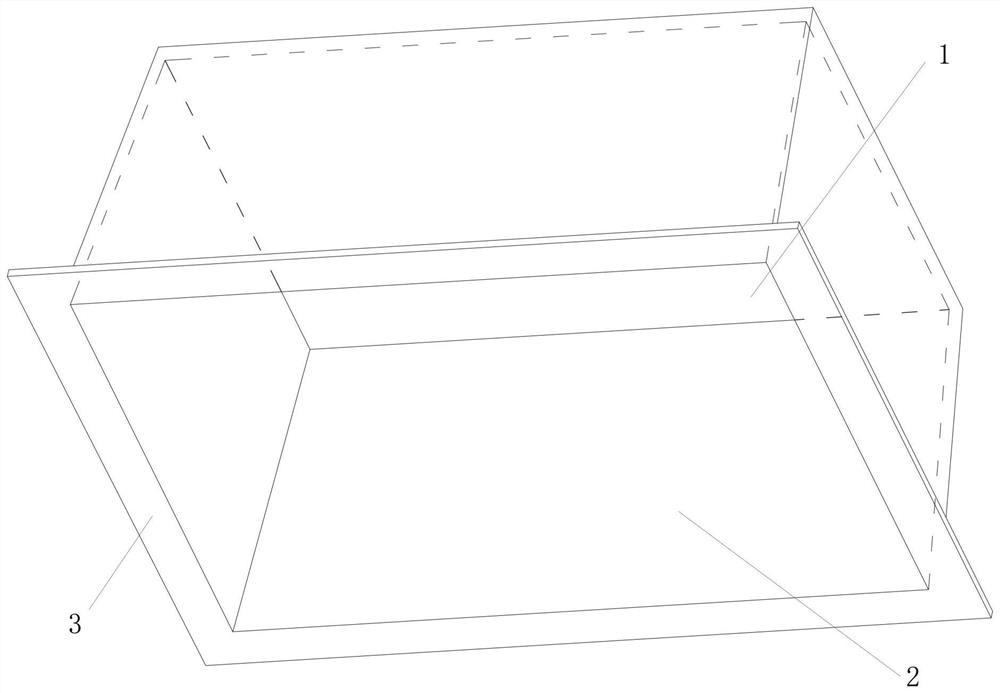

Telescopic mobile chute tube

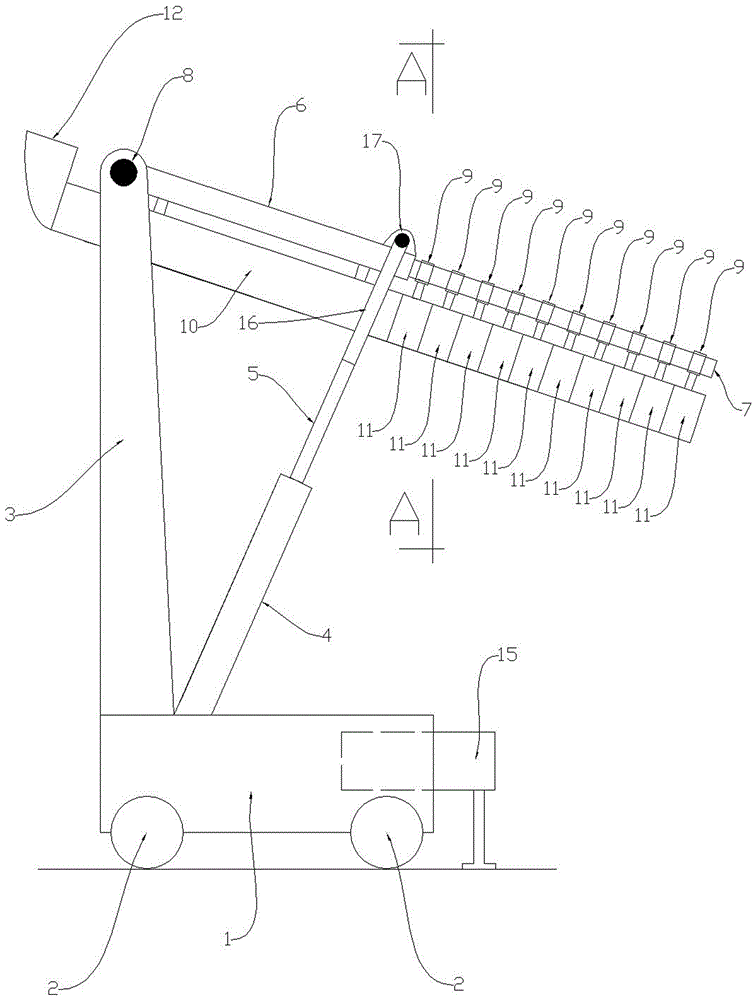

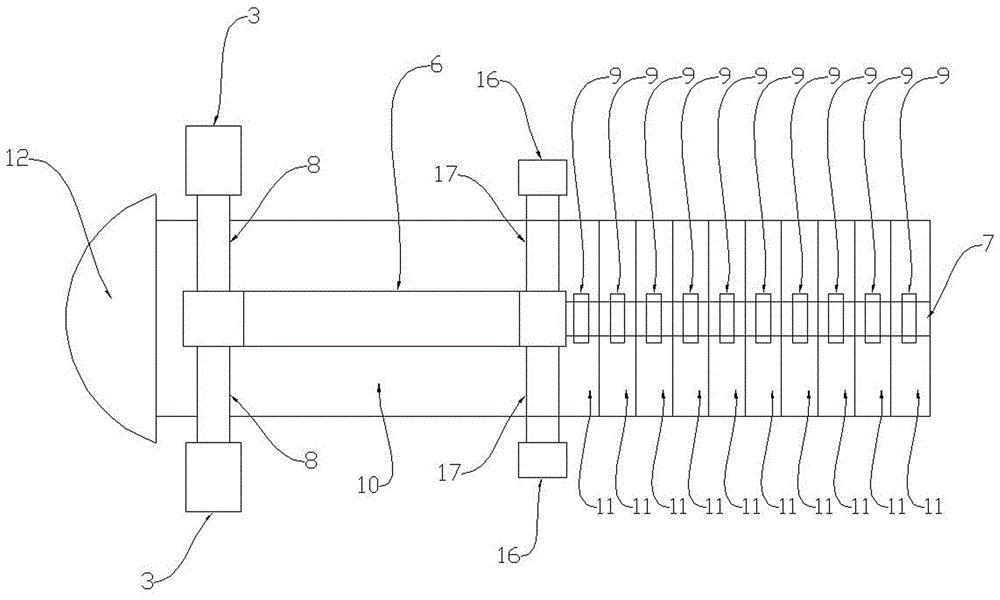

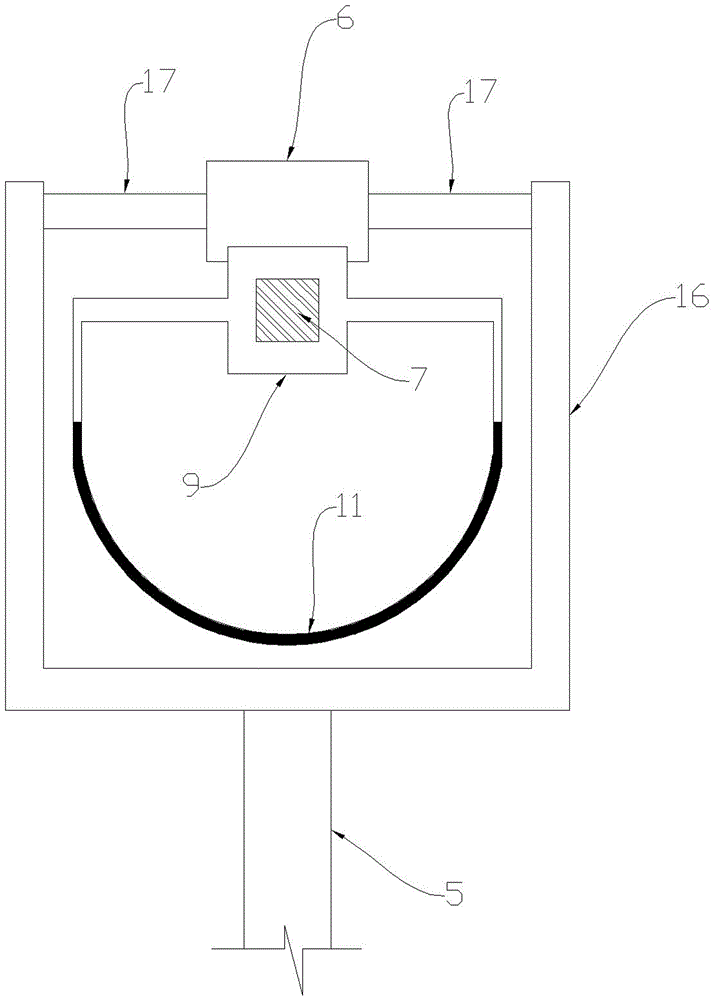

ActiveCN106760543AReduce labor intensityImprove pouring efficiencyRoads maintainenceBuilding material handlingHydraulic cylinderVehicle frame

The invention provides a telescopic mobile chute tube which is mainly used for concrete pouring in the field of constructional engineering and is high in pouring efficiency and capable of saving concrete and reliving the labor intensity of workers. The telescopic mobile chute tube is mainly composed of a vehicle frame, wheels, a stand rack, a hydraulic cylinder, a hydraulic piston, a telescopic rod, mobile racks, a fixed chute tube body, a plurality of mobile chute bodies and a feed hopper. According to the main working principle of the telescopic mobile chute tube, concrete slides over the fixed chute tube body and the mobile chute bodies from top to bottom, slides out of the mobile chute tube body at the foremost end and enters a pouring point; if the concrete needs to be poured to a place far away, the telescopic rod is rightwards stretched, the front end of the telescopic rod drives the mobile chute tube body at the foremost end to forwards move, and when a limiting ring of the mobile chute tube body at the foremost end makes contact with a limiting ring of the second section of mobile chute tube body, the second section of mobile chute drum body is pulled out, and in the same way, the other sections of mobile chute tube bodies are pulled out; and the inclination angle and the height of concrete discharging can be changed by stretching and retracting the hydraulic piston.

Owner:平邑经发科技服务有限公司

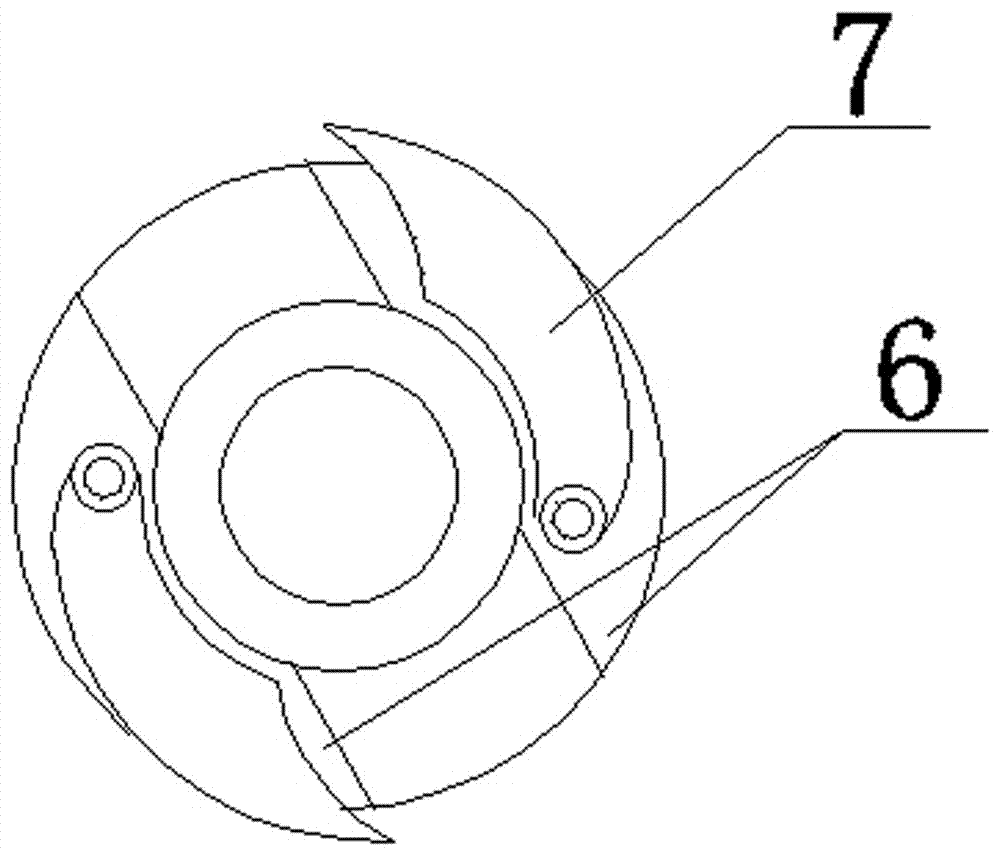

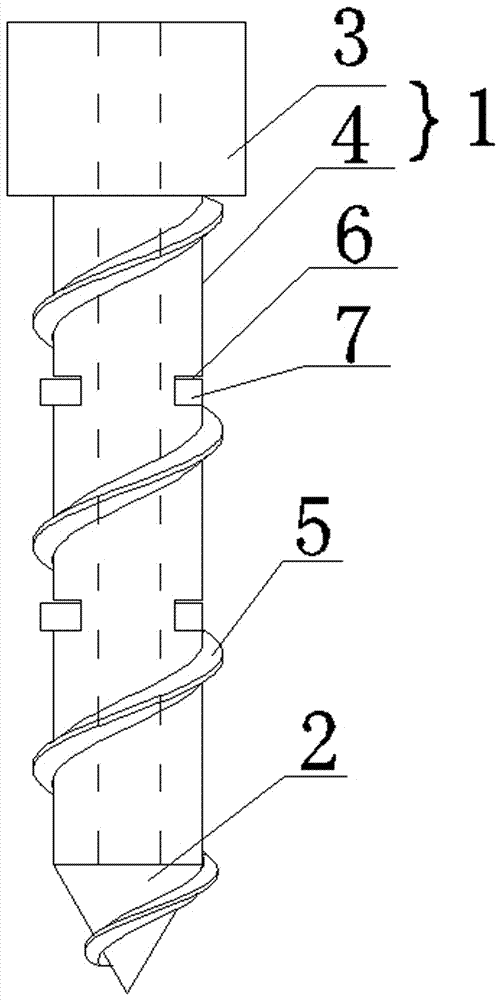

Prefabricated concrete pipe pile for overhead power transmission line

ActiveCN107090847AReduce weightLow costSolid waste managementFoundation engineeringUltimate tensile strengthPower transmission

The invention discloses a prefabricated concrete pipe pile for an overhead power transmission line. The prefabricated concrete pipe pile comprises a hollow pipe pile and a pile head; the hollow pipe pile comprises an upper pipe pile and a lower pipe pile, the outer diameter of the upper pipe pile is larger than that of the lower pipe pile, and a screw is arranged on the exterior of the lower pipe pile; a pile expanding device is arranged on the lower pipe pile and comprises two arc-shaped grooves which are formed in the symmetrical positions of the same circumference of the lower pipe pile, an annular steel plate matched with the corresponding arc-shaped groove is hinged to the bottom of each arc-shaped groove, the tail end of each annular steel plate stretches out of the corresponding arc-shaped groove, and the direction that the annular steel plates are arranged in the arc-shaped grooves is consistent with the screwing-in direction of the screw. According to the prefabricated concrete pipe pile for the overhead power transmission line, foundation settlement can be reduced, the rigidity of the pipe pile can be improved, the using amount of concrete can be decreased, and the construction cost of the prefabricated pipe pile can be reduced; in addition, the strength of the concrete is high, the contact area of the prefabricated pipe pile and soil mass is large, and therefore the bearing capacity of the prefabricated pipe pile can be enhanced.

