Construction method of composite pile

A construction method and technology of composite piles, which are applied in the field of building foundation engineering, can solve problems such as environmental damage, and achieve the effects of improved construction efficiency, reduced cost, and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

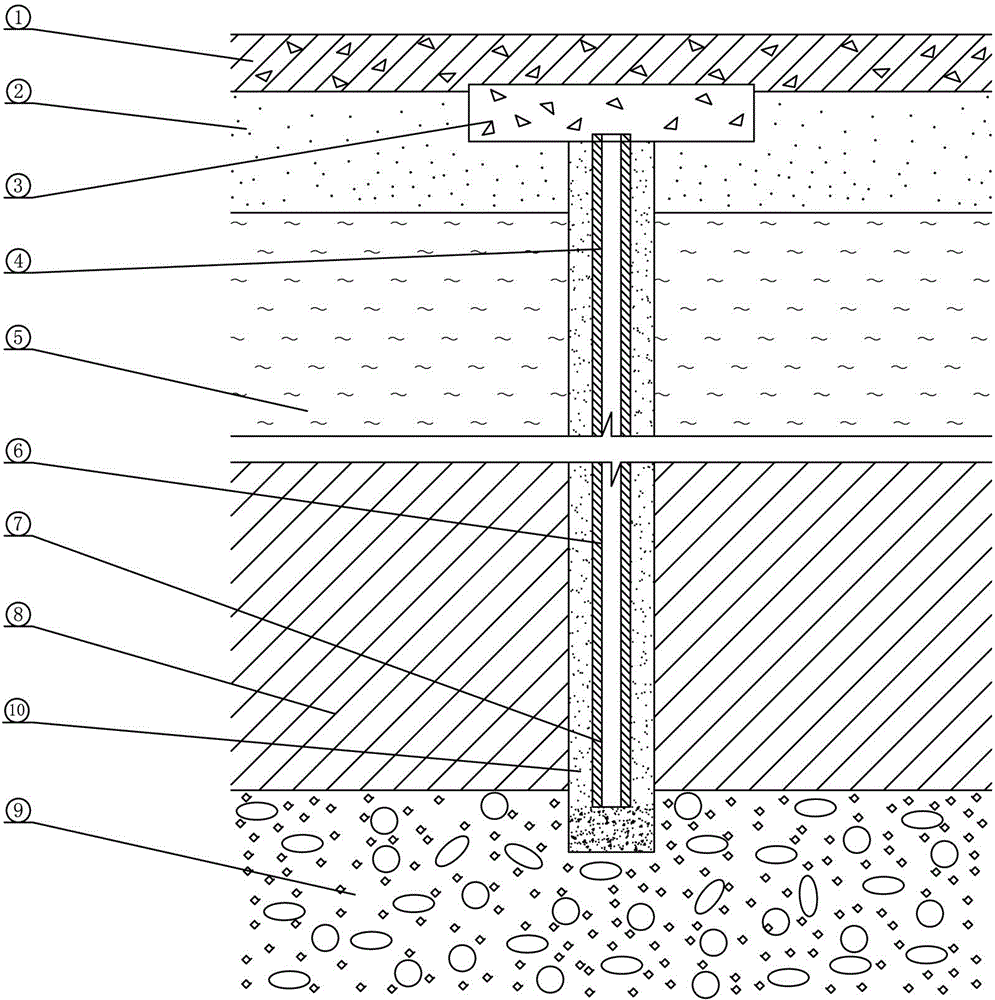

[0013] Such as figure 1 In the shown embodiment, the composite pile of the present invention is a prestressed pipe pile embedded in cement soil, and this embodiment adopts a multi-section prestressed pipe pile.

[0014] Its construction method is as follows:

[0015] (1) With the assistance of a crane, use a vibratory hammer to sink a steel casing with a diameter of Φ900mm, a length of 20m, and a wall thickness of 16mm into the mud layer ⑤.

[0016] (2) Use a rotary drilling rig to take out the soil in the steel casing, and the steel casing remains in the soil layer to act as a wall protection.

[0017] (3) Put the 20m-long drill pipe of the variable-speed cement mixing pile driver from the steel casing to the bottom of the pipe, and then slowly stir it into the lower soil layer after connecting the rod, and then pour it into the lower soil layer of the steel casing. Inject cement slurry and air, the cement content is 25%, the cement slurry water-cement ratio is 1.0, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com