Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Reliable steering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

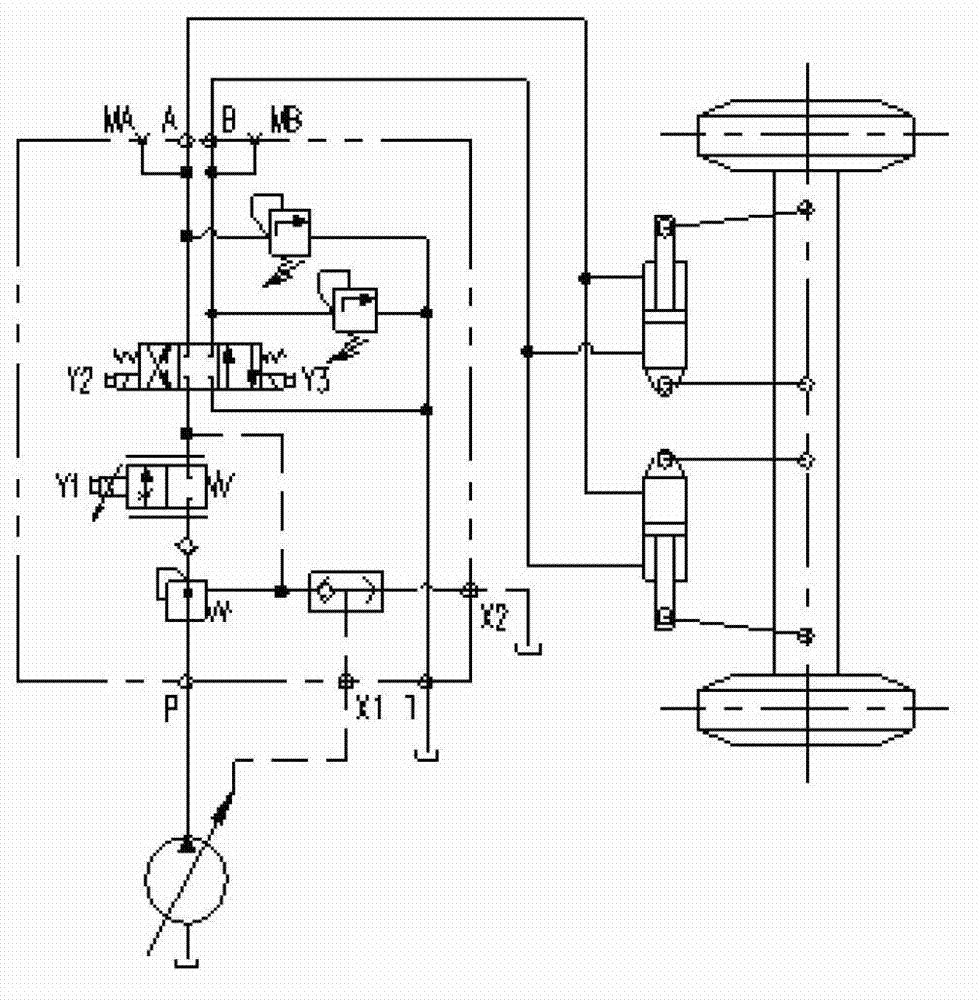

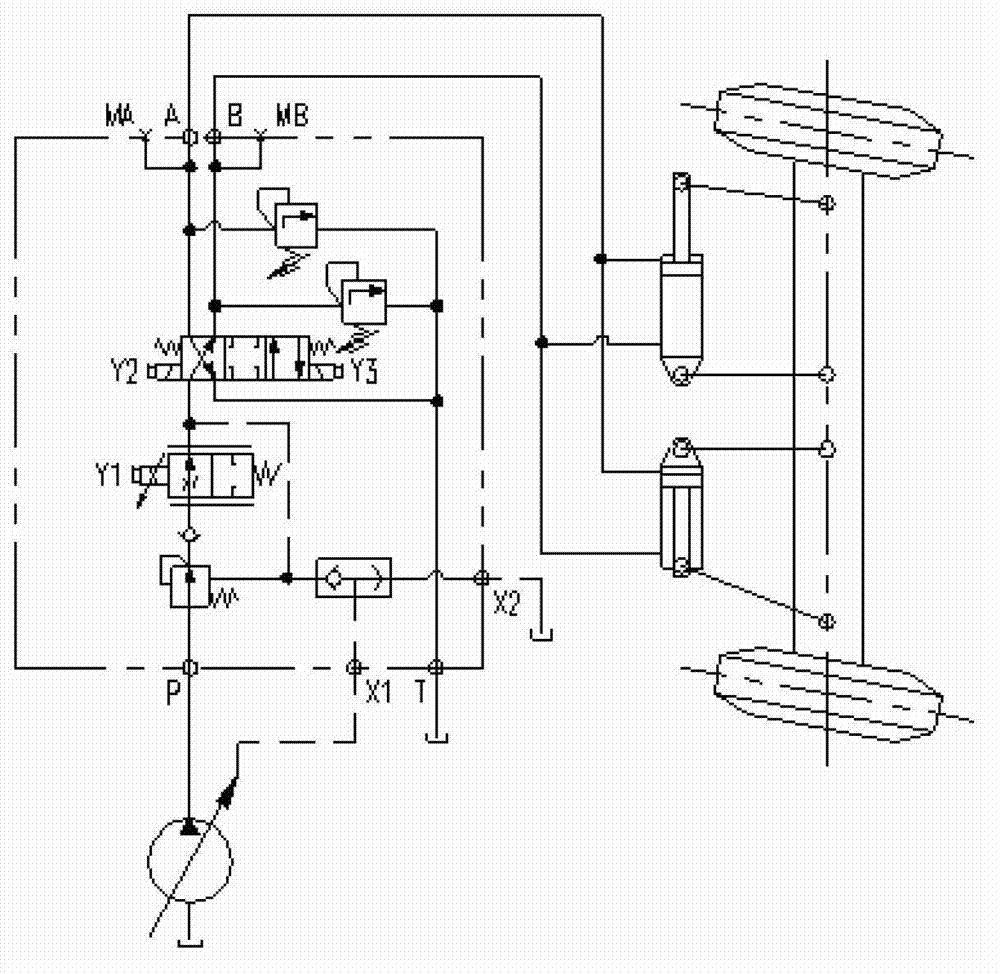

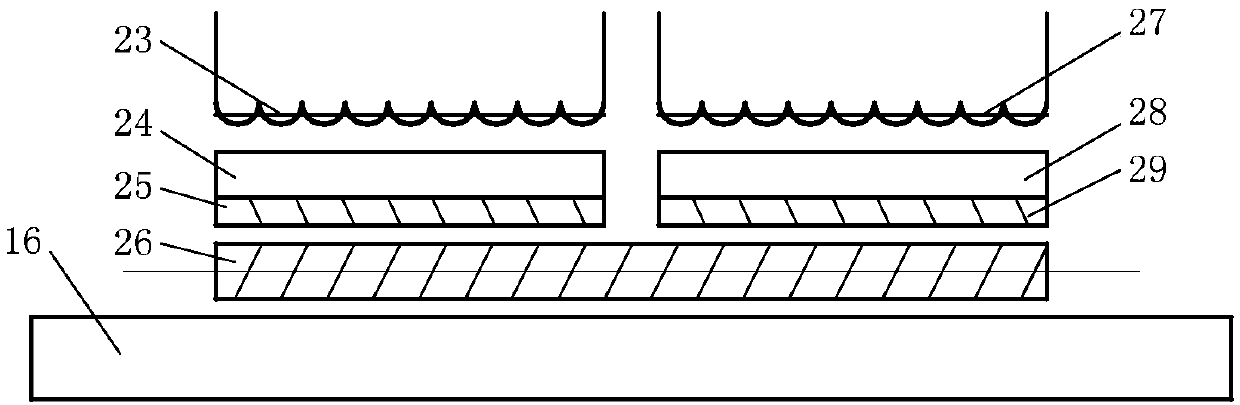

Proportional steering valve, proportional steering hydraulic circuit, proportional steering system and vehicle

ActiveCN102862603AIncreased sensitivityEliminate or reduce flow cut-off areaFluid steeringInlet channelHydraulic circuit

A proportional steering valve comprises a reserving valve and a proportional throttle valve (4). The reversing valve is provided with an oil inlet port (10), an oil return port (11), a first working port (12) and a second working port (13), an output port (14) of the proportional throttle valve is communicated with the oil inlet port (10), and an input port (15) of the proportional throttle valve is connected with one end of an internal oil inlet channel (23). The invention further provides a proportional steering hydraulic circuit comprising the proportional steering valve and provides a proportional steering system and a vehicle. Functions of flow control and reversing are achieved by the aid of the proportional throttle valve and an electronic control valve respectively, and accordingly, steering is realized by combined control, response speed is increased conveniently, and flexibility in steering is improved remarkably. In addition, cost is low and pollution resistance capacity is strong due to utilization of common hydraulic elements.

Owner:ZOOMLION HEAVY IND CO LTD

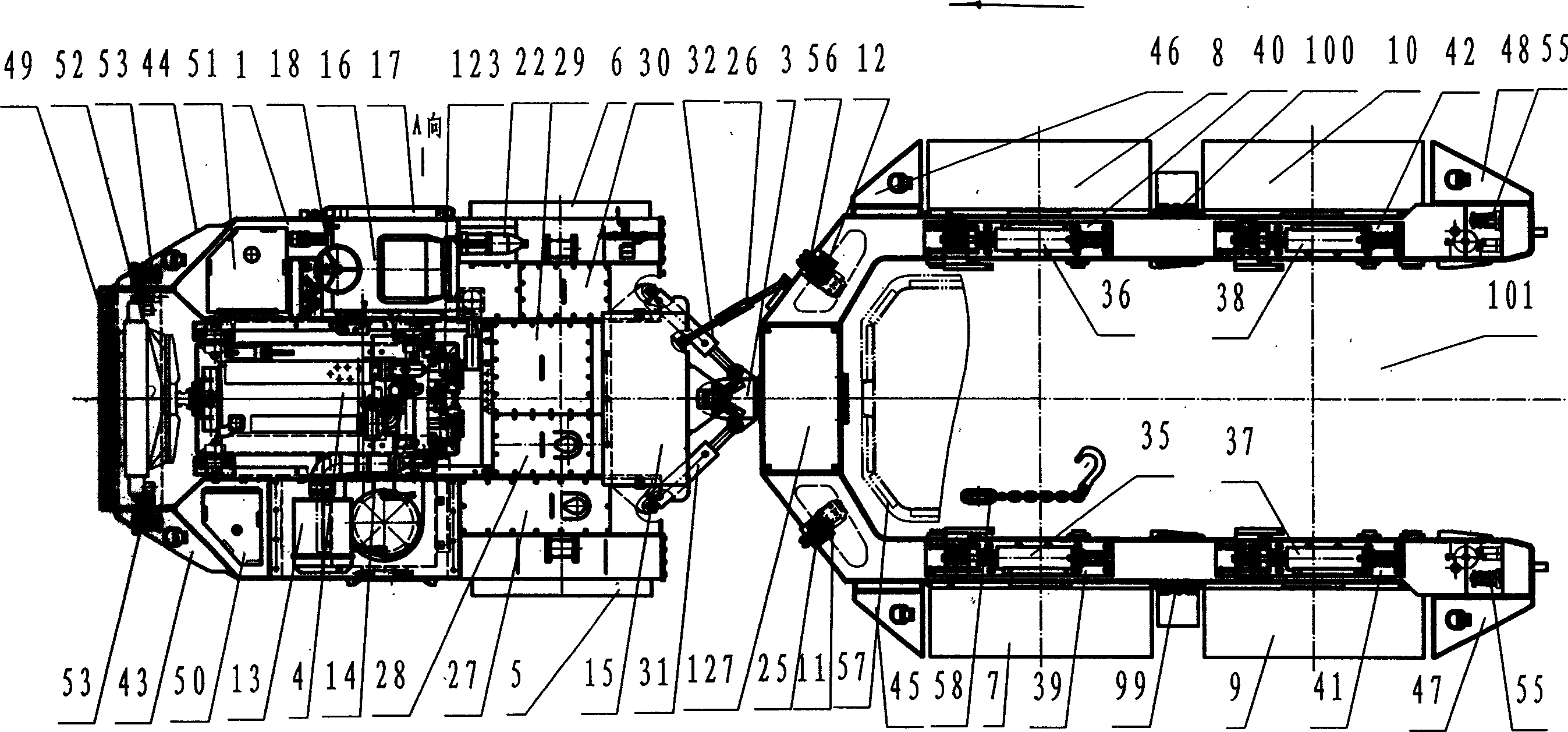

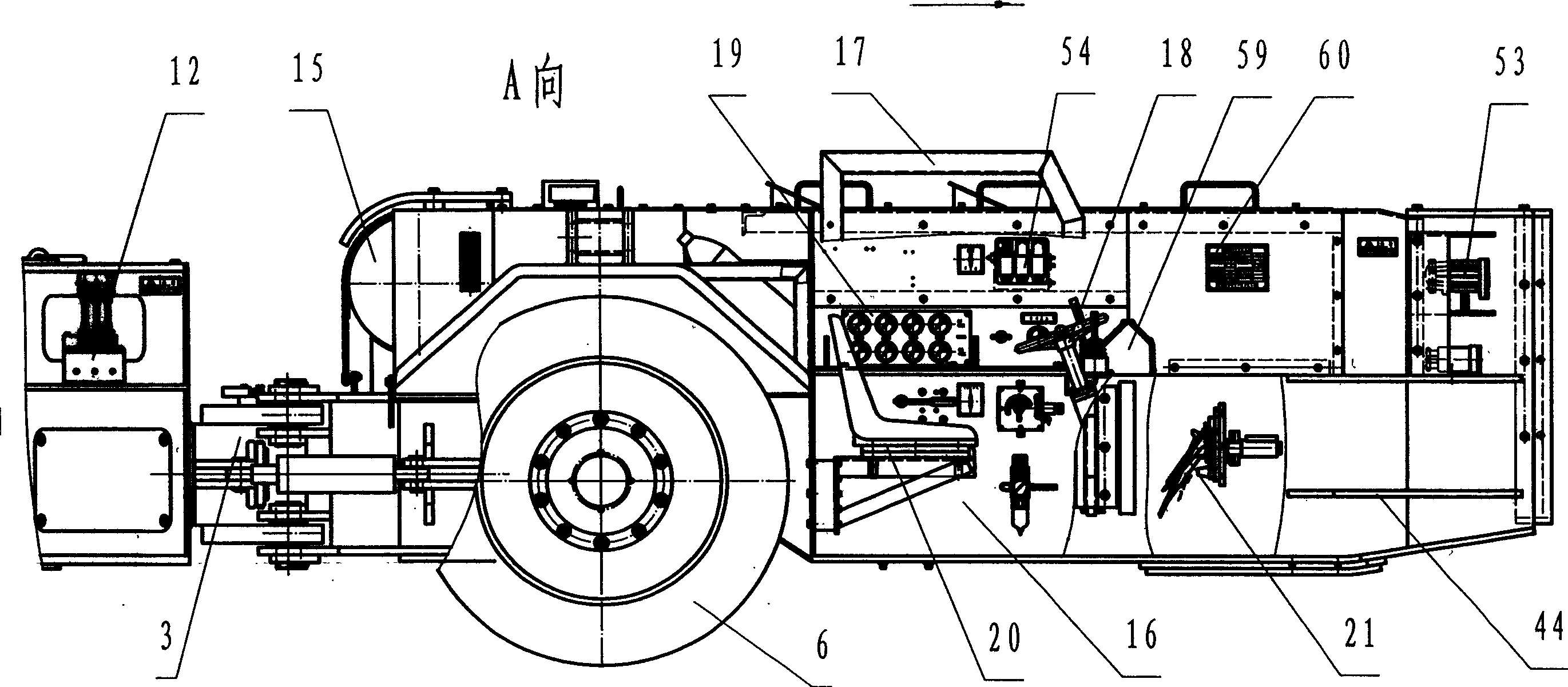

Explosion-proof support transporting vehicle for coal mine

ActiveCN1792673AAdvancedReasonable design structureItem transportation vehiclesElectricityControl system

An anti-explosion carrier vehicle for transporting supporting frames or heavy machines in coal mine is composed of front and back machine frames, steering linkwork, diesel engine, hydraulic system, lifting mechanism, clamping unit, admission and exhaust protecting unit, water cooling unit, running mechanism, feeding hopper, and operation control system. The hydraulic drive is used to control running, lifting, clamping and steering. The water, electricity, gas and hydraulic system are controlled in linkage mode. The anti-explosion design is taken.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP

Sleeve motor steer-by-wire device and control method

PendingCN107792168AReduce radial sizeCompact structureMechanical steering gearsElectrical steeringRoller screwReduction drive

The invention discloses a sleeve motor steer-by-wire device and a control method. The steer-by-wire device comprises a steering wheel, a steering pipe column connected with the steering wheel, a leftside wheel steering transmission mechanism connected with a left side wheel, a right side wheel steering transmission mechanism connected with a right side wheel and a mechanical steering transmissionmechanism connected with the steering pipe column through an electromagnetic clutch. The steering pipe column is connected with a road sensing / assistant power motor through a reducer, the steeringdevice further comprises a steer-by-wire execution mechanism, the steer-by-wire execution mechanism comprises a first sleeve motor, a second sleeve motor and a planetary roller screw mechanism drivenby the first sleeve motor and / or the second sleeve motor. The sleeve motor steer-by-wire device adopts the double sleeve motors and the planetary roller screw mechanism, and sufficiently utilizes the axial spaces of a rack and a tie rod protective sleeve to reduce the radial sizes of the motors, is high in transmission efficiency, and liable to improve the driving consistency of the double sleeve motors when working with a heavy load.

