Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Reliable vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

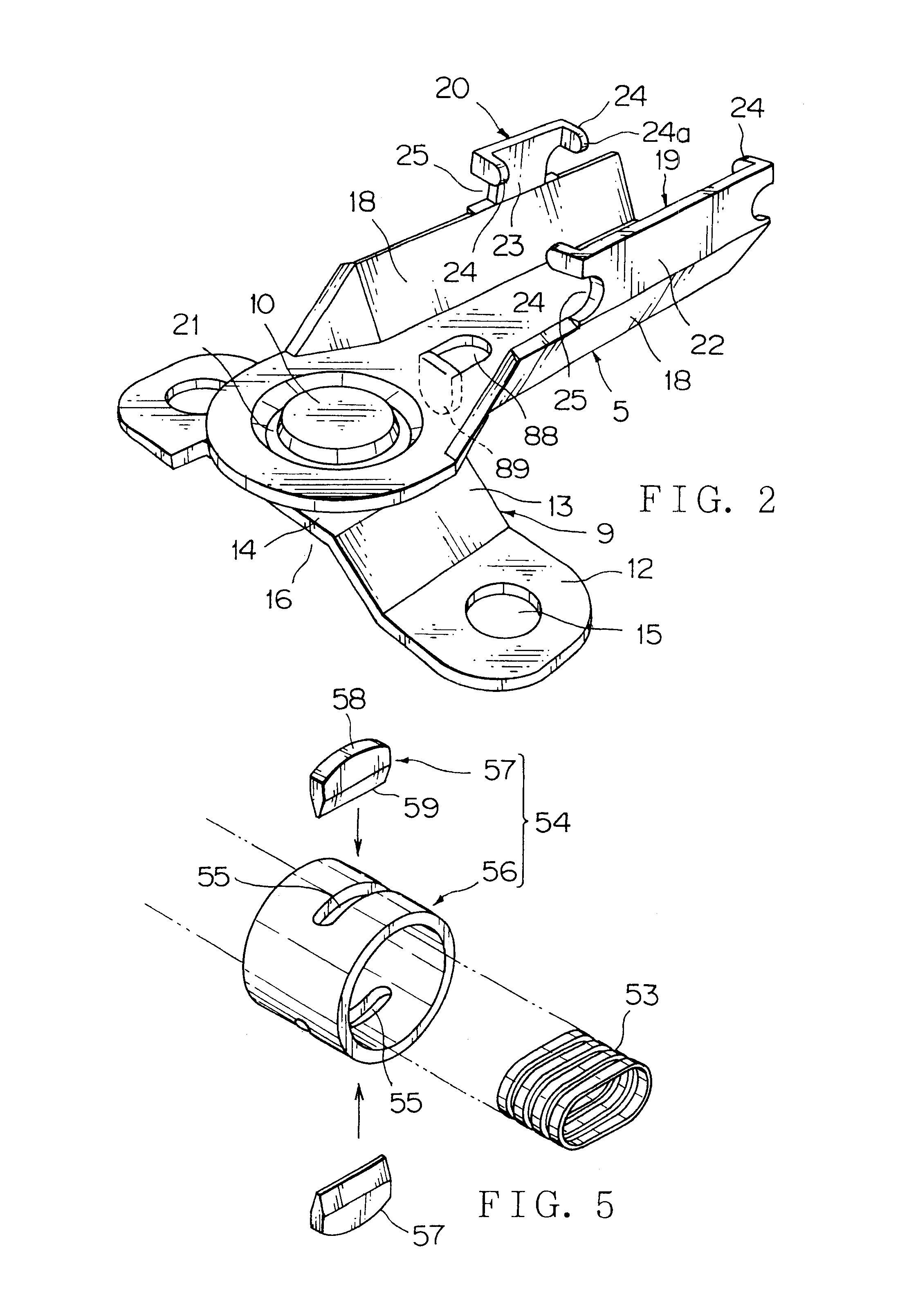

Wiring harness arrangement assembly for sliding door of car

InactiveUS6881902B2Damage permanent deformationUndesirable permanent deformationCoupling device connectionsInsulated cablesEngineeringMechanical engineering

Owner:YAZAKI CORP

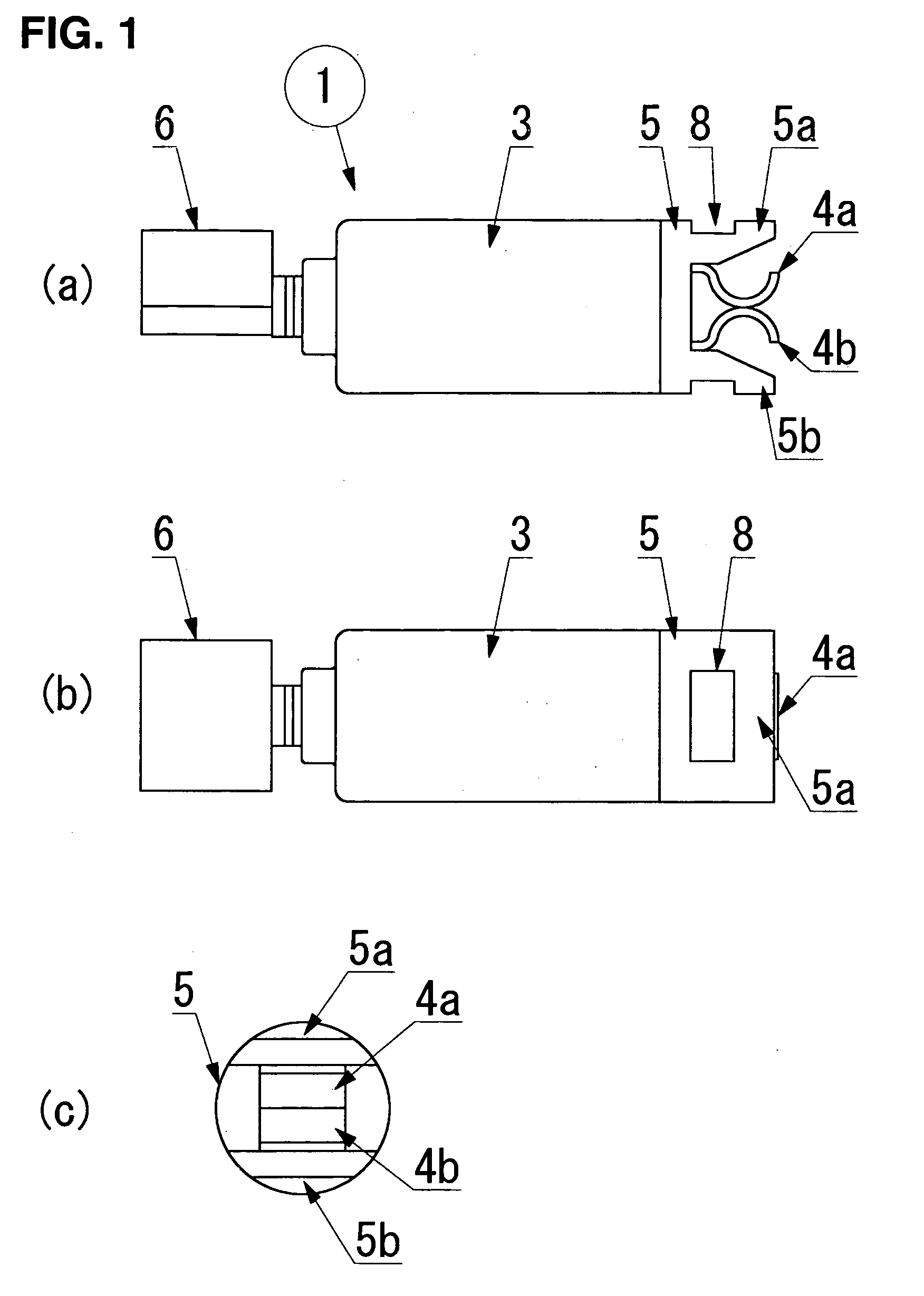

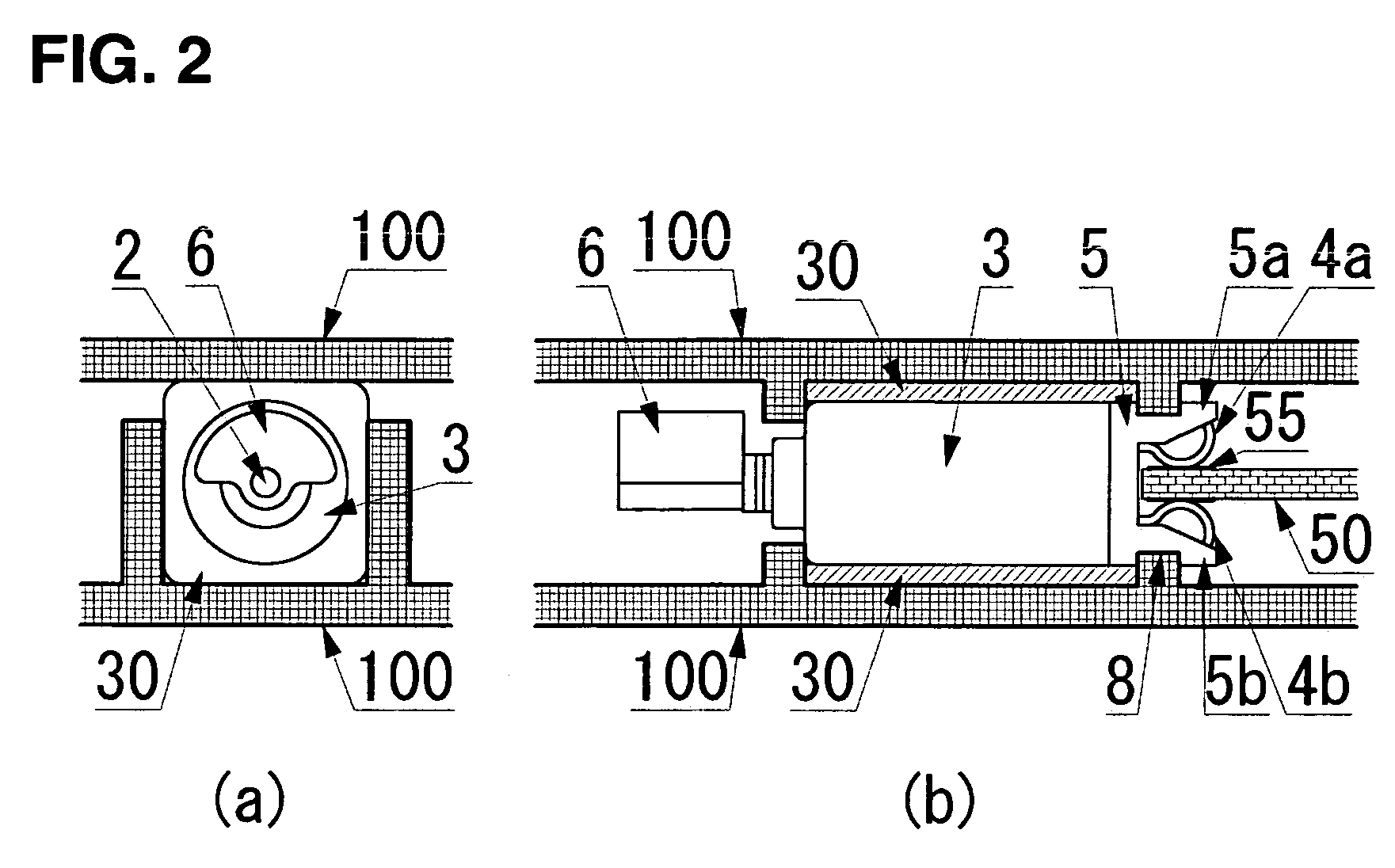

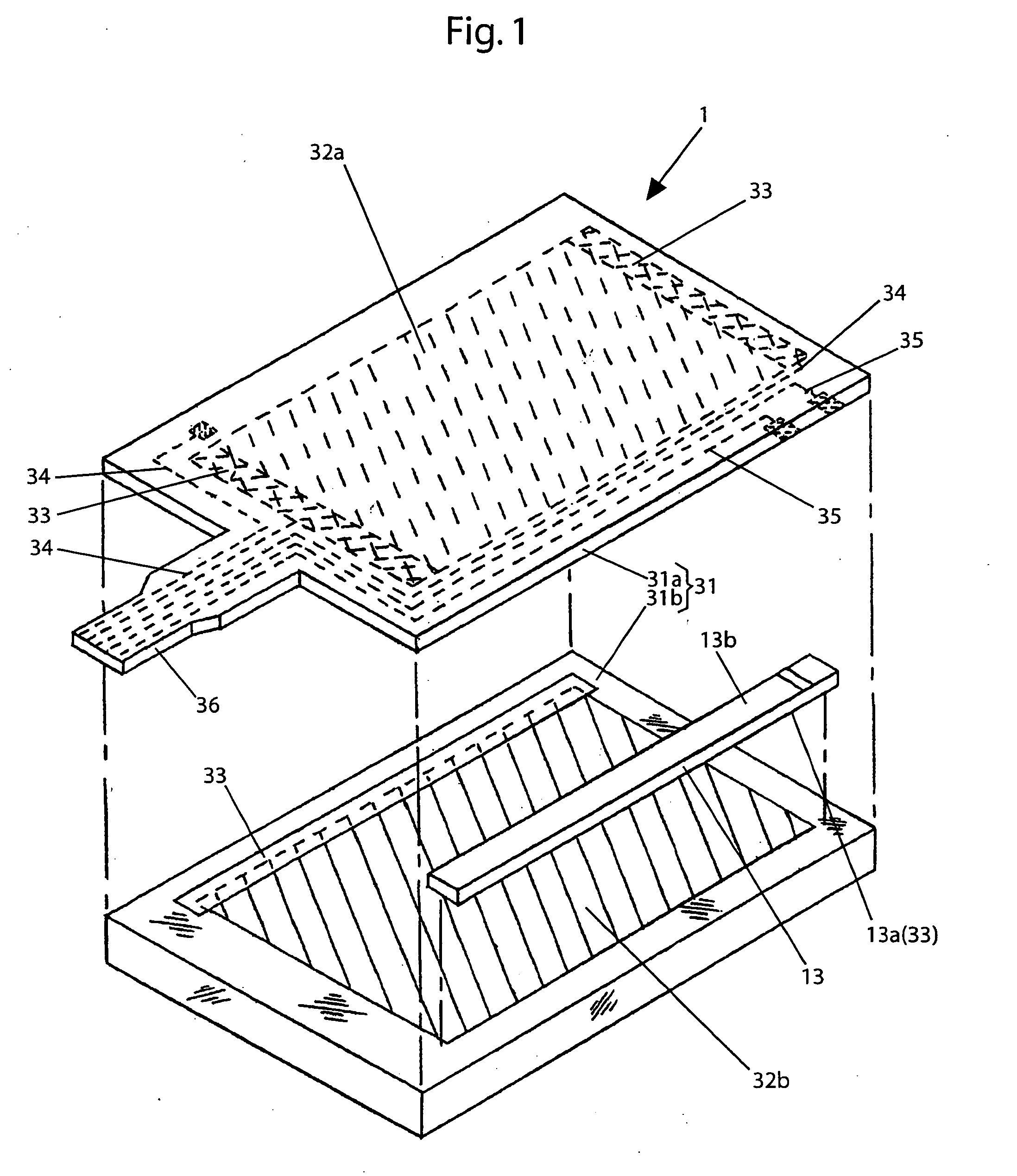

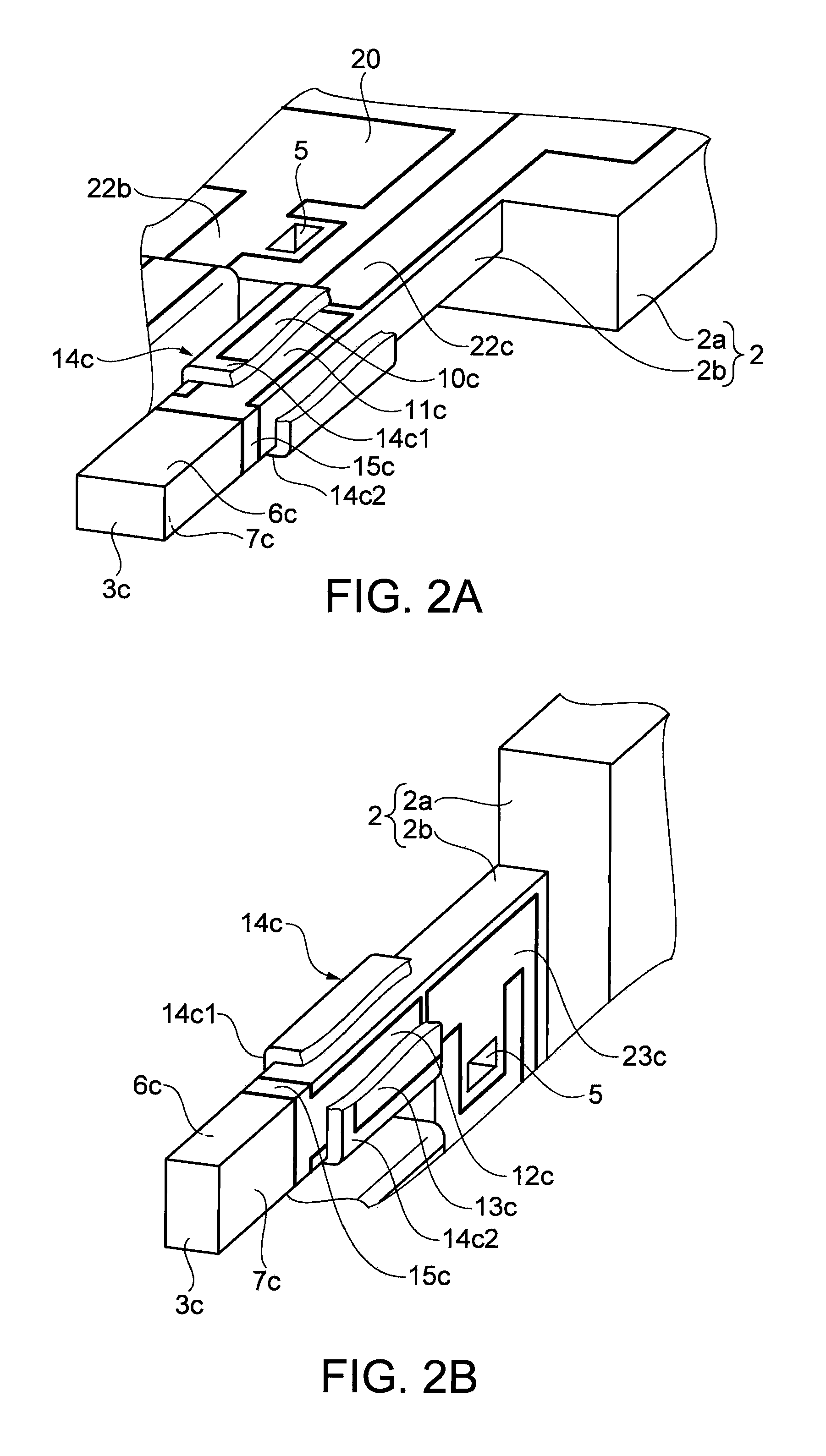

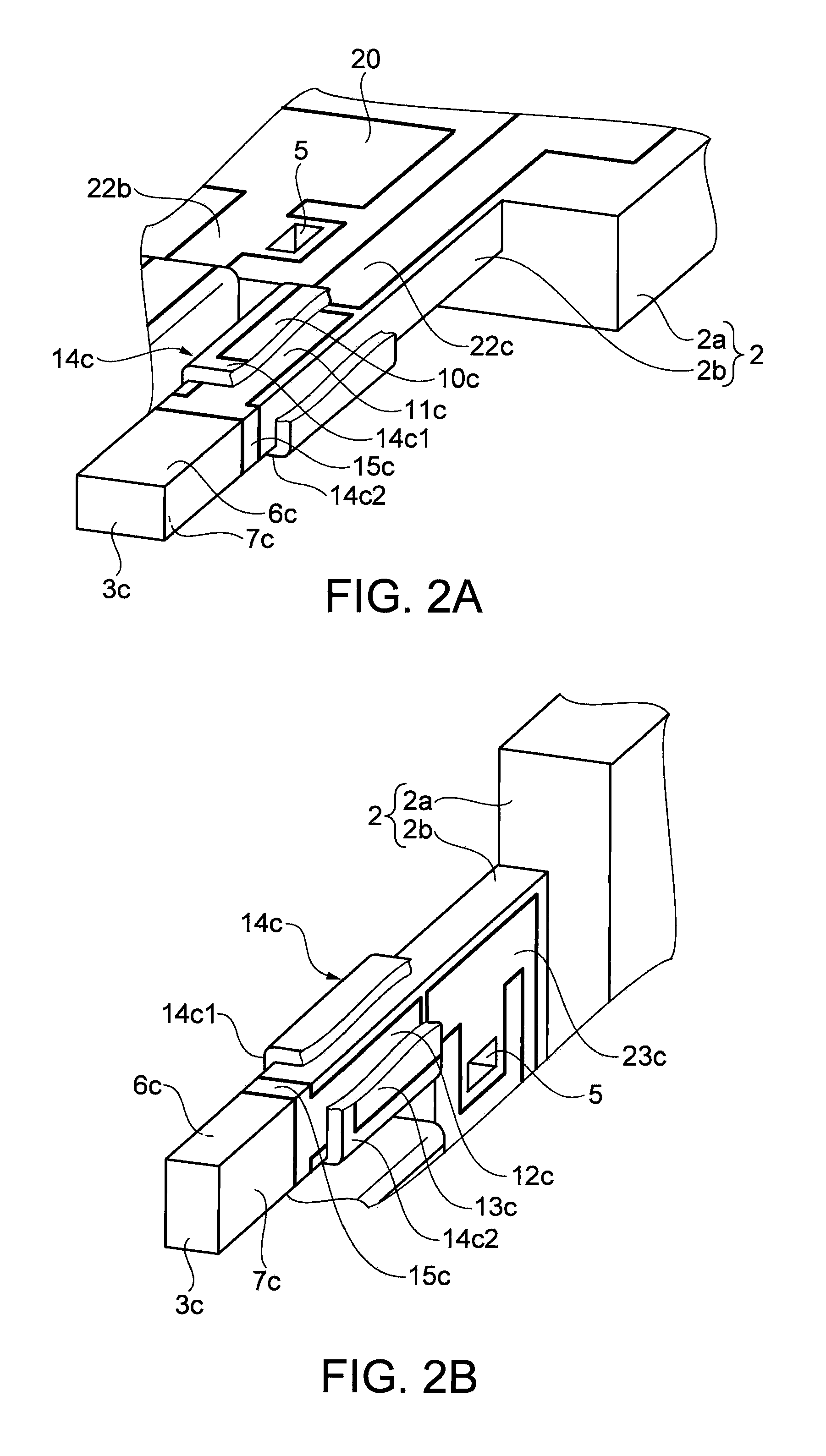

Vibration-generating small motor and portable electronic apparatus

InactiveUS20060138885A1Stable operationHigh connection reliabilityMechanical vibrations separationStructural associationStatorElectricity

The present invention is a vibration-generating small-sized motor that comprises within an external housing case thereof a stator and a rotor, a commutation mechanism, a power supply terminal that connects electrically with an electrode or a power supply land of the electronic equipment, and a terminal-blade mount on which the power supply terminal is mounted, wherein the power supply terminal includes a pair of resilient terminal blades that are located on the terminal-blade mount provided at a face of the external housing case of the motor, facing each other and pressing together, and the electrode or the power supply land on the circuit board are clamped between the resilient terminal blades, whereby the vibration-generating small-sized motor can be electrically connected to the power supply of the electronic equipment. Accordingly, the power supply terminal of the vibrating motor mounted in the portable electronic equipment can be electrically connected to the electrode or the power supply land on the circuit board in the electronic equipment with high reliability and this connection can be maintained continually over a long period.