Owner:STATE GRID CORP OF CHINA +2

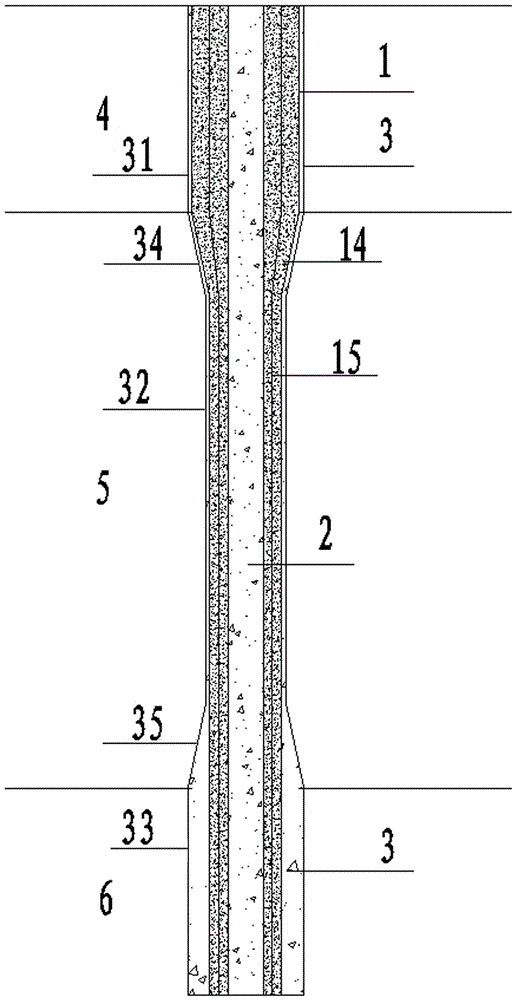

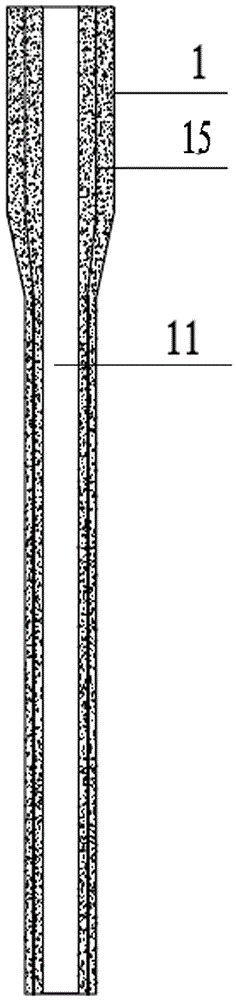

Upper portion and lower portion enlarged type cement soil composite pipe pile

InactiveCN106480878AImprove bearing capacityImprove performanceBulkheads/pilesSoil horizonPrecast concrete

An upper portion and lower portion enlarged type cement soil composite pipe pile comprises a precast concrete pipe pile body, a central hole is formed in the precast concrete pipe pile body and filled with a first cement soil pile body, a second cement soil pile body is arranged outside the precast concrete pipe pile body and comprises an upper segment, a middle segment and a lower segment, the diameters of the upper segment and the lower segment of the second cement soil pile body are larger than that of the middle segment thereof, and a first variable-diameter segment and a second variable-diameter segment are arranged between the upper segment and the middle segment as well as between the middle segment and the lower segment respectively. Compared with a single-diameter pipe pile equal in height and made of equivalent concrete, the upper portion and lower portion enlarged type cement-concrete composite pipe pile has the advantages that the bearing capacity of a pile foundation is higher, and the composite pipe pile can be made shorter on the premise that bearing capacity design requirements are met; shaft resistance of the pile foundation can be given to full play, and accordingly the composite pipe pile is particularly suitable for geological conditions with upper soil layers superior to lower soil layers.

Owner:周同和

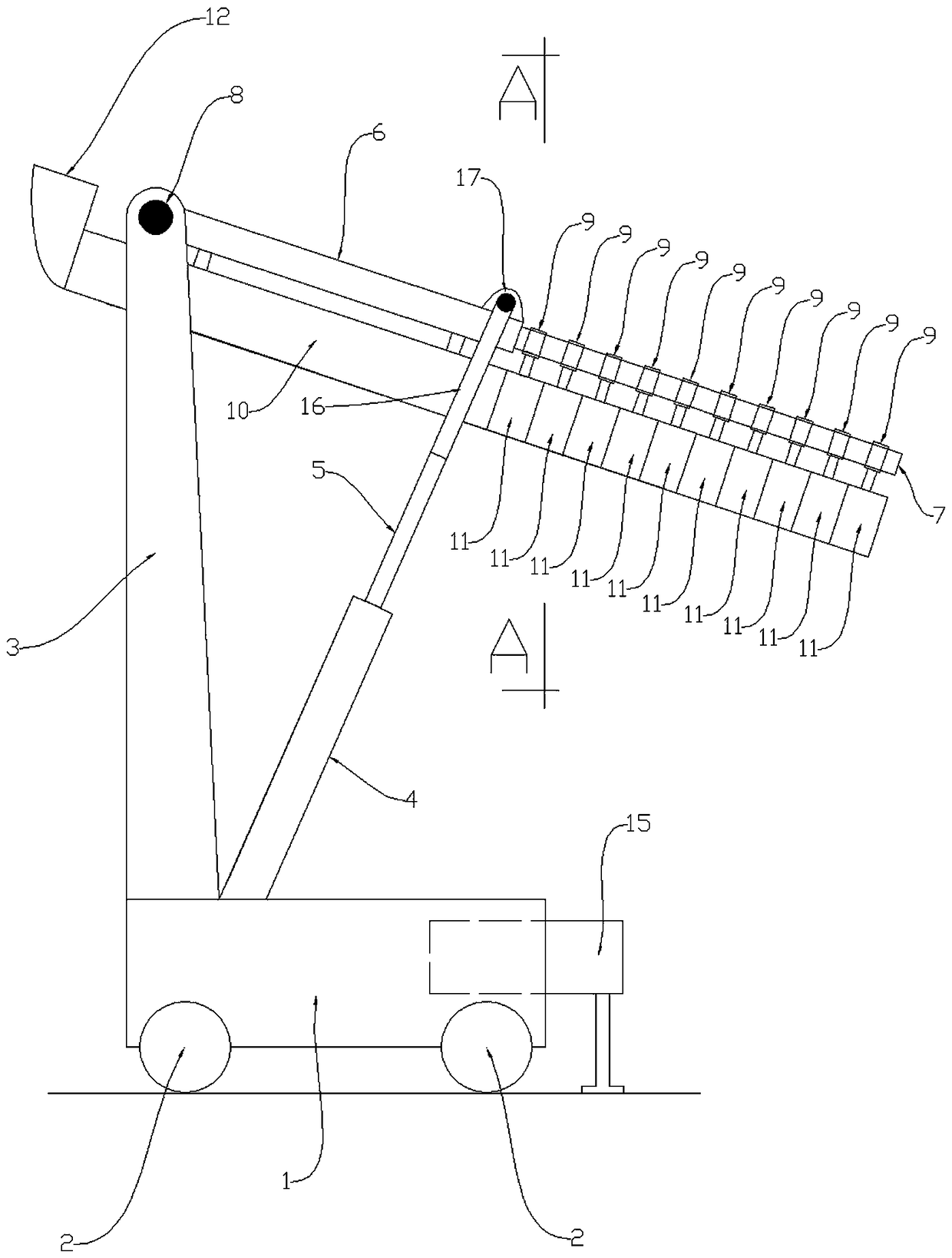

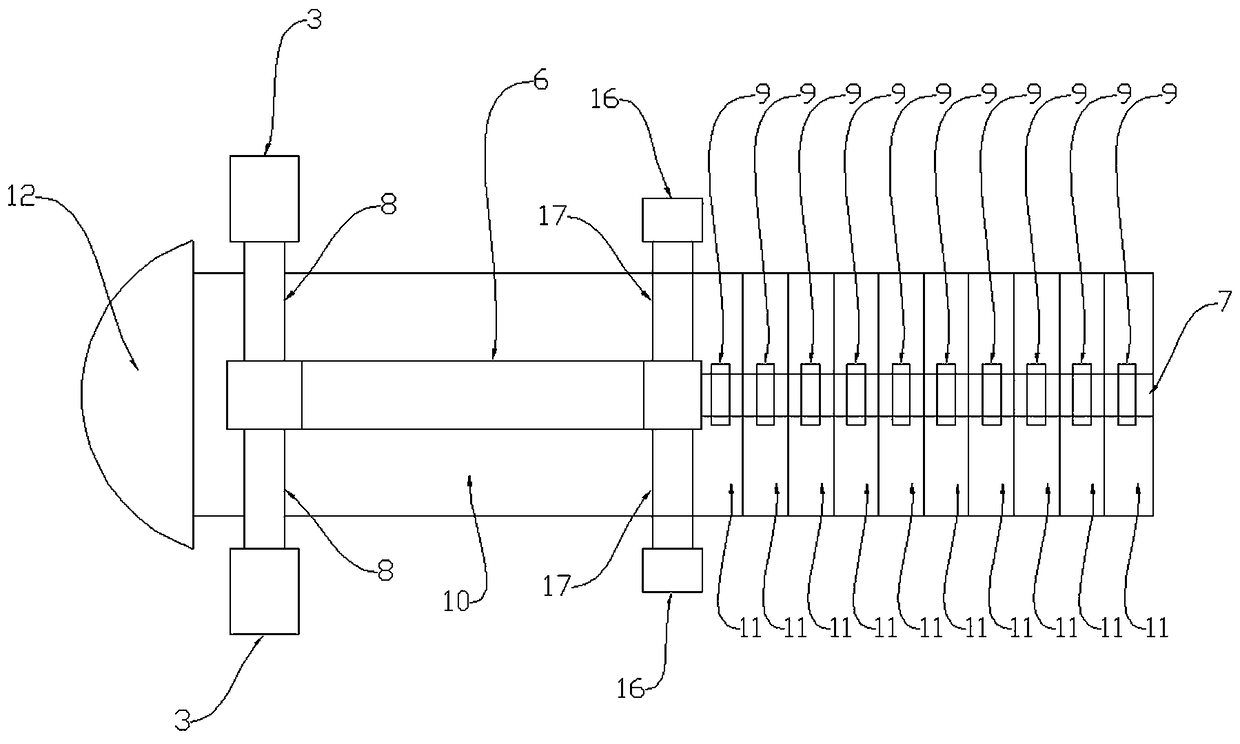

Improved type telescopic movable chute tube

ActiveCN106677540AReduce labor intensityImprove pouring efficiencyBuilding material handlingHydraulic cylinderVehicle frame

The invention discloses an improved type telescopic movable chute tube. The improved type telescopic movable chute tube is mainly used for pouring concrete in the field of constructional engineering. The improved type telescopic movable chute tube is high in pouring efficiency, concrete is saved, and the labor intensity is relieved. The improved type telescopic movable chute tube mainly comprises a vehicle frame, wheels, an n-shaped vertical frame, a hydraulic cylinder, a hydraulic piston, a telescopic rod, a movable frame, a fixed chute tube body, movable chute tube bodies, a feed hopper, a front support device and an n-shaped frame. According to the main working principle of the improved type telescopic movable chute tube, the concrete slides over the fixed chute tube body and the multiple movable chute tube bodies from top to bottom, slides out from the movable chute tube body at the most front end and enters a pouring point; if the concrete needs to be poured to a far place, the telescopic rod is stretched rightwards, the front end of the telescopic rod drives the movable chute tube body at the most front end to move frontwards, after a limiting ring of the movable chute tube body at the most front end touches a limiting ring of the second section of movable chute tube body, the second section of movable chute tube body is pulled out, and in the same way, the rest sections of movable chute tube bodies are pulled out; and the hydraulic piston is stretched out or retracted, and the inclined angle of concrete discharge and the discharge height can be changed.

