A kind of h-shaped hollow anti-slide pile

An anti-sliding pile and hollow technology, applied in sheet pile walls, construction, excavation, etc., can solve the problems of increasing the amount of concrete, increasing the cost of the pile body, wasting building materials, etc., to reduce construction costs, reduce construction difficulty, and save money. The effect of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

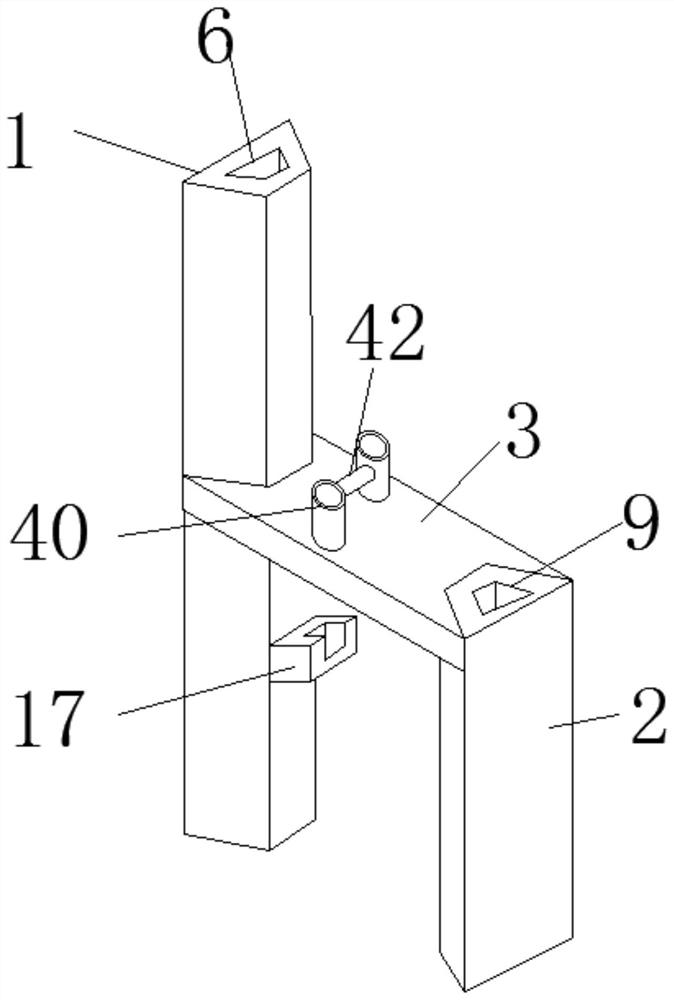

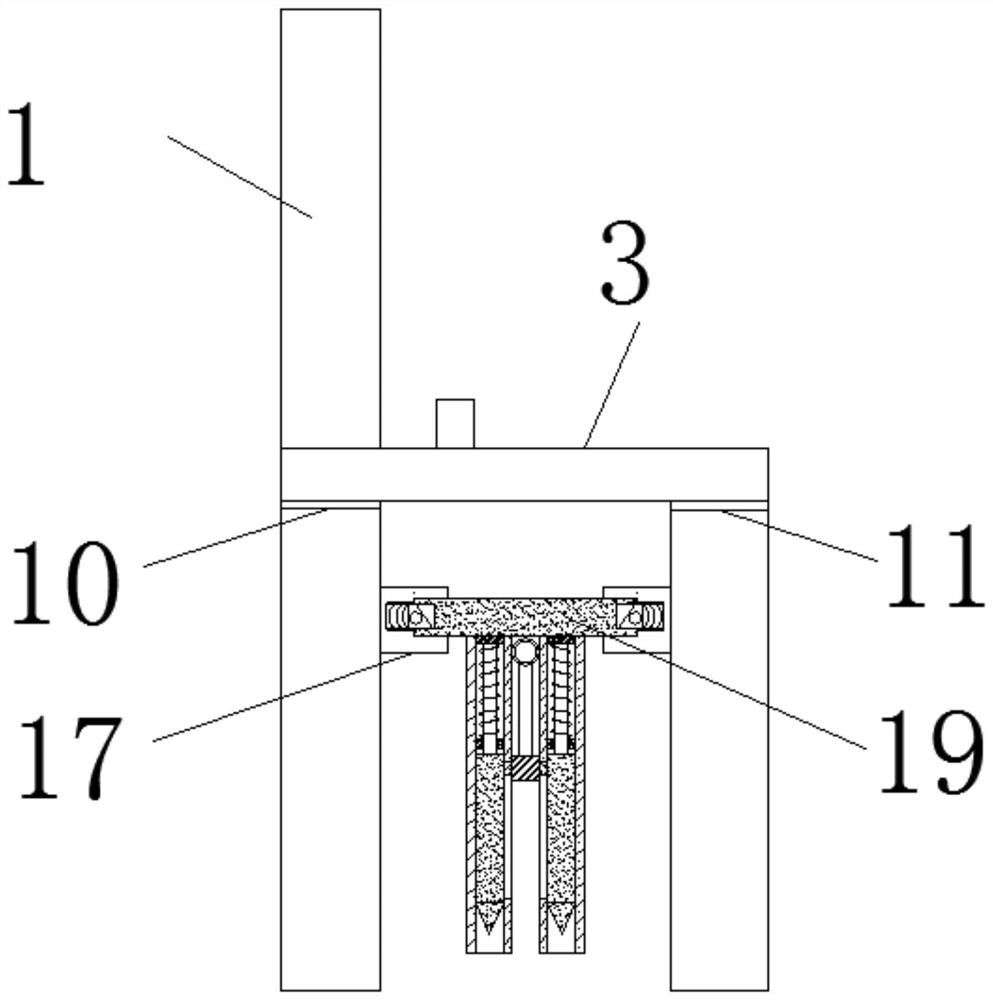

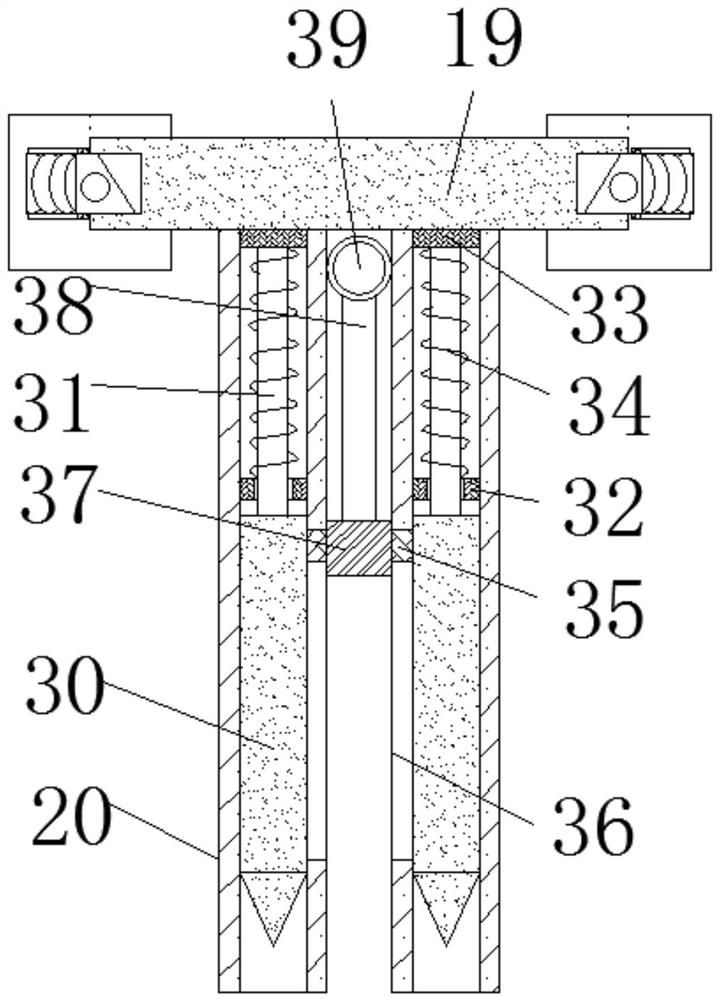

[0032] see Figure 1-12 , an h-shaped hollow anti-slide pile according to an embodiment of the present invention, comprising a front pile 1 and a rear pile 2, a beam 3 is connected between the front pile 1 and the rear pile 2, and the front pile 1 includes a pile Front-end-4 and pile rear-end-5, the thickness of pile front-end-4 exceeds pile rear-end-5, and hollow hole-6 is arranged between described pile front-end-4 and described pile rear-end-5, and described rear pile 2 includes pile front end 2 7 and pile rear end 2 8, the thickness of pile front end 2 7 is greater than pile rear end 2 8, and a hollow hole 2 9 is arranged between the pile front end 2 7 and the pile rear end 2 8, so The front pile 1 is provided with a front pile projection 10 near the crossbeam 3, and the rear pile 2 is provided with a rear pile projection 11 near the crossbeam 3. The front pile projection 10 and the rear pile projection Blocks 11 are located below the beam 3, the bottoms of the front pile...

Embodiment 2

[0037] see Figure 6-7 , the included angles between the pile front end 4 and the hollow hole 6 are both 50°-60°, and the included angles between the pile front end 2 7 and the hollow hole 9 are both 50°-60°.

[0038] In order to facilitate the understanding of the above-mentioned technical solution of the present invention, the working principle or operation mode of the present invention in the actual process will be described in detail below.

[0039] In actual application, determine the position of the front pile 1, use excavators and rock drills to excavate the rock and soil in an isosceles trapezoidal shape, and use a pump to continuously pump out the water in the hole during the hole digging process, and ensure that the bottom of the hole is clean and clean , so as not to affect the construction of the pile, the bottom of the front pile is respectively pierced through the sliding body 14, the sliding belt 12 and finally stretched into the sliding bed 13, and hammered to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com