Electronic cigarette atomizer

An electronic cigarette atomizer and atomizing tube technology, applied in the field of electronic cigarettes, can solve the problems of liquid leakage, increasing the volume of the atomizer, and requiring frequent replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing;

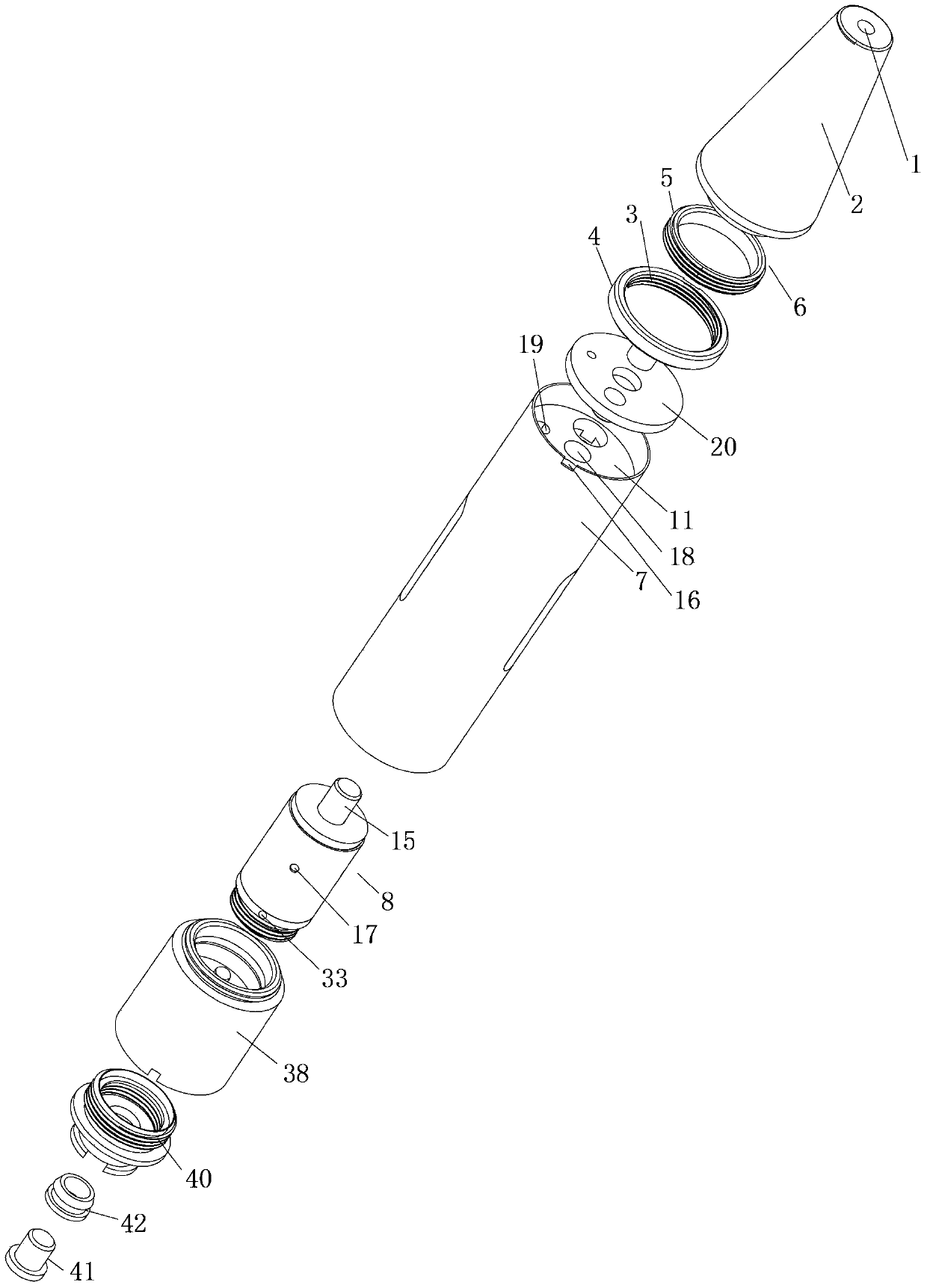

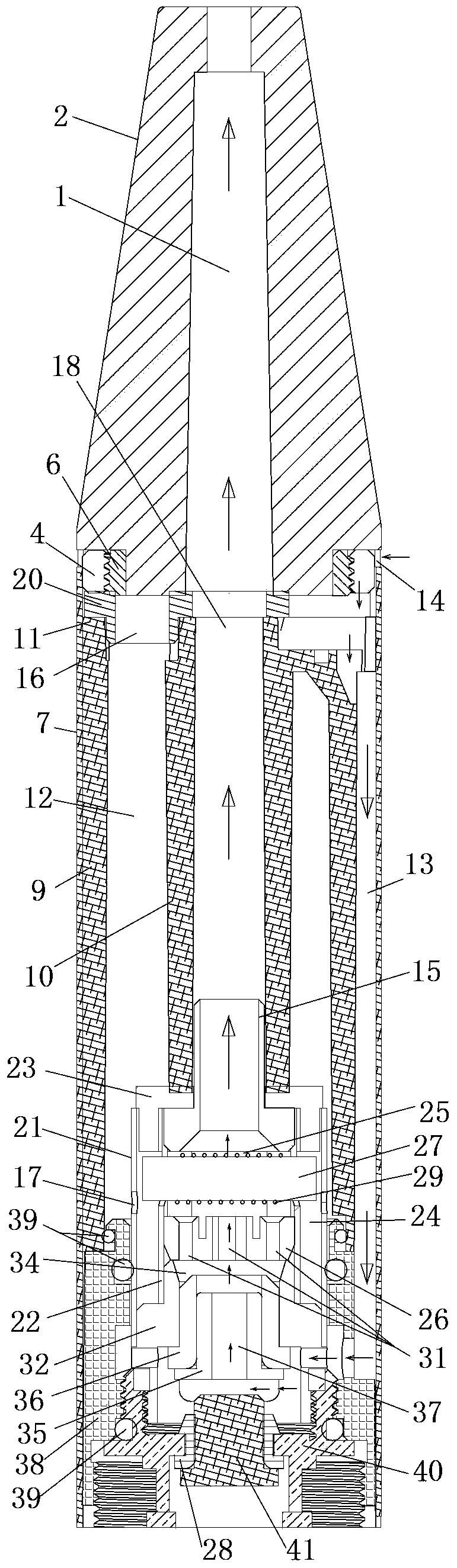

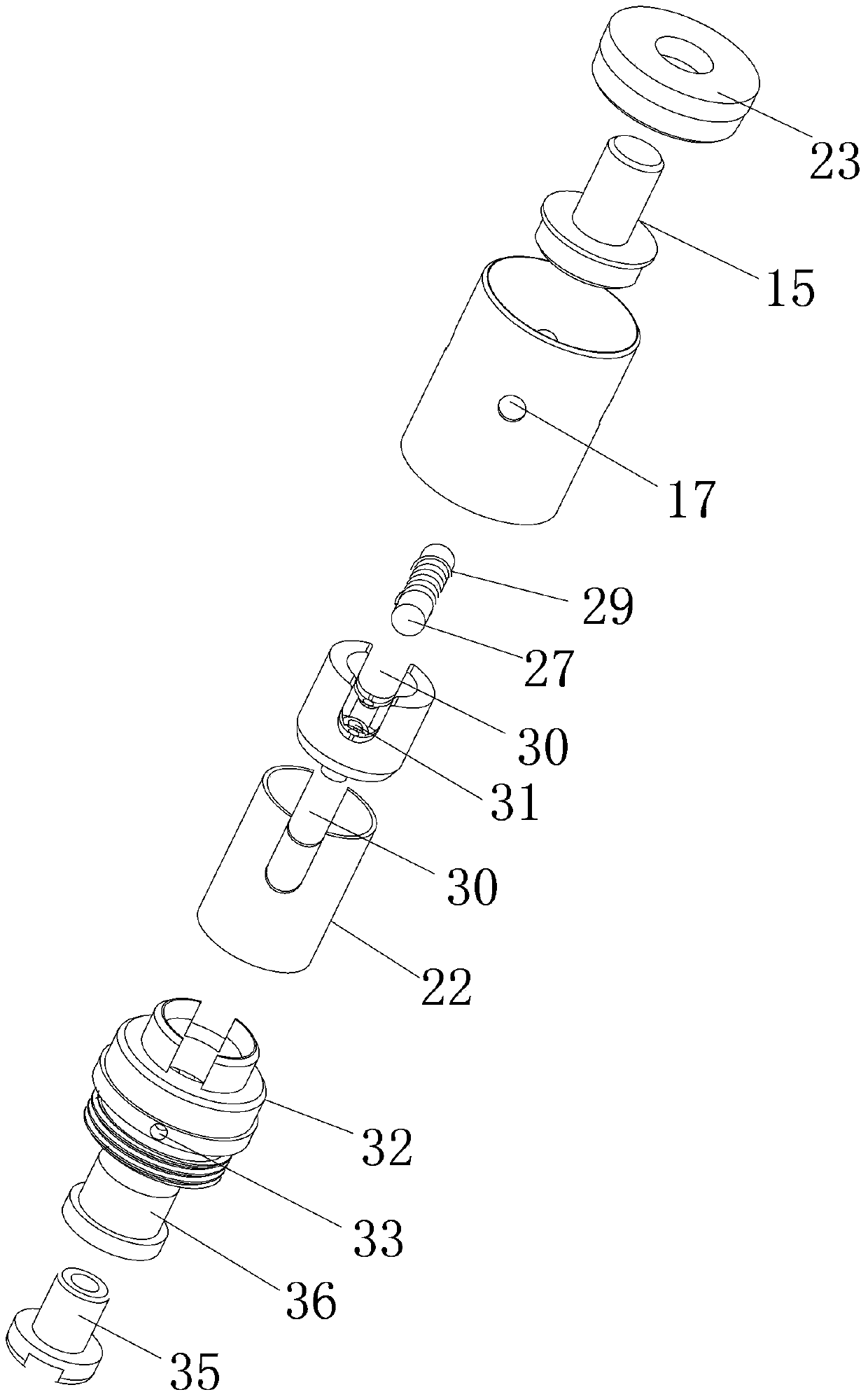

[0022] refer to Figure 1 to Figure 4 , an electronic cigarette atomizer, including a cigarette holder 2 with a smoking hole 1, an atomizing tube 7 made of metal material that is detachably connected to the cigarette holder, that is, an external threaded ring 4 with an internal thread 3 is fixed in the atomizing tube, The cigarette holder is fixed with an internal thread ring 6 with an external thread 5, and the cigarette holder is assembled on the atomizing tube 7 through the cooperation of the external thread ring 4 and the internal thread ring 6, and the atomizing tube 7 is provided with an atomizing head 8; The chemical pipe 7 is provided with a first inner tube 9, a second inner tube 10 positioned in the first inner tube 9, and a connection cover 11 that connects the first inner tube and the second inner tube to the same end and makes the end form a seal, In this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com