Owner:ZHEJIANG WANDA AUTOMOBILE DIRECTION MACHINE CO LTD +1

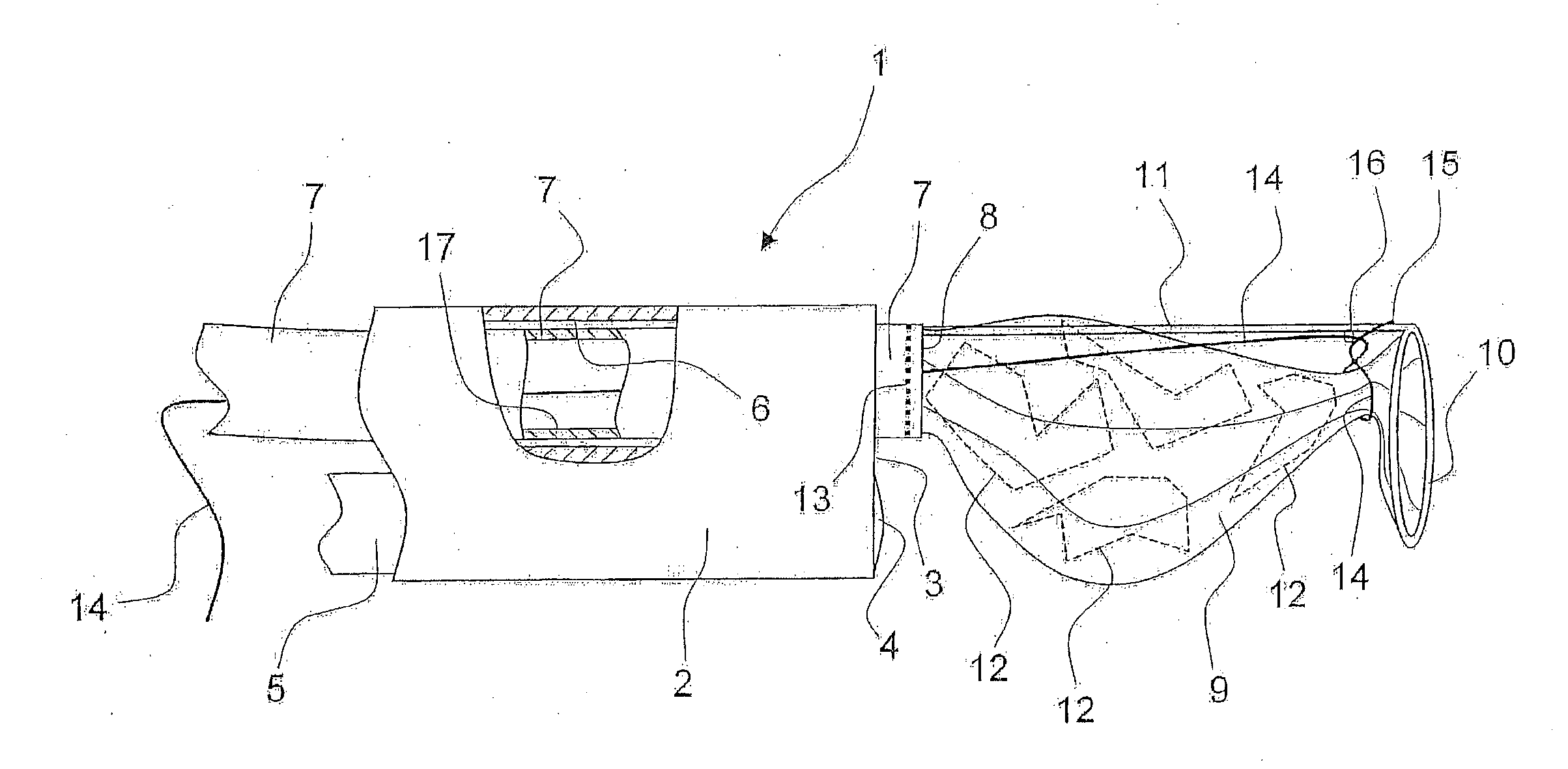

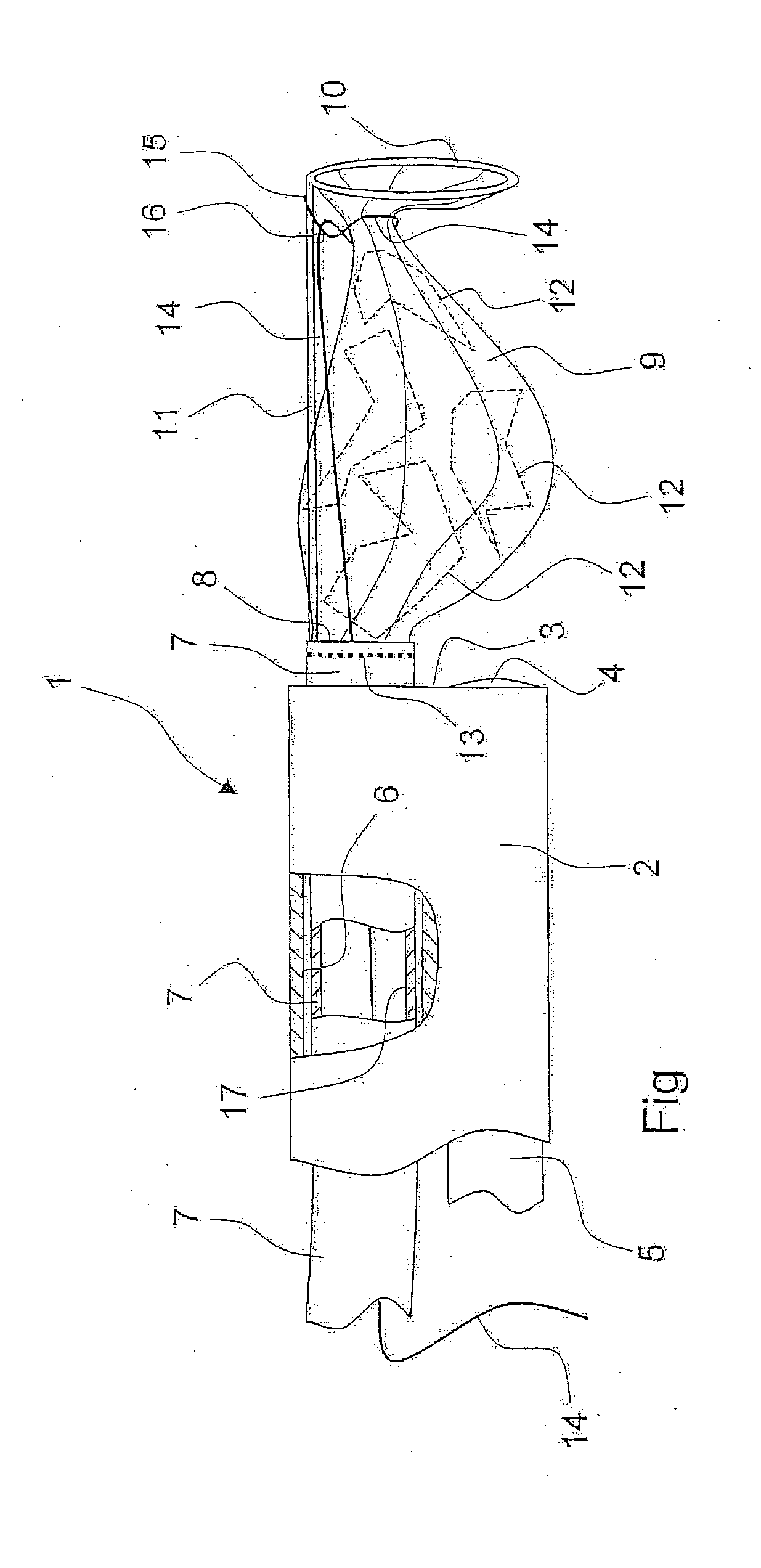

Ureteral calculus suction instrument having a shaft

ActiveUS20130231677A1Reliable steeringReliable controlEndoscopesSurgical instrument detailsEngineeringUreteral calculus

A ureteral calculus suction instrument having a shaft through which a suction channel that can be connected to a suction device passes, wherein a collecting container having a distal opening and a proximal opening is arranged distally from the shaft, of which openings the proximal opening is connected to the distal end of the suction channel

Owner:OLYMPUS WINTER & IBE

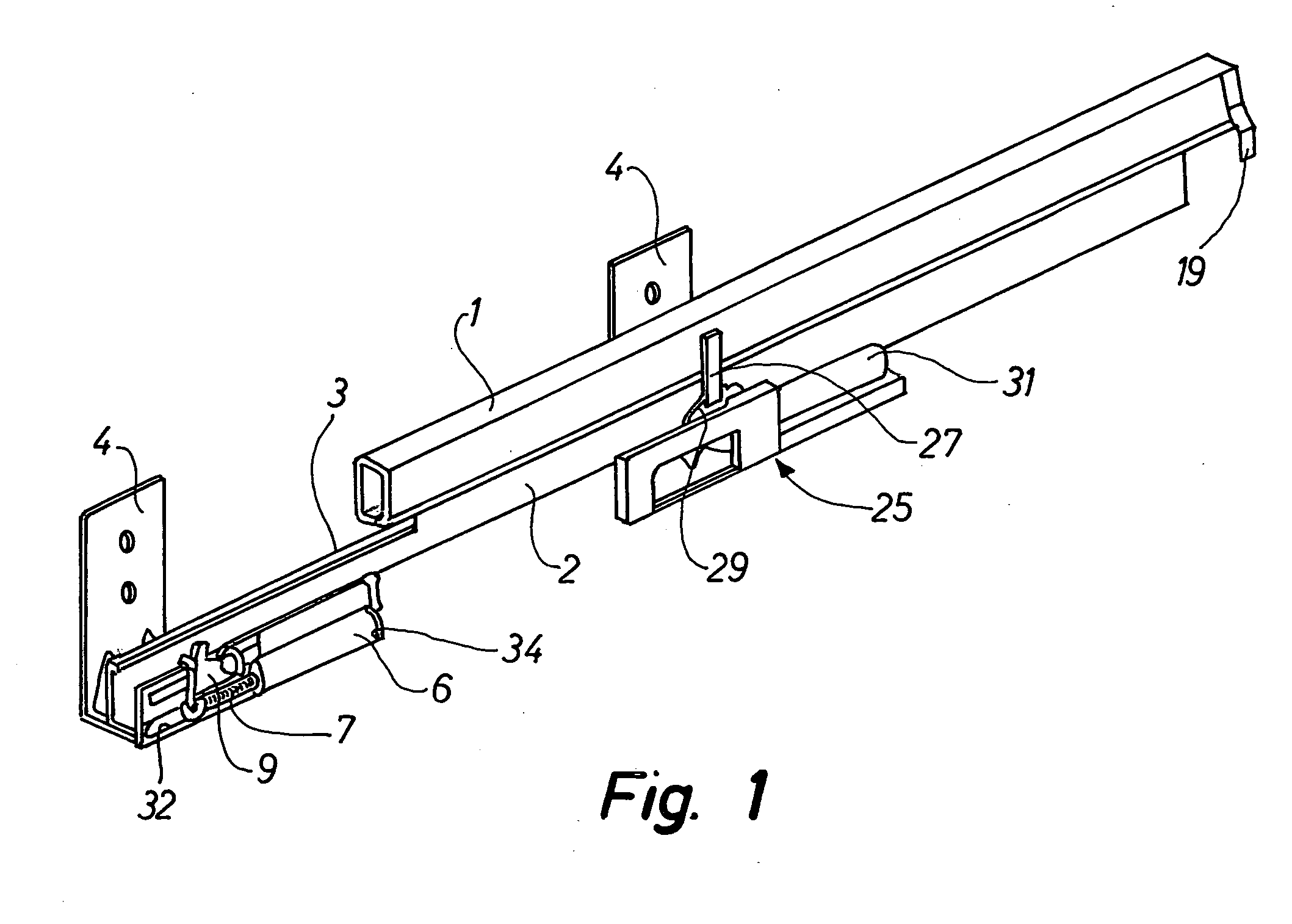

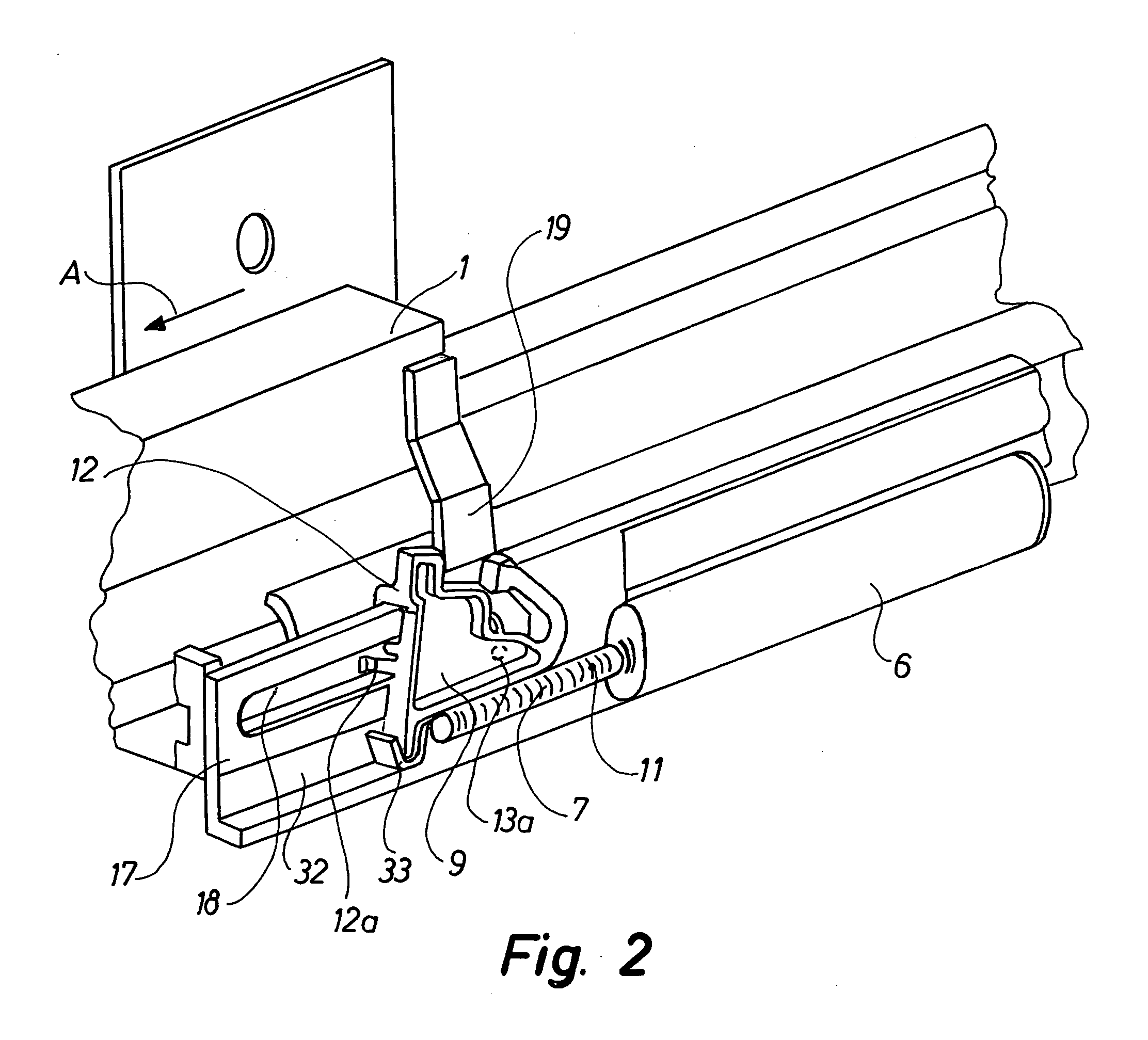

Device for securing a soft ending of the opening movement of a drawer

InactiveUS20100293746A1Reliable steeringClose reliableBuilding braking devicesWing openersReciprocating motionEngineering

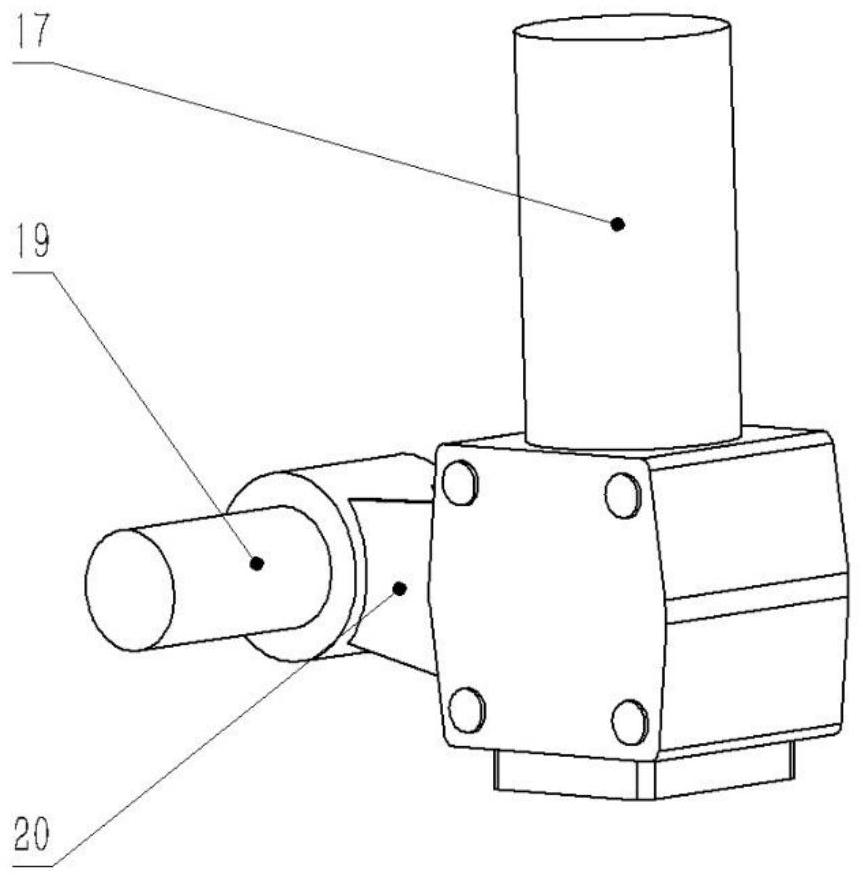

Device for securing a soft ending of the opening movement of a drawer as the latter is drawn towards an outer limit stop (10), the drawer being mounted in a (not-shown) furniture body and capable of being pulled out from said body, and in which there may be one or more rails (1, 3) between the drawer and the furniture body. The device comprises a damper (6) filled with a fluid medium attached to the furniture body—or to a rail of the furniture body—and a piston with a piston rod (7) being reciprocable in said damper (6), the free end of the piston rod (7) being attached to a tilt-able rocker (9). Whenever the piston rod (7) close to its outermost position is moved in and out in the damper (6), the rocker can be moved on a guide portion (17)—mounted at the damper (6)—between a first end position (FIG. 2) close to the damper, in which a first pin (19) mounted at the back of the drawer may engage with the rocker (9), and a second end position (10) far from the damper (6), in which the piston rod (7) is in its outermost position. This device can work in an especially reliable way.

Owner:INTER IKEA SYST

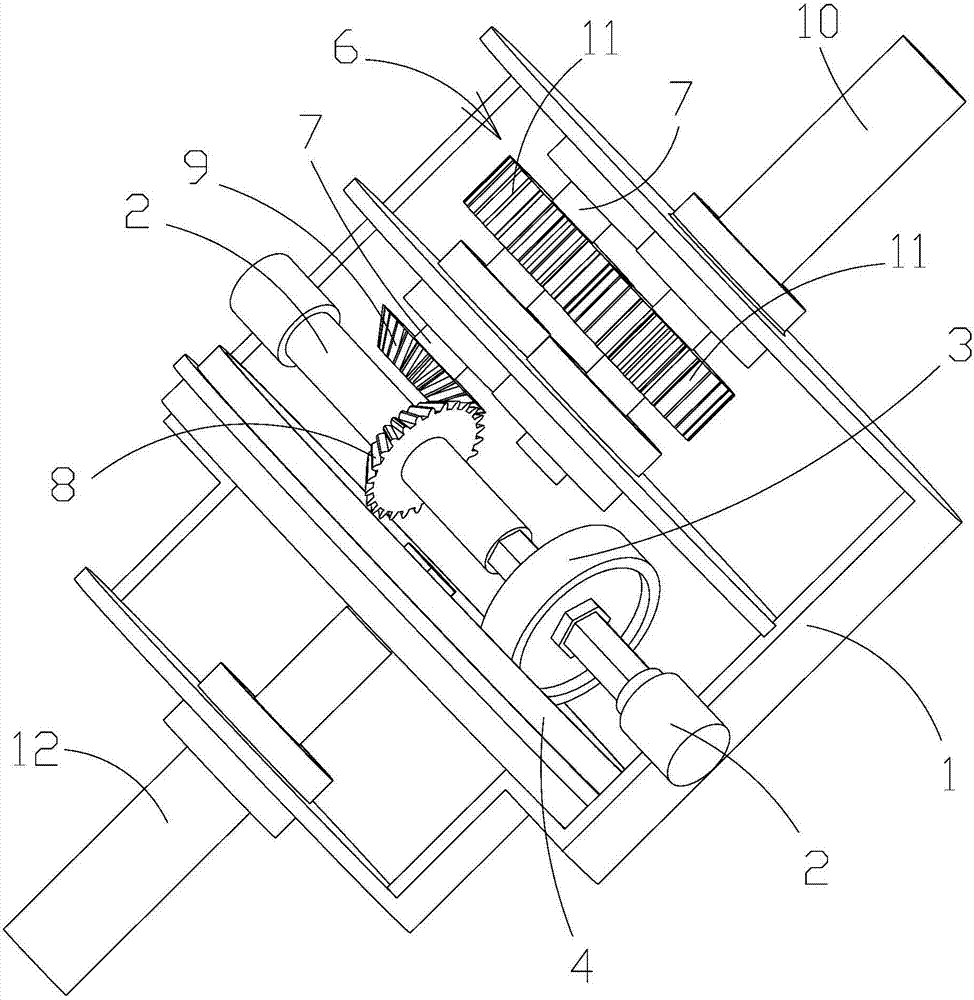

Electric vehicle deceleration and differential integrated rear axle assembly

The invention relates to an electric vehicle reduction and differentiation integrated rear axle assembly which is an integrated assembly of a motor, a reducing mechanism, a differential mechanism and a rear axle of an electric vehicle. The integrated assembly is applied to rear axle drive systems of freight vehicles, passenger vehicles, electric three-wheeled vehicles, electric four-wheeled vehicles and the like. The integrated assembly comprises the motor, the reducing mechanism, the differential mechanism, a reduction and differential case and the rear axle. The rear axle comprises a rear axle stand, a first drive half-axle, a second drive half-axle, a first braking fixed plate, a second braking fixed plate, a brake block, a brake cam, a first hub and a second hub. The reduction and differential case is installed on the rear axle stand and is fixed by screws; the reducing mechanism comprises a reducing gear shaft, a reduction transition gear and a reduction transition pinion; and the differential mechanism comprises a differential mechanism housing, a differential gear, a first satellite gear, a second satellite gear, a satellite gear shaft, a first spline gear, a second spline gear and a fifth bearing. The differential mechanism housing is installed below the reduction and differential case through the fifth bearing and a bearing support, and the differential gear is arranged outside the differential mechanism housing.