Owner:平邑经济开发区投资发展有限公司

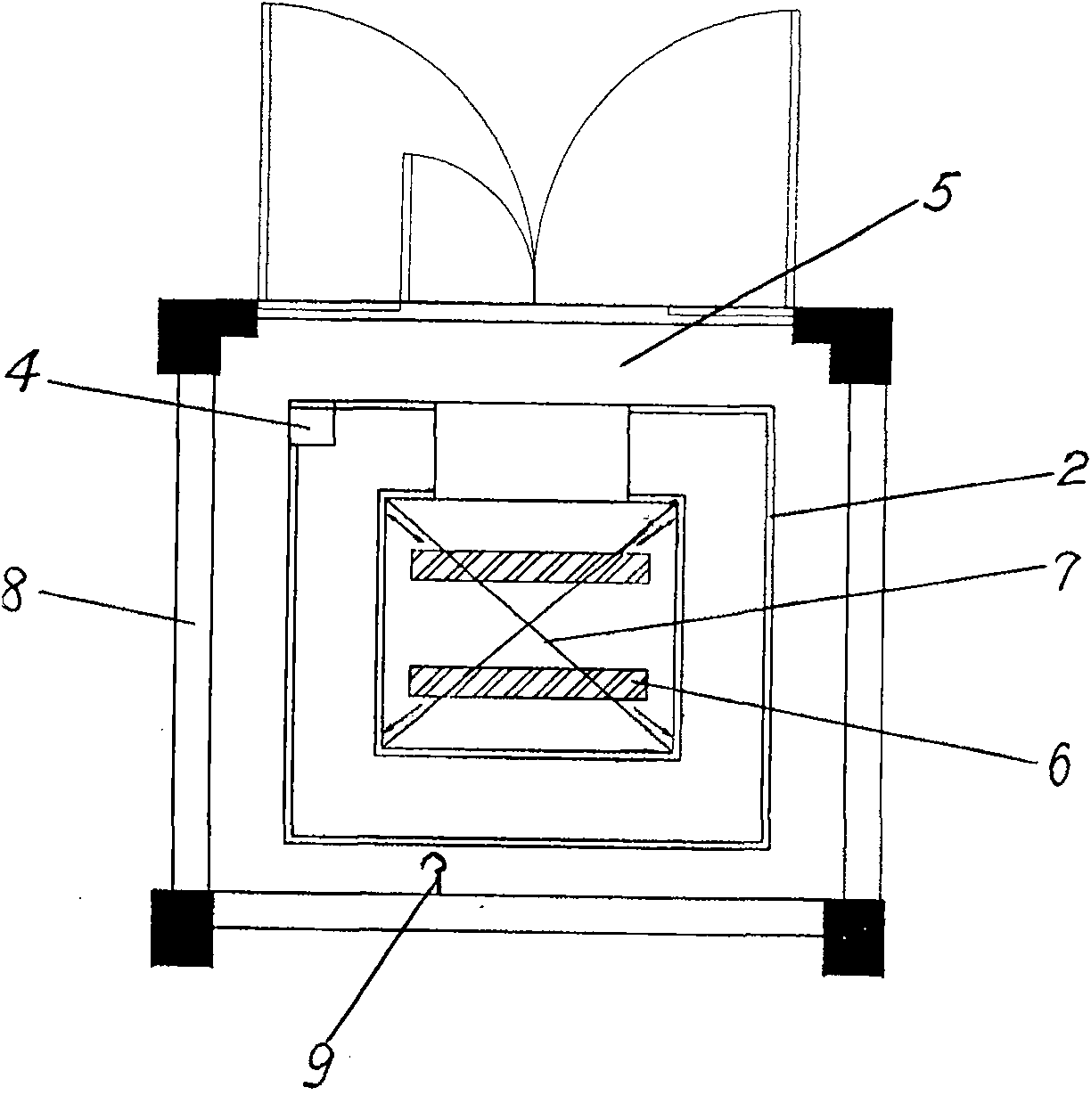

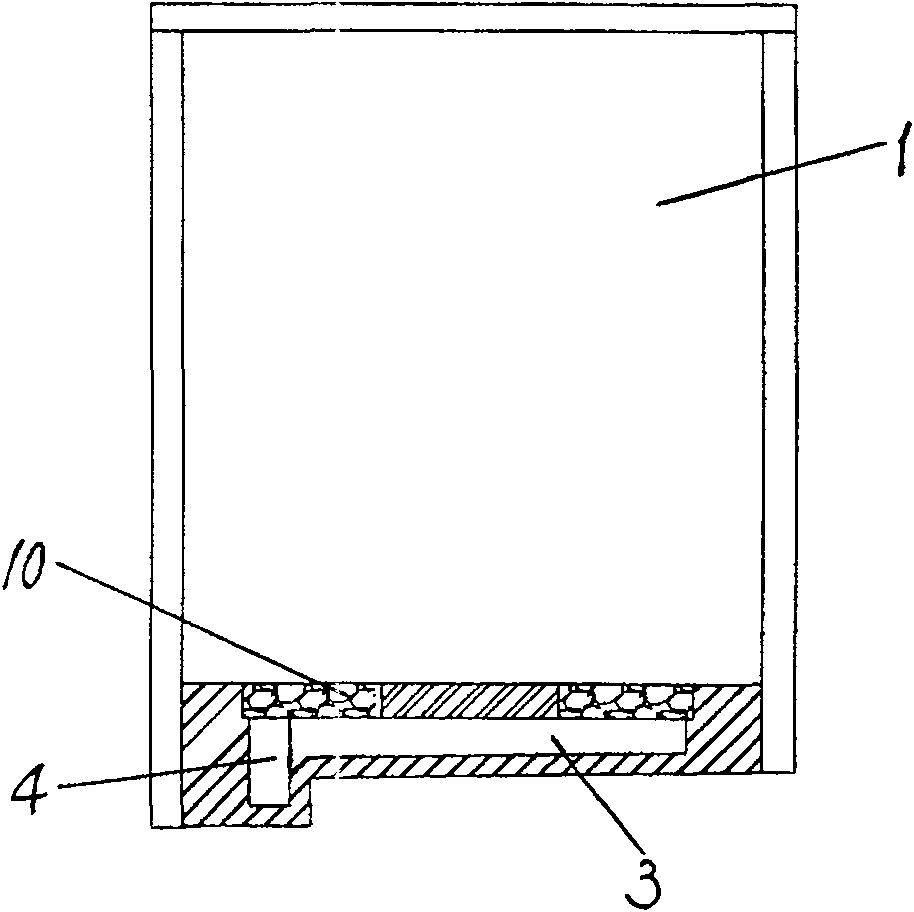

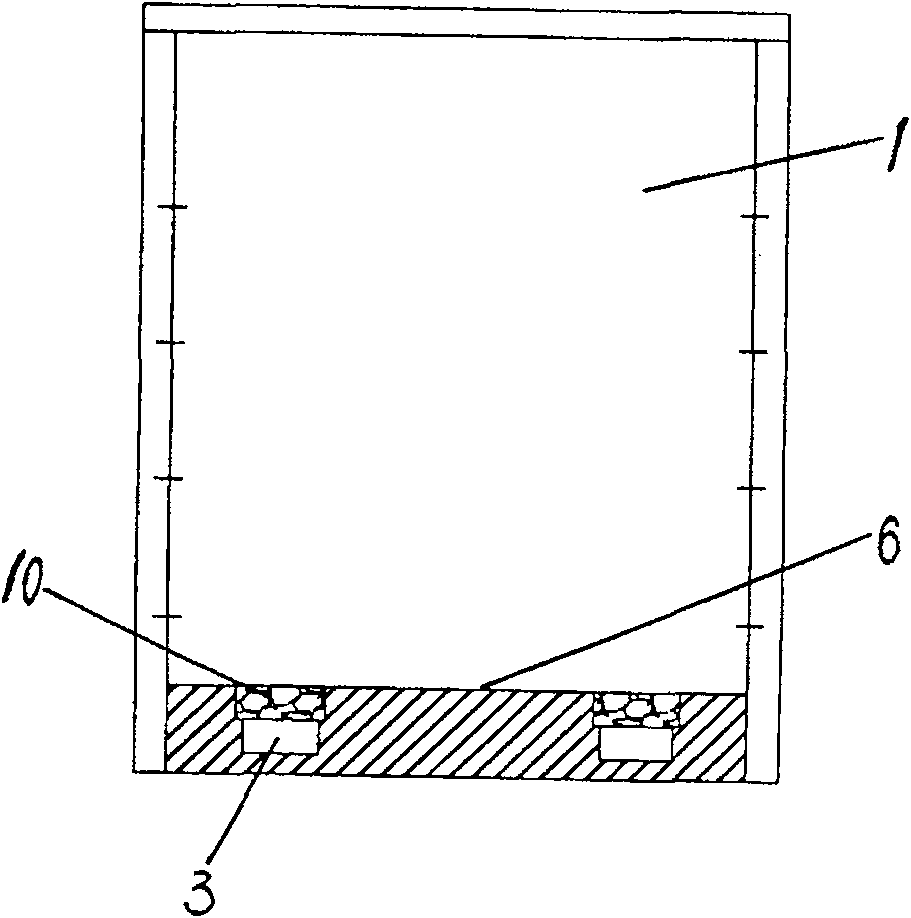

Foundation construction for installation of oil-immersed type transformer

InactiveCN101202153AThe influence of soft connection modeMeet storageTransformers/reacts mounting/support/suspensionFrame basedFire control

The invention relates to a base structure used for installing an oil immersed transformer. The invention is arranged in a transformer room where a box-shaped base is arranged. An oil collecting groove is arranged around the internal part of the box-shaped base. The oil collecting groove is communicated with an oil collecting pit positioned at an end of the oil collecting groove. A cement level-ground is arranged on the outer edge of the box-shaped base. A plurality of flat bars are pre-embedded in the middle of the box-shaped base and are fixed by reinforced cables. And a plurality of flat bars are pre-embedded in a wall of the transformer room and a steel hook is also pre-embedded on the wall so as to pull the transformer. By adopting the structure of the transformer box-shaped base of the invention, the structure can be free from a building frame base and the weight of the transformer is born by the box-shaped base. Then, although the box-shaped base causes slight settlement to the ground, the adopted flexible connection of cables can not be affected. The transformer base of the invention needs no piling so as to save an investment cost. The arrangement of the oil collecting grooves around the internal part of the box-shaped base can drain the oil for storage so as to meet fire control requirement.

Owner:BAOSTEEL ENG & TECH GRP

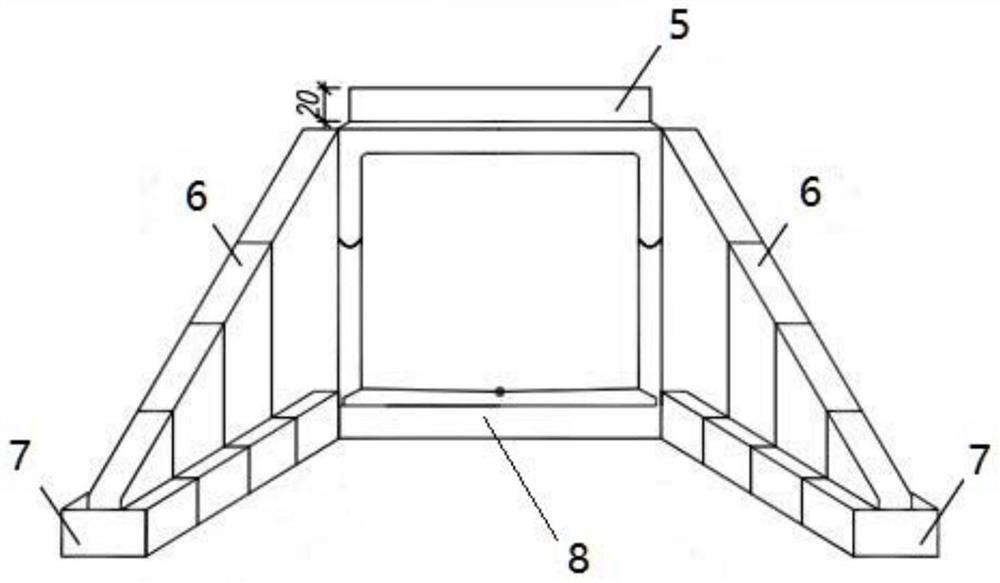

Prefabricated installation construction method for fabricated box culvert

The invention discloses an assembly type box culvert prefabrication installation construction method, an assembly type box culvert comprises a plurality of mutually connected box culvert sections and holes at two ends, each box culvert section comprises a top plate, a bottom plate and side walls, two ends of each top plate are respectively spliced with the side walls, the bottoms of the two side walls are in cast-in-place connection, a cast-in-place part is the bottom plate, and a cast-in-place part is connected with the bottom plate; the top plates, the bottom plate and the two side walls form a box-shaped channel, supporting feet protruding outwards are arranged at the bottoms of the side walls, two connectors of the top plates and the side walls are in an elbow shape and are freely hinged, and when different box-shaped culvert sections are connected, the top plates are connected through bent bolts. Prefabrication can be performed in the field in advance, the construction time is greatly shortened, the construction period is shortened, and civilized and green construction is promoted; during excavation construction, the working face is small, and damage and pollution to ground surface underground water and soil are greatly reduced; the quality of the culvert can be effectively improved, the appearance and the percent of pass of a protective layer are greatly improved, and good economic and social benefits are achieved.