Owner:NAMIKI SEIMITSU HOSEKI KK

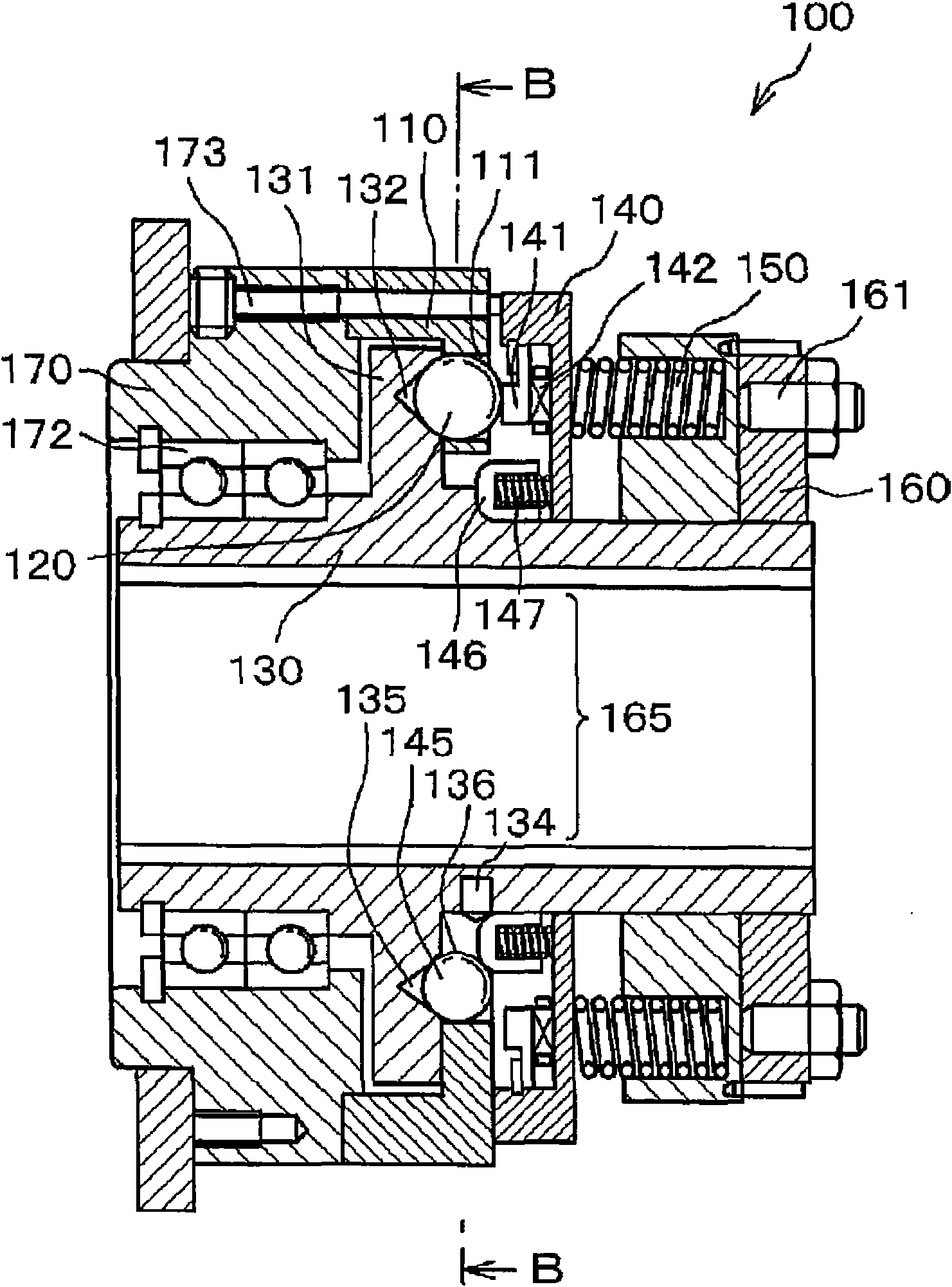

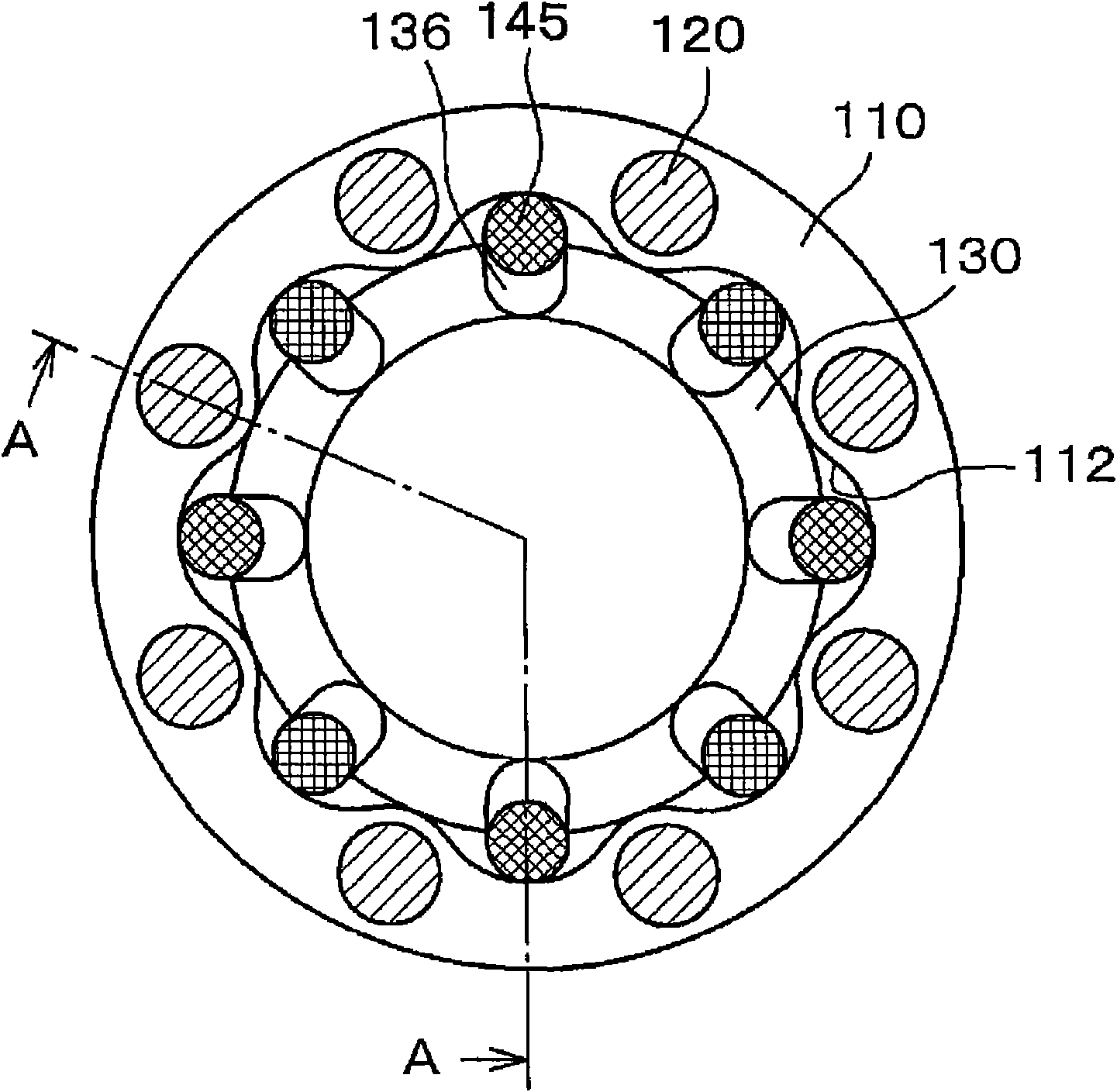

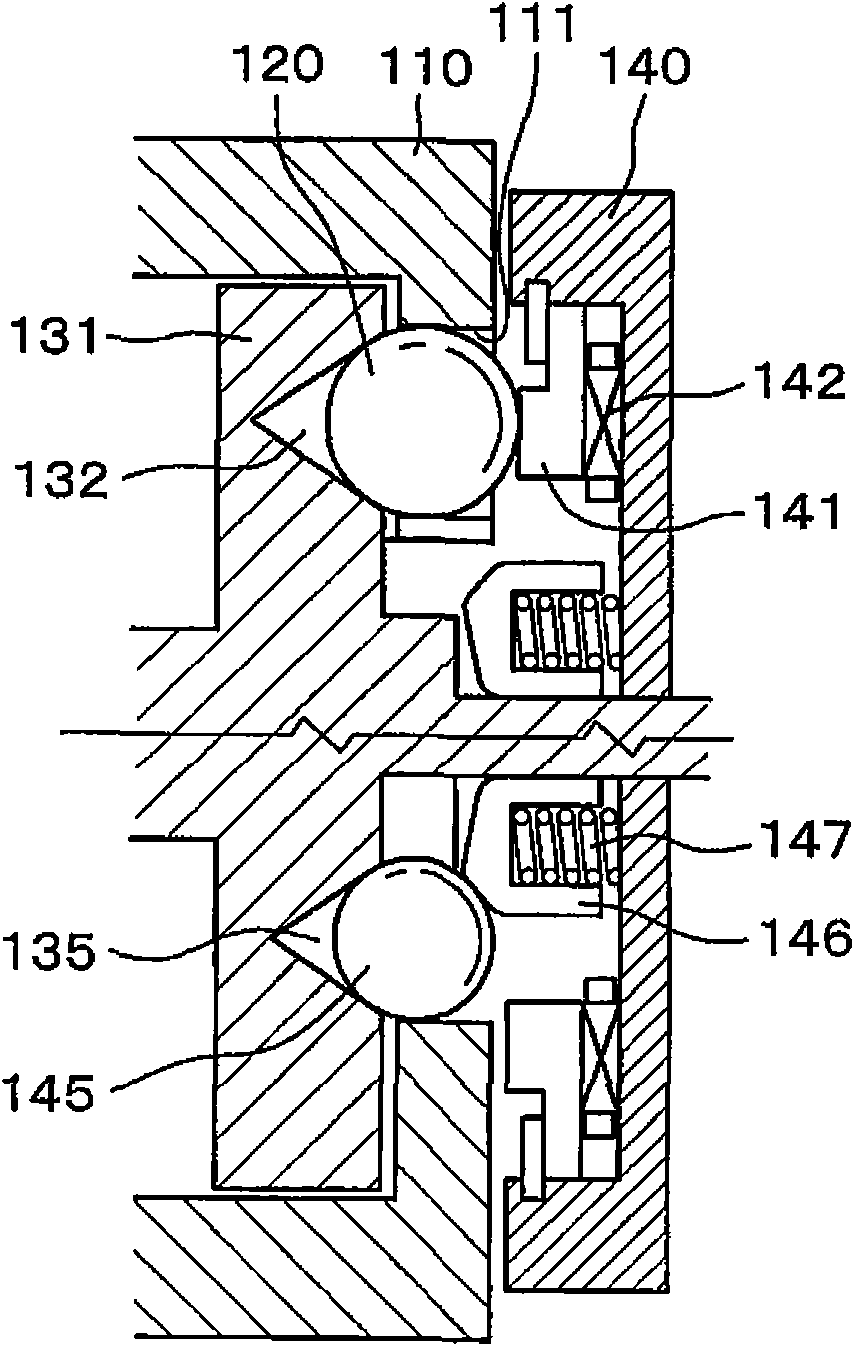

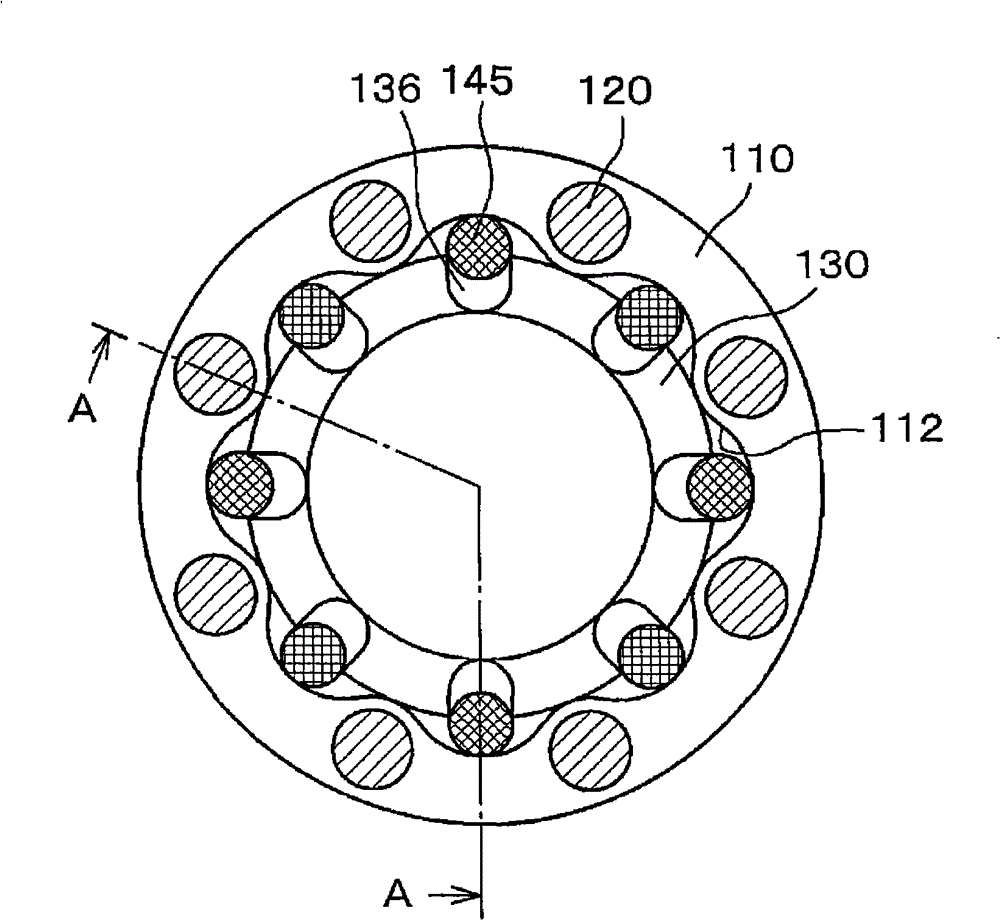

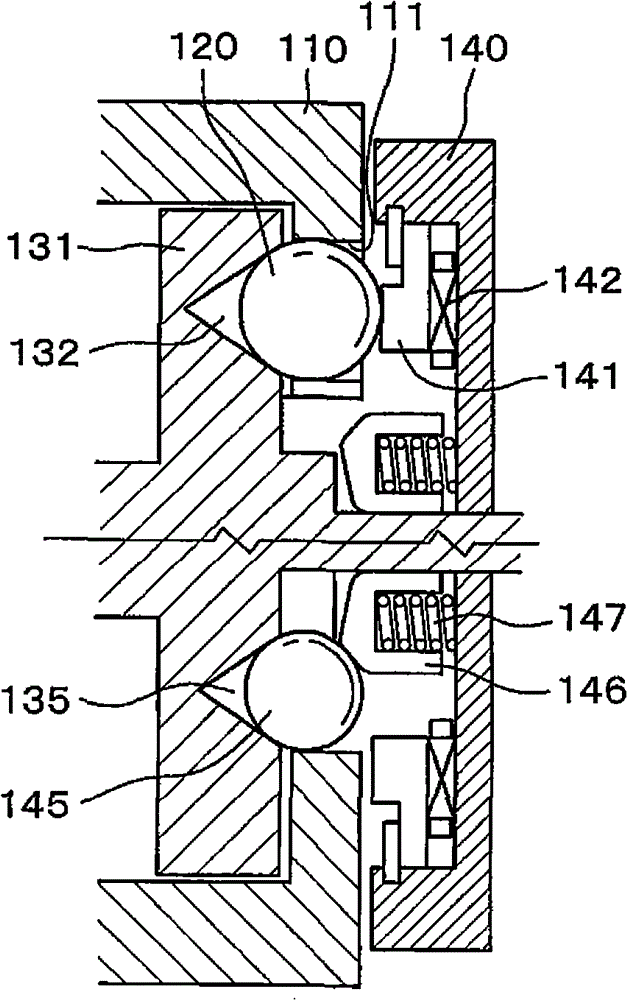

Overload protection device

InactiveCN101561020AAvoid vibration and noiseAccurate working torqueAutomatic clutchesRetaining ringFlange

The invention provides a overload protection device, capable of keeping the rotary drive partition state and preventing from generating the vibration and noise because of the transference the path of the push pressure and accurately setting the operation torque and making a holding mechanism work reliably. the overload protection device has a central flange (110), a hub flange (131) and a push compressed plate for pushing a steel ball (120) to rotate and drive, wherein a holding mechanism (165) for keeping the partition in the over loading comprises a retaining ring (146) mounted at the central flange side of the push pressure plate (140) and a holding ball (145) arranged at the internal circumstance side of the central flange (110).

Owner:TSUBAKI E&M +1

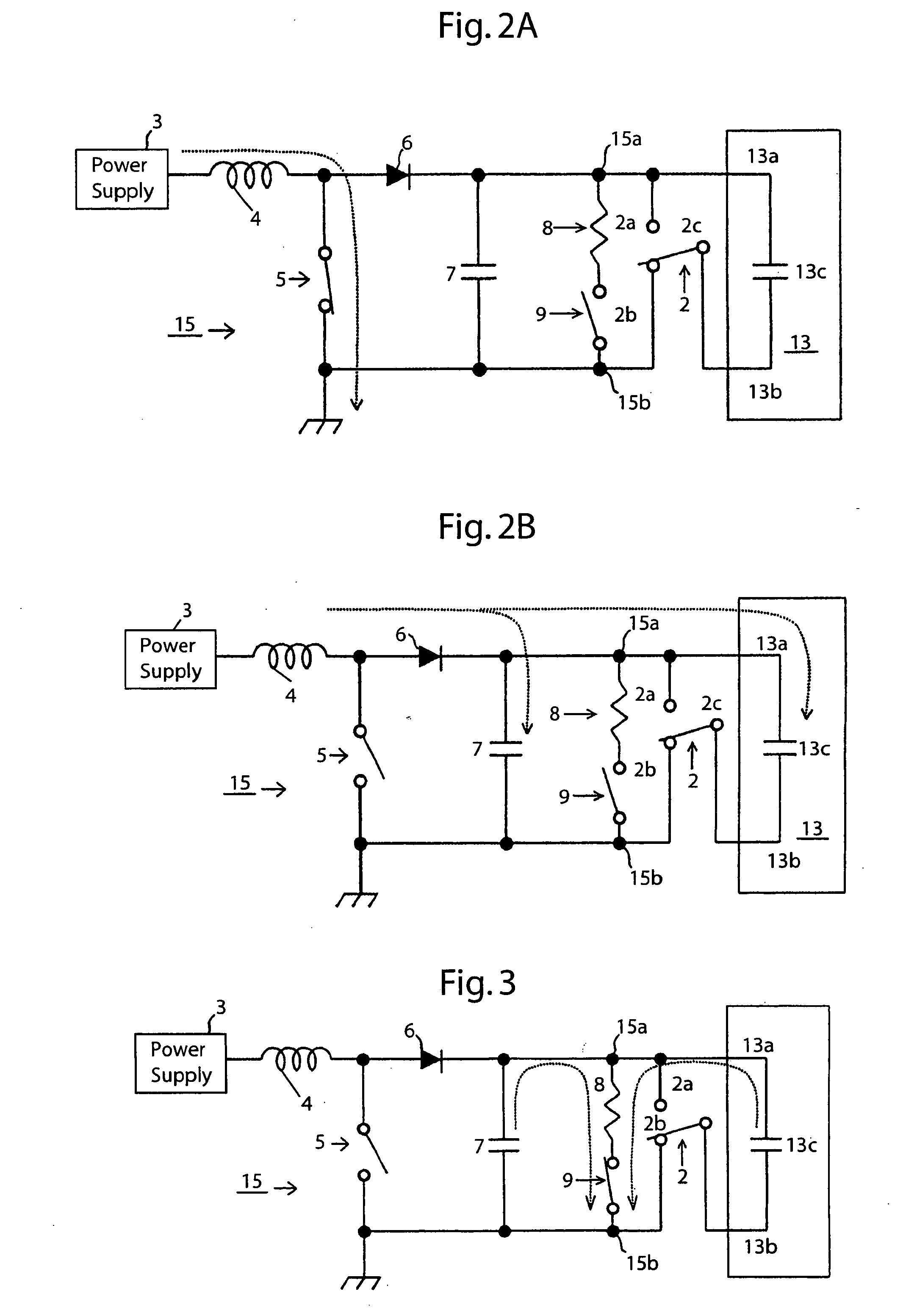

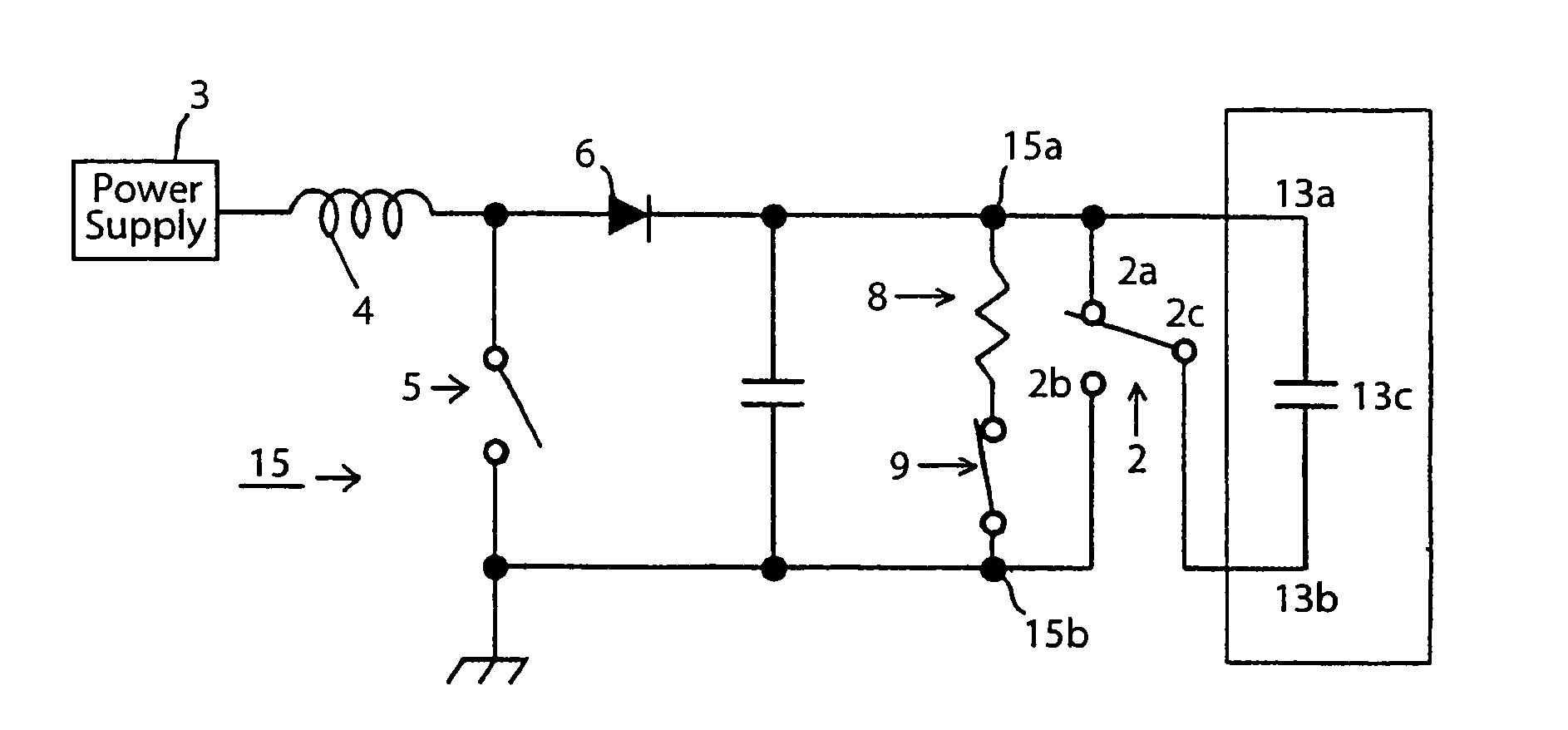

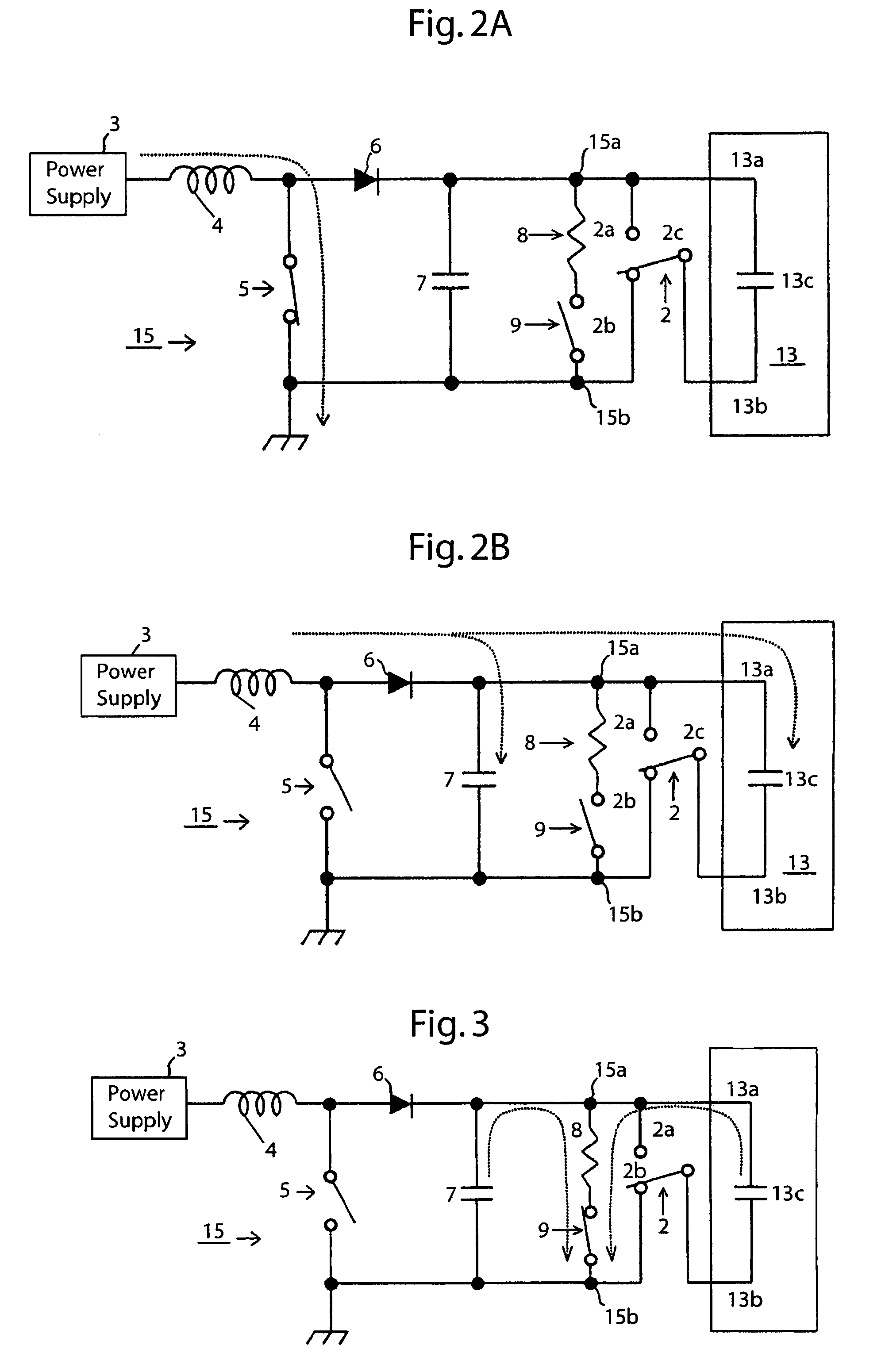

Touch panel input device

InactiveUS20060017705A1No deteriorationSufficient amplitudeCathode-ray tube indicatorsInput/output processes for data processingElectricityEngineering

The present invention provides a touch panel input device that reliably prevents degradation of a piezoelectric substrate. During inactive periods in which a touch panel input device is not used, the connection between a set of output terminals of an AC power supply circuit and a set of associated drive electrodes on the piezoelectric substrate is switched with a selector switch so that the drive electrodes are shorted. During inactive periods, no DC potential is applied to the set of drive electrodes even if a charged conductive body comes into contact with the drive electrodes or a drive power source pattern connected thereto. This makes it possible to prevent the degradation of the piezoelectric substrate.

Owner:RICHMOND EEI +1

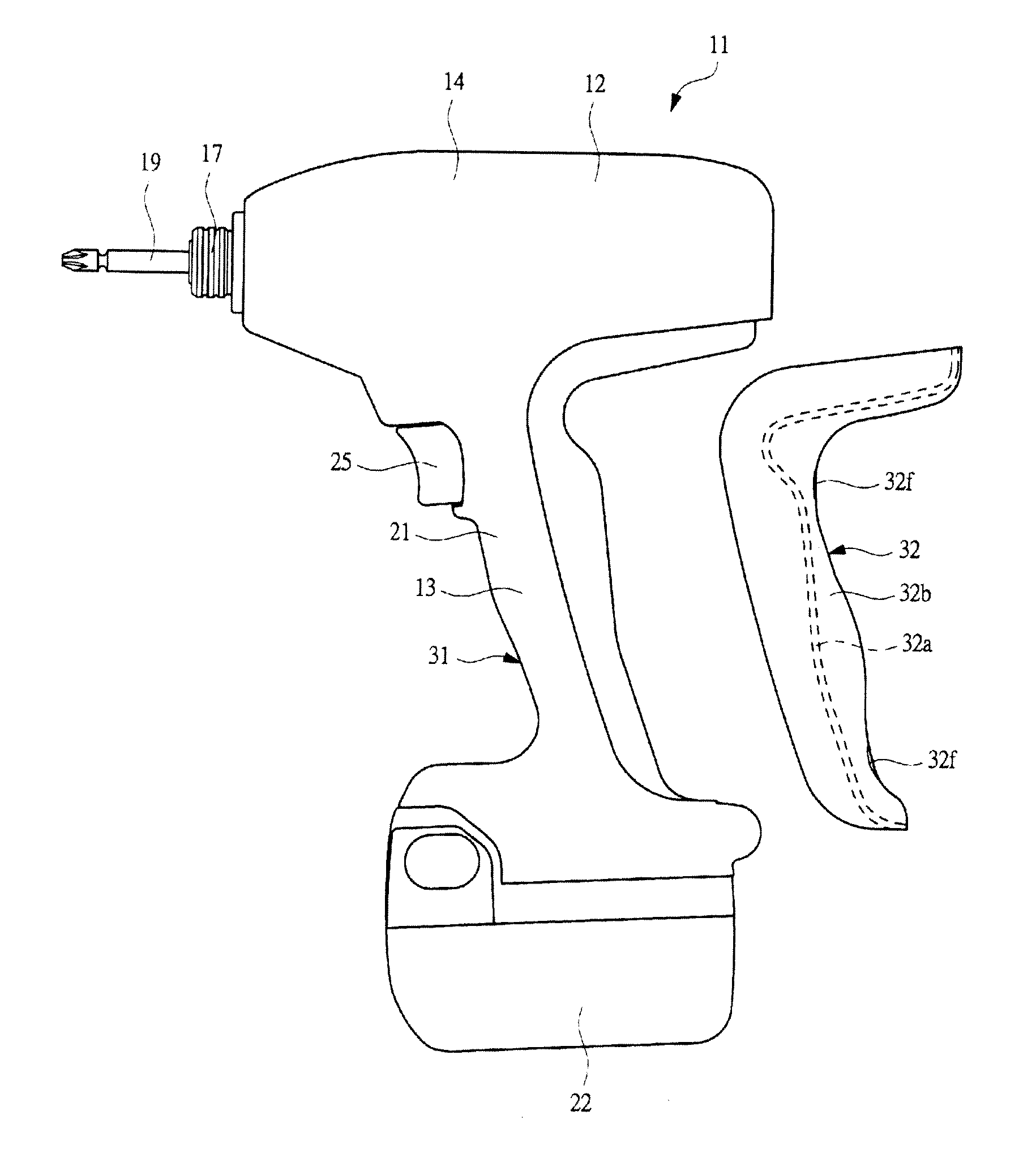

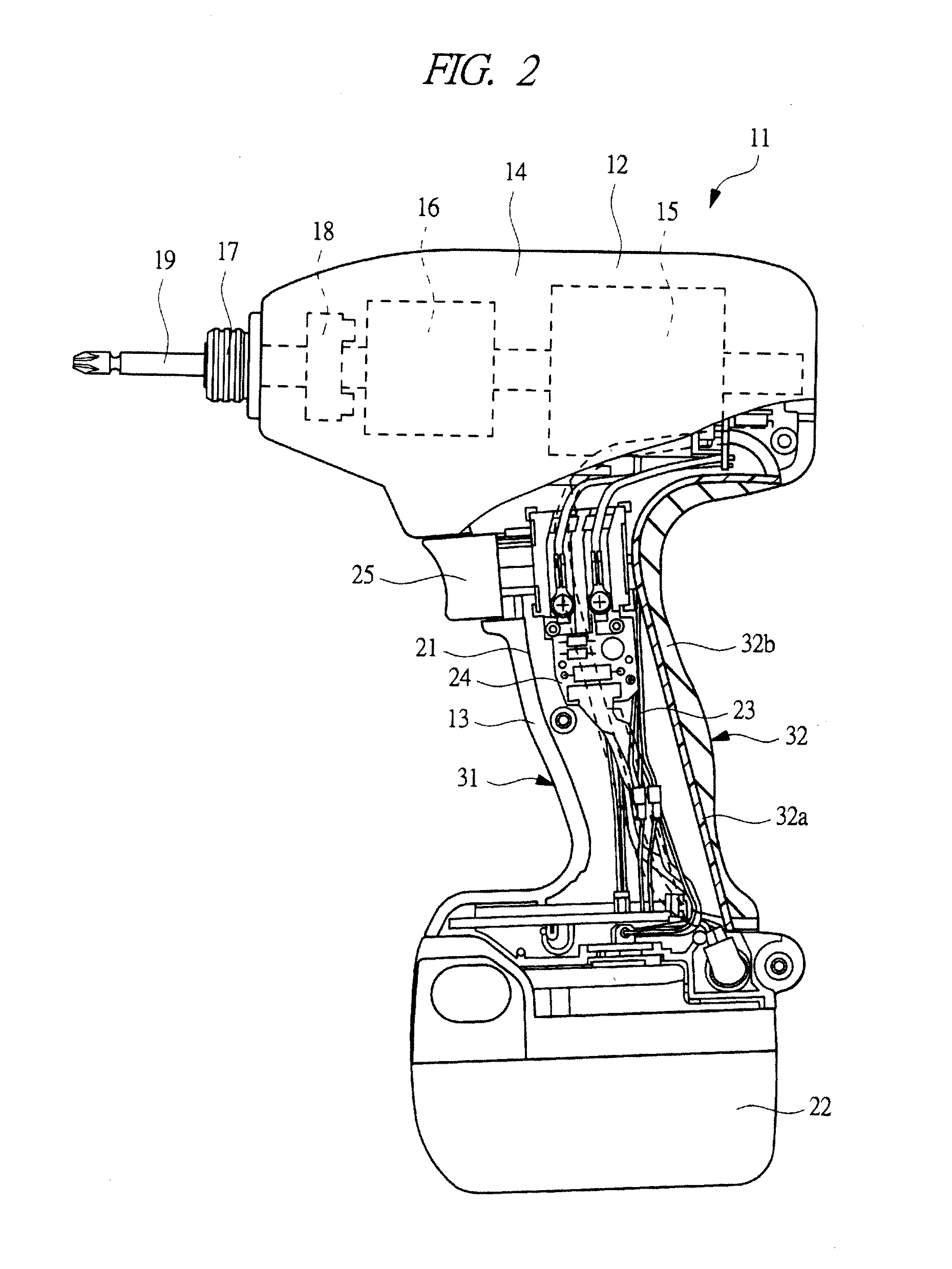

Power tool

InactiveUS20130277079A1Uneven thicknessReliably absorbing vibrationPortable percussive toolsPortable power-driven toolsCompression moldingEngineering

A hand-held power tool capable of reducing strain on a worker's fingers which might be caused by vibration and reaction during work is provided. A grip section, which is extending from substantially a central part in an axial direction of the body portion toward a direction substantially perpendicular to the axial direction, is integrally provided on a body portion having a motor housing. A grip housing configuring the grip section is provided so as to extend from the motor housing. The grip housing includes a housing body including a pair of housing pieces and a cover sandwiched to be held by the housing pieces. The cover includes a compression-molded article in which a resin cover body and a rubber member are integrally formed by compression molding.