Owner:薛建南

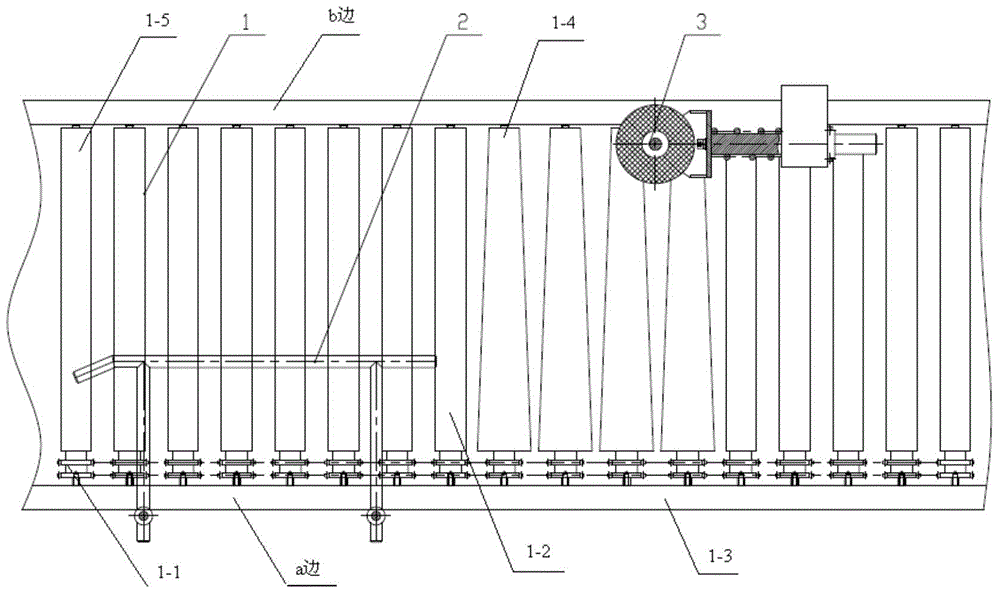

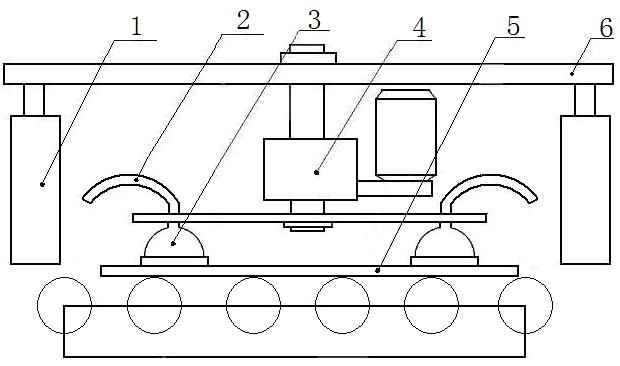

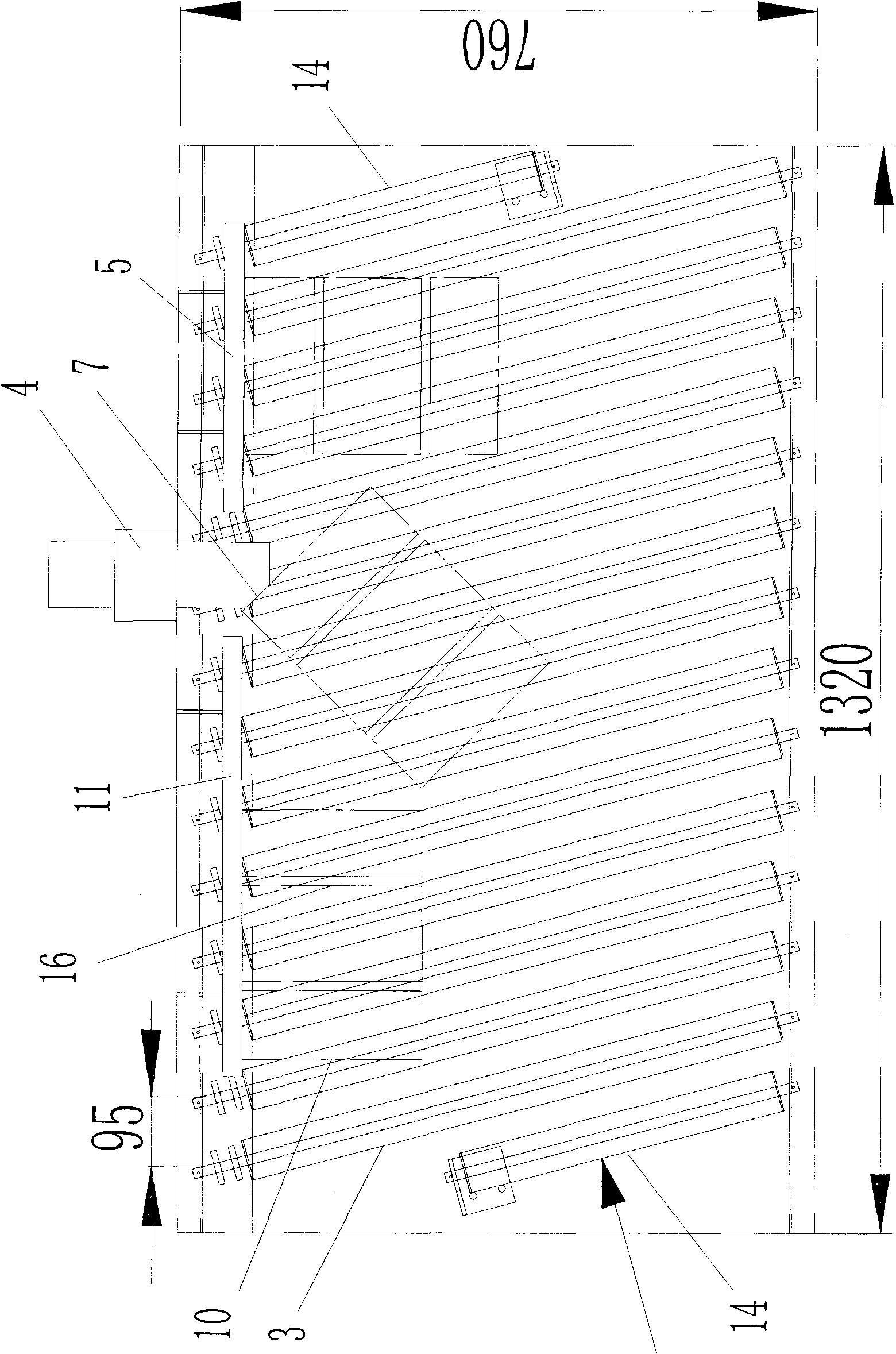

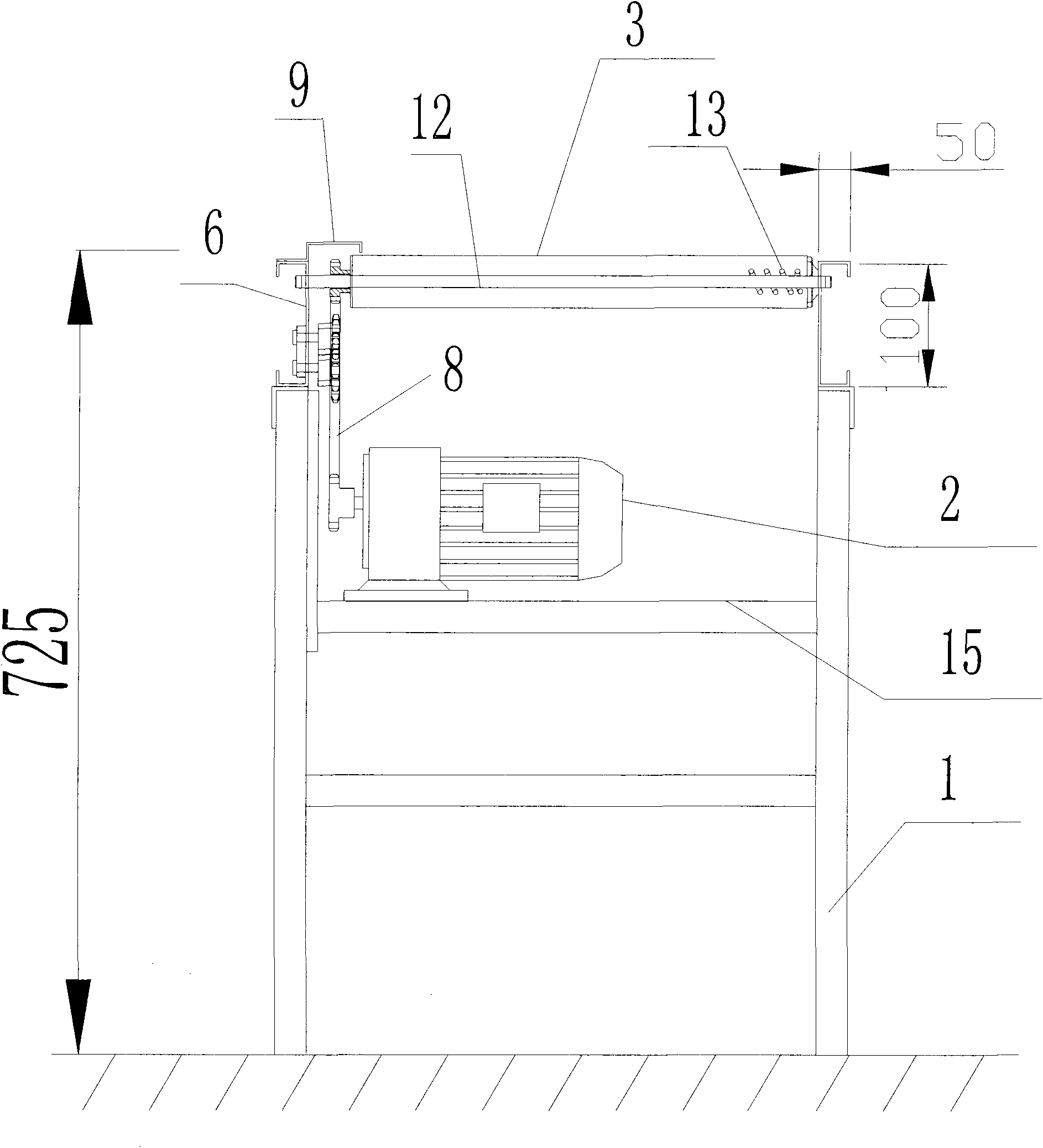

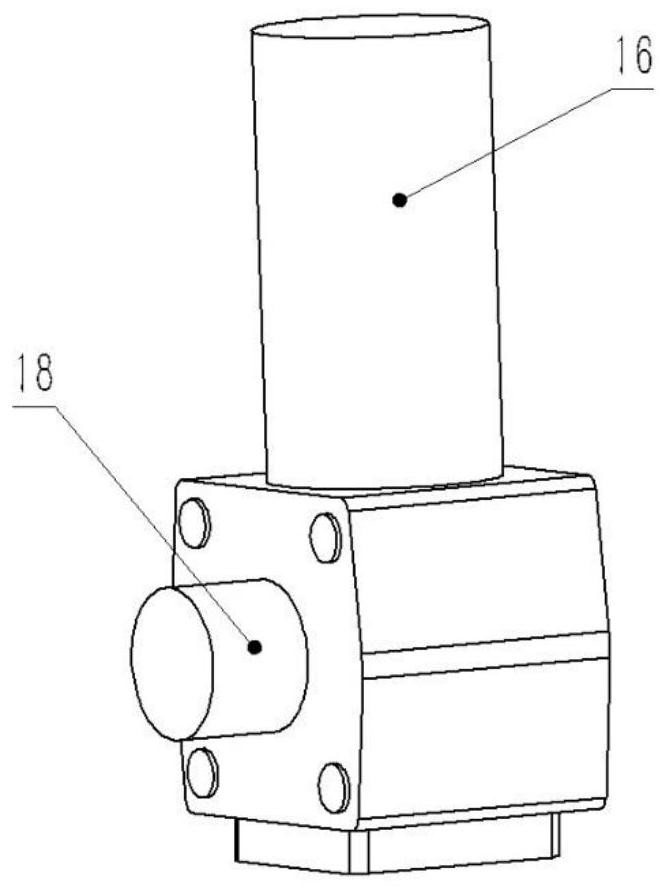

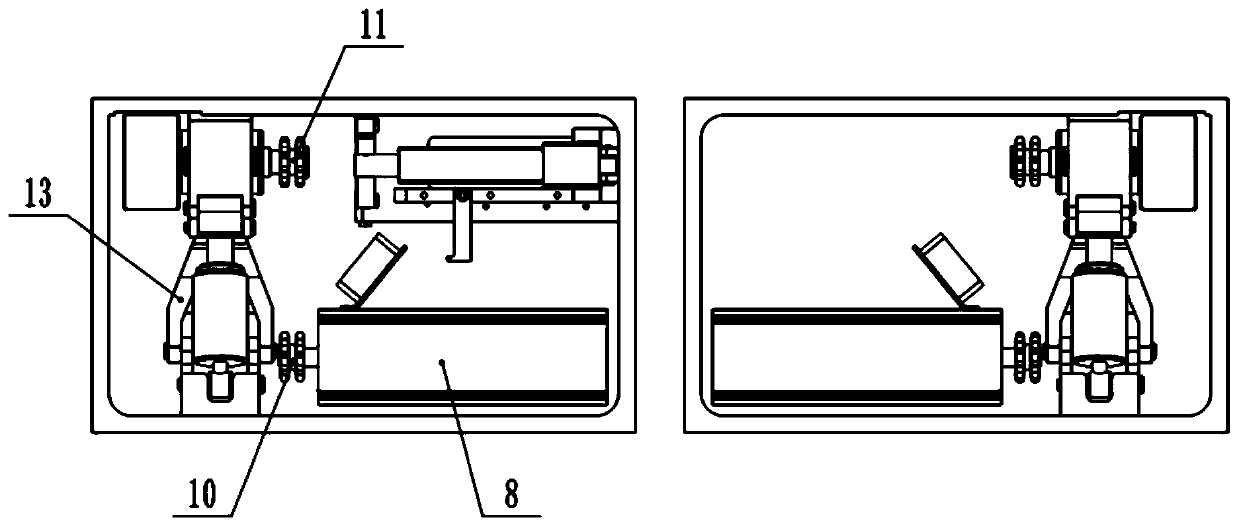

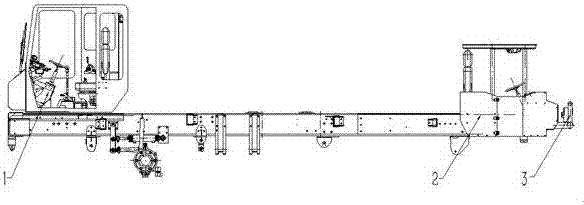

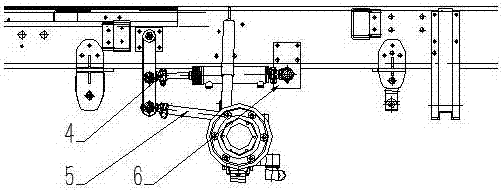

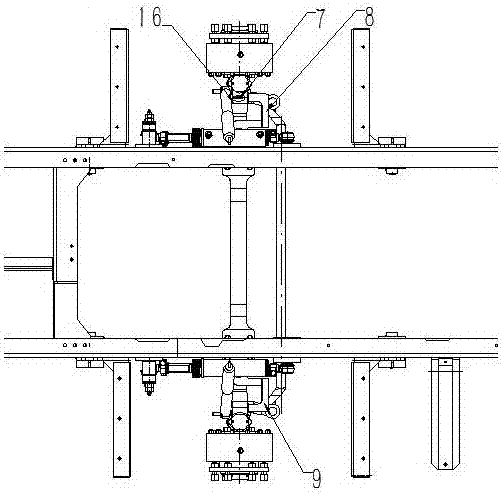

Steering conveying system

InactiveCN104590865AAchieve steeringReliable steeringConveyor partsRoller-waysDifferential functionMechanical engineering

The invention relates to the technical field of packing conveying equipment, in particular to a steering conveying system. The steering conveying system is characterized by comprising a packing material conveying line (1), a guide guardrail (2) and a steering mechanism (3), wherein the packing material conveying line (1) comprises a driving device, a conveying roller line and connecting side plates; the driving device is used for driving the conveying roller line to move; multiple conical power rollers are arranged in the middle of the conveying roller line, and the rest are common power rollers; the connecting side plates are positioned at the two sides of the conveying roller line; the guide guardrail (2) is positioned in front of the area of the conical power rollers, and is used for adjusting the position of a packing material; and the steering mechanism (3) is mounted on the connecting side plate at the side b of the packing material conveying line (1), and is positioned in the area of the conical power rollers. The steering conveying system has the beneficial effects of fully using the differential function of the conical rollers for realizing the steering of the packing material, designing an adjusting handle for conveniently adjusting and fixing the position and designing a spring buffer device for protecting the steering conveying system and the packing material from being intensely collided.

Owner:BEIJING AREOSTANARD NEW TECH +2

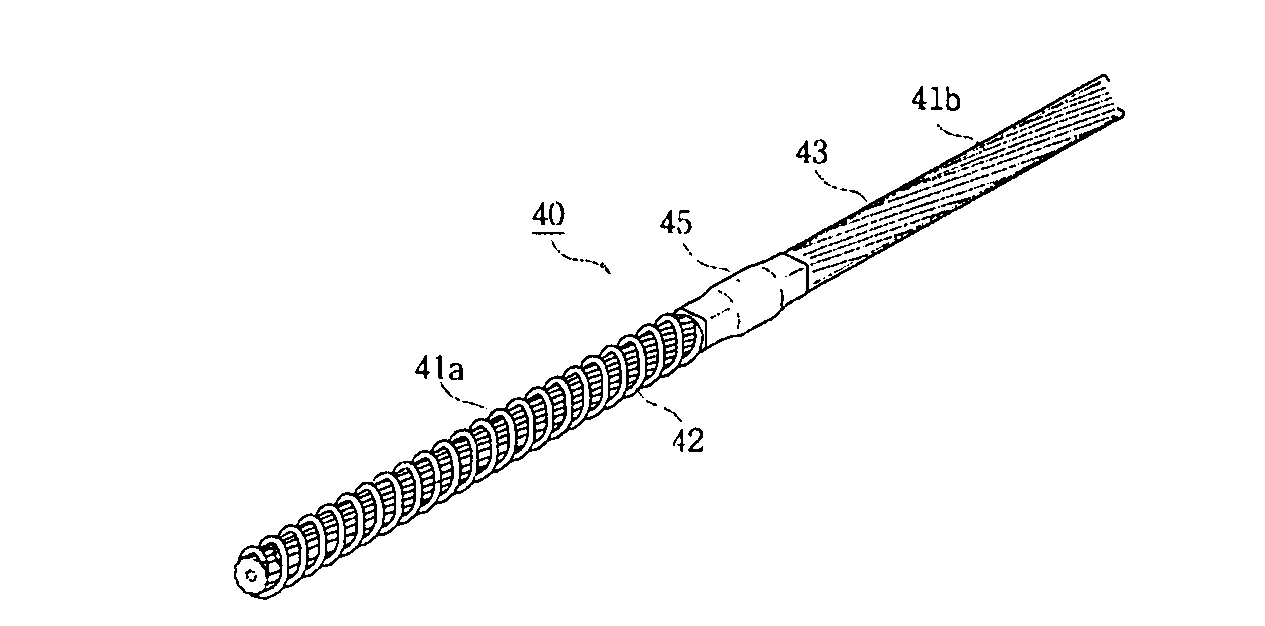

Inner cable for push-pull control cable and method for fabricating the same

InactiveUS20090095118A1Increased durabilityEasy to operateSteering ruddersRope making machinesControl systemPush pull

Disclosed is an inner cable for a push-pull control cable and a method for manufacturing the inner cable. The inner cable of a push-pull control cable applied to various control system including a steering system and a method for manufacturing the inner cable can generally increase durability of a control cable and reliability of a steering system, and can be easily manufactured. The inner cable includes a core wire with a predetermined length, which is formed by twisting a plurality of wire strands; a coiled wire, which is assembled with one end of the core wire in such a manner that the coiled wire winds the outer circumferential surface of the core wire in a spiral shape; and synthetic resin coating formed at a remaining part of the core wire, except for a part assembled with the coiled wire.

