Construction method utilizing steel-strand strand pulling machine to perform fast strand pulling during construction of prestress structures

A technology of prestressed structure and construction method, which is applied in the direction of building construction, construction material processing, erection/assembly of bridges, etc., which can solve the problem that steel strands cannot fully meet the requirements of braiding, consume a lot of manpower and material resources, and reduce construction costs and other problems, to achieve the effects of fast and efficient beam-through construction, improving work efficiency and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

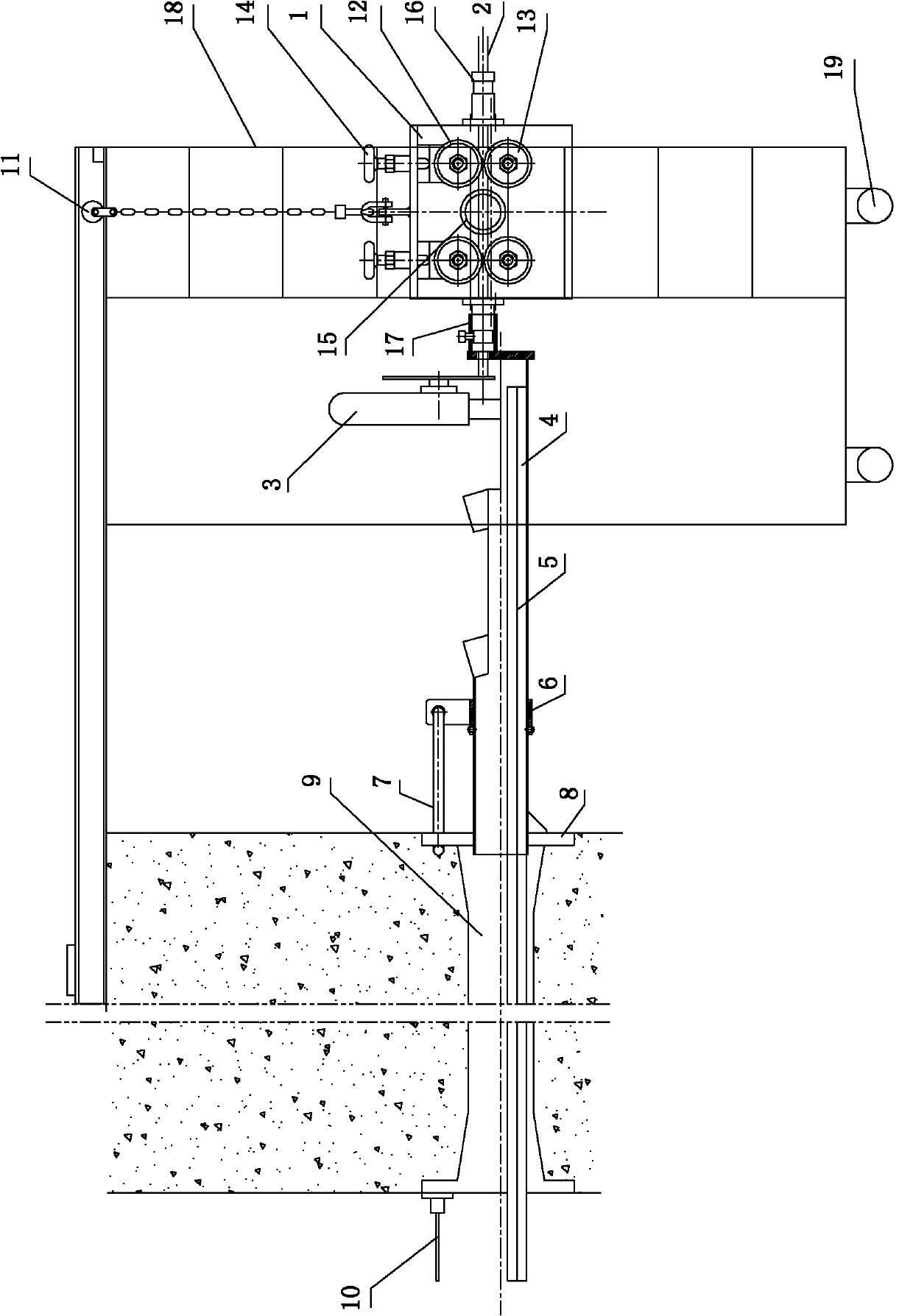

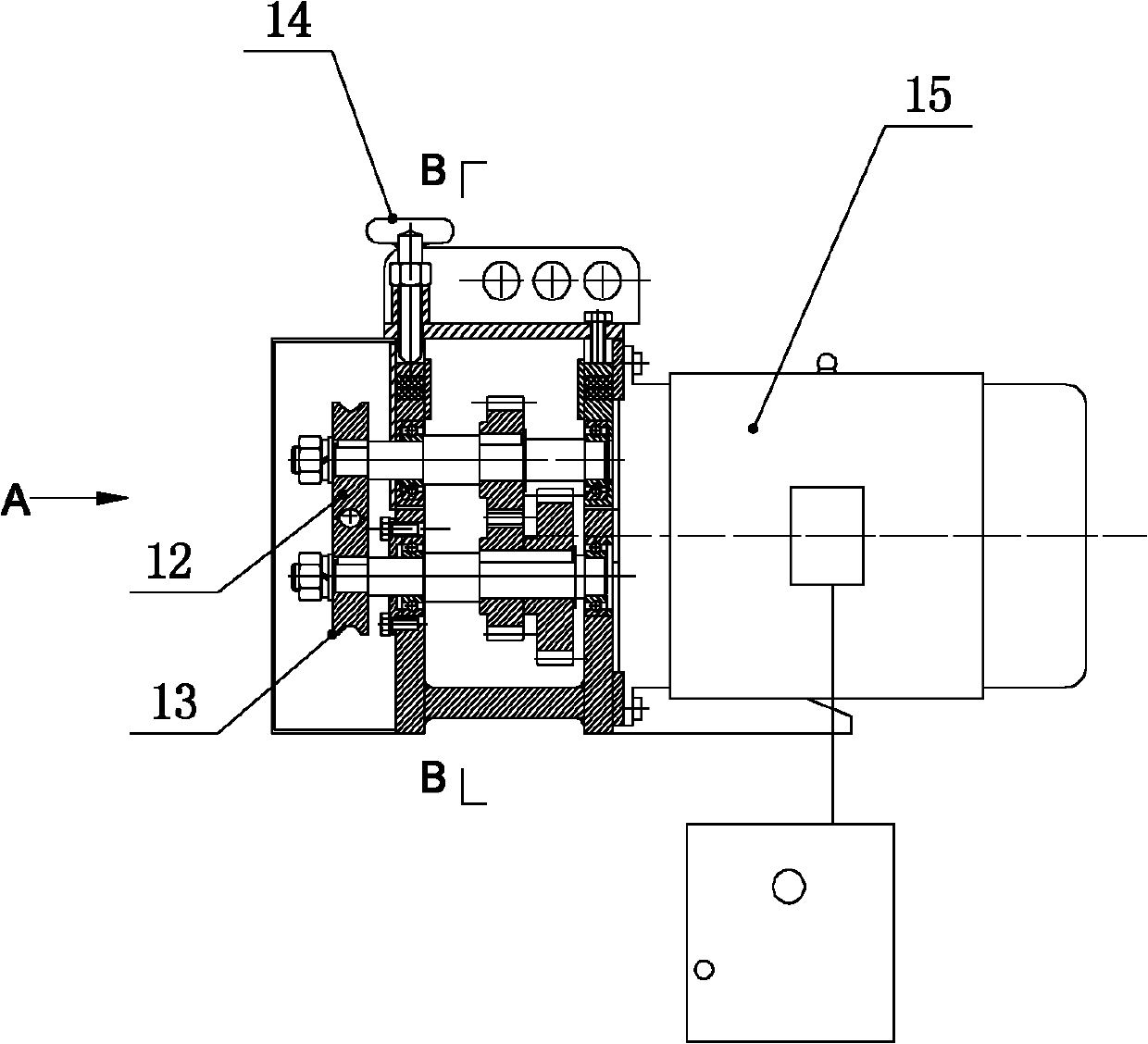

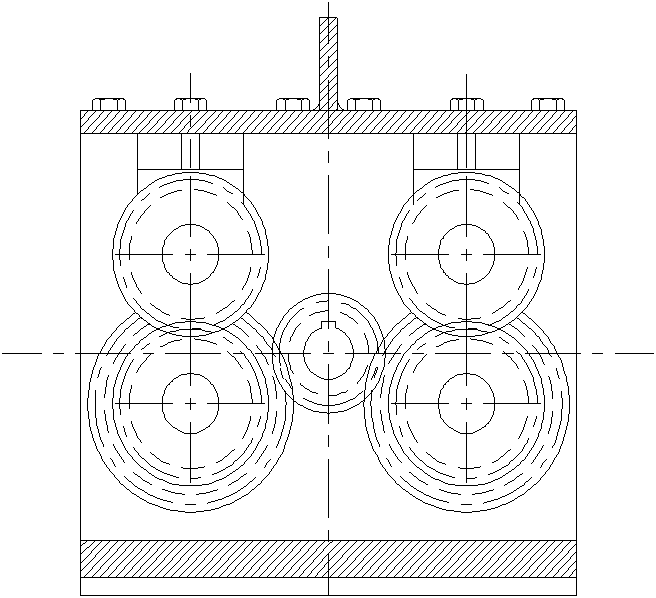

[0023] A construction method for fast threading of steel strands using a steel strand threading machine in the construction of prestressed structures, as attached Figure 2-4 As shown, the steel strand threading machine 1 used has two pairs of pressure rollers arranged at a certain interval, and each pair of pressure rollers includes a corresponding upper pressure roller 12 and a lower pressure roller 13, and the upper pressure roller 12 and the lower pressure roller 13 are all driven to rotate by the drive mechanism, and the upper and lower pressure wheels can clamp the steel strand 2 to advance or retreat. The driving mechanism includes a motor 15 and a gear transmission mechanism driven by the motor 15, and the gear transmission mechanism drives the upper pressing wheel 12 and the lower pressing wheel 13 to rotate respectively. An adjustment m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com