Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Safe and fast construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

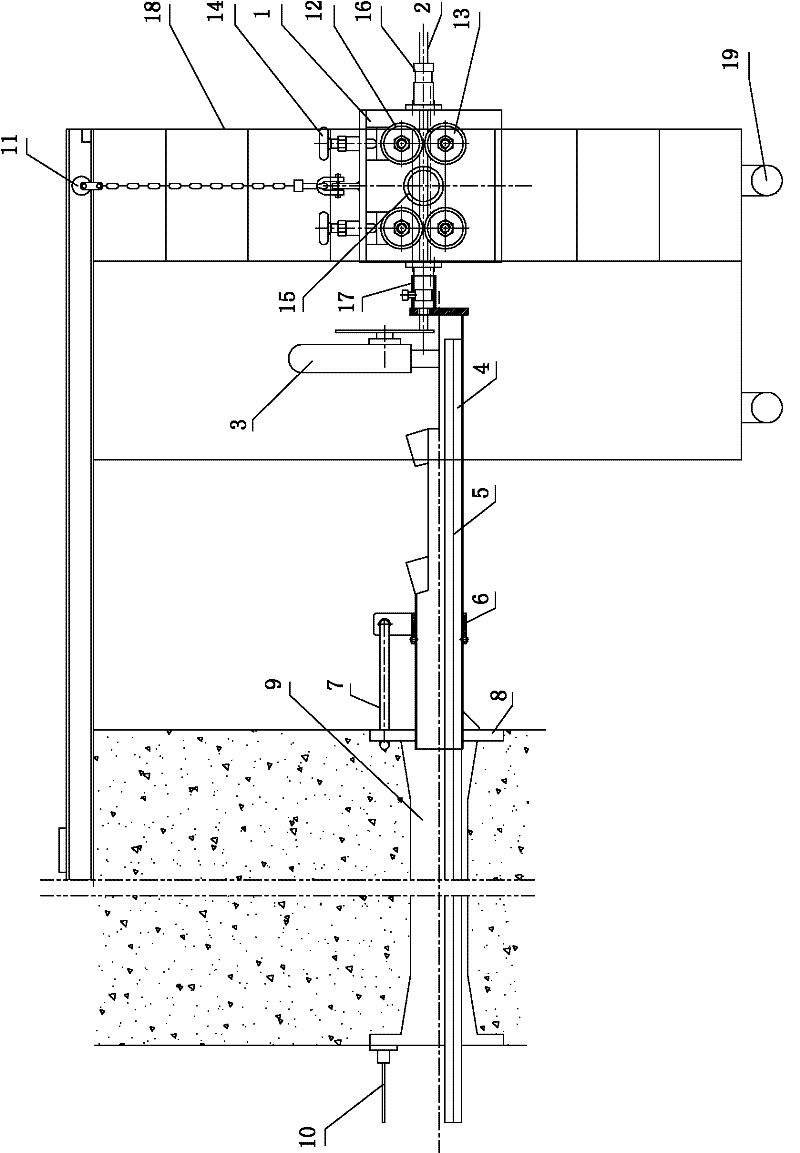

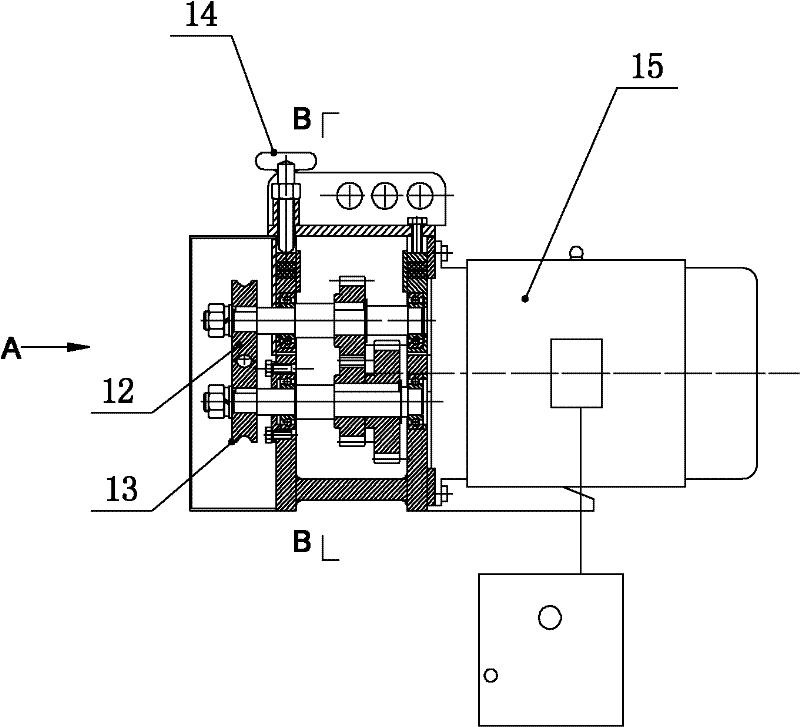

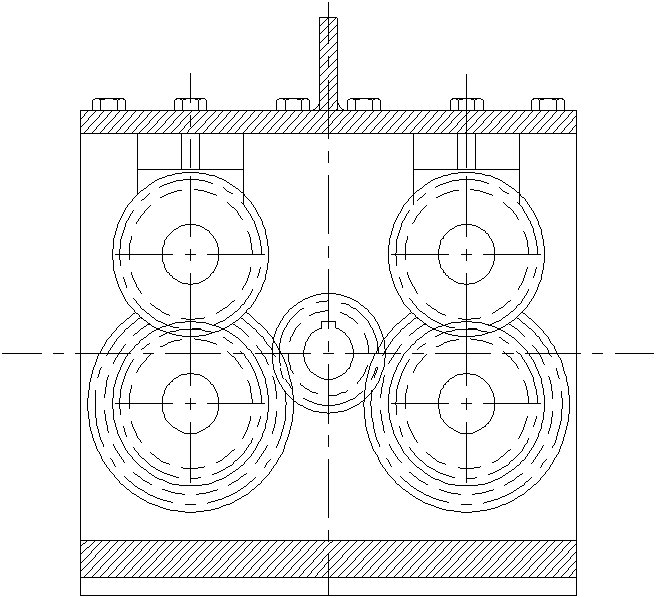

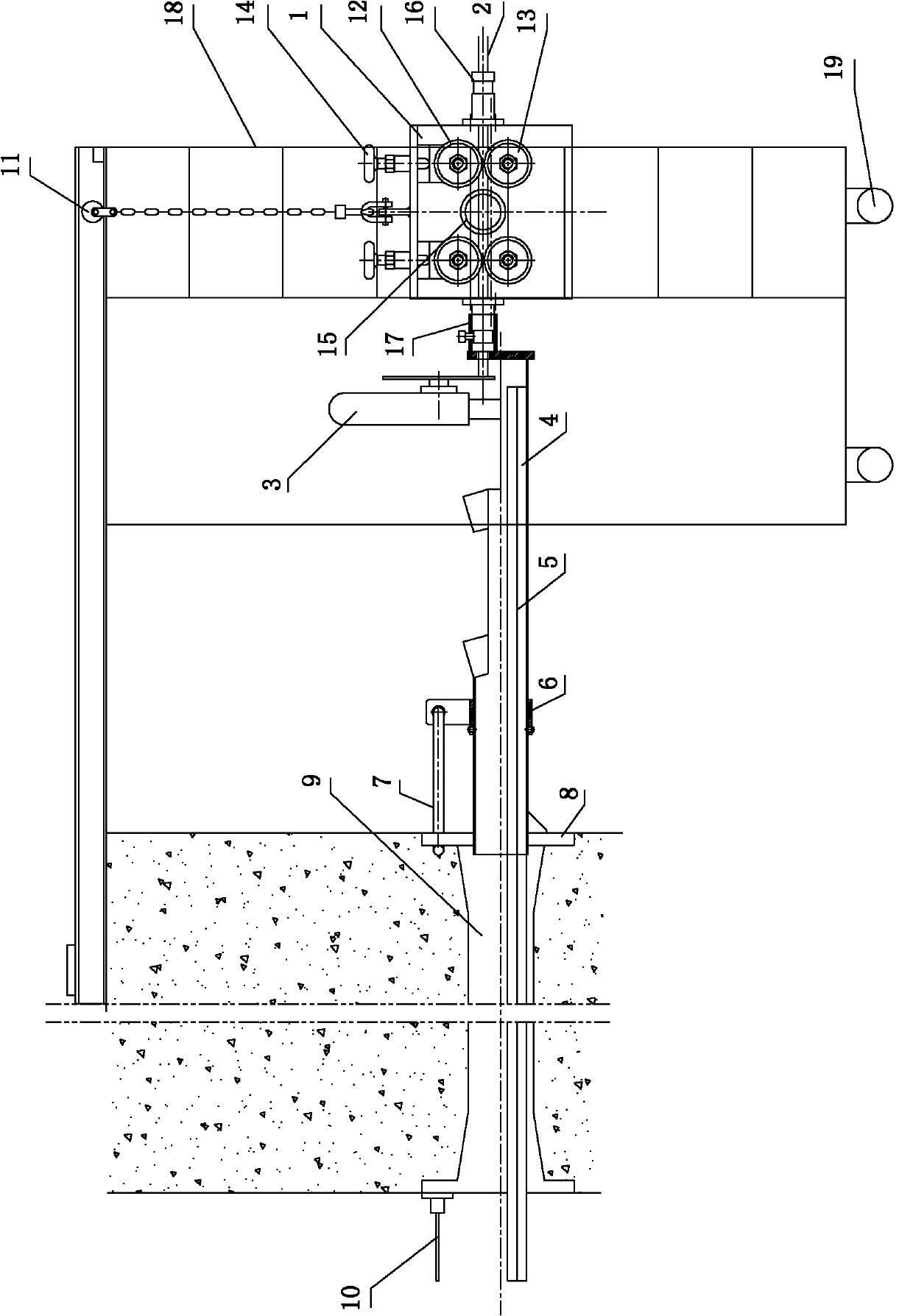

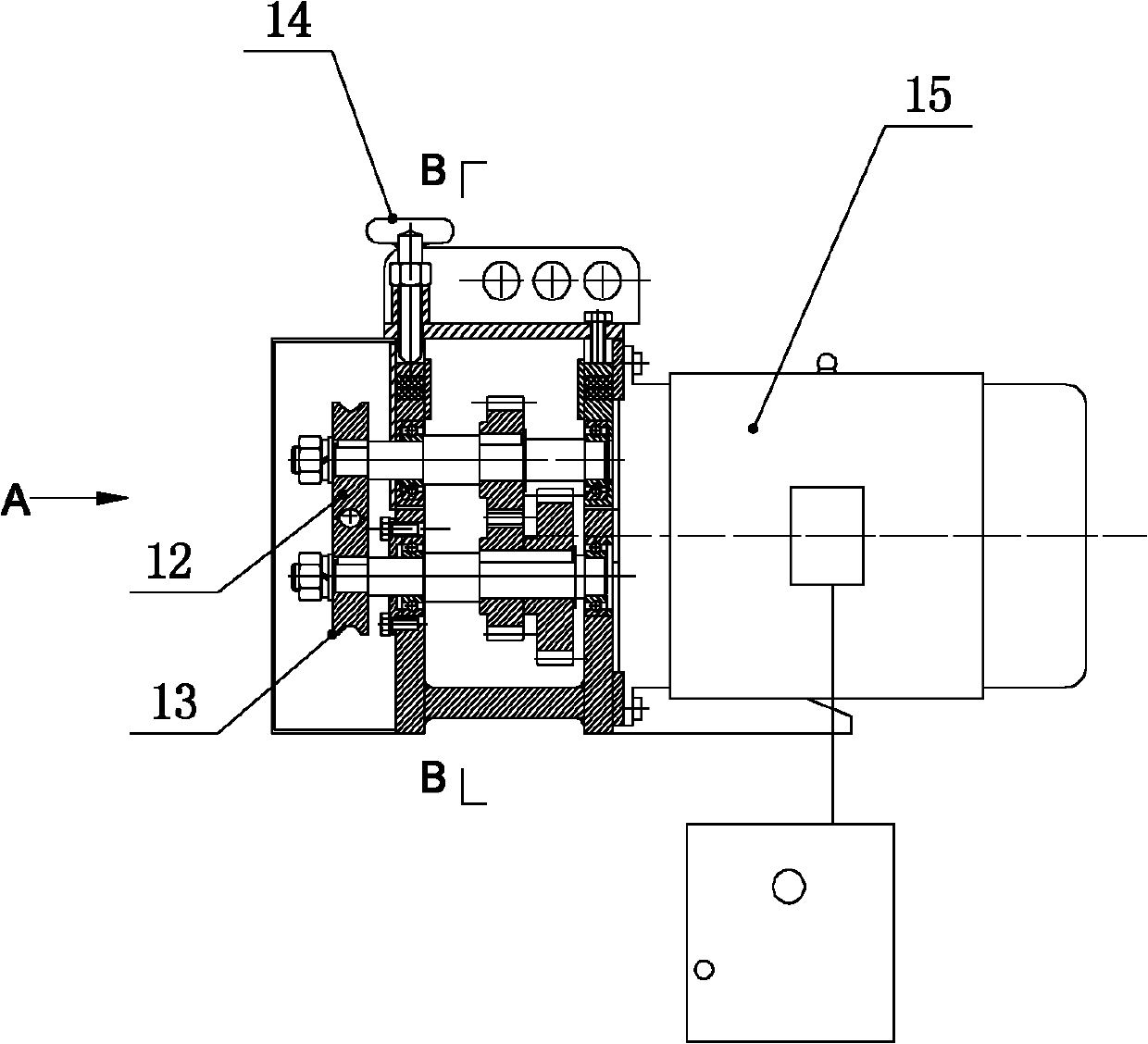

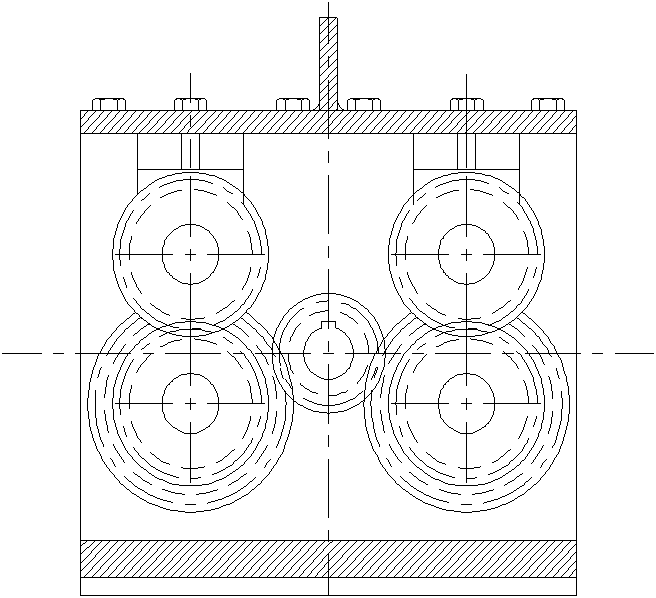

Construction method utilizing steel-strand strand pulling machine to perform fast strand pulling during construction of prestress structures

InactiveCN102383377AAvoid wastingReduce investmentBridge erection/assemblyBuilding material handlingPre stressArchitectural engineering

The invention discloses a construction method utilizing a steel-strand strand pulling machine to perform fast strand pulling during construction of prestress structures, which belongs to the technical field of building construction. The steel-strand strand pulling machine is provided with two pairs of pressing wheels capable of clamping steel strands to advance or retreat are arranged at intervals. The steps are that fixing the steel-strand strand pulling machine on a movable strand pulling platform through a pull piece in suspension mode, cleaning mortar on a mortar filling port of an anchorbacking plate on an opening of a prestress hole passage, then connecting the steel-strand strand pulling machine with the prestress hole passage to be strand-pulled, further utilizing the steel-strand strand pulling machine to enable the steel strands to be strand-pulled according to numbers till the steel strands reach predetermined positions, utilizing a cutting device to cut off the steel strands, and accordingly the strand pulling work of one steel strand is completed. Repeating the steps till the strand pulling work of all the steel strands of the prestress hole passage is completed, andthe steel strands are automatically bundled according to stacking mode after cut from bottom to top. The construction method utilizing the steel-strand strand pulling machine to perform fast strand pulling during construction of prestress structures integrates fast blanking, fast bundling and fast stand-pulling into a whole, thereby being convenient to operate and fast and efficient in strand-pulling construction.