Owner:KIM YOUNG CHOONG

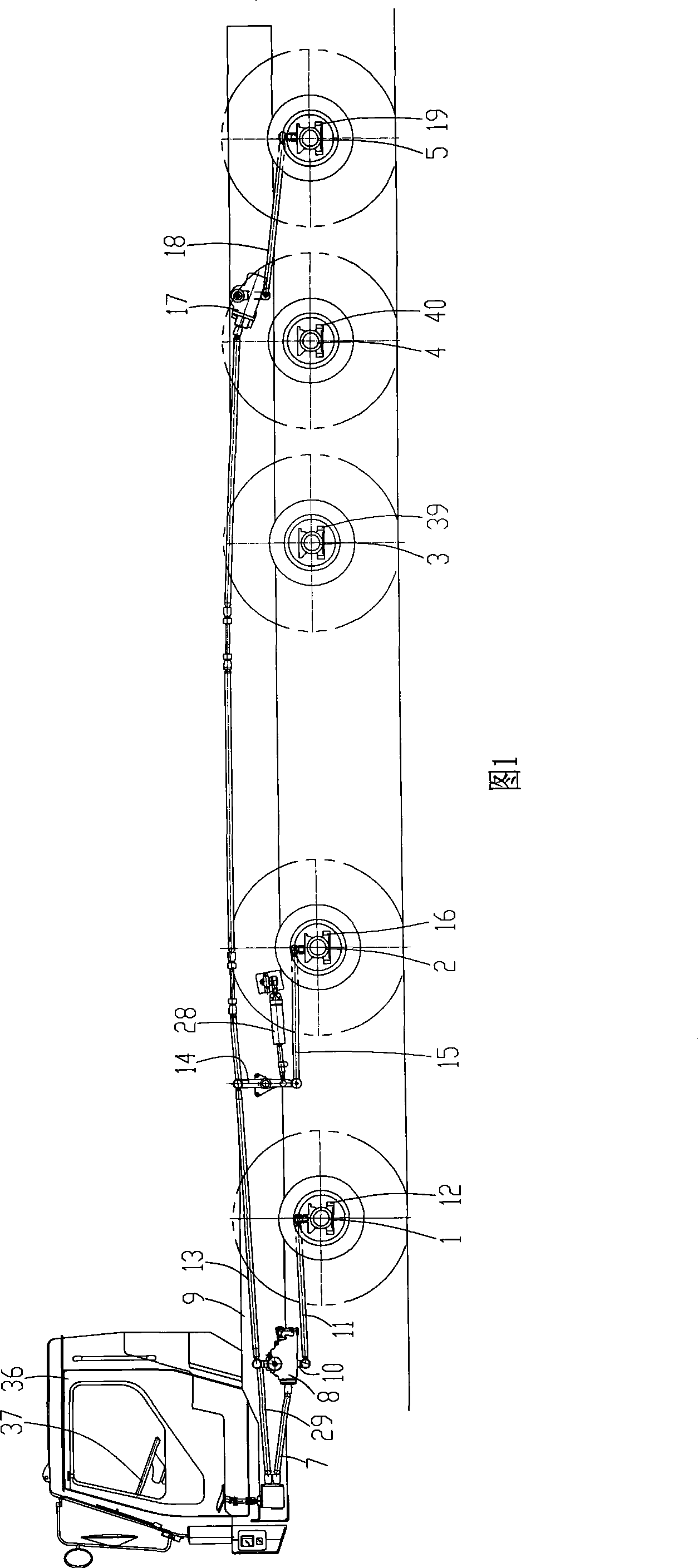

Five-shaft heavy-duty car steering system

The invention relates to a steering system for a five-axle heavy duty car. The forward-rotation output shaft of a right angle gear box is connected with the input end of a front steering gear through the transmission shaft of a first front axle, the output end of the front steering gear is hinged with the middle part of a driving arm, the lower end of the driving arm is connected with a steering arm on a first wheel hub through the longitudinal tie of a first front axle, the upper end of the driving arm is connected with the upper end of an oscillating arm through the upper tie rod of a second front axle, the middle part of the oscillating arm is hinged on a longitudinal beam, and the lower end of the oscillating arm is connected with a steering arm on a second wheel hub through the longitudinal tie of a second front axle; after being decelerated, the backward-rotation output shaft of the right angle gear box is connected with the input end of a rear steering gear through a transmission shaft mechanism, and the output end of the rear steering gear is connected with a steering arm on a fifth wheel hub through the longitudinal tie of a fifth axle. The transmission part of the steering system is under very small stress, the flexibility and the reliability of steering can be guaranteed, the operation is labor saving, and the steering system has the advantages of simple structure, easy assembly, light overall weight, low consumption of materials and low production cost.

Owner:BEIBEN TRUCKS CHONGQING

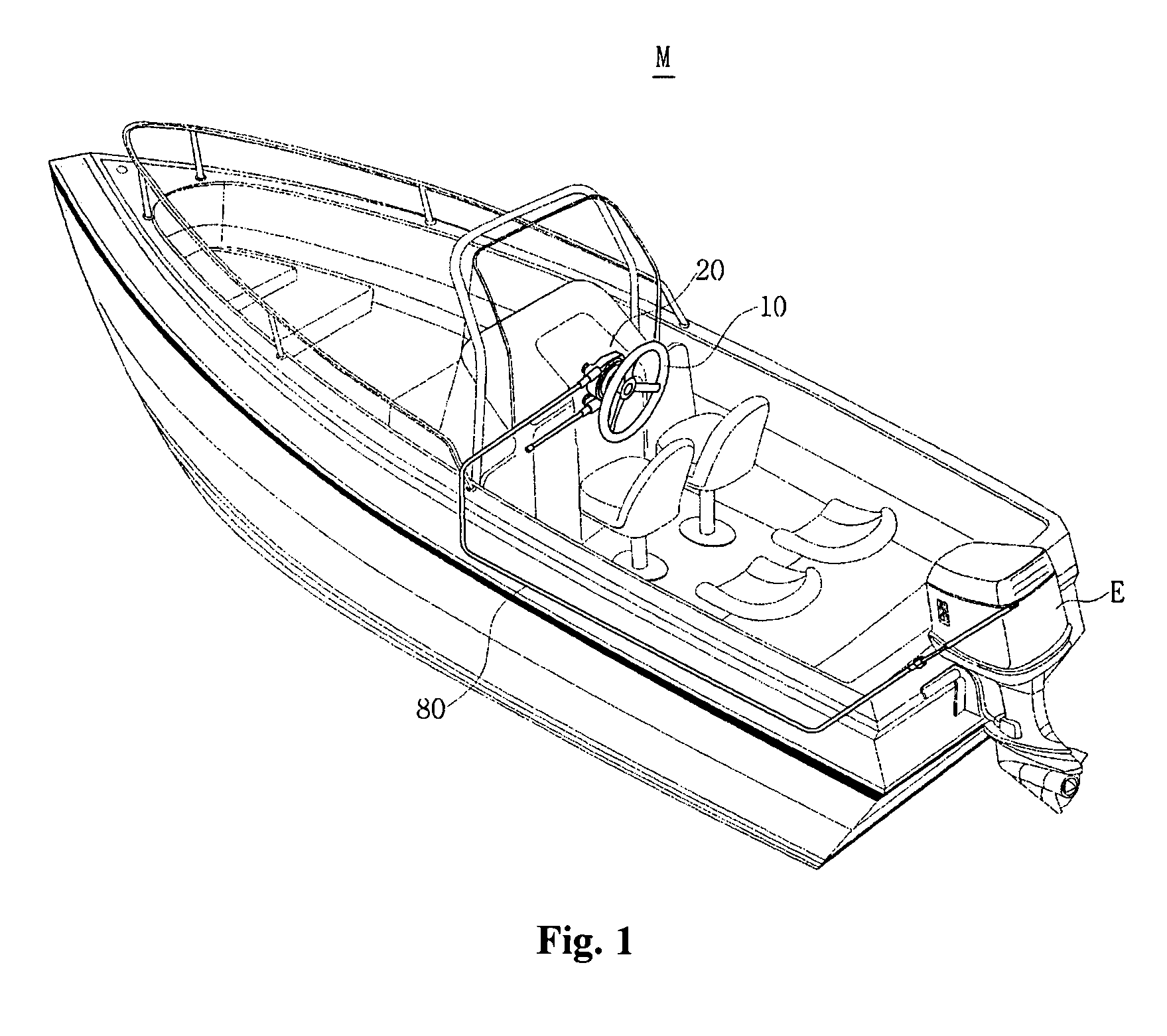

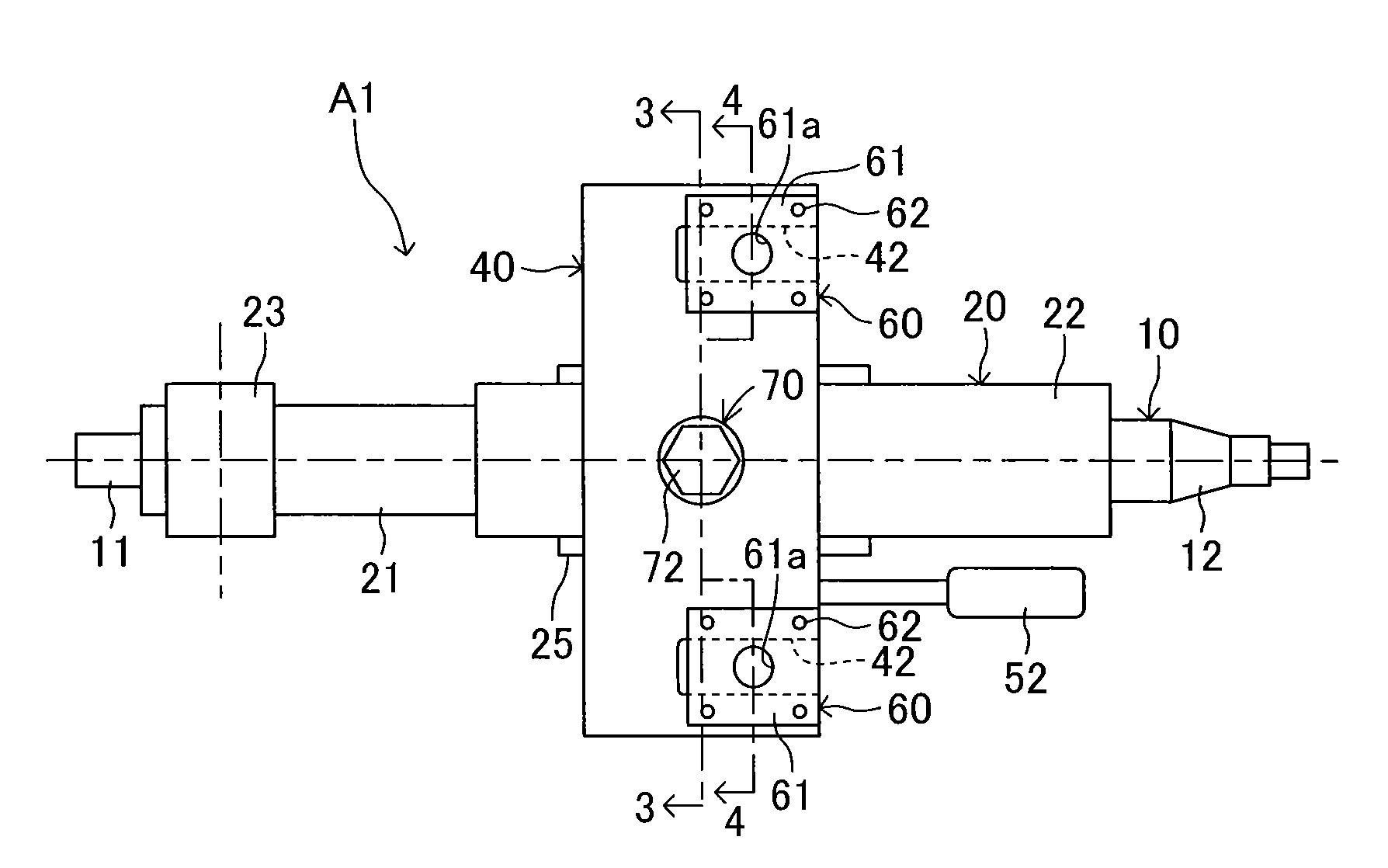

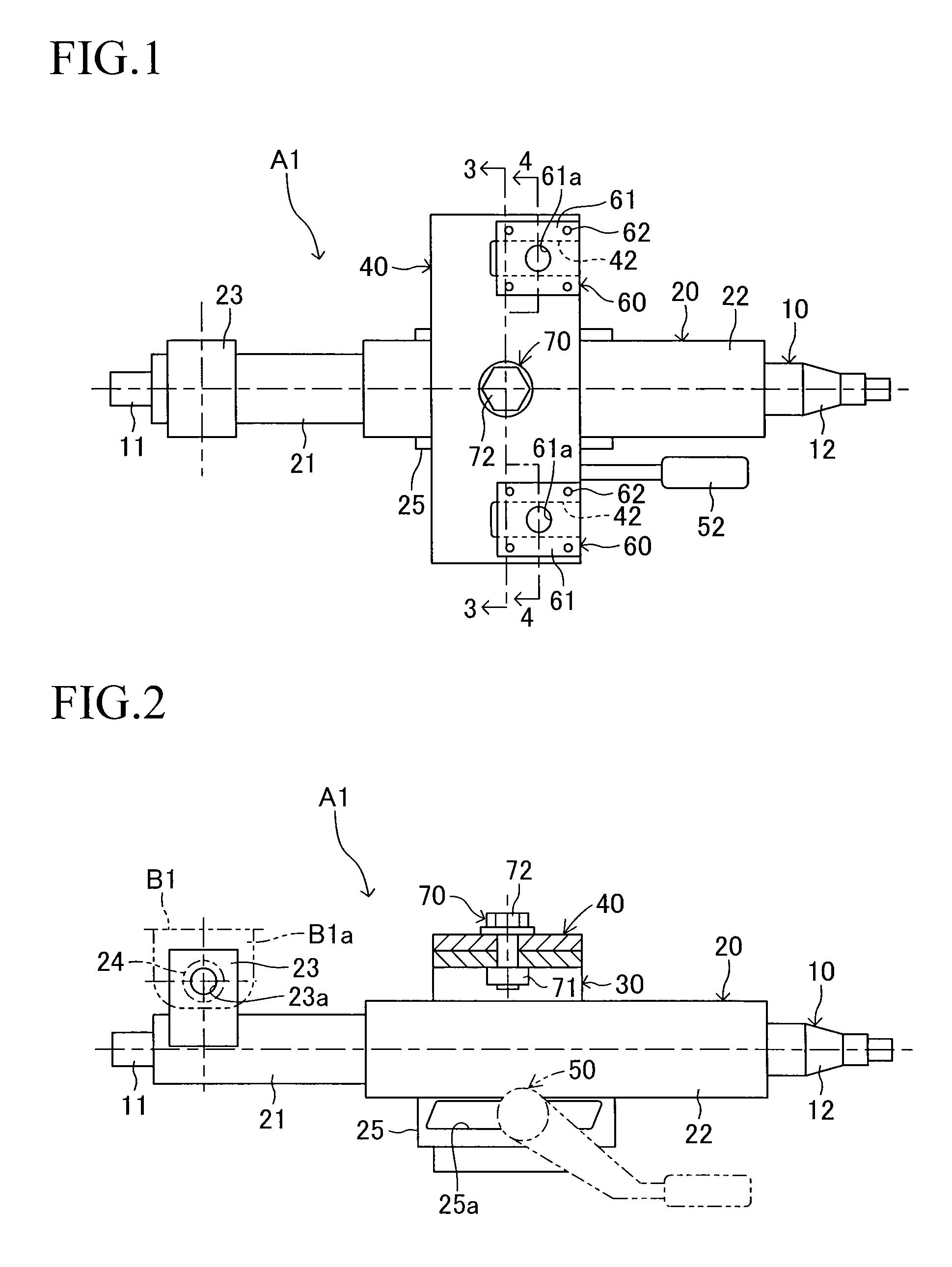

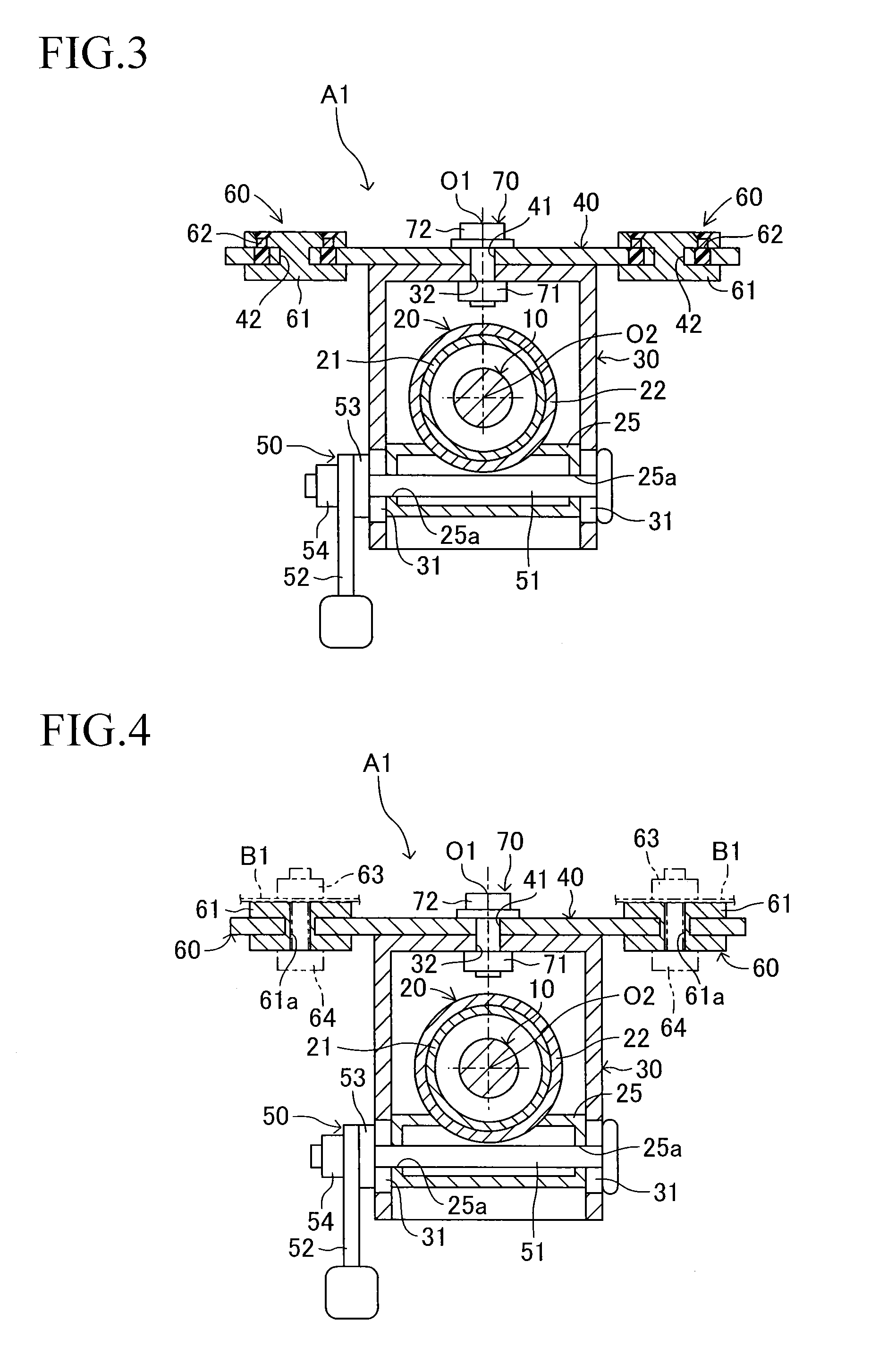

Steering column device

ActiveUS20150090066A1Increase displacementImprove productivitySteering columnsSteering columnCentre of rotation

A steering column device including a first bracket for supporting a column tube that supports a steering shaft, a second bracket coupled to the first bracket and assembled onto a vehicle body, and a disengaging mechanism provided on the second bracket that allows the column tube to be disengaged from the vehicle body forward along a column axis direction under a set load when a secondary impact is caused with a collision of a vehicle. The first bracket and the second bracket are coupled to each other through an intermediation of a coupling mechanism in a relatively rotatable manner, and a rotation center of relative rotation intersects an axis center of the steering shaft. The first bracket and the second bracket perform relative rotation when an external force exceeding a predetermined value is applied to the disengaging mechanism along the column axis direction before the first bracket, the second bracket, the disengaging mechanism are assembled onto the vehicle body.

