Integrated pipe pile and its vertical controller

A vertical controller and integrated technology, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of difficult to ensure the quality of concrete pouring, multiple configuration of steel bars, and difficult construction, so as to save concrete and reduce engineering quantity , The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

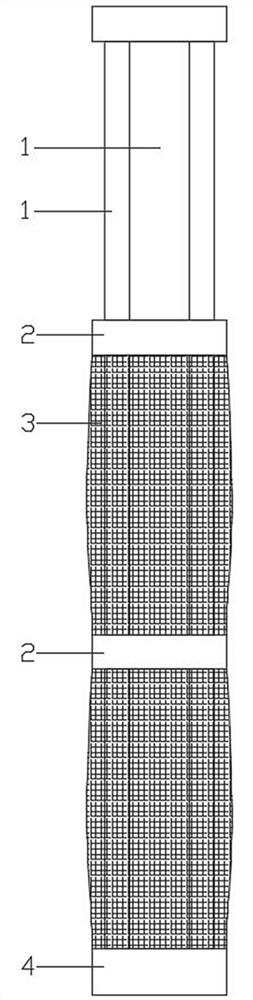

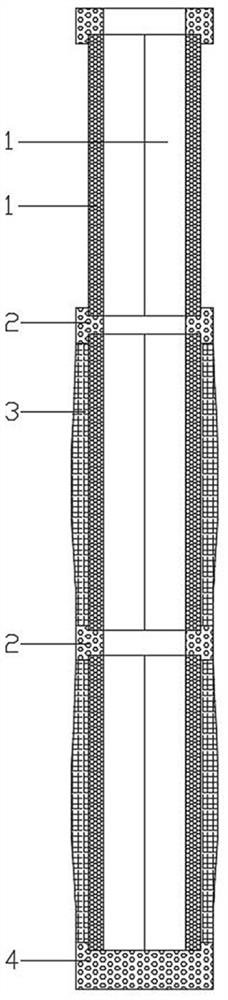

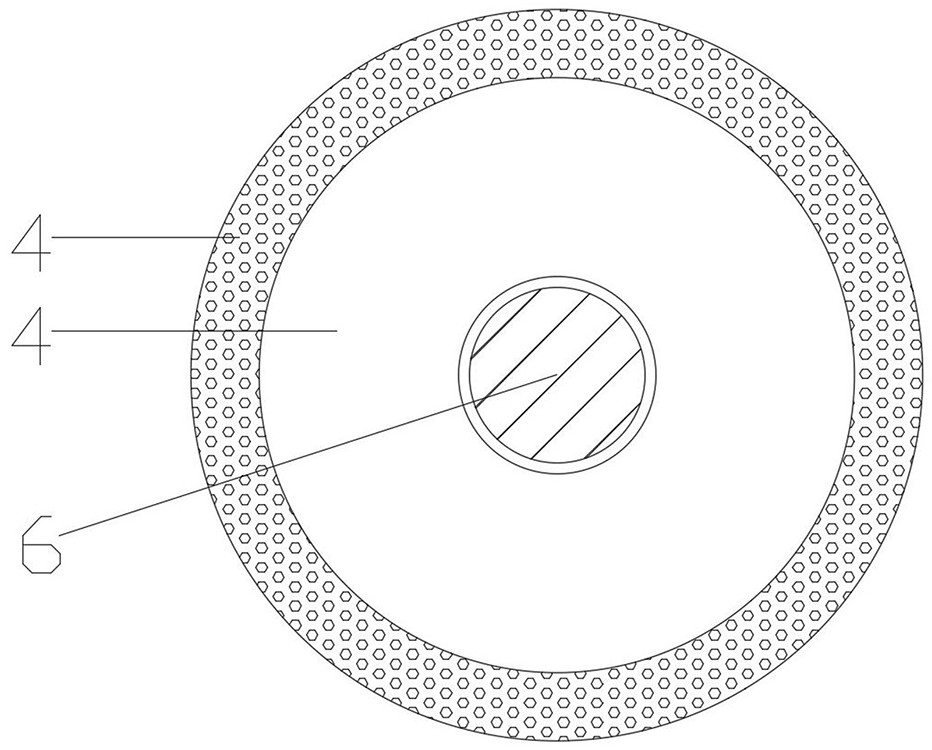

[0044] see Figures 1 to 7 As shown in the figure, the pile strip 1 is vertically arranged on the periphery of the pipe pile, the inner side plate faces the center of the pipe pile, the adjacent left and right end faces are pressed against each other and automatically prevent inward movement, and the upper and lower end faces are pressed against each other or against each other. Tighten the anti-slip confinement ring 2; the anti-slip confinement ring 2 arranged in the horizontal direction constrains the outward movement or vertical displacement of the pile strip 1 in the horizontal and vertical directions to form a ring-shaped pile body, and a pile armor is arranged on the outside of the pile body 3. The annular pile body is arranged in the notch on the upper surface of the end pressure seat 4 and is restricted by the end pressure seat 4 to move radially outward and vertically in the horizontal direction. The outside of the pile armor 3 is the soil body of the pile hole wall 5,...

Embodiment 2

[0050] A construction method for a vertical controller for an integrated pipe pile, comprising the following steps:

[0051] The first step: at the predetermined position, use mechanical equipment to form holes in the soil of the site to form pile holes;

[0052] The second step: assemble the end pressure seat, the pile strip and the anti-slip restraint ring to form the first section, that is, the bottom section of the annular pile body, and put it into the pile hole;

[0053] Step 3: Use the vertical controller to adjust the vertical position of the first section of the annular pile body, and then continue to assemble the pile strip and the anti-slip restraint ring to form the second section of the annular pile body;

[0054] Step 4: Use the vertical controller to adjust the vertical position of the assembled annular pile, and then continue to assemble the pile strip and anti-slip restraint ring to form the third annular pile. The set elevation at which the shaped pile body ...

Embodiment 3

[0058] A construction method for a vertical controller for an integrated pipe pile, comprising the following steps:

[0059] The first step: at the predetermined position, use mechanical equipment to form holes in the soil of the site to form pile holes;

[0060] Step 2: Assemble the end pressure seat, the pile strip and the anti-slip restraint ring, and tension and lock each prefabricated member of the pipe pile to form a complete annular pile body;

[0061] The third step: use the vertical controller to adjust the vertical position of the overall annular pile body, and place the complete annular pile body into the set elevation of the pile hole;

[0062] The fourth step: constructing the pile armor, if necessary, install the pouch of the pile armor in the second step above, and grouting the pouch to form the pile armor;

[0063] Step 5: Earthwork excavation, after reaching the set elevation, fill the interior of the pipe pile with soil or construction waste as needed.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com