Owner:HITACHI KOKI CO LTD

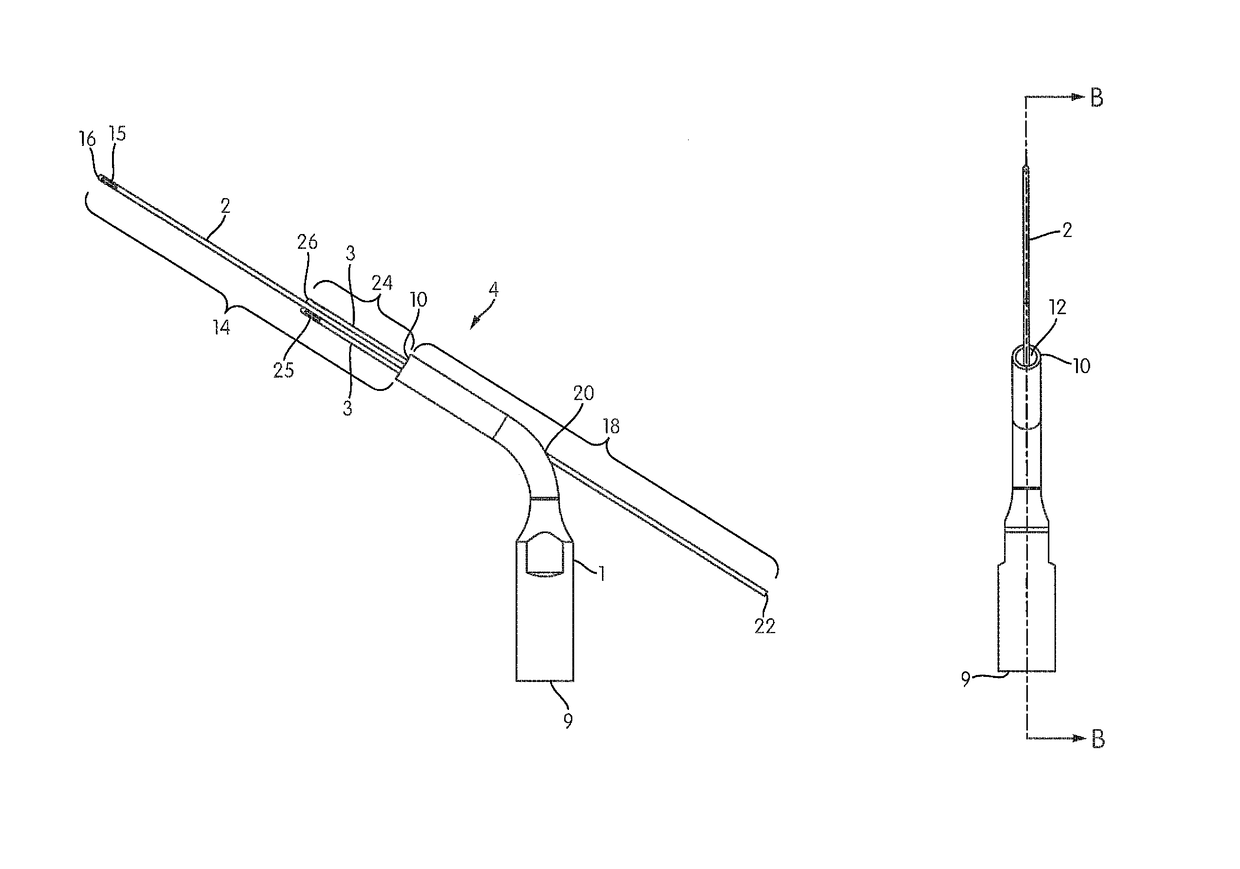

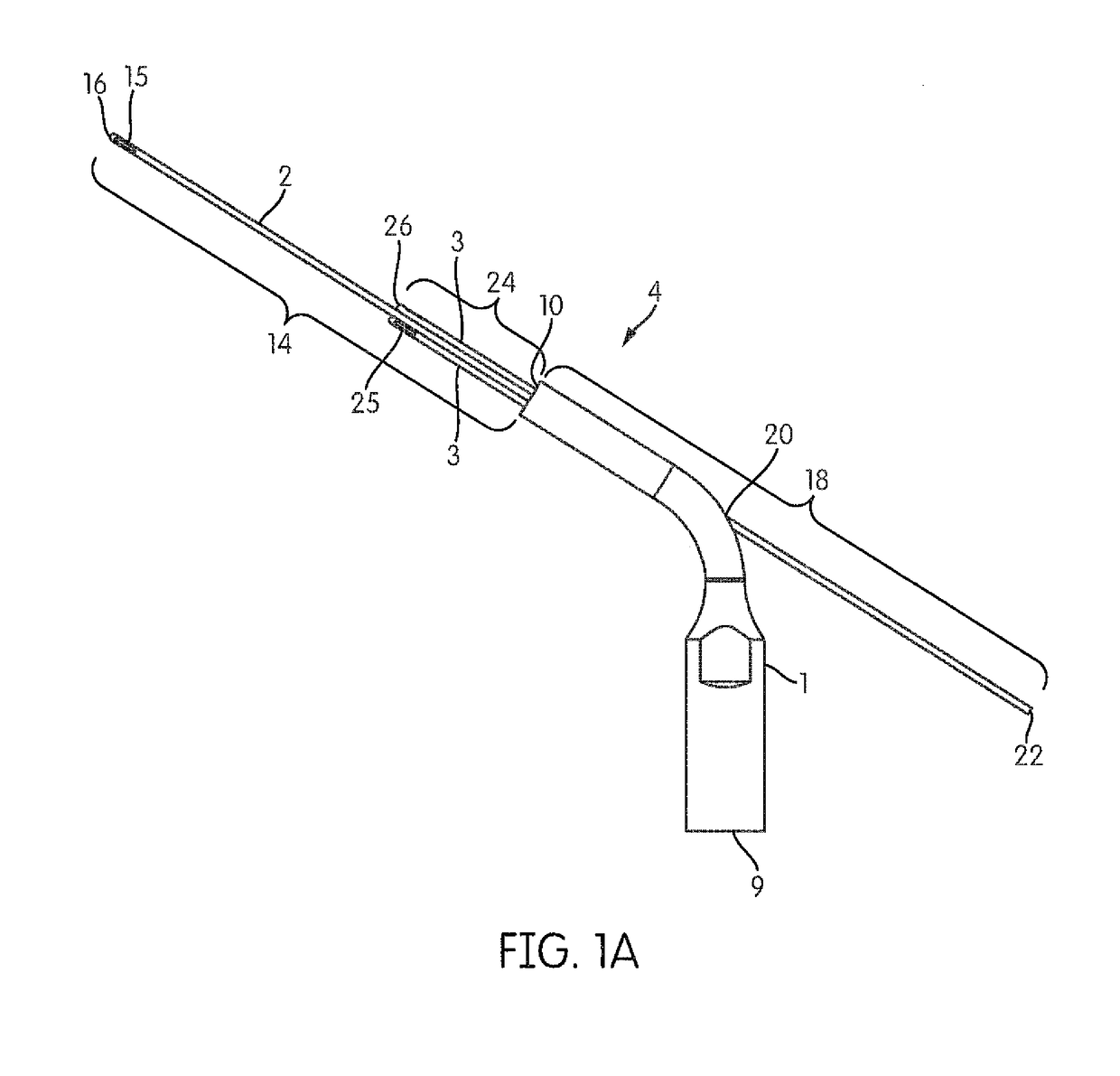

Ultrasonic tip assembly

A tip assembly for use with a dental tool, the tip assembly comprising a housing for attaching to the dental tool, at least one aspiration needle having a passageway extending at least partially through the aspiration needle, a substantial length of the aspiration needle, or at least from one end to the other end of the aspiration needle, the passageway providing a single continuous path to aspirate the irrigant and / or debris from the root canal cavity of the tooth, and at least one irrigation needle having a passageway extending at least partially through the irrigation needle, a substantial length of the irrigation needle, or at least from one end to the other end of the irrigation needle, the passageway provides a continuous flow path for delivering fluid / irrigant from a reservoir in communication with a proximal end of the irrigation needle to the distal end of the irrigation needle and into a root canal / coronal opening of a tooth.