Owner:TOYOTA JIDOSHA KK

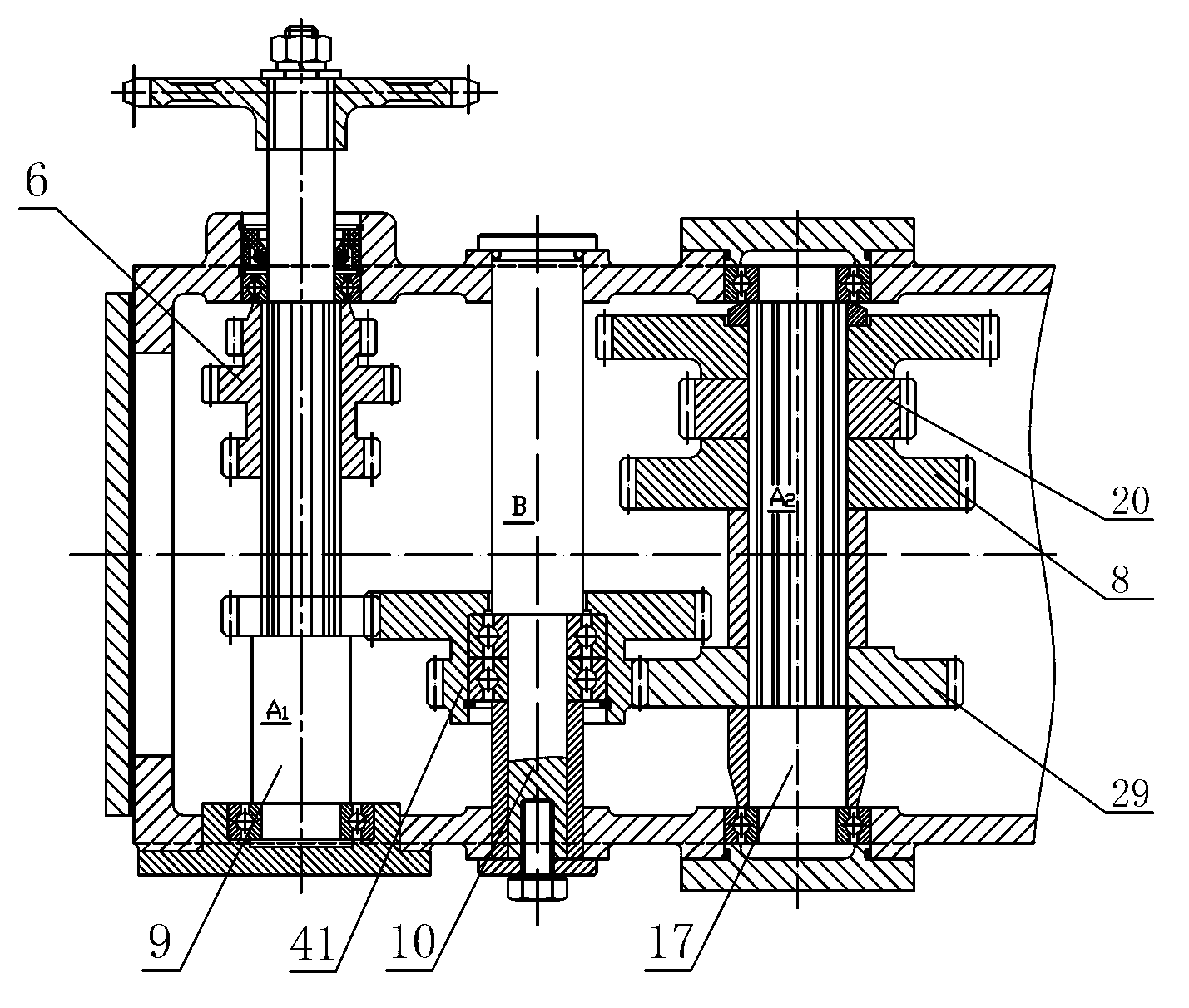

Bogie for rail vehicle, rail vehicle, and rail transit system

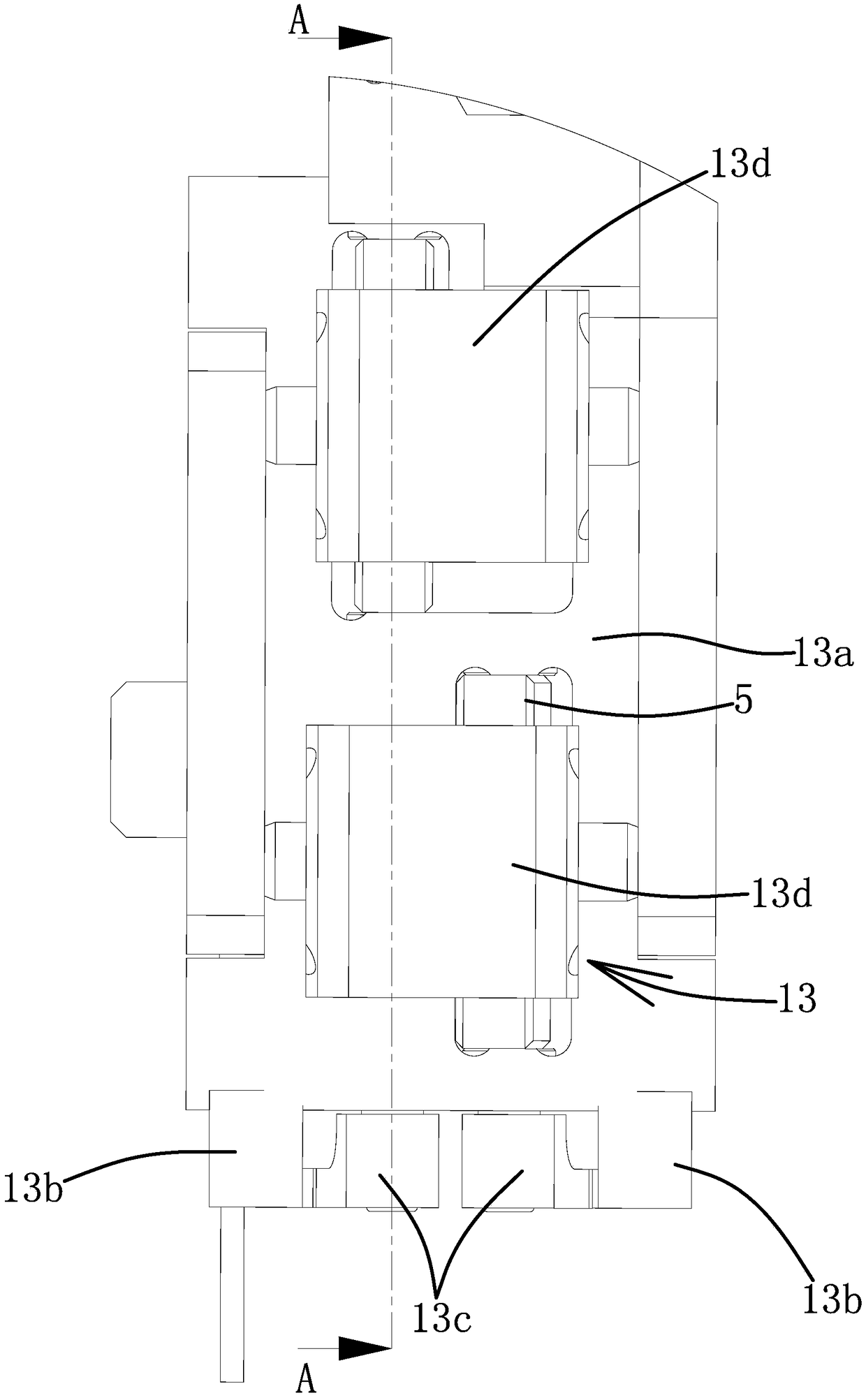

PendingCN110316214ASmooth steeringReliable steeringRail derailment preventionBogiesSelf guidedVehicle frame

The invention discloses a bogie for a rail vehicle, the rail vehicle, and a rail transit system. The bogie includes: a bridge main body, a guide frame, and a slewing bearing; the bridge main body is connected with a vehicle frame of the rail vehicle; the guide frame is rotatably mounted on the bridge main body relative to the bridge main body in a horizontal direction; and the slewing bearing includes an outer ring and an inner ring rotatably fitted in the outer ring, the guide frame is mounted on the outer ring, the bridge main body is provided with a slewing bearing mounting seat, and the inner ring is installed on the slewing bearing mounting seat. The bogie of the rail vehicle of embodiments of the invention can be self-guided, and has the advantages of smooth steering, and the like.

Owner:BYD CO LTD

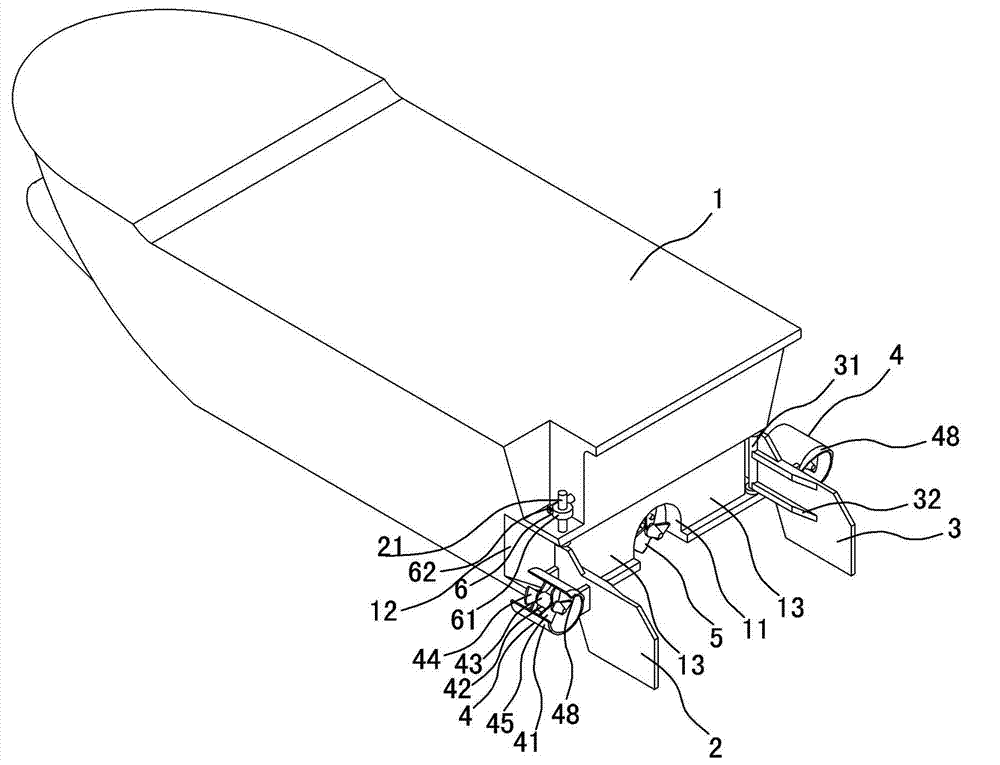

Dual-rudder multi-powder ship capable of braking

ActiveCN103112578AShorten the timeHigh turnoverSteering by propulsive elementsPropulsive elementsMechanical engineeringRudder

The invention relates to a dual-rudder multi-powder ship capable of braking. The ship comprises a hull (1), wherein the left side and the right side of the back of the hull (1) are respectively equipped with a left rudder (2) and a right rudder (3), and propelled brakes (4) are arranged on the left rudder (2) and the right rudder (3) respectively. The dual-rudder multi-powder ship has a fast steering speed, and has the functions of hard braking, hard turning and reverse sailing; and the sailing and speed increasing are faster, the navigational speed is also faster, and the reverse astern and turning are more convenient. Due to the fact that the braking and hard turning ability are better, accident engendered due to failing to brake timely and turning can be avoided. The ship is more mobile, flexible and accurate when the ship backs the sails to be aligned with the ship position and small area water area so as to adjust course, and the time consumption is shorter, so that the time which a large ship closes to a wharf and bears off the wharf can be greatly reduced, thereby significantly improving ship turnover ability and transfer capacity of ports.

Owner:王军辉

Flatwise-mounted glass turnover table

The invention discloses a flatwise-mounted glass turnover table, belonging to the technical field of glass grinding machinery. The flatwise-mounted glass turnover table which comprises air cylinders, suction discs, a rotating head and a flat beam; the air cylinders are arranged at two ends of the flat beam; the middle part of the flat beam is provided with the rotating head driven by a motor; and the rotating suck discs are fixed at tow ends of a transverse arm fixedly connected with the rotating head. Due to the adoption of the structure, compared with the prior art, the invention has the advantages of high production efficiency, low cost, steering reliability, adsorption firmness and space saving.

Owner:LINYI YOUNG SUNRISING MACHINERY

Steering transmission ratio control method and control device, steering system and vehicle

ActiveCN107235070ATurn to indirectTurn on securitySteering linkagesMechanical steering gearsDrive wheelEngineering

The invention belongs to the technical field of vehicle steering and provides a steering transmission ratio control method and control device, a steering system and a vehicle. The vehicle steering transmission ratio control method comprises the steps that the peripheral surface of a ratio-varying driving wheel is connected with the table face of a ratio-varying turntable used for outputting steering power, so that the ratio-varying driving wheel drives the ratio-varying turntable to rotate when rotating; and the distance between the central axes of the ratio-varying driving wheel and the ratio-varying turntable is adjusted in the radial direction of the ratio-varying turntable to change the transmission ratio, accordingly, the transmission ratio is changed correspondingly according to different driving conditions, and convenient, rapid and safe steering is achieved.

Owner:GREAT WALL MOTOR CO LTD

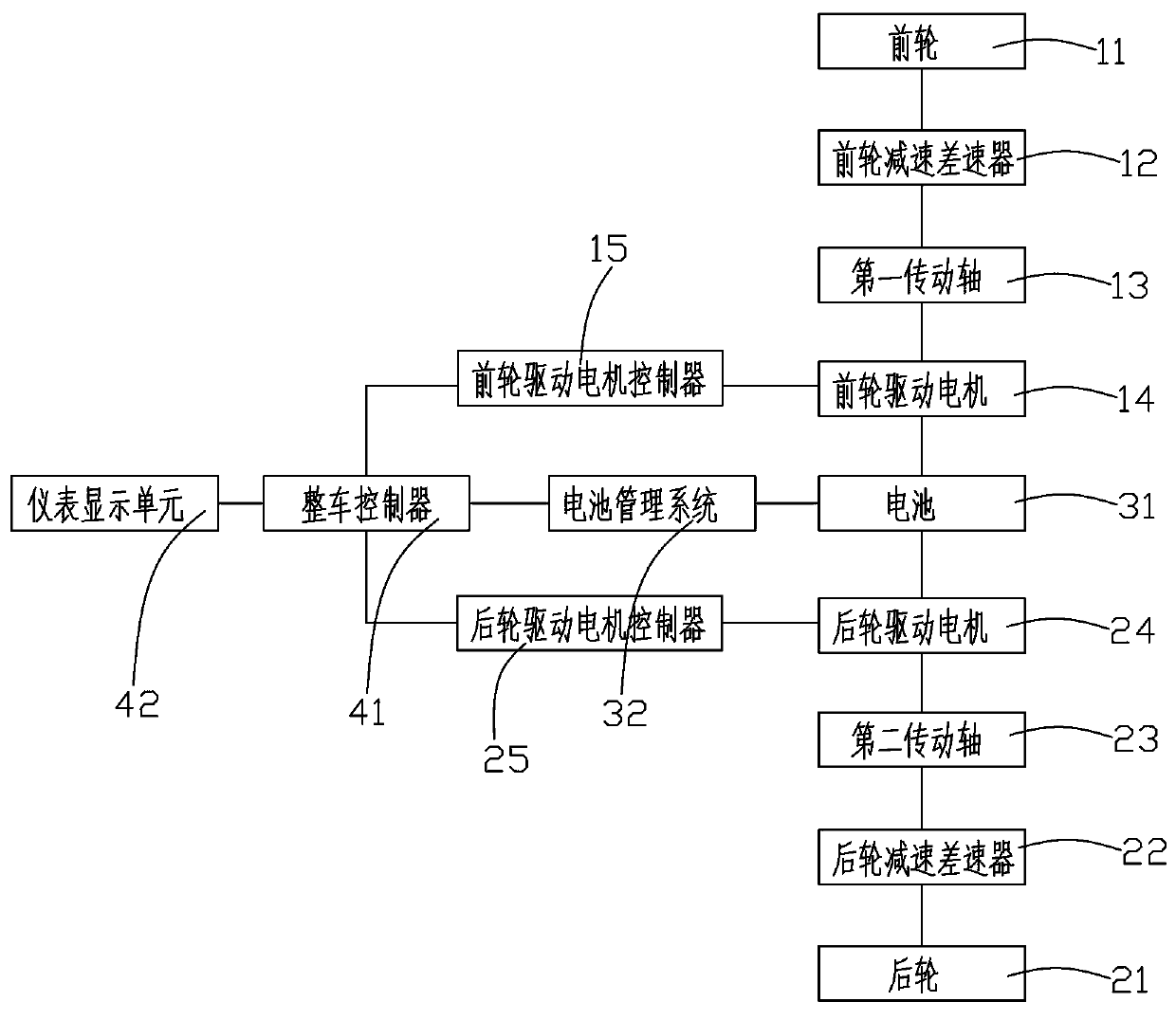

Dual-motor four-wheel electric vehicle driver and control system thereof

InactiveCN103465780AImprove power sourceGuaranteed stabilitySpeed controllerVehicular energy storageControl systemDrive shaft

A dual-motor four-wheel electric vehicle driver and control system thereof comprises a front wheel, a front-wheel deceleration differential, a front-wheel drive motor controller, a rear wheel, a rear-wheel deceleration differential, a rear-wheel drive motor controller, a drive motor and a battery. The battery provides power to the drive motor which includes a front-wheel drive motor and a rear-wheel drive motor, the front-wheel drive motor controller is electrically connected with the front-wheel drive motor and controls the same to rotate, an output shaft of the front-wheel drive motor is in transmission connection with the front-wheel deceleration differential through a first transmission shaft, and the front-wheel deceleration differential is connected with the front wheel. The rear-wheel drive motor controller is electrically connected with the rear-wheel drive motor and controls the same to rotate, an output shaft of the rear-wheel drive motor is in transmission connection with the rear-wheel deceleration differential through a second transmission shaft, and the rear-wheel deceleration differential is connected with the rear wheel. The dual-motor four-wheel electric vehicle driver and the control system thereof has the advantages of simple structure, environmental friendliness, low cost, good performance and the like, the weight of the whole vehicle is reduced and transmission efficiency is improved.

