Bottom plate structure with rock foundation, of underground structure

A technology for rock foundations and underground structures, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve the problems of a single calculation model for subway structures and does not consider the influence of geological conditions on the structural floor, and reduce the number of floor and side panels. The effect of stress on the bottom of the wall, reducing the thickness and reducing the cost of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

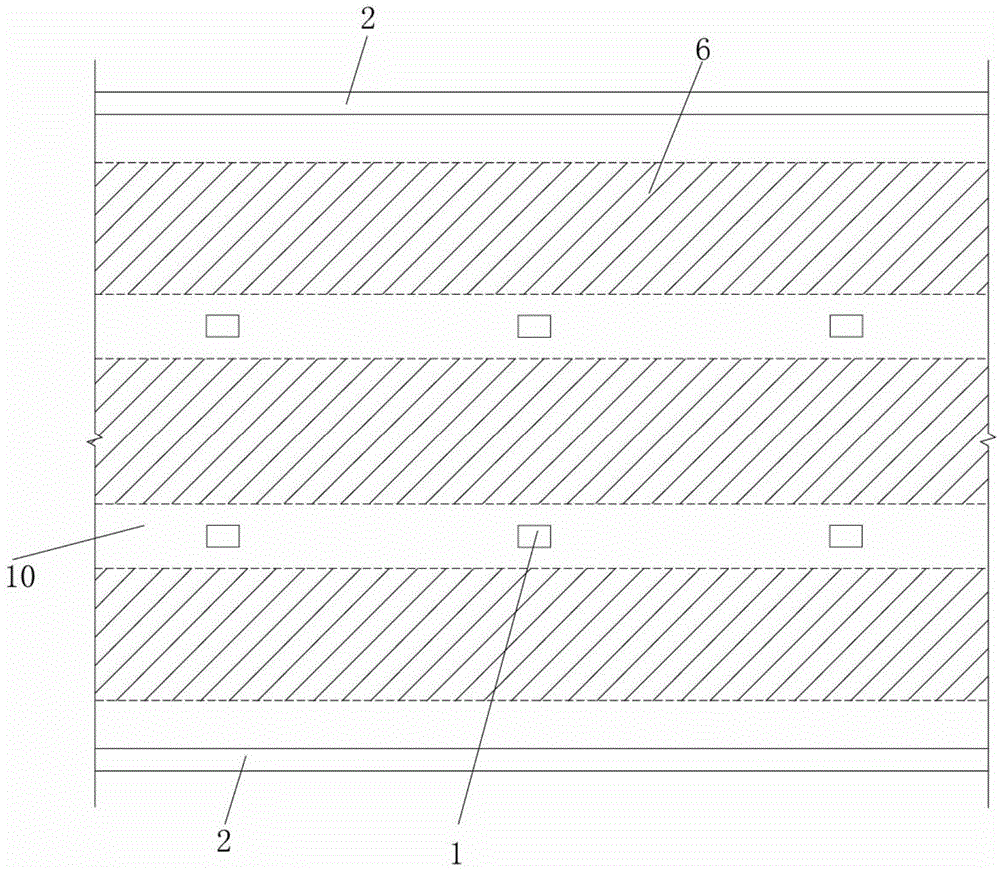

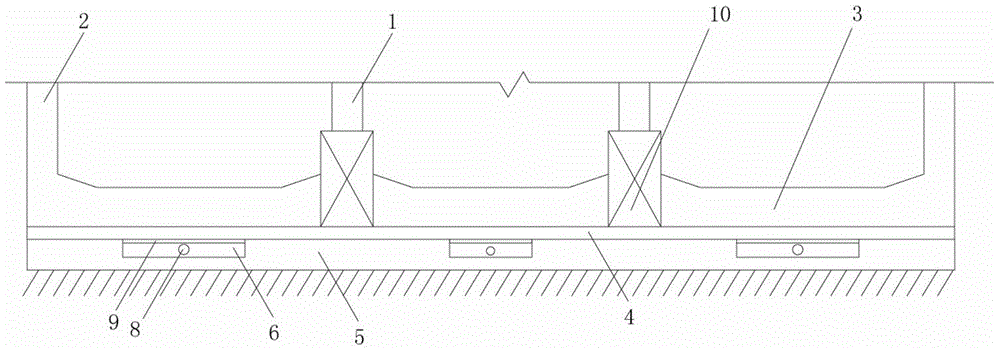

[0037] Such as Figure 1-2 As shown, the Kaifusi Station of the Changsha-Zhuzhou-Tanzhou Intercity Railway is a 3-story underground station with a thickness of about 3.5m. The station structure is a 3-span box-shaped structure with a longitudinal column spacing of 12m. The structural size according to the conventional design: the thickness of the roof is 0.80m, the thickness of the first and second basement floors is 0.4m, the thickness of the structural side wall 2 is 1m, the thickness of the bottom plate 3 is 1.2m, and the cross-section of the column 1 is 0.8m×1.2m. The geology of the site is: artificial fill, silty clay, garden gravel, strongly weathered slate, moderately weathered slate and weakly weathered slate, the structural floor 3 is located on the weakly weathered slate, and the thickness of the weakly weathered slate above floor 3 is greater than 10m , The saturated compressive strength of weakly weathered slate is 9.7-13MPa, medium weathered slate and weakly weath...

Embodiment 2

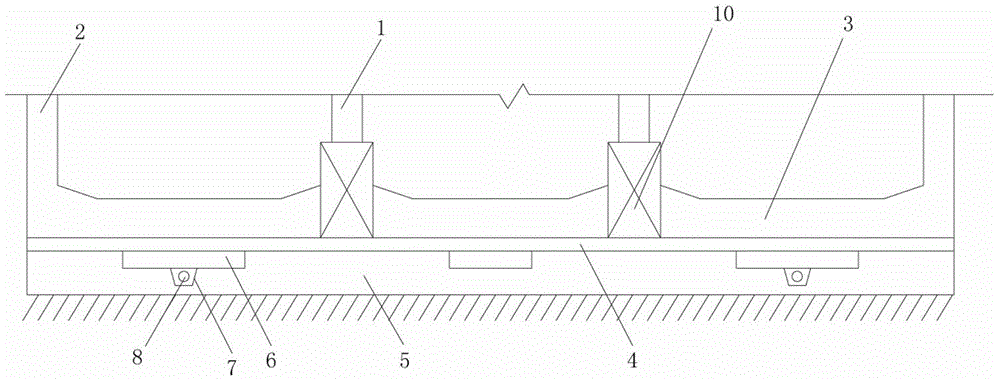

[0040] Such as figure 1 , 3As shown, the Kaifusi Station of the Changsha-Zhuzhou-Tanzhou Intercity Railway is a 3-story underground station with a thickness of about 3.5m. The station structure is a 3-span box-shaped structure with a longitudinal column spacing of 12m. The structural size according to the conventional design: the thickness of the roof is 0.80m, the thickness of the structural side wall 2 is 1m, the thickness of the bottom plate 3 is 1.2m, and the section of the column 1 is 0.8m×1.2m. The geology of the site is: artificial fill, silty clay, garden gravel, strongly weathered slate, moderately weathered slate and weakly weathered slate, the structural floor 3 is located on the weakly weathered slate, and the thickness of the weakly weathered slate above floor 3 is greater than 10m , The saturated compressive strength of weakly weathered slate is 9.7-13MPa, medium weathered slate and weakly weathered slate are almost impervious to water. Due to the safety requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com