Owner:CHINA FIRST HIGHWAY ENG

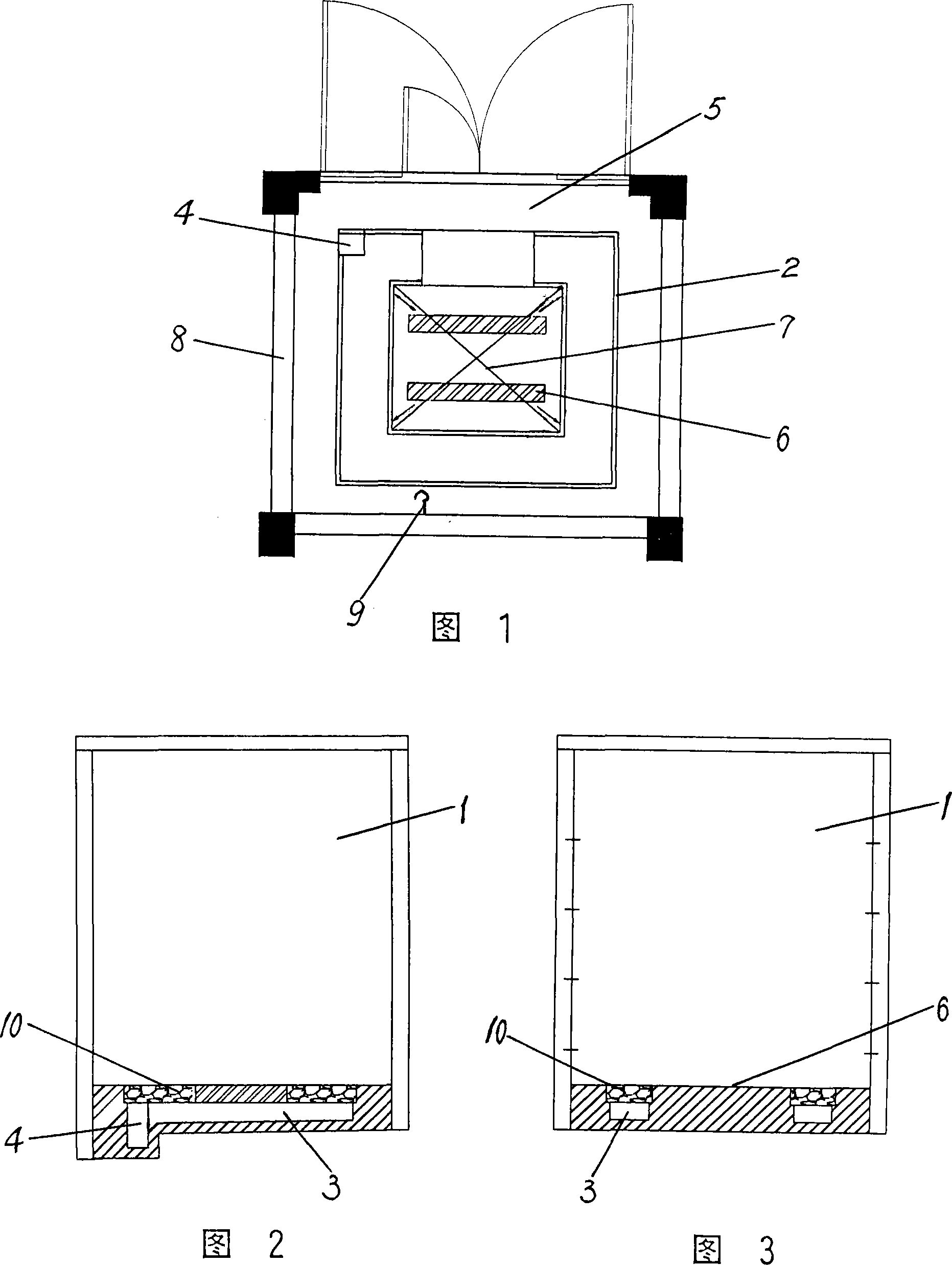

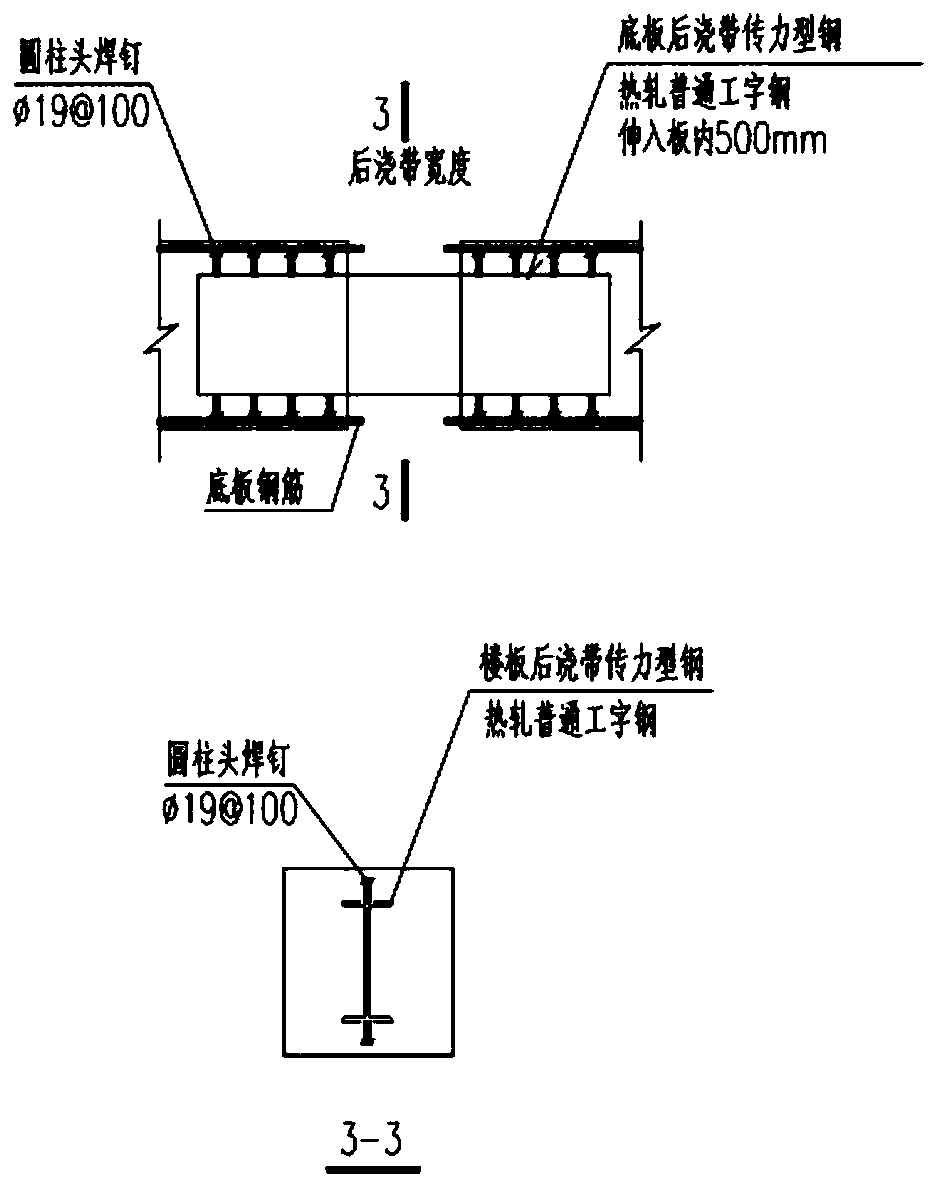

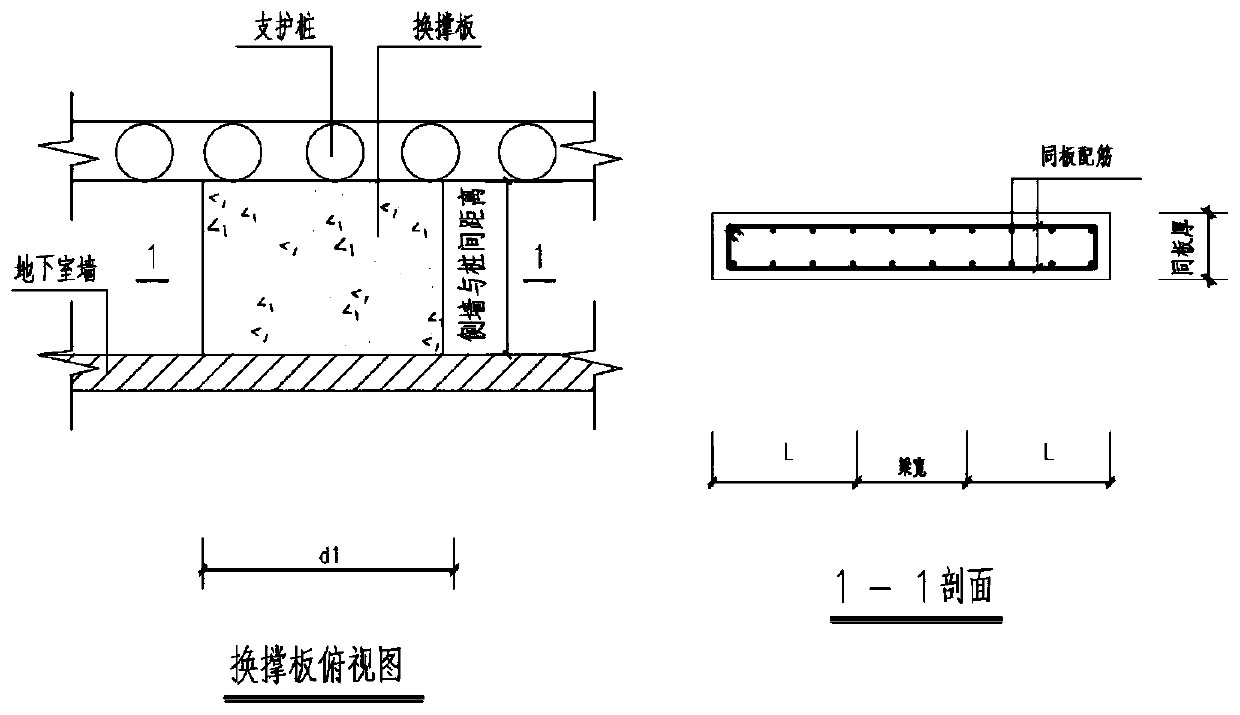

Deep foundation pit supporting inner support changing method

InactiveCN110185043AReduce workloadLow costArtificial islandsExcavationsUltimate tensile strengthBuilding construction

The invention discloses a deep foundation pit supporting inner support changing method and belongs to the technical field of deep foundation pit supporting. The deep foundation pit supporting inner support changing method comprises the following steps: S1, before support changing block construction, cleaning the contact part of a support pile and a support changing block; S2, adopting concrete tofill the space between a bottom plate and the support pile to form a support changing strip, and pouring grooves between every two adjacent support piles; S3, additionally arranging joist steel force-transferring components at positions, at a post-cast strip, of the bottom plate, and arranging one joist steel force-transferring component every 2.5 m; and S4, when the strength of the support changing block reaches 80% of the design strength, symmetrically detaching the support one by one. The method has the following characteristics: the workload of support changing is less, concrete is saved,and the cost is low; when the strength of the support changing block reaches 80% of the design strength, the inner support can be detached, the characteristic of shortening the construction period isrealized, and the safety and stability are high.

Owner:CHINA MCC17 GRP

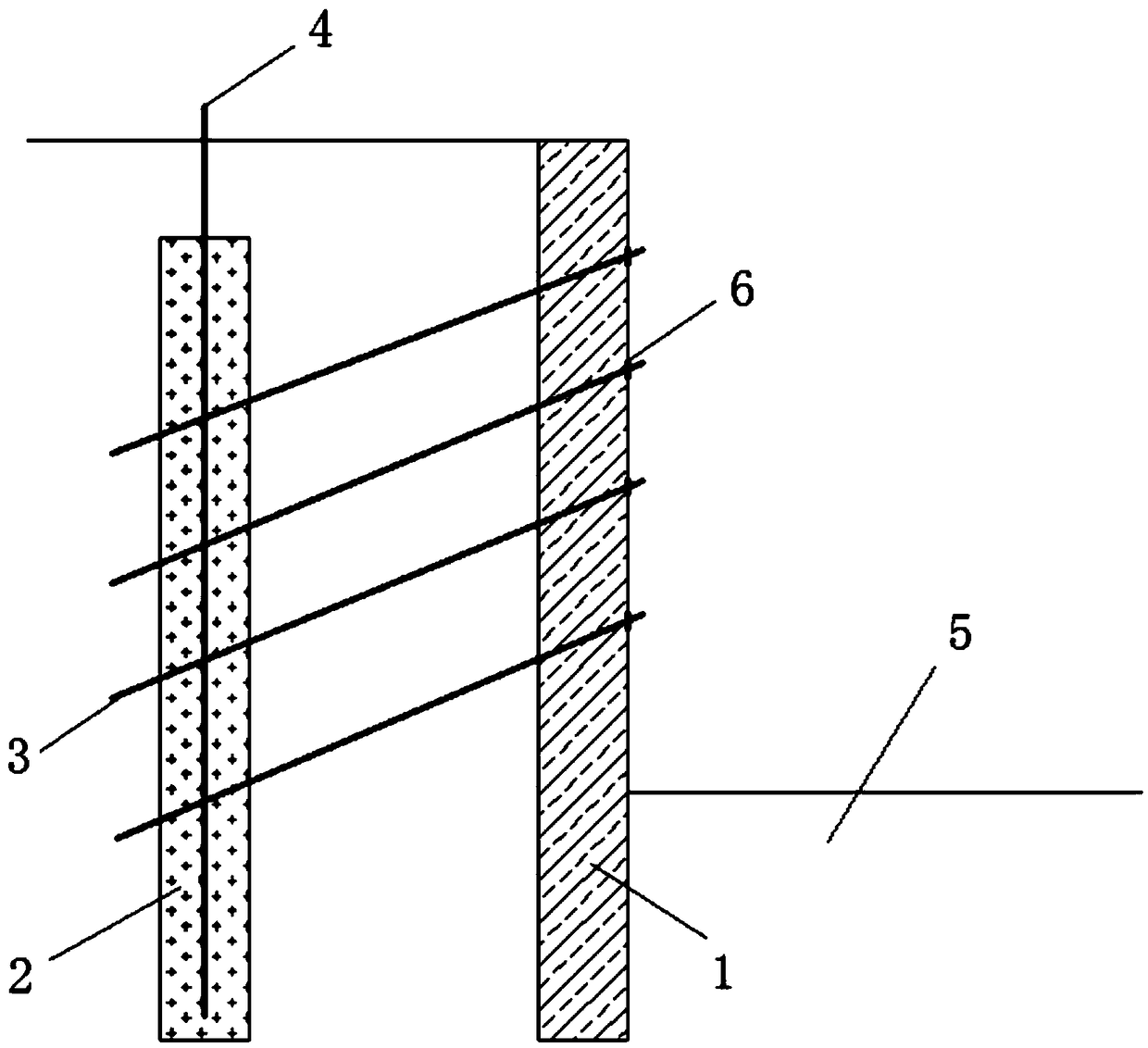

Construction method of piled anchor and liquid nitrogen frozen earth wall combined support system

InactiveCN108797601AImprove bearing capacityReliable support performanceExcavationsBulkheads/pilesRock boltLiquid nitrogen

The invention discloses a construction method of a piled anchor and liquid nitrogen frozen earth wall combined support system. The construction method comprises the following steps of 1, uniformly arranging slope protection piles along the edge of a foundation pit, wherein the slope protection piles are long auger drilling cast-in-situ bored piles; 2, driving anchor rods into the stratum in an inclined manner, and anchoring the anchor rods through lock beams after the anchor rods penetrate the slope protection piles and are stretched; and 3, arranging a frozen earth wall in foundation soil, and anchoring the frozen earth wall and the anchor rods together by means of the freezing effect of the liquid nitrogen frozen earth wall. The construction method has the advantages that the construction method is good in waterproofness and can adapt to various complex environments and geological conditions; steel and concrete are saved, and safety and environmental friendliness are achieved; and the freezing speed is high, and freezing strength is high.

Owner:王海霖

Bottom plate structure with rock foundation, of underground structure

InactiveCN105484288AReduce stressReduce thicknessArtificial islandsUnderwater structuresEngineeringRebar

The invention belongs to the technical field of underground structure engineering, and particularly relates to a bottom plate structure with a rock foundation, of an underground structure. The bottom plate structure with the rock foundation is characterized by comprising columns, side walls, a bottom plate, bottom plate longitudinal beams, a concrete cushion layer, the rock foundation and soft cushion layers, wherein the side walls and the bottom plate longitudinal beams are arranged above the bottom plate; the columns are arranged on the top surfaces of the bottom plate longitudinal beams; the concrete cushion layer is arranged at the bottom of the bottom plate; the rock foundation is arranged at the bottom of the concrete cushion layer; and the soft cushion layers are arranged at the bottom of the concrete cushion layer. According to the invention, stresses on the bottom plate and the sidewalls of the underground structure, the thicknesses of the bottom plate and the sidewalls, and reinforcements of the bottom plate and the sidewalls, can be reduced, thus anti-floating pile construction can be omitted, and raw materials can be saved; and good vertical bearing capacity and water isolation performance of the rock foundation are adequately utilized, thus the stresses on the bottom plate and the bottoms of the sidewalls can be reduced, concrete and steel bars can be saved, and engineering costs can be decreased.

Owner:CHINA RAILWAY TUNNEL SURVEY & DESIGN INST

Upper-expansion cement composite pile

InactiveCN106759301AImprove bearing capacityImprove performanceBulkheads/pilesCement compositesEngineering

The invention discloses an upper-expansion cement composite pile which comprises a precast concrete tubular pile, wherein a center hole is formed in the precast concrete tubular pile and filled with a first cement pile; a second cement pile is arranged outside the precast concrete tubular pile; the second cement pile comprises upper and lower sections; the pile diameter of the upper section is greater than that of the lower section; and a first variable-diameter section is arranged between the upper section and the lower section. Compared with a single-diameter pile body of the same length and equal concrete dosage, the upper-expansion cement composite pile disclosed by the invention has larger pile foundation bearing capacity; on the premise of meeting the bearing force design requirements, relatively short pile is realized; and meanwhile, the capability development of the side resistance of the pile foundation is stronger, and the upper-expansion cement composite pile is particularly suitable for the geological conditions that upper soil is obviously superior to lower soil.