Owner:RAILWAY NO 10 ENG GRP CO LTD

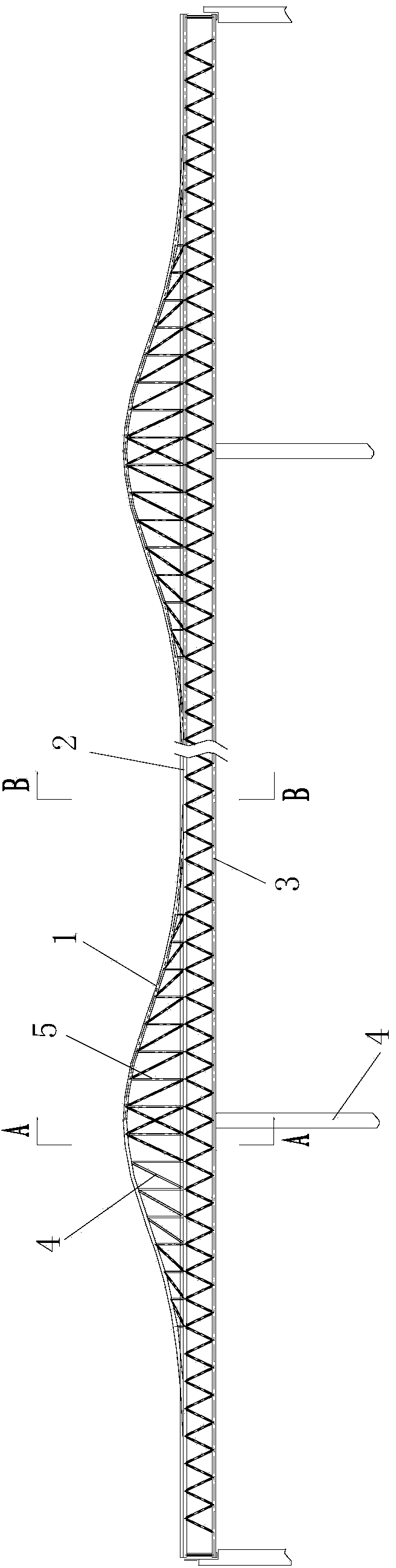

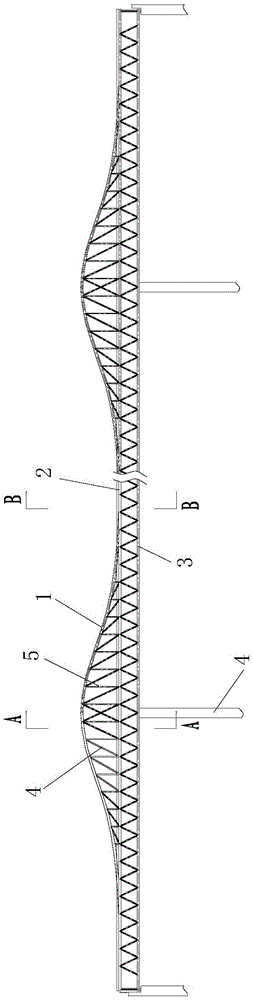

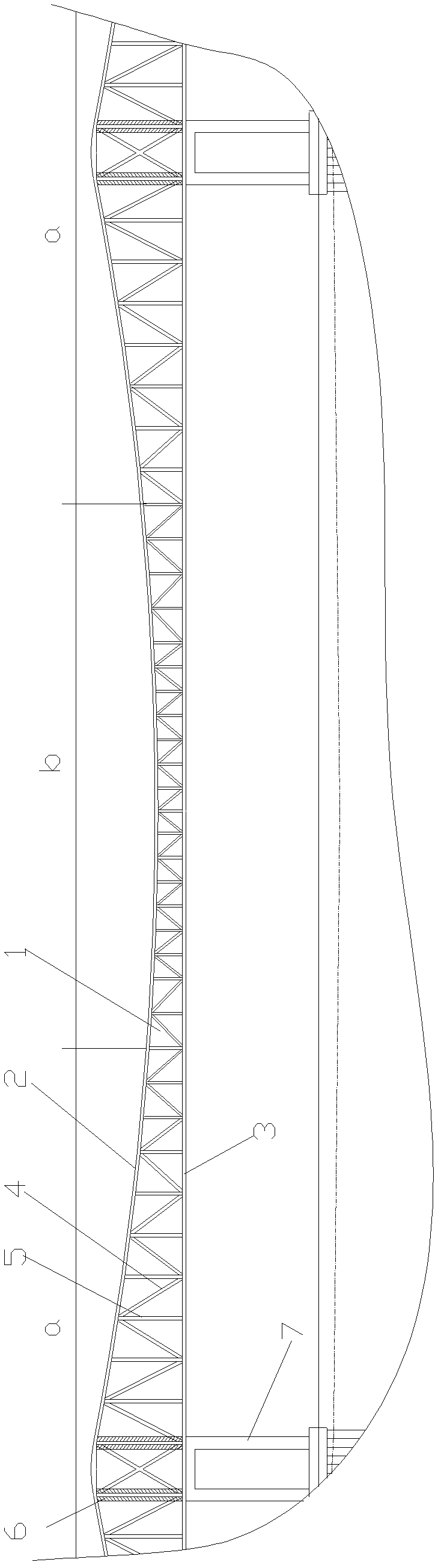

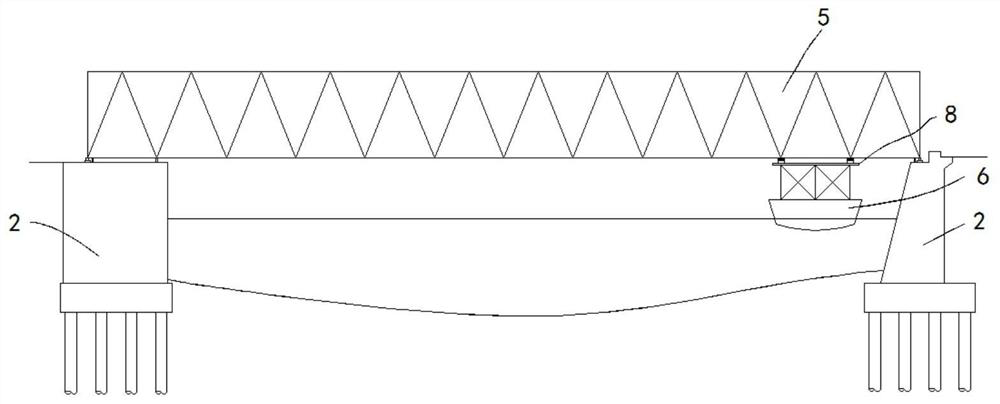

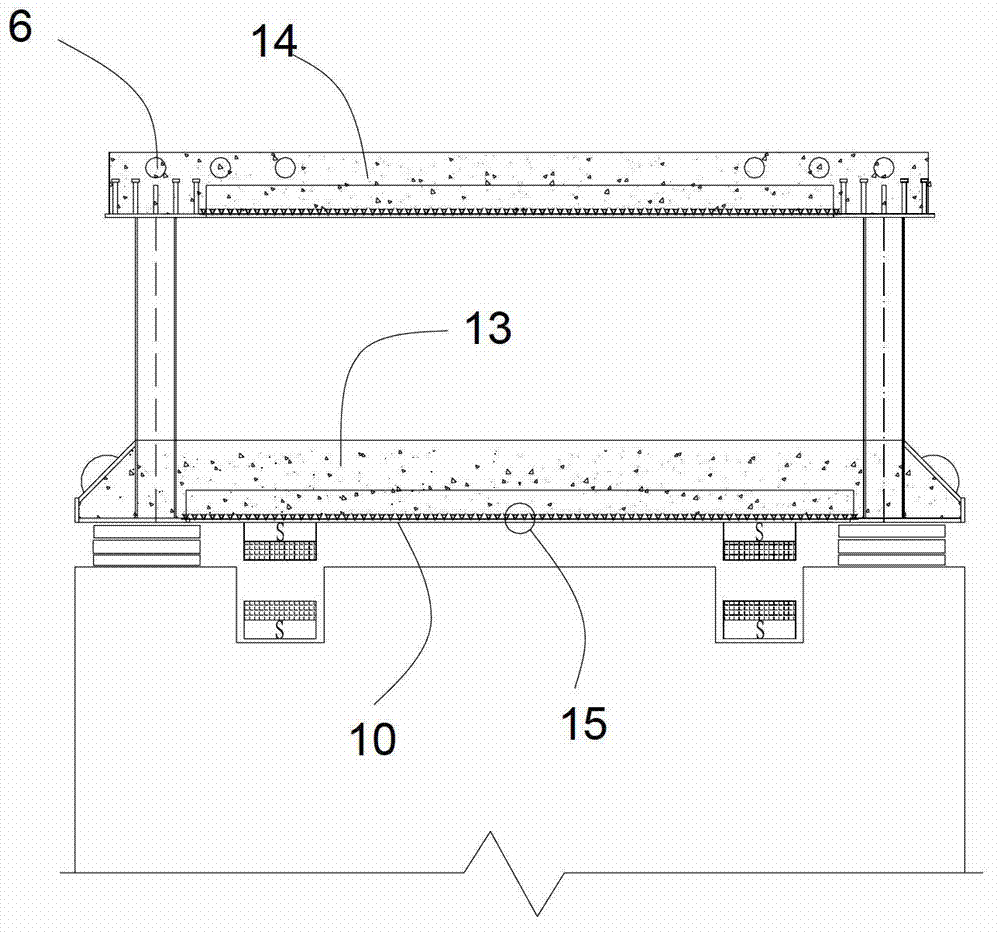

Half-through steel truss-concrete combined continuous steel bridge

ActiveCN104032668AAvoid tensile crackingReduce adverse effectsTruss-type bridgeBridge materialsMaterials scienceBending moment

The invention discloses a half-through steel truss-concrete combined continuous steel bridge. The steel bridge comprises a main truss beam which consists of steel truss beams, wherein an upper chord, a middle chord and a lower chord are respectively arranged on each steel truss beam; a steel box-concrete combined structure formed by concrete bridge road plates is formed between the middle chords. The concrete bridge road plate is arranged at the position of the middle chord, the upper chord of the main beam in the hogging moment section of the top of a continuous steel bridge pier is pulled, the lower chord is compressed, and the concrete bridge road plate is basically positioned in the compressed section; the middle chord of the main beam in the sagging moment section of the continuous steel bridge and the combined structure with the concrete bridge road plate are the specific compressed section, the lower chord is the specific pulled section, and the problem of the cracking caused by the pulling of the concrete bridge road plate; the upper structure of the bridge is constructed in an assembly manner, the construction period is shortened, each construction link and the quality are easy to control, the stressing of the bridge is clear, and the construction is safe and fast.

Owner:CHONGQING JIAOTONG UNIVERSITY

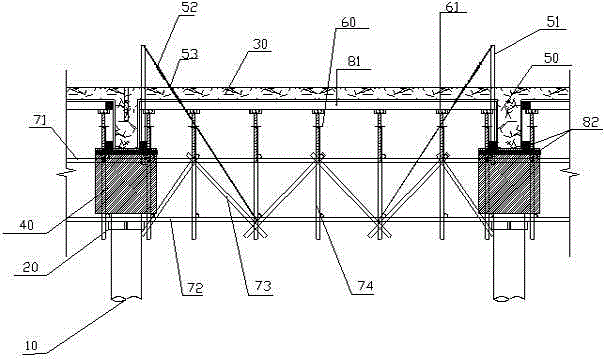

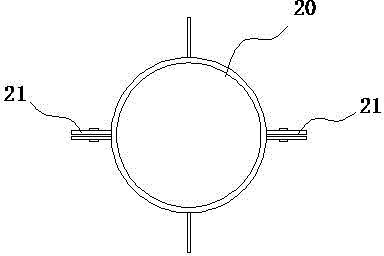

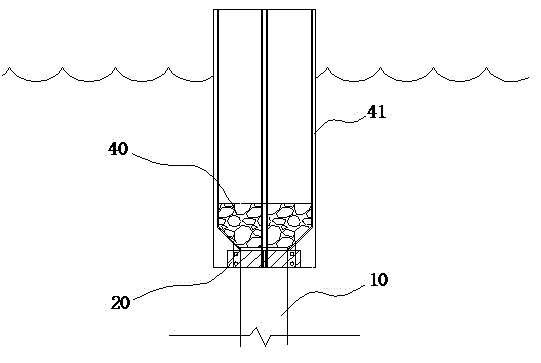

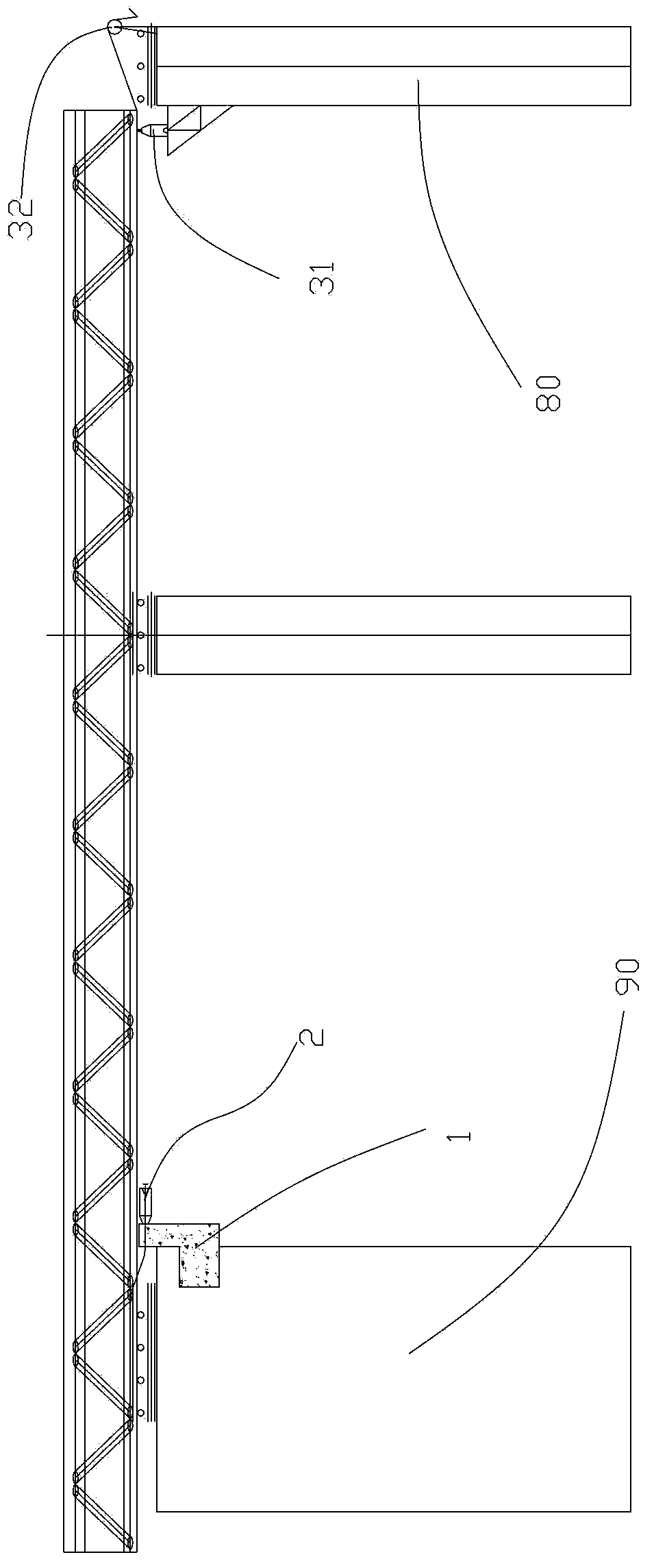

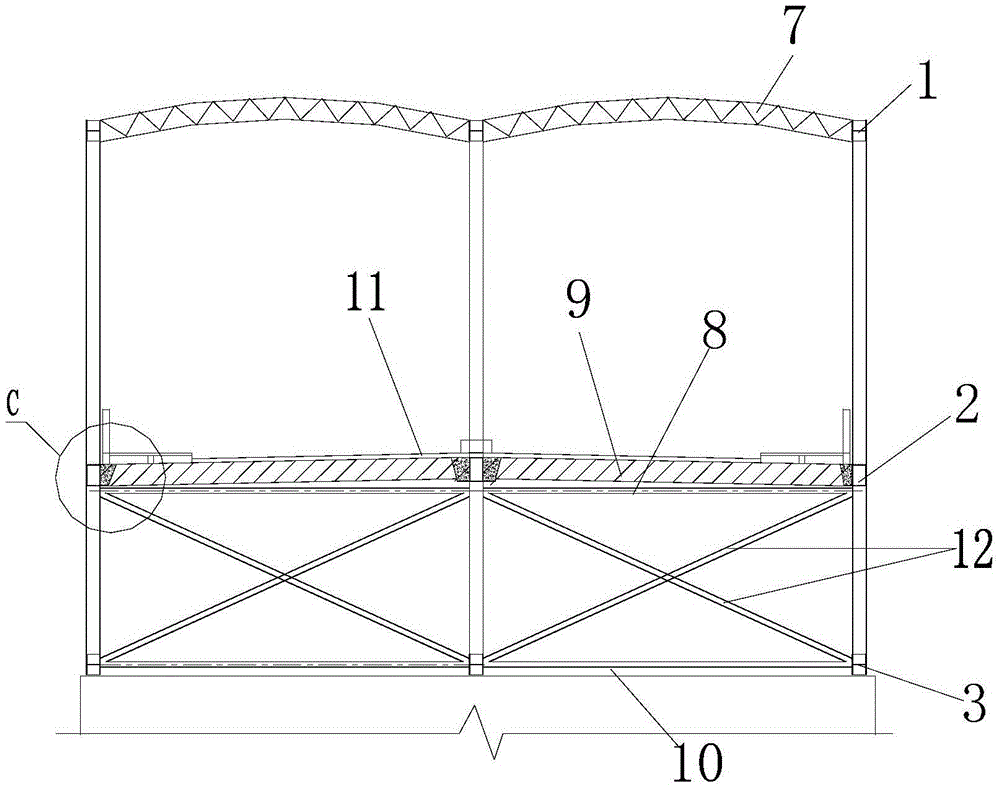

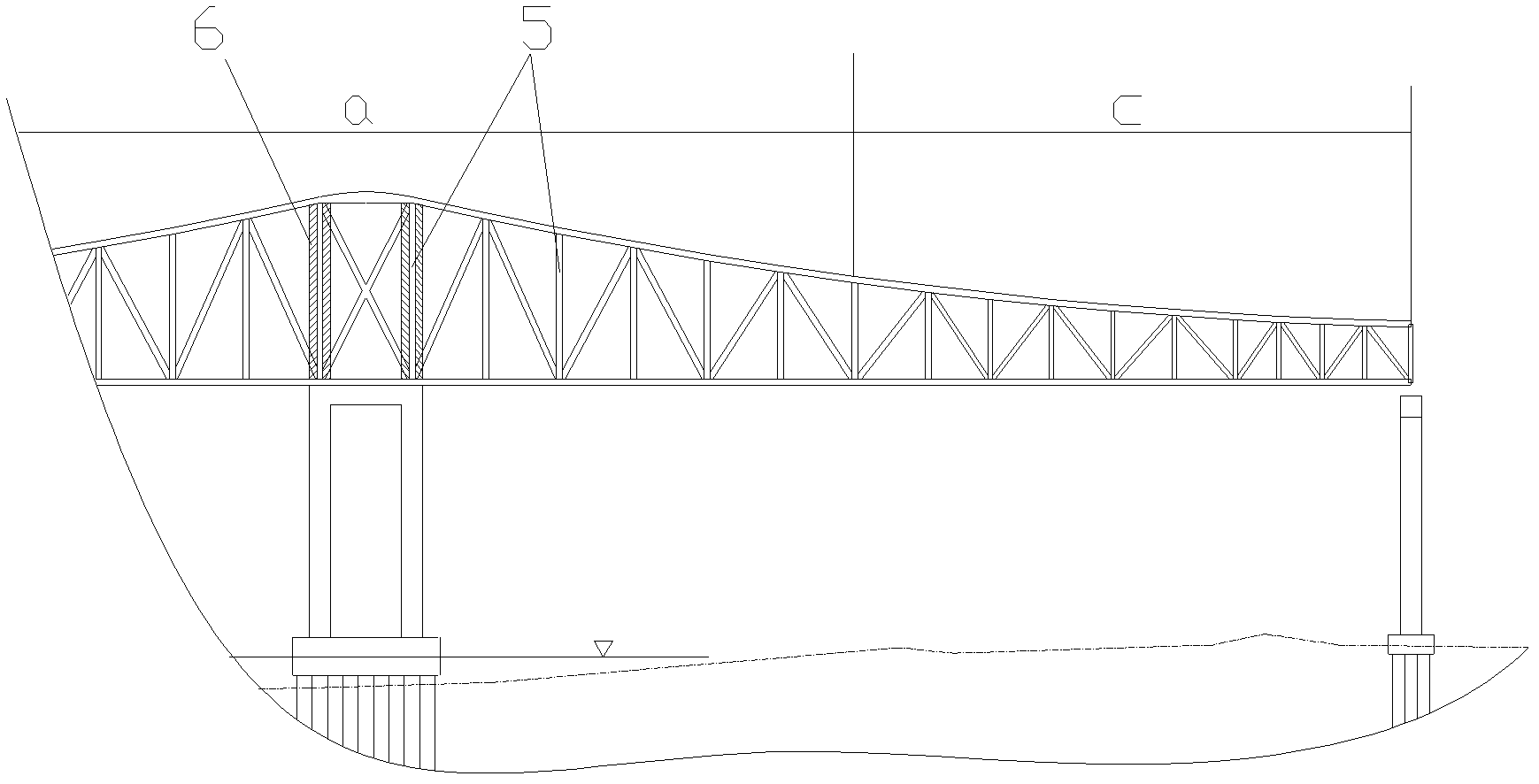

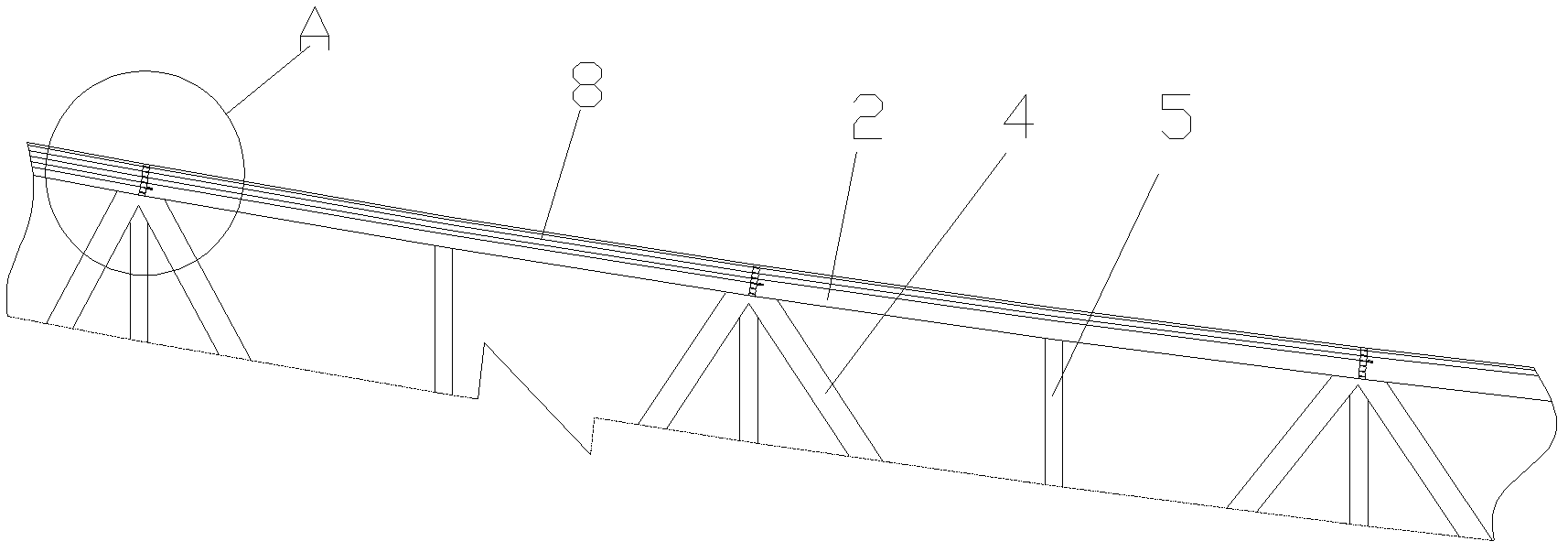

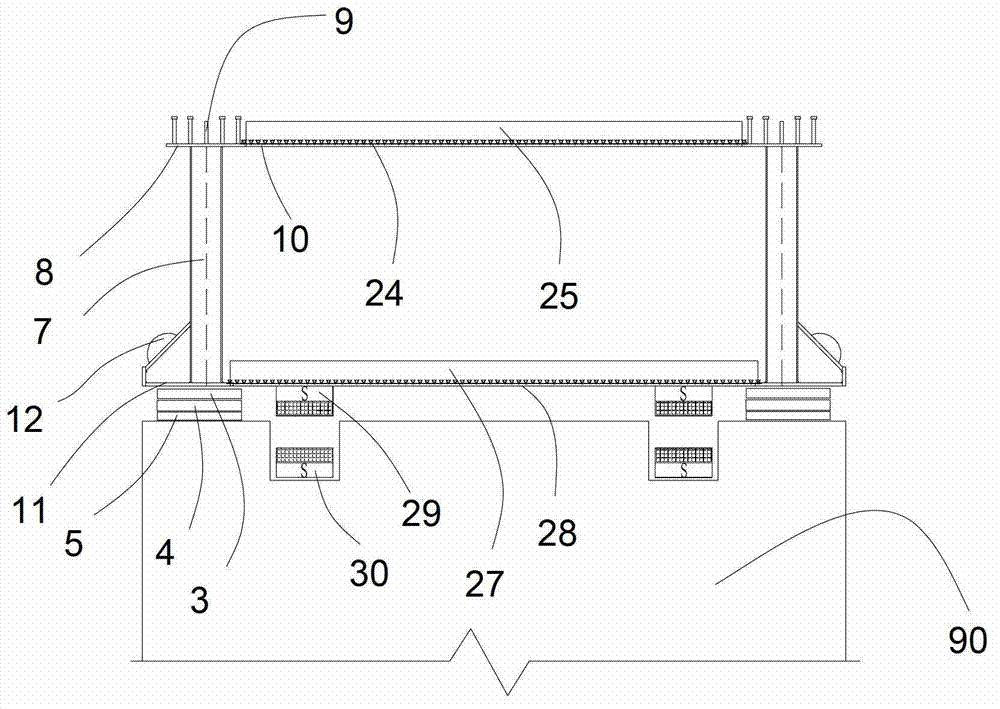

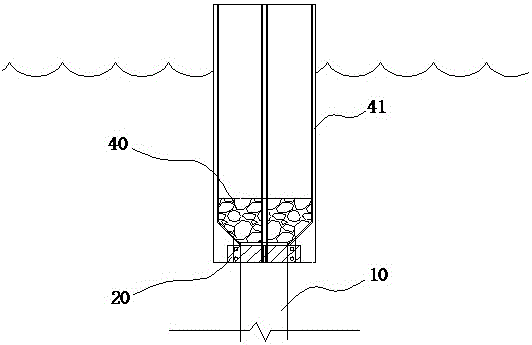

Space truss formwork supporting system and construction method thereof

ActiveCN104480922AImprove stabilityAdaptableArtificial islandsUnderwater structuresSupporting systemConcrete beams

The invention discloses a space truss formwork supporting system and a construction method thereof; the space truss formwork supporting system comprises a precast tubular pile arranged in the water, a steel hoop fixed on the precast tubular pile, a concrete bearing table formed at the top of each pile by casting and a steel tube stand column, a diagonal draw bar used for connecting the stand column and a truss chord member node, a space truss composed of the steel tube and fastener embedded in the bearing table; a jacking is mounted on the stand column of the space truss, the wood brace is arranged on the jacking, a template is mounted on the wood brace for binding the reinforcing steel bar and casting the concrete beam slab. The space truss formwork supporting system takes the precast tubular pile as the fulcrum in the limit situation of the topographic condition, the non-floor type space truss formwork supporting system is used for the construction of the beam and slab reinforcing steel bar and concrete, the conventional vertical support system is changed into the space horizontal support system; the computer analog technology is adopted and the space truss is made of the steel tube and used as the bearing support system of the cast-in-place beam and slab, the structure safe construction is guaranteed and the construction is quick and safe.

