Mechanical hole forming technology applied to karst landform

A mechanical hole-forming and karst technology, used in construction, sheet pile walls, infrastructure engineering, etc., can solve problems such as not being able to play a good supporting role, prevent hole collapse, ensure effective pouring, save money cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, steps and characteristics of the mechanical hole-forming method under karst landform proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. And its effect, detailed description is as follows.

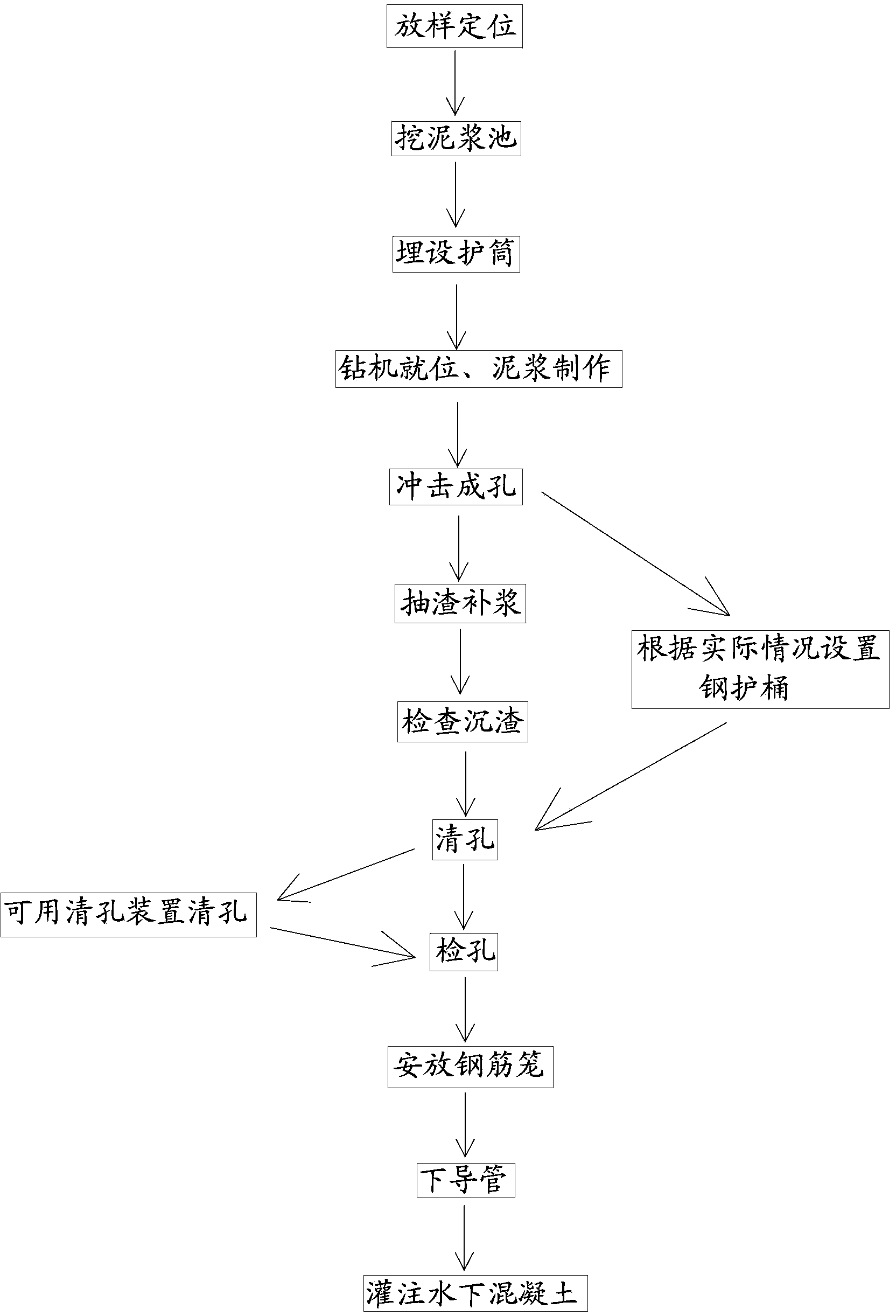

