Three-axis vibration controllable intelligent feeder

A feeder and shaft vibration technology, which is applied to vibrating conveyors, transportation and packaging, conveyors, etc., can solve the problems of complex structure of vibration devices, unfavorable promotion, and high production costs, so as to enhance work accuracy and improve work efficiency , Accurate and reliable effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

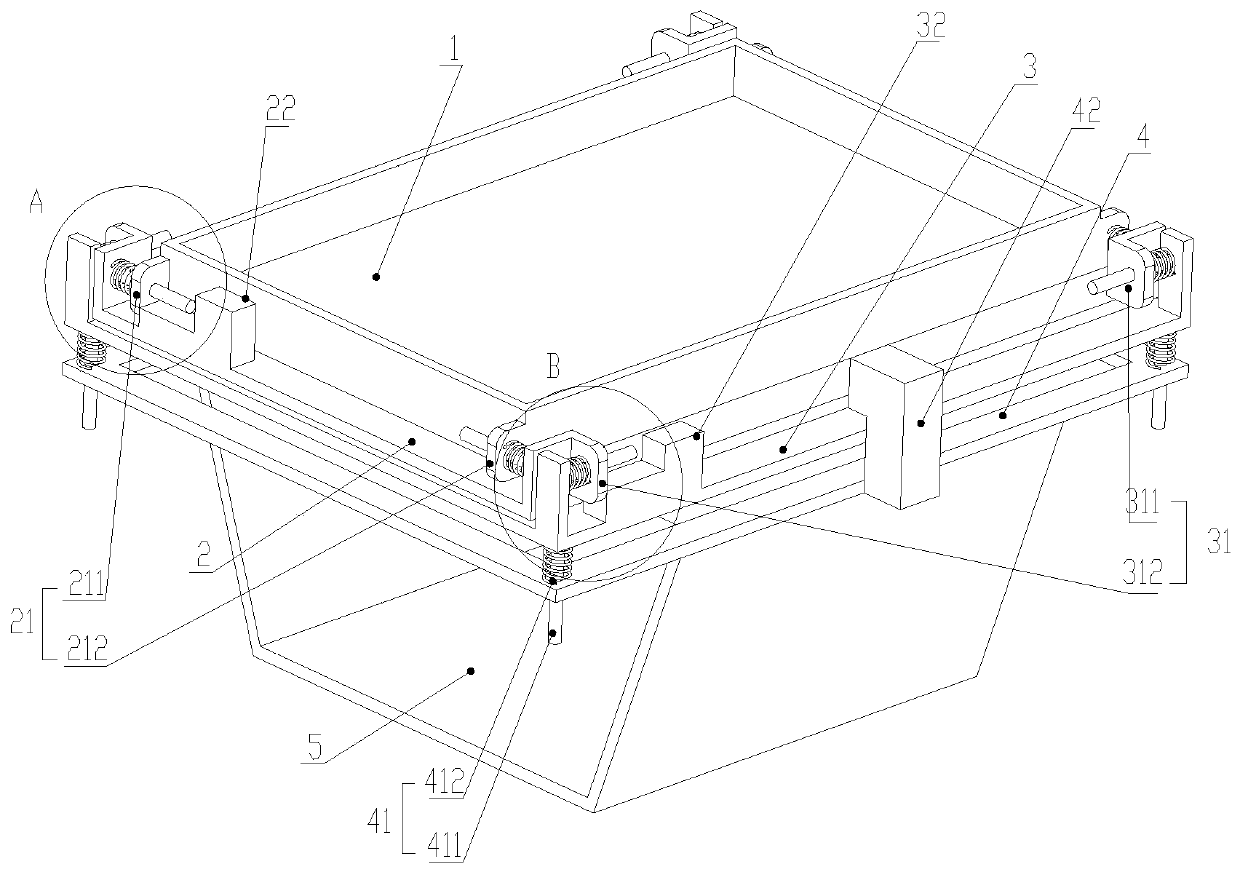

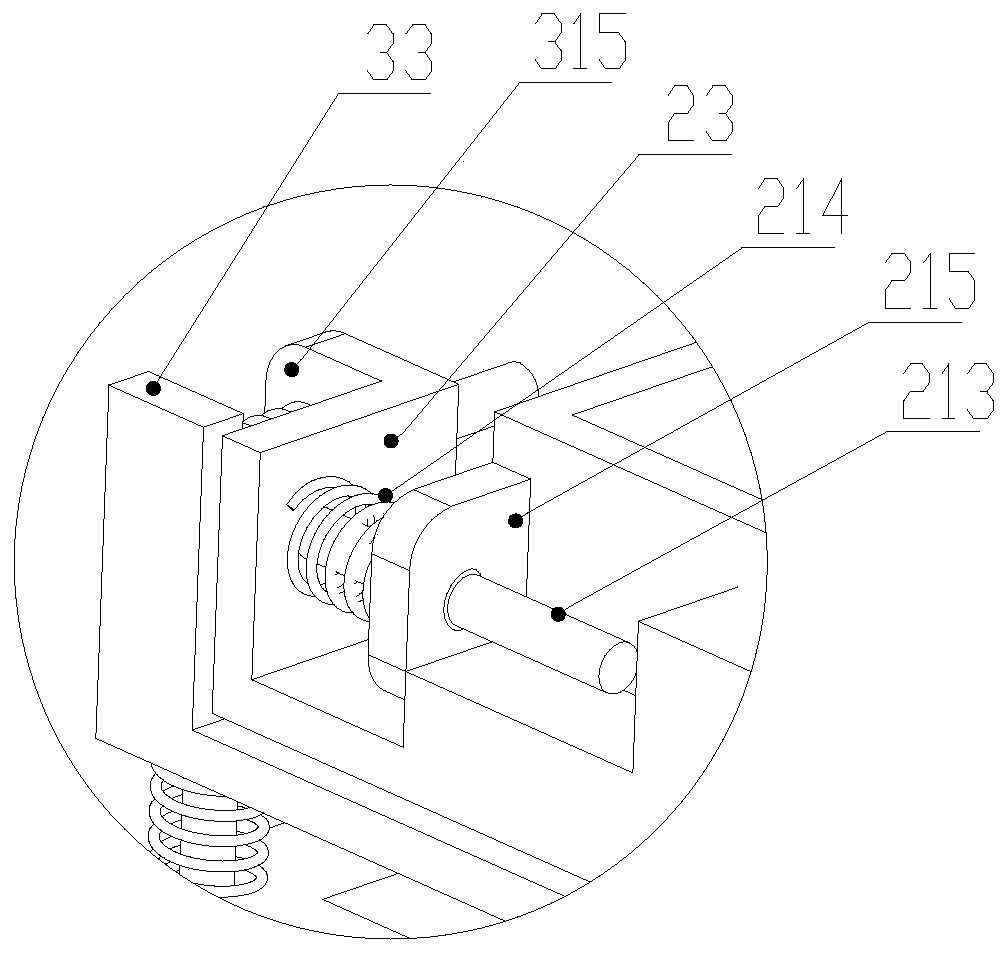

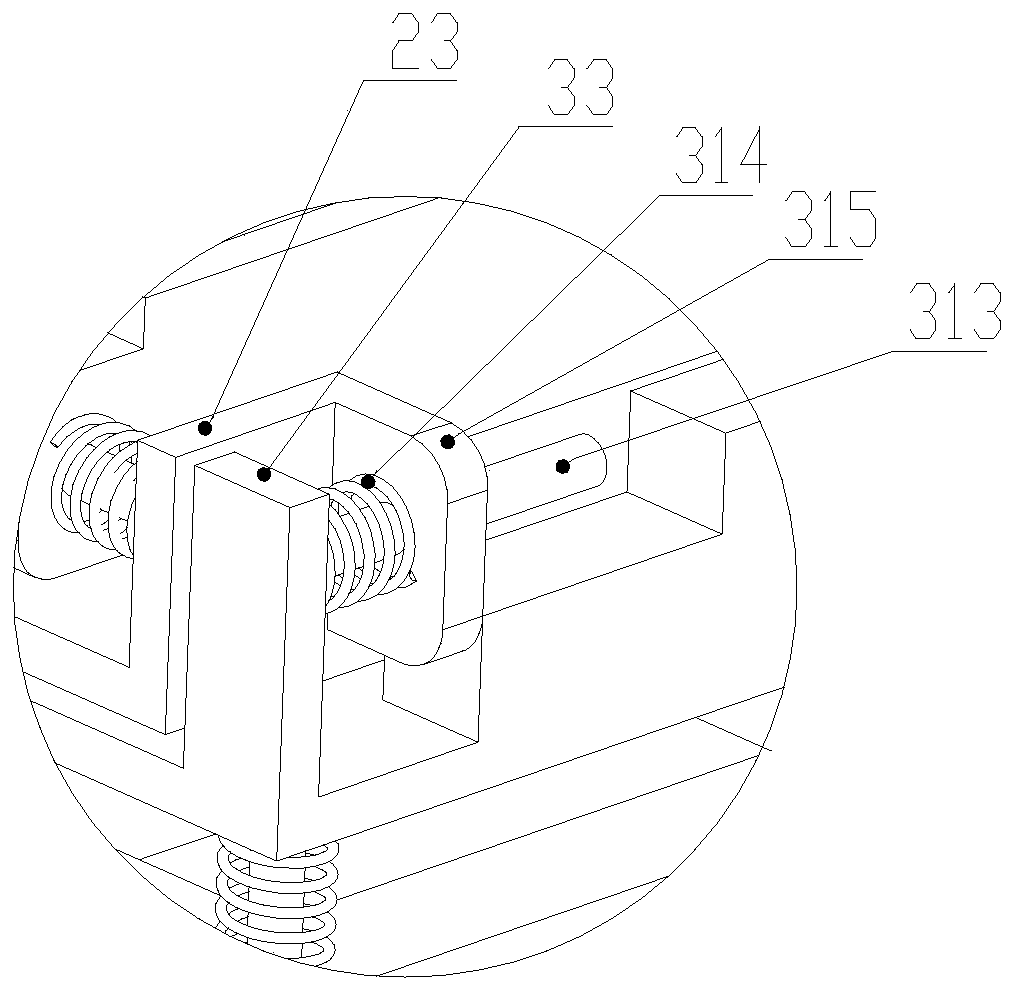

[0030] Such as Figure 1 to Figure 3 As shown, a three-axis vibration controllable intelligent feeder includes a vibrating table top 1, a lateral guide base 2 is provided below the vibrating table top 1, and a lateral guide base 2 is provided with The transverse elastic component 21, the transverse elastic component 21 connects the transverse guide base 2 and the vibration table 1;

[0031] A longitudinal guide base 3 is provided below the transverse guide base 2, and the transverse guide base 2 is sleeved in the longitudinal guide base 3. The longitudinal guide base 3 is provided with longitudinal elastic components 31 along the left and right sides parallel to the vibrating table surface 1. The longitudinal elasticity The component 31 connects the longitudinal guide base 3 and the transverse guide base 2;

[0032] A vertical guide base 4 is provided below the longitudinal guide base 3, and a vertical elastic component 41 is arranged on the vertical guide base 4 along a dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com