Owner:GUANGZHOU HENGSHENG CONSTR ENG

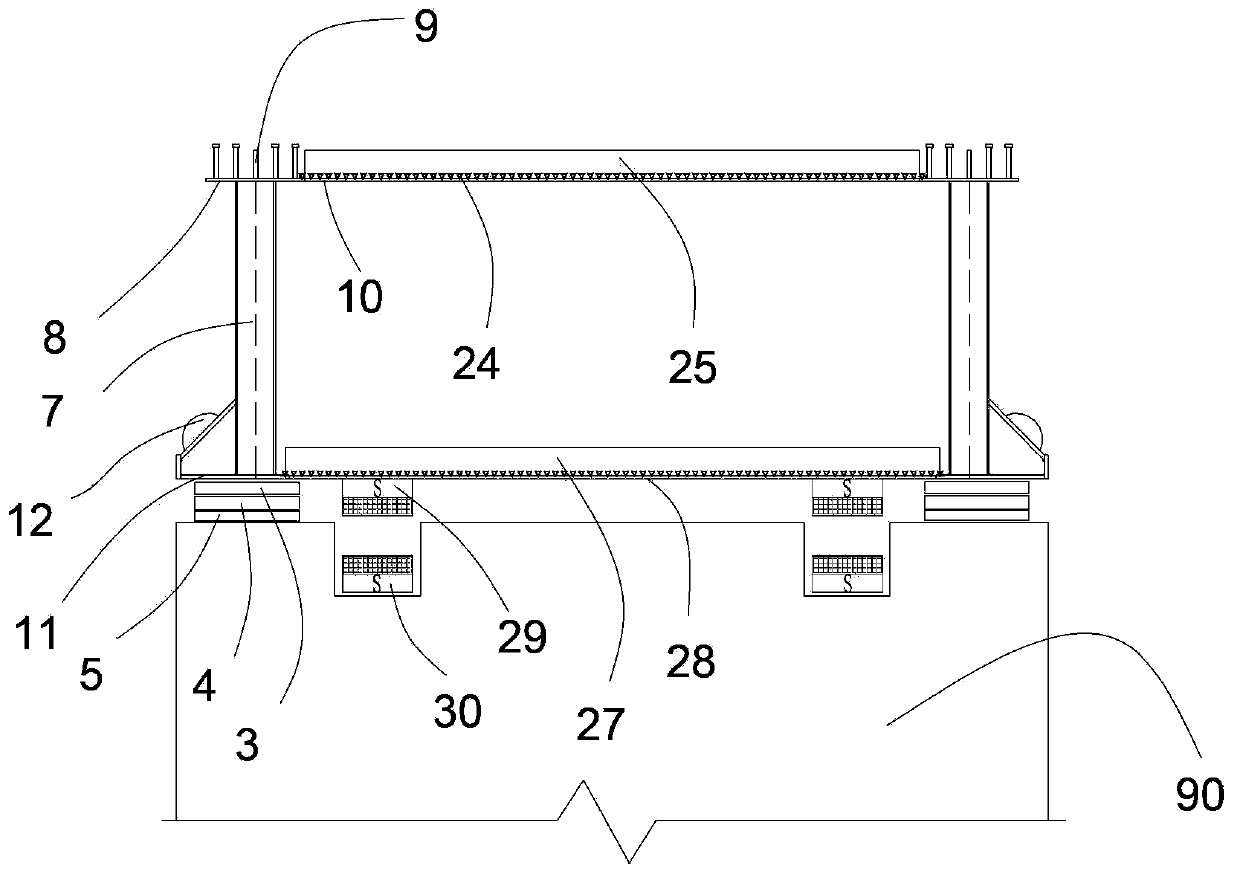

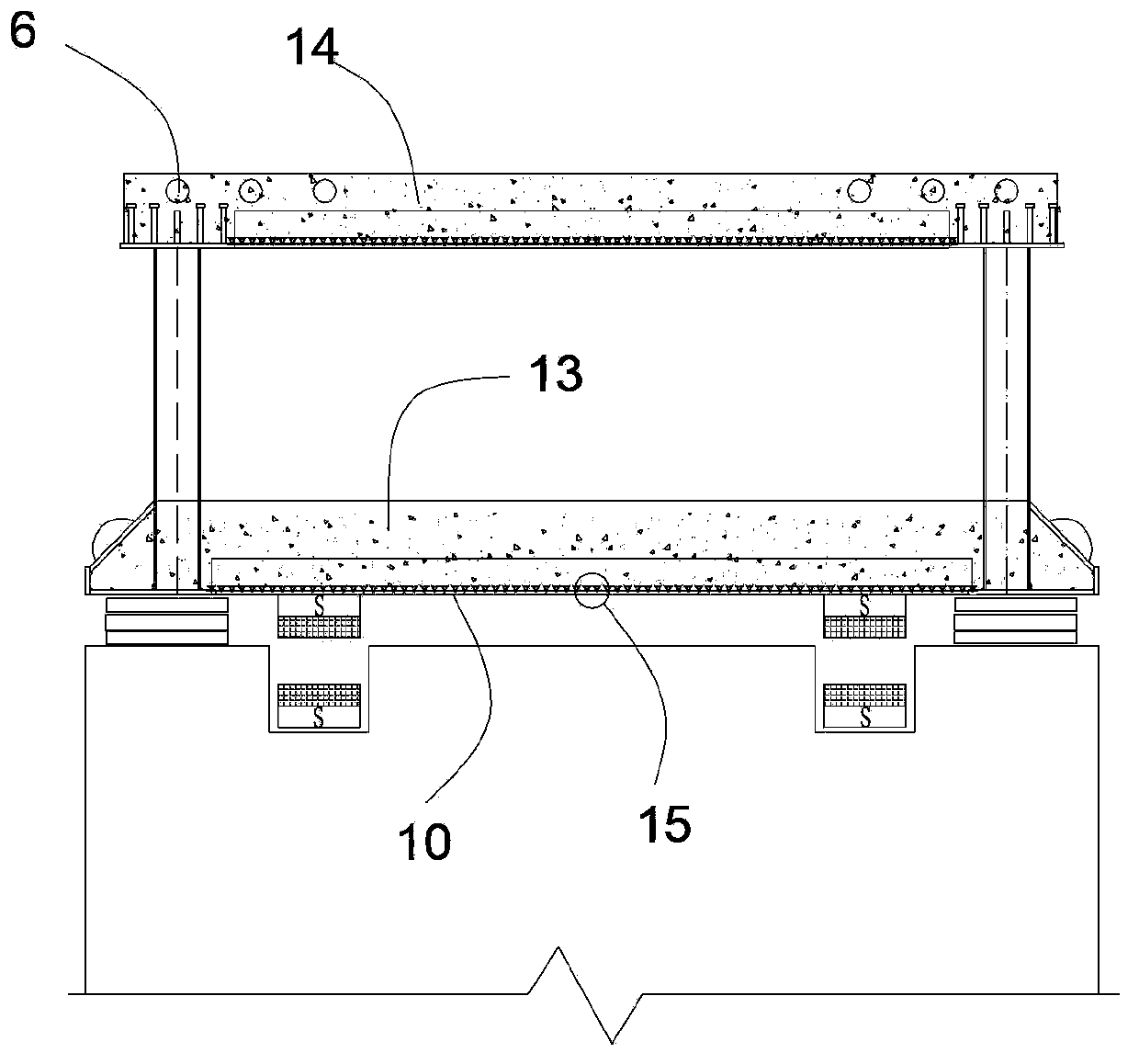

Bridge magnetic levitation pushing system and two-stage cantilever manufacturing method

A bridge magnetic levitation pushing system comprises a magnetic levitation pushing main beam hollow box-shaped structure and a magnetic levitation pushing platform. The magnetic levitation pushing platform comprises a pushing platform base, two bottom surface steel plates, two electromagnets, two Teflon sliding plates and a plurality of steel tube concrete rollers. The magnetic levitation pushing main beam hollow box-shaped structure comprises a steel truss abdomen bridge framework and two permanent magnets. According to the bridge magnetic levitation pushing system, by means of the repulsive force of a magnetic field, the magnetic levitation pushing main beam hollow box-shaped structure is pushed so that friction force and resistance in pushing-pulling traction can be reduced and continuous pushing operations can be carried out, pushing is needless to be interrupted, the construction progress is quick, construction is safe and efficient, construction cost is reduced, noise is low in pushing, fuel is needles, environment is protected, energy is saved, and operations are simple. The invention further relates to a two-stage cantilever manufacturing method.

Owner:桥博建筑科技(东莞)有限公司 +1

Existing old small bridge and culvert corrugated steel reinforcing construction method

InactiveCN111676836ASolve the disease problemReliable factory production materialsBridge erection/assemblyBridge strengtheningDiseaseSolid wall

The invention discloses an existing old small bridge and culvert corrugated steel reinforcing construction method. The method comprises the steps: S1, carrying out on-site survey setting-out; S2, carrying out corrugated steel component manufacturing and entry inspection; S3, excavating the foundation of the old small bridge; S4, constructing a solid wall type abutment on the foundation;S5, pre-burying channel steel connecting pieces on the top surface of the foundation or the abutment;S6, carrying out corrugated steel plate piece assembling and arch installation; S7, carrying out anticorrosivecoating on the inner side of the corrugated steel plate on site; and S8, filling the space between the corrugated steel plate arch and the original bridge with concrete. The method has the advantagesof being safe and rapid in construction, short in construction period, environmentally friendly in construction, low in construction cost, remarkable in benefit, capable of effectively solving the problem that diseases are gradually generated in the using process of existing old small bridges and culverts and the like.

Owner:青海路拓工程设施制造集团有限公司

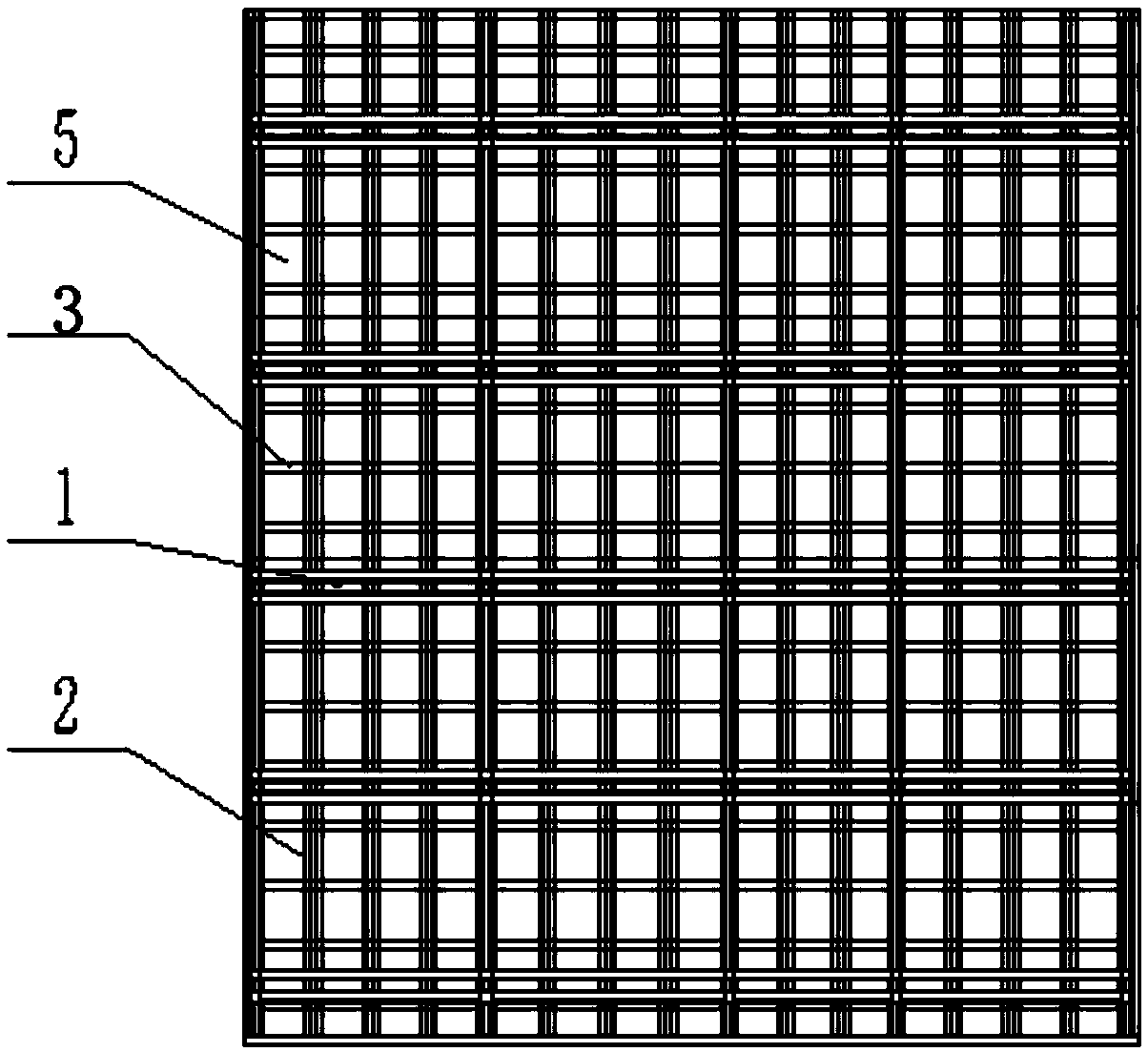

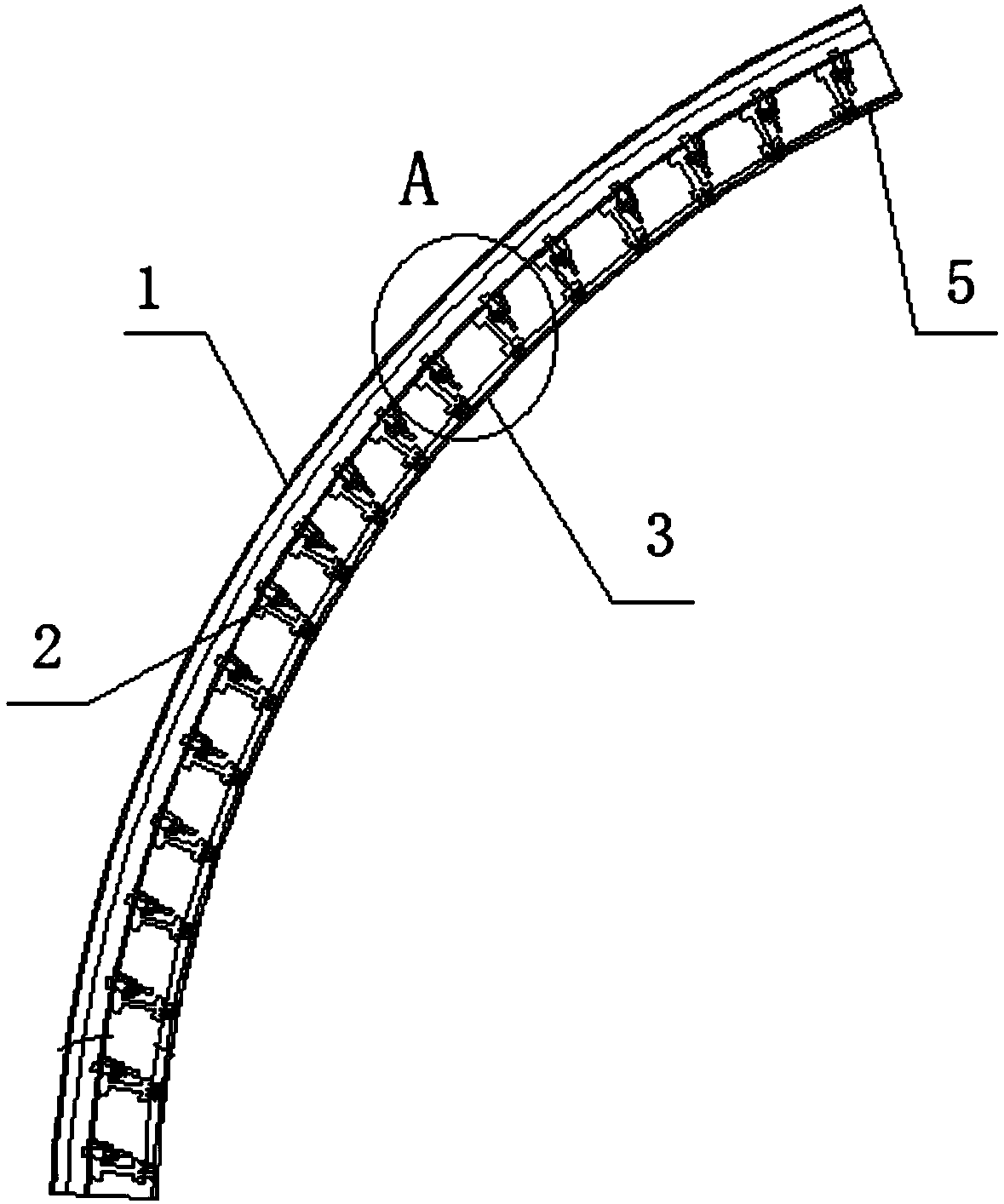

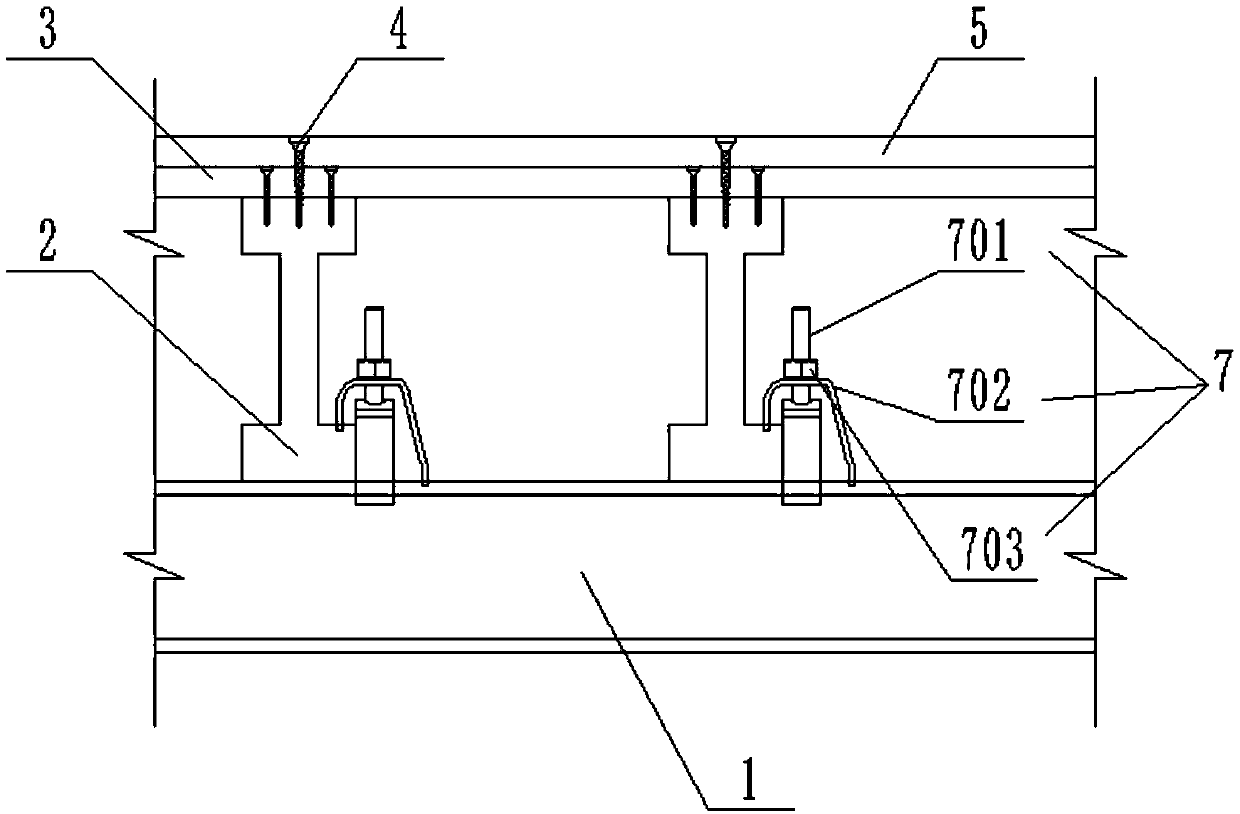

Arc-shaped backing plate used for adjusting curved formwork and mounting process thereof

PendingCN109518606AReduce investmentSafe and fast constructionBridge erection/assemblyCushioningHigh turnover

The invention discloses an arc-shaped backing plate used for adjusting a curved formwork, which comprises a plurality of annular steel back arrises, a plurality of connecting beams, a plurality of annular cushioning battens and a wooden formwork panel, wherein the annular steel back arrises are arranged at intervals to form a cylindrical structure; the connecting beams are mounted on the inner wall of the cylindrical structure formed by the annular steel back arrises at intervals and vertically connected to the annular steel back arrises; the annular cushioning battens are mounted on the innerwall of the cylindrical structure formed by the annular steel back arrises at intervals and perpendicular to the connecting beams; and the wooden formwork panel is annularly mounted on the inner wallof a cylindrical structure formed by the annular cushioning battens. The purpose of adjusting the radian of the wooden formwork panel is achieved by adjusting the thickness of different annular cushioning battens. The arc-shaped backing plate disclosed by the invention can be used for adjusting the radian of the curved formwork, and has the advantages of less input, quick and safe construction, high turnover utilization rate and strong adaptability.