Owner:DENTSPLY SIRONA INC

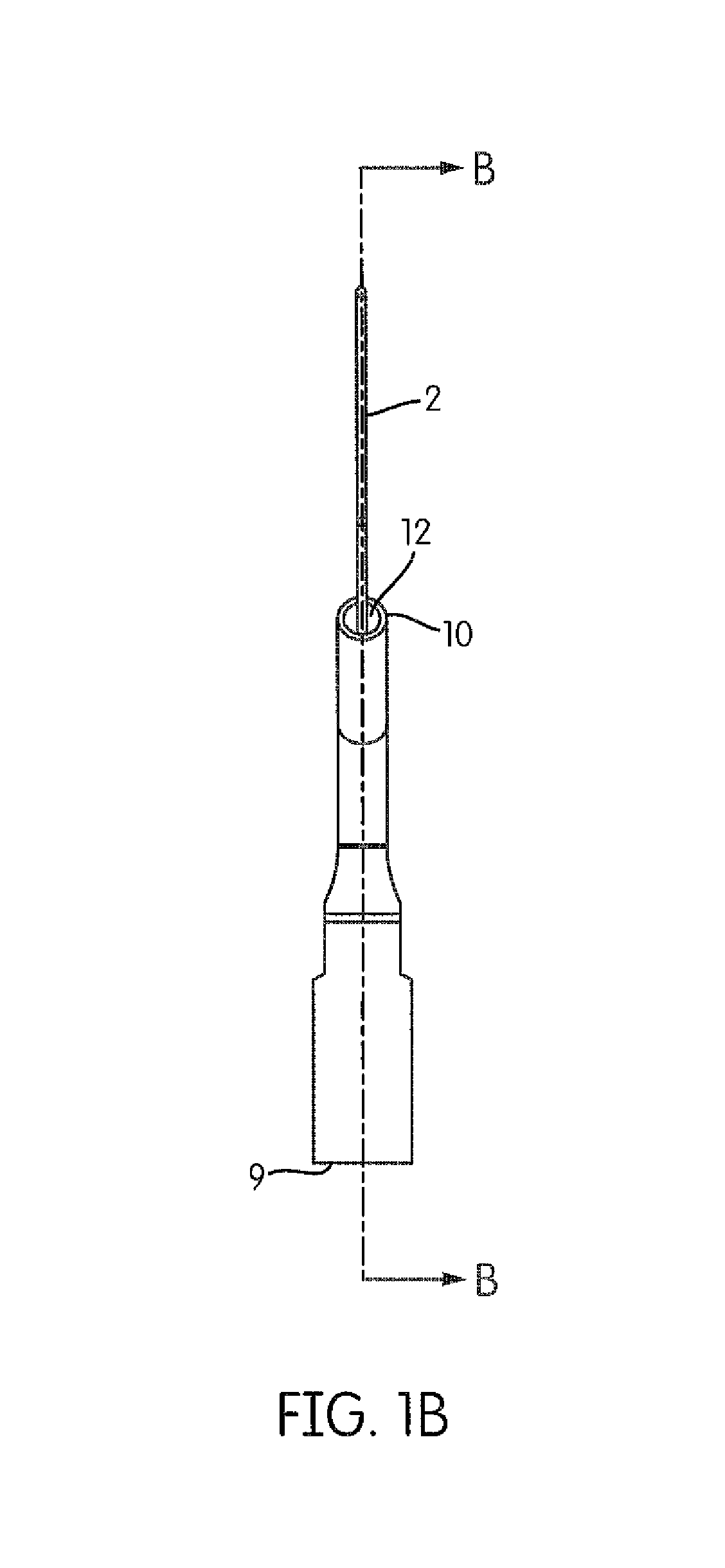

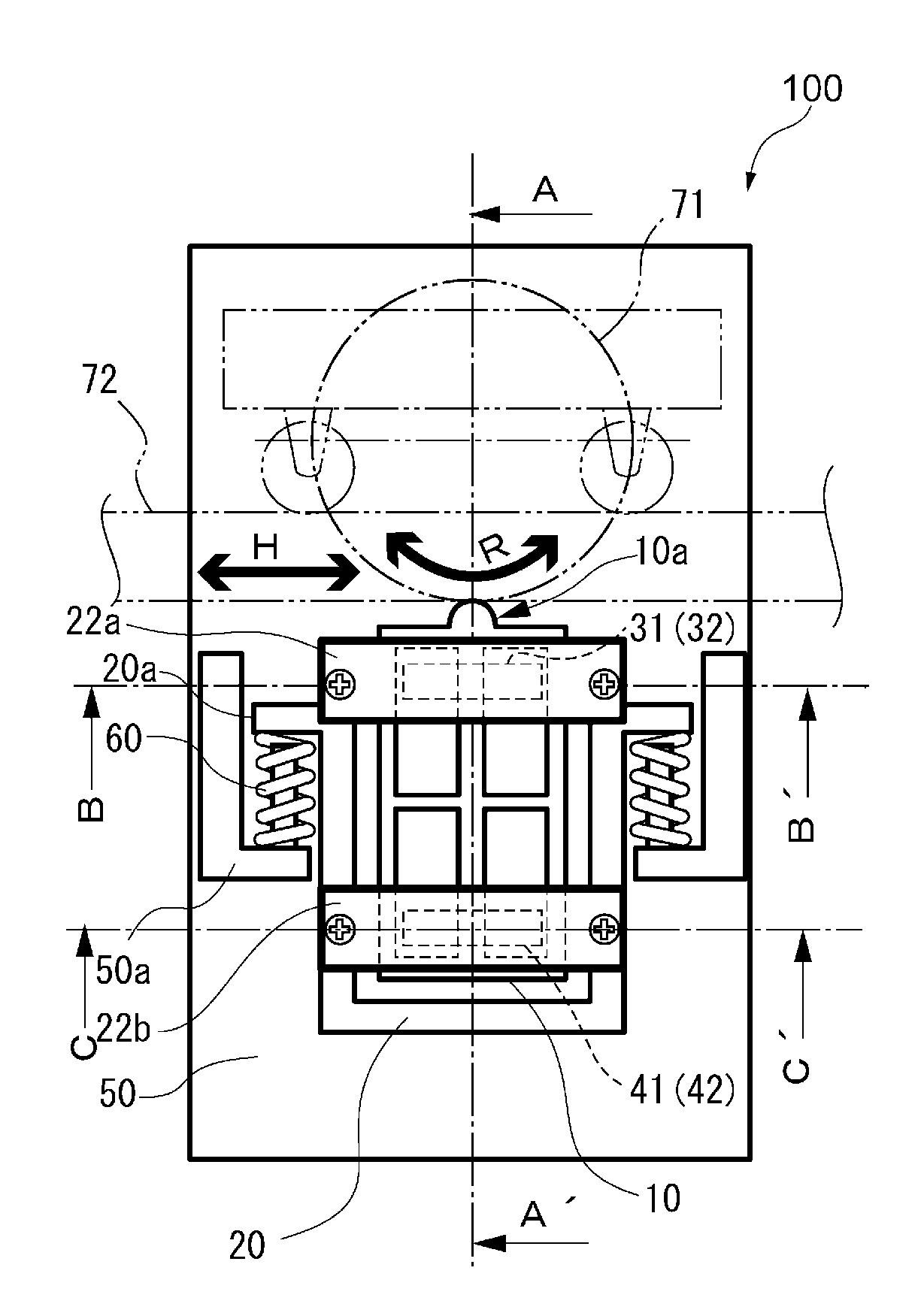

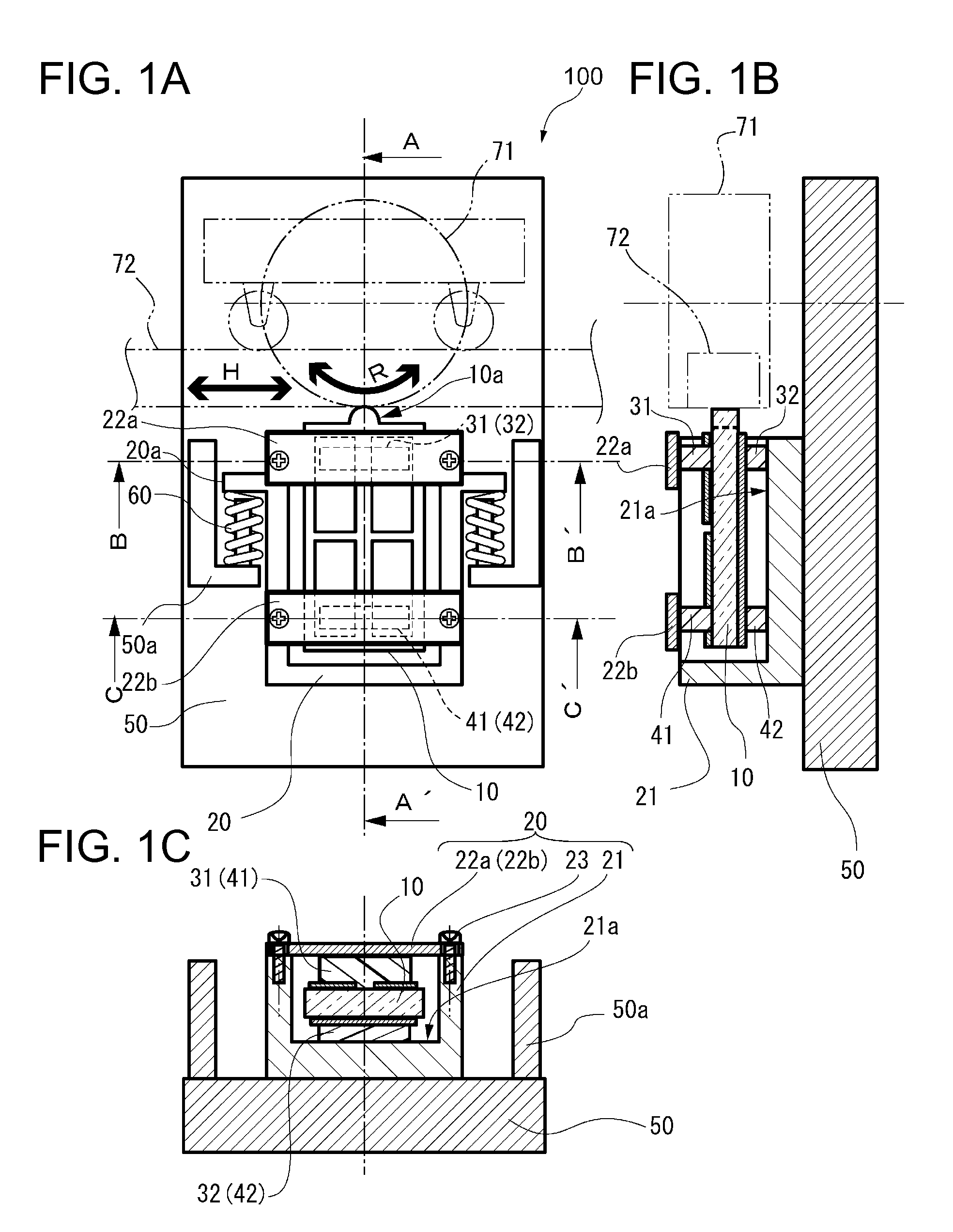

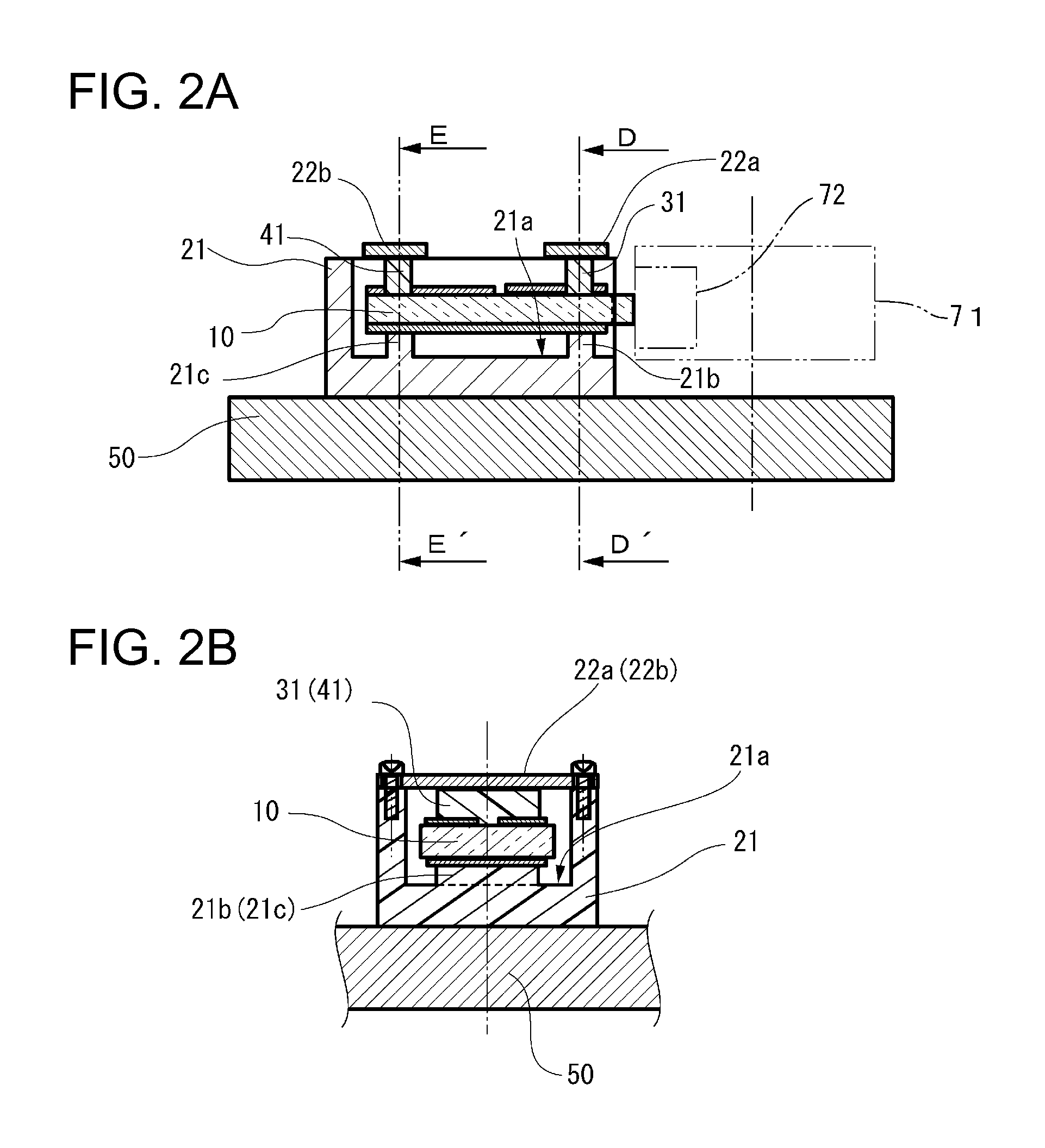

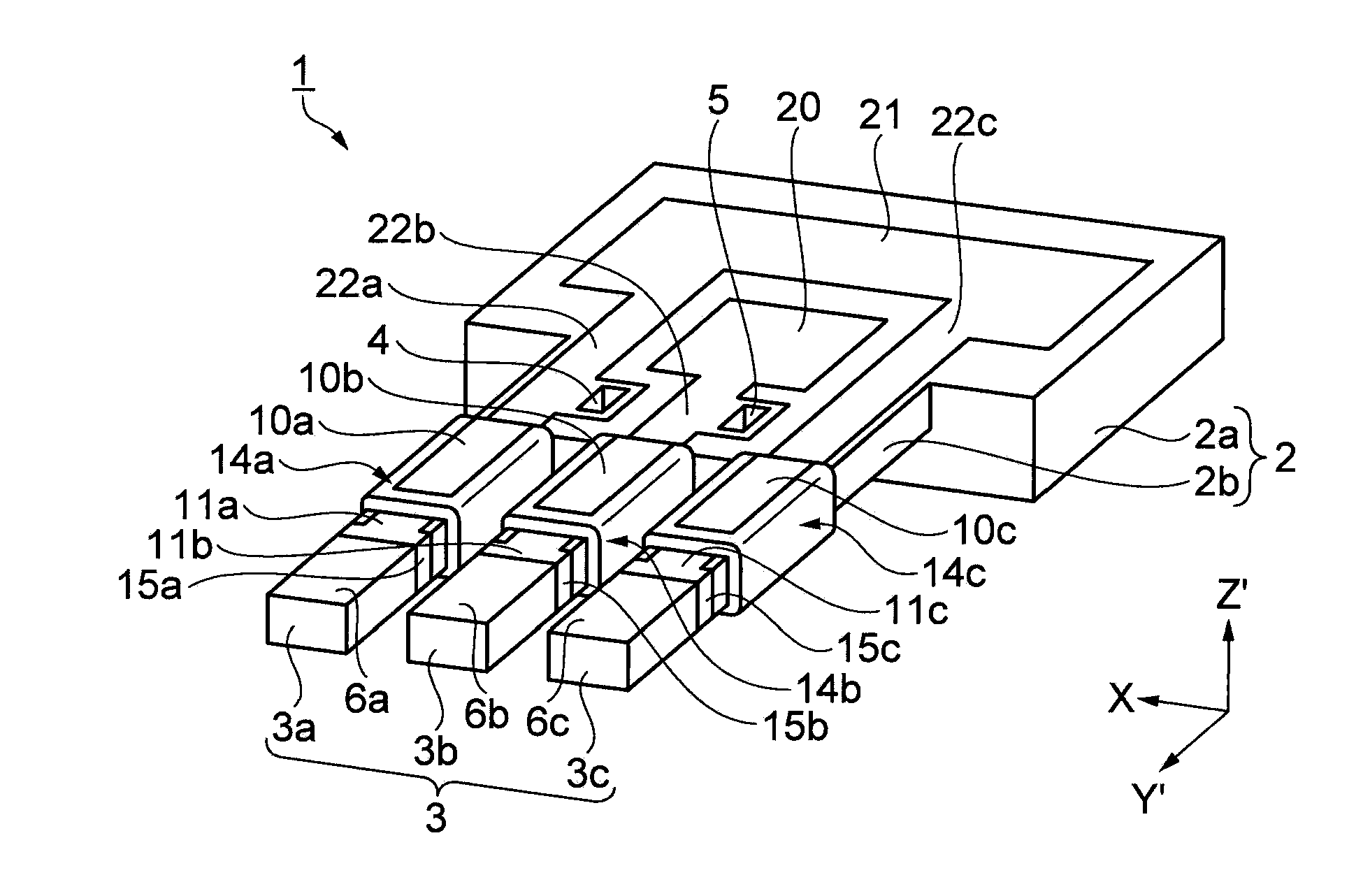

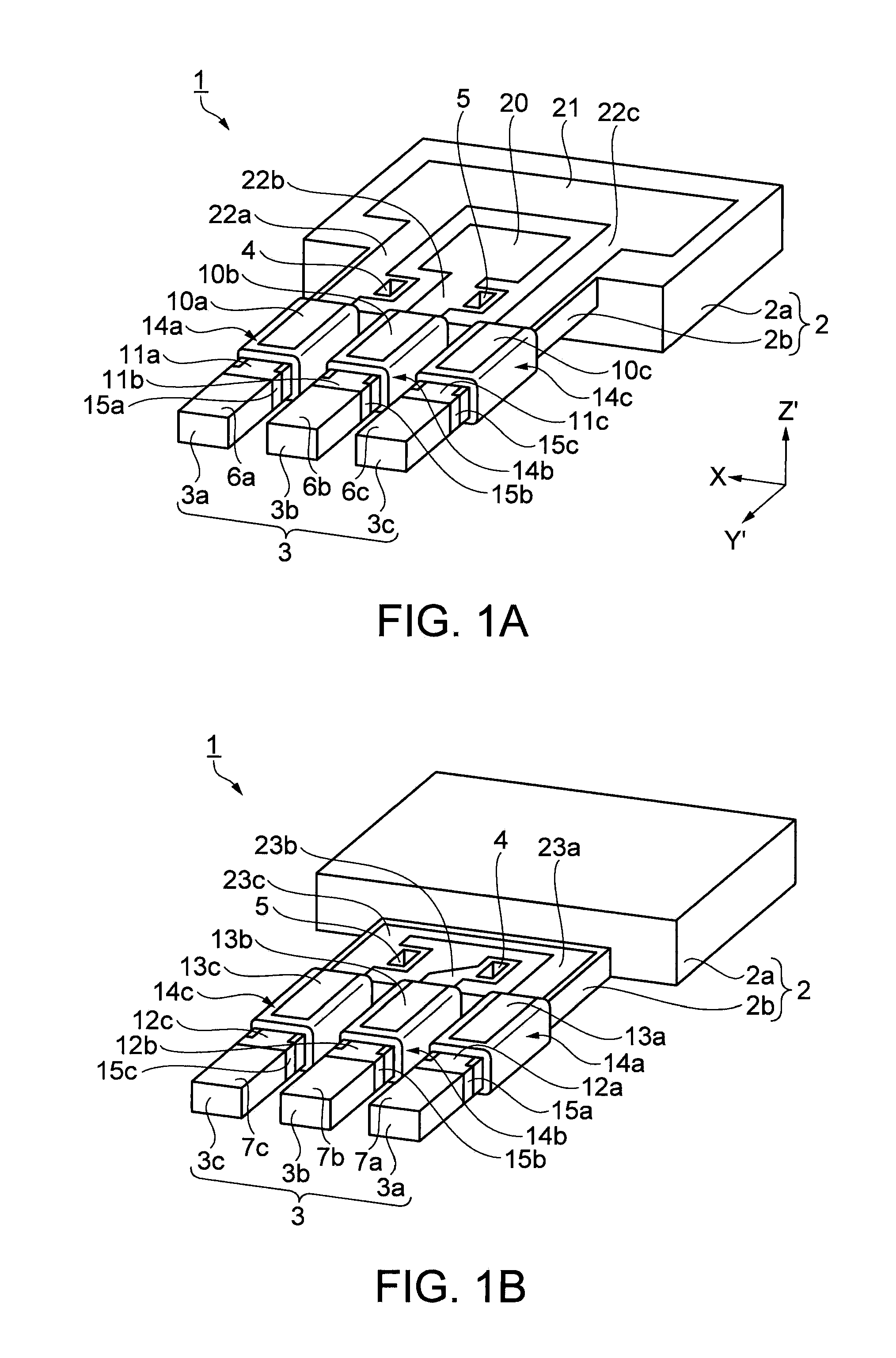

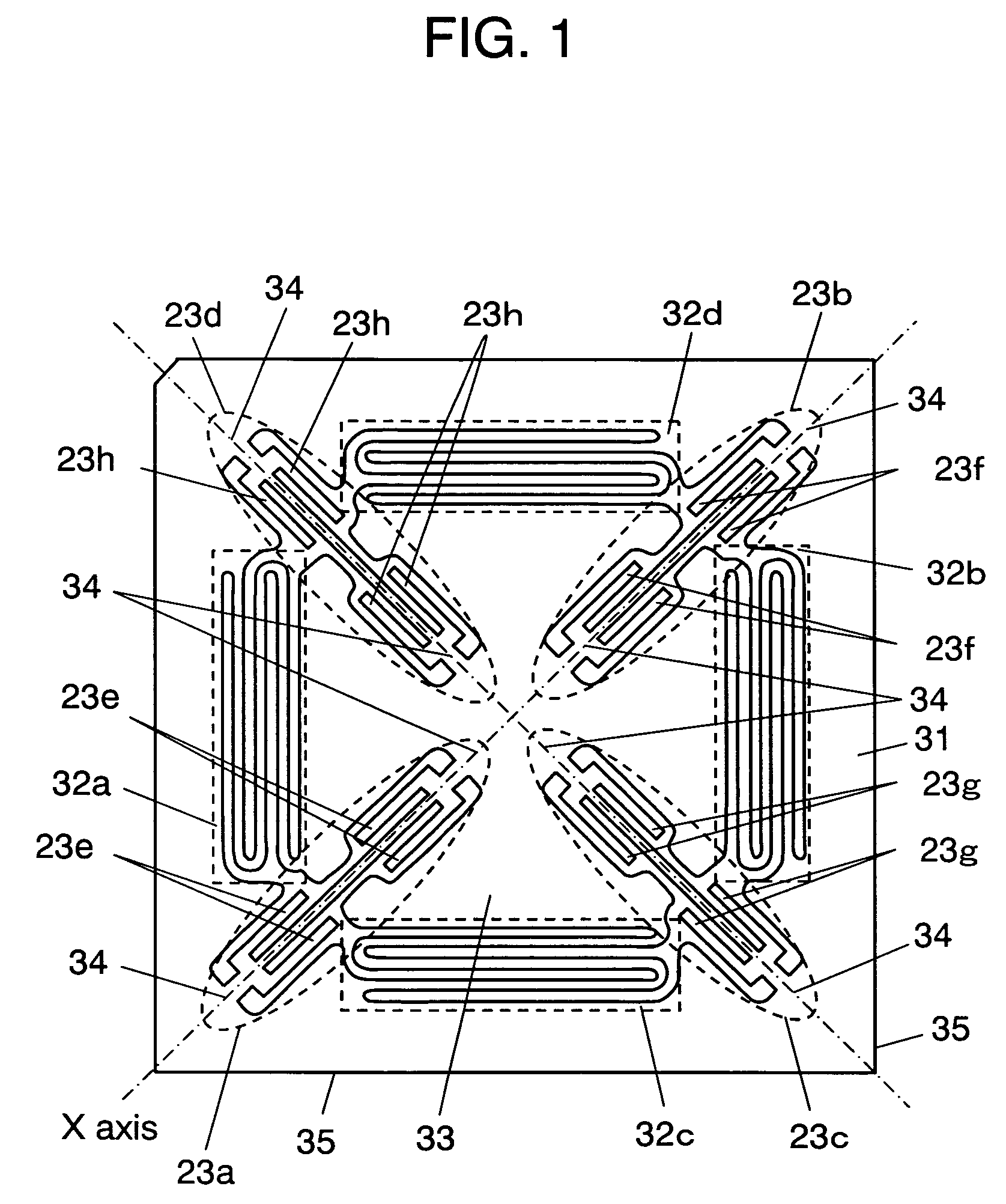

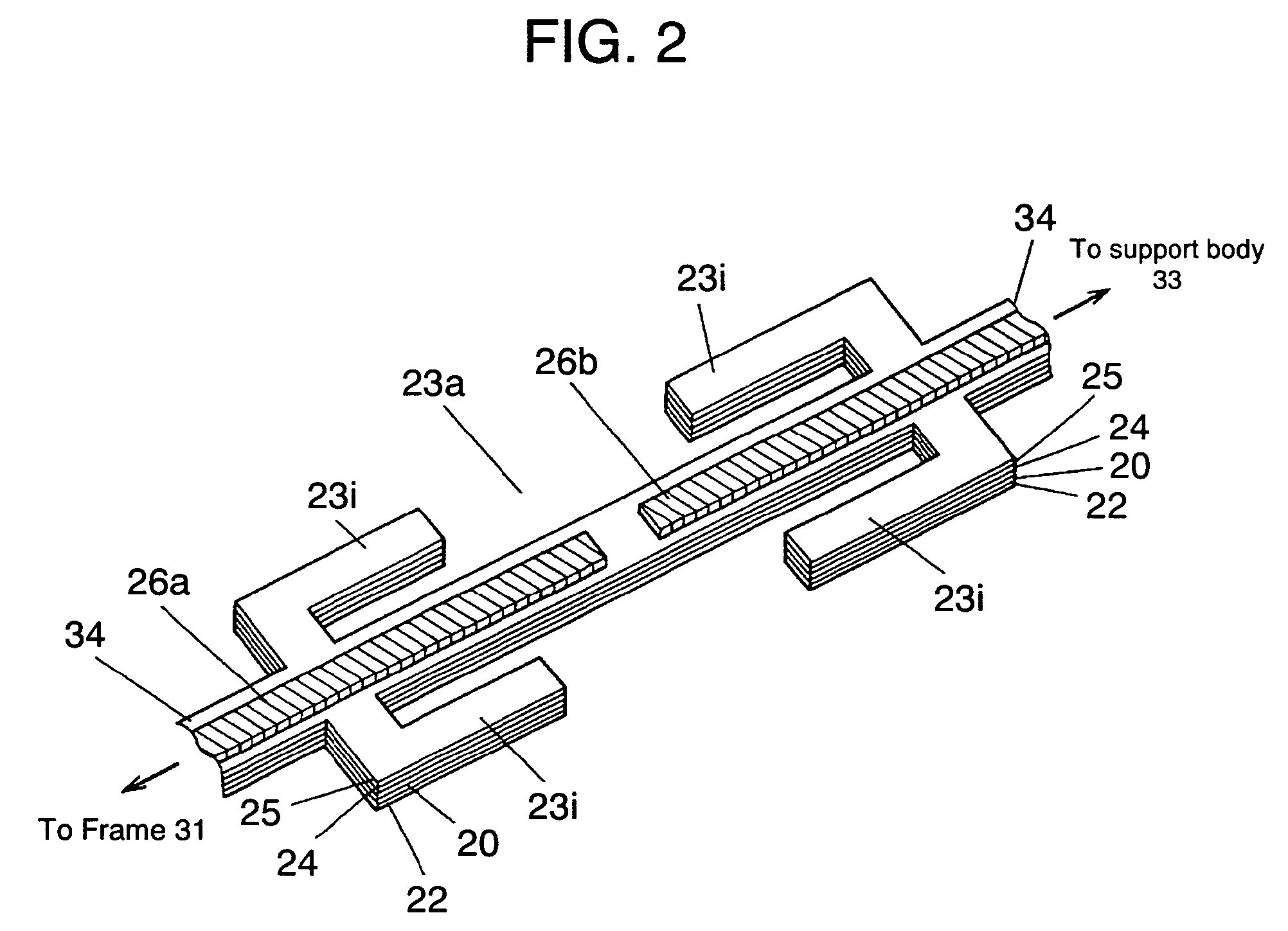

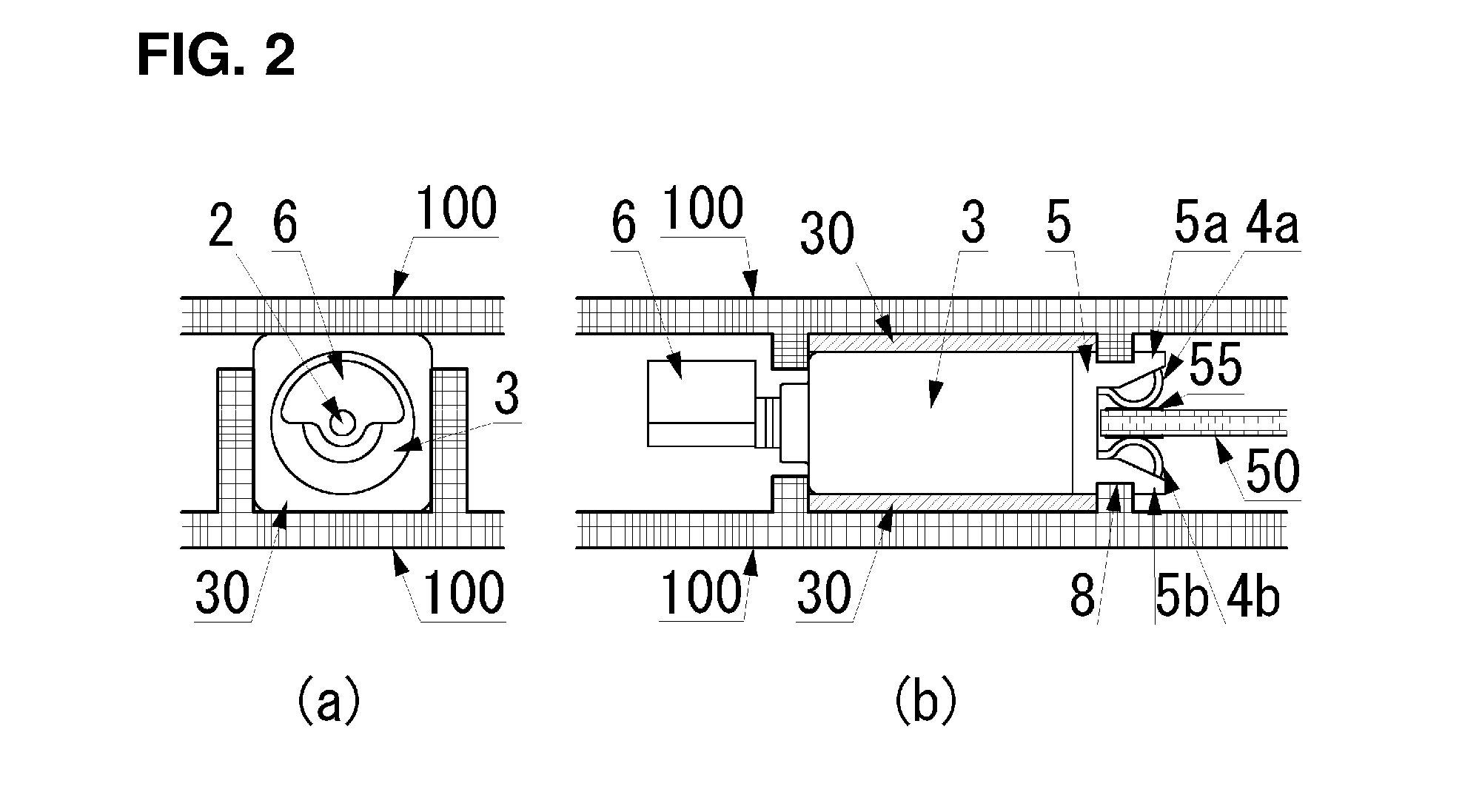

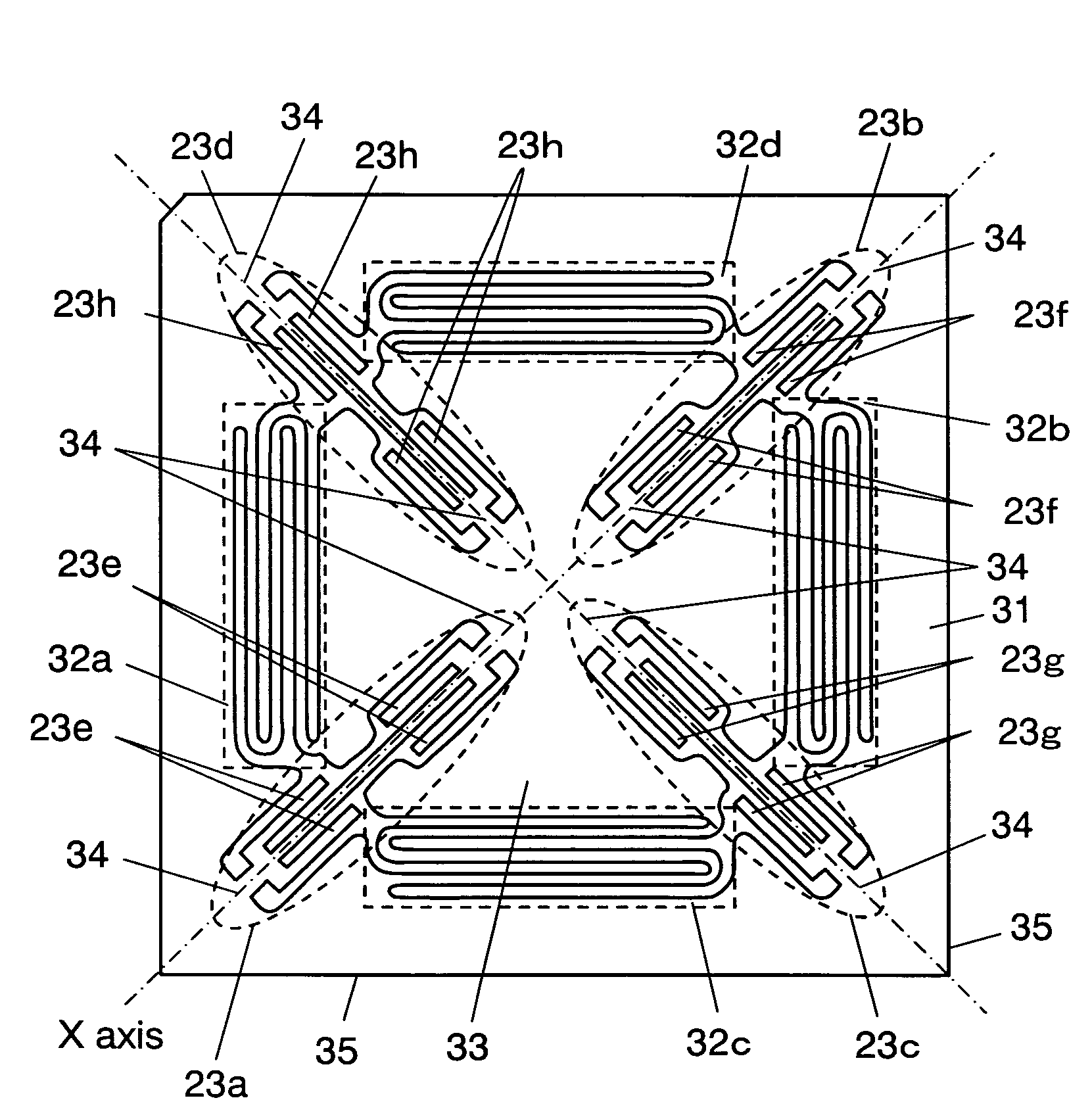

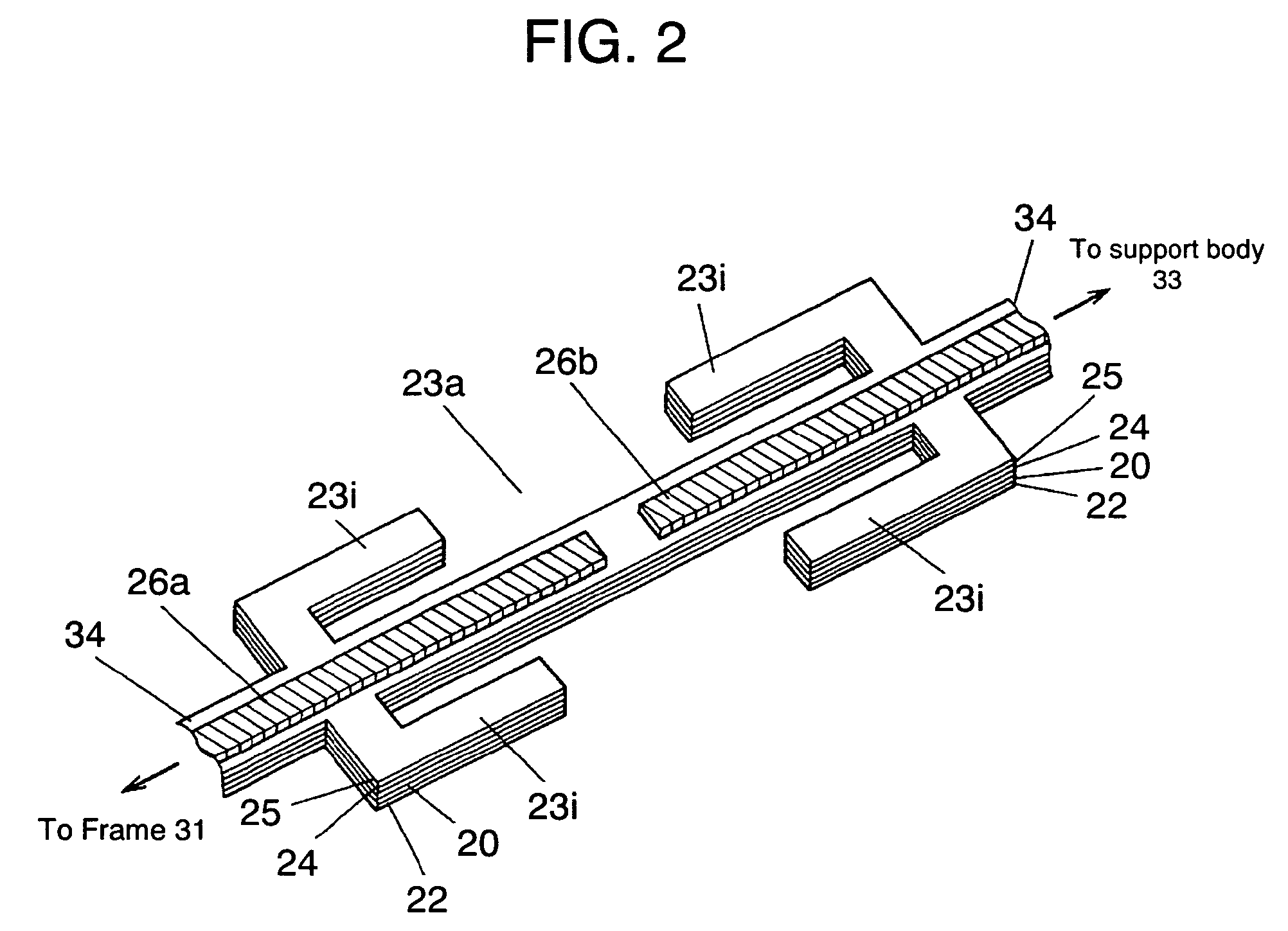

Actuator, robot hand, robot, electronic component carrying device, electronic component inspection device, and printer

InactiveUS20130140954A1Containment leakReliable vibrationPiezoelectric/electrostriction/magnetostriction machinesGripping headsRobot handEngineering

An actuator includes a vibrating piezoelectric element, and a holding unit that holds the piezoelectric element, in which the holding unit is disposed on a vibrating surface of the piezoelectric element, and includes a first support unit and a second support unit that are disposed on one side of the piezoelectric element, and a third support unit and a fourth support unit that are disposed on the other side of the piezoelectric element.

Owner:SEIKO EPSON CORP

Axial vibrator

ActiveCN103742076ASolve the pressure problemHigh Efficiency DrillingVibration drillingHorizontal wellsEngineering

The axial vibrator belongs to the field of drilling tools, in particular to an axial vibrator. The axial vibrator can produce an axial vibrating through adopting pressure pulses produced by a circumferential vibrator or a pulser to effectively solve the pulling problem of drill string of high angle extended-reach wells and horizontal wells. The axial vibrator is simple in structure and reliable in vibrating. The pulser can be replaced and pressure oscillation of slurry can be changed; therefore, the vibration power can be adjusted and the adjustability is strong.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

Horizontal vibration linear motor

ActiveCN103618428AIncreased resistance to the above failuresAvoid defects that damage scrapDynamo-electric machinesVibration amplitudeQuality level

The invention provides a horizontal vibration linear motor which comprises a motor shell, a cover plate and a vibration assembly. The cover plate is installed on the motor shell in a covering mode, an installation space is formed by the cover plate and the motor shell, the vibration assembly is hung in the installation space through location of elastic supporting pieces located on the two opposite lateral walls of the motor shell respectively and comprises a vibration block and a permanent magnet installed on the vibration block, the permanent magnet can drive the vibration assembly to perform reciprocated vibration in the direction basically parallel to the bottom face of the motor shell under the effect of the magnetic field force and enables the two elastic supporting pieces located on the opposite lateral walls to be correspondingly stretched and retracted in the vibration process, and a limiting device for limiting the reciprocated vibration amplitude of the vibration block is further installed in the installation space. According to the horizontal vibration linear motor, the capacity for overcoming faults such as short circuits can be improved, and the whole quality level of machines with the motor is easily improved.

Owner:金龙机电(淮北)有限公司

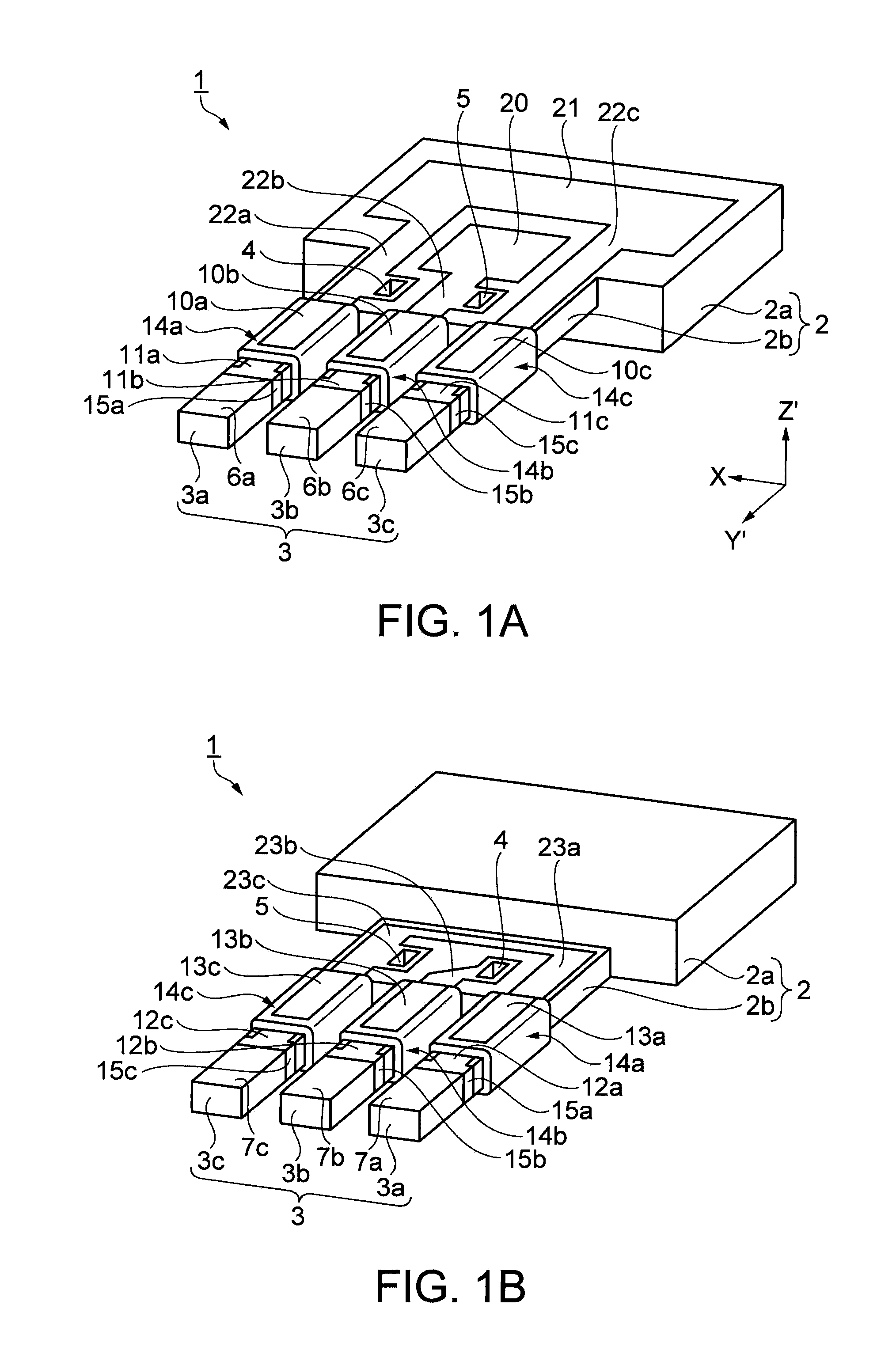

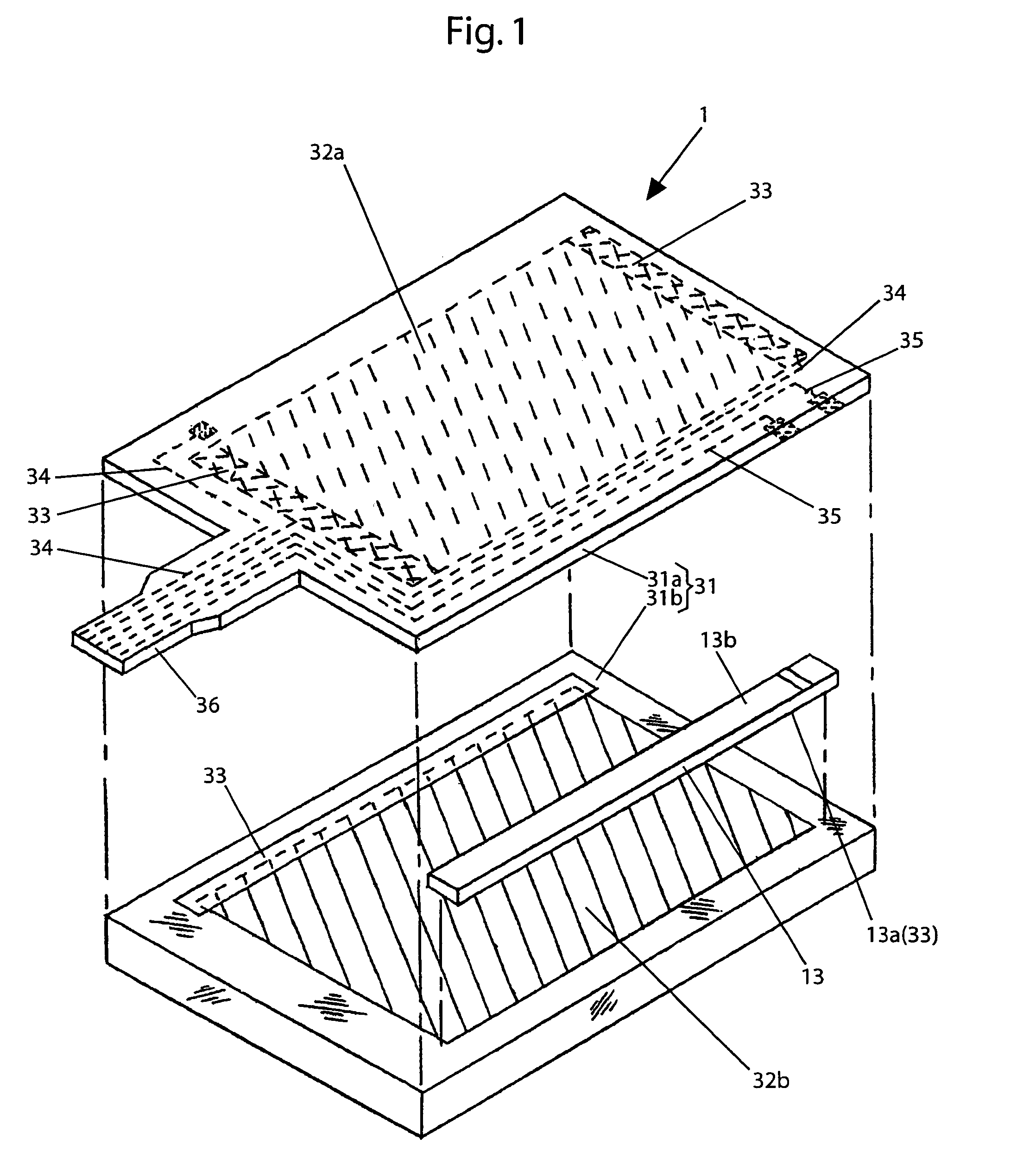

Flexural vibration piece, flexural vibrator, and electronic apparatus

InactiveUS20100320875A1Highly accurate vibration characteristicWell formedPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesOptoelectronicsElectronic equipment

A flexural vibration piece includes: a base portion; a vibrating arm extending from the base portion and having a first surface, a second surface opposing the first surface, and side surfaces connecting the first surface and second surface, wherein a laminated structure including a first electrode, a second electrode, and a piezoelectric layer disposed between the first electrode and second electrode, is formed on each of the first surface and second surface, the piezoelectric layer formed on the first surface side and the piezoelectric layer formed on the second surface side have mutually opposite polarization directions, and the first electrode formed on the first surface side and the first electrode formed on the second surface side are connected to each other.

