Explosion-proof support transporting vehicle for coal mine

A support truck, explosion-proof technology, applied in the direction of freight vehicles, goods transport vehicles, motor vehicles, etc., can solve the problems of harsh ground conditions, difficult handling of heavy equipment, and high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

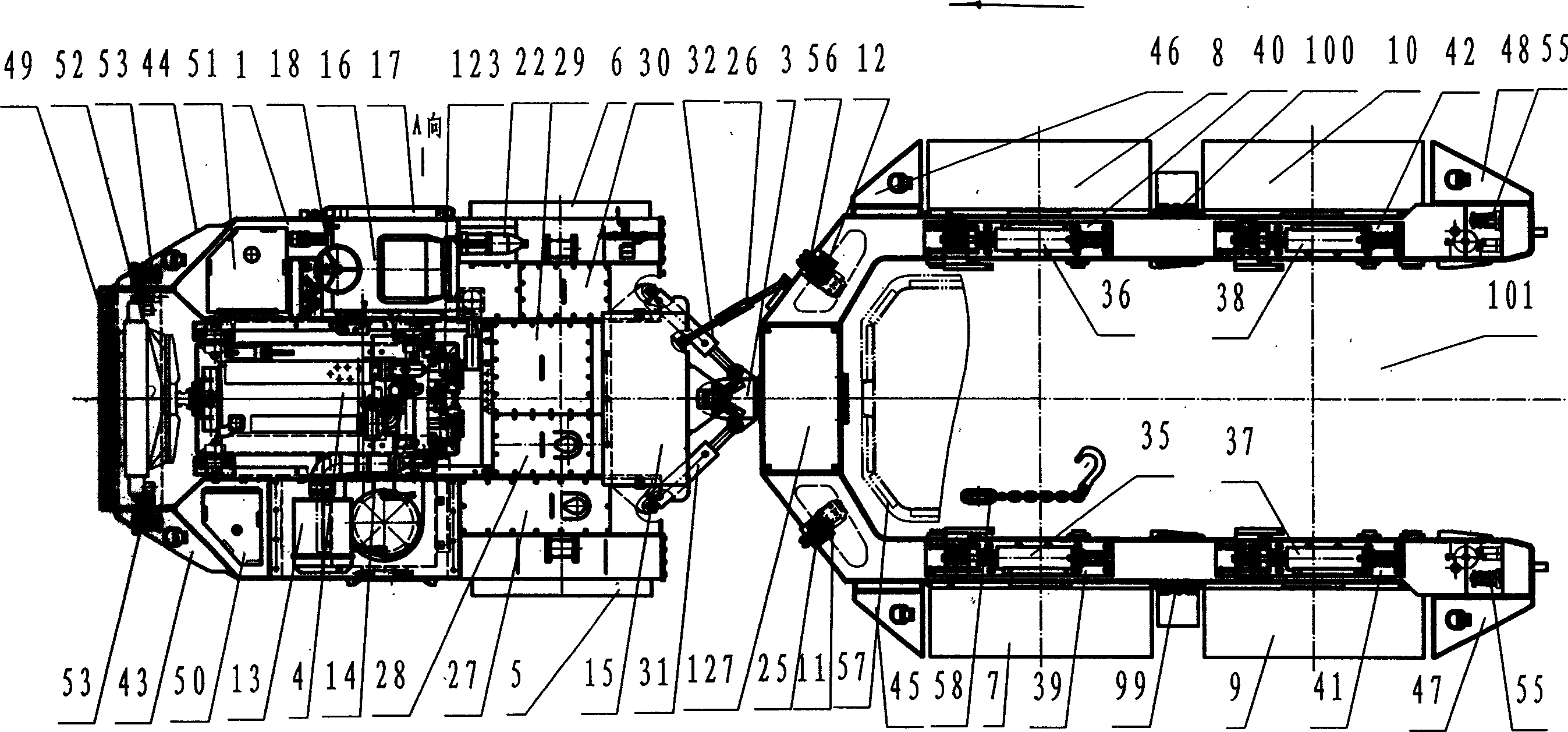

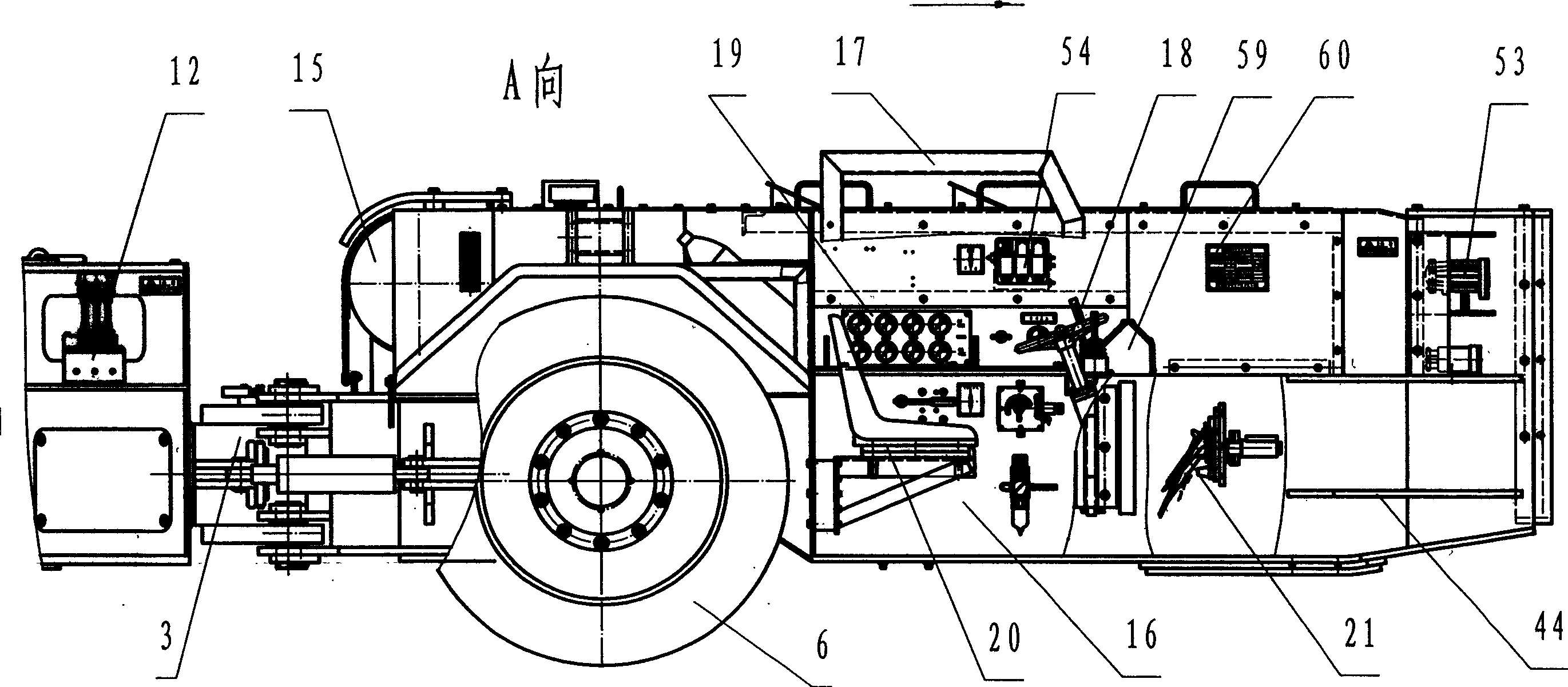

[0039] The present invention will be further described below in conjunction with accompanying drawing:

[0040] figure 1 , 2 As shown in , 3, this truck is a large and heavy mechanical equipment with a dead weight of 24 tons and a load capacity of 40 tons. Since it is operated and transported in the harsh environment of the coal mine underground, all mechanisms and parts have been designed for explosion protection. The front frame 1. Rear frame 2, hinge mechanism 3, front wheels 5, 6, rear wheels 7, 8, 9, 10 form a complete machine model.

[0041] The articulation mechanism 3 is a universal rotation connection structure, and the steering cylinders 31, 32, the pull rod 26 and the bearing structure complete the functions of turning, pulling and connecting.

[0042] The front wheels 5, 6 and the rear wheels 7, 8, 9, 10 are all solid high-strength tires to adapt to walking in the harsh environment of the underground. This walking mechanism is a rear-wheel drive structure. Hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com