Owner:CHINA COMM 2ND NAVIGATIONAL BUREAU 2ND ENG +1

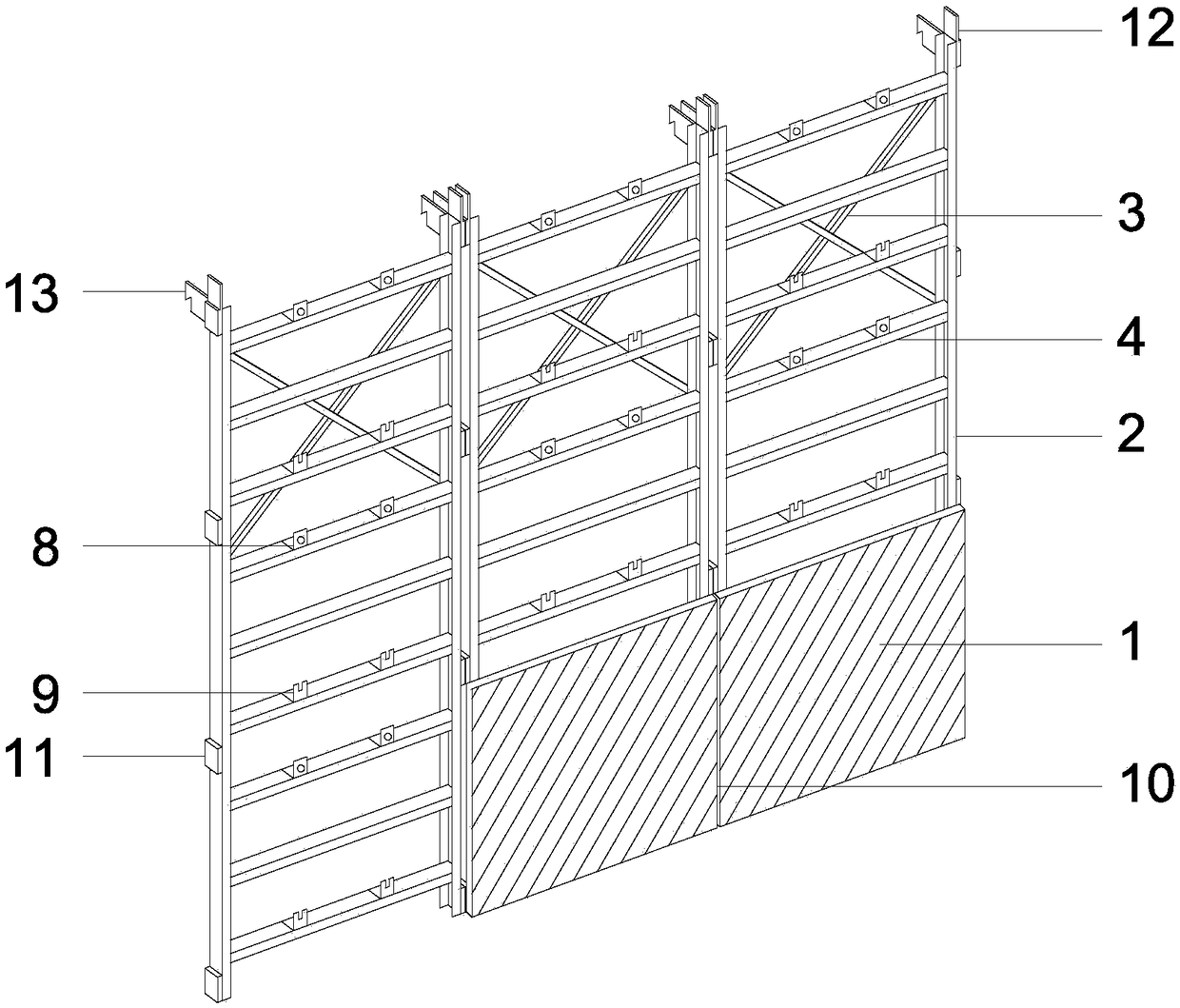

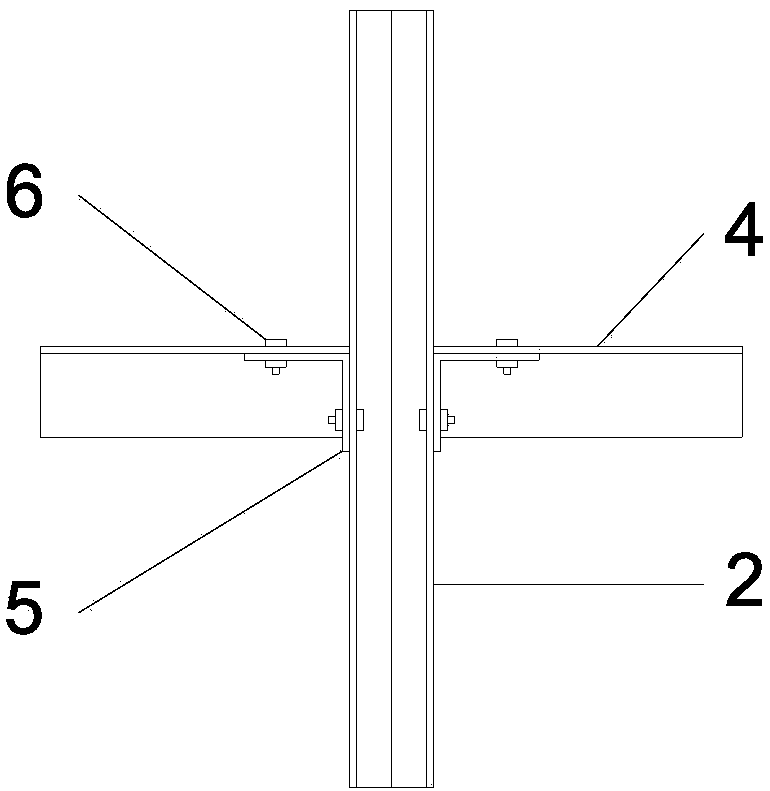

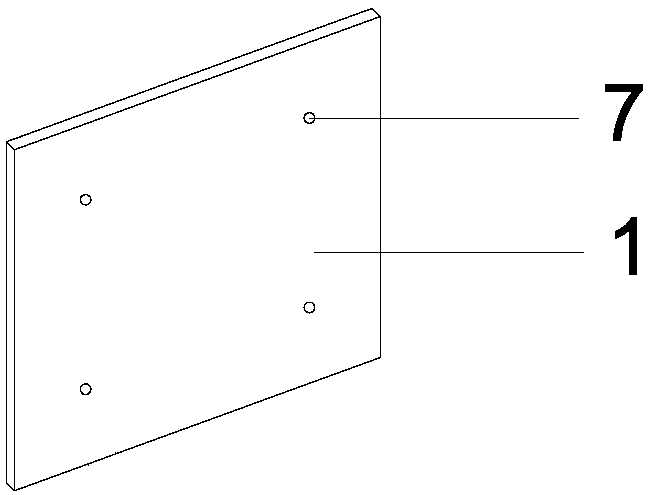

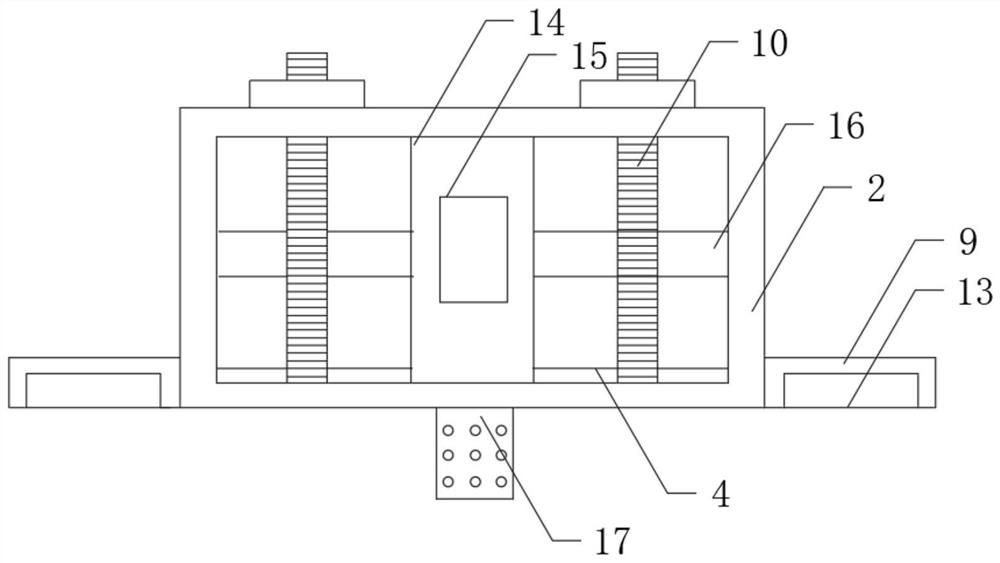

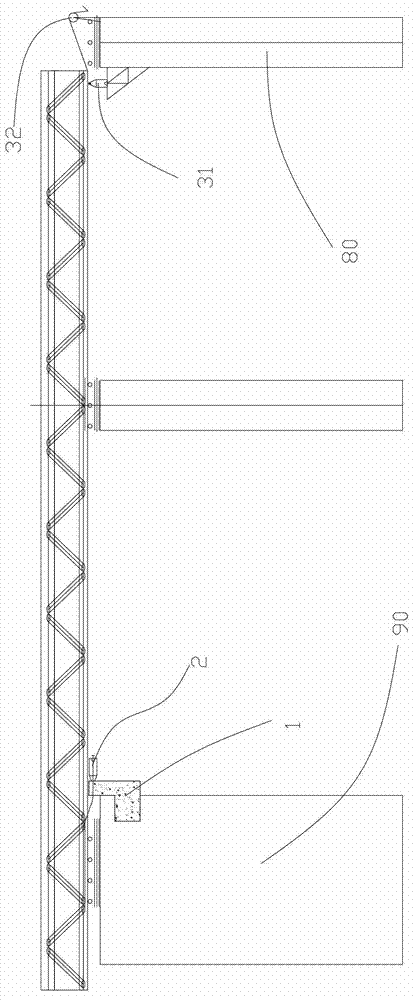

Bedding face stone or artificial board curtain wall structure and method

The invention discloses a bedding face stone or artificial board curtain wall structure and method. The bedding face stone or artificial board curtain wall structure and method solves the problem thatin the prior art, a curtain wall structure needs to be cut on-site and welded and assembled on-site, and has the beneficial effects that factory production is realized, prefabrication or assembly onsite can be realized, the dependence on skilled workers is reduced and the quality of assembly is ensured. According to the scheme, the bedding face stone or artificial board curtain wall structure comprises at least one set of curtain wall unit, and the curtain wall units each comprises at least two stand columns. A plurality of cross beams are connected between every two adjacent stand columns by bolts, and the cross beams are arranged in parallel with each other. The cross beams are provided with connecting pieces, and the bolts pass through the connecting pieces to be connected with the back side of a stone or an artificial board. Structural hanging pieces for hanging and connecting the curtain wall units to building wall embedded parts are arranged on the inner sides of the tops of the stand columns.

Owner:济南历下控股集团有限公司

Intermediate steel truss-concrete composite continuous steel bridge

ActiveCN104032668BAvoid tensile crackingReduce adverse effectsTruss-type bridgeBridge materialsMaterials scienceConcrete composites

The invention discloses a half-through steel truss-concrete combined continuous steel bridge. The steel bridge comprises a main truss beam which consists of steel truss beams, wherein an upper chord, a middle chord and a lower chord are respectively arranged on each steel truss beam; a steel box-concrete combined structure formed by concrete bridge road plates is formed between the middle chords. The concrete bridge road plate is arranged at the position of the middle chord, the upper chord of the main beam in the hogging moment section of the top of a continuous steel bridge pier is pulled, the lower chord is compressed, and the concrete bridge road plate is basically positioned in the compressed section; the middle chord of the main beam in the sagging moment section of the continuous steel bridge and the combined structure with the concrete bridge road plate are the specific compressed section, the lower chord is the specific pulled section, and the problem of the cracking caused by the pulling of the concrete bridge road plate; the upper structure of the bridge is constructed in an assembly manner, the construction period is shortened, each construction link and the quality are easy to control, the stressing of the bridge is clear, and the construction is safe and fast.