Owner:周同和

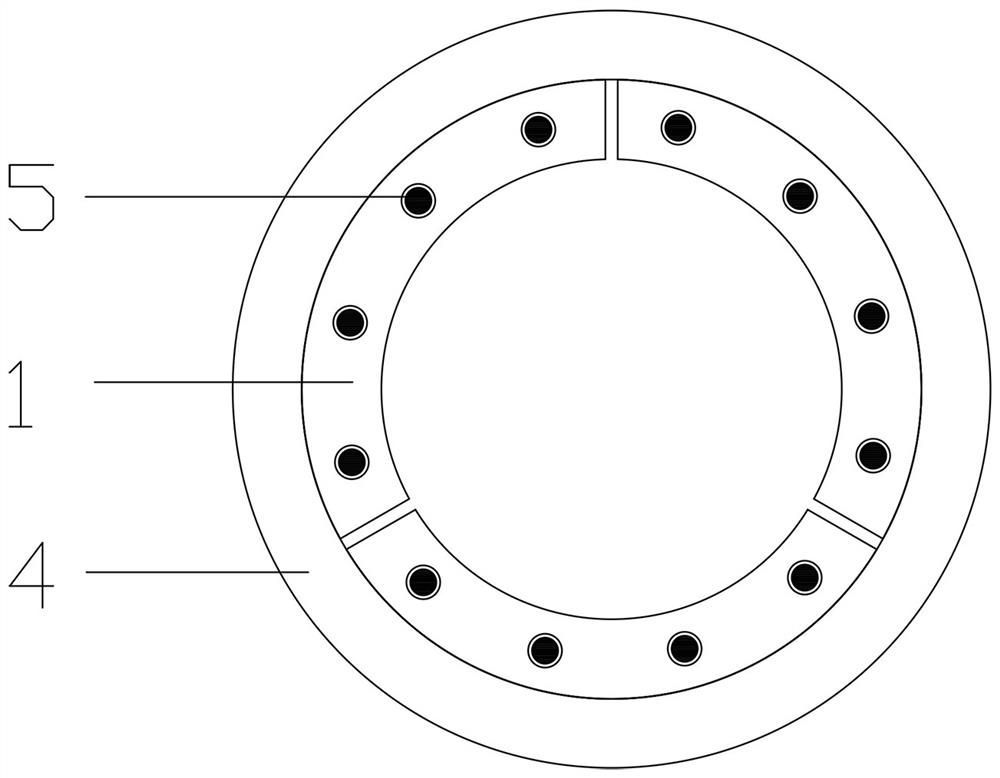

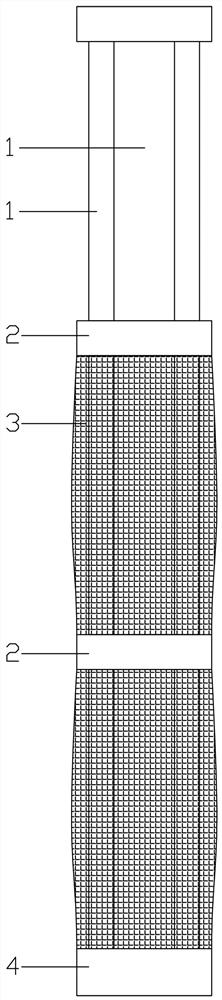

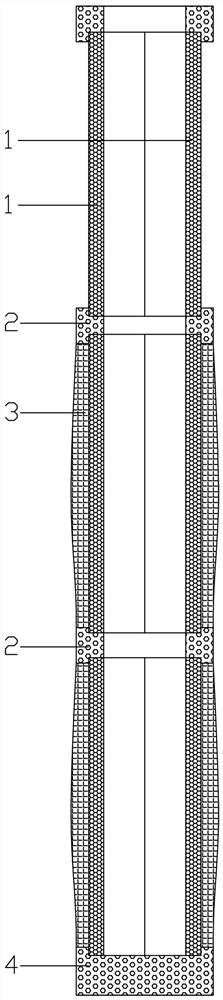

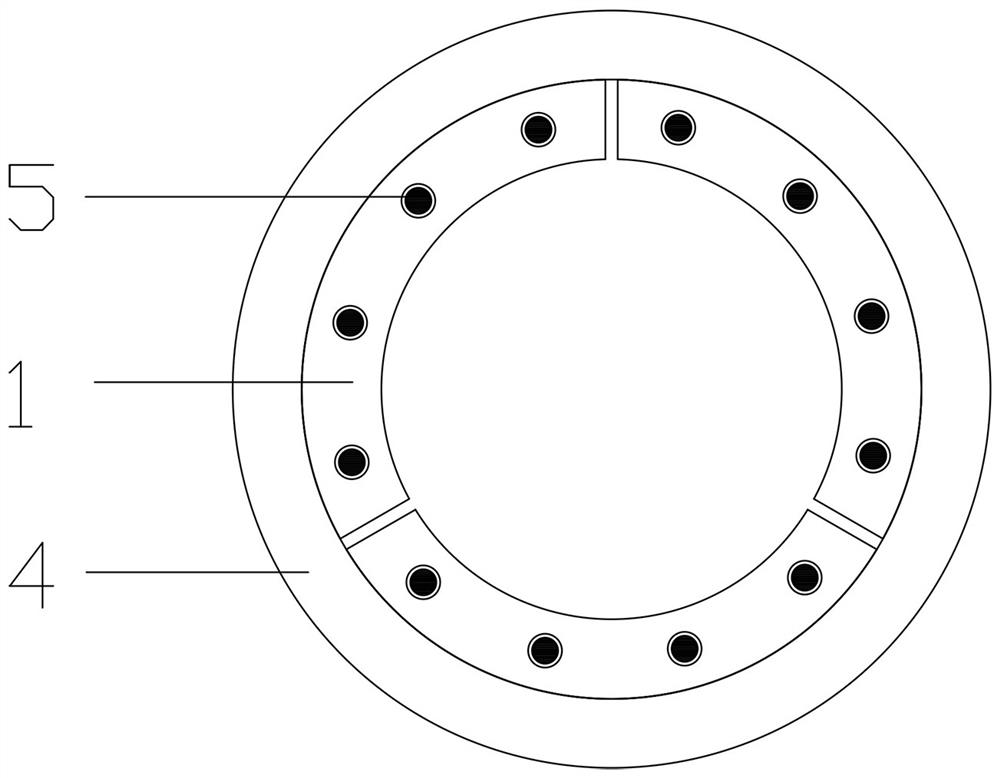

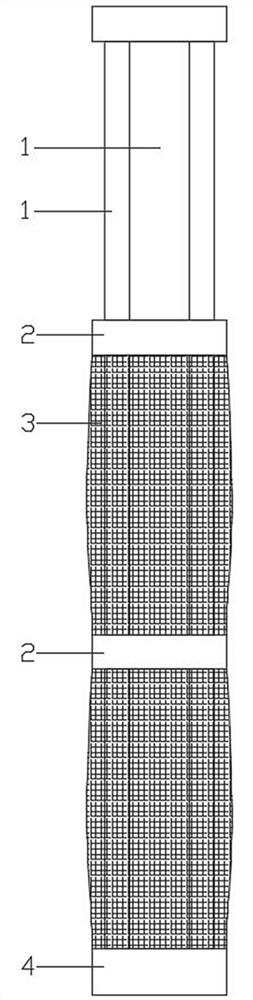

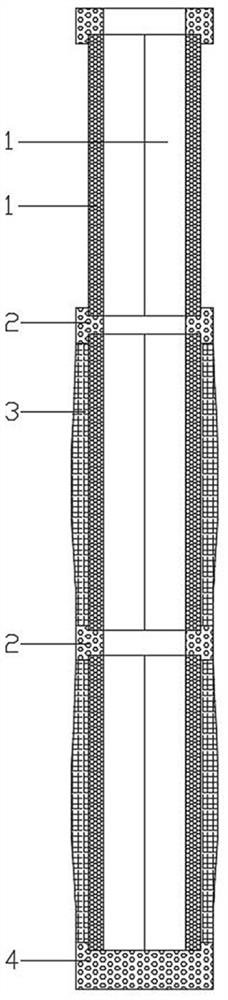

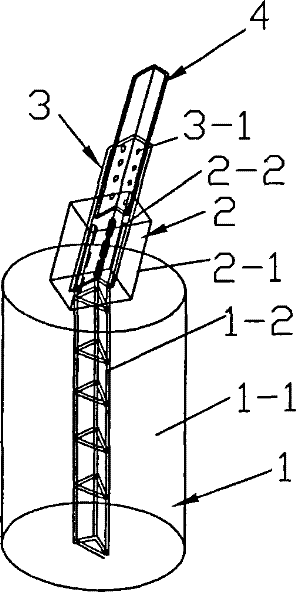

Anchor tensioning device for integrated pipe pile

ActiveCN112482371AReduce shared costsSave materialBulkheads/pilesSocial benefitsArchitectural engineering

The invention belongs to the technical field of pile foundations, and provides an anchor tensioning device for an integrated pipe pile. The device comprises a set of precast concrete members and pilesA, wherein the precast concrete members form a pile body, and each precast concrete member comprises a pile batten plate, an anti-slip constraint ring and an end pressing seat, the pile batten platesare vertically and annularly arranged on the periphery of the annular pipe pile, the end pressing seats are located at the bottom end of the integrated pipe pile and bears end resistance, the pile batten plates are restrained and fixed in the vertical direction and the radial direction, the anti-sliding restraining rings are horizontally arranged at the up-down splicing positions of the pile batten plates and restrain vertical and radial displacement of the pile batten plates, the anchor tensioning device tensions and integrates all concrete members into the pile body, and the piles A are arranged on the peripheries of the pile batten plates and the inner side of pile hole wall soil body and used for transmitting positive pressure and frictional resistance of the pile hole wall soil body.The device has the advantages of cost reduction, convenient construction, energy saving, environmental protection, quality improvement, reduction of on-site manual operation, and has substantial economic and social benefits.

Owner:ZHENGZHOU UNIV MULTI-FUNTIONAL DESIGN & RES ACAD CO LTD +1

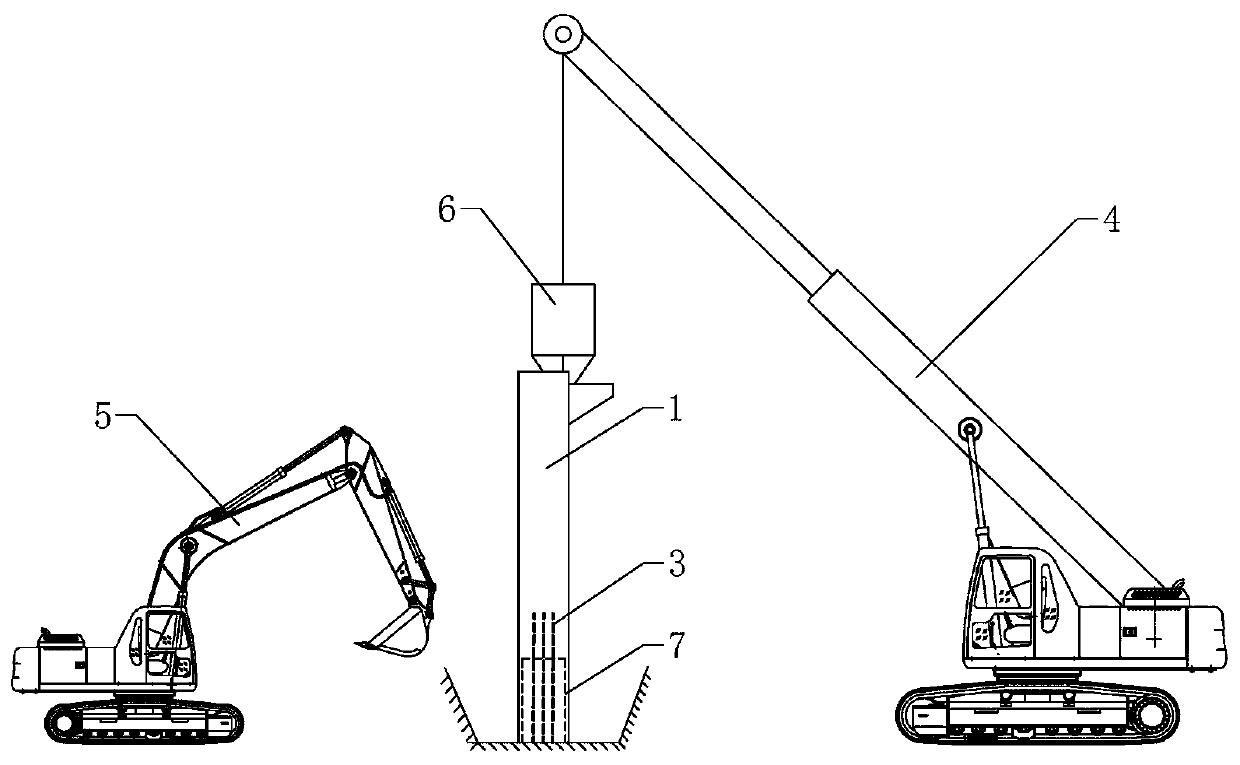

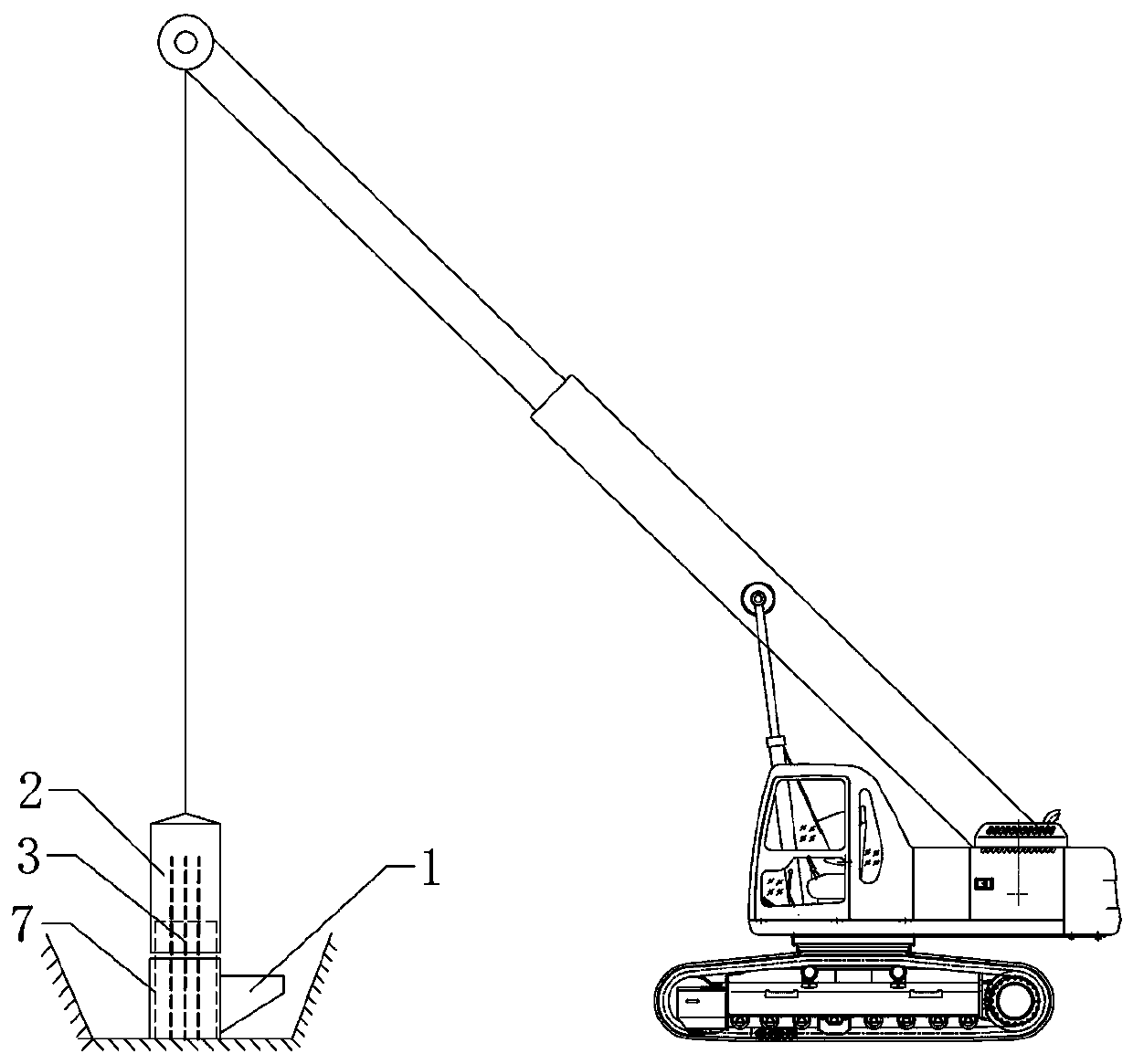

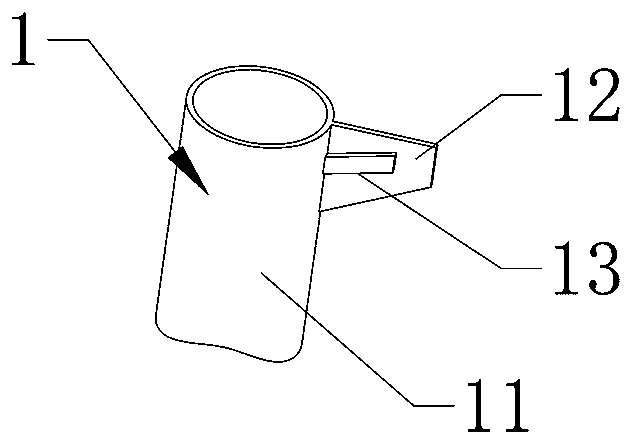

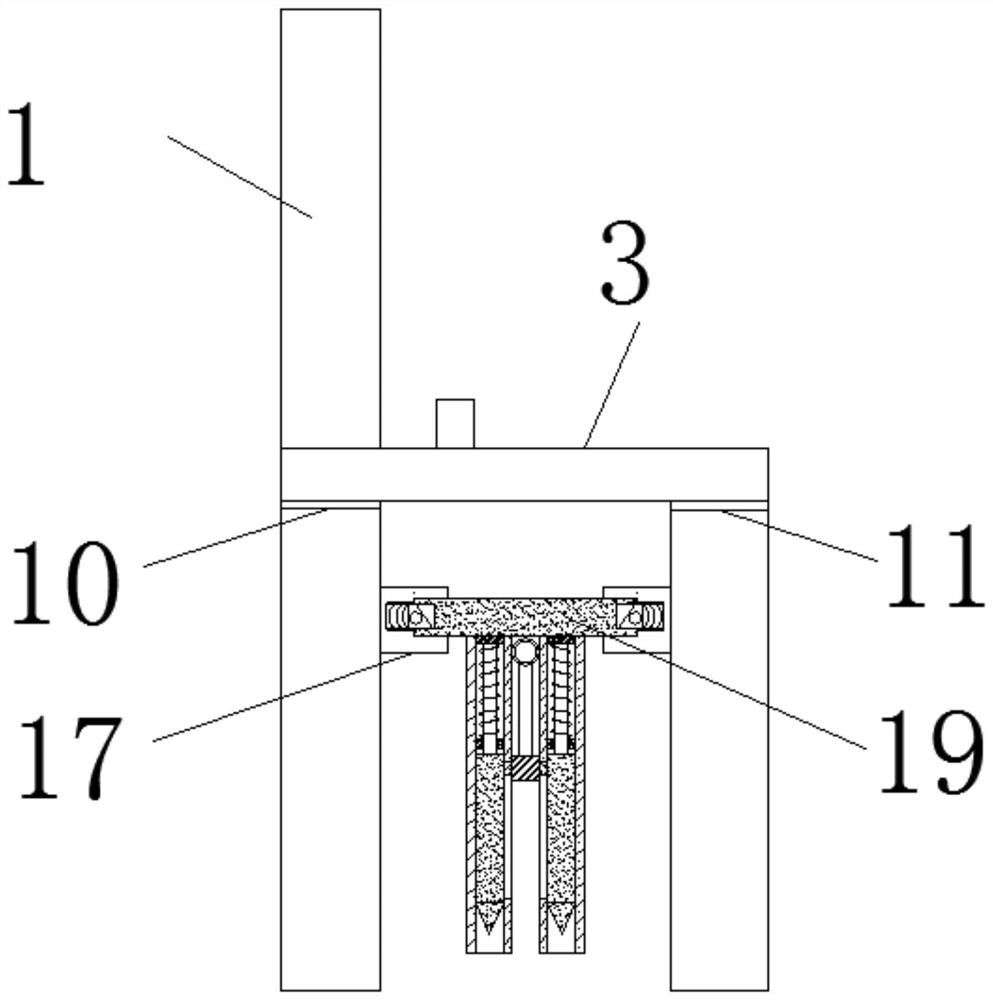

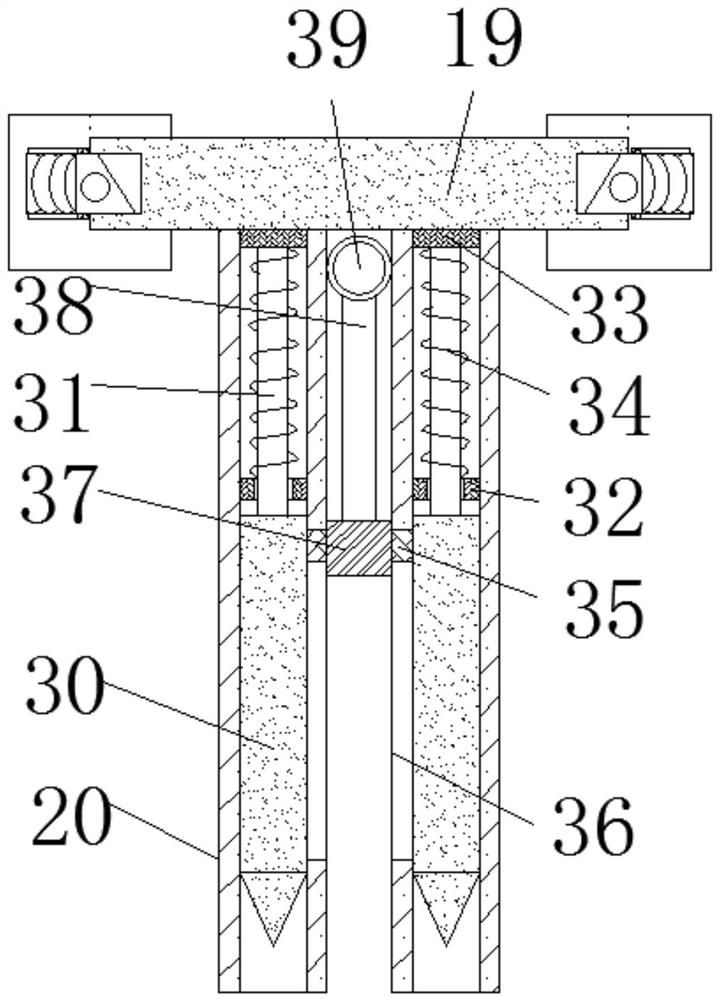

A method for pulling out prestressed pipe piles of a bridge abutment and its supporting equipment

