Foundation construction for installation of oil-immersed type transformer

A technology for oil-immersed transformers and transformer rooms, which is applied in the directions of transformer/reactor installation/support/suspension, etc., to achieve the effect of satisfying storage, saving investment costs, and saving concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

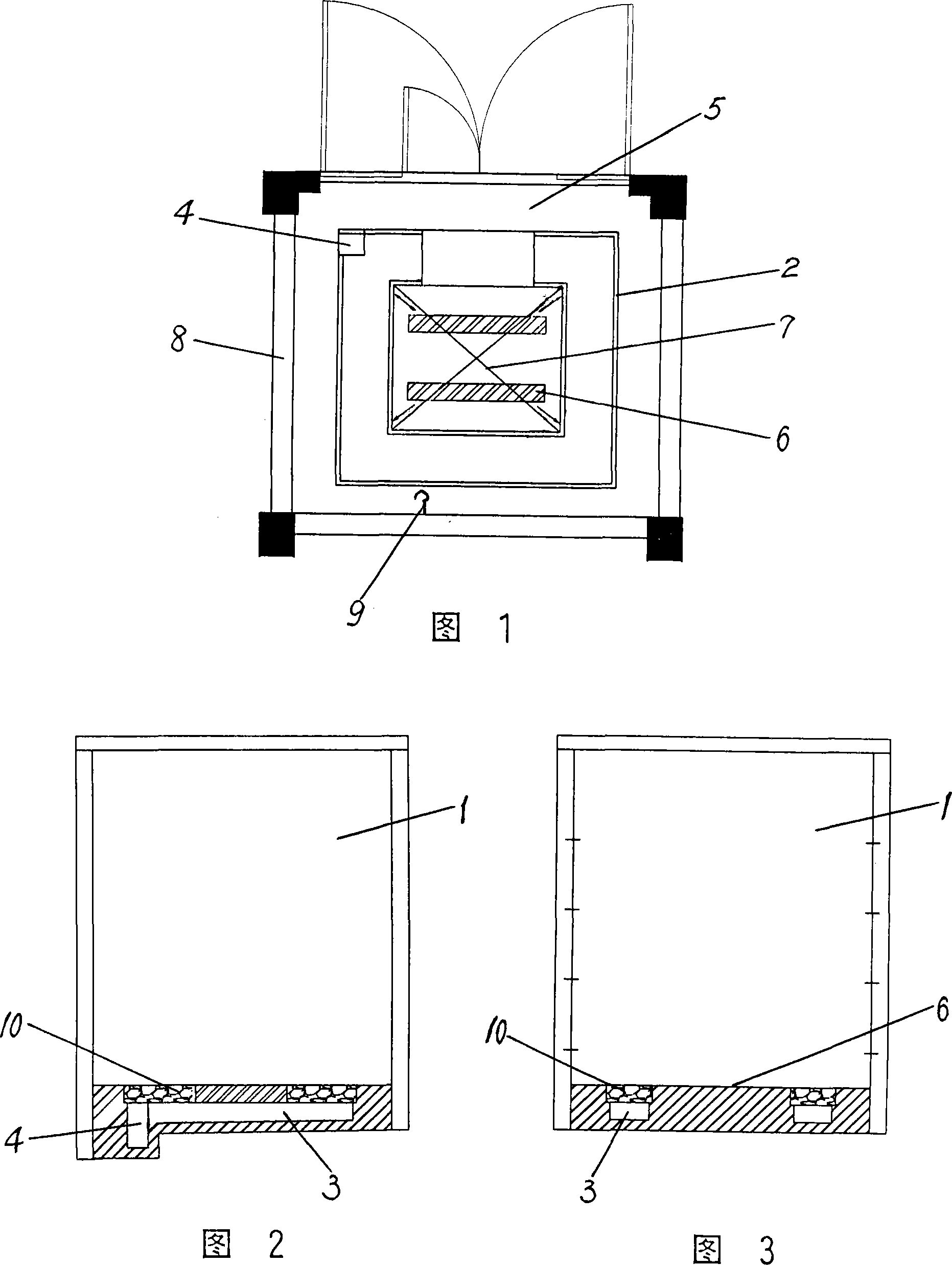

[0011] Referring to Fig. 1 to Fig. 3, a basic structure for installing an oil-immersed transformer of the present invention is arranged in a transformer room 1, and the size of the transformer room is determined according to the weight and shape of the transformer.

[0012] The transformer room 1 has an integral box-shaped foundation 2 for installing an oil-immersed transformer. An oil collecting tank 3 is provided around the box-shaped foundation 2, and the oil collecting tank 3 can discharge transformer accident oil and store it. An oil sump 4 is arranged at the end of the oil sump 3, and the oil sump 4 communicates with the oil sump 3, so that it is convenient to extract and clean up the discharged oil. The periphery of the box foundation 2 is a cement floor 5. Several flat steels 6 are pre-embedded in the middle of the box-shaped foundation 2, and these flat steels 6 are fixed by reinforcing cables 7, which is beneficial to bearing and fixing the weight of the transformer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com