General composite die

A combined mold and side mold technology, applied in molds, mold trays, mold panels, etc., can solve the problem of high cost of steel molds and aluminum molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

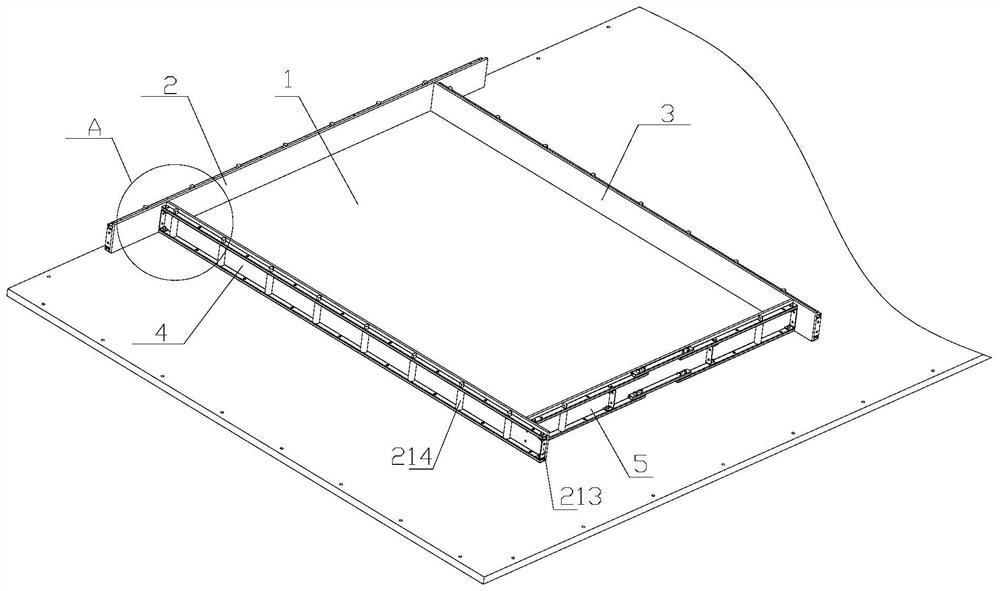

[0064] like figure 1 - Figure 11 As shown, a general composite mold for partition walls includes a mold table 1, a first side mold 2 is fixedly installed on the mold table 1, one end of the first side mold 2 is connected to one end of the second side mold 3, and the other end is connected to One end of the third side form 4 , the second side form 2 and the third side form 3 are installed oppositely, and the other ends of the second side form 2 and the third side form 3 are connected through a modular combination side form 5 .

[0065] The first, second and third side molds 2, 3 and 4 are all common side molds.

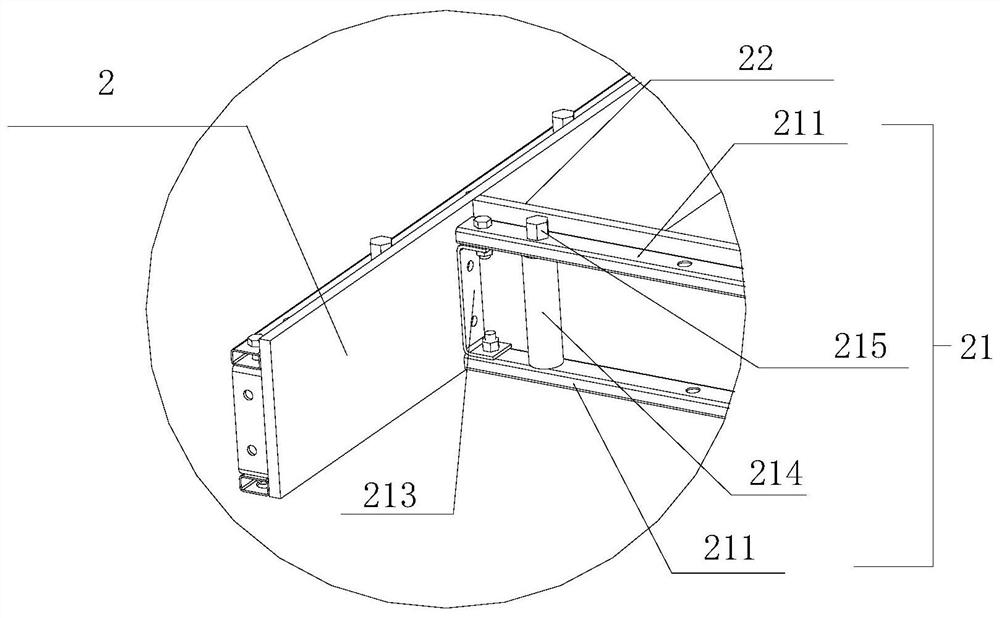

[0066] The universal side form includes a movably connected first frame 21 and a first plastic plate 22 connected to the first frame 21 by means of self-tapping screws or universal glue.

[0067] The first frame 21 includes at least two rods 211 arranged in parallel, the two ends of the adjacent rods 211 are detachably provided with the first connecting piece 213 th...

Embodiment 2

[0081] like Figure 12-Figure 17 Shown, a kind of beam-column universal combination mold, it comprises the bottom mold 12 that horizontally arranges, and one side of described bottom mold 12 connects the bottom surface of second side mold 3 through connection box 7, and the other side connects the bottom surface of second side mold 3 through connection box 7. The bottom surface of the three-side mold 4, the second side mold 3 and the third side mold 4 are relatively installed, and the two ends of the bottom mold 12 are respectively equipped with end molds 6, the second side mold 3, the third side mold The side mold 4 is spliced with the two end molds 6 to form a beam-column forming space.

[0082] The bottom mold 12 and the second and third side molds 3 and 4 are all common side molds in Embodiment 1, so they will not be repeated here.

[0083] The connection box 7 includes a first connection side 71 and a second connection side 72 connected at right angles, and the first c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com