Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Reduced assembly weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

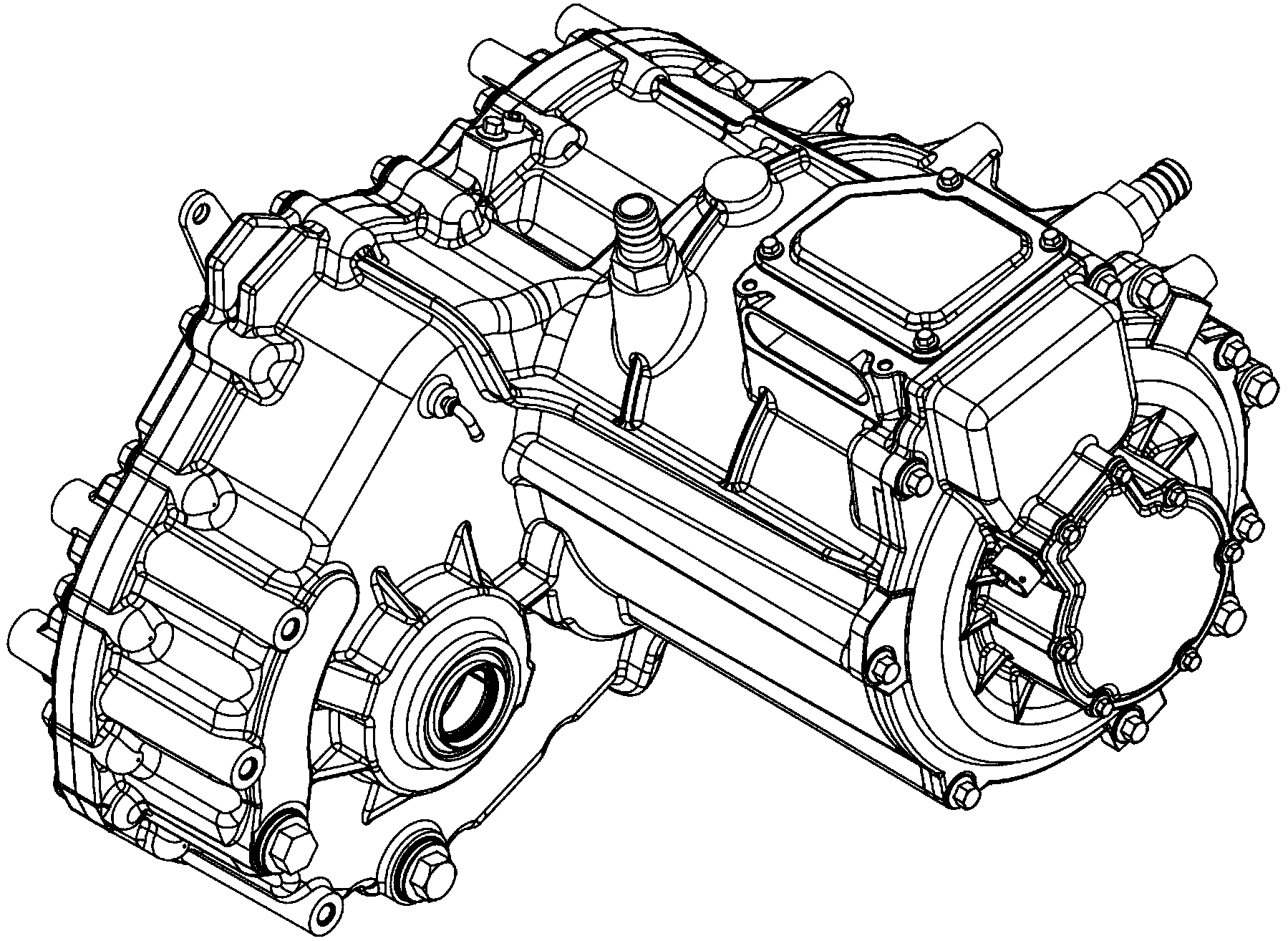