Owner:SEIKO EPSON CORP

Touch panel input device

InactiveUS7432915B2No deteriorationSufficient amplitudeInput/output processes for data processingElectricityTouchpad

Owner:RICHMOND EEI +1

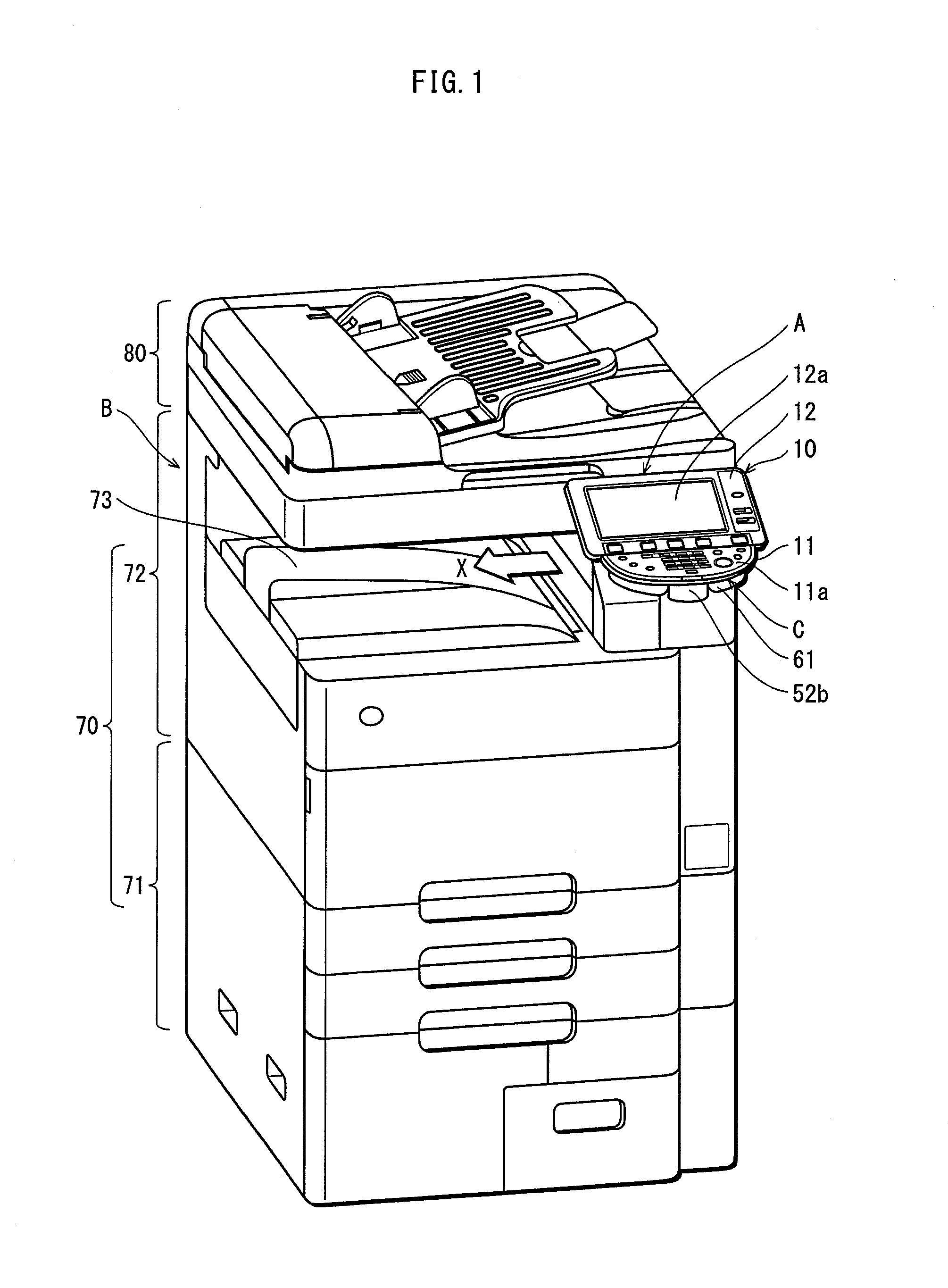

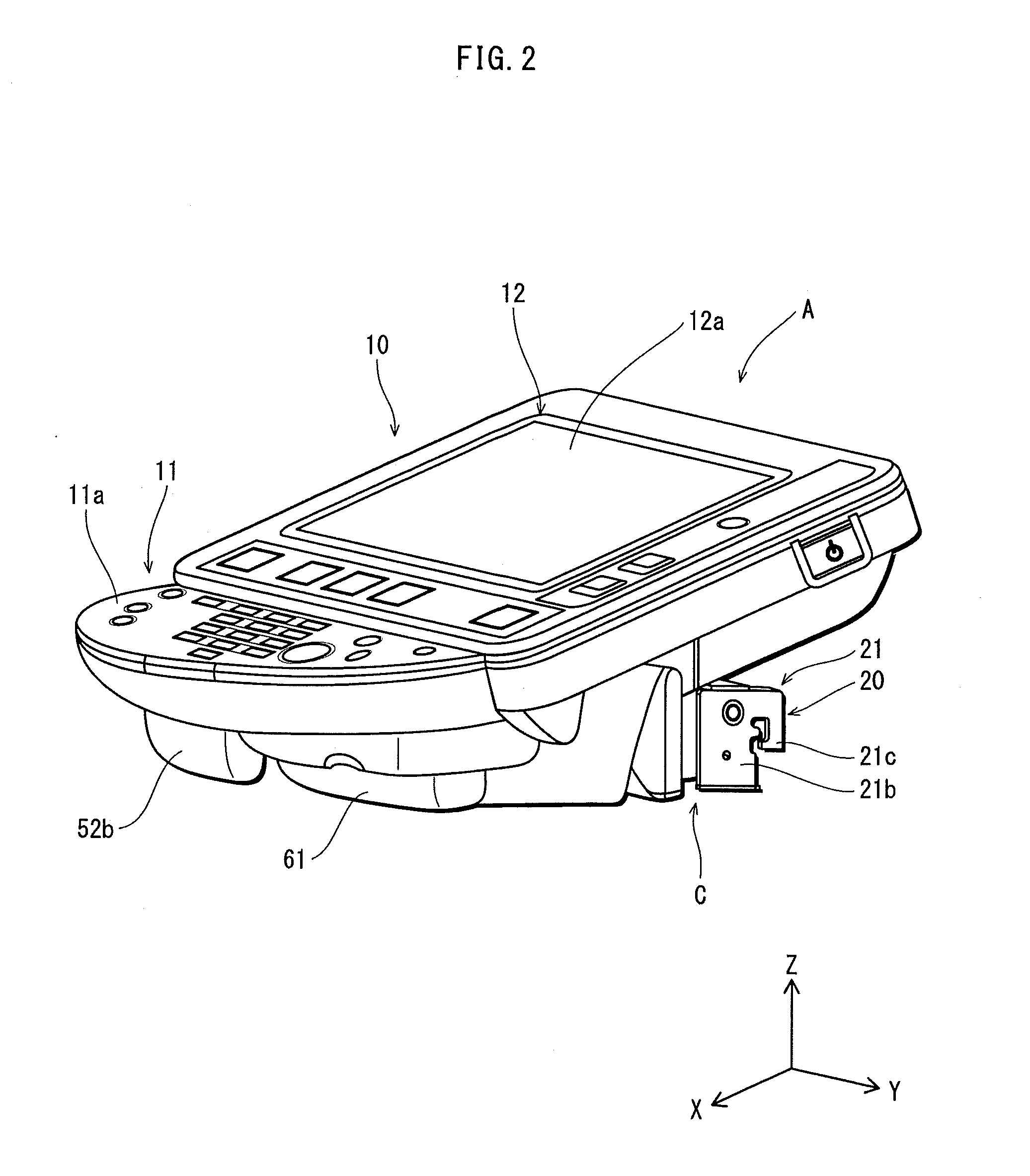

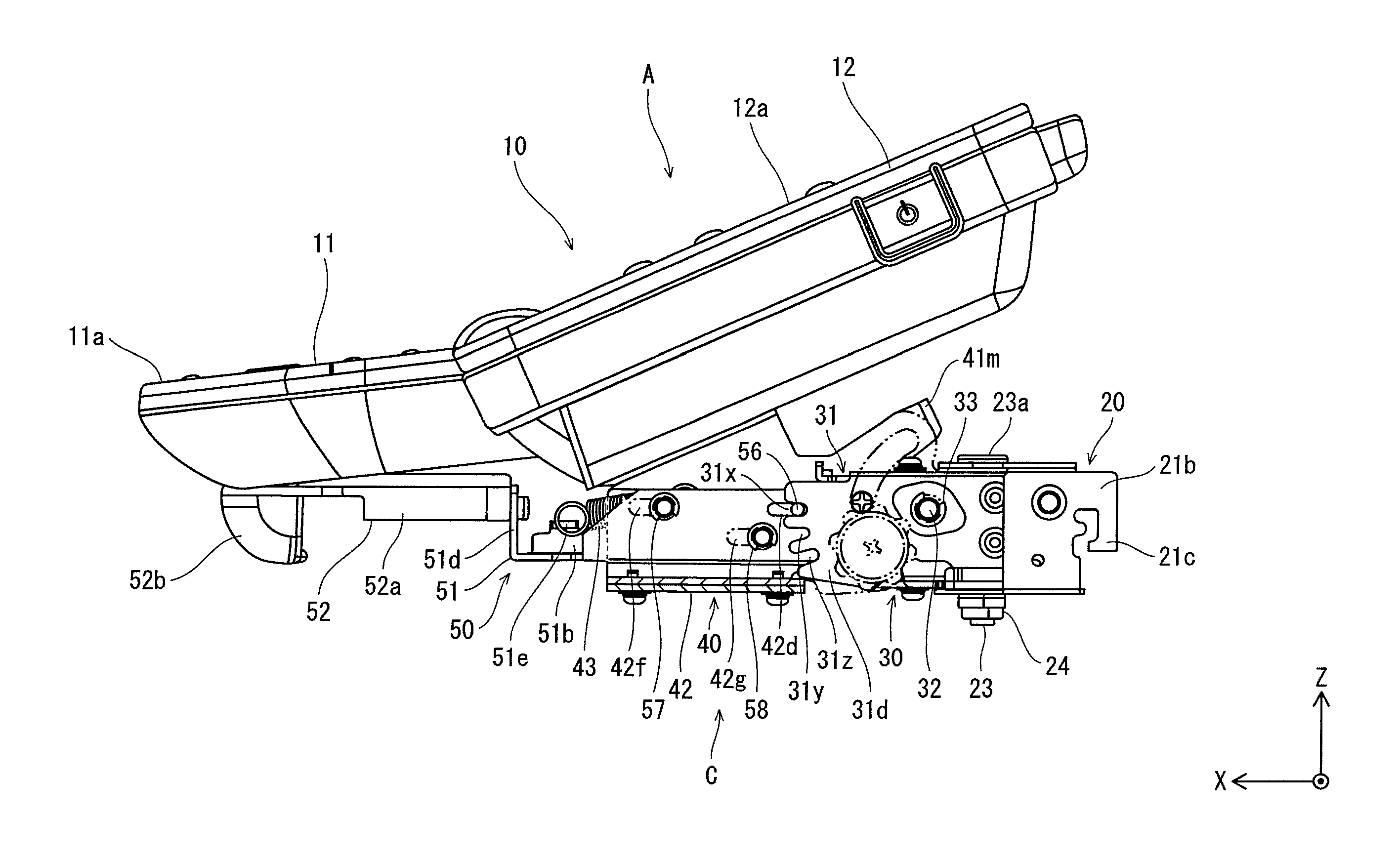

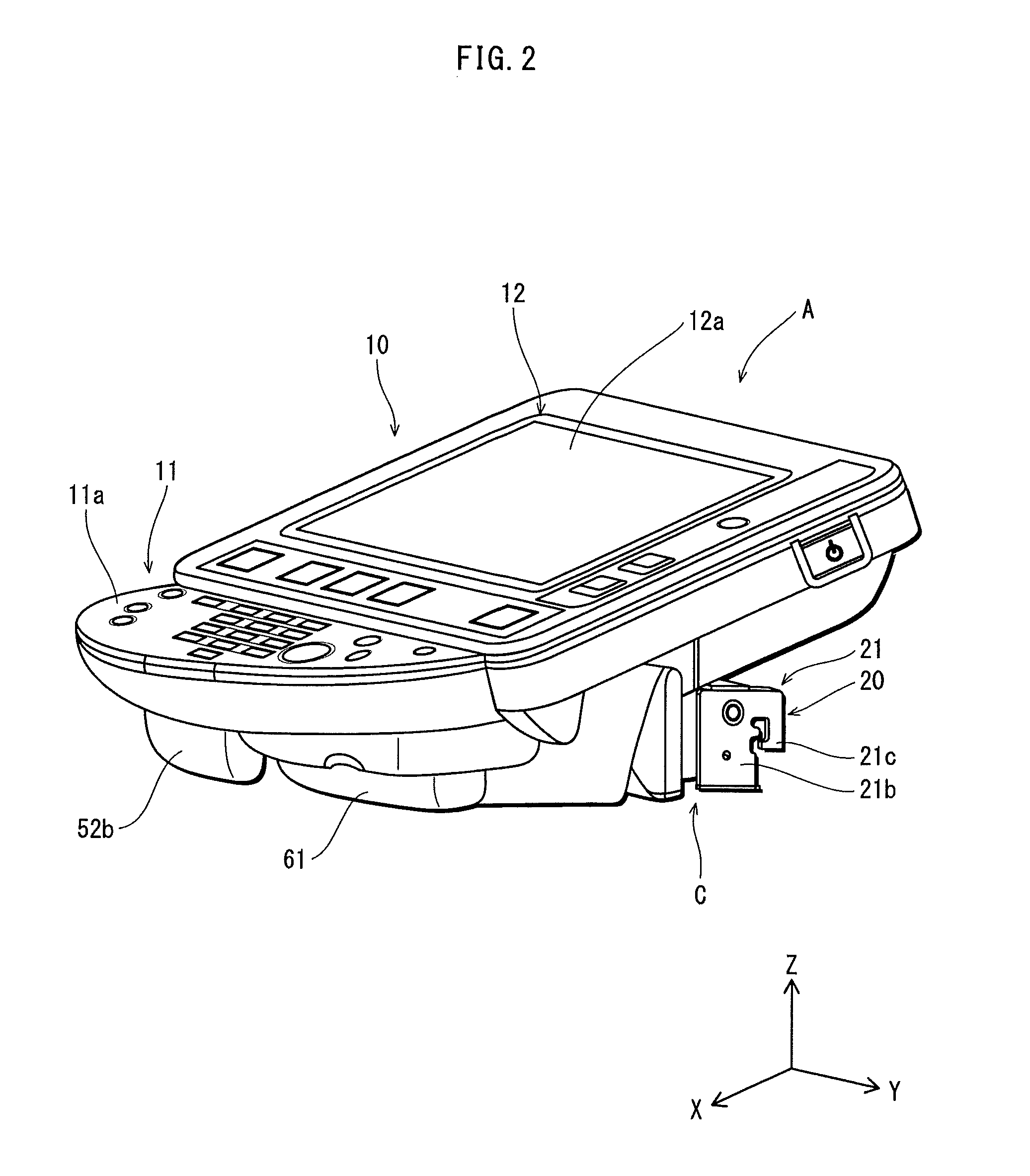

Control panel support mechanism, control panel assembly, and image forming apparatus

InactiveUS20110235254A1Reliable vibrationDigital data processing detailsStands/trestlesMechanical engineeringEngineering

Owner:KONICA MINOLTA BUSINESS TECH INC

Flexural vibration piece, flexural vibrator, and electronic apparatus

InactiveUS8304967B2Well formedReduce capacityPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksOptoelectronicsElectrode

A flexural vibration piece includes: a base portion; a vibrating arm extending from the base portion and having a first surface, a second surface opposing the first surface, and side surfaces connecting the first surface and second surface, wherein a laminated structure including a first electrode, a second electrode, and a piezoelectric layer disposed between the first electrode and second electrode, is formed on each of the first surface and second surface, the piezoelectric layer formed on the first surface side and the piezoelectric layer formed on the second surface side have mutually opposite polarization directions, and the first electrode formed on the first surface side and the first electrode formed on the second surface side are connected to each other.

Owner:SEIKO EPSON CORP

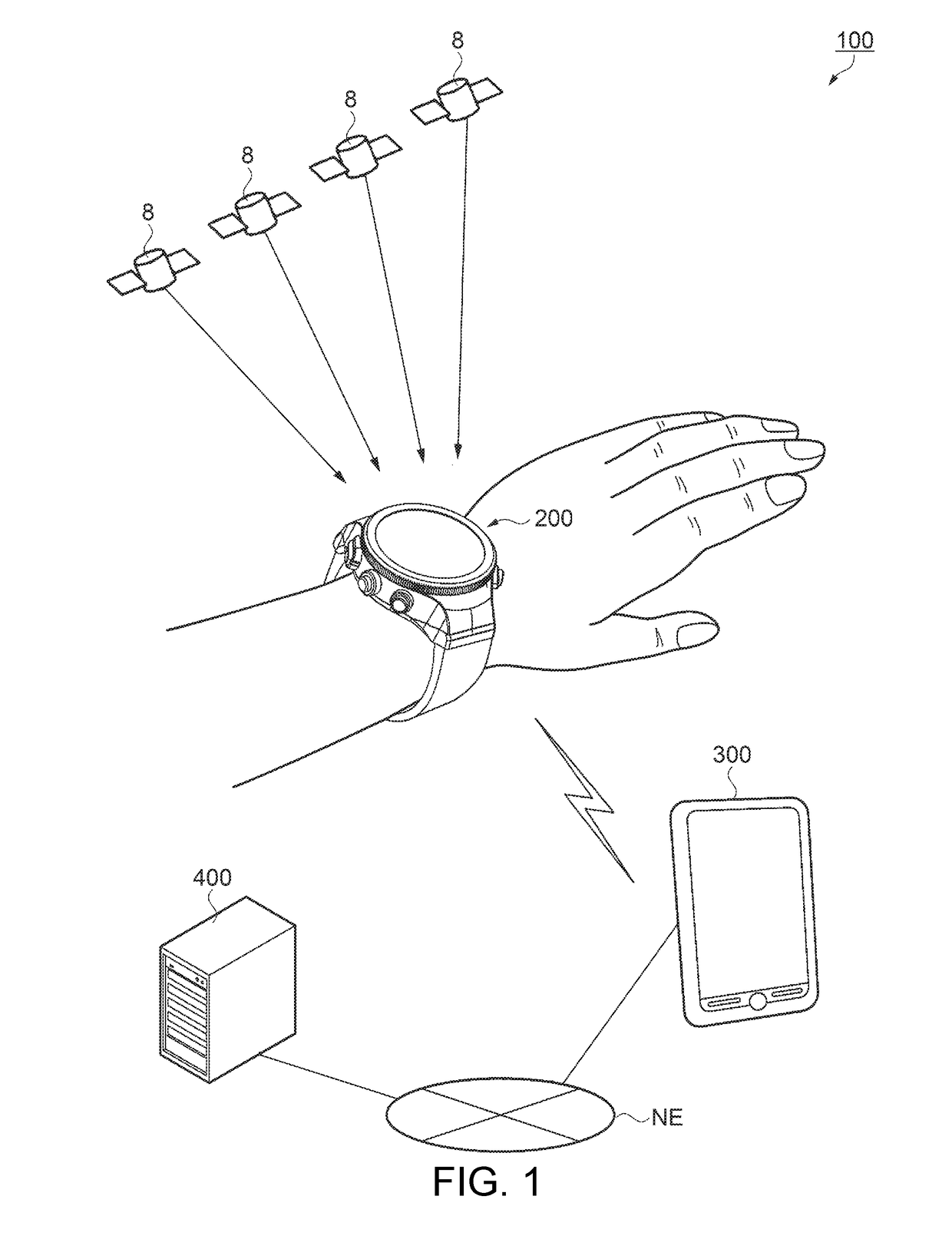

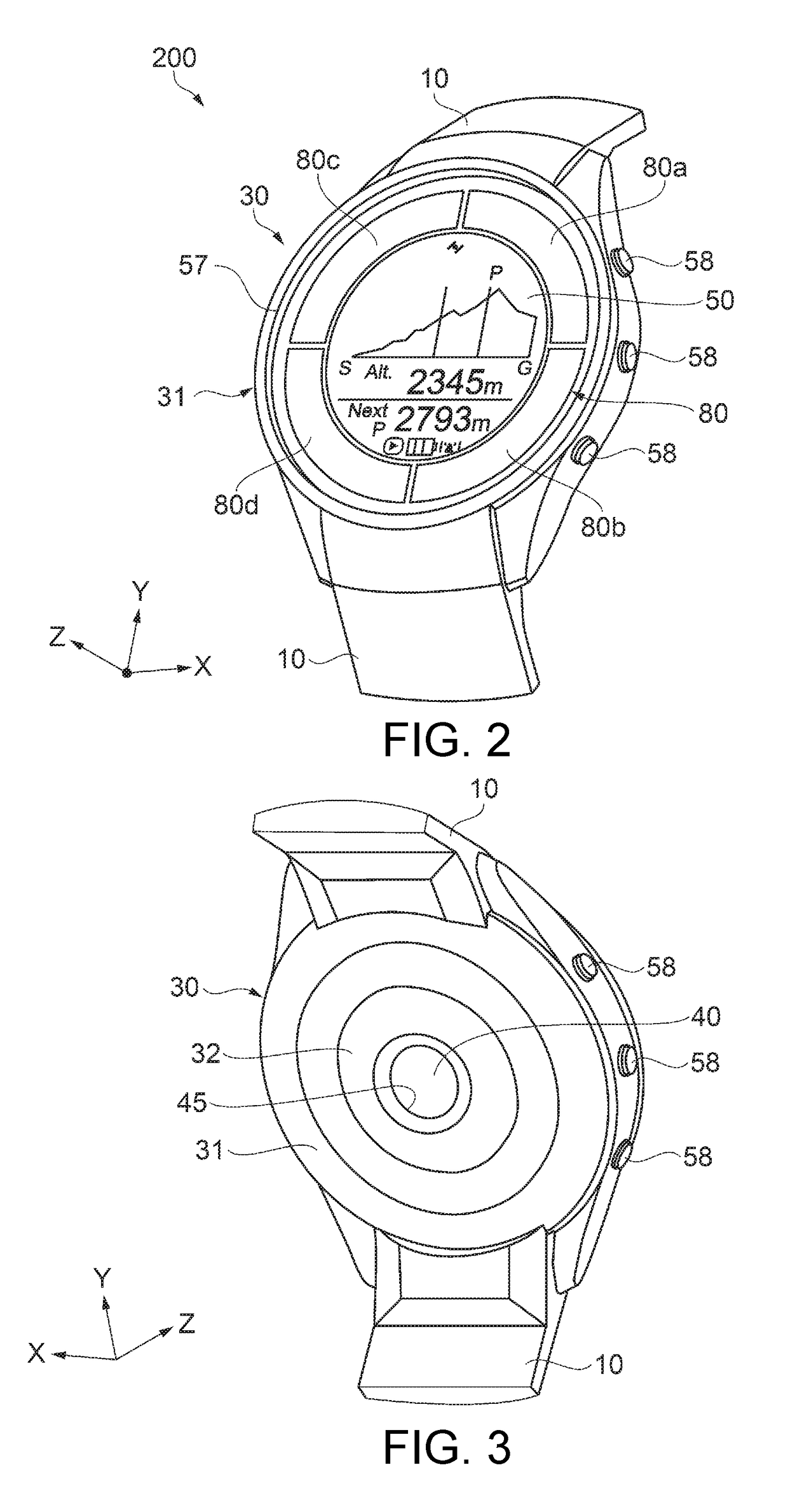

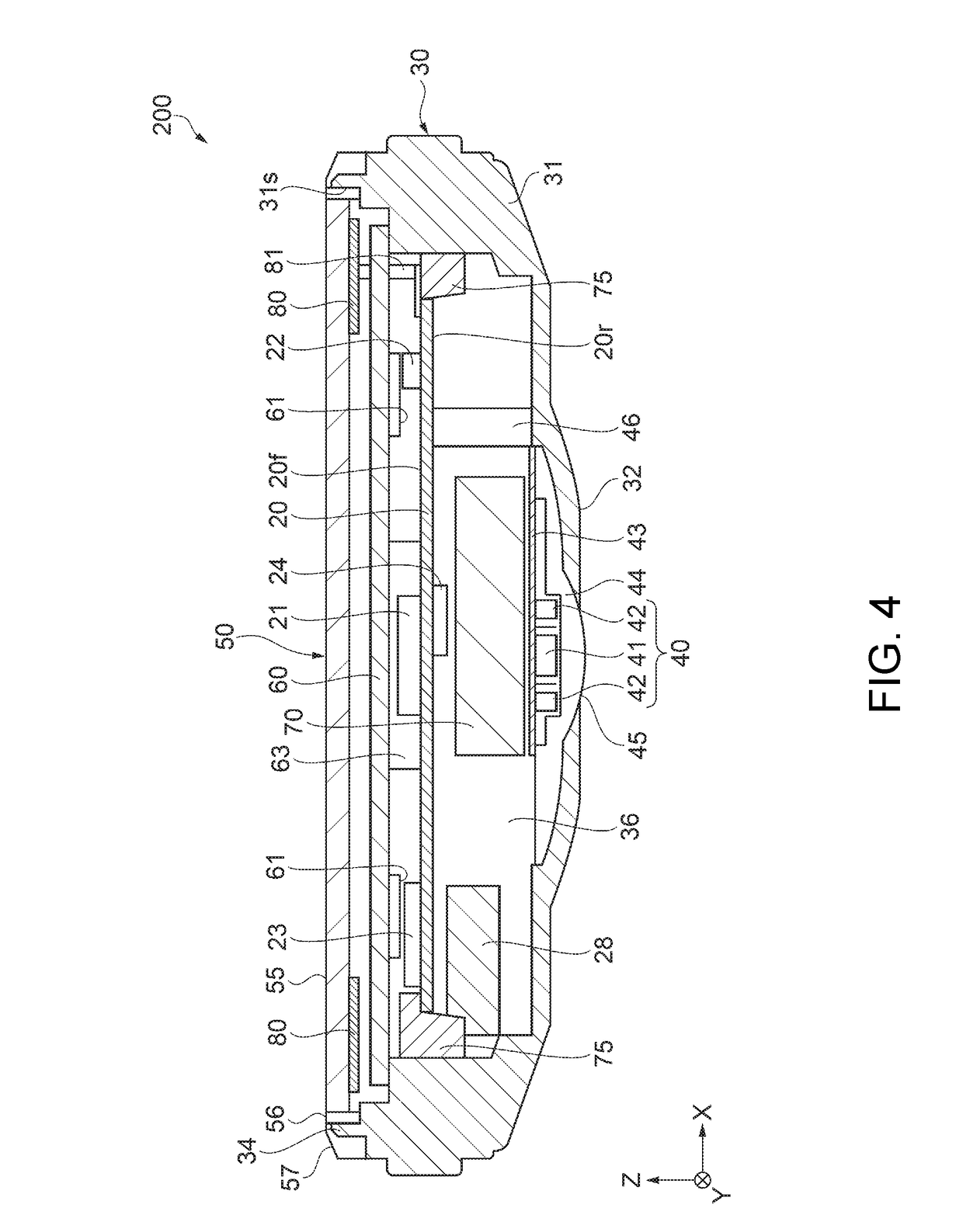

Portable electronic apparatus and wrist apparatus

ActiveUS20190025767A1Easy to detectSurface lightElectronic time-piece structural detailsElectric power supply circuitsEngineeringSolar battery

A wrist apparatus as a portable electronic apparatus includes a case, a solar battery that is provided in the case and has an outer circumference along the outer edge of the case and an inner circumference the perimeter of which is shorter than that of the outer circumference, and an acceleration sensor that is provided in the case and disposed in a position where the acceleration sensor overlaps with the solar battery in a plan view of light receiving surface of the solar battery.