Owner:CHONGQING JIAOTONG UNIVERSITY

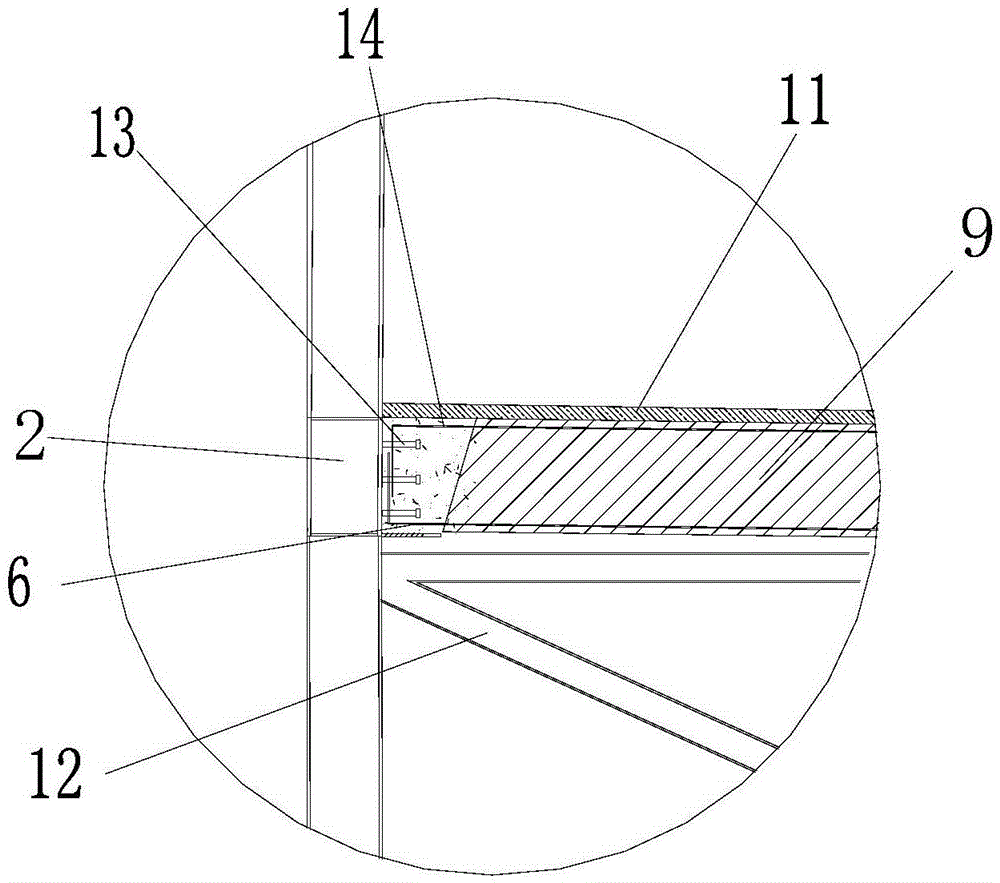

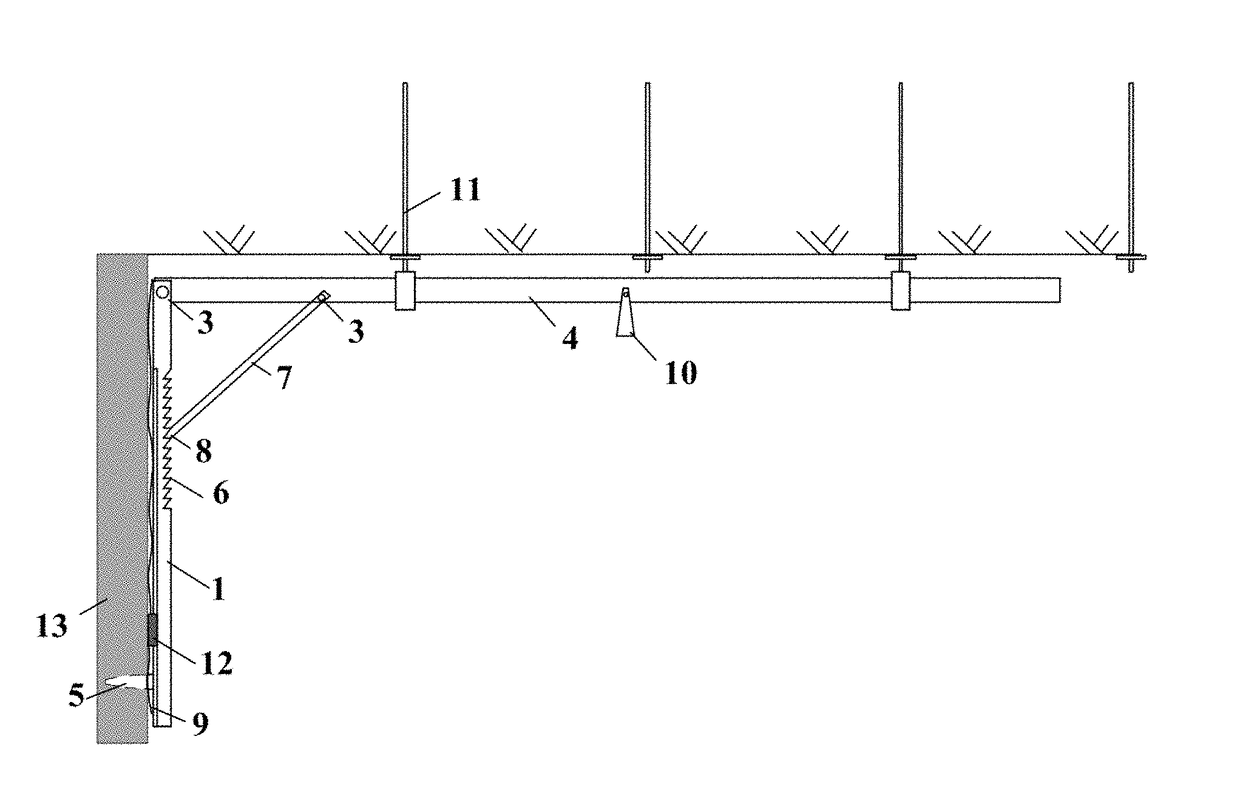

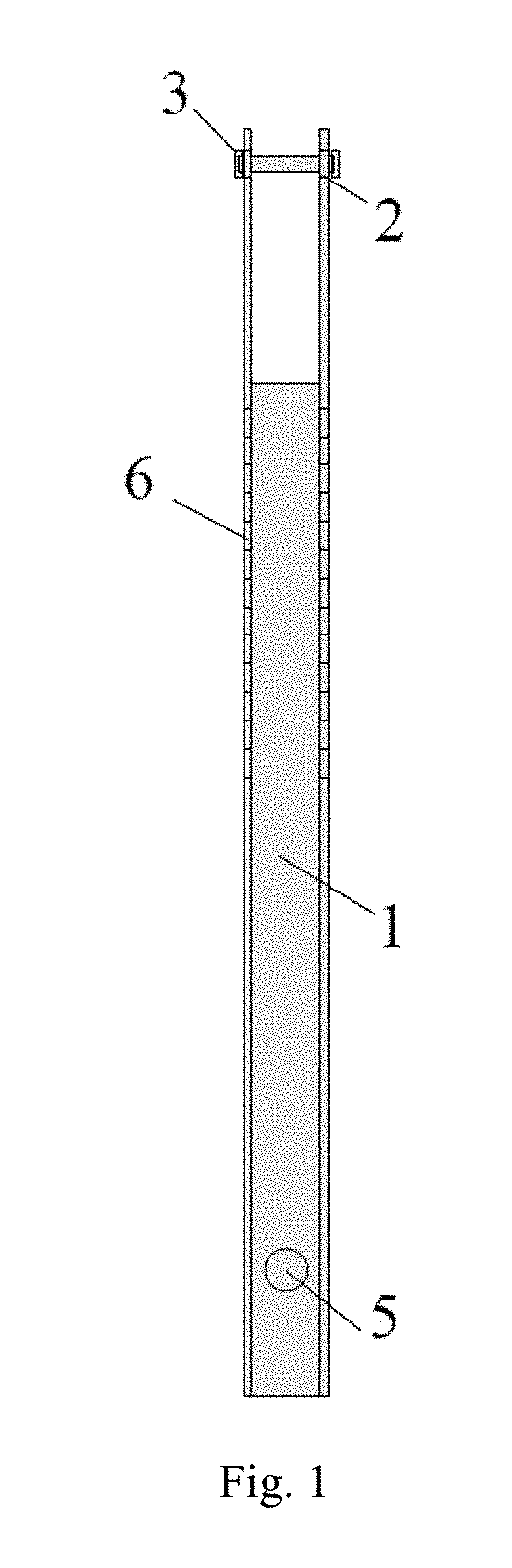

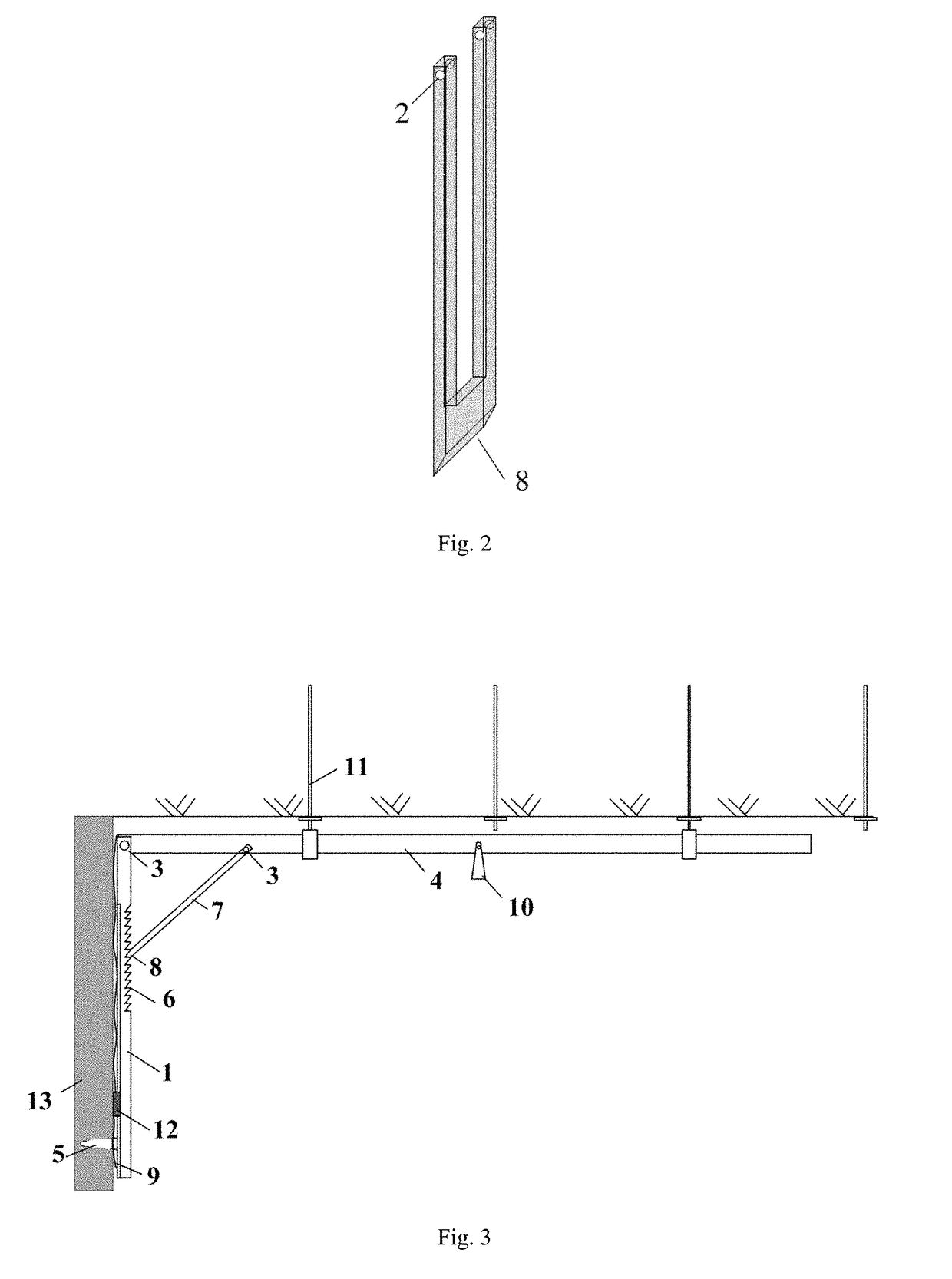

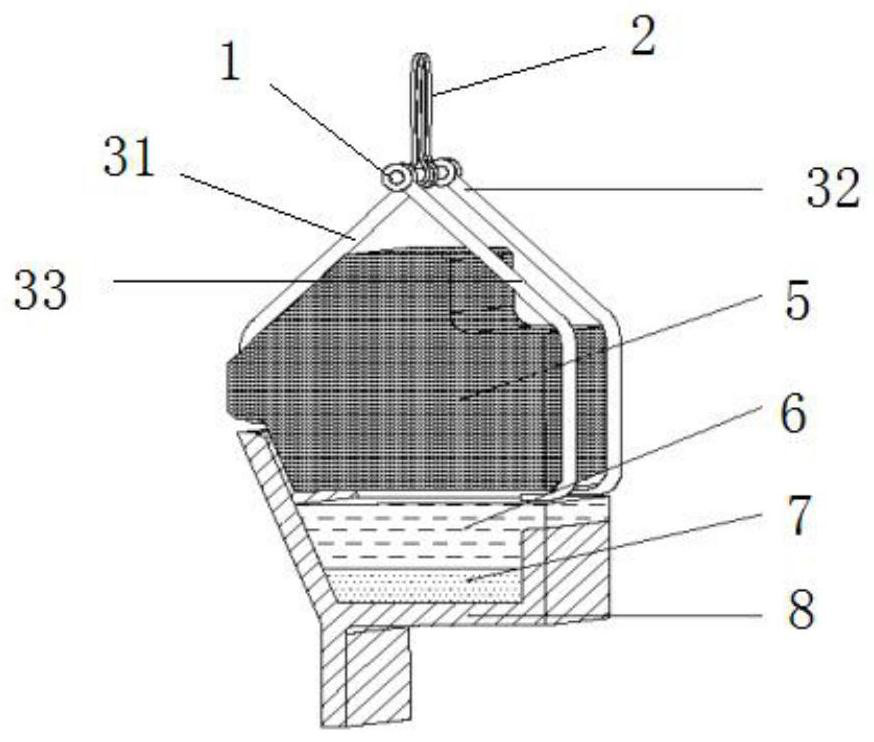

Anti-spalling blocking bar for large cross-section coal gallery excavation work surface and supporting method

InactiveUS20180195389A1Increase the bearing areaEnsure stabilityTunnel liningProps/chocksSafety indexReusability

Disclosed are an anti-spalling blocking bar for a large cross-section coal gallery excavation work surface and a supporting method. The anti-spalling blocking bar comprises a blocking bar (1) and a support bar (7). Both a top portion of the blocking bar and an end of the support bar are provided with screw holes (2). A steel peg (5) is provided on an outer side of a bottom portion of the blocking bar. Locking teeth (6) is provided on an inner side of a mid-upper portion of the blocking bar, and a locking catch (8) is provided on one end of the support bar. The blocking bar and support bar are secured, using the screw hole and a screw bolt, to a temporary support device. After removing coal, a tool is used to hammer the blocking bar so as to wedge the steel peg thereof into a coalface (13). The locking catch of the support bar is held within the locking teeth to support a coal heading. After use, the blocking bar and support bar can be retrieved and suspended, using a hanging device, from the temporary support device. The anti-spalling blocking bar offers the advantages of easy installation, good support, reusability, convenient storage, and the like. The invention reduces the probability of personnel injury caused by coal loosening and falling from the heading, shortens the time for establishing coal heading support, and enhances a safety index and an excavation speed of a large cross-section coal gallery excavation work surface.

Owner:CHINA UNIV OF MINING & TECH

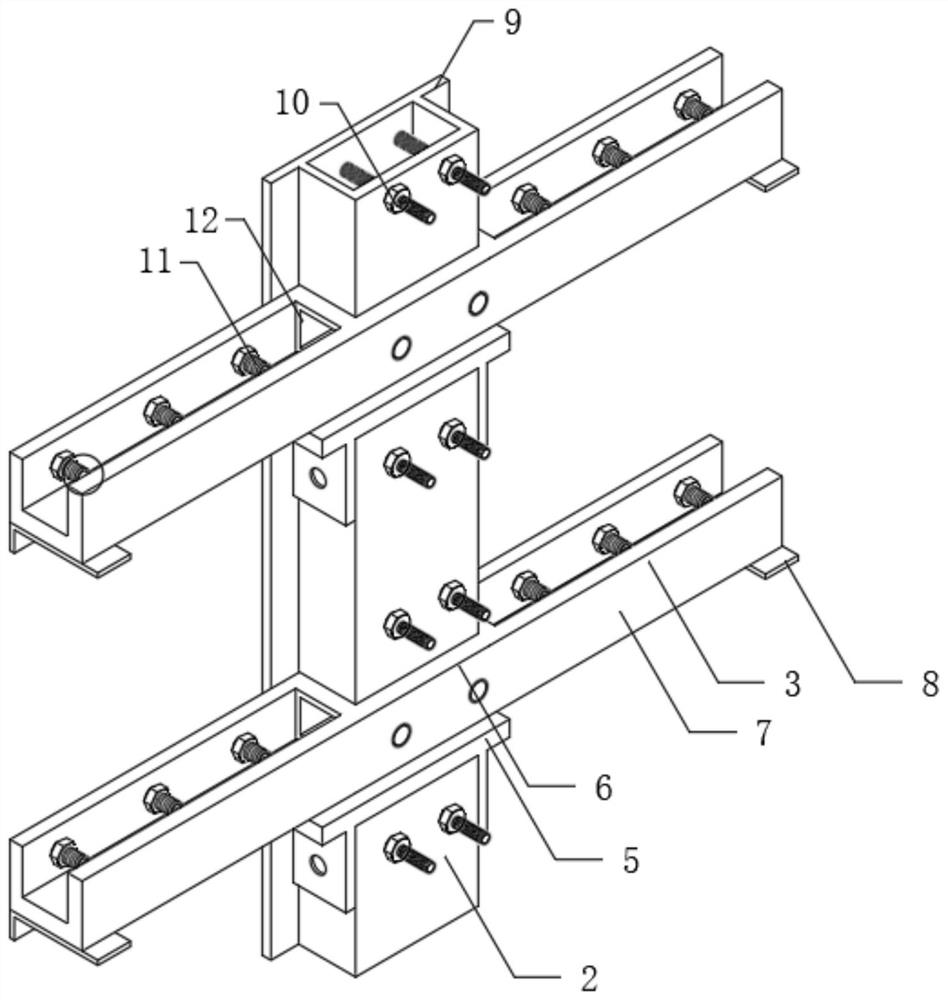

Fabricated type curtain wall decorative column structure and method

The invention discloses a fabricated type curtain wall decorative column structure and method which solves the problem in the prior art that the decorative column needs to be mounted in a welded modeby a scaffold on the spot and has the beneficial effects that factory-like production can be achieved, assembly can be carried out in a factory, and dependence on skilled workers is reduced. Accordingto the technical scheme, the fabricated type curtain wall decorative column structure comprises a plurality of vertical stand columns forming a rectangular column body. Beams are arranged between every two stand columns in the rectangular column body to connect the columns. A wall baffle panel is fixed on one side of the rectangular column body. Decoration boards are fixed on the sides without the wall baffle panel of the rectangular column body. Structural hanging pieces for enabling the rectangular column body to be hanged to the curtain wall structure pre-embedded parts are arranged in theinner side of the wall baffle panel. Bolted connections are correspondingly carried out between the beams and the stand columns, the wall baffle panel and the stand columns, the decoration boards andthe stand columns or the beams.

Owner:济南历下控股集团有限公司

Construction method utilizing steel-strand strand pulling machine to perform fast strand pulling during construction of prestress structures

InactiveCN102383377BAvoid wastingReduce investmentBridge erection/assemblyBuilding material handlingPre stressArchitectural engineering

The invention discloses a construction method utilizing a steel-strand strand pulling machine to perform fast strand pulling during construction of prestress structures, which belongs to the technical field of building construction. The steel-strand strand pulling machine is provided with two pairs of pressing wheels capable of clamping steel strands to advance or retreat are arranged at intervals. The steps are that fixing the steel-strand strand pulling machine on a movable strand pulling platform through a pull piece in suspension mode, cleaning mortar on a mortar filling port of an anchorbacking plate on an opening of a prestress hole passage, then connecting the steel-strand strand pulling machine with the prestress hole passage to be strand-pulled, further utilizing the steel-strand strand pulling machine to enable the steel strands to be strand-pulled according to numbers till the steel strands reach predetermined positions, utilizing a cutting device to cut off the steel strands, and accordingly the strand pulling work of one steel strand is completed. Repeating the steps till the strand pulling work of all the steel strands of the prestress hole passage is completed, andthe steel strands are automatically bundled according to stacking mode after cut from bottom to top. The construction method utilizing the steel-strand strand pulling machine to perform fast strand pulling during construction of prestress structures integrates fast blanking, fast bundling and fast stand-pulling into a whole, thereby being convenient to operate and fast and efficient in strand-pulling construction.

Owner:RAILWAY NO 10 ENG GRP CO LTD

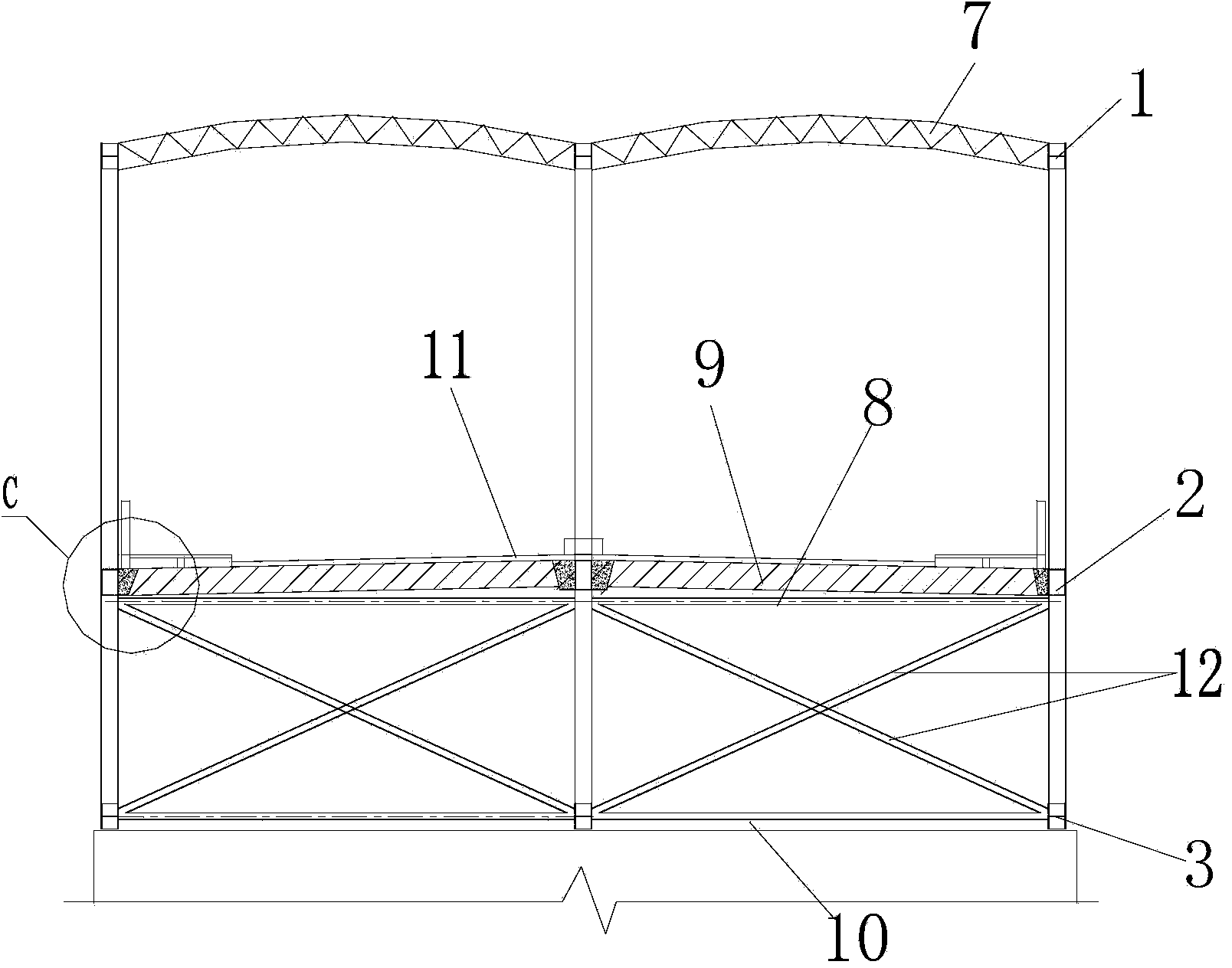

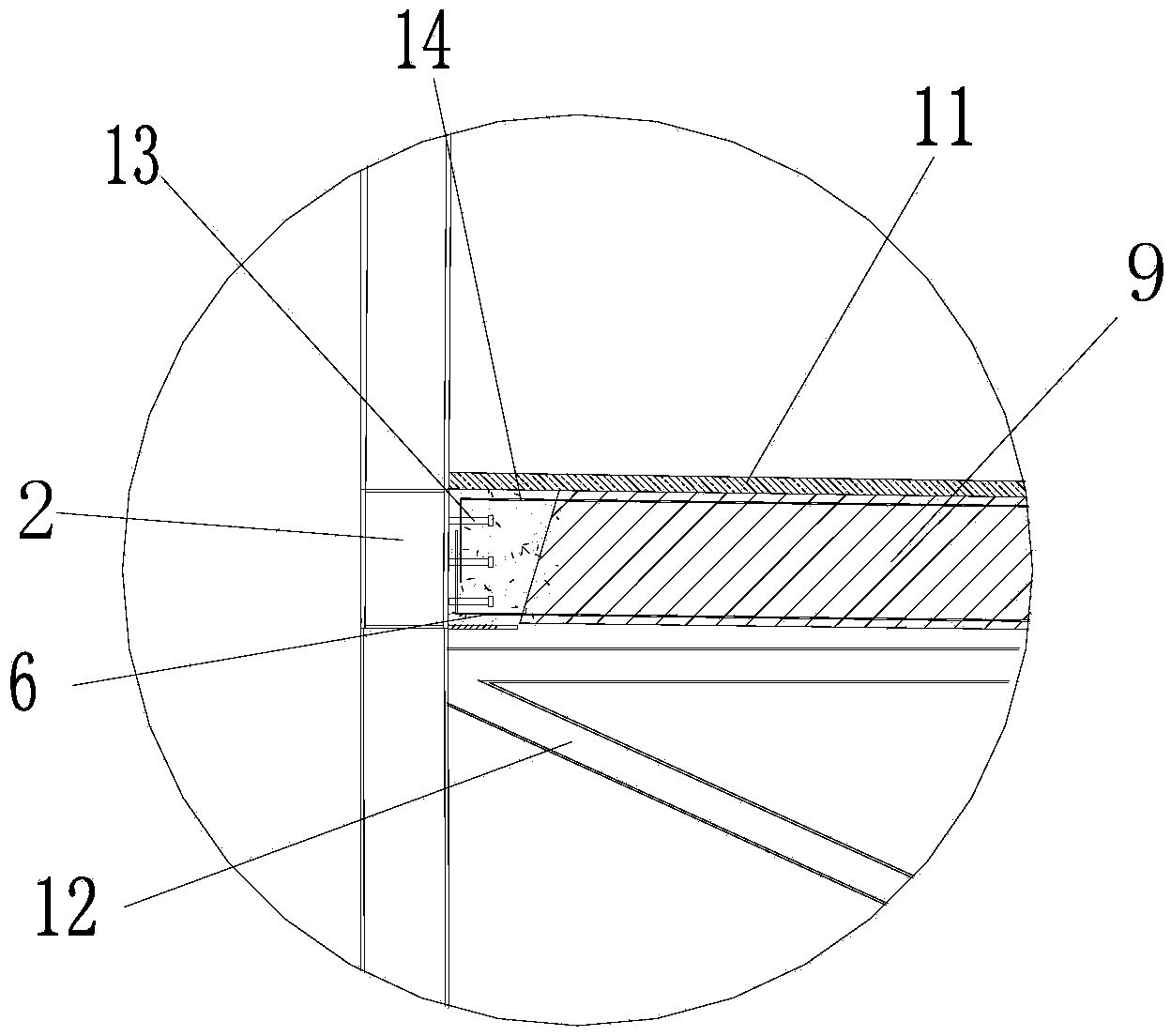

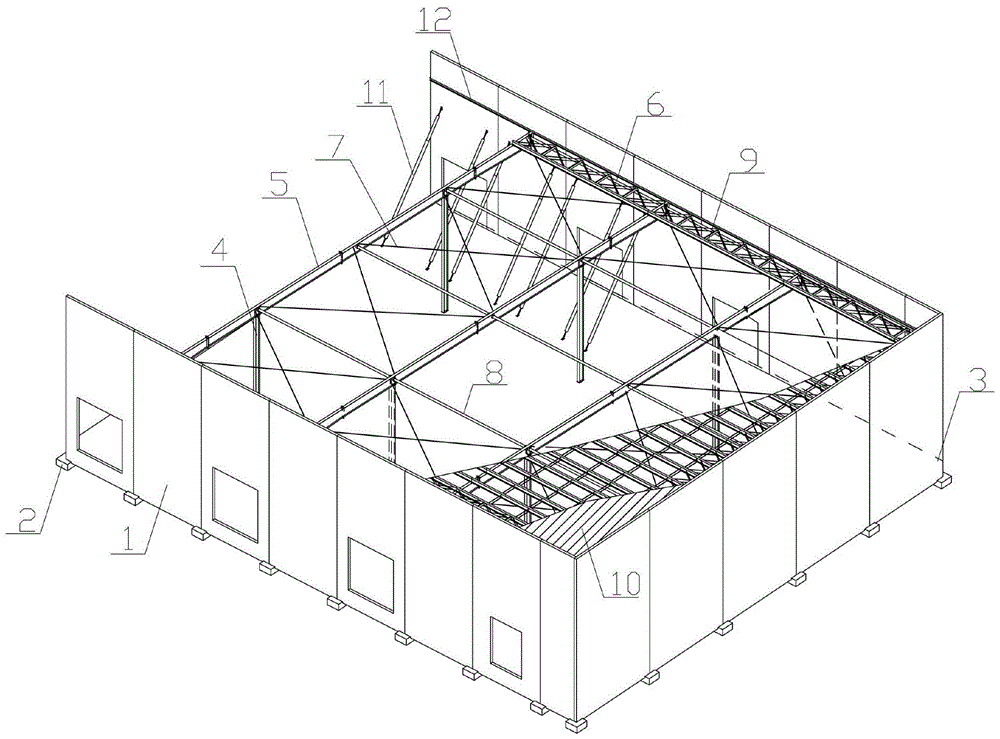

Lifting type building and its construction method

ActiveCN104213632BBeautiful and durableSafe and fast constructionBuilding roofsWallsAerodromeArchitectural engineering

The present invention provides a lifting type building, which includes a floor, a wall, and a metal roof panel; it is characterized in that the wall is directly fixed on the floor, and the floor under the wall is evenly arranged with A number of foundations under the wall; several rows of central columns are evenly arranged on the floor inside the wall, continuous section steel is arranged on the inner surface of the wall, steel roof trusses are fixedly installed on the central columns, and the steel roof trusses The ends are respectively fixedly connected on the continuous section steel; the lifting type building and its construction method method of the present invention use the roof wall connection support instead of the skin to transmit the shear force, so that the design method is more in line with the domestic norms; the lifting wall is It is an enclosure component and also the main load-bearing and force-transmitting component. It is prefabricated on the poured indoor floor (including the decorative structure), installed and positioned by a crane, and supported by temporary supports at the same time; the exterior facade is beautiful and durable, and the construction is more efficient. Safe and fast.