Owner:四川峰谷源新能源有限公司

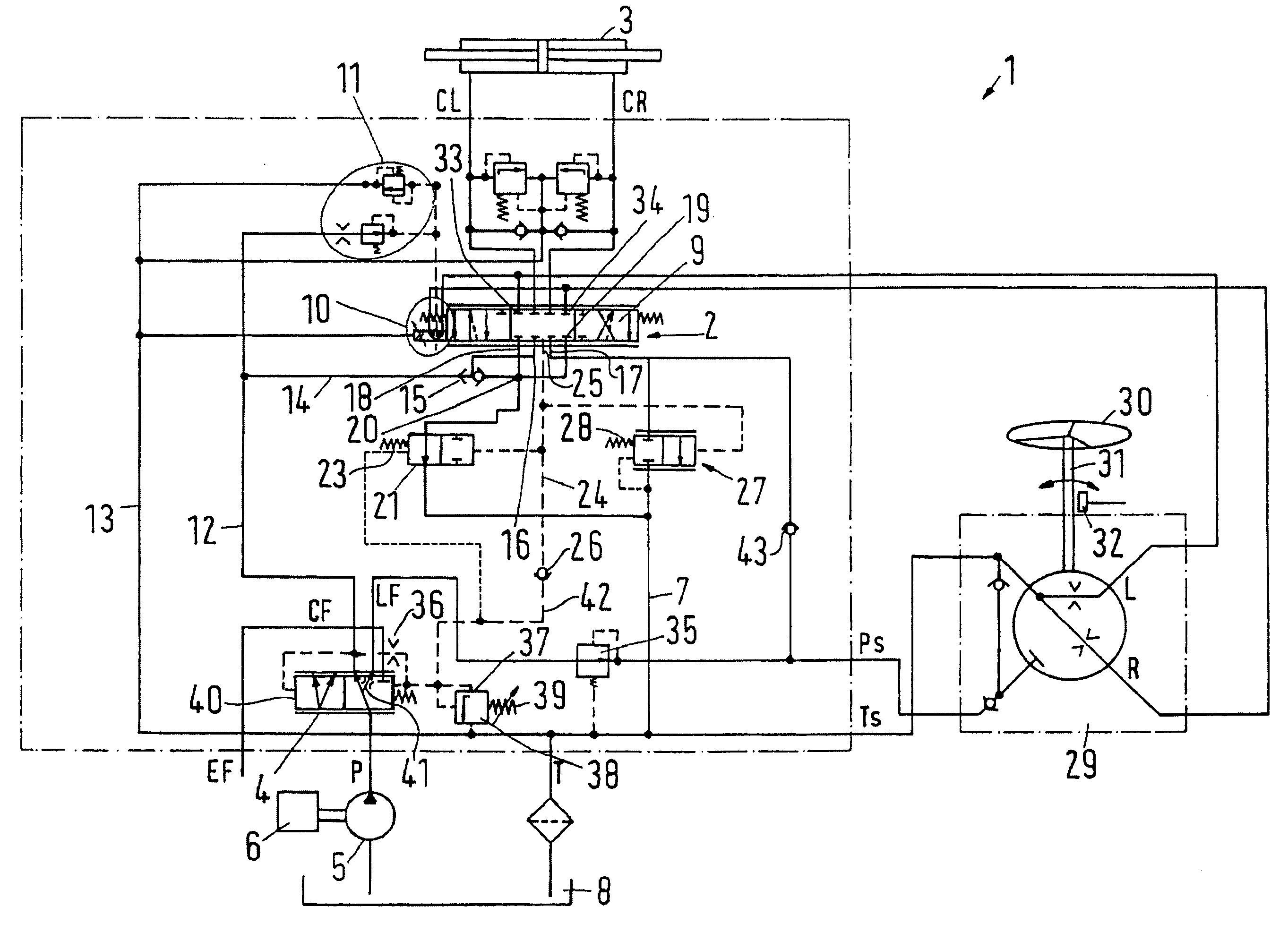

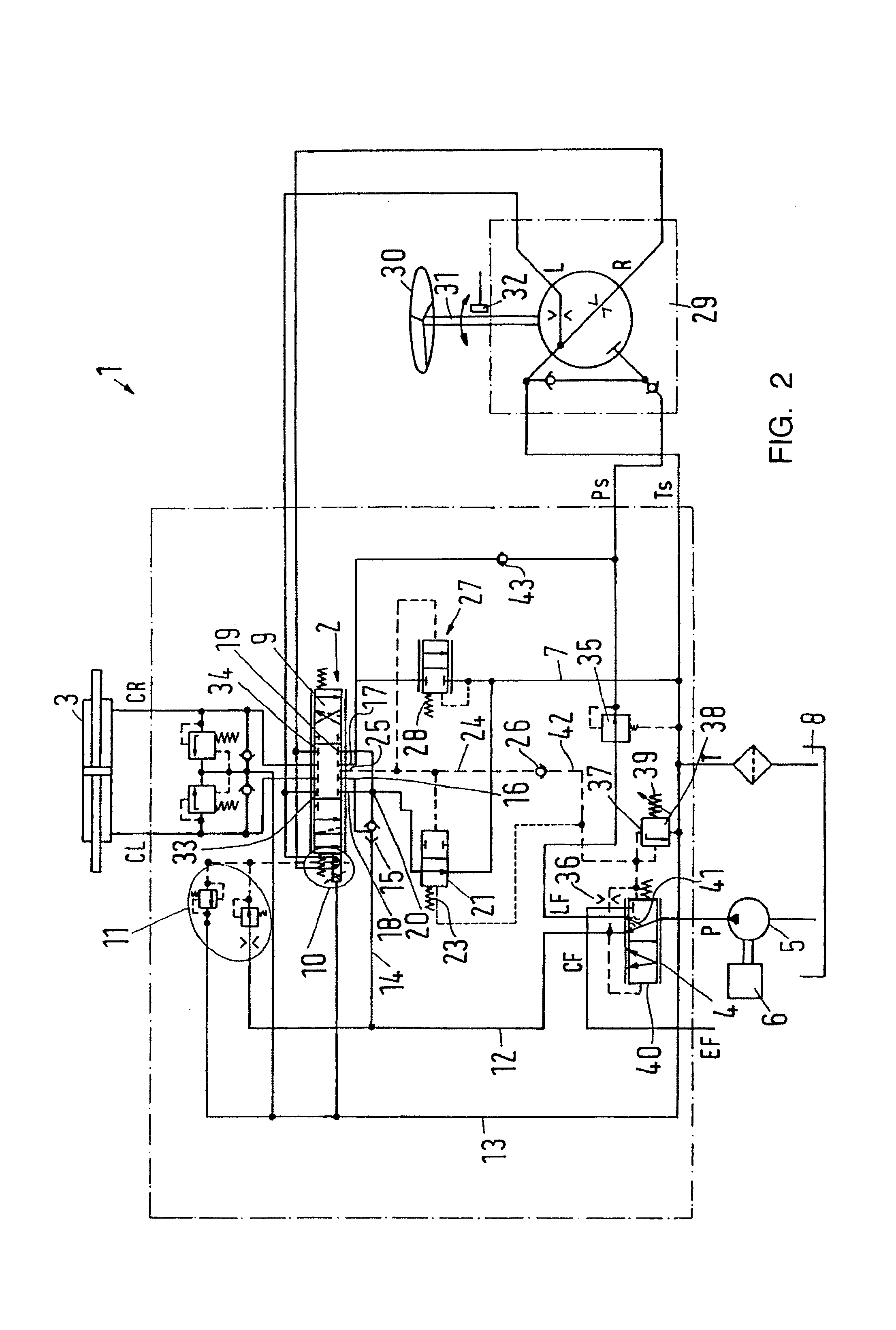

Hydraulic steering arrangement

InactiveUS7152401B2Sufficient supplySmooth connectionFluid couplingsFluid steeringEngineeringHigh pressure

A hydraulic steering arrangement includes a steering valve, a steering motor, connected with a high-pressure connection and a low-pressure connection via the steering valve, and with a steering unit, connected via the steering valve with a pilot pressure valve, whose outlet is connected with the low-pressure connection. It is endeavoured to improve the steering behaviour. For this purpose, the pilot pressure valve is opened, before the steering valve creates a connection between the high-pressure connection and the steering motor.

Owner:DANFOSS PAUER SOLYUSHENS APS

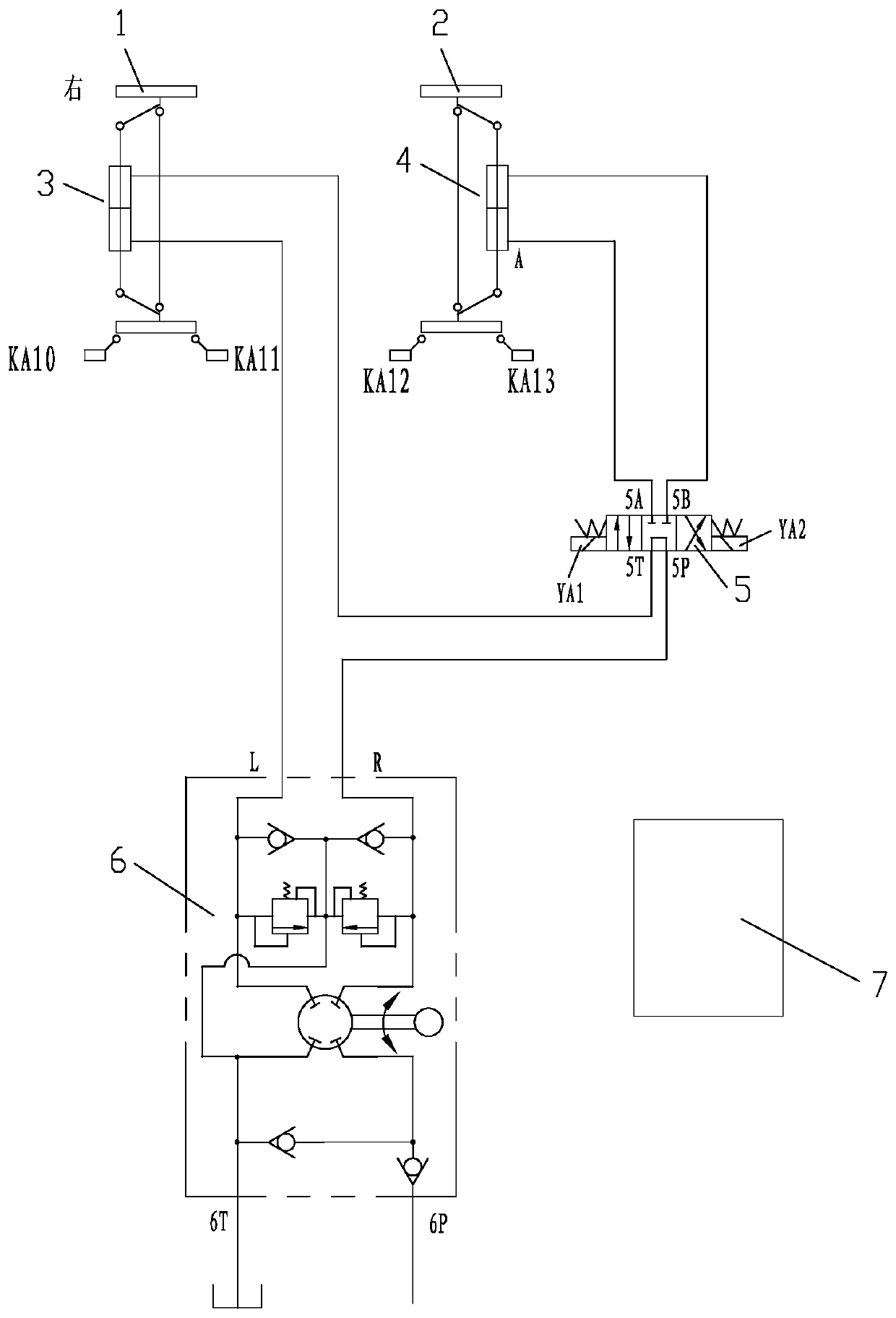

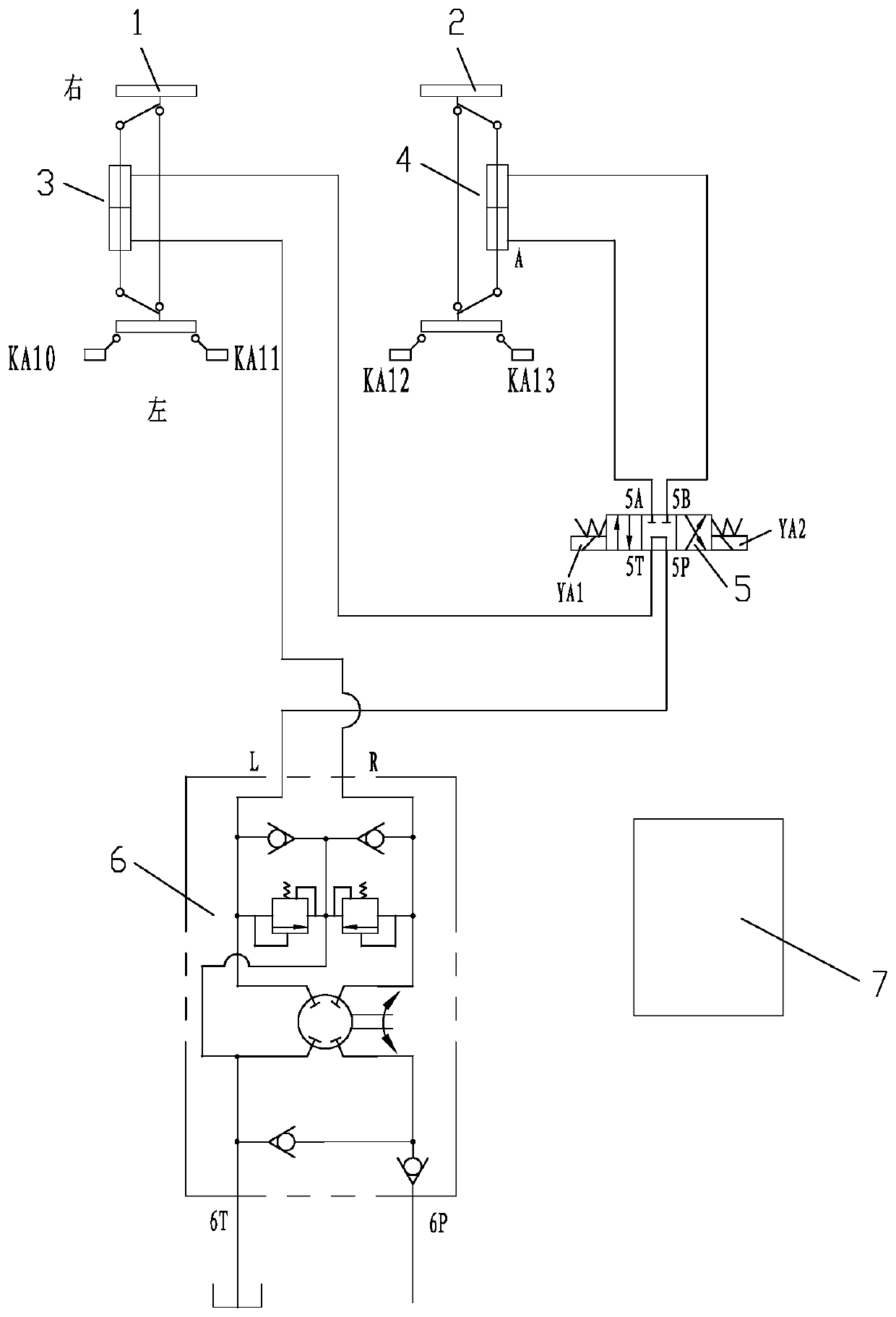

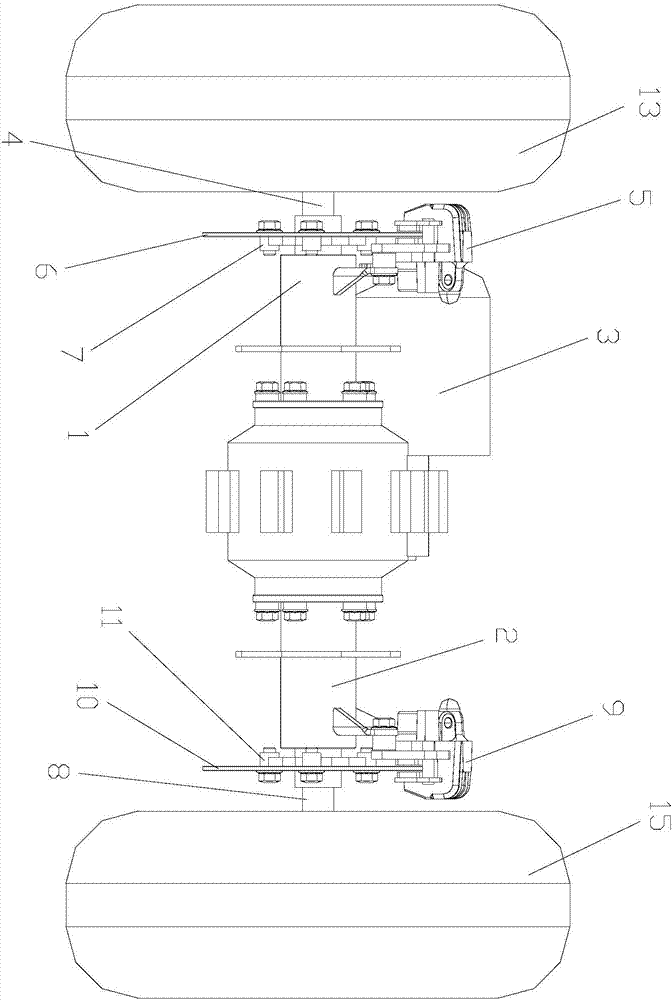

Airplane tractor special four-wheel steering system and steering control method

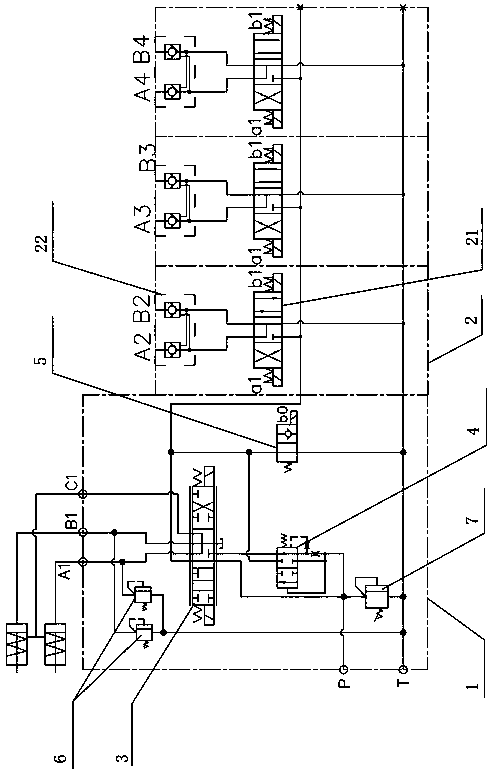

ActiveCN110861708AReduce in quantityLow costSteering linkagesFluid steeringFour-way valveAutomatic control

The invention discloses an airplane tractor special four-wheel steering system and a steering control method. The system comprises a front-rear-wheel steering oil cylinder, an electromagnetic valve, afull-hydraulic steering gear and a controller, wherein the front-rear-wheel steering oil cylinder is provided with two oil cavities; two distribution ports of the steering gear are controlled by a vehicle steering wheel so that the two distribution ports alternately supply oil and return oil; the electromagnetic valve is a three-position four-way valve, an oil inlet of the electromagnetic valve is connected with one distribution port of the full-hydraulic steering gear, a first port and a second port are connected with two oil cavities of one of front or rear wheel steering oil cylinders correspondingly, and two oil cavities of the other oil cylinder are connected with the other distribution port of the steering gear and an oil return port of the electromagnetic valve correspondingly. Thecontrol method is implemented based on the system. The airplane tractor special four-wheel steering system and the steering control method have beneficial benefits of simple system structure, low failure rate and three steering modes; and the control method realizes automatic control through the PLC and detects and corrects the centering state of the wheels so as to ensure accurate synchronization of front and rear wheel deflection and eliminate potential safety hazards of vehicle deviation.