Owner:SEIKO EPSON CORP

Vibration Piezoelectric Acceleration Sensor

InactiveUS20080223132A1Improve reliabilityReliable vibrationAcceleration measurement using interia forcesSemiconductor/solid-state device detailsResonanceClassical mechanics

A vibration piezoelectric acceleration sensor including a pair of diaphragms linearly and oppositely disposed on a frame, a support body supporting the diaphragm, and a holding part holding the support body slidably in a linear direction, and another pair of diaphragms disposed linearly and oppositely crossing the pair of diaphragms detecting acceleration in two axes, i.e. X and Y directions. The diaphragms are extended and retracted by the acceleration transmitted to the support body through the holding part, changing a natural oscillation frequency. Accordingly, a high change ratio of resonance frequency can be provided with the detection of the acceleration, and the acceleration in two axes directions can be detected without being affected by a change in temperature.

Owner:PANASONIC CORP

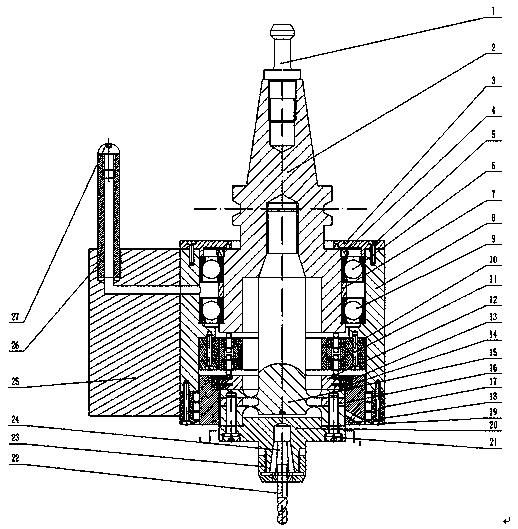

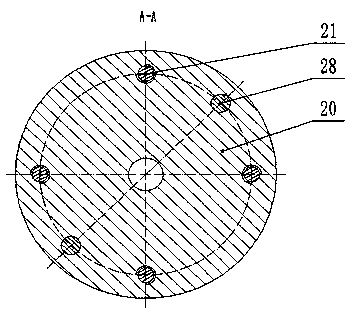

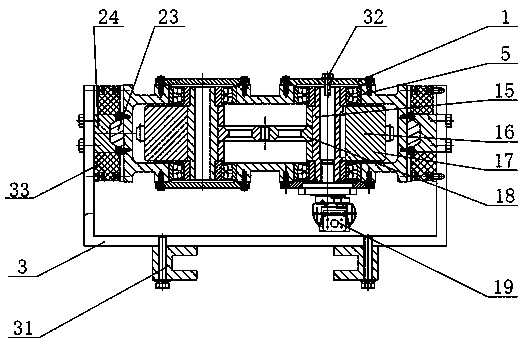

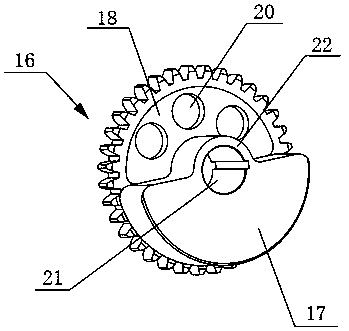

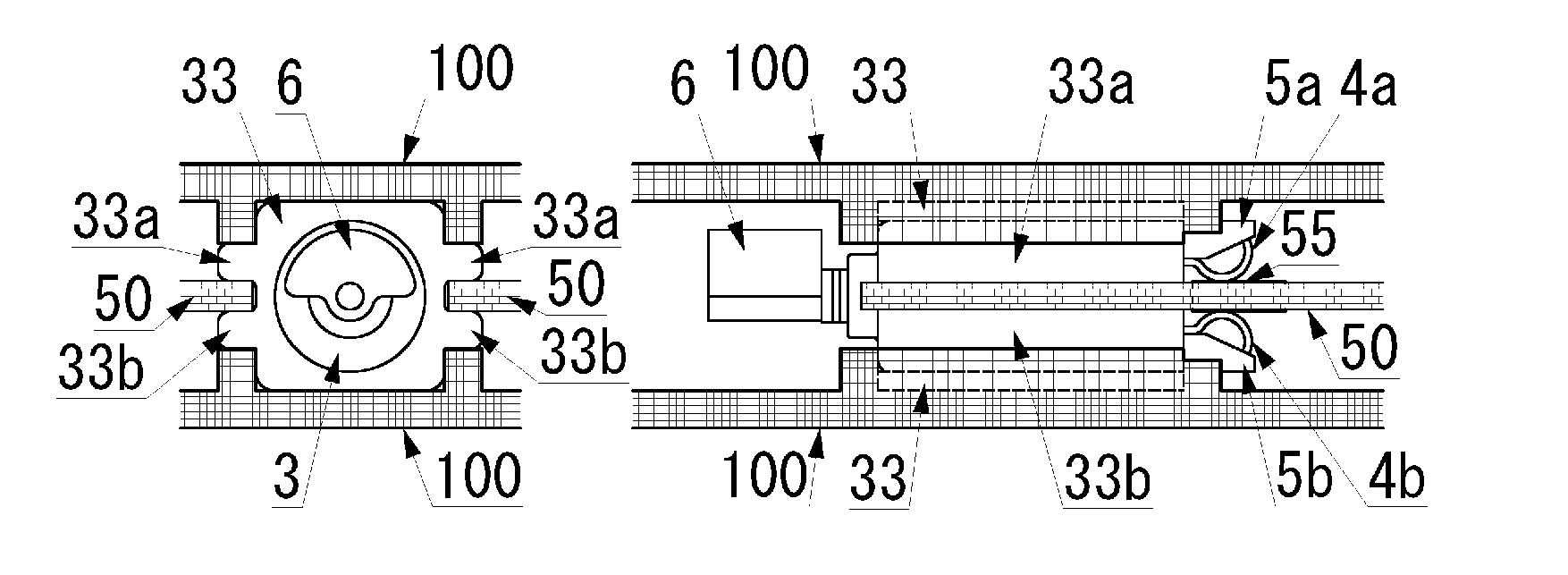

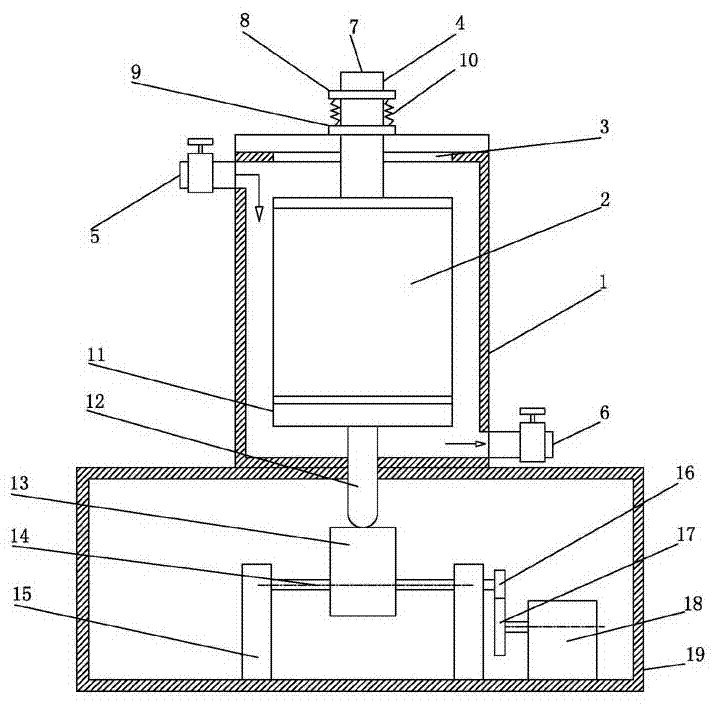

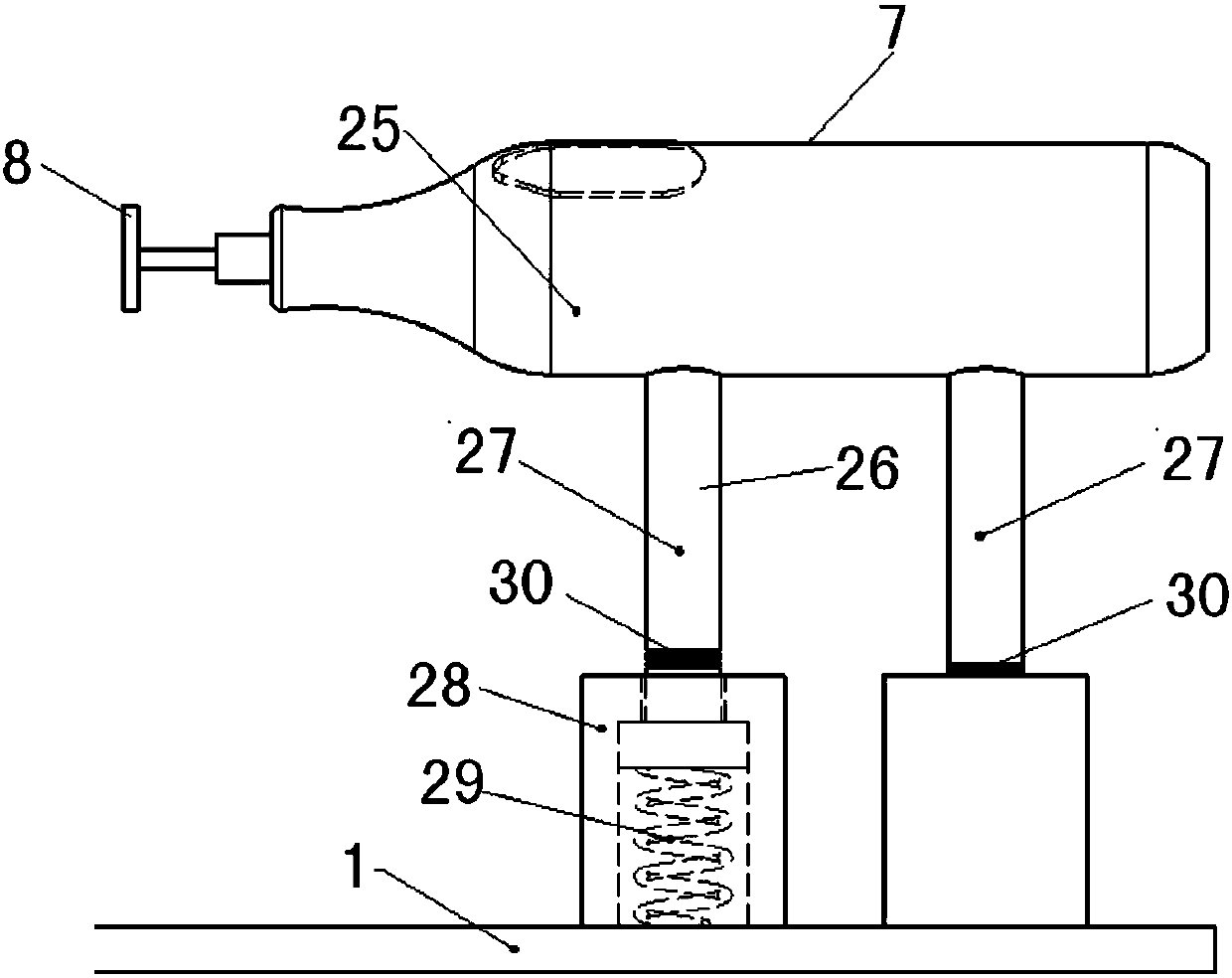

Mechanical low-frequency vibration drilling device

PendingCN109158638AAccurate amplitudeReliable vibrationBoring/drilling componentsBoring/drilling machinesLow frequency vibrationHinge angle

The invention discloses a mechanical low-frequency vibration drilling device. The outer surface of the lower end of an end face cam with a taper shank is rotationally connected with the upper portionof an inner cavity of a device shell. An annular flexible hinge is arranged in the inner cavity of the device shell. A vibration output rod is arranged at the lower end of the annular flexible hinge,and a driven end face cam is arranged on the upper portion of the annular flexible hinge. The lower end face of the end face cam with the taper shank and the upper end face of the driven end face camare both sine-ruled surfaces. A fixed disc is arranged in the middle of the inner cavity of the device shell, and penetrating holes are evenly distributed in the fixed disc along the circumference. Each penetrating hole is internally provided with a sliding block. Idler wheels are arranged at the two ends of each sliding block correspondingly, wherein the two idler wheels are in rolling contact with the lower end face of the end face cam with the taper shank and the upper end face of the driven end face cam. According to the mechanical low-frequency vibration drilling device, through rotationof a main shaft, low-frequency axial vibration is generated while the vibration output rod rotates at the high speed, and precise and efficient drilling of materials such as titanium alloys and composite materials which are difficult to machine is achieved.

