Deep foundation pit supporting inner support changing method

A technology for deep foundation pit support and support piles, which is applied in excavation, infrastructure engineering, water conservancy engineering and other directions to achieve the effects of small workload, high safety and stability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

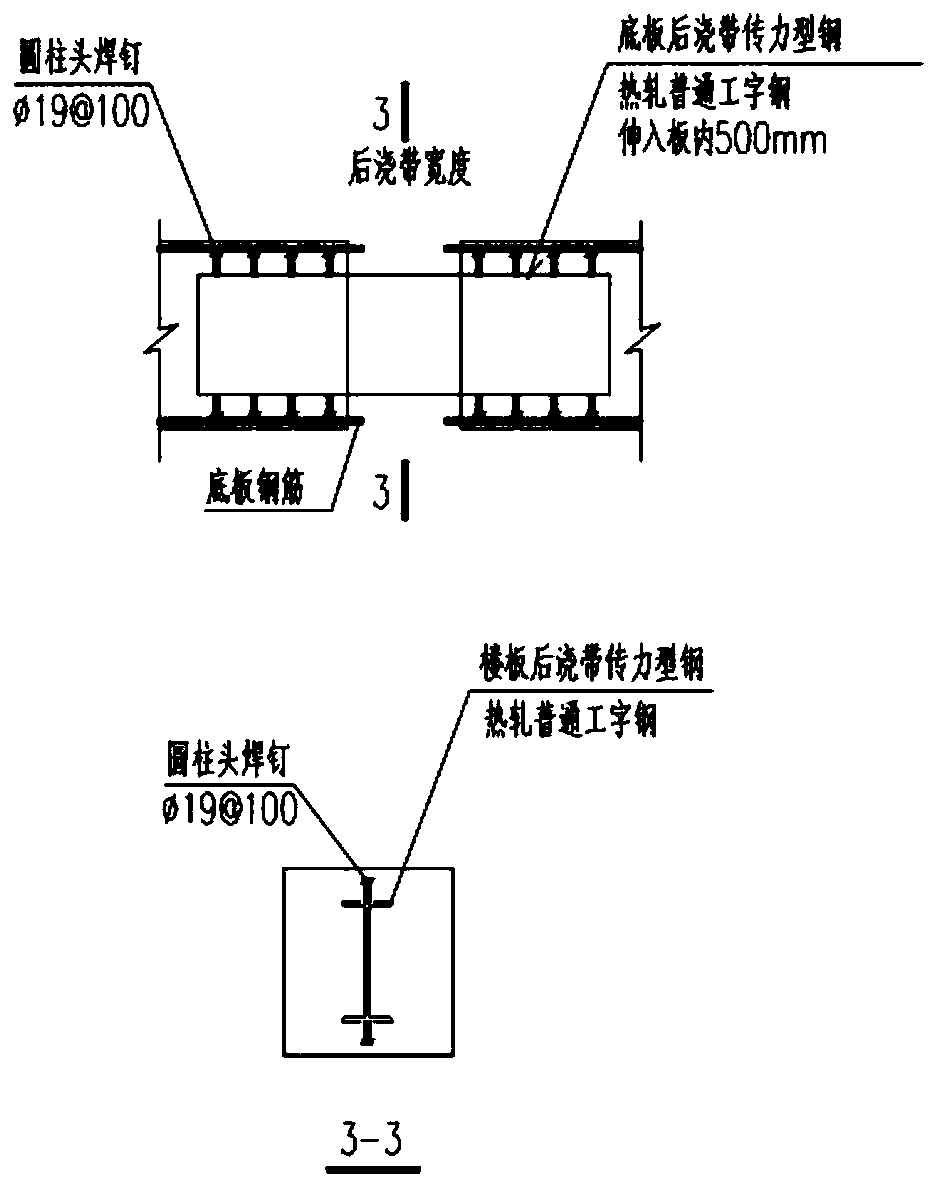

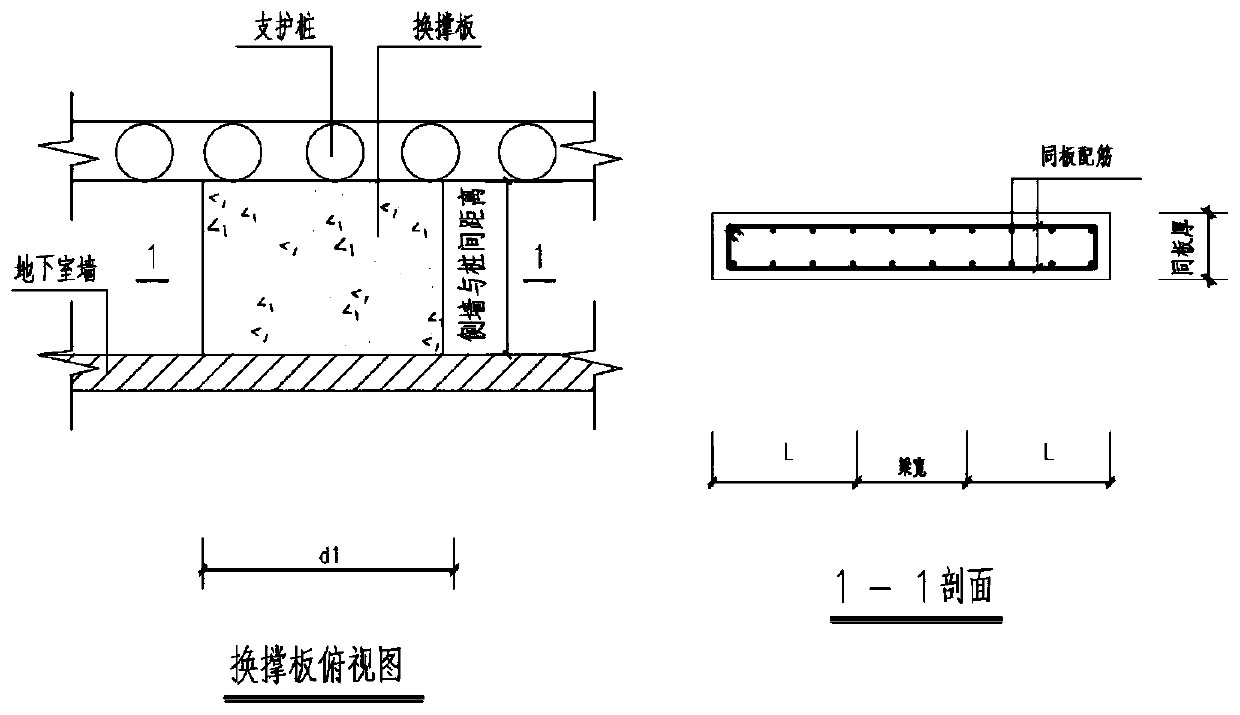

[0020] Such as Figure 1-2 As shown, in the present embodiment, a deep foundation pit support internal support change method, the deep foundation pit support internal support change structure includes a support change belt and a force transmission member, the support change belt is set on the supporting pile and Between the floor slabs, the force transmission member is set in the post-cast belt of the floor slab, the force transmission member is welded with cylindrical head welding nails, and is connected to the floor steel bar. The thickness of the support belt is the same as that of the floor slab, and the force transmission member The depth of the end of the slab is not less than 500mm, the diameter of the cylindrical head welding nail is 19mm, the spacing is not more than 100mm, the force transmission member is 25a I-beam, and the following steps are adopted:

[0021] Step 1: Clean the contact parts of the supporting pile and the supporting block before the construction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com