ActiveCN106677183BConstruction hole expansion rate is smallShorten the timeBulkheads/pilesPre stressBridge deck

The invention relates to the field of various pipe piles, in particular to a bridge abutment prestressed pipe pile pulling-out method and a matched device thereof. The matched device comprises an excavator, a crane, a vibration hammer and auxiliary tools, wherein the auxiliary tools comprise a sinking steel pipe, a clamp plate and a tensile reinforcement. The method comprises the steps of sinking of the sinking steel pipe, pulling out of a pile body, pulling out of the sinking steel pipe and the like. All matched facilities of water jet and impact construction methods are avoided, noise is low, and the construction speed is high.

Owner:THE 3RD ENG CO LTD OF CHINA RAILWAY 16TH BUREAU GRP CO LTD

Sand lining tooth-shaped pile with excellent performance and construction method thereof

PendingCN109440802AImprove bearing capacityQuality improvementBulkheads/pilesEarthquake resistanceWork time

The invention relates to a sand lining tooth-shaped pile with excellent performance and a construction method thereof. The sand lining tooth-shaped pile comprises a pile body, a plurality of trapezoidal teeth are arranged on the pile body at intervals; and the trapezoidal teeth are trapezoidal narrow teeth, or are the trapezoidal wide teeth and the trapezoidal narrow teeth, wherein the trapezoidalwide teeth and the trapezoidal narrow teeth are alternately-distributed. According to the sand lining tooth-shaped pile and the construction method thereof, the single-pile ultimate bearing capacityis improved remarkably, is improved by 60% or above compared with a conventional tubular pile, is improved by 70%-90% compared with a cast-in-place concrete cast-in-place pile, and is improved by 35%compared with a tooth grain surface drainage pile with a sand lining; and the quality is reliable and controllable. According to the sand lining tooth-shaped pile and the construction method thereof,the pile delivering depth can reach 12-15 m, the start working time of engineering can be strived, and the construction period can be greatly shortened; and a large amount of earth and rock excavationaround a foundation pit is omitted, so that the construction speed is high, the cost is low, and the earthquake resistance is facilitated.

Owner:郭兆泉

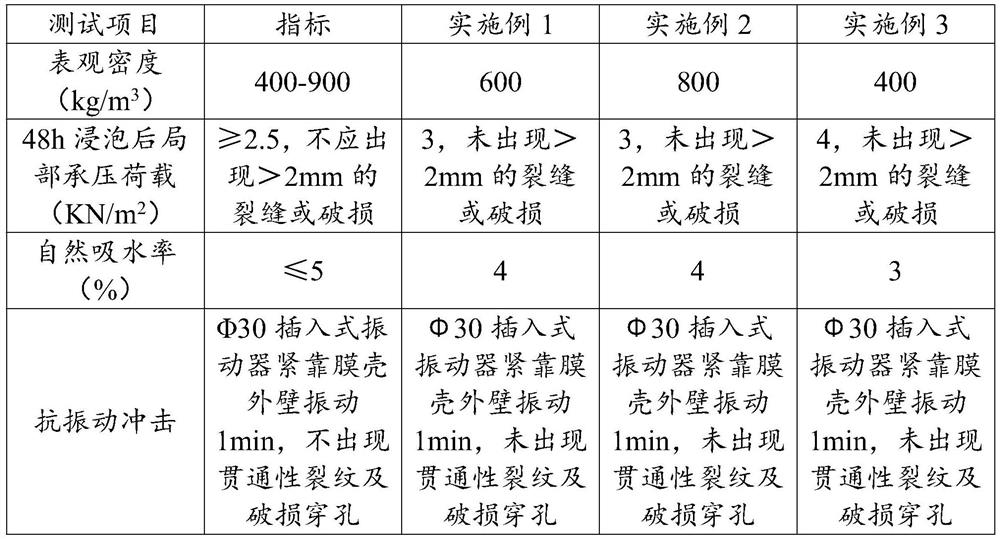

Membrane shell material used for multi-ribbed floor system, membrane shell containing membrane shell material and preparation method for membrane shell

The invention discloses a membrane shell material used for a multi-ribbed floor system. The membrane shell material comprises the following raw materials in parts by weight: 40 to 60 parts of aluminoferrite cement, 20 to 25 parts of fluorgypsum, 20 to 25 parts of composite gypsum, 6 to 10 parts of fly ash, 10 to 15 parts of glass fiber gridding cloth, 5 to 10 parts of chopped glass fibers, 10 to 20 parts of glass water, 2 to 5 parts of a coagulant and 40 to 60 parts of water. The preparation method comprises the following steps: (1) weighing all raw materials; (2) stirring the aluminoferrite cement, the fluorgypsum, the composite gypsum, the fly ash and a first part of the glass water, and carrying out standing; (3) adding the chopped glass fibers, a second part of the glass water, the coagulant and the water; and (4) uniformly spraying an obtained mixture into a mold by a plurality of times, and carrying out drying in the air, and carrying out molding. The membrane shell used for themulti-ribbed floor system does not absorb water or seep water, is light in material, short in molding period, high in strength, firm and durable, and can be widely applied to large-span and large-baycast-in-place reinforced concrete multi-ribbed floor buildings in industrial and civil buildings.

Owner:甘肃华军建筑材料有限责任公司

Concrete frame structure

InactiveCN102031828AImprove seismic performanceTo achieve the effect of changing sectionBuilding constructionsSelf weightEnergy analysis

The invention provides a concrete frame structure which comprises a joint, an upright column and a cross beam forming a concrete frame, wherein the outline dimension of the section of the joint is equal to the outline dimension of the maximum section connecting the upright column and the cross beam; the upright column is provided with a vertical mortise along the axial direction of the upright column; the cross beam is provided with a transverse mortise along the axial direction of the cross beam; the joint is provided with 1-6 tenons which are tightly combined with the upright column or the cross beam through the end of the vertical mortise or the transverse mortise; and the joint and the upright column and the cross beam connected with the joint form the concrete frame together. In the invention, the design principles of 'strong joints and weak bars', 'strong columns and weak beams', 'strong shearing and weak bending' and the like are simultaneously realized in the concrete frame structure, so that the concrete frame structure has an excellent energy dissipation mechanism under the earthquake effect, is favorable for resisting the earthquake, can save concrete and reduces the self weight of the structure.

Owner:程夷

An improved telescopic movable chute

ActiveCN106677540BReduce labor intensityImprove pouring efficiencyBuilding material handlingHydraulic cylinderVehicle frame

The invention discloses an improved type telescopic movable chute tube. The improved type telescopic movable chute tube is mainly used for pouring concrete in the field of constructional engineering. The improved type telescopic movable chute tube is high in pouring efficiency, concrete is saved, and the labor intensity is relieved. The improved type telescopic movable chute tube mainly comprises a vehicle frame, wheels, an n-shaped vertical frame, a hydraulic cylinder, a hydraulic piston, a telescopic rod, a movable frame, a fixed chute tube body, movable chute tube bodies, a feed hopper, a front support device and an n-shaped frame. According to the main working principle of the improved type telescopic movable chute tube, the concrete slides over the fixed chute tube body and the multiple movable chute tube bodies from top to bottom, slides out from the movable chute tube body at the most front end and enters a pouring point; if the concrete needs to be poured to a far place, the telescopic rod is stretched rightwards, the front end of the telescopic rod drives the movable chute tube body at the most front end to move frontwards, after a limiting ring of the movable chute tube body at the most front end touches a limiting ring of the second section of movable chute tube body, the second section of movable chute tube body is pulled out, and in the same way, the rest sections of movable chute tube bodies are pulled out; and the hydraulic piston is stretched out or retracted, and the inclined angle of concrete discharge and the discharge height can be changed.

Owner:平邑经济开发区投资发展有限公司

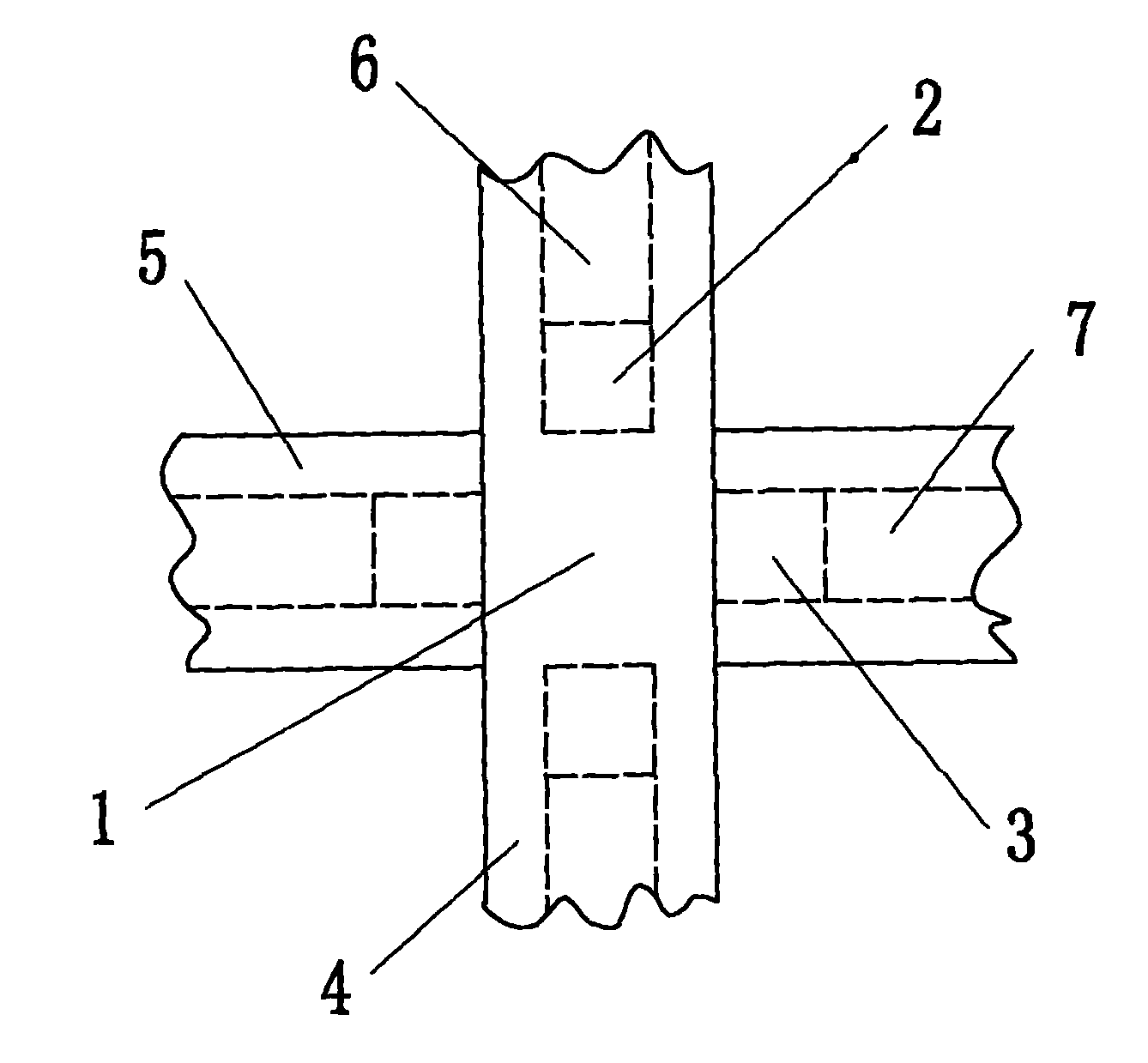

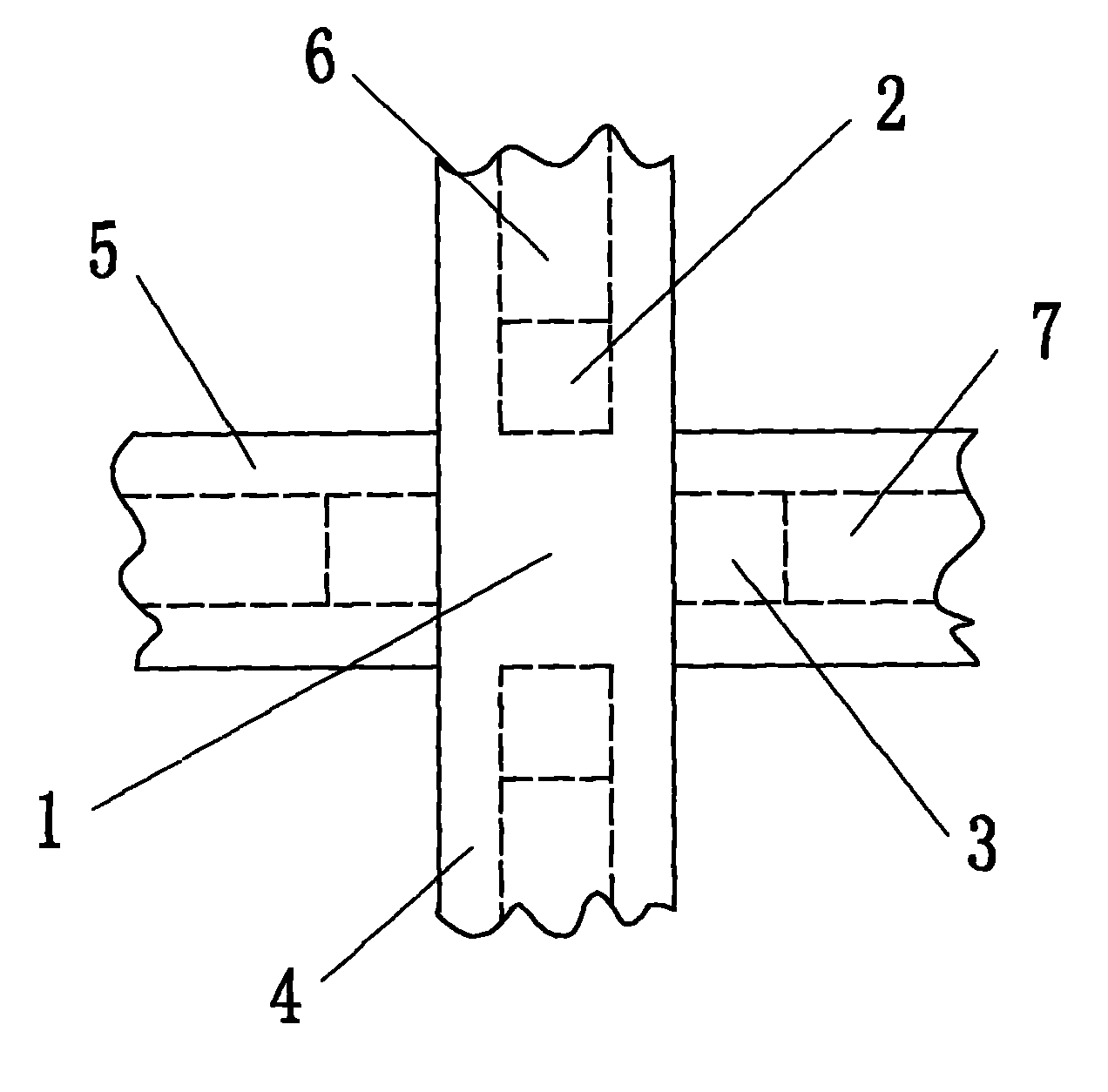

H-shaped hollow anti-slide pile

The invention discloses an h-shaped hollow anti-slide pile which comprises a front pile and a rear pile. A cross beam is connected between the front pile and the rear pile, the front pile comprises afirst pile front end and a first pile rear end, a first hollow hole is formed between the first pile front end and the first pile rear end, and the rear pile comprises a second pile front end and a second pile rear end. A second hollow hole is formed between the second pile front end and the second pile rear end, a front pile protruding block is arranged at the position, close to the cross beam, of the front pile, a rear pile protruding block is arranged at the position, close to the cross beam, of the rear pile, and the front pile protruding block and the rear pile protruding block are both located below the cross beam. The bottom of the front pile and the bottom of the rear pile penetrate through a sliding belt and are located in a sliding bed, the top of the front pile and the top of the rear pile are located in a sliding body, first steel bars are embedded in the front pile, and second steel bars are embedded in the rear pile. The h-shaped hollow anti-slide pile has the beneficialeffects that the soil arch effect of soil between piles is brought into full play, and supporting of the anti-slide pile to landslides is better facilitated.