Owner:HENAN POLYTECHNIC UNIV

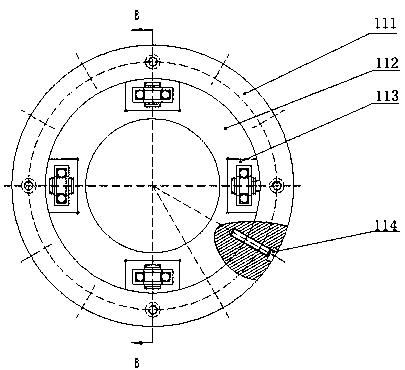

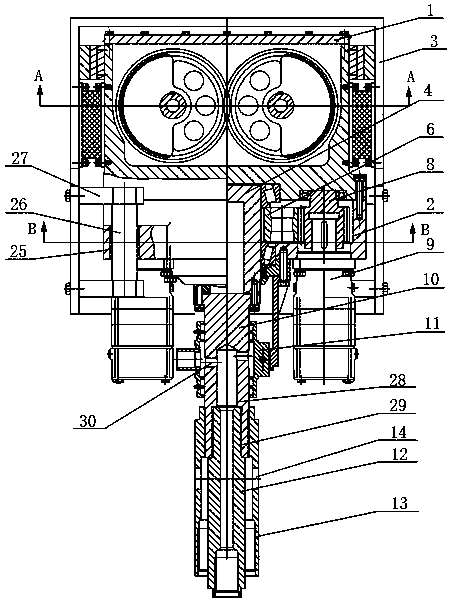

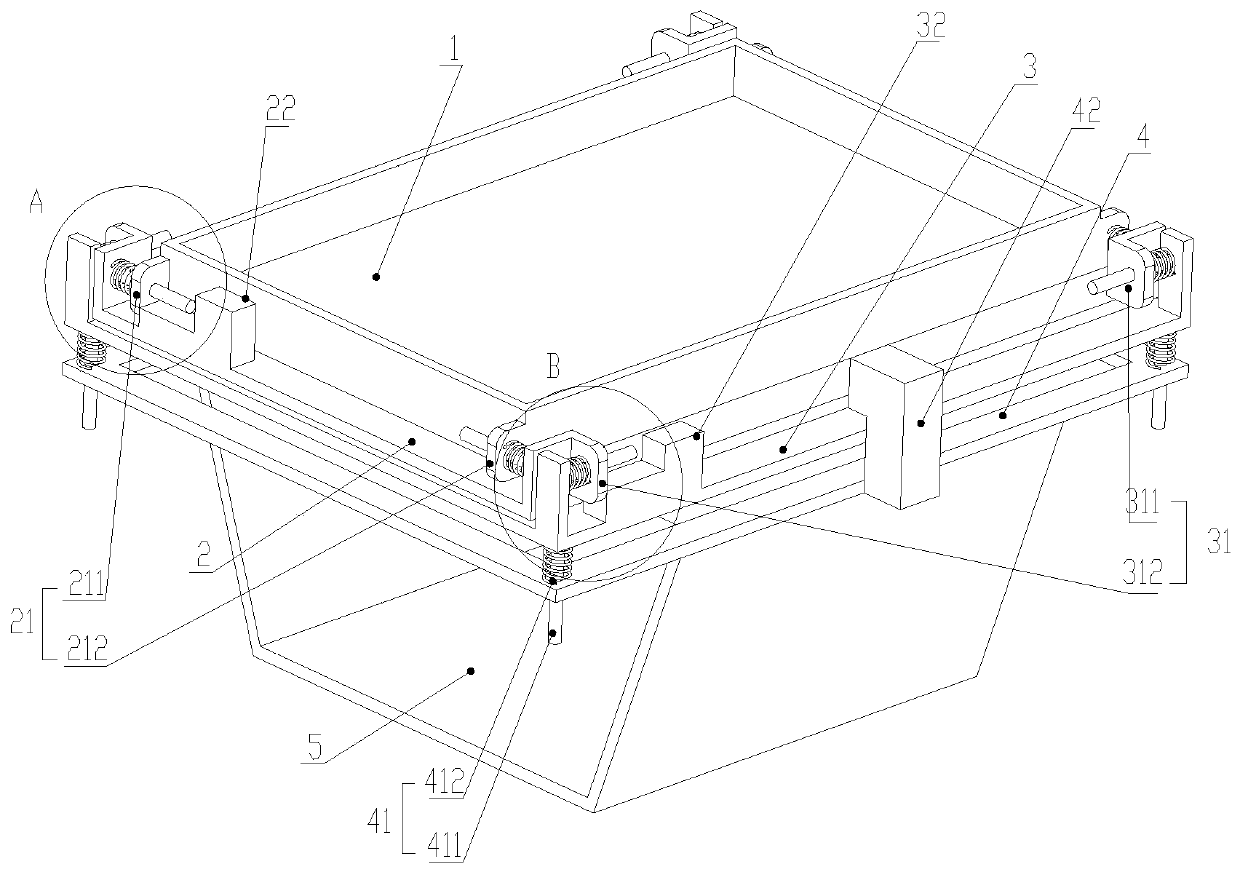

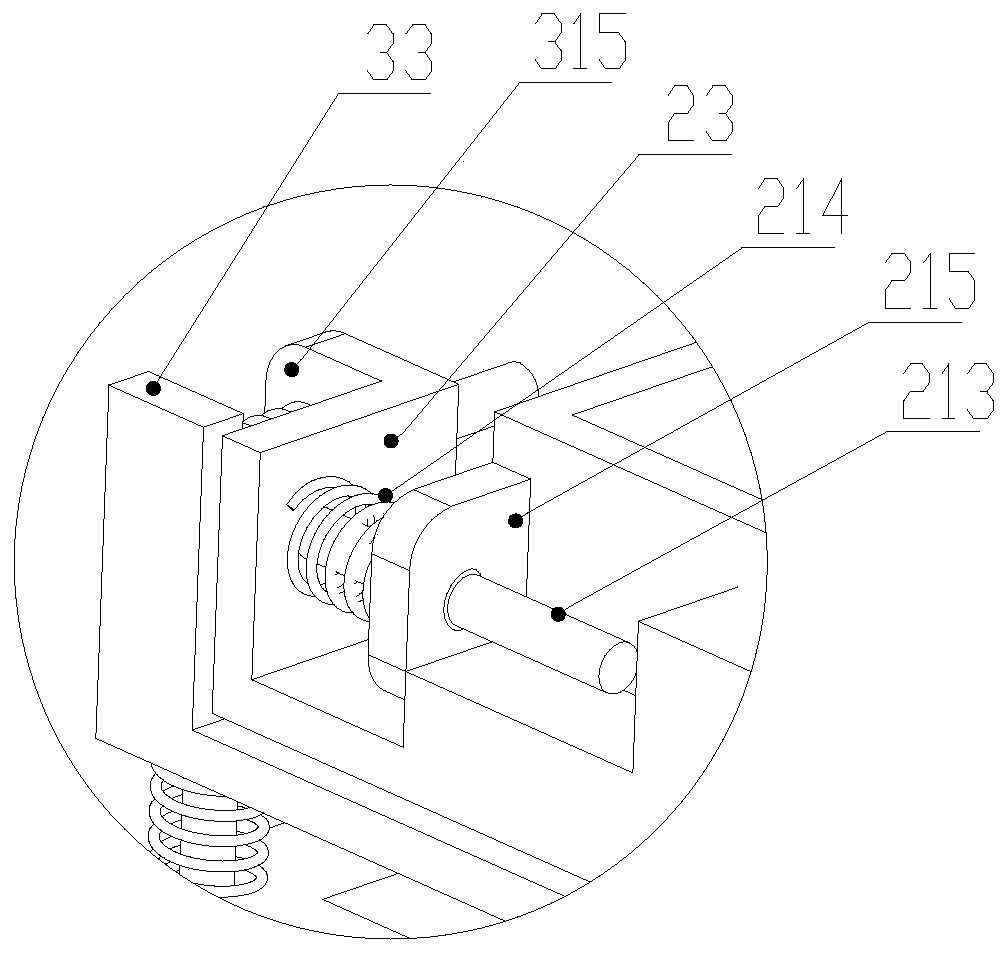

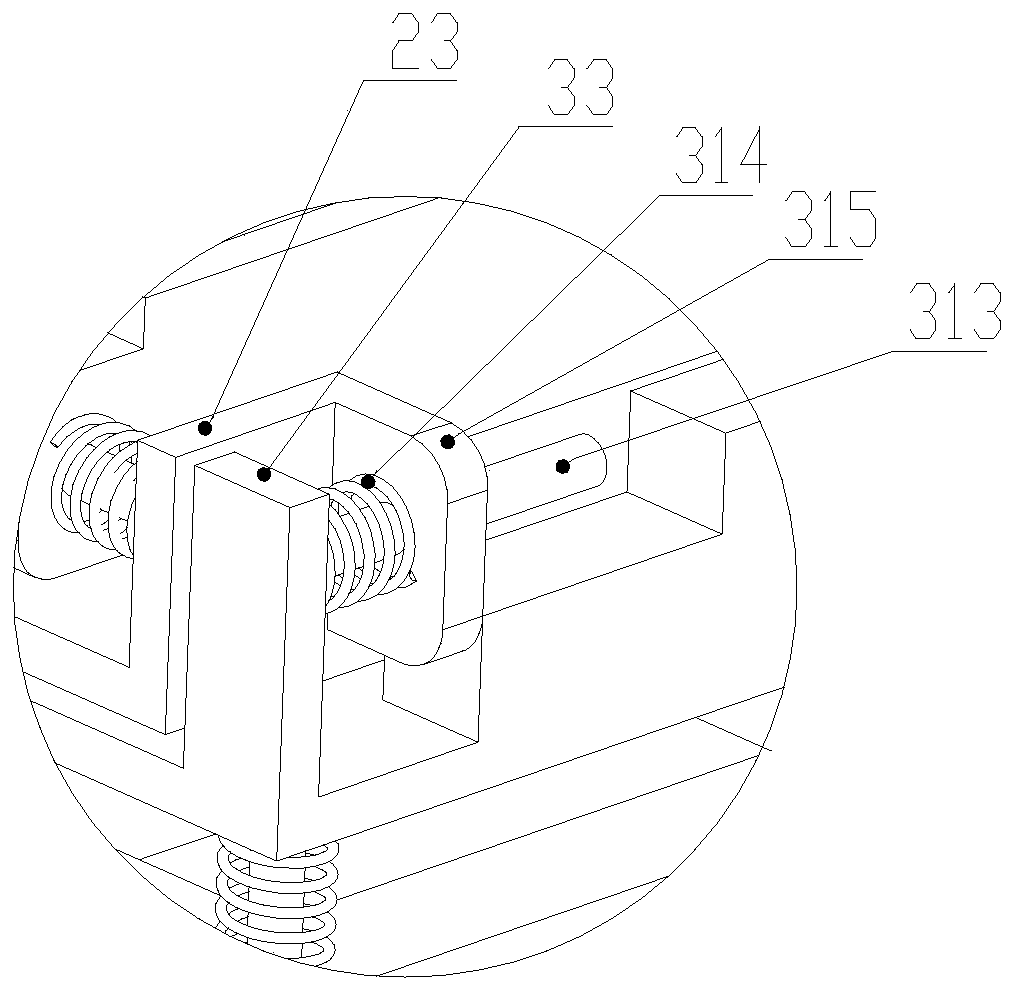

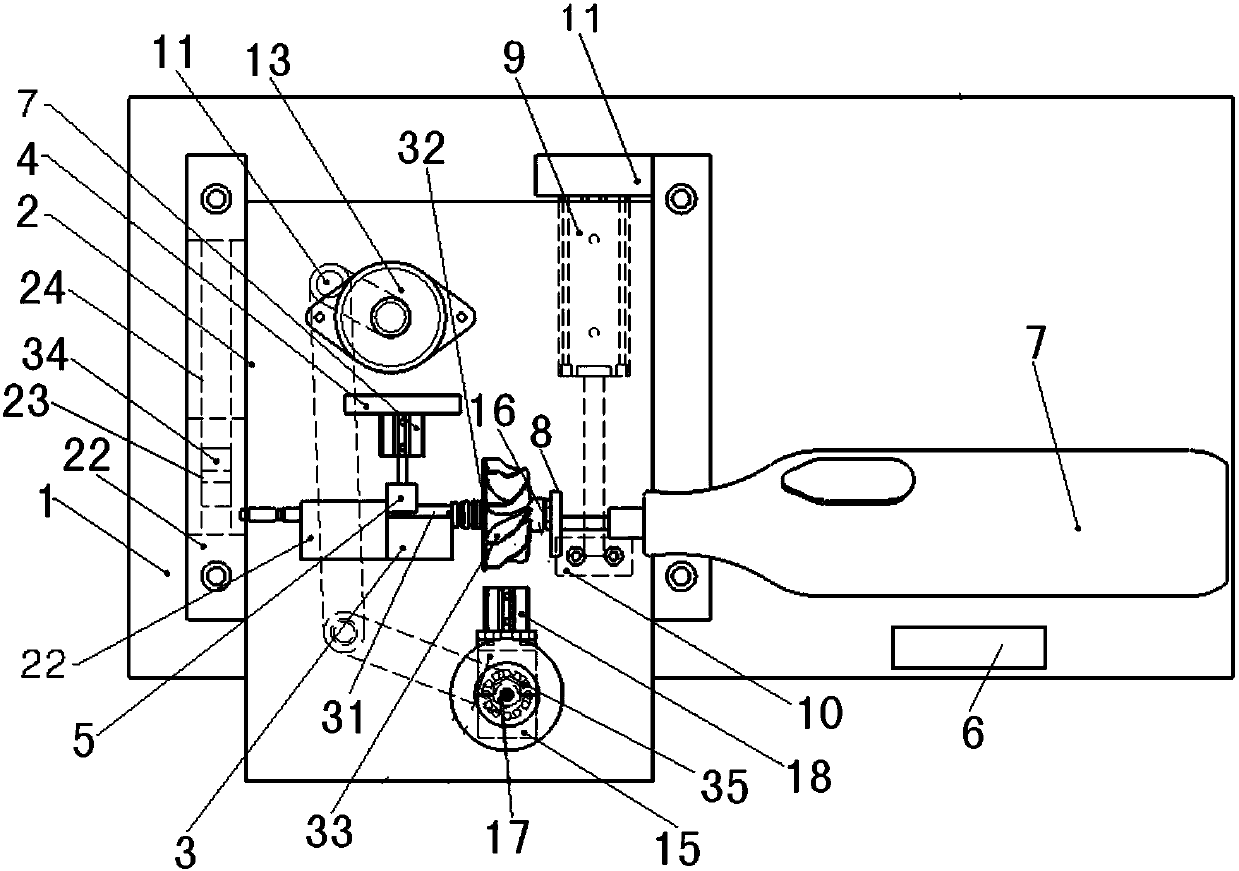

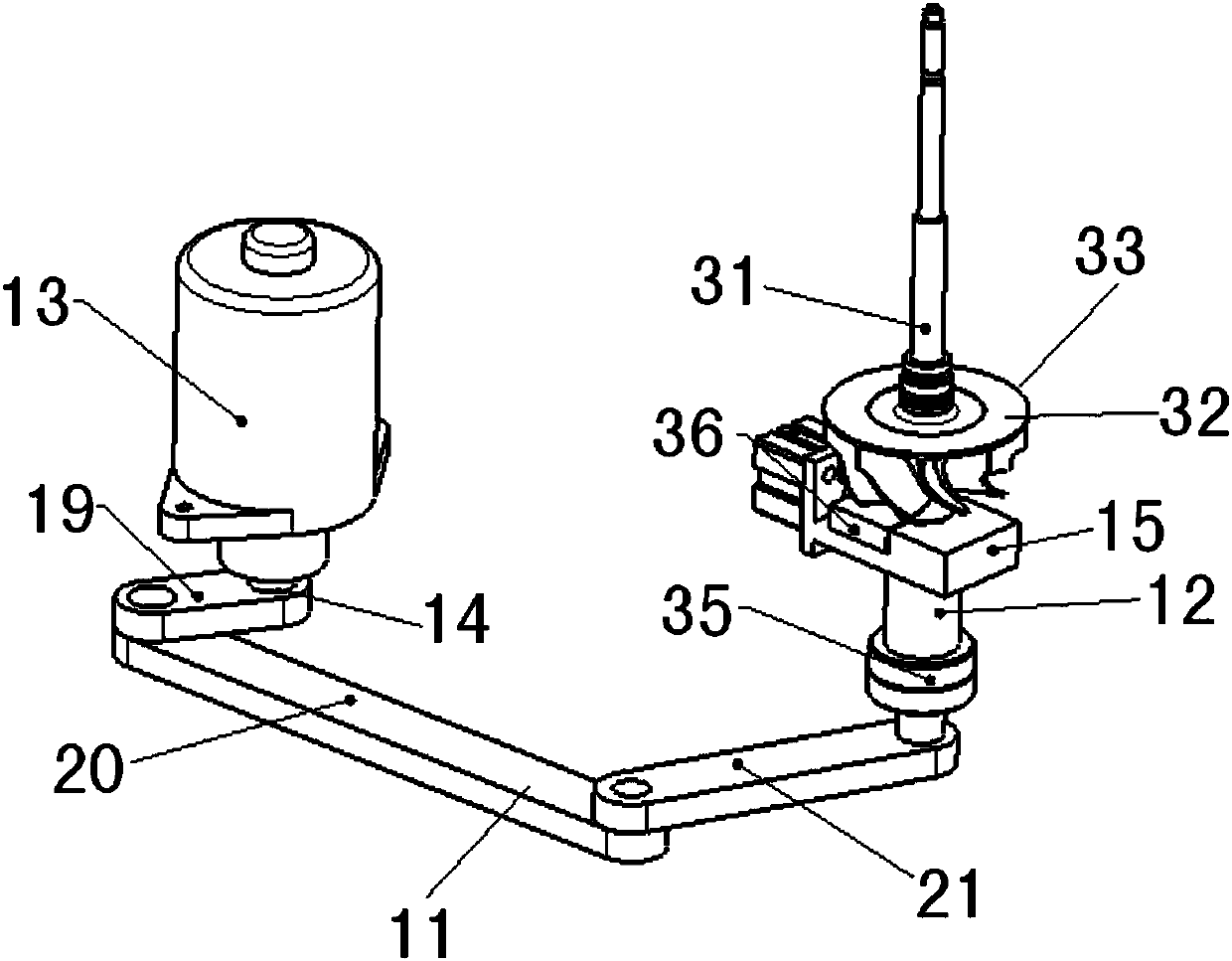

Vibrating type power head device

The invention discloses a vibrating type power head device which includes a vibration assembly and an external box which is arranged outside of the vibration assembly; a guiding mechanism is arrangedbetween the vibration assembly and the external box; the vibration assembly includes a vibration box and a gear box, the front end of the gear box is connected to a drill tool by the output joint, andthe rear end is detachably connected to the vibration box. The vibration box directly drives the gear box and the spindle to vibrate together; the vibration box and the gear box are fixedly connected, ; thus driving the drill tool to vibrate and rotary drilling simultaneously; the damage of the main axle can effectively reduced when the vibration is vibrated, so that the transmission line of thevibration is more reasonable. Moreover, the vibration box and the gear box can ensure that the vibration assembly only take the axial vibration displacement in the axial direction, but restrict the unreasonable vibration in other directions by the guiding mechanism, so that the generate and transmit of the excitation force is stable and reliable, the impact direction is consistent, and the workingefficiency of drilling is improved.

Owner:无锡市安曼工程机械有限公司

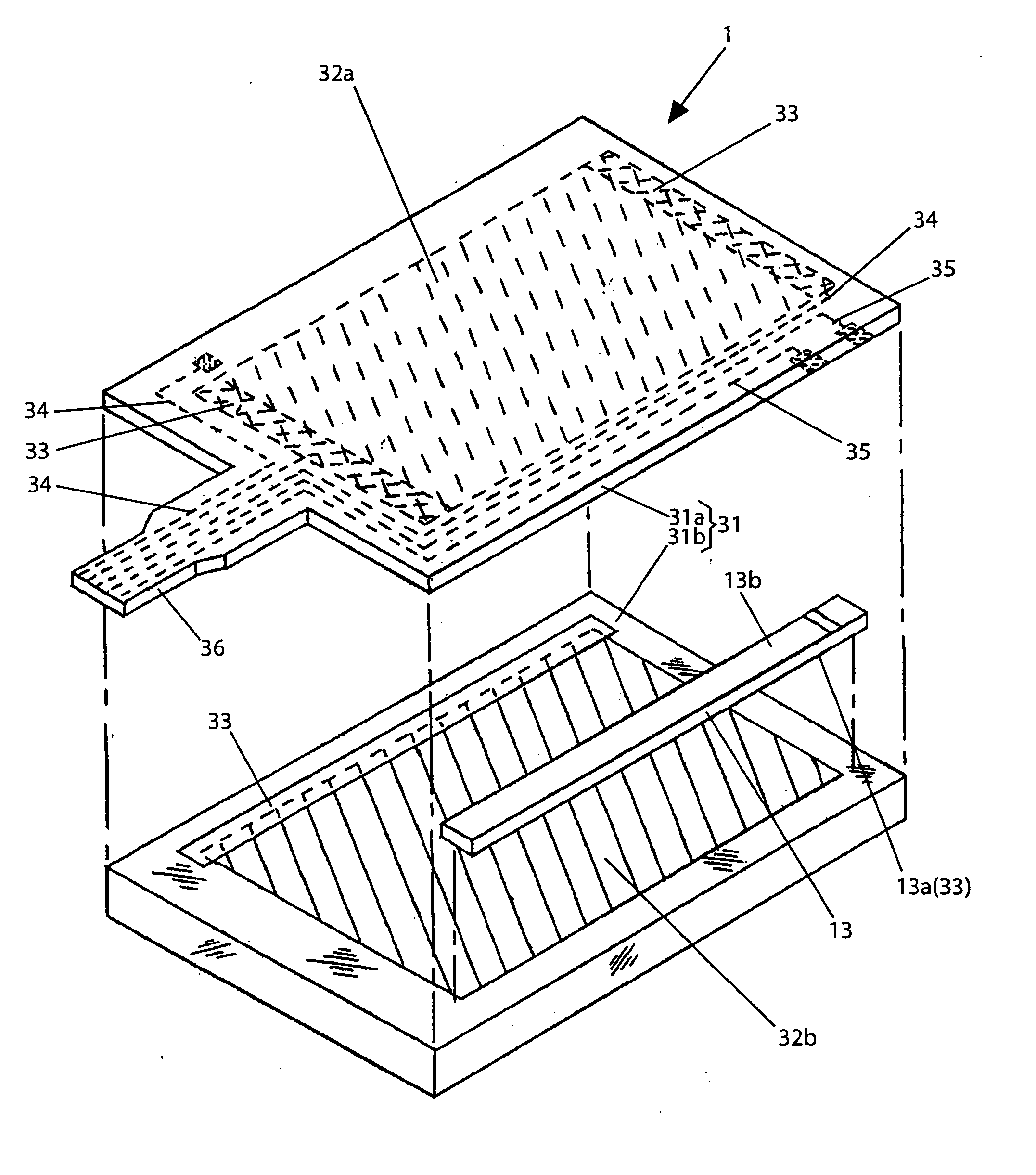

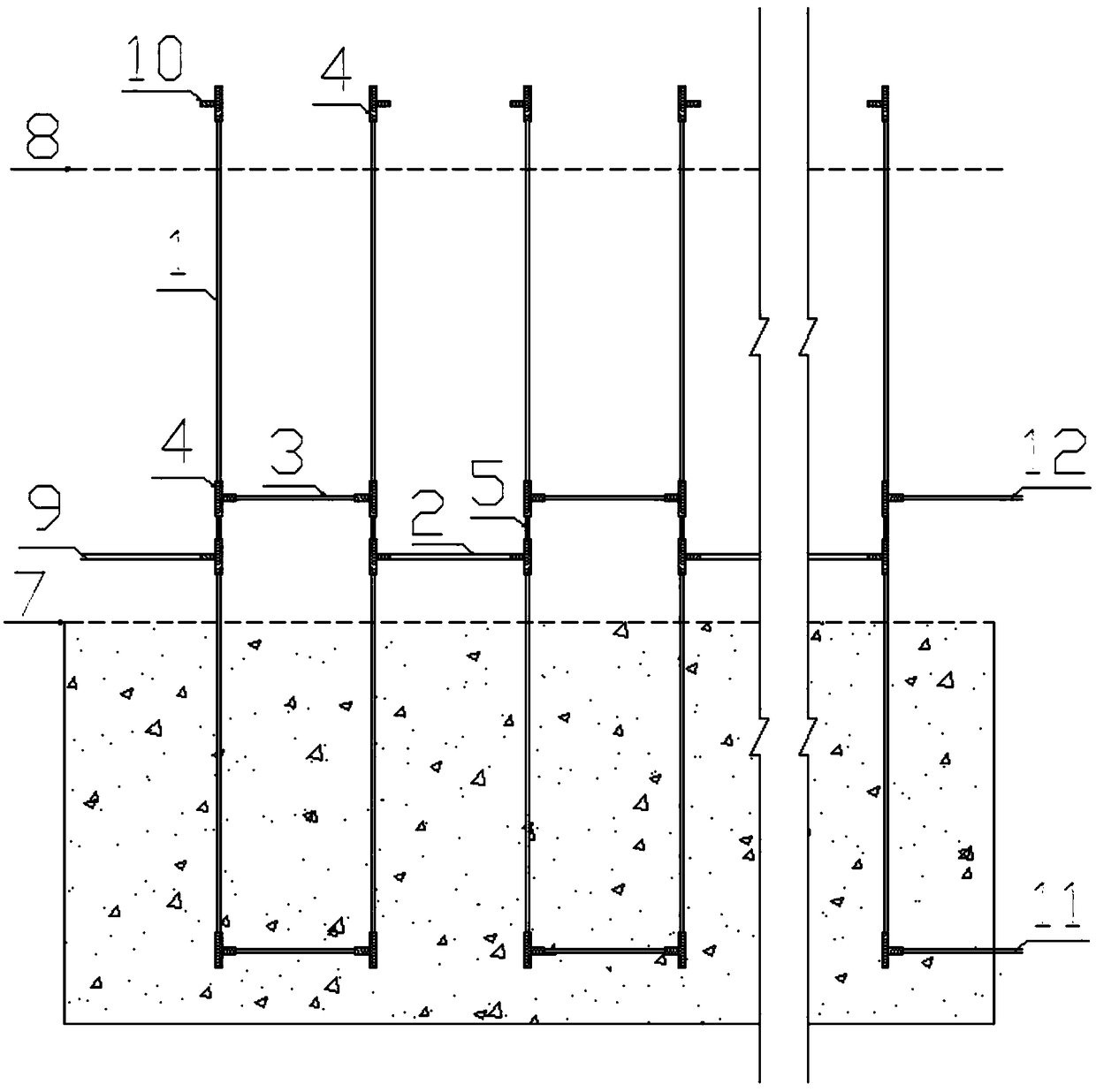

Assembled cooling water pipe convenient for construction of narrow bin surface

ActiveCN109235388AReduce vibration disturbanceVibrate comprehensivelyWater-power plantsHydro energy generationCooling effectEngineering

The invention relates to an assembled cooling water pipe convenient for construction of a narrow bin surface and belongs to the technical field of concrete pouring construction. The assembled coolingwater pipe mainly consists of a three-branch pipe joint, a horizontal pipe, a vertical pipe and an interlayer connecting piece, and according to the principle that 'part of pre-distributed, multi-directional connection, connecting after pouring', the three-branch pipe joint is fixed at an appointed position of a foundation bin surface in advance, and concrete is poured after the vertical pipe is assembled, at this time, there is no obstruction in the horizontal direction, and after pouring, the upper layer horizontal pipe is connected to complete a cooling pipeline. And the top end joint of the cooling pipeline can be used as the basis of the next cooling pipeline for connection and circulation operation. According to the assembled cooling water pipe, the problems that the traditional cooling water pipe arrangement in the thin-wall concrete structure can only be bound by the steel bar net, the cooling effect is influenced by the fact that the path of one pipe is too long to be finished, the pouring quality is poor due to the fact that the vibration is not in place, and the like are solved; and the process is simple, the assembly is convenient, and the cooling effect is ensured.

Owner:POWERCHINA CHENGDU ENG

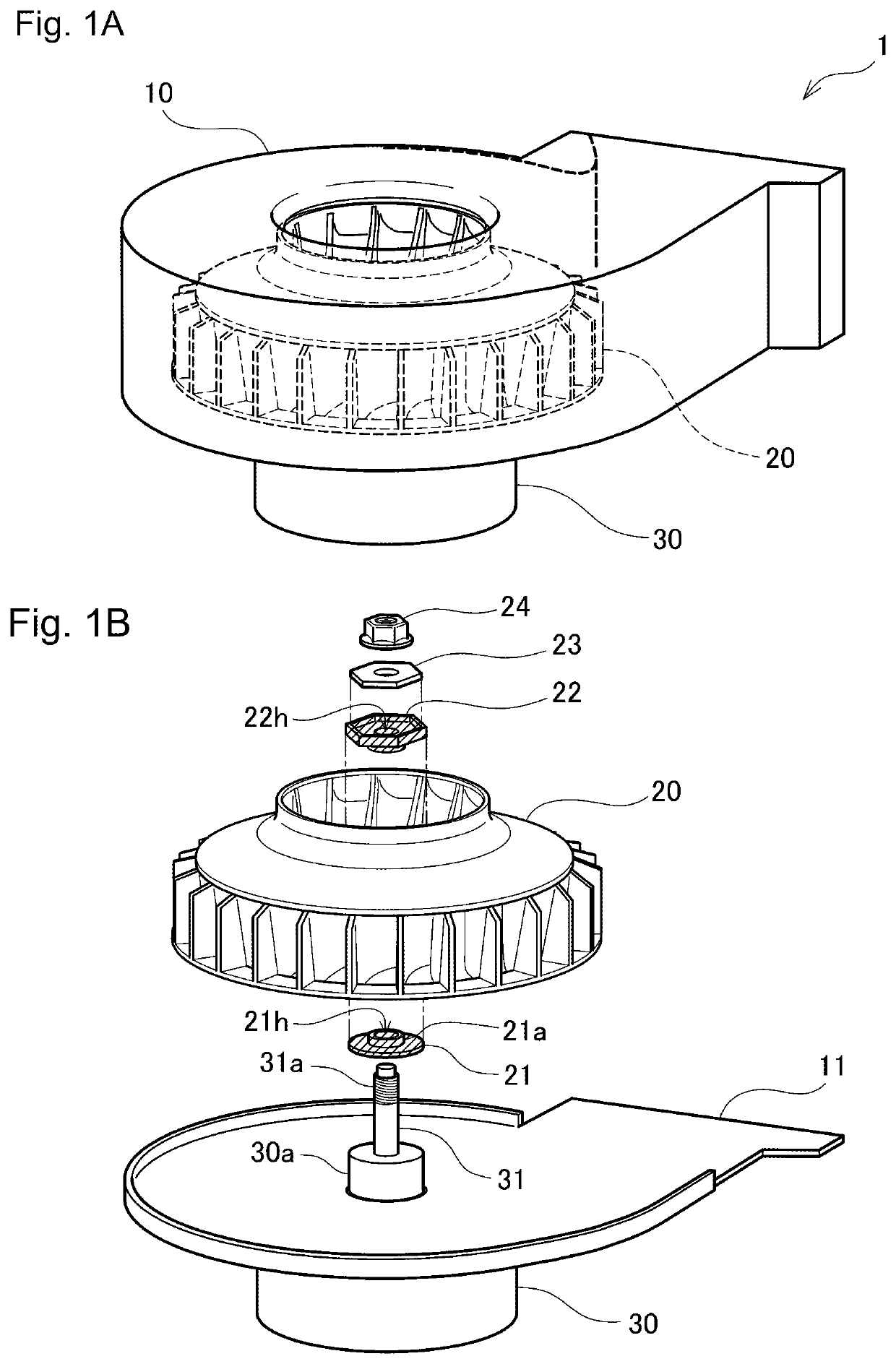

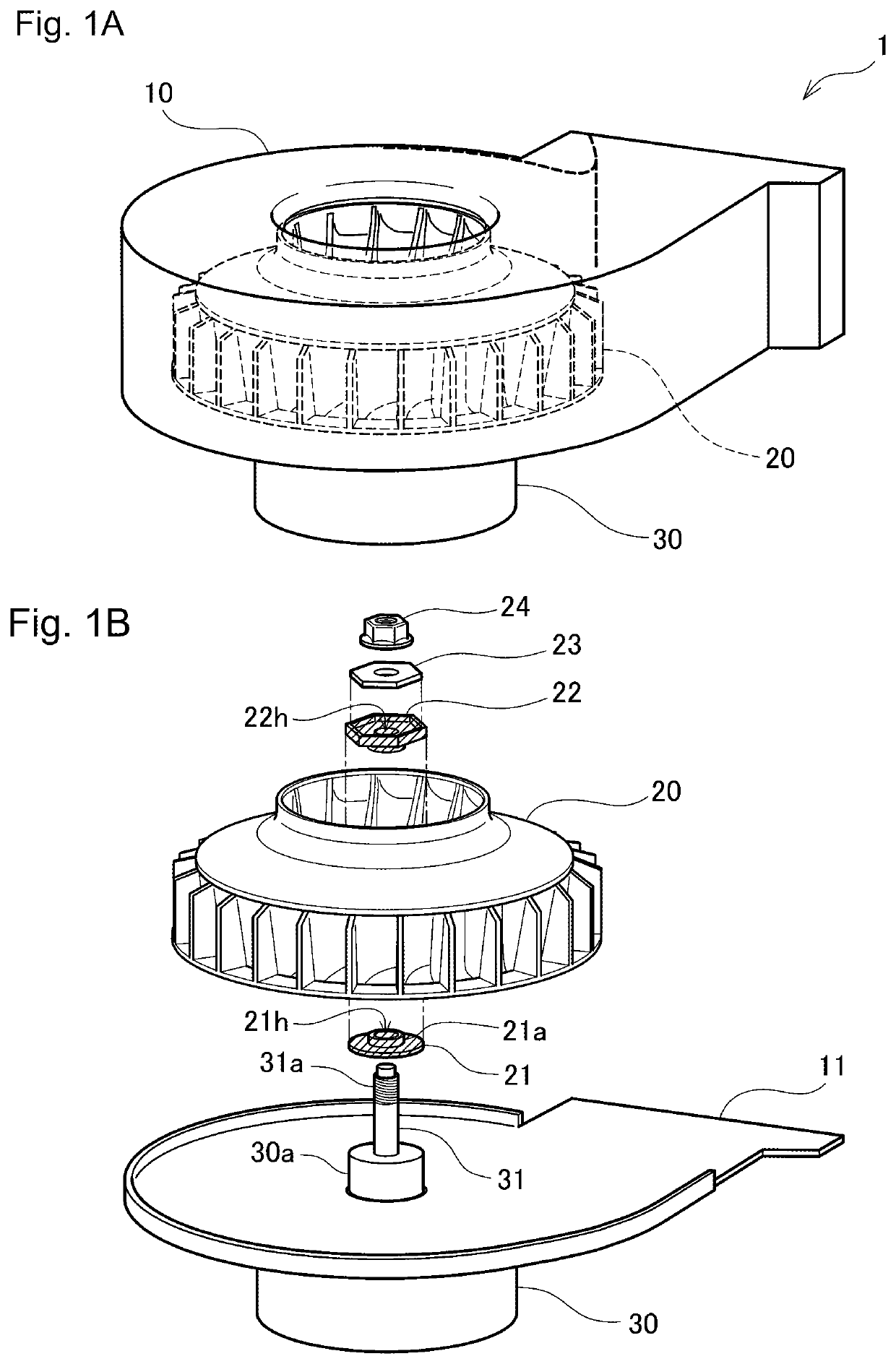

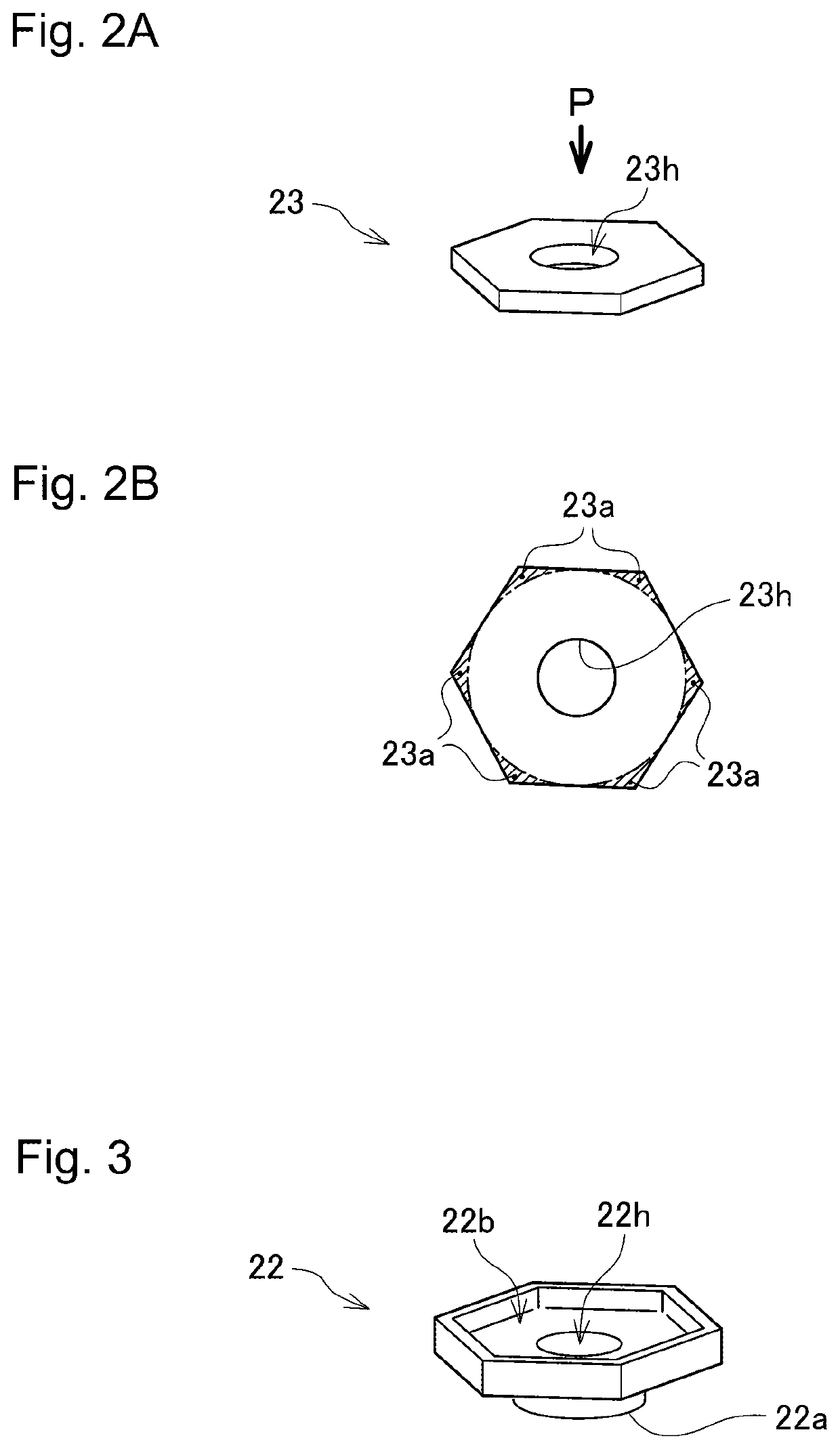

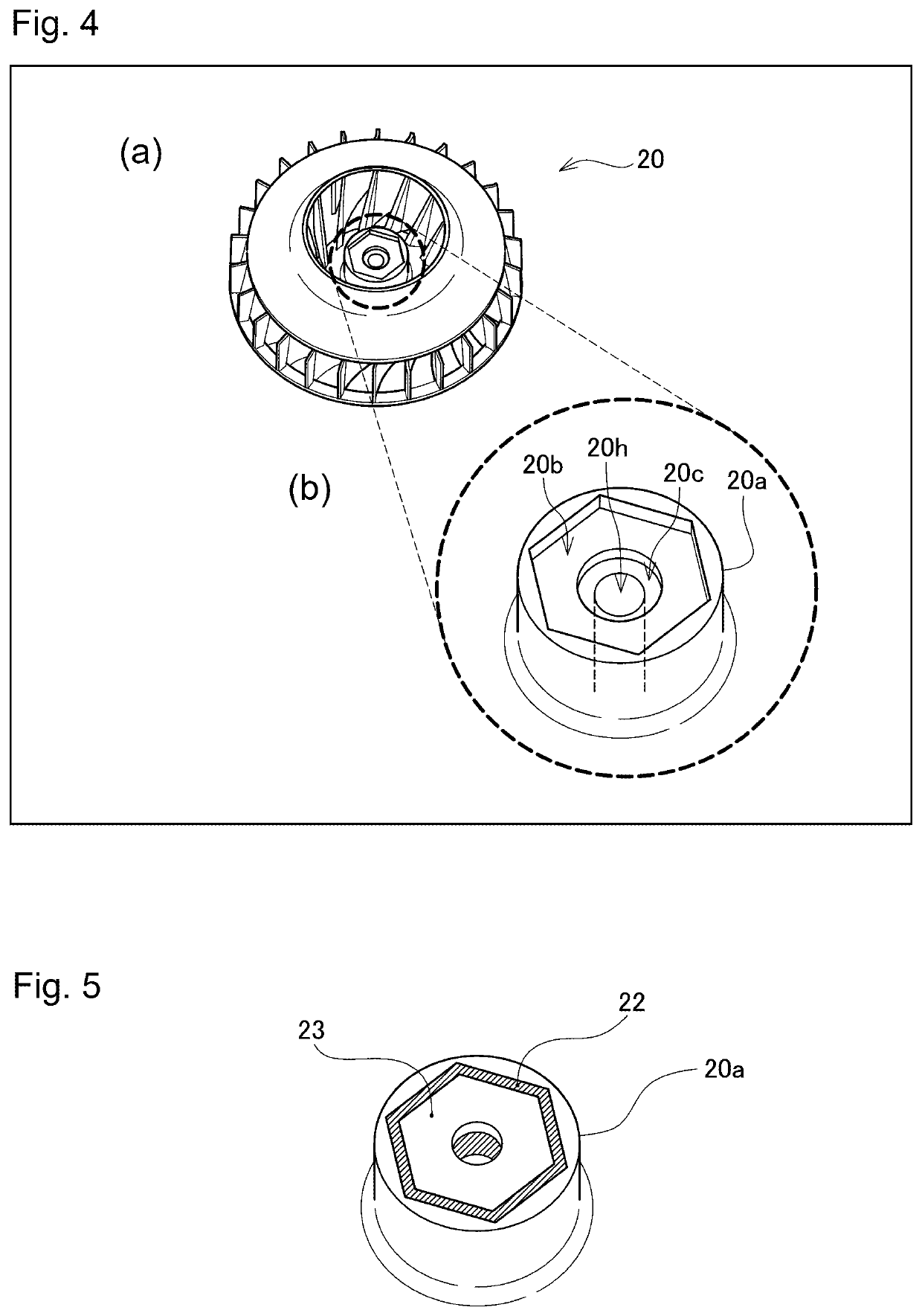

Blower fan

A blower fan including an impeller easily mounted on the rotational shaft of a motor generates less noise. The impeller is mounted on the rotational shaft of the motor using a fastener with an elastic vibration isolator and a washer in between. The washer has a predetermined shape including radial projections from a circumference about a central receiving hole. The vibration isolator has the predetermined shape larger than the predetermined shape of the washer, and has a first recess having the predetermined shape on its top surface to receive the washer fittingly. The impeller has a second recess having the predetermined shape on its top surface to receive the vibration isolator fittingly. The vibration isolator thus separates the impeller mounted on the rotational shaft from the washer in both the axial and rotational directions of the motor to reduce vibrations in both directions propagating to the impeller, generating less noise.

