Highway roadbed abutment backfilling gravel inverted filter layer pavement device

A technology of reverse filter layer and roadbed, which is applied in the direction of filters, roads, roads, etc., can solve the problems of high labor cost, large construction randomness of workers, and unqualified quality of reverse filter layer, so as to facilitate maintenance and replacement and reduce sharing cost, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be clearly and completely described below in conjunction with the accompanying drawings, so that those skilled in the art can fully implement the present invention without creative work.

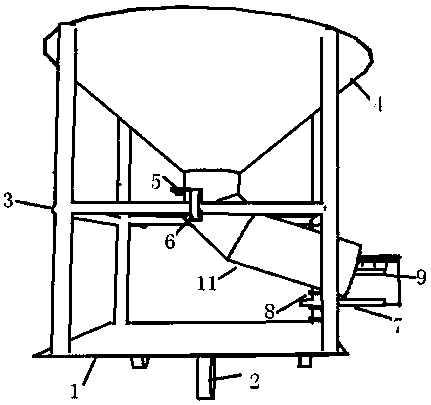

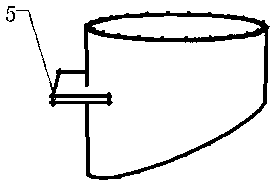

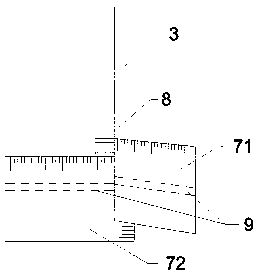

[0021] The specific embodiment of the present invention is: as Figure 1-6 As shown, a paving device for backfilling gravel reverse filter layer on the back of road subgrade platform includes a main frame 3, a bottom plate 1, a hopper 4, a diversion pipe 11, a limiter 7, a flow regulating plate 5, a walking wheel 2, a sieve plate 10, the main frame 3 is arranged above the bottom plate 1, the main frame 3 includes a main frame and a balance frame, the hopper 4 is arranged on the main frame 3, and the traveling wheels 2 are arranged at the bottom of the bottom plate 1, and the The guide tube 11 is arranged at the bottom of the hopper 4, and the guide tube 11 includes vertical tubes, corners and oblique tubes from top to bottom. The notch is inserted, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com