Owner:CHONGQING TECHKING IND CO LTD

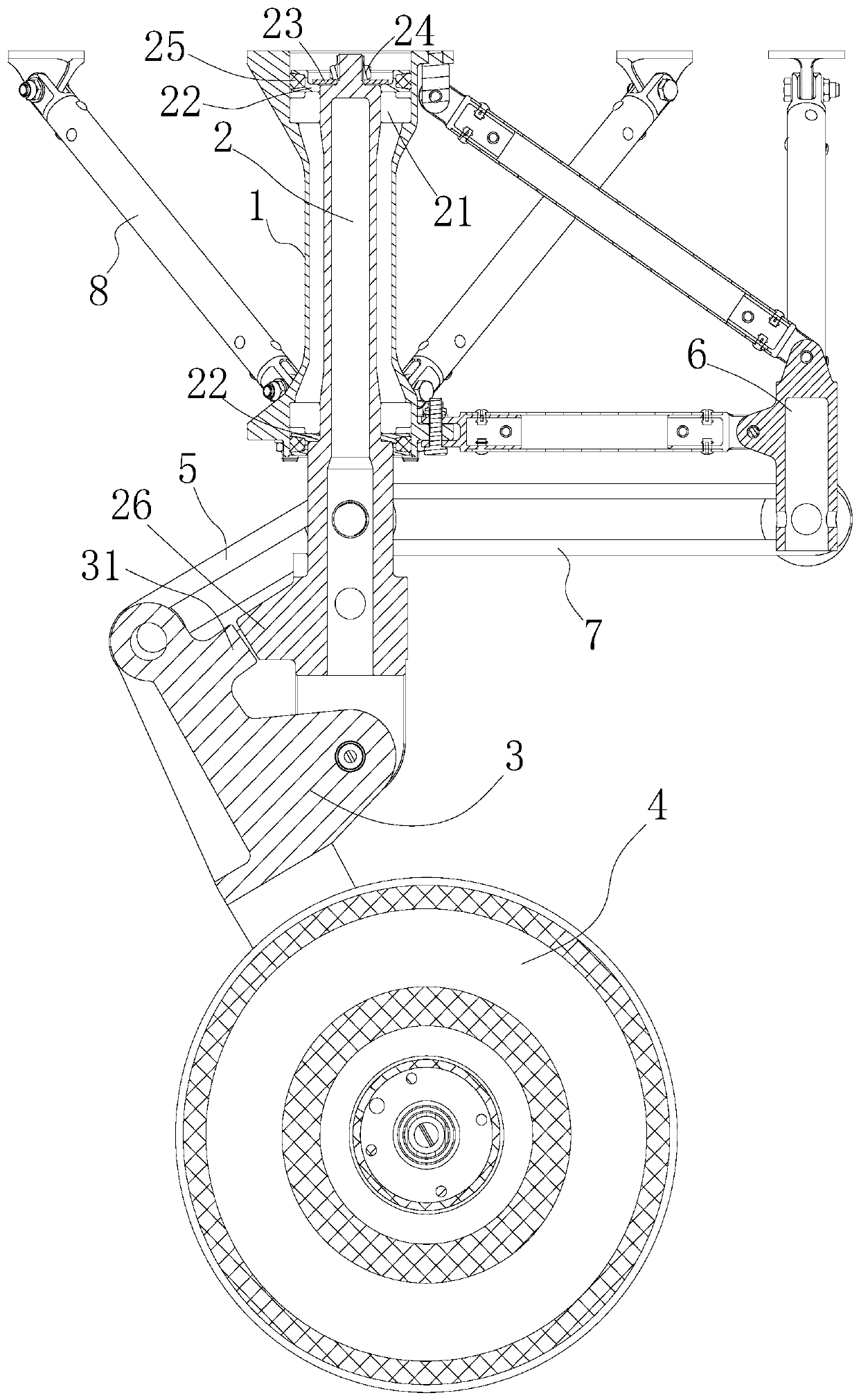

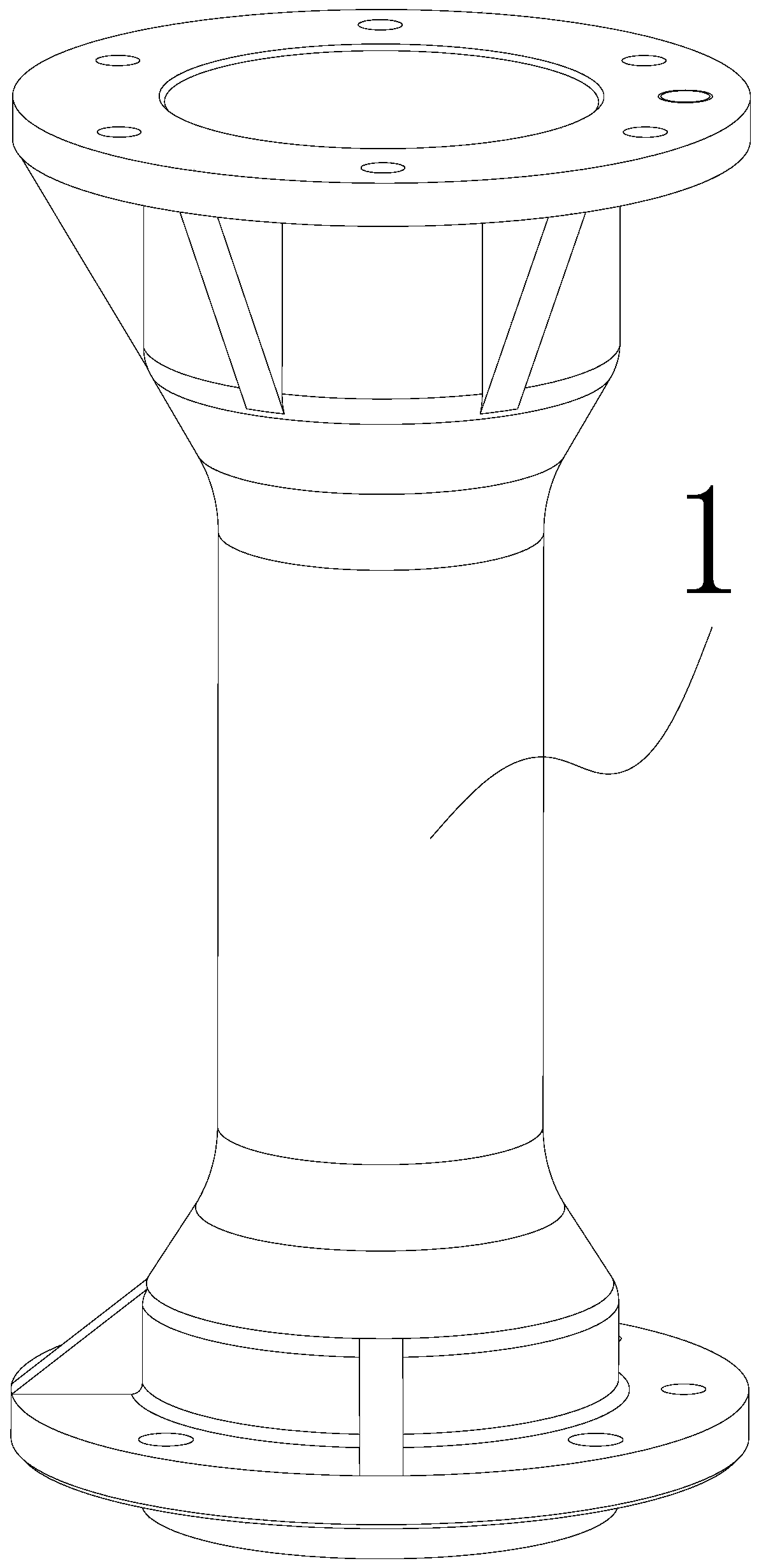

Airship landing gear

The invention discloses an airship landing gear which comprises a sleeve vertically arranged at the bottom of an airship body, wherein a rotating mandrel is rotatably installed in the sleeve, a wheelfork is hinged to the lower end of the rotating mandrel, and an articulated shaft is in the horizontal direction; an airship wheel is arranged on the wheel fork, the axis of the airship wheel is parallel to the hinge shaft of the rotating mandrel and the wheel fork, and the axis of the airship wheel is positioned on one side of the articulated shaft of the rotating mandrel and the wheel fork; a first elastic body is arranged between the wheel fork and the rotating mandrel, the connection point of the first elastic body and the rotating mandrel, the connection point of the first elastic body and the wheel fork, and the articulated shaft of the rotating mandrel and the wheel fork form a triangle; the airship landing gear further comprises a centering fixing piece, at least one second elasticbody is arranged between the two sides of the rotating mandrel and the centering fixing piece correspondingly, and when moments generated by the second elastic bodies on the two sides of the rotatingmandrel are equal in magnitude and opposite in direction, the axis of the airship wheel is perpendicular to the advancing direction of an airship. The airship landing gear has the advantages of simple structure, light weight and simple machining.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Oblique rolling shaft angle turning machine of emulsion explosive production line

InactiveCN101875589AStable productivitySmooth transmissionExplosive working-up apparatusProduction lineEmulsion explosive

The invention discloses an oblique rolling shaft angle turning machine of an emulsion explosive production line, which comprises a support, a speed reduction motor, power rollers, an angle turning block and a guide strip, wherein the speed reduction motor is connected with the power rollers for driving, a plurality of the power rollers are uniformly arranged on cross beams on two sides of the support in parallel, the included angle between each power roller and the cross beam is 60 degrees, the angle turning block is arranged on one side of the support, the angle turning block is provided with a 45-degree chamfer angle, the chamber angle faces to the rotation forward direction of the power rollers, the guide strip is arranged on one side of the support located by the angle turning block, and the guide strip is positioned behind the angle turning block. The oblique rolling shaft angle turning machine has smooth transmission, accurate turning and high efficiency.

Owner:广东宏大民爆集团有限公司

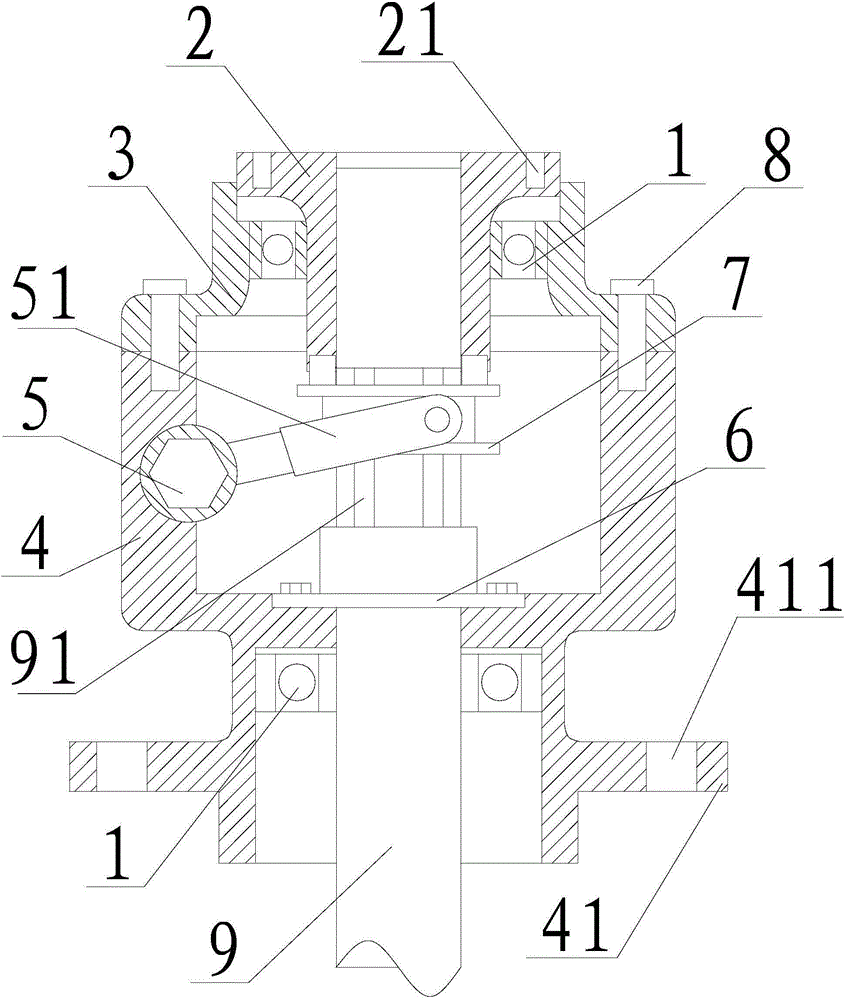

Small radius steering clutch of cultivator

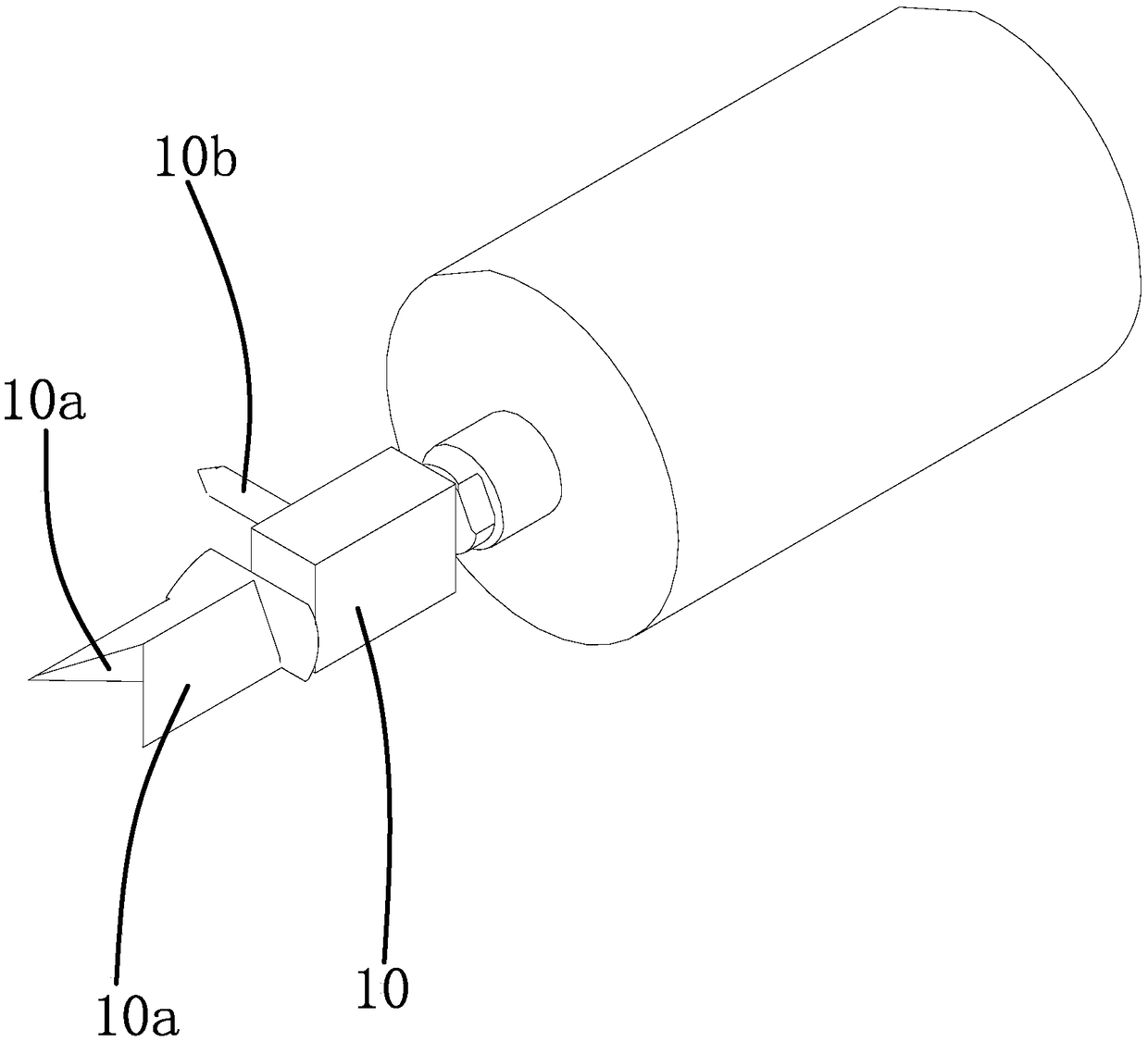

InactiveCN104541788AReliable steeringSmall turning radiusHarvestersInterengaging clutchesDrive shaftEngineering

The invention discloses a small radius steering clutch of a cultivator. The small radius steering clutch comprises a wheel fixing barrel, a cover body, a shell, a shifting fork barrel shaft, a seal ring, a connector and bolts, wherein the cover body is fixedly connected with the shell by virtue of 2 to 8 bolts, a fixed seat is arranged on the shell, the shifting fork barrel shaft is installed in the fixed seat, a shifting fork is arranged on the shifting fork barrel shaft, the shifting fork is provided with a shifting fork rod, the tail end of the shifting fork rod is in a semispherical shape, the wheel fixing barrel is installed in the cover body, 3 to 6 bolt fixing holes are formed in the wheel fixing barrel, a transmission shaft is installed in the wheel fixing barrel, the transmission shaft is provided with an outer spline, the outer spline is connected with the connector in a sleeving manner, the connector and the wheel fixing barrel are respectively provided with a connecting tooth, the connector is provided with a slide groove, and the shifting fork rod is arranged in the slide groove. By adopting the small radius steering clutch, more reliability in steering of the cultivator is realized, the turning radius is small, flexibility inn operation can be realized, the structure is simple, suitability for different cultivators of different model numbers can be realized, and the adaptability is high.

Owner:新昌县捷马科技有限公司

Old pipeline inspection robot based on telescopic wheel train

PendingCN114184238AImprove adaptabilityWide range shootingMeasurement devicesManipulatorCamera moduleGear train

The invention discloses an old pipeline detection robot capable of steering and damping. The two front wheel assemblies are connected with the rear wheel assembly through the corresponding front and rear wheel connecting assemblies respectively, a steering mechanism is arranged between the front wheel assemblies and the rear wheel assembly, the two sides of the steering mechanism are connected with the two front and rear wheel connecting assemblies respectively, and a camera module is installed on the steering mechanism. The rear wheel assembly is used for providing advancing power for the inspection robot, the front-rear wheel connecting assemblies are used for damping, the steering mechanism provides steering force for the front wheel assembly through the two front-rear wheel connecting assemblies, and steering of the inspection robot is achieved after the front wheel assembly adjusts the advancing angle of the inspection robot. The robot can adapt to different pipeline pavement conditions and realize obstacle crossing and shock absorption; the robot can smoothly run in the old pipeline, the inspection work of the old pipeline is achieved, and the robot has the advantages of being good in universality, high in working efficiency and the like.

Owner:HANGZHOU DIANZI UNIV

Tool grinder

PendingCN109465708AImprove grinding efficiencyWork reliablyGrinding drivesGrinding feed controlEngineeringGrinding wheel

The invention provides a tool grinder and belongs to the technical field of machinery. By means of the tool grinder, the problem that an existing tool grinder only can carry out one-time grinding machining, and the grinding efficiency is relatively low is solved. The tool grinder comprises a rack. The rack is provided with a workbench and a lifting mechanism which drives the workbench to ascend and descend back and forth. The workbench is provided with a floating clamp which can clamp a workpiece and a motor which can drive the floating clamp to rotate. One side of the workbench is provided with an installation frame, the installation frame can horizontally and transversely move and horizontally and longitudinally move relative to the workbench, and the installation frame is provided witha rotating disk and a rotating mechanism which drives the rotating disk to rotate. The rotating disk is evenly provided with a plurality of motors. Rotating shafts of the motors are provided with grinding wheels. The tool grinder has the advantages that the grinding efficiency is relatively high and the tool grinder works stably and reliably.

Owner:TAIZHOU BEIPING MASCH TOOL CO LTD

Bearing vehicle chassis trolley

The invention relates to the technical field of bearing vehicles, specifically to a bearing vehicle chassis trolley. The bearing vehicle chassis trolley comprises a chassis, a steering mechanism, a left steering wheel set and a right steering wheel set; the steering mechanism, comprises a left connecting rod, a first middle connecting rod, a shifting fork, a push rod, a second middle connecting rod and a right connecting rod; the left steering wheel set is rotationally connected with the left end of the left connecting rod; the right end of the left connecting rod is rotationally connected with the left end of the first middle connecting rod; the right steering wheel set is rotationally connected with the right end of the right connecting rod; the left end of the right connecting rod is rotationally connected with the right end of the second middle connecting rod; the shifting fork comprises a left end, a right end and a raised end which are integrally molded; the left end and the right end of the shifting fork are correspondingly and fixedly connected to the right end of the first middle connecting rod and the left end of the second middle connecting rod; the push rod is arrangedparallel to the first middle connecting rod and the second middle connecting rod; the push rod comprises a tail end and a movable end; the tail end is fixedly connected to a chassis; and the movable end is rotationally connected to the raised end of the shifting fork. The technical scheme of the bearing vehicle chassis trolley has the advantages that the structure is compact, the steering is flexible and the bearing vehicle chassis trolley can be accurately controlled.

Owner:CHONGQING CAERI AUTOMOBILE TEST EQUIP DEV +1

Forward and backward rotating tracked vehicle transmission

ActiveCN109058411AReliable steeringReduce stepsGearingNon-deflectable wheel steeringControl theoryRADIUS

A forward and backward rotating tracked vehicle transmission comprises a power input component, a variable transmission component, a forward and backward rotating component and a driving component which are mounted in a box body component; the power input component is connected with the variable transmission component; the variable transmission component is connected with the forward and backwardrotating component; and the forward and backward rotating component is connected with the driving component. By controlling a rotation speed of a differential planetary gear carrier to realize transmission and reverse driving of a steering gear, a tracked vehicle is enabled to reliably steer and steer in a forward and backward rotating manner, the steering and forward and backward rotating are operated by using a single scheme, the operation step is not increased, the structure is simple, and the operation is convenient; and meanwhile, the steering radius of the tracked vehicle is in proportion to the operation travel of a steering operation mechanism so that the steering accuracy is high and the efficiency is high.