Owner:RINNAI CORP

Control panel support mechanism, control panel assembly, and image forming apparatus

InactiveUS8923720B2Reliable vibrationDigital data processing detailsStands/trestlesVertical alignmentMechanical engineering

Owner:KONICA MINOLTA BUSINESS TECH INC

Blower fan

ActiveUS10883514B2Reduce vibrationReduce noisePump componentsPump installationsImpellerRotational axis

A blower fan including an impeller easily mounted on the rotational shaft of a motor generates less noise. The impeller is mounted on the rotational shaft of the motor using a fastener with an elastic vibration isolator and a washer in between. The washer has a predetermined shape including radial projections from a circumference about a central receiving hole. The vibration isolator has the predetermined shape larger than the predetermined shape of the washer, and has a first recess having the predetermined shape on its top surface to receive the washer fittingly. The impeller has a second recess having the predetermined shape on its top surface to receive the vibration isolator fittingly. The vibration isolator thus separates the impeller mounted on the rotational shaft from the washer in both the axial and rotational directions of the motor to reduce vibrations in both directions propagating to the impeller, generating less noise.

Owner:RINNAI CORP

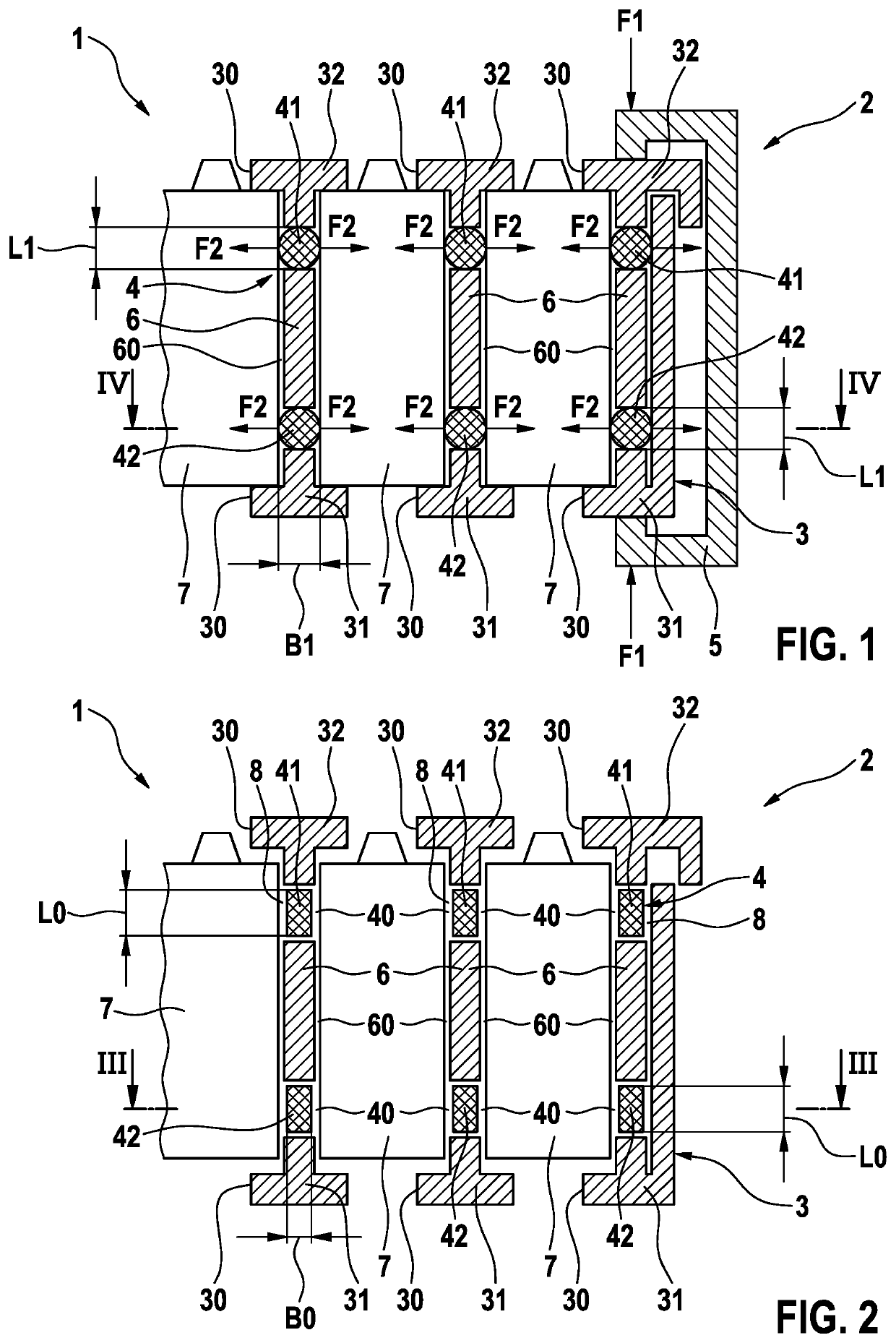

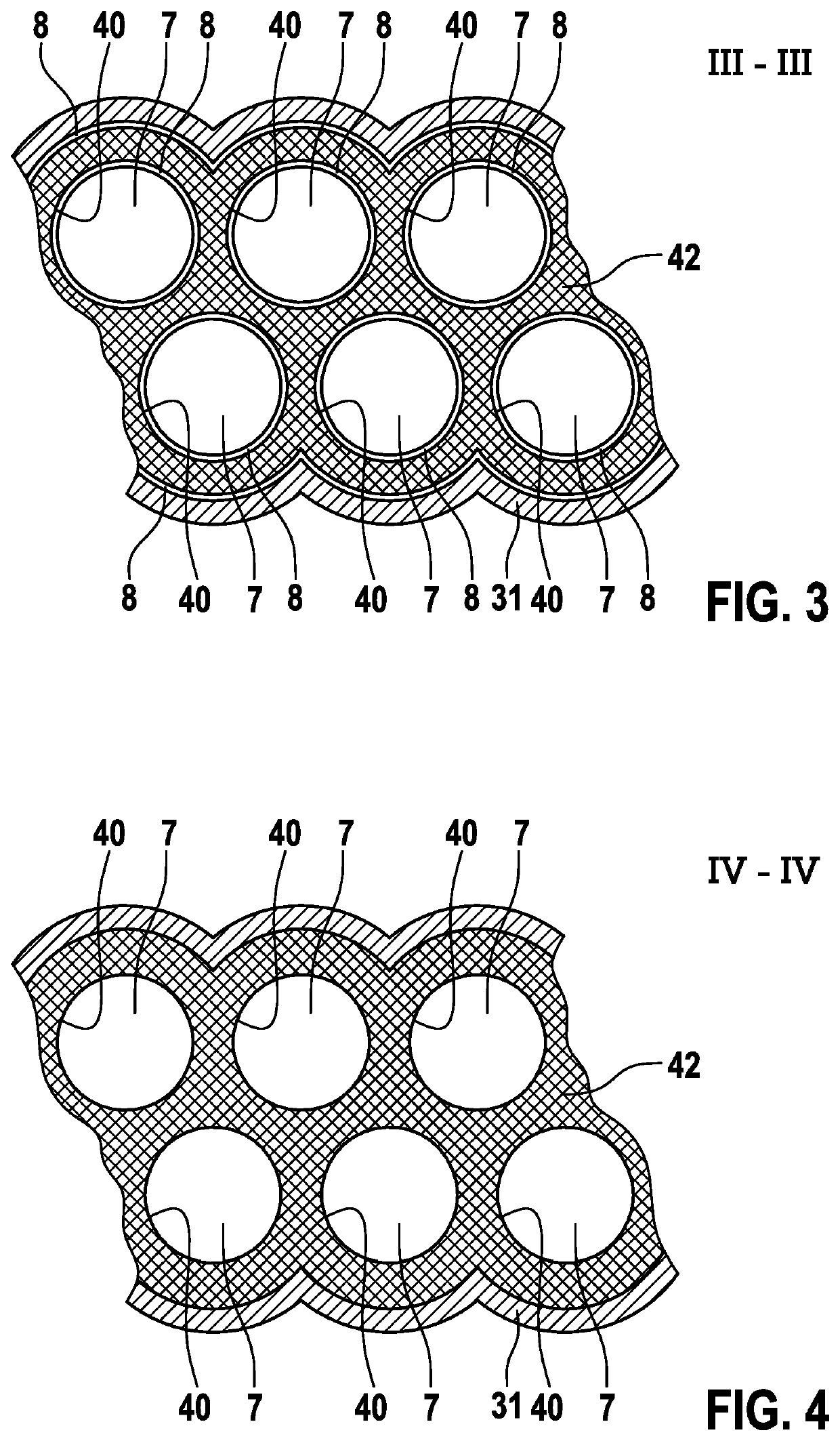

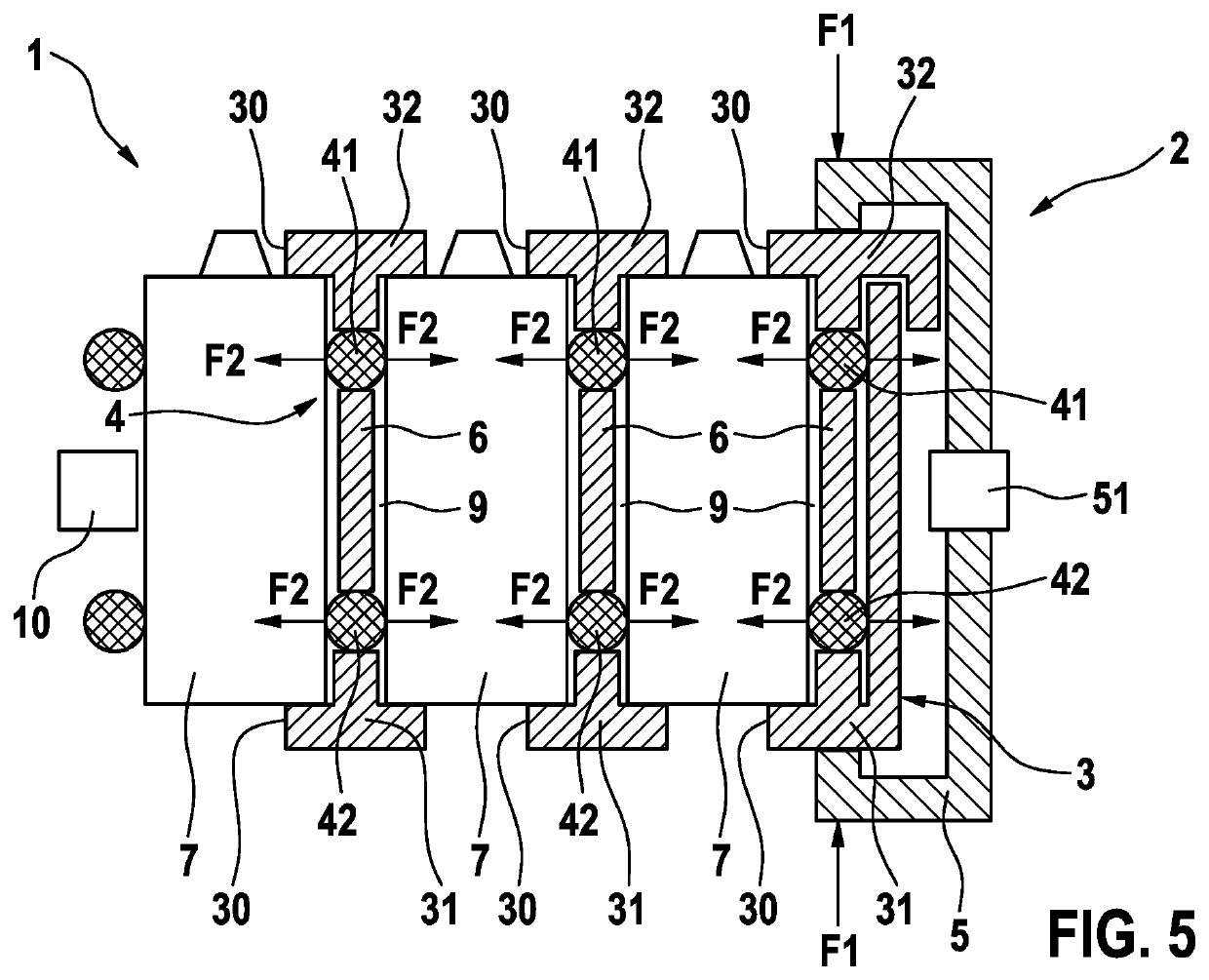

Battery cell holder and battery system

PendingUS20210313649A1Improve sealingSimple and weight-optimized constructionFinal product manufactureSecondary cells manufactureStructural engineeringMechanical engineering

A battery cell holder. The battery cell holder includes: a housing made of an inelastic material, which is configured to receive a plurality of individual battery cells; an elastic intermediate unit having a plurality of passthrough openings, each passthrough opening being configured to receive one battery cell; and a preload device that is configured to exert a preload force on the elastic intermediate unit in such a way that the elastic intermediate unit becomes elastically deformed in order to clamp the battery cells.

Owner:ROBERT BOSCH GMBH

Overload protection device

Owner:TSUBAKI E&M +1

Three-axis vibration controllable intelligent feeder

ActiveCN107934408BImprove applicabilityReliable vibrationJigging conveyorsVertical vibrationEngineering

The invention provides a three-axis vibration controllable intelligent feeder. The three-axis vibration controllable intelligent feeder sequentially comprises a vibrating table top, a transverse guidebase, a longitudinal guide base and a vertical guide base from top to bottom, wherein the transverse guide base is arranged in the longitudinal guide base in a sleeved mode; the transverse guide baseis connected with the vibrating table top through transverse elastic assemblies, and drives the vibrating table top to vibrate transversely; the longitudinal guide base is connected with the transverse guide base through longitudinal elastic assemblies, and indirectly drives the vibrating table top to vibrate longitudinally; the vertical guide base is connected with the longitudinal guide base through vertical elastic assemblies, and indirectly drives the vibrating table top to vibrate in the vertical direction; and the vibrating table top can vibrate in a single direction and can also vibrate in two or three directions at the same time. According to the three-axis vibration controllable intelligent feeder, a transverse vibration control module, a longitudinal vibration control module anda vertical vibration control module are arranged so that starting and stopping of vibration, vibration directions and amplitude of vibration can be controlled in real time, and the degree of automation of vibration of parts on the vibrating table top is further improved.

Owner:斐晟机械电子(苏州)有限公司

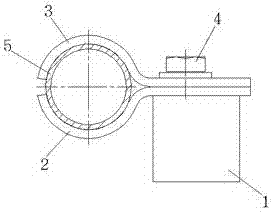

Hydraulic oil pipe clamp

InactiveCN102777700APrevent left and right movementAvoid deformationPipe supportsEngineeringMaterial Perforation

The invention discloses a hydraulic oil pipe clamp which comprises a fixed clamp, a movable clamp and a fastening member, wherein one end of the fixed clamp is fixed on the upper side of a support, the movable clamp is arranged on the upper side of the fixed clamp, the fastening member is arranged on one end of the movable clamp, one end of the movable clamp is fixedly connected with one end of the fixed clamp through a fastening member, the other end of the movable clamp is of a convex arc-shaped structure, the other end of the fixed clamp is of a concave semi-arc-shaped structure, the convex arc-shaped structure on the other end of the movable clamp is an elliptical arc structure which is combined by two sections of arcs with respectively circle centers horizontally deviating from the symmetric center line of the convex arc shape, the radiuses of the arcs are matched with the radius of a clamped oil pipe, when the other end of the movable clamp is used for clamping the oil pipe, and a gap exists between the highest point on the inner side of the convex arc shape on the upper end of the movable clamp and the highest point of the arc of the oil pipe. The hydraulic oil pipe has a simple structure, is stable and reliable in locking without easily causing vibration, avoids deformation, sealing-off and perforation of the hydraulic oil pipe, and ensures that the whole hydraulic system of engineering machinery normally operates.

Owner:中外合资沃得重工(中国)有限公司

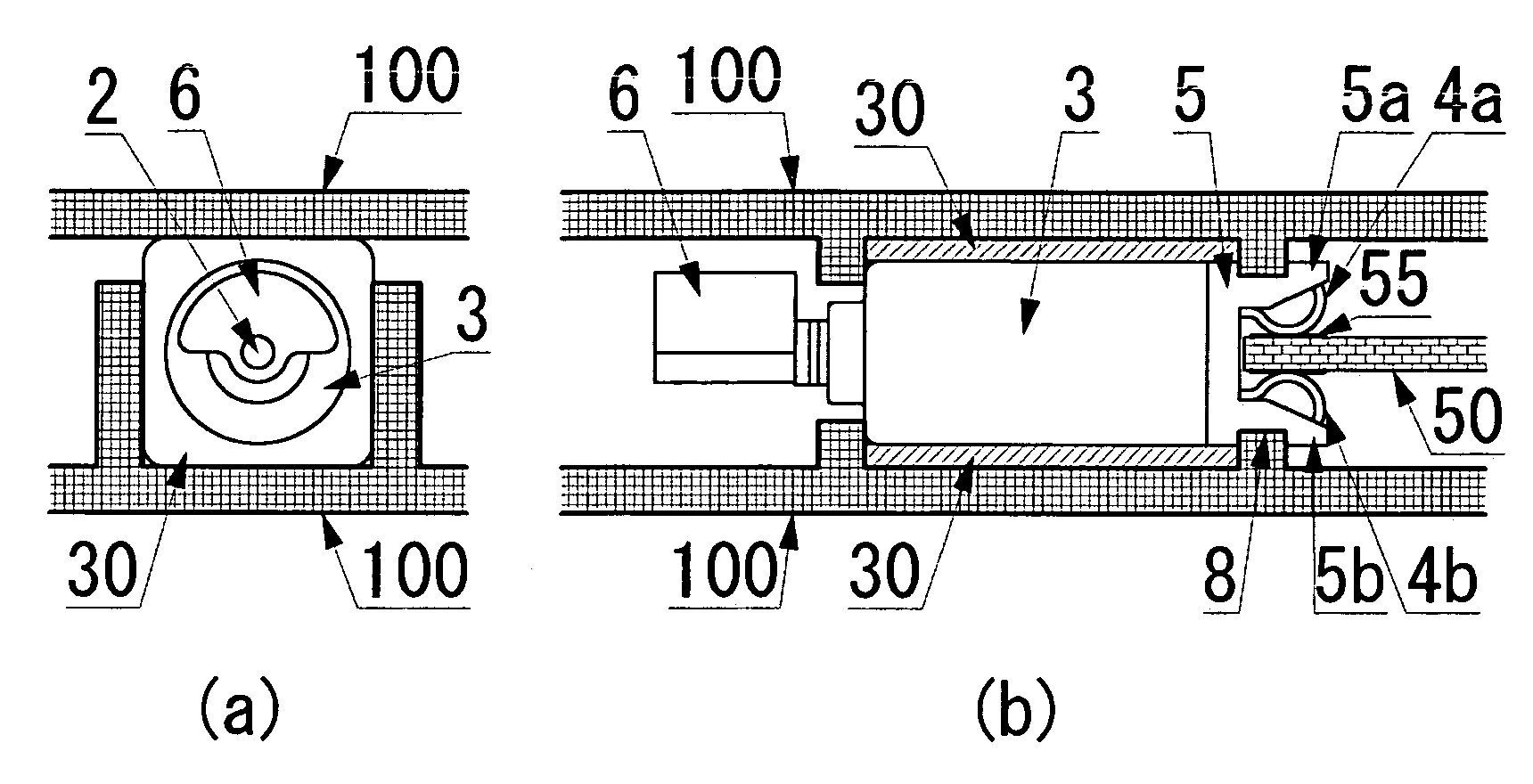

Vibration-generating small-sized motor and portable electronic equipment therewith

InactiveUS20140125170A1Shorten the lengthEasy to assembleMechanical vibrations separationMechanical energy handlingElectricityEngineering

The present invention is a vibration-generating small-sized motor that comprises within an external housing case thereof a stator and a rotor, a commutation mechanism, a power supply terminal that connects electrically with an electrode or a power supply land of the electronic equipment, and a terminal-blade mount on which the power supply terminal is mounted, wherein the power supply terminal includes a pair of resilient terminal blades that are located on the terminal-blade mount provided at a face of the external housing case of the motor, facing each other and pressing together, and the electrode or the power supply land on the circuit board are clamped between the resilient terminal blades, whereby the vibration-generating small-sized motor can be electrically connected to the power supply of the electronic equipment. Accordingly, the power supply terminal of the vibrating motor mounted in the portable electronic equipment can be electrically connected to the electrode or the power supply land on the circuit board in the electronic equipment with high reliability and this connection can be maintained continually over a long period.

Owner:NAMIKI PRECISION JEWEL CO LTD

Vibration piezoelectric acceleration sensor

InactiveUS7587941B2Reliable vibrationAcceleration measurement using interia forcesSemiconductor/solid-state device detailsResonanceClassical mechanics

Owner:PANASONIC CORP

Vibrating pollution-discharging water purifier

InactiveCN107469426AEasy to cleanEfficient cleaning and sewage dischargeStationary filtering element filtersEngineeringPollution

The invention discloses a vibrating pollution-discharging water purifier in the field of water purifiers. The vibrating pollution-discharging water purifier comprises a filter element housing, a central pipe, a filter element, an end cover, a water inlet and a pollution discharge port; the water purifier also comprises an upper fixed seat fixed at the extended out end of the central pipe, and also comprises a lower fixed seat fixedly arranged on the end cover; and the water purifier also comprises two extension springs separately fixedly arranged on the upper and lower fixed seats, and also comprises a vibrating seat located in a filter element housing; a vibrating shaft is arranged at the lower end of the vibrating seat; the water purifier also comprises a vibrating mechanism which comprises a shell, a rotary shaft, a fixed seat, a motor and also comprises an eccentric wheel matched with the lower end of the vibrating shaft; the eccentric wheel sleeves the rotary shaft; two ends of the rotary shaft are rotatably mounted on the fixed seat, separately, and one end of the rotary shaft extends out of the fixed seat; the fixed seat is fixed in the shell; a driven gear is arranged at the extended out end of the rotary shaft; a driving gear is arranged on the motor; the driving gear is engaged to the driven gear. The water purifier cleans dirt in the water purifier efficiently and discharges the same.

Owner:镇江巨商智能科技有限公司

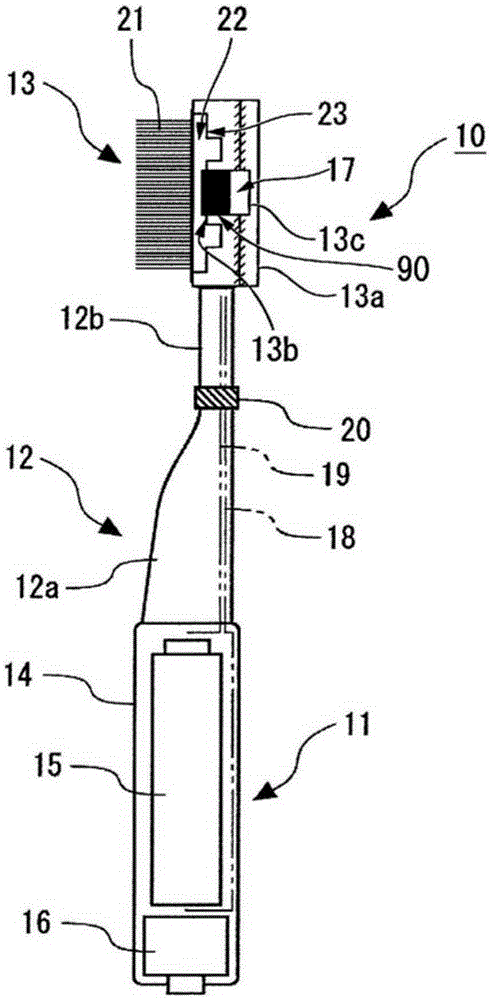

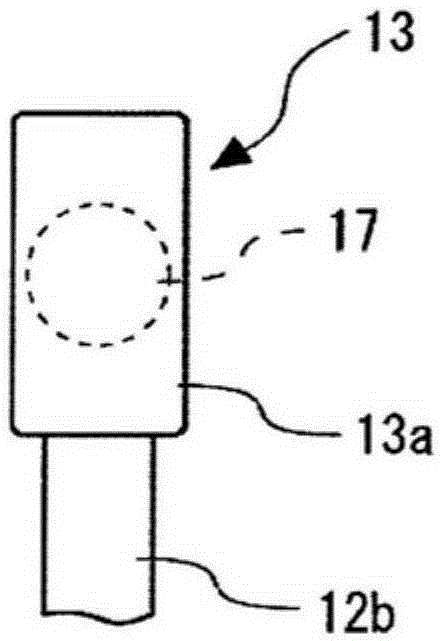

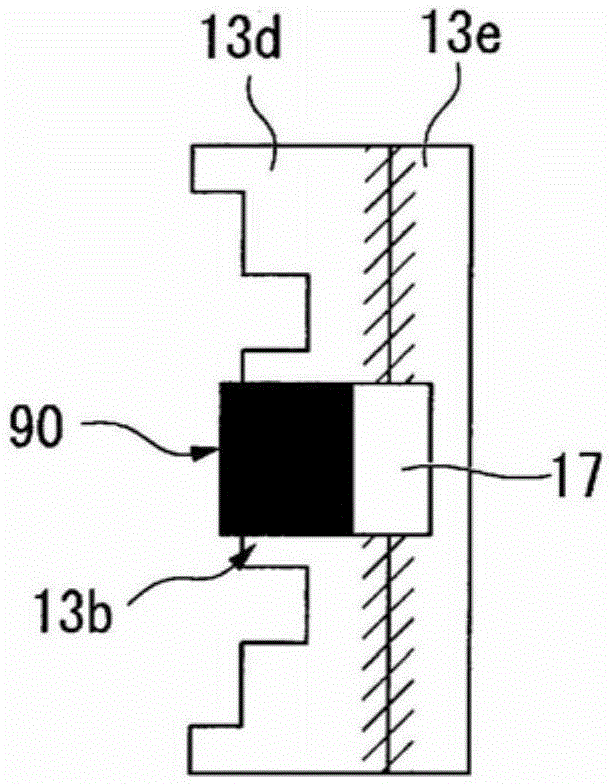

electric toothbrush

ActiveCN104203148BGuaranteed StrengthReliable vibrationBrush bodiesTooth cleaningElectricityNeck parts

Provided is an economical electric toothbrush that can reliably vibrate a head part while ensuring teeth-cleaning operability in the mouth, and in which a smaller size and lighter weight are achieved, and portability is improved. This electric toothbrush (10) comprises a head part (13), a neck part (12), and an operating part (11), wherein the head part (13) has a coin-shaped vibrating motor (17) on the bottom surface side of the head part, and a detachable brush plate (22) on the upper surface side of the head part; a battery and switch part are stored in the operating part (11); and the toothbrush is vibrated by the vibrating motor that is operated by electricity supplied from the battery.

Owner:LION CORP

A supercharger turbine assembly heavy removal tooling

ActiveCN105751043BReliable vibrationReduce vibrationGrinding drivesGrinding machinesEngineeringTurbine

The invention provides a supercharger turbine assembly de-weighting tool. A support plate (2) is installed on a tool rack (1) of the de-weighting tool; a limiting plate (3) is arranged on the support plate (2); a turbine main shaft clamping groove is formed in the side surface of the limiting plate (3); an air cylinder A push block (5) is installed on an air cylinder A (4); the air cylinder A (4) can be connected with a control component (6) which is capable of controlling the air cylinder A push block (5) to stretch; an electric grinding head (7) is arranged on the tool rack (1); a grinding wheel (8) is arranged on the electric grinding head (7); and the electric grinding head (7) is connected with the control component (6) which is capable of controlling the grinding wheel (8) of the electric grinding head (7). The supercharger turbine assembly de-weighting tool is simple in structure, and is capable of conveniently and rapidly completing the turbine small head de-weighting process and the turbine back de-weighting process of supercharger turbine assemblies, effectively reducing the vibration and noise generated by superchargers and prolonging the service life of the superchargers.

Owner:JAPHL POWERTRAIN SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com