Owner:核工业湖州勘测规划设计研究院股份有限公司

Foundation construction for installation of oil-immersed type transformer

InactiveCN100576374CThe influence of soft connection modeMeet storageTransformers/reacts mounting/support/suspensionFrame basedFire control

The invention relates to a base structure used for installing an oil immersed transformer. The invention is arranged in a transformer room where a box-shaped base is arranged. An oil collecting groove is arranged around the internal part of the box-shaped base. The oil collecting groove is communicated with an oil collecting pit positioned at an end of the oil collecting groove. A cement level-ground is arranged on the outer edge of the box-shaped base. A plurality of flat bars are pre-embedded in the middle of the box-shaped base and are fixed by reinforced cables. And a plurality of flat bars are pre-embedded in a wall of the transformer room and a steel hook is also pre-embedded on the wall so as to pull the transformer. By adopting the structure of the transformer box-shaped base of the invention, the structure can be free from a building frame base and the weight of the transformer is born by the box-shaped base. Then, although the box-shaped base causes slight settlement to the ground, the adopted flexible connection of cables can not be affected. The transformer base of the invention needs no piling so as to save an investment cost. The arrangement of the oil collecting grooves around the internal part of the box-shaped base can drain the oil for storage so as to meet fire control requirement.

Owner:BAOSTEEL ENG & TECH GRP

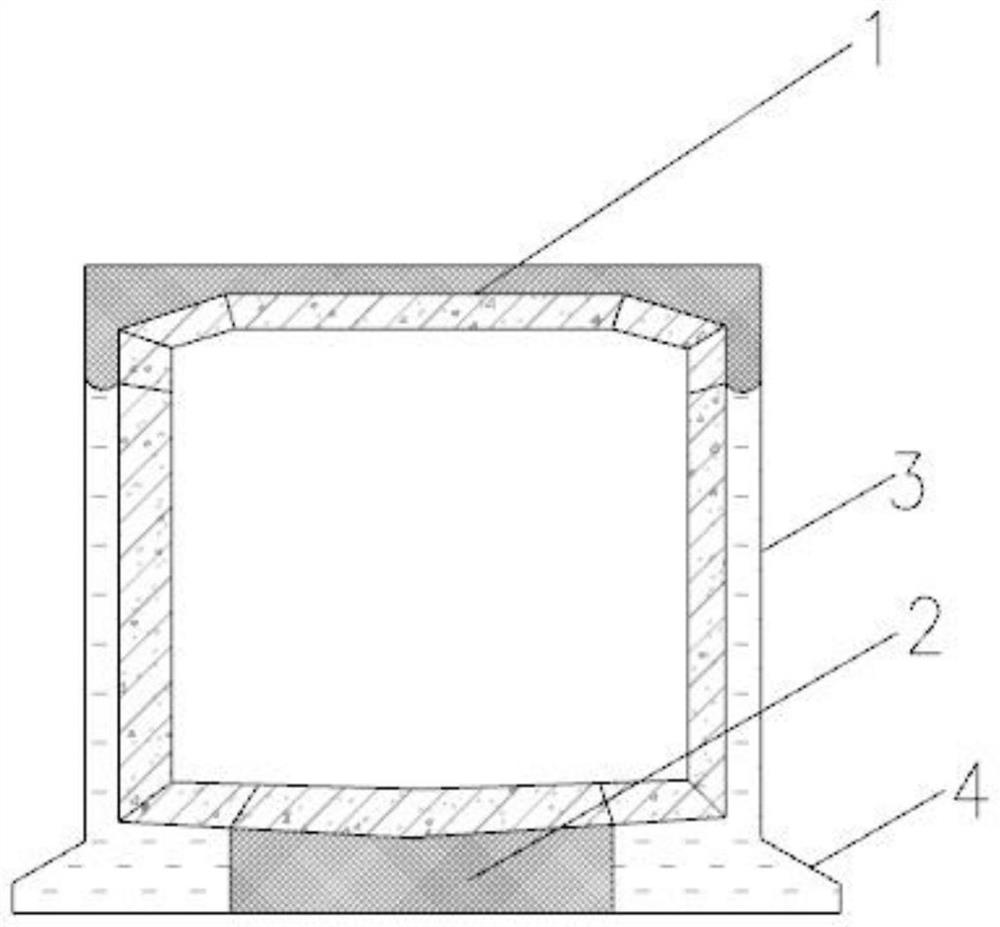

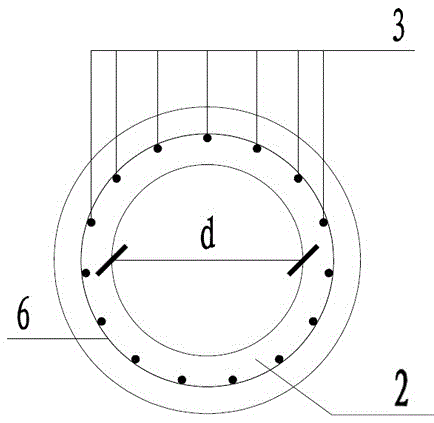

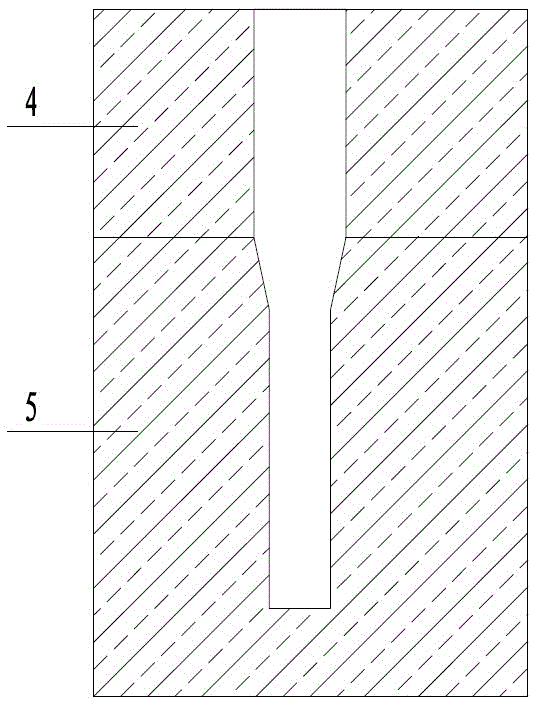

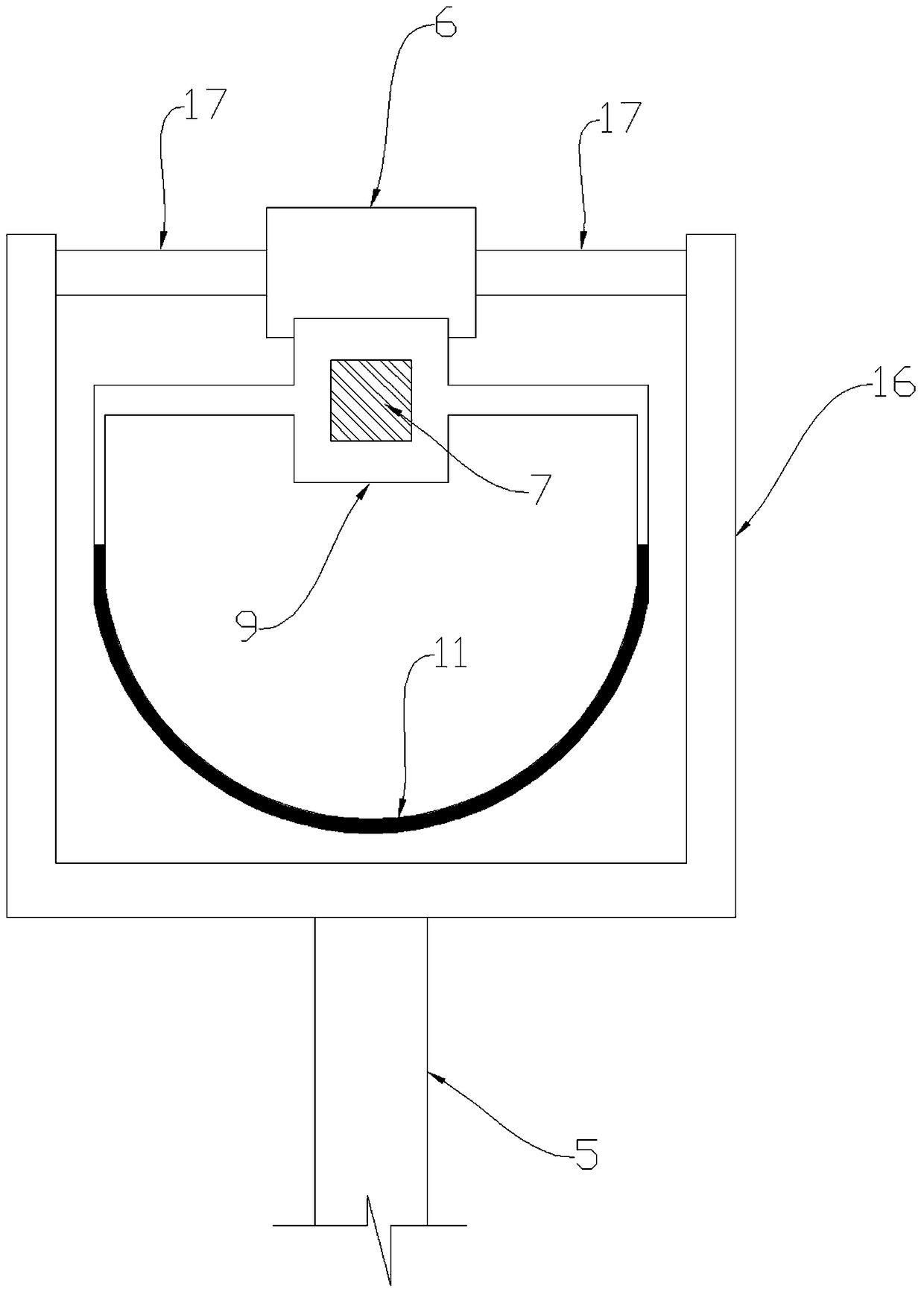

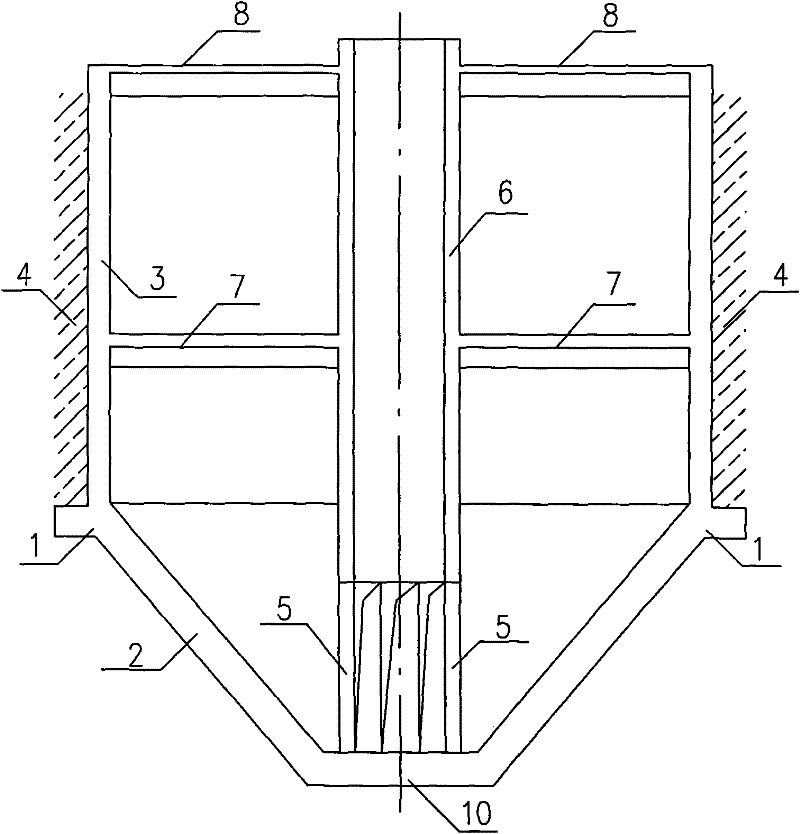

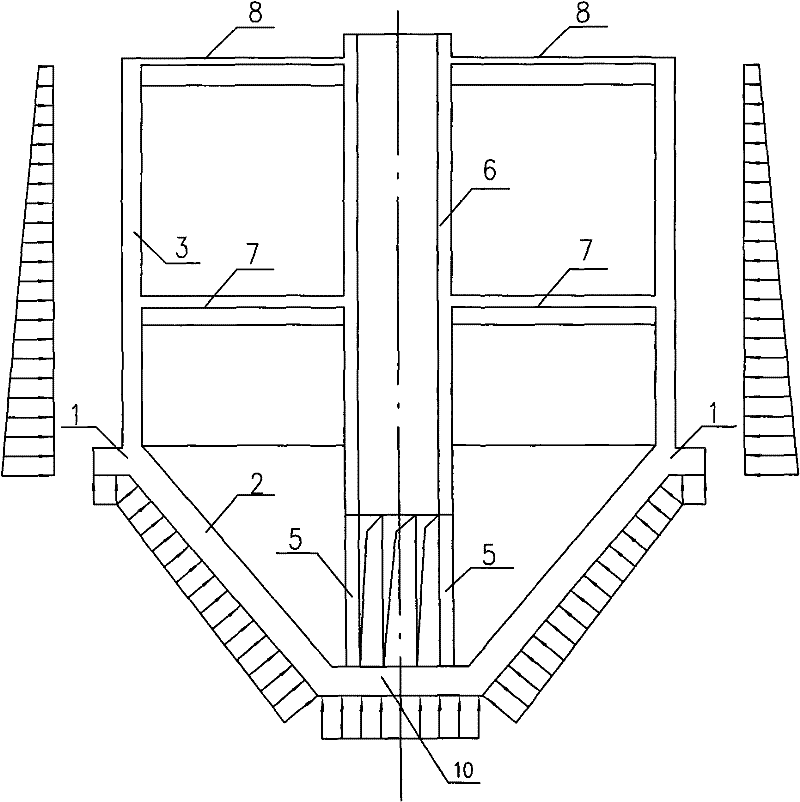

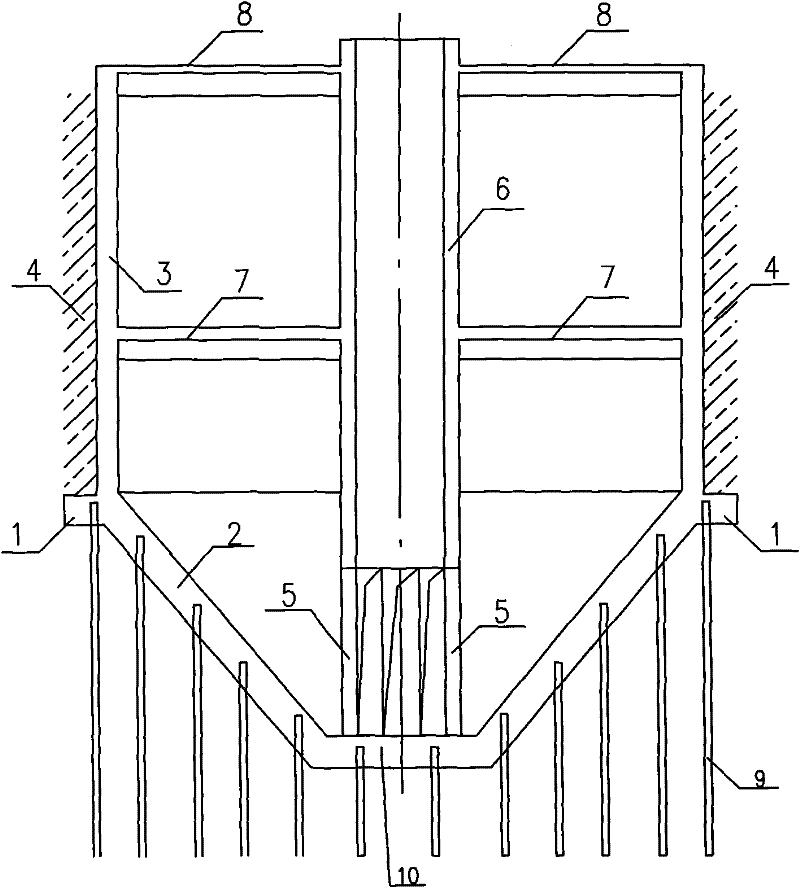

A swirling pool and its construction method

ActiveCN101642637BIncrease buoyancySaving concreteSedimentation settling tanksRational systemStructure system

The invention relates to a swirl pool, comprising an inclined cone (2) and an outer cylinder (3), the key point of which is that the inclined cone (2) and / or the outer cylinder (3) are additionally provided with at least one protruding ring beam (1). The present invention also relates to the construction method of the swirl pool. The invention has strong anti-floating ability, low investment, and can exert the force transmission effect of the arch body of the inclined cone, reduce the thickness of the outer cylinder and the inclined cone, and the whole structural system has reasonable layout, simple force transmission, and coordinated rigidity; at the same time, The invention can reduce the earthwork excavation operation surface of the foundation pit, reduce the difficulty of precipitation, and provide conditions for slope stability.

Owner:CISDI ENG CO LTD

Anchors for integrated pipe piles

ActiveCN112482371BReduce shared costsSave materialBulkheads/pilesSocial benefitsArchitectural engineering

Owner:ZHENGZHOU UNIV MULTI-FUNTIONAL DESIGN & RES ACAD CO LTD +1

Integrated pipe pile and its vertical controller

ActiveCN112482368BReduce shared costsSave materialBulkheads/pilesSocial benefitsArchitectural engineering

Owner:ZHENGZHOU UNIV MULTI-FUNTIONAL DESIGN & RES ACAD CO LTD +1

Mechanical hole forming technology applied to karst landform

