Prefabricated concrete pipe pile for overhead power transmission line

A technology of overhead transmission lines and prefabricated pipe piles, which is applied in construction and infrastructure engineering, etc., can solve the problems of small contact area and unfavorable piling, and achieve the effects of improving interface structure, reducing cost, enhancing strength and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

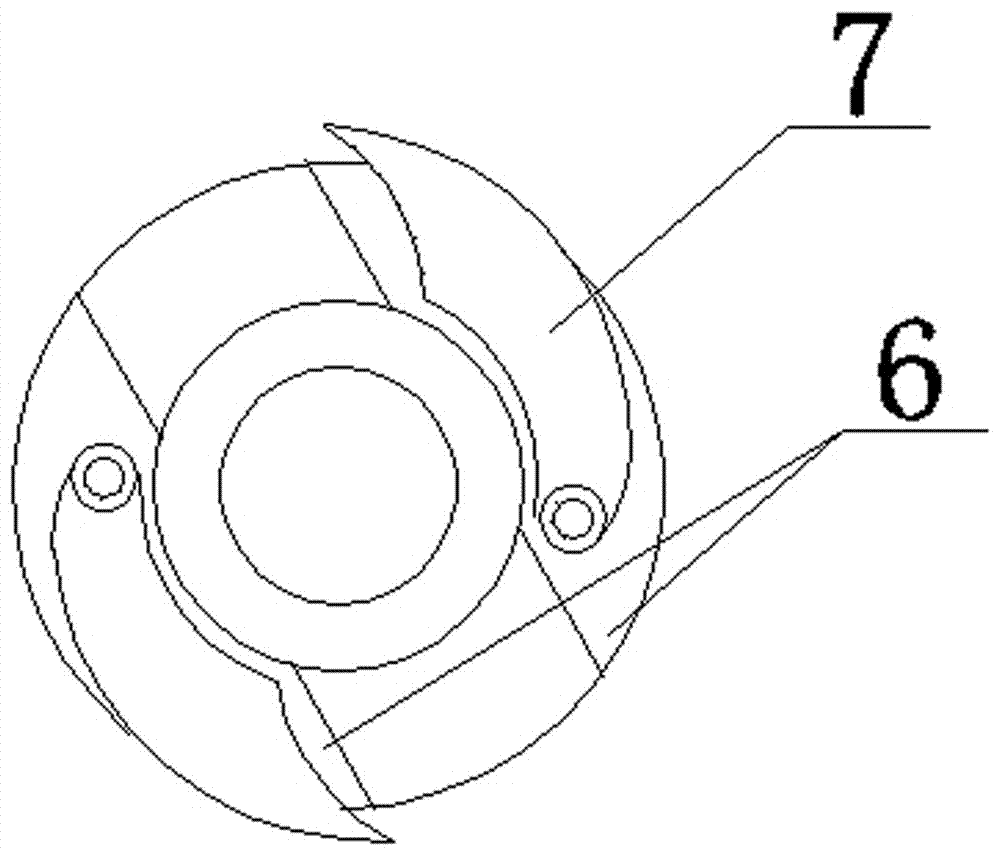

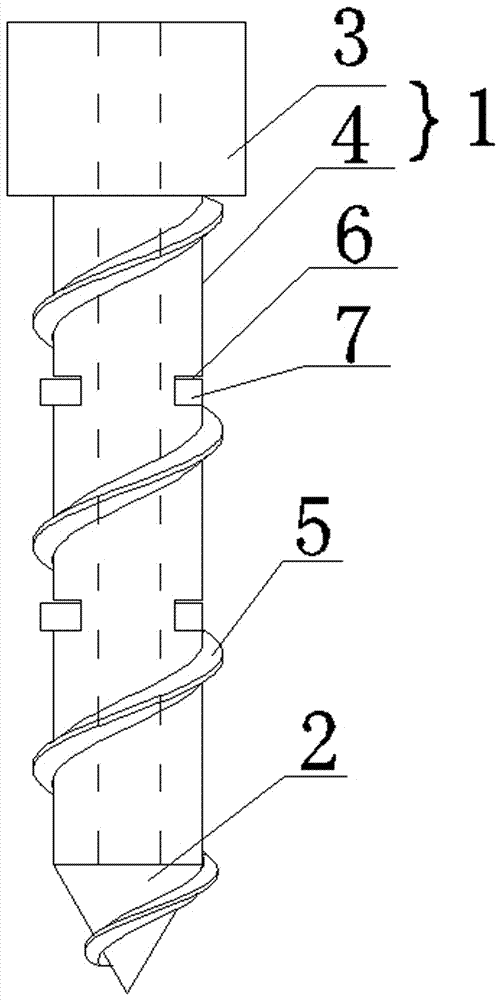

[0030] A concrete prefabricated pipe pile for overhead transmission lines, such as Figure 1-2 As shown, it includes a hollow pipe pile 1 and a pile head 2, wherein the hollow pipe pile 1 is a hollow structure with a circular cross section, and the pipe pile is filled with reinforced concrete. The hollow structure can reduce weight and cost; the pile head 2 is a conical type structure, it is easier to screw into the ground below.

[0031] The hollow pipe pile 1 includes an upper pipe pile 3 and a lower pipe pile 4, wherein the inner diameter of the upper pipe pile 3 and the lower pipe pile 4 are the same, and the outer diameter of the upper pipe pile 3 is larger than the outer diameter of the lower pipe pile 4. This structure is adopted It can reduce foundation settlement, increase the rigidity of pipe piles, save subsequent concrete usage, and reduce the cost of prefabricated pipe piles.

[0032] The lower pipe pile 4 is provided with a helix 5 outside, and the helix can be ...

Embodiment 2

[0038] The structure of embodiment 2 is basically the same as that of embodiment 1, the difference is: as image 3 As shown, the spiral 5 extends to the pile head 2, making it easier to insert the pile, and the length ratio of the upper pipe pile 3 and the lower pipe pile 4 in this embodiment is 1:5.

[0039] The concrete is made of the following raw materials in parts by weight: 265 parts of Portland cement, 52 parts of coal ash powder, 24 parts of silica fume, 740 parts of sand, 920 parts of stone, 145 parts of water, and 8 parts of polycarboxylate superplasticizer , 11 parts of steel fiber, 14 parts of glass fiber, 22 parts of polyvinyl acetate emulsion, 3 parts of isobutyl triethoxysilane, 2 parts of 3-aminopropyl triethoxysilane, 0.3 parts of rosin soap and methyl fiber 8 parts of plain sodium.

[0040] Among them, the particle size of the stone is 10-15mm, and the mud content is ≤2%.

Embodiment 3

[0042] Embodiment 3 The structure of the prefabricated pipe pile is the same as that of Embodiment 1, except that the concrete is made of the following raw materials in parts by weight: 270 parts of Portland cement, 54 parts of coal ash powder, 22 parts of silica fume, and 750 parts of sand 940 parts of stone, 150 parts of water, 7 parts of polycarboxylate superplasticizer, 12 parts of steel fiber, 13 parts of glass fiber, 24 parts of polyvinyl acetate emulsion, 3 parts of isobutyltriethoxysilane, 3-amino 3 parts of propyl triethoxysilane, 0.4 parts of rosin soap and 6 parts of sodium methylcellulose.

[0043] Among them, the particle size of the stone is 10-15mm, and the mud content is ≤2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com