Owner:SHANGHAI OPEN STEEL JOIST

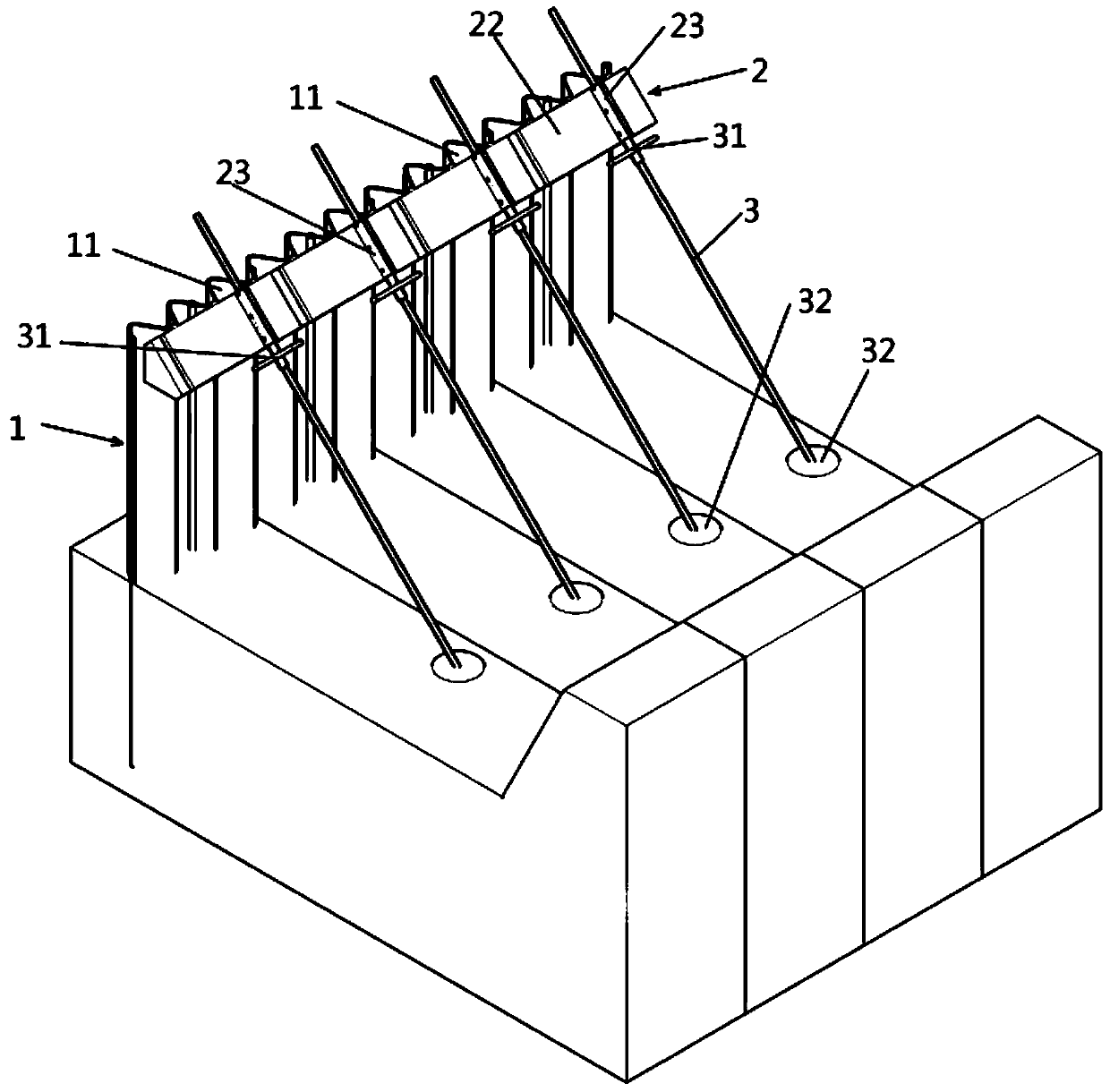

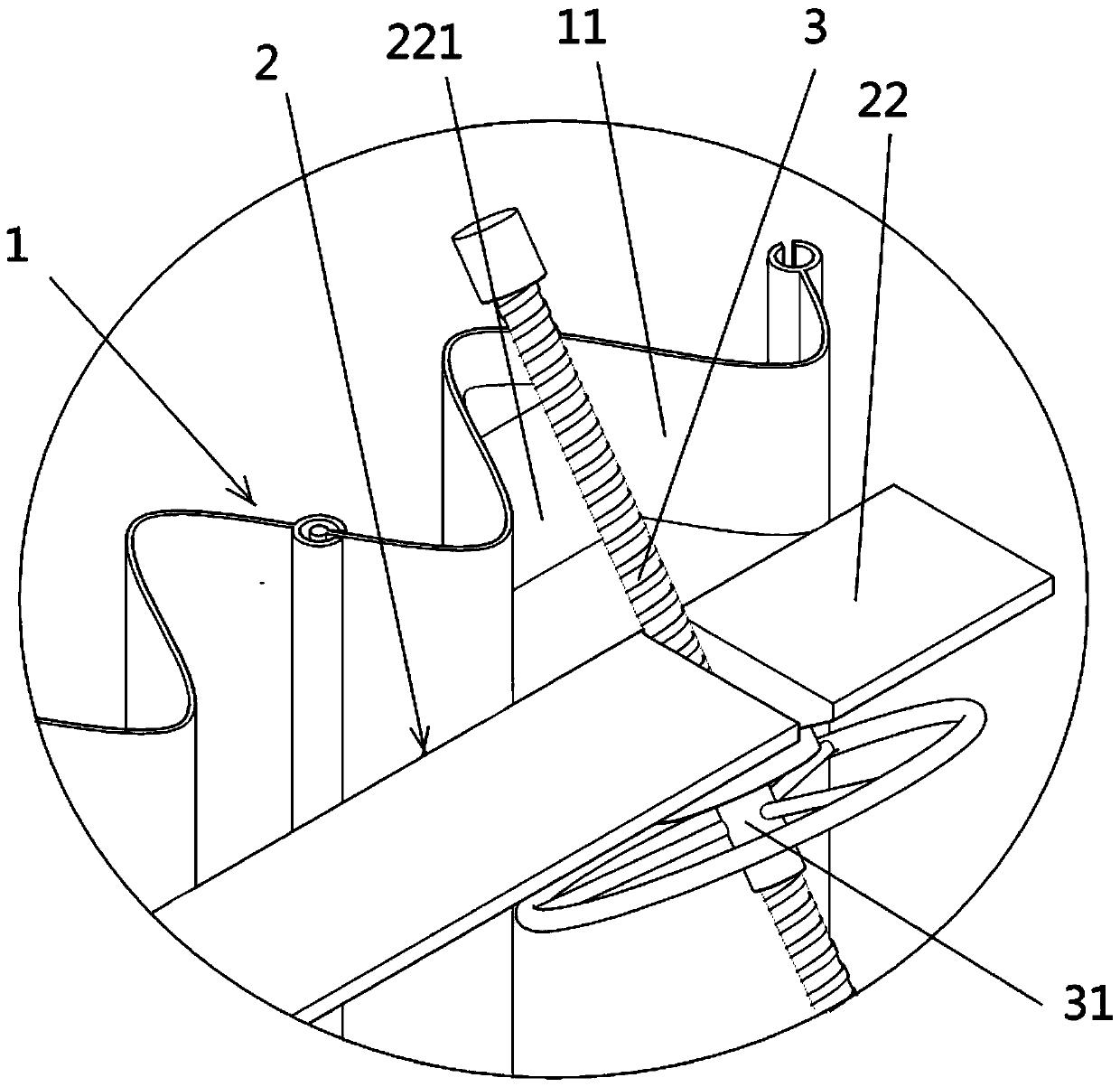

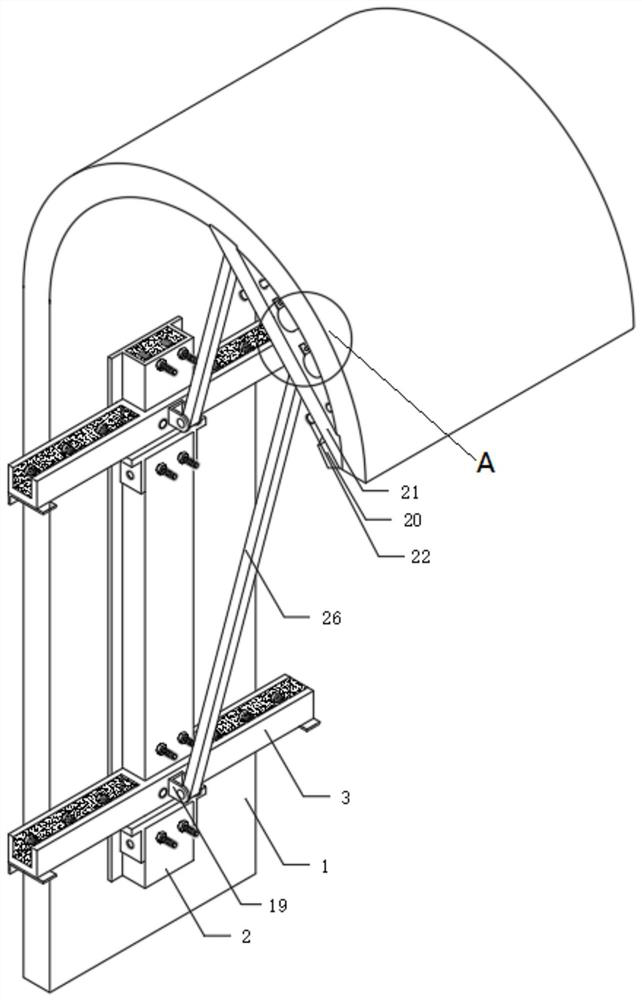

Construction method of inclined throwing support protector and inclined throwing support protector

The invention discloses a construction method of an inclined throwing support protector and the inclined throwing support protector. The inclined throwing support protector comprises a purlin structure fixed at the upper edge part of a surrounding wall, and an inclined throwing support movably / detachably arranged on the purlin structure; a locking mechanism for locking the purlin structure and theinclined throwing support is arranged between the purlin structure and the inclined throwing support; and inclined support legs are arranged at the lower end part of the inclined throwing support. After the purlin structure is mounted on the surrounding wall, the inclined throwing support is connected to soil through inclining to one side of the surrounding wall on the purlin structure; the lowerend part of the inclined throwing support forms a support point on the soil; and the inclined throwing support and the purlin structure are locked. The excavation is not needed during installing of the inclined throwing support, so that the construction is quick and safe, the dismantling and the recovery are convenient, and the production cost is greatly reduced.

Owner:麦廊建设有限公司

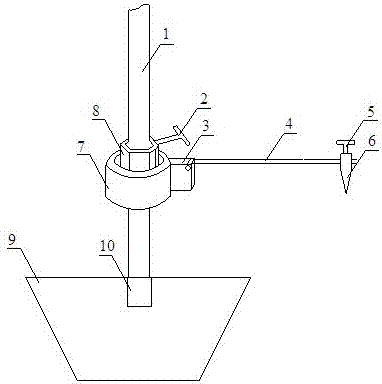

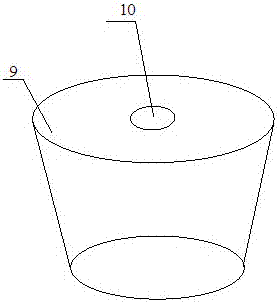

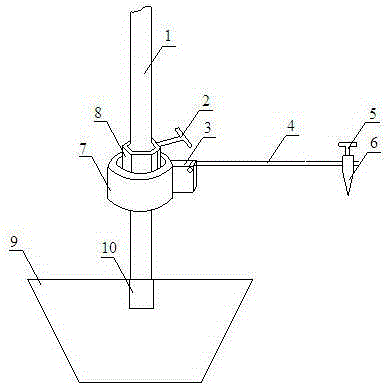

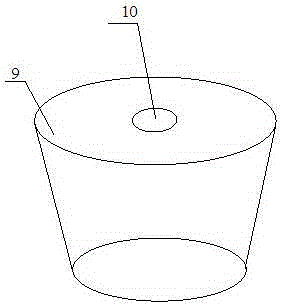

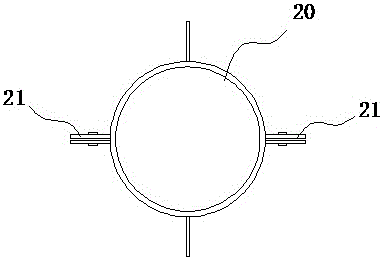

A circle centering tool

ActiveCN105178148BSimple structureIngenious designRoads maintainenceArchitectural engineeringFrustum

The invention discloses a circle centering tool for drawing circles, which belongs to the field of municipal construction tools. The invention comprises a vertical rod, on which a height adjustment ring capable of moving up and down along the vertical rod is sleeved, and the height adjustment ring is fixedly connected with the inner ring of the bearing; a connection block is fixedly arranged on the outer wall of the bearing outer ring, and the connection block is hingedly connected with the telescopic rod , the telescopic rod is perpendicular to the vertical rod; the telescopic rod is sleeved with a marking pen capable of moving left and right along the telescopic rod. Firstly, place the truncated conical carrier on the hole of the cover plate. The truncated circular carrier will not fall when it is located in the hole of the cover plate, and the outer wall of the truncated circular carrier is closely attached to the well wall. The vertical rod is inserted into the vertical rod bearing socket, and the vertical rod bearing socket is coaxially arranged with the conical platform; therefore, the center of the vertical rod bearing socket is the center of the shaft. According to the construction situation, adjust the height of the nib of the engraving pen by adjusting the height adjustment ring; according to the construction situation, adjust the length of the telescopic rod, and use the engraving pen to draw a circle. Construction personnel can cut and reinforce the construction area according to the drawn area.

Owner:SHANDONG HUITONG CONSTR GRP CO LTD

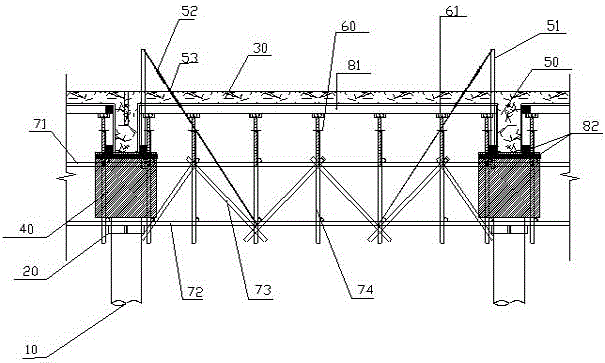

Through prestress steel truss and concrete combined continuous steel structure bridge and construction method thereof

InactiveCN102535327BLight weightGive full play to the advantages of tensile strengthTruss-type bridgeBridge structural detailsButt jointPre stress

Owner:CCCC CIVIL ENG SCI & TECH +1

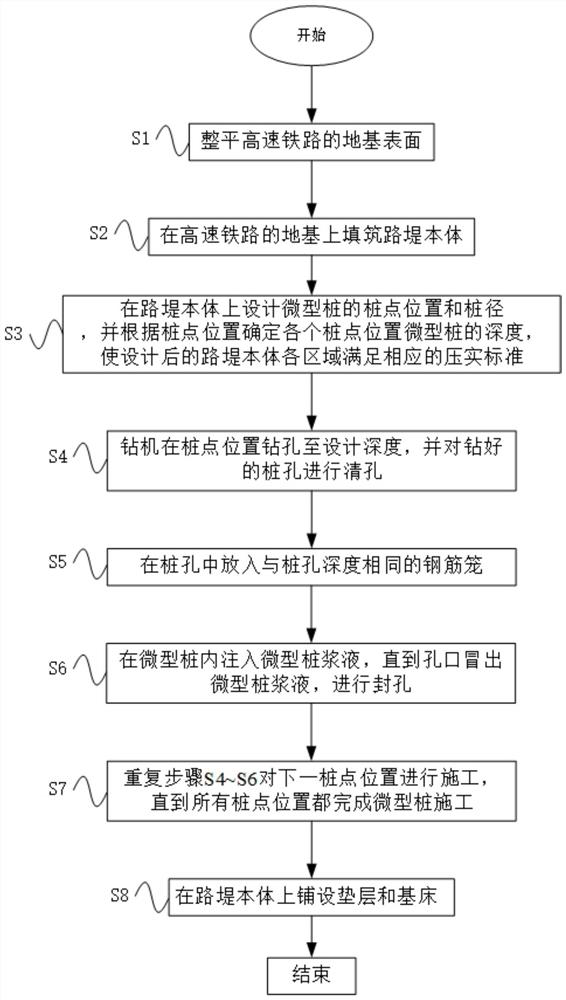

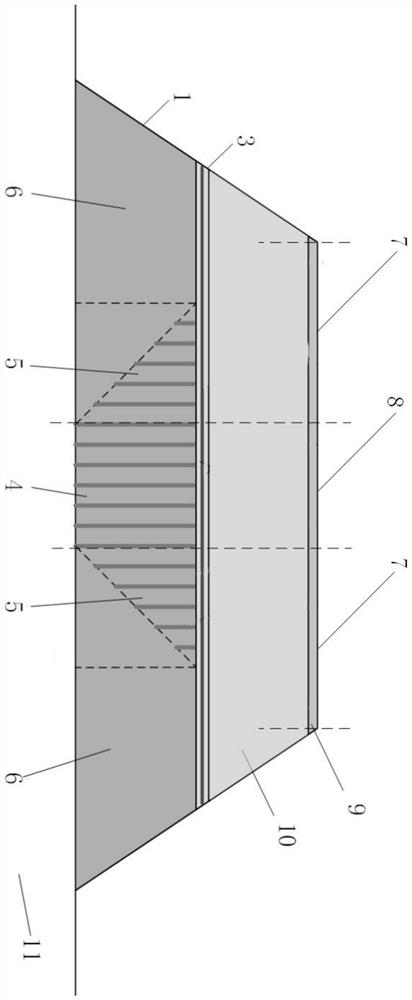

A Micropile Reinforcement Method for Controlling the Transverse Uneven Settlement of High-Speed Railway Wide Embankment

ActiveCN110952386BReduce economic costsGuarantee the effect of horizontal uneven settlementRailway tracksBulkheads/pilesStructural engineeringGeotechnical engineering

The invention relates to a method for reinforcing micro-piles to control the lateral uneven settlement of wide embankments of high-speed railways. The reinforcing method includes the following steps: leveling the surface of the foundation, filling the embankment body on the foundation, and designing micro-pile piles on the body of the embankment Point position and corresponding pile diameter, and determine the depth of micro-piles at each pile point position according to the pile point position, so that each area of the designed embankment body meets the corresponding compaction standards, lay micro-pile at the pile point position, and lay on the embankment body Cushion and bedding. Compared with the prior art, the present invention uses chemically improved soil with low economic cost and poor ability to control settlement as the filling material of the embankment body, and arranges micro-piles with uniform density and length running through the embankment body under the main line. The arrangement density and depth of the micropile decrease linearly with the increase of the distance from the main line reinforcement area, which can ensure the control of the horizontal uneven settlement effect of the high-speed rail wide embankment while reducing the economic cost of the embankment, and the construction is convenient and rapid.

Owner:TONGJI UNIV

A floating erection method of a bridge

ActiveCN112482246BBalanced and easy to controlControl balanceBridge erection/assemblyClassical mechanicsAbutment

The present application relates to a floating erection method of a bridge, comprising the following steps: setting an installation platform next to the abutment on one side of the bank; assembling a rotating device on the abutment; assembling a beam body on the installation platform , and connect one end of the beam body with the rotating device; connect the tugboat with the beam body, and drive the beam body to rotate around the abutment to a set position through the tugboat; drop the beam. This method assembles the beam body on the installation platform without setting up temporary structures such as guide beams and brackets beside the pier, which simplifies the construction steps; the tugboat supports one end of the beam body by using the buoyancy of the water, and the other end passes through the rotation of the bank. The device is supported to form a force-bearing structure in a simply supported state. When the tugboat is driving the beam body to rotate, the beam body is in a simply supported equilibrium state, which is easy to control and is not prone to overturning, which improves safety; The addition of permanent structures such as the prestressed structure of the cap and the rotating structure of the pier column reduces the difficulty of construction.

