Bridge magnetic levitation pushing system and two-stage cantilever manufacturing method

A magnetic levitation and jacking technology, which is applied in bridge construction, bridge erection/assembly bridge, etc., can solve the problems of damaged PTFE slide, high construction cost, slow construction process, etc., to reduce friction and resistance, and low construction cost , The effect of fast construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

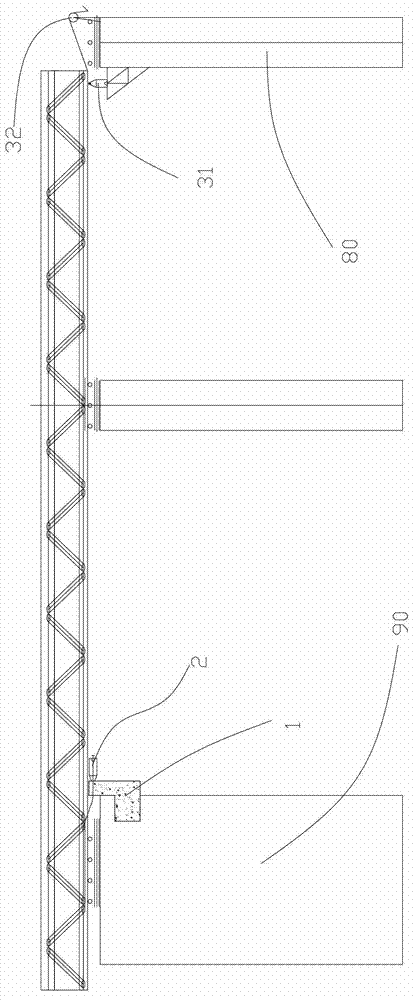

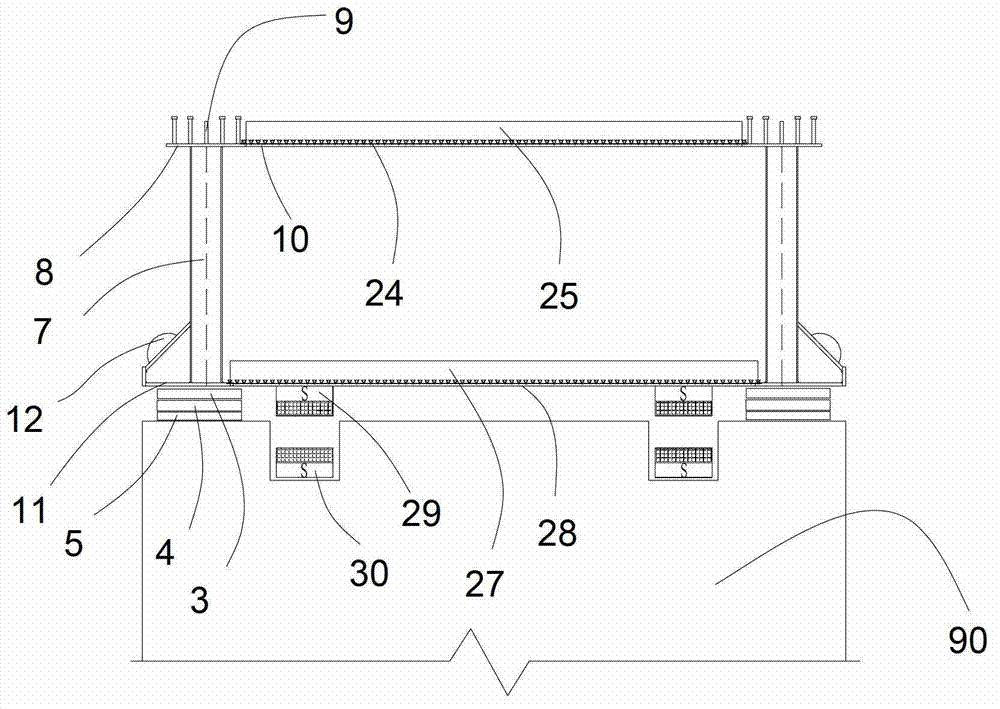

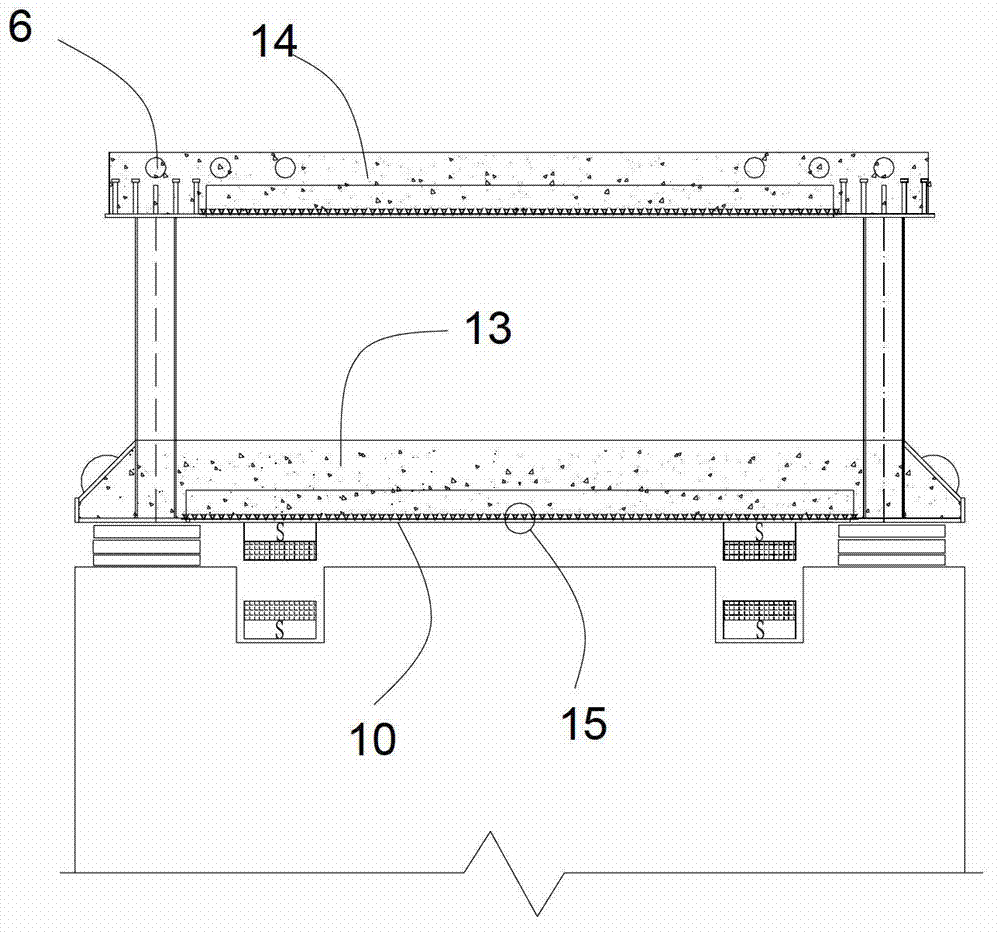

[0030] See Figure 1 to Figure 5 , The present invention relates to a bridge maglev jacking system, and its preferred embodiment includes a maglev jacking main girder hollow box structure and a maglev jacking platform. The magnetic levitation jacking platform includes a jacking platform 1, a jack 2, two bottom steel plates 5, two electromagnets 30, two PTFE slides 4, several steel tube concrete rollers 3 and a jacking anchor pad 15. The hollow box-shaped structure of the main girder for maglev jacking includes a steel truss web bridge frame and two permanent magnets 29 .

[0031] The pushing platform 1 is installed on the right end of the abutment 90, the jack 2 is installed on the pushing platform 1, and the two bottom steel plates 5 are pre-embedded in the left and right ends of the top surface of the abutment 90 respectively, and each bottom ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com