Owner:HUNAN AGRICULTURAL UNIV

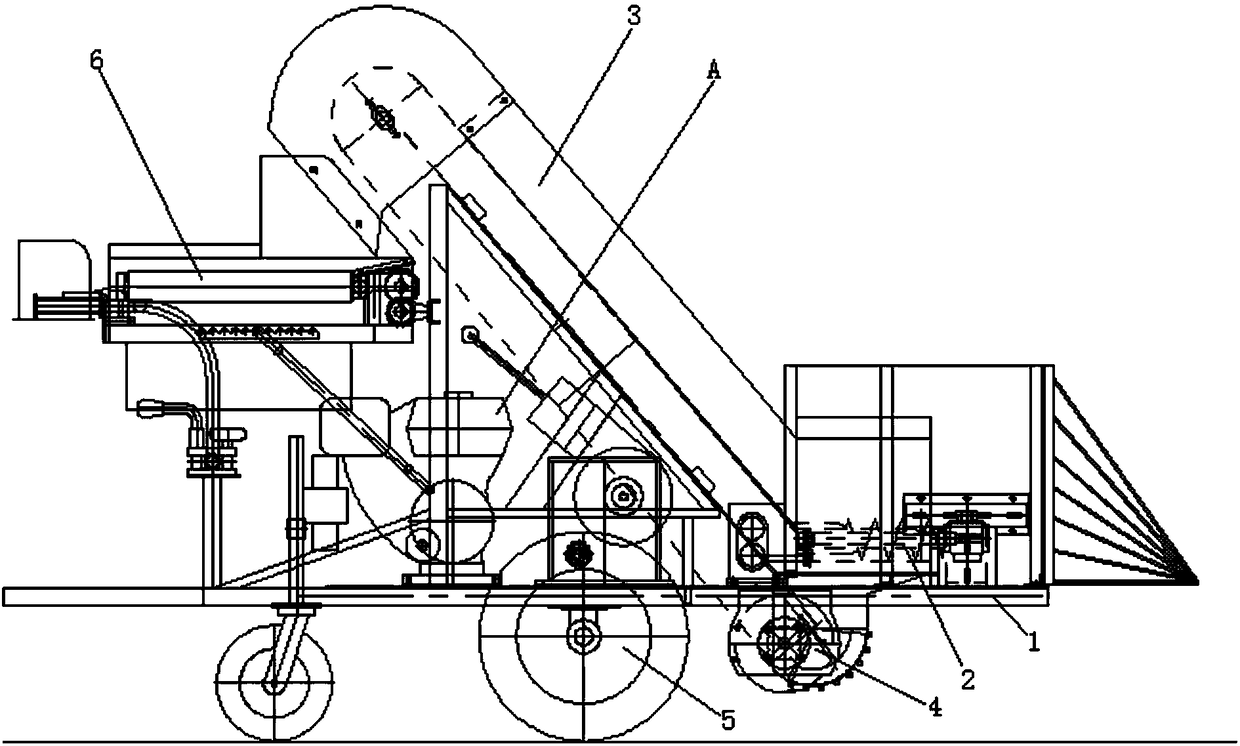

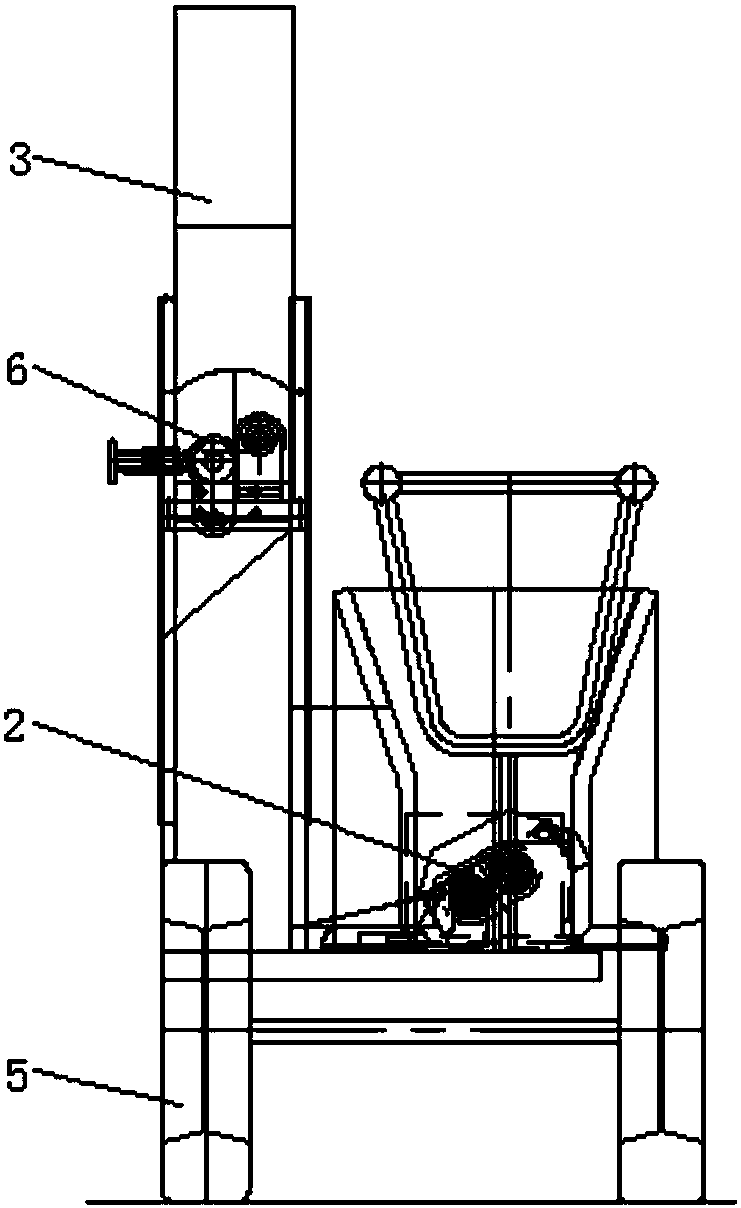

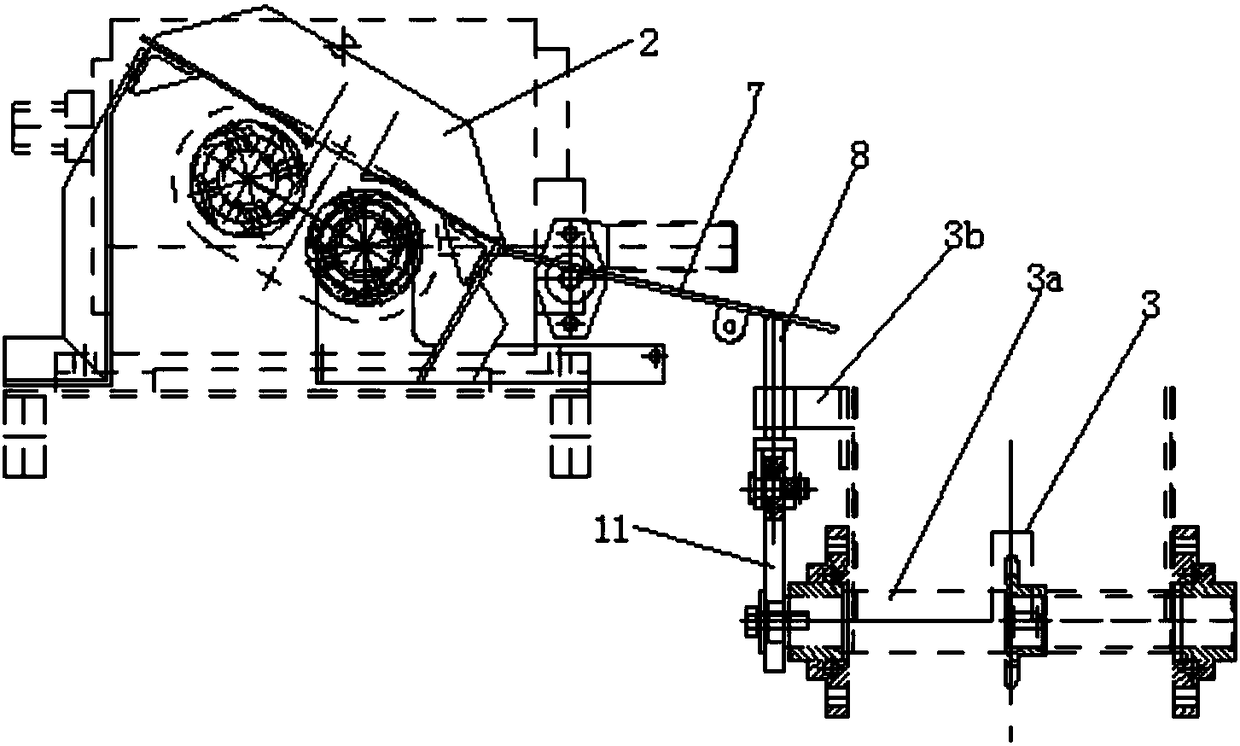

Corn harvesting machine

The invention discloses a corn harvesting machine. A spike picking mechanism is mounted at the front part of a stander, a straw crushing mechanism is arranged below the rear part of the spike pickingmechanism, a lifting mechanism is arranged on the left side of the rear part of the spike picking mechanism and is obliquely arranged in a front-low and rear-high manner, and a peeling mechanism is arranged below the rear part of a high end of the lifting mechanism; and a guiding plate is arranged between the spike picking mechanism and the lifting mechanism and is obliquely distributed in a left-low and right-high manner, a lower end of the guiding plate is supported by a top rod, and the top rod can alternately move up and down under the action of a driving mechanism. According to the corn harvesting machine, baby corns are guided into the lifting mechanism through an eccentric vibration device, so that a blocking phenomenon is effectively avoided; the corns are conveyed from a horizontal manner to a stereoscopic manner, so that the conveying is convenient and rapid; and meanwhile, the injury of the corns caused due to the contact with a spike picking roll can be prevented, and straws can be adequately and integrally crushed at a relatively low rotation speed. The corn harvesting machine is simple and compact in complete machine structure, occupies a small space and is beneficialto the development of a complete machine to the direction of miniaturization.

Owner:重庆市恒昌农具制造有限公司

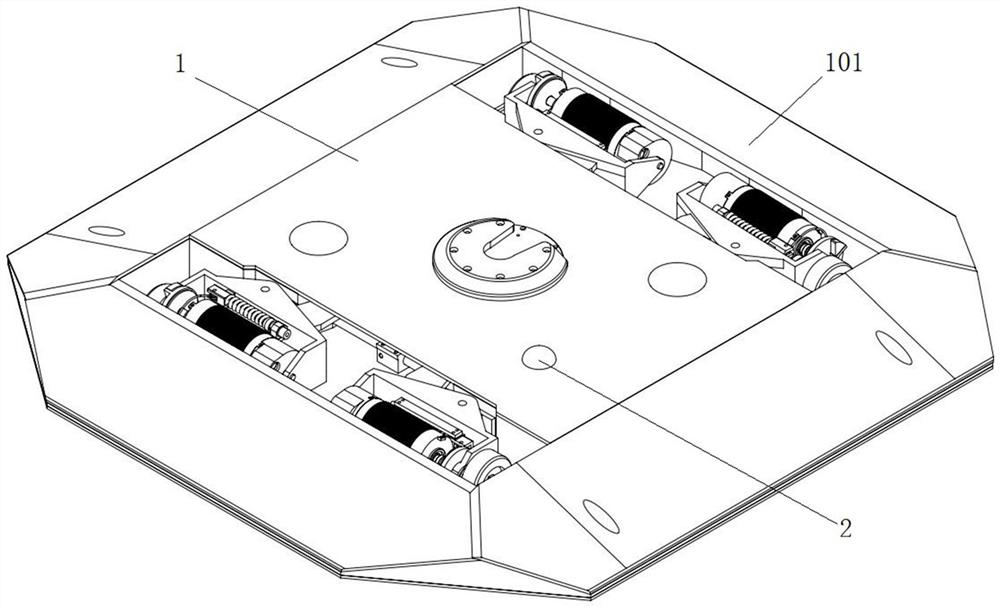

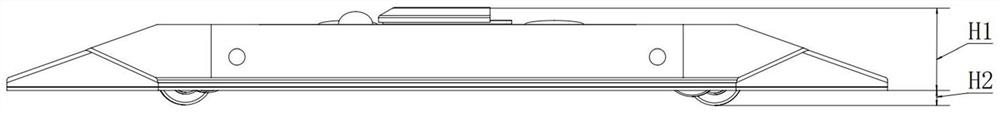

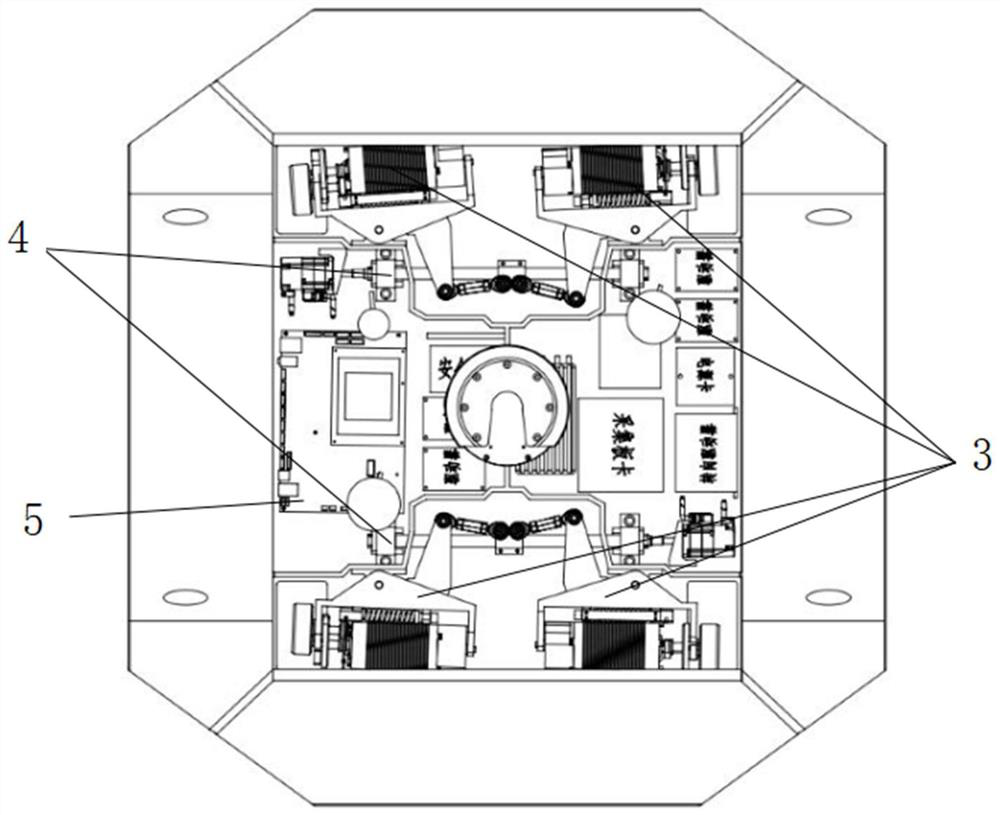

Target object carrying platform car for vulnerable traffic participants

PendingCN114184394AReduce the overall heightLower the altitudeVehicle testingDrive wheelSuspension (vehicle)

The invention discloses a vulnerable traffic participant target object carrying platform car which comprises a chassis frame system, and a driving system, a steering system and a suspension system are installed on the chassis frame system. The driving system comprises two driving mechanisms arranged in the longitudinal direction of the chassis frame system, each driving mechanism comprises two driving assemblies arranged in the axial direction of the chassis frame system, and each driving assembly comprises a driving wheel; the steering system comprises two sets of steering assemblies arranged in the longitudinal direction of the chassis frame system, and the steering assemblies are rotationally connected with the two sets of driving assemblies in the driving mechanisms on the corresponding sides. The suspension system comprises suspension assemblies installed on the driving assemblies, and the suspension assemblies are integrally arranged in the horizontal direction. According to the scheme, the turning radius is small, and the overall height is low, so that operation of road traffic participants can be simulated more truly, the situation that the carrying platform vehicle is captured by an environment sensing system of a tested vehicle is reduced, and the accuracy of a test result is improved.

Owner:CHONGQING UNIV OF TECH

Double-driving system of concrete mixer carrier vehicle

ActiveCN107284337AEnsure safetyGuaranteed independenceConcrete transportationSteering wheelVehicle frame

The invention relates to a double-driving system of a concrete mixer carrier vehicle The double-driving system of the concrete mixer carrier vehicle comprises a vehicle frame; a front steering assembly is arranged in front side of the vehicle frame; a steering execution assembly is arranged under the vehicle frame; a back driving assembly is arranged on the back side of the vehicle frame; the back driving assembly is arranged inside a back cab; the front steering assembly comprises a front steering wheel, a first front steering support, a second front steering support and a full hydraulic pressure steering device; the steering execution assembly comprises a steering power cylinder assembly with a connector, a steering transverse pull rod assembly, an oil cylinder seat, a right bending arm, a left bending arm, a rocking arm seat, a rocking arm, a copper sleeve and a straight-through type pressure injection oil cup; the back driving assembly comprises an expanded cab, an auxiliary support seat, a fixing frame, a pedal fixing seat, a cab bottom plate and a chair seat. The double-driving system of the concrete mixer carrier vehicle realizes two-direction driving through switching between front driving and back driving, solves a problem that the vehicle is hard to turn around in a narrow roadway, solves a problem that vehicle collision happens due to a poor reversing vision and improves a phenomenon that original mechanical steering is labor-consuming.

Owner:LAIZHOU YATONG HEAVY EQUIP

Multifunctional speed changing box

The invention discloses a multifunctional speed changing box which comprises a box body, an input shaft assembly, and left and right output shaft assemblies which are in power transmission connection with the input shaft assembly by a middle speed changing shaft assembly, wherein the left and right output shaft assemblies are fixedly sleeved with bull gears respectively; a reverse gear shaft assembly serving as transfer power transmission is arranged between the middle speed changing shaft assembly and the input shaft assembly; a brake shaft assembly is arranged among the middle speed changing shaft assembly and the left and right output shaft assemblies, and comprises a brake input gear which is in power transmission connection with the middle speed changing shaft assembly, left and right brake output gears meshed with the bull gears correspondingly, and steering yokes which control the left and right brake output gears to form the power transmission connection with the two end faces of the brake input gear respectively and correspondingly; and the brake shaft assembly is in power transmission connection with a second output shaft assembly by a transition shaft assembly. The speed changing box comprehensively has functions of speed changing, steering, parking, main output, second output, clutch and the like.

Owner:CHONGQING PANLONG TECH DEV

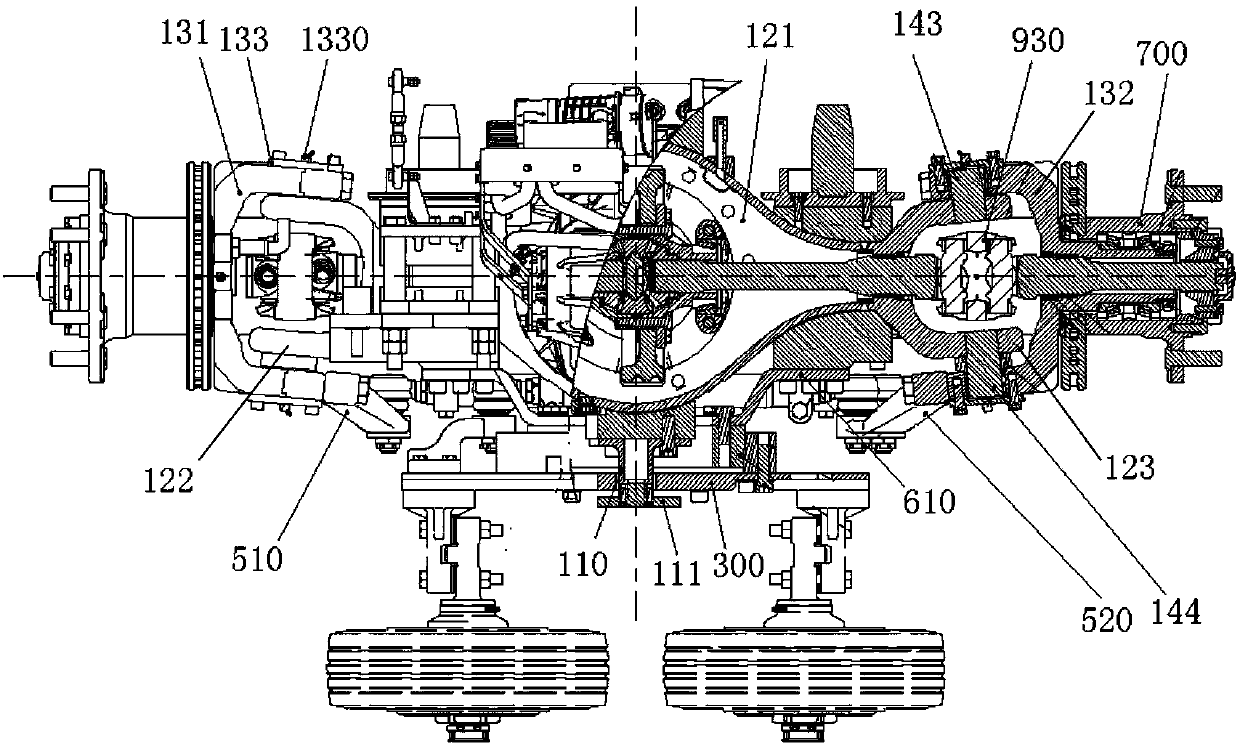

Electric ATV motor integrated rear axle

PendingCN107054031AReduce lossReasonable structureElectric propulsion mountingAxle unitsFriction lossElectric machinery

An electric ATV motor integrated rear axle comprises a left rear axle cylinder and a right rear axle cylinder. A differential motor is connected between the left rear axle cylinder and the right rear axle cylinder, a left semi-shaft is arranged in the left rear axle cylinder, a left disc brake is mounted on the left rear axle cylinder, the left disc brake is provided with a left disc brake plate in a matched mode, a right semi-shaft is arranged in the right rear axle cylinder, a right disc brake is mounted on the right rear axle cylinder, and a right disc brake plate is arranged on the right disc brake in a matched mode. The electric ATV motor integrated rear axle has the beneficial effects that a power unit, a reducing mechanism, a differential mechanism, a transmission mechanism and a braking mechanism are integrated to be a whole, transmission components such as a chain, a chain wheel, a chain wheel seat and a transitional transmission gear shaft are omitted, the torque is increased, the transmission moment force is large, transmission is smooth and steady, the transmission friction loss is greatly reduced, the output power loss is small, the service life is long, and maintenance is convenient; and during turning of an electric ATV, through differential transforming of the differential motor, safe, reliable and stable steering is ensured.

Owner:JINYUN KAYO MOTOR MACHINERY

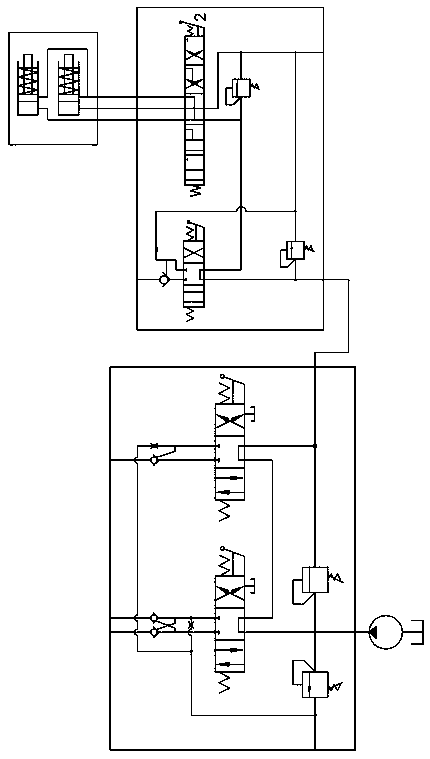

Track harvester hydraulic control system and control method

PendingCN108953260AReliable steeringSimple structureServomotor componentsMowersHydraulic controlControl system

The invention discloses a track harvester hydraulic control system and a control method, and solves the problem of unreliable steering of a paddy machine due to incapability of realizing a steering priority function by a traditional multi-way valve. The track harvester hydraulic control system comprises a main oil inlet, an oil return port, a control valve and a work valve; the control valve comprises a control reversing valve and a priority valve; the control reversing valve is provided with a first position, a second position and a third position; and when the control reversing valve is positioned in the first position and the third position, pressure oil in an oil inlet of the priority valve enters a right side spring cavity of the priority valve through a first throttling hole to cooperate with pressure oil in the oil inlet of the priority valve selected by a left side control cavity of the priority valve for controlling the position of a valve rod of the priority valve. The control method comprises the following steps: when the steering oil cylinder and the work valve are acted, the reversing valve and the priority valve are controlled to realize steering priority actions. Thetrack harvester hydraulic control system has the advantages of simple structure, convenience to assemble, reliable action, long service life and the like.

Owner:SHENGBANG GRP +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com