Owner:中铁大桥局第七工程有限公司

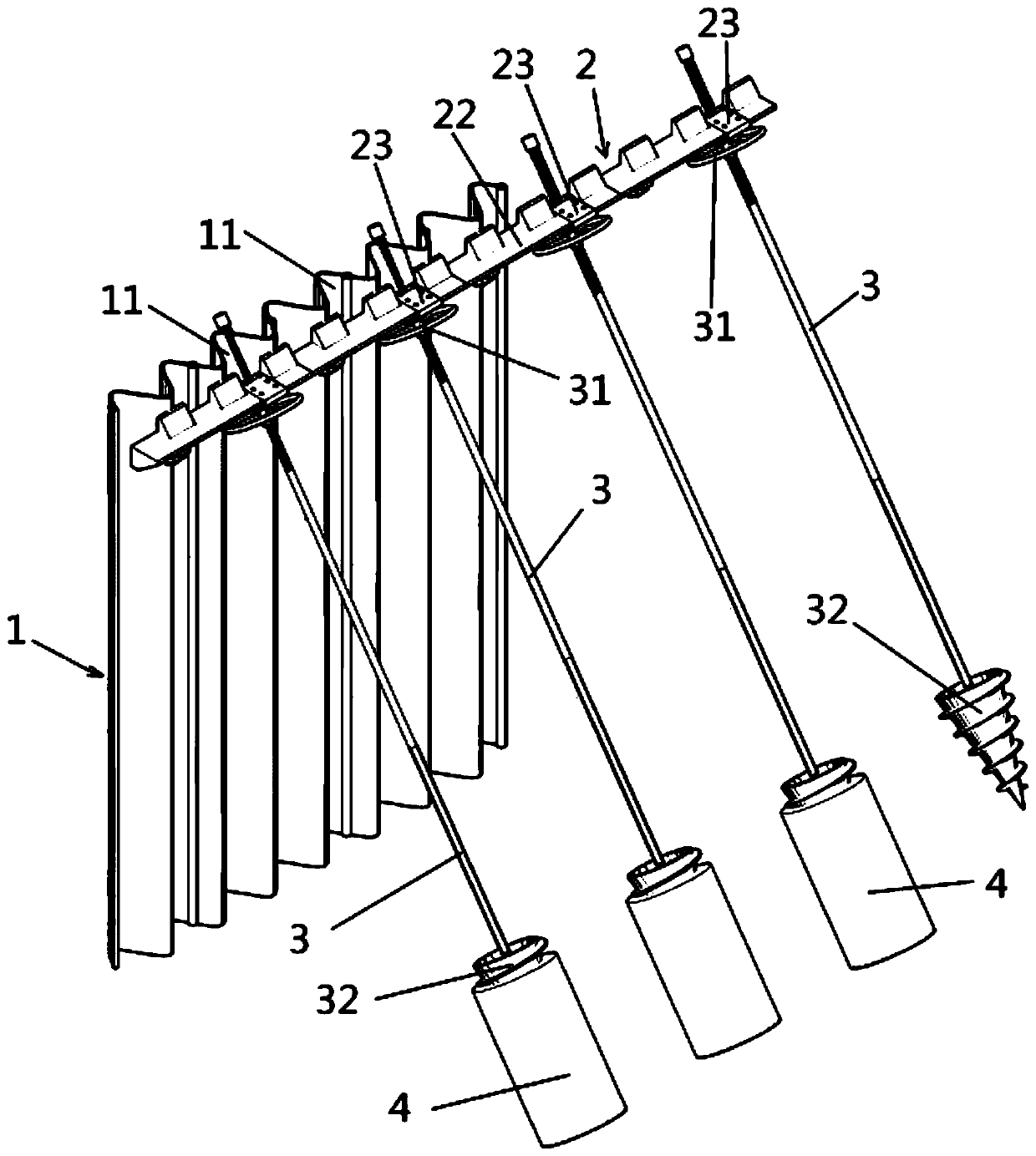

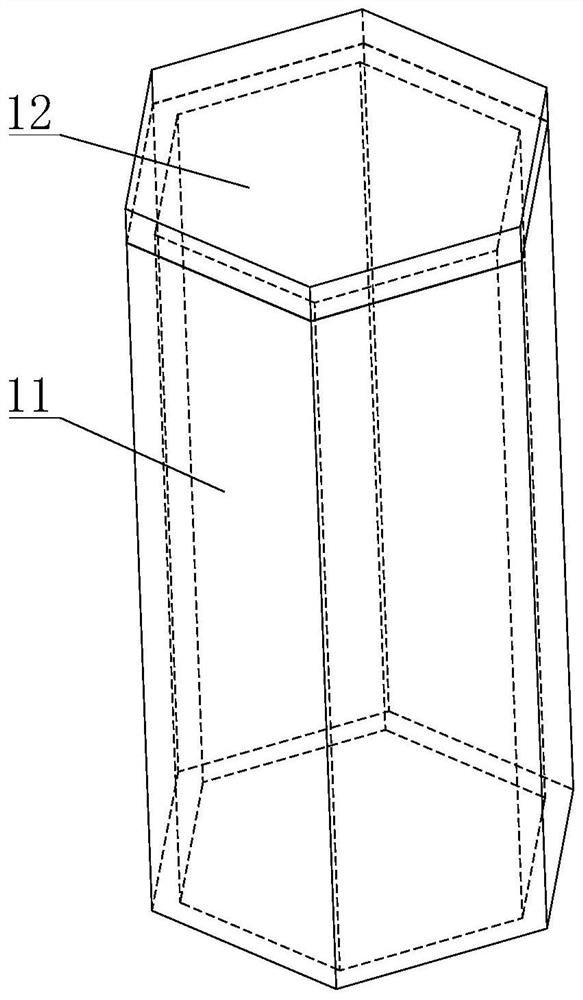

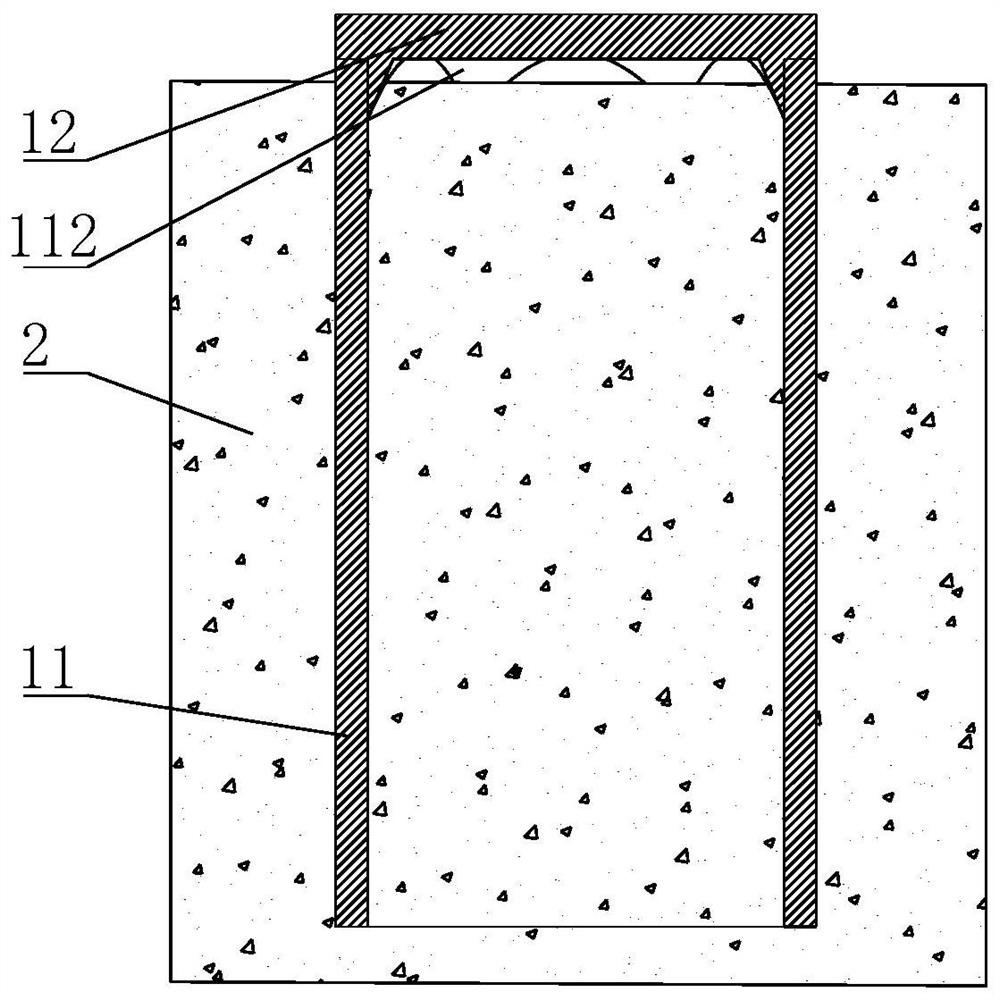

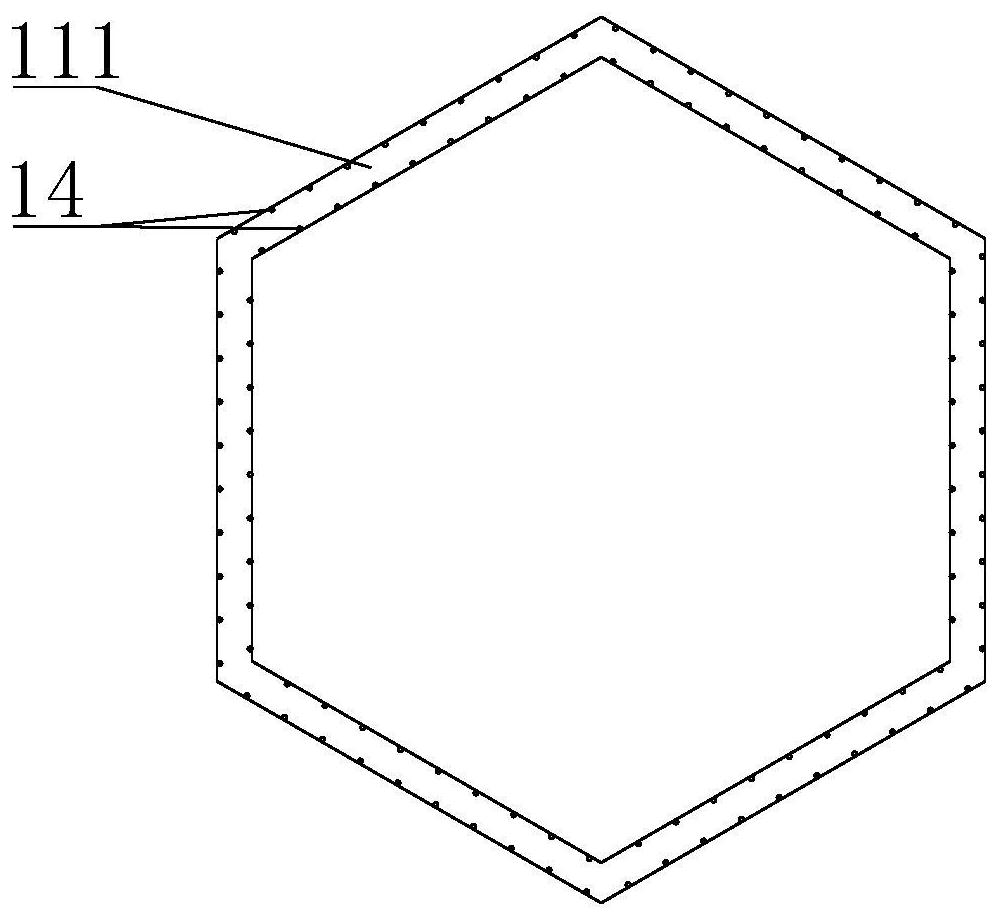

Wall type foundation and construction method thereof

PendingCN114075832AImprove carrying capacityReduce gravityFoundation engineeringPull forceArchitectural engineering

The invention provides a wall type foundation and a construction method thereof. An integral foundation unit is arranged; an enclosing wall of the whole foundation unit comprises a plurality of side walls; a plurality of side walls form an integral polygonal cylindrical foundation structure; and a sealing top is positioned on an enclosing wall and is connected with the side wall. By arranging the integral enclosing wall, joints formed by sequentially connecting the side walls are avoided, so various problems caused by the joints of the side walls are avoided; a hollow closed-loop structure formed by connecting a plurality of side walls is adopted, bearing capacity is provided through interaction of the hollow closed-loop structure and soil bodies on the two sides and the lower ends of the surrounding side walls after the hollow closed-loop structure is implanted into the soil bodies, friction force inside and outside the walls is fully utilized, the bearing capacity of the foundation is increased, stability of the structure is improved, and the structure is safe and reliable; and meanwhile, transverse pulling force on the side walls is achieved by sealing the tops of the positioning covers on the enclosing walls, the bearing capacity of the whole foundation unit is greatly improved, and better economical efficiency and practicability are achieved.

Owner:ANHUI ROAD & BRIDGE GRP

Slip-casting inorganic insulation board and preparation method thereof

The invention relates to a non-grouting-molded inorganic thermal insulation board and a preparation method thereof. The components of the grouted-molded inorganic thermal insulation board are: 500-600 parts of high-alumina cement, 100-200 parts of ordinary silicon cement, desulfurization 100-200 parts of gypsum, 350-450 parts of vitrified microbeads, 3 parts of hydroxypropyl methylcellulose, 1 part of 6mmPP fiber, 8 parts of glass fiber mesh, 4 parts of non-woven fabric, 4 parts of animal protein foaming agent, 1000 parts of water. The grouting-molded inorganic thermal insulation board has high strength, is not easy to pulverize, has low water absorption, strong adhesion to the wall, is not easy to fall off, and has low thermal conductivity, which has a good energy-saving and thermal insulation effect. Therefore, the grouting molding The inorganic thermal insulation board has two functions of fire prevention and energy-saving insulation at the same time, so that the building is safer and more energy-saving, and the building meets the requirements of energy-saving, environmental protection, and green buildings.

Owner:上海复培新材料科技有限公司

A safe and quick construction method for column concrete pouring

InactiveCN106703293BImprove convenienceImprove securityStrutsForms/shuttering/falseworksEngineeringSteel frame

The invention discloses a safe and quick construction method for pouring cylinder body concrete. The safe and quick construction method comprises the following steps: A, mounting a coaming; B, mounting a lifting frame: arranging a plurality of screw rods pointing upwards on the ground of the outer side of a cylindrical structure of a steel frame, mounting a screw rod lifting device on each screw rod, separately arranging arc-shaped guide rails on the screw rod lifting devices and splicing the arc-shaped guide rails to form an annular guide rail; C, mounting a safety fence: mounting a movable base on the annular guide rail, and mounting a circular or square safety fence on the movable base; D, pouring, E, drying and solidifying. By adoption of the mode, the safe and quick construction method for pouring the cylinder body concrete, disclosed by the invention, has the advantages that by matching the screw rod lifting devices with the movable base, convenience and safety of construction of an operator are greatly improved, the construction speed is high, and more time and labor are saved; no traditional working platform needs to be set up, so less time is consumed, and higher safety in construction is realized.

Owner:CHINA CHANGSHU CONSTR GRP

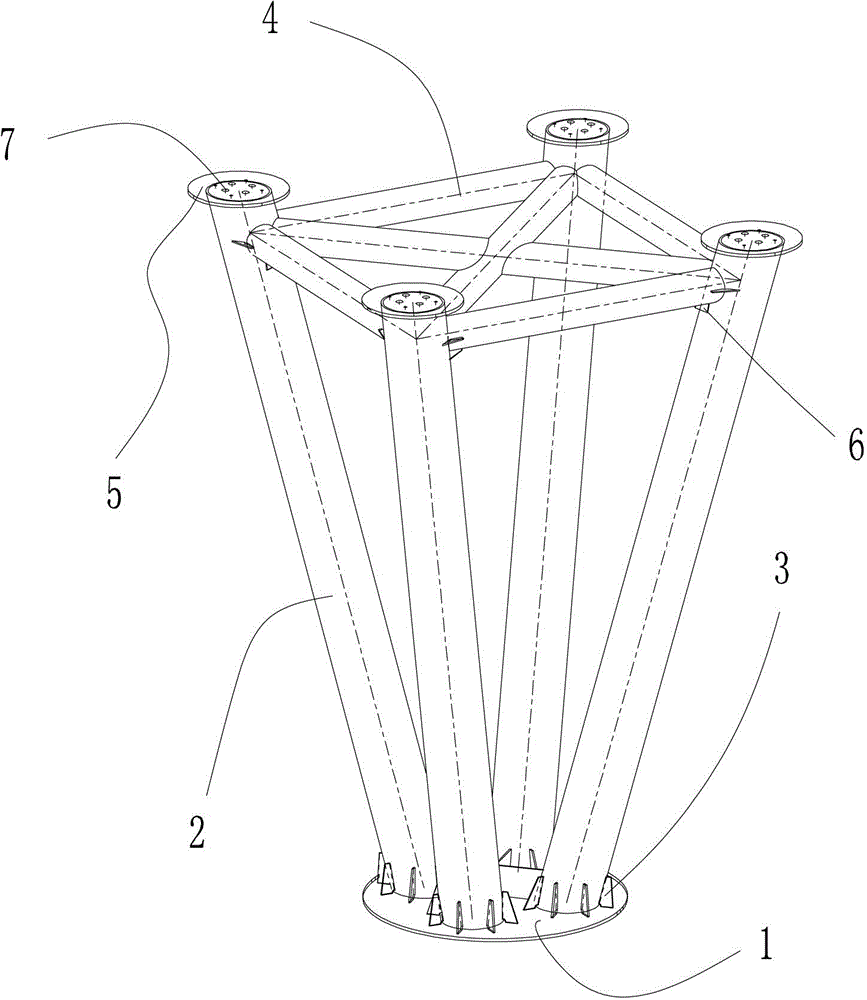

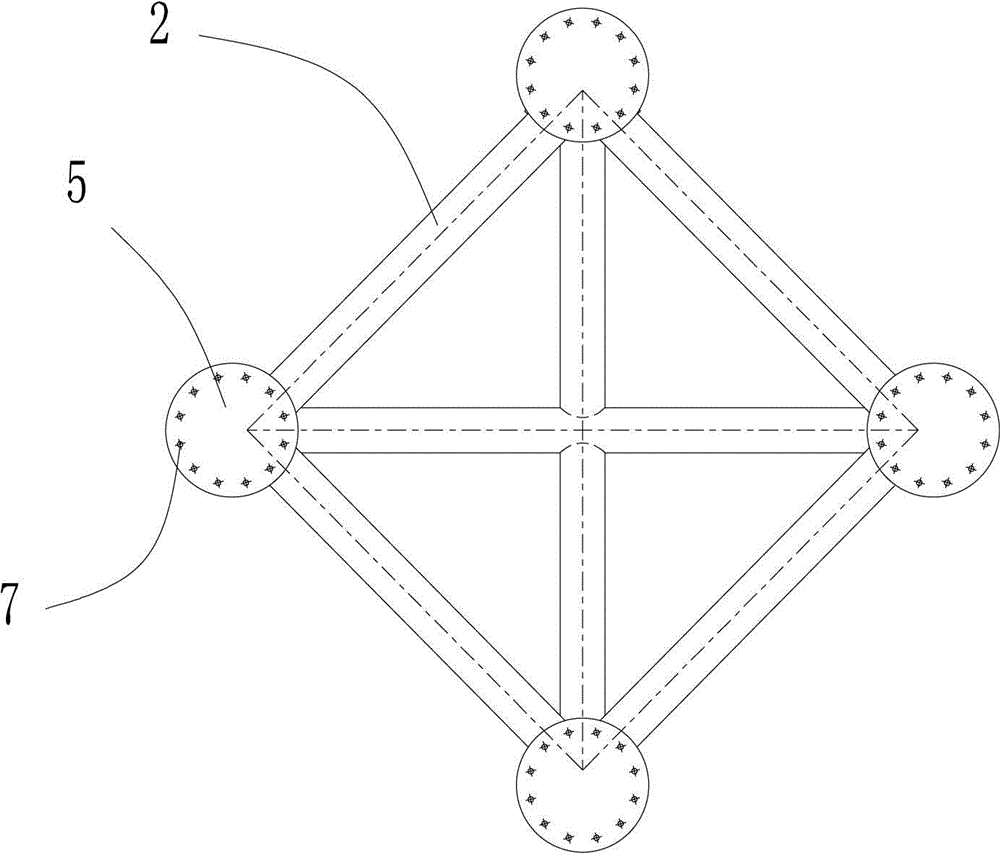

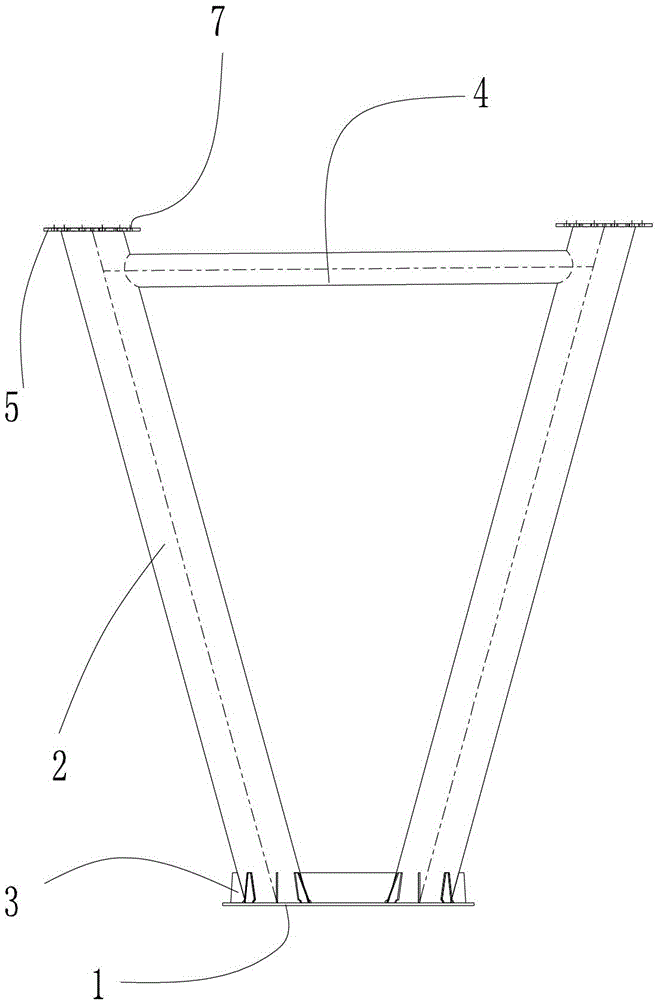

Bridge space radioactive concrete-filled steel tube bridge pier and construction method thereof

ActiveCN103243638BSave spaceSave landBridge structural detailsBridge erection/assemblySteel tubeFlange

A bridge space radioactive concrete-filled steel tube bridge pier comprises a flange, a plurality of bridge pier bottom stiffening plates, four bridge pier support beams, six tie beam stiffening plates, four pier top anchor plates and a plurality of tie beam stiffening plates. Four mounting positions in even distribution along the circumferential direction are reserved on the top surface of the flange; bottom walls of the four bridge pier support beams are mounted at the four mounting positions on the flange respectively; a tapered space is formed by encircling of the four bridge pier support beams, and the cross section of the tapered space is decreased gradually from top to bottom; one pier top anchor plate is mounted on the top wall of each bridge pier support beam; and a plurality of anchor bolt preformed holes in even distribution are reserved on each pier top anchor plate. A pile foundation of the bridge pier is centralized blow a bearing platform, and occupied urban space is small. Formwork-free pouring of bridge pier concrete pouring is achieved, and the bridge pier is convenient and efficient to construct, safe and rapid, excellent in structural behavior of rod pieces, higher in rigidity of a main beam, good in stability and the like. The invention further relates to a construction method of the bridge space radioactive concrete-filled steel tube bridge pier.

Owner:SHENZHEN BRIDGE DOCTOR DESIGN & RES INSTITUDE CO LTD +1

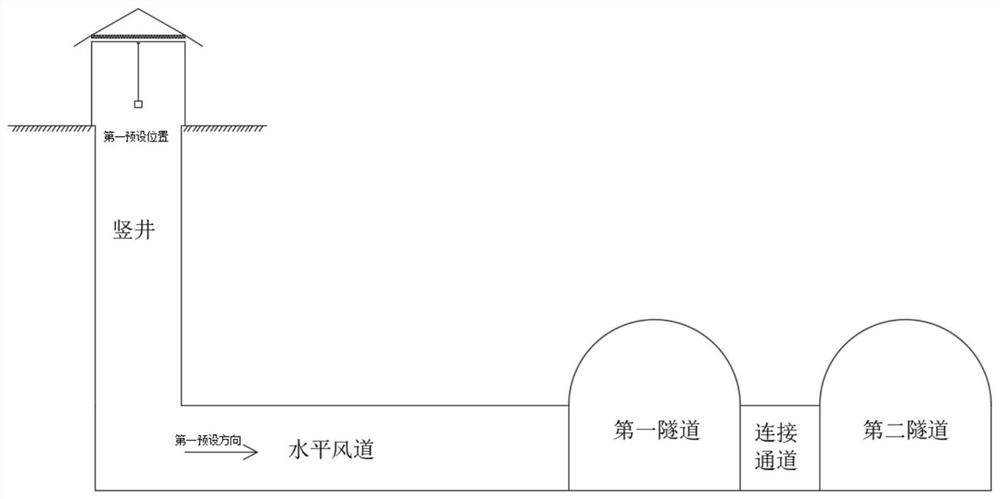

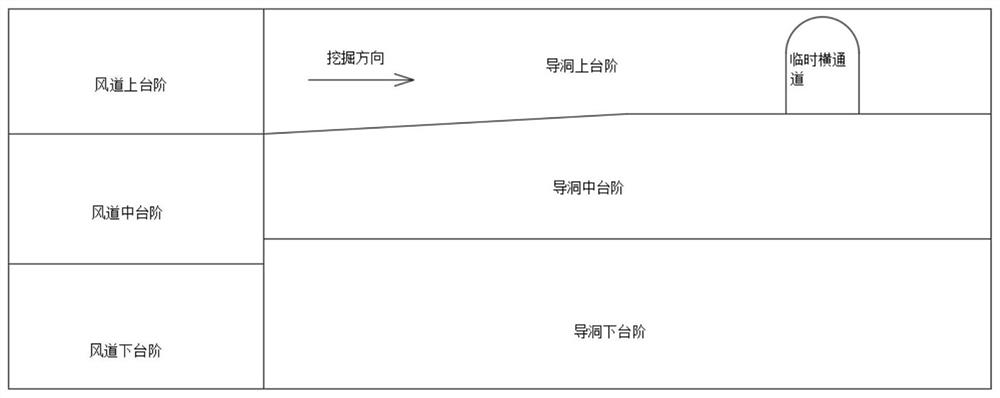

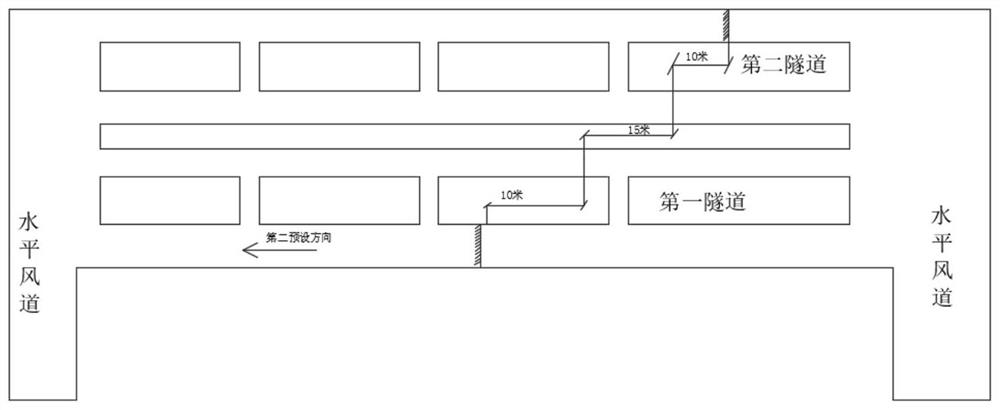

Parallel double-island type tunnel construction method

PendingCN114856612AImprove construction efficiencySafe and fast constructionClimate change adaptationHydro energy generationTunnel constructionRapid construction

The invention discloses a parallel double-island type tunnel construction method which comprises the following steps that a vertical shaft is built at a first preset position on the ground, and after the vertical shaft is built, a horizontal air duct is built at the bottom of the vertical shaft towards a second preset position in the first preset construction direction; along with construction of the horizontal air duct, a first tunnel and a second tunnel which are spaced from each other are sequentially built in the formed horizontal air duct in the second preset direction, and in the construction process of the first tunnel and the second tunnel, connecting channels are arranged at preset intervals in the second preset construction direction, and the connecting channel is used for communicating the first tunnel with the second tunnel. According to the construction method, synchronous construction of the two tunnels can be conveniently achieved, the construction efficiency is improved, and safe and rapid construction of the double-island type station tunnel is guaranteed.

Owner:CIVIL ENG OF CHINA CONSTR SECOND ENG BURESU

Fixed-center circle drawing tool

ActiveCN105178148ASimple structureIngenious designRoads maintainenceArchitectural engineeringEngineering

The invention discloses a fixed-center circle drawing tool and belongs to the field of municipal construction tools. The fixed-center circle drawing tool comprises a vertical rod. The vertical rod is sleeved with a height adjustment ring which can move up and down along the vertical rod. The height adjustment ring is fixedly connected with an inner ring of a bearing. A connecting block is fixedly arranged on the outer wall of an outer ring of the bearing. The connecting block is connected with a telescopic rod in a hinged mode. The telescopic rod is perpendicular to the vertical rod. The telescopic rod is sleeved with a line scribing pen which can move leftwards and rightwards along the telescopic rod. Firstly, a circular-truncated-cone-shaped carrier platform is placed at a hole of a cover plate, the circular-truncated-cone-shaped carrier platform is located at the hole of the cover plate and does not fall, and the outer wall of the circular-truncated-cone-shaped carrier platform is tightly attached to the wall of a well. The vertical rod is inserted in an insertion hole of the vertical rod, and the insertion hole of the vertical rod is coaxial with the circular-truncated-cone-shaped carrier platform. In this way, the center of the insertion hole of the vertical rod is the circle center of a shaft. The height of the pen point of the line scribing pen is adjusted by adjusting the height adjustment ring according to the construction condition. The length of the telescopic rod is adjusted according to the construction condition, and a circle is drawn by means of the line scribing pen. The construction range can be cut and reinforced by constructors according to a drawn range.

Owner:SHANDONG HUITONG CONSTR GRP CO LTD

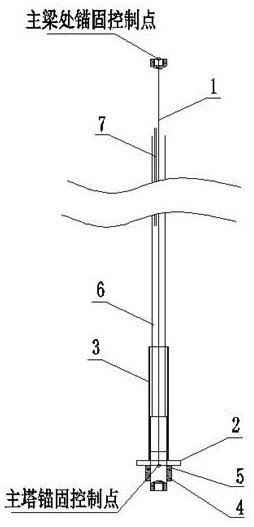

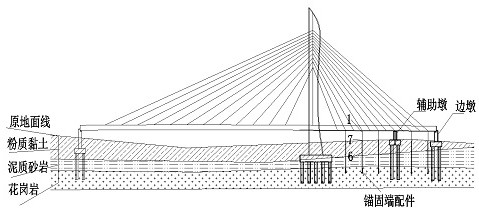

Asymmetric cable-stayed bridge side span section ground anchor prestress equivalent counterweight system and construction method

InactiveCN112523072AImprove economyOvercome the disadvantages of complex design and constructionCable-stayed bridgeBridge structural detailsPre stressArchitectural engineering

The invention discloses an asymmetric cable-stayed bridge side span section ground anchor prestress equivalent counterweight system, and aims to solve specific technical problems that an asymmetric single-tower double-cable-plane cable-stayed bridge is short in side span and a cable bent tower bears unbalanced force due to the fact that main span beams and side span beams are different in length.The specific construction method comprises the steps that when the main beam is constructed, the stay cables are anchored in the rock stratum soil under the beam block at the same position in the vertical direction after side span, certain prestress is applied to the ground anchor, a prestress anchoring system can be directly pre-buried at the auxiliary pier in the construction process, and a novel equivalent balance weight structure system is formed. The structure has better economical efficiency, is convenient to construct and safe and reliable in structure, reduces the counterweight concrete material of the side span section of the traditional asymmetric cable-stayed bridge, and overcomes the defect of complex design and construction of a large temporary support for construction.

Owner:ANHUI HIGHWAY BRIDGE ENG CO LTD +1

pcss shear connection structure

ActiveCN103334374BGuaranteed long-term safe useImprove performanceBridge structural detailsBuilding constructionsCouplingEngineering

A PCSS shear force coupled construction, comprising a steel structure (2) and an assembly-type prefabricated concrete bridge road plate. The prefabricated concrete bridge road plate comprises a concrete bridge road plate body (1) and a shear transferring structure (3) integrally cast with the concrete bridge road plate body (1) via a shear connector, and is fixedly mounted on the steel structure (2) via the shear transferring structure (3). Directly mounting the assembly-type prefabricated concrete bridge road plate on the steel structure (2) during the construction process facilitates the control of the construction process, significantly reduces the construction cycle, and exposes the coupling part of a composite beam, thus facilitating daily monitoring and maintenance, requiring less time out of service during maintenance and repair, and ensuring normal use of a bridge.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG +1

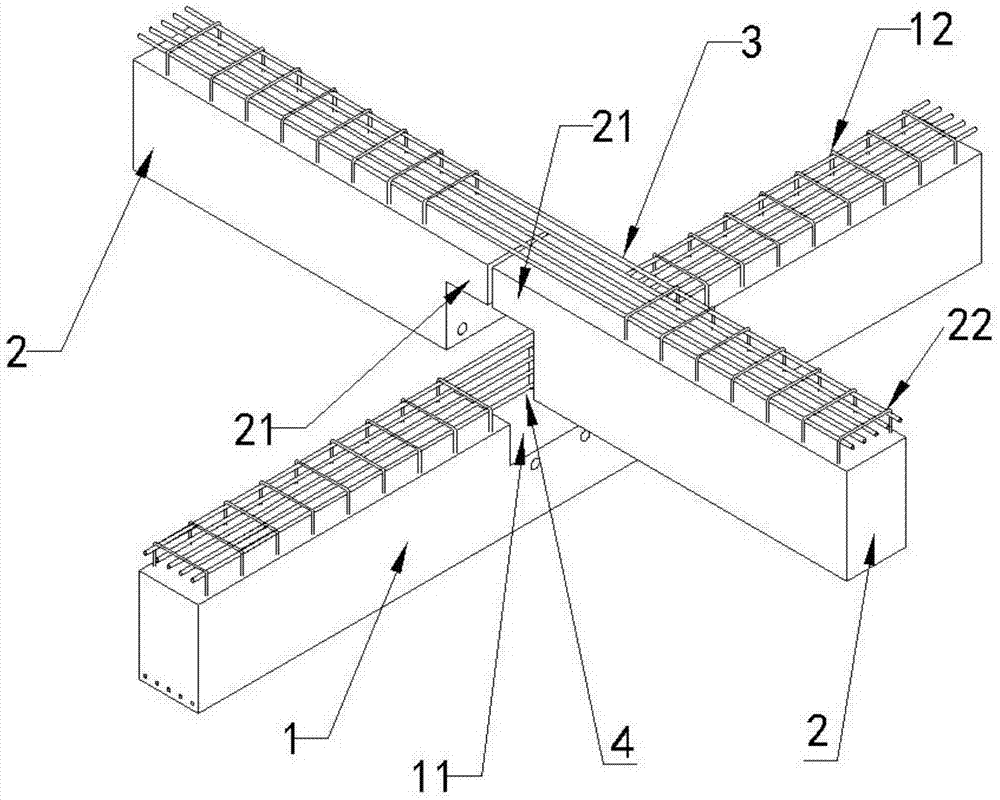

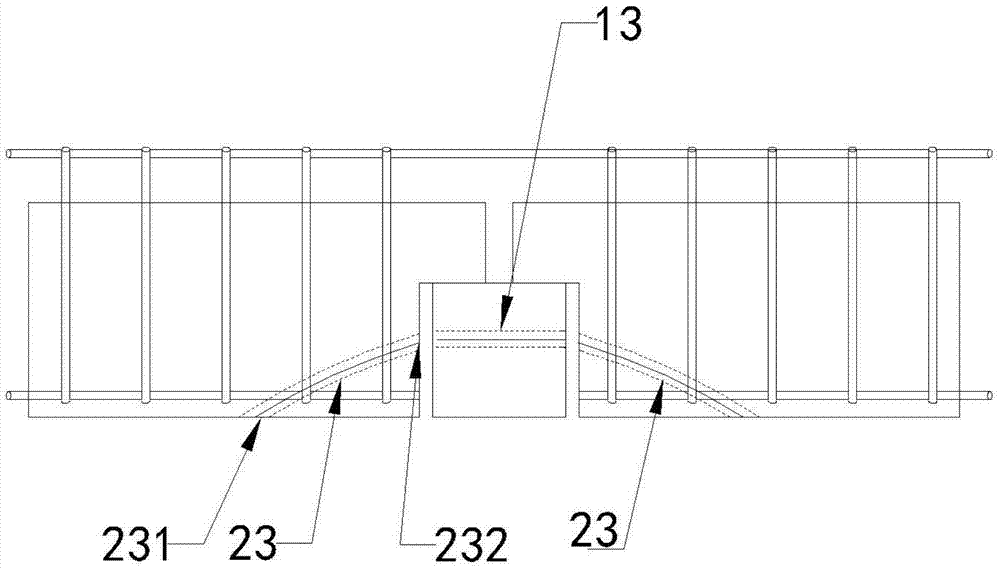

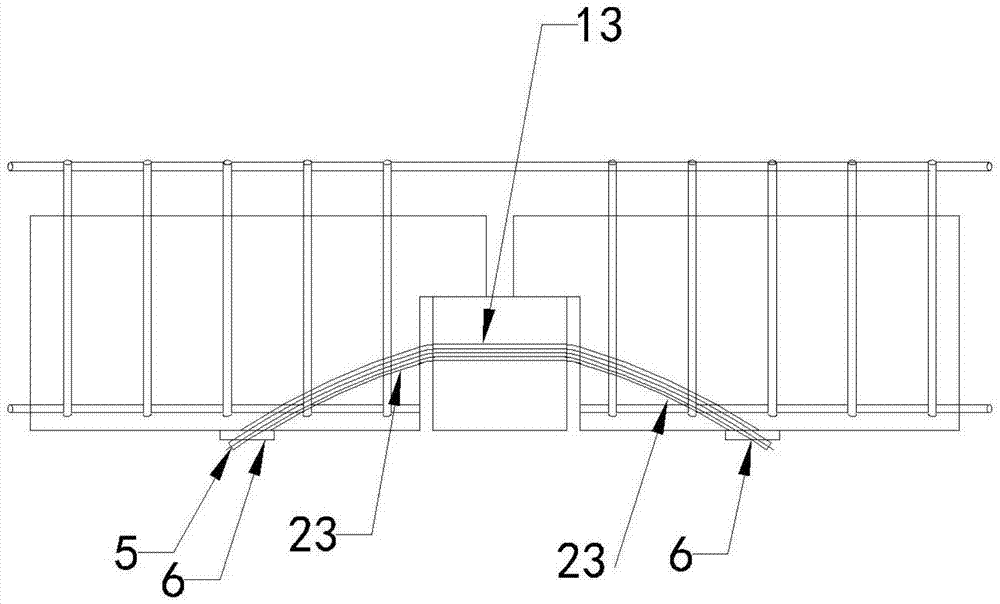

A construction method of a concrete beam cross connection structure provided with tension reinforcement

The invention discloses a construction method for a concrete beam cross connection structure provided with tensile steel bars. The structure comprises a pre-cast concrete composite beam, and the concrete composite beam includes a female beam and a male beam connected by mortise and tenon, wherein the male beam The beam body at the end of the beam is formed with perforations respectively. After the tensioned steel bars pass through the perforations, the ends are tensioned and fixed by riveting plates, so that the bottom of the beam forms a continuous structure. In terms of construction methods, the concrete composite beam is prefabricated, and passed through the mother beam in turn. Installation, installation of public beams, fixing of connecting parts, fixing of tensioned steel bars, installation of floor layers and pouring are integrated into one process. Compared with traditional structures, precast concrete composite beams greatly guarantee the quality of components without requiring a lot of internal and external work. For the scaffolding project, the cost of the floor is reduced by more than 10%. Compared with the traditional construction technology, the construction period can be shortened by half, the safety is greatly improved, and the comprehensive benefits are extremely significant.

Owner:南通欧本建筑科技有限公司

Prefabricated assembly type tunnel wall reinforcing structure and using method thereof

InactiveCN112196587AGuaranteed stabilityStable structureMining devicesUnderground chambersArchitectural engineeringTunnel wall

The invention discloses a prefabricated assembly type tunnel wall reinforcing structure and a using method thereof. The prefabricated assembly type tunnel wall reinforcing structure comprises a tunnelwall structure, a reinforcing column and a reinforcing beam, the reinforcing column is fixedly arranged at one side of the tunnel wall structure, the reinforcing beam is fixedly installed at the topand the bottom of the reinforcing column, and the reinforcing beam is composed of an installing frame and two transverse fixing beams; and the transverse fixing beams are fixedly mounted at the two ends of the mounting frame correspondingly, the mounting frame is fixedly connected with the reinforcing column through a main gasket arranged at the joint of the mounting frame and the reinforcing column, and the bottoms of the ends of the transverse fixing beams are fixedly connected with the tunnel wall structure through side gaskets. According to the reinforcing structure, after prefabrication production is conducted in a factory and a to-be-assembled component arrives at a construction site, integral installation is conducted, the structure is reliable, safe, rapid and convenient, too manyconstruction facilities do not need to be prepared on site, inner pouring rods are installed in the reinforcing column and communicate with the reinforcing beam and side bonding plates correspondingly, integral pouring forming can be achieved, and construction is safe and rapid.

Owner:温州源铭振跃科技有限公司

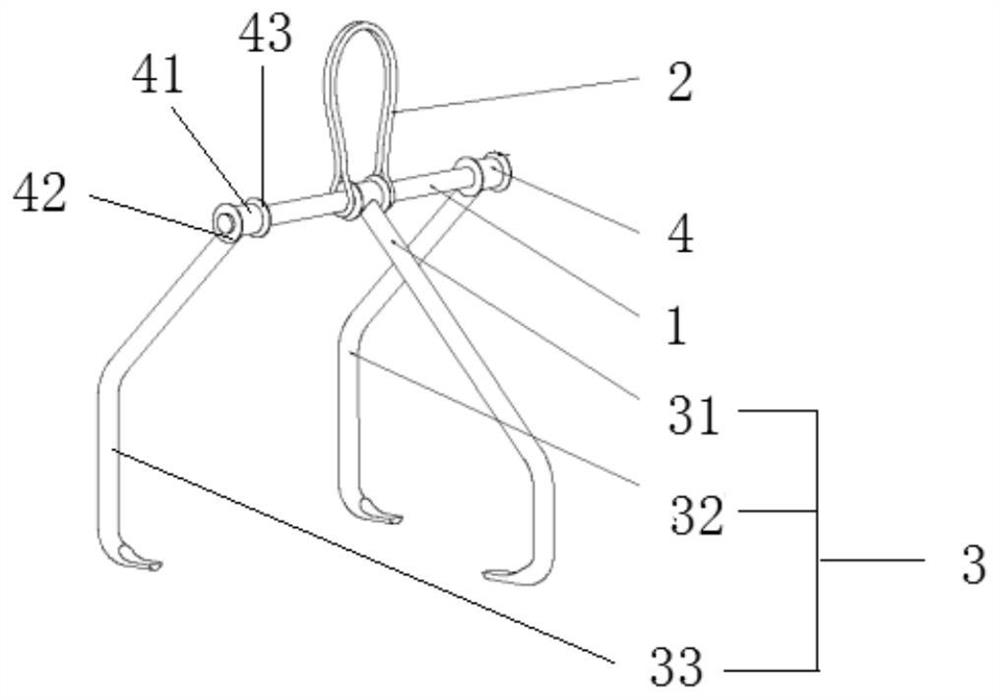

Disassembling and assembling tool for frame brick of annular heating furnace and using method of disassembling and assembling tool

PendingCN113790603ASafe and fast constructionImprove securityLinings repairLoad-engaging elementsBrickEngineering

The invention provides a disassembling and assembling tool for a frame brick of an annular heating furnace and a using method of the disassembling and assembling tool, and relates to the technical field of building construction. The disassembling and assembling tool comprises a fixing shaft, a first suspension assembly and a second suspension assembly, wherein the first suspension assembly is connected to the fixing shaft and used for lifting the fixing shaft upwards; the second suspension assembly comprises a plurality of suspension legs, the plurality of suspension legs are movably connected to the fixing shaft, and the ends of the suspension legs are arranged to comprise flat structures and used for stretching into the annular heating furnace. The disassembling and assembling tool has the advantages that the disassembling and assembling tool is in place at a time in the installing process, and a wood board is cushioned with a hammer and slightly knocked so that the disassembling and assembling tool can be in place; and lotus petals are not touched during disassembling, light castable at the lower portion is not touched during installing, the disassembling and assembling tool is tighter when lifted and clamped, the disassembling and assembling tool is not prone to sliding off and injuring constructors in the lifting process, the manufacturing process is simple, the production cost is low, the safety is high, and using is convenient and fast.

Owner:MCC TIANGONG GROUP

Bridge magnetic levitation pushing system and two-stage cantilever manufacturing method

Owner:桥博建筑科技(东莞)有限公司 +1

Space truss formwork system and its construction method

ActiveCN104480922BImprove stabilityAdaptableArtificial islandsUnderwater structuresSupporting systemConcrete beams

The invention discloses a space truss formwork supporting system and a construction method thereof; the space truss formwork supporting system comprises a precast tubular pile arranged in the water, a steel hoop fixed on the precast tubular pile, a concrete bearing table formed at the top of each pile by casting and a steel tube stand column, a diagonal draw bar used for connecting the stand column and a truss chord member node, a space truss composed of the steel tube and fastener embedded in the bearing table; a jacking is mounted on the stand column of the space truss, the wood brace is arranged on the jacking, a template is mounted on the wood brace for binding the reinforcing steel bar and casting the concrete beam slab. The space truss formwork supporting system takes the precast tubular pile as the fulcrum in the limit situation of the topographic condition, the non-floor type space truss formwork supporting system is used for the construction of the beam and slab reinforcing steel bar and concrete, the conventional vertical support system is changed into the space horizontal support system; the computer analog technology is adopted and the space truss is made of the steel tube and used as the bearing support system of the cast-in-place beam and slab, the structure safe construction is guaranteed and the construction is quick and safe.

Owner:GUANGZHOU HENGSHENG CONSTR ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com