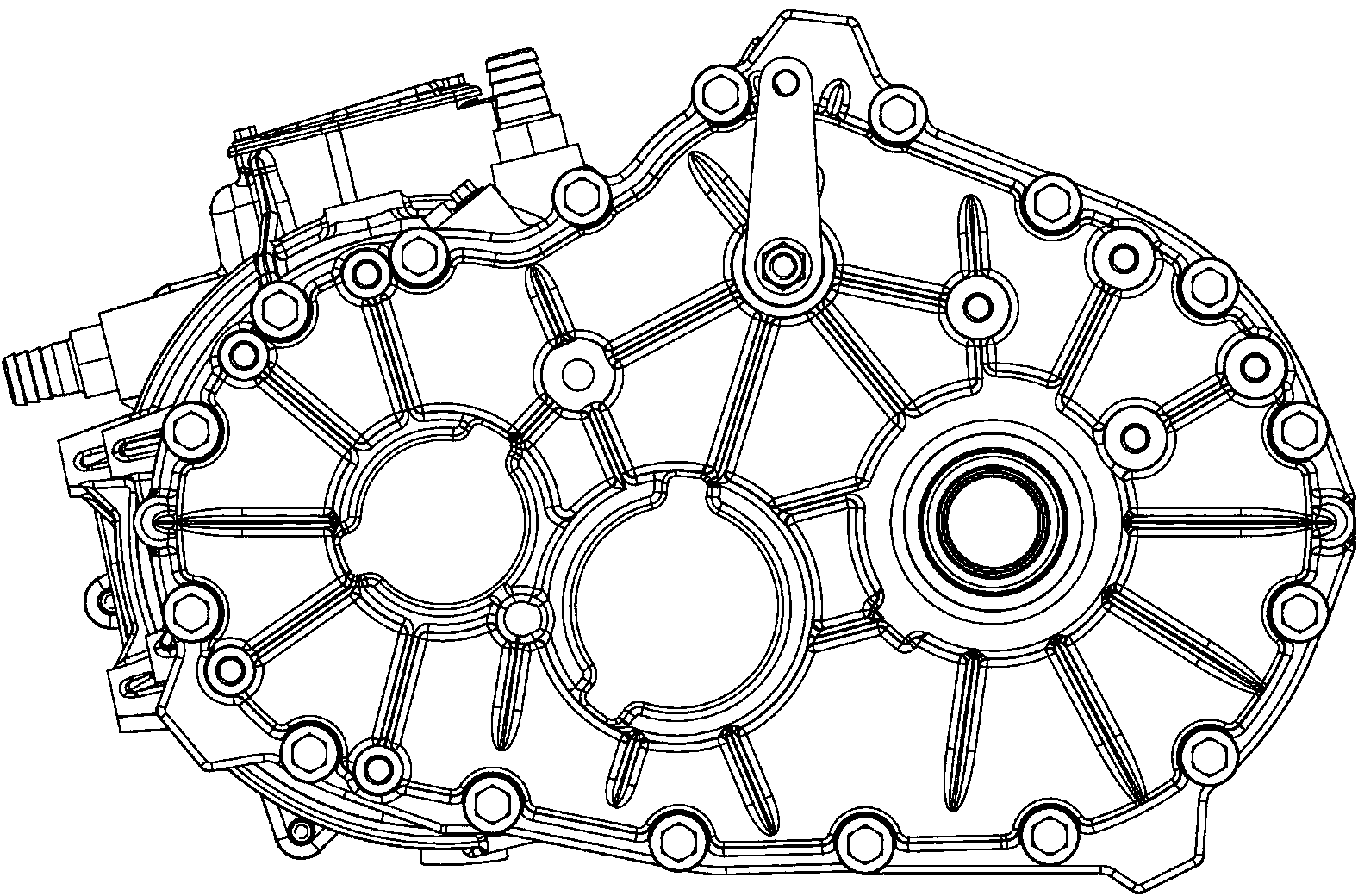

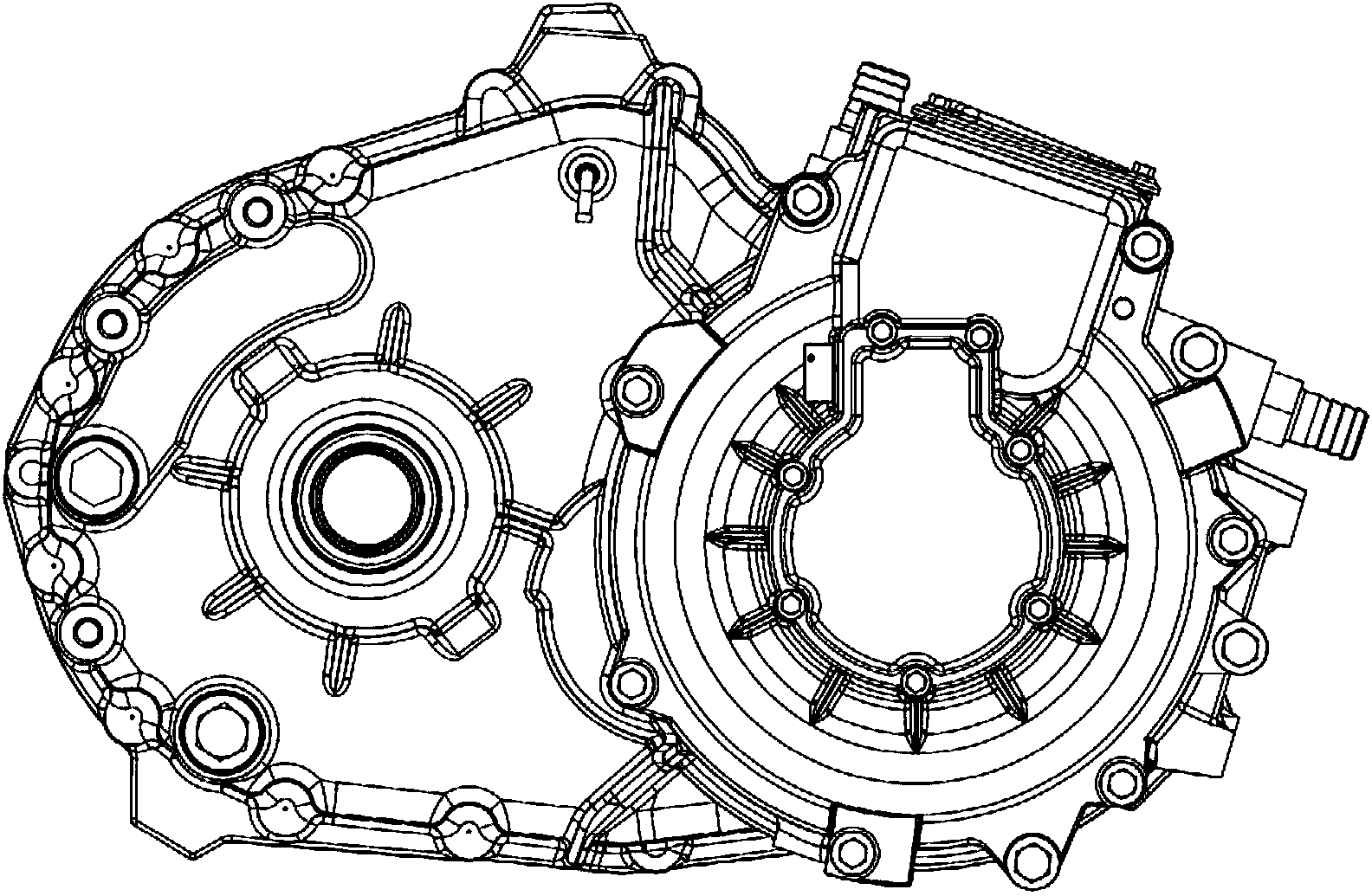