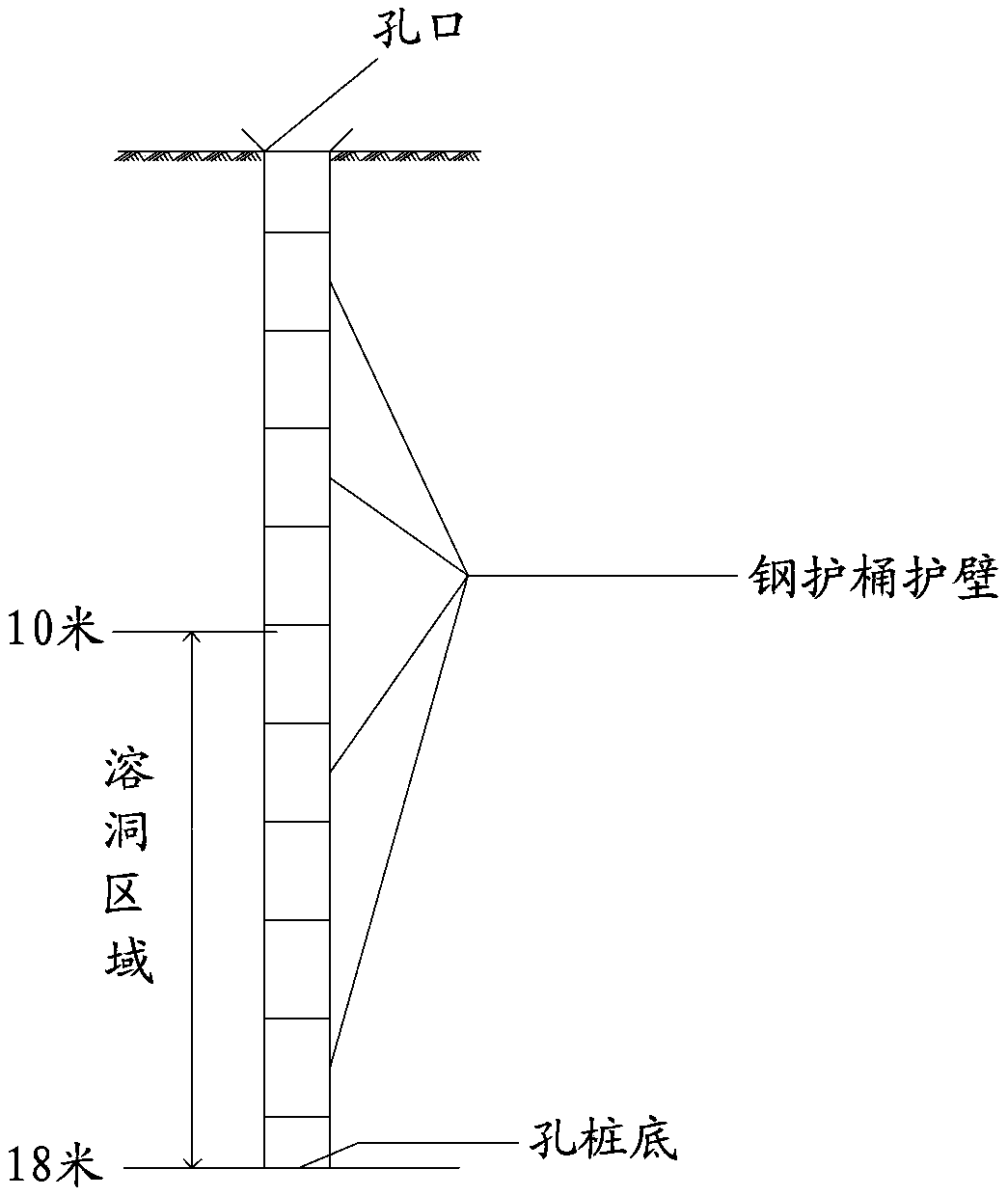

[0017] Such as figure 1 As shown, it is a process flow diagram of the mechanical hole-forming method under karst landforms of the present invention, setting out and positioning, digging mud pools, laying casings, drilling rigs in place, making mud, impacting holes, pumping slag to replenish slurry, checking sediment, clearing holes, Check the hole, place the reinforcement cage, lower the conduit, and pour the underwater concrete. Wherein, the hole cleaning process can use a self-made hole cleaning device to remove impurities in small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com