The invention relates to a mechanical hole forming technology applied to karst landform. The technology comprises the following steps of: laying off and positioning; digging a mud pit; burying a pile casing; arranging a drill in place and making mud; forming holes by using an impact machine, wherein when a karst cave is greater than or equal to 3m in depth during construction, a steel pile casing dado is arranged; pumping out sediment and supplementing mud; checking the sediment; clearing off the holes by using a home-made hole cleaning device; checking the holes; arranging a steel reinforcement cage; arranging guide pipes; and pouring underwater concrete. By the mechanical hole forming technology, the probability of occurrence of hole collapse, overfilling of concrete and the like can be lowered, karst cave areas can be effectively protected, the effect of saving concrete is achieved and the cost is further reduced; moreover, by the mechanical hole forming technology, a unit in charge of construction can be effectively helped to clear off sediment from the bottoms of holes, hole piles in collapsed holes can be cleared quickly, the specific depth of a hole pipe can be measured by construction workers.

Owner:中色十二冶金建设有限公司

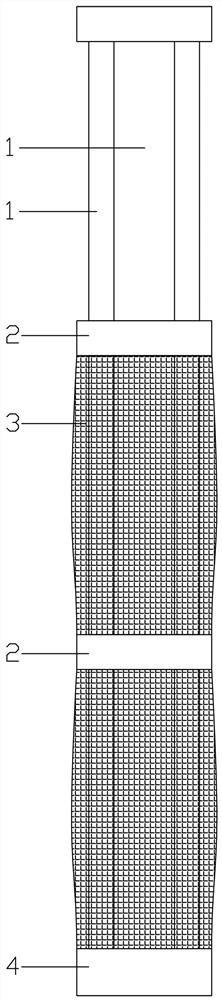

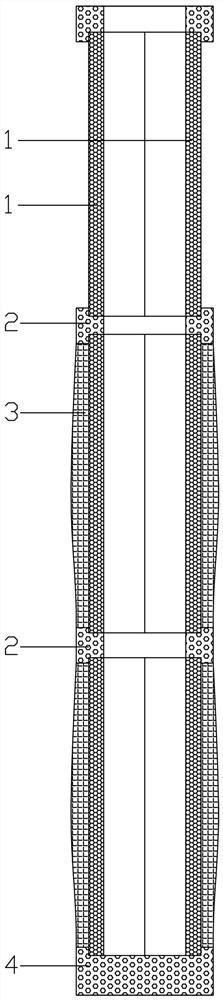

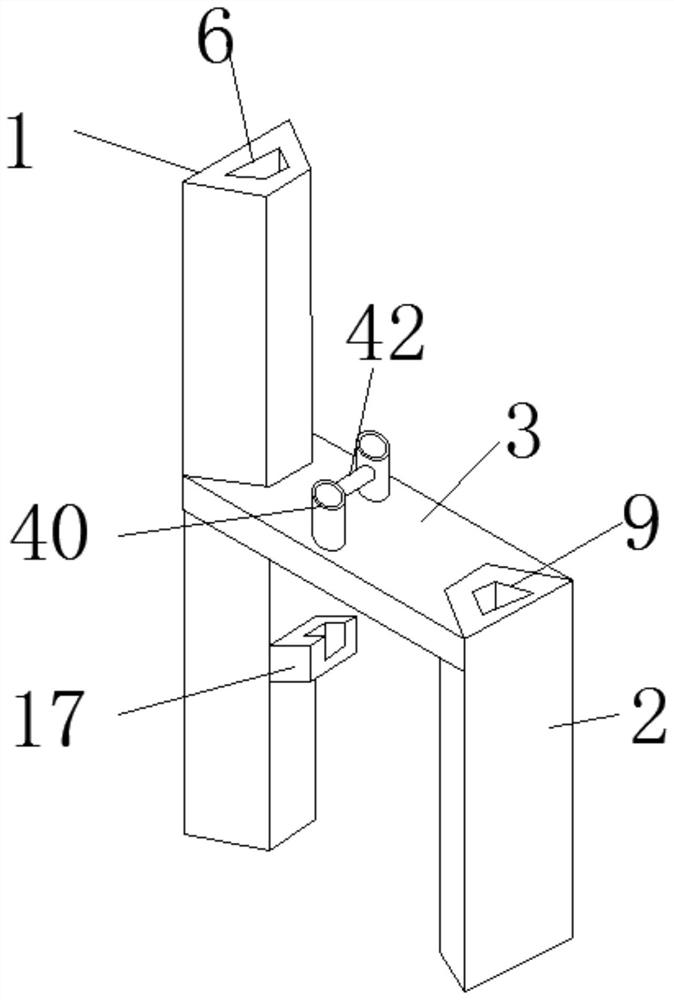

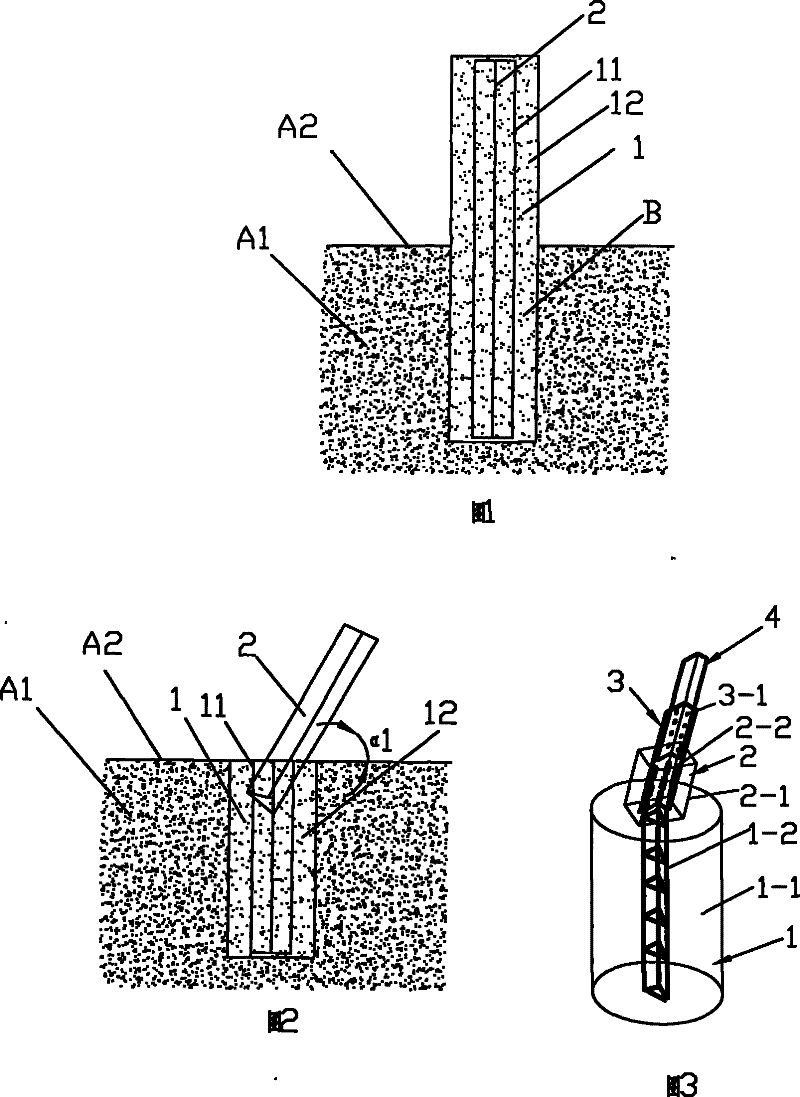

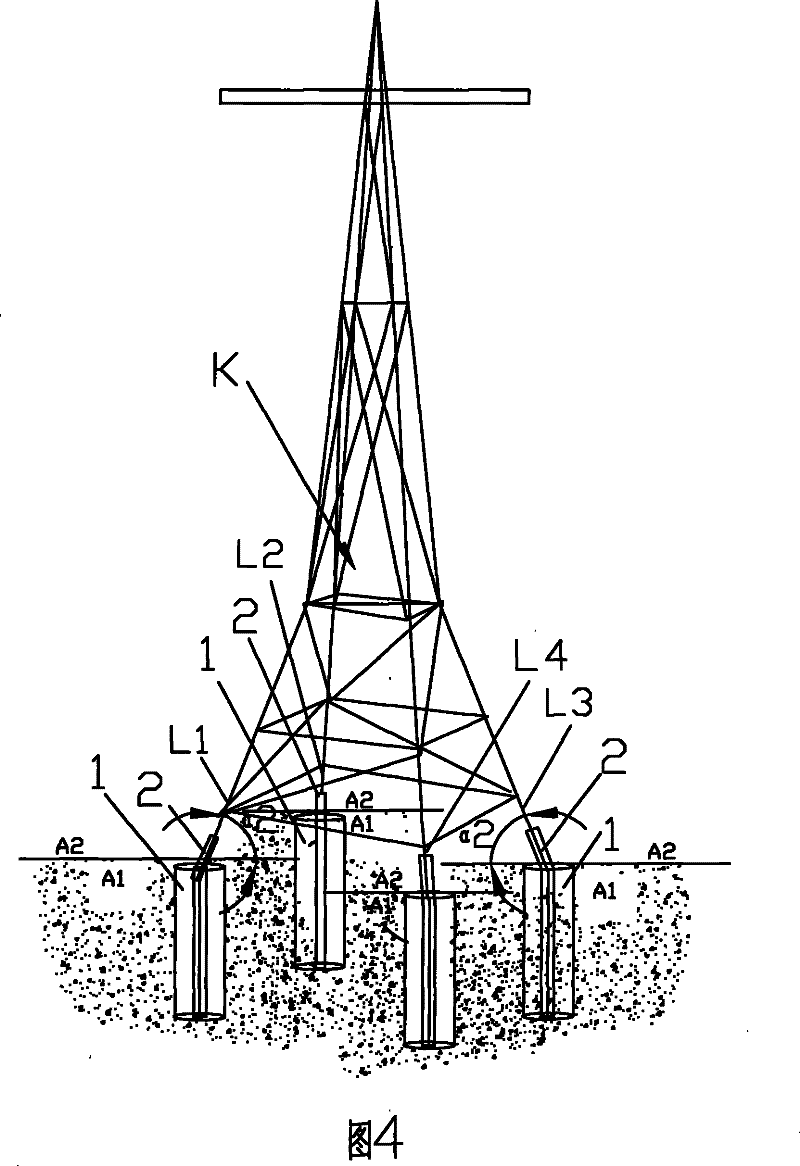

Novel structure inclined inserting digging hole pile foundation

The present invention relates to a novel structure inclined inserted excavation pile foundation which is composed of a vertical foundation pile (1) and an oblique cylinder (2) which is arranged at the top of the foundation pile. The invention is characterized in that the foundation pile (1) is established under the foundation (A1) to form a base supporting force-bearing point. The oblique cylinder (2) is obliquely inserted into the top of the foundation pile (1) and forms an angle alpha 1 with the top of the foundation pile (1). The top of the oblique cylinder (2) is extended with a tower legconnecting structure (3) which is exposed from the earth singly or with the top of the oblique cylinder (2). The top of the tower leg connecting structure (3) is provided with a plurality of bolt holes (3-1). The invention has the advantages of reducing the bending moment of pile shaft at the ground, improving the force bearing state of the foundation pile, facilitating the stability of the foundation pile and the whole pile body, and the invention also has the advantages of reducing the work capacity for digging the pile, saving concrete, economizing cost, increasing the working efficiency. The invention is suitable for the pile foundation of the high voltage power transmission circuit at the massif area.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

A kind of h-shaped hollow anti-slide pile

The invention discloses an h-shaped hollow anti-sliding pile, which comprises a front pile and a rear pile, a beam is connected between the front pile and the rear pile, and the front pile includes a pile front end and a pile rear end. A hollow hole 1 is provided between the front end 1 of the pile and the rear end 1 of the pile. The rear pile includes a front end 2 and a rear end 2 of the pile. Hole 2, the front pile is provided with a front pile bump near the crossbeam, and the rear pile is provided with a rear pile bump near the crossbeam, and both the front pile bump and the rear pile bump are located Below the crossbeam, the bottoms of the front pile and the rear pile run through the slide belt and are located in the slide bed, the tops of the front pile and the rear pile are located in the slide body, and a steel bar is embedded inside the front pile. , the inside of the back pile is embedded with two steel bars. Beneficial effects: the soil arch effect of the soil between the piles is fully brought into play, and the anti-slide pile is more conducive to supporting the landslide.

Owner:核工业湖州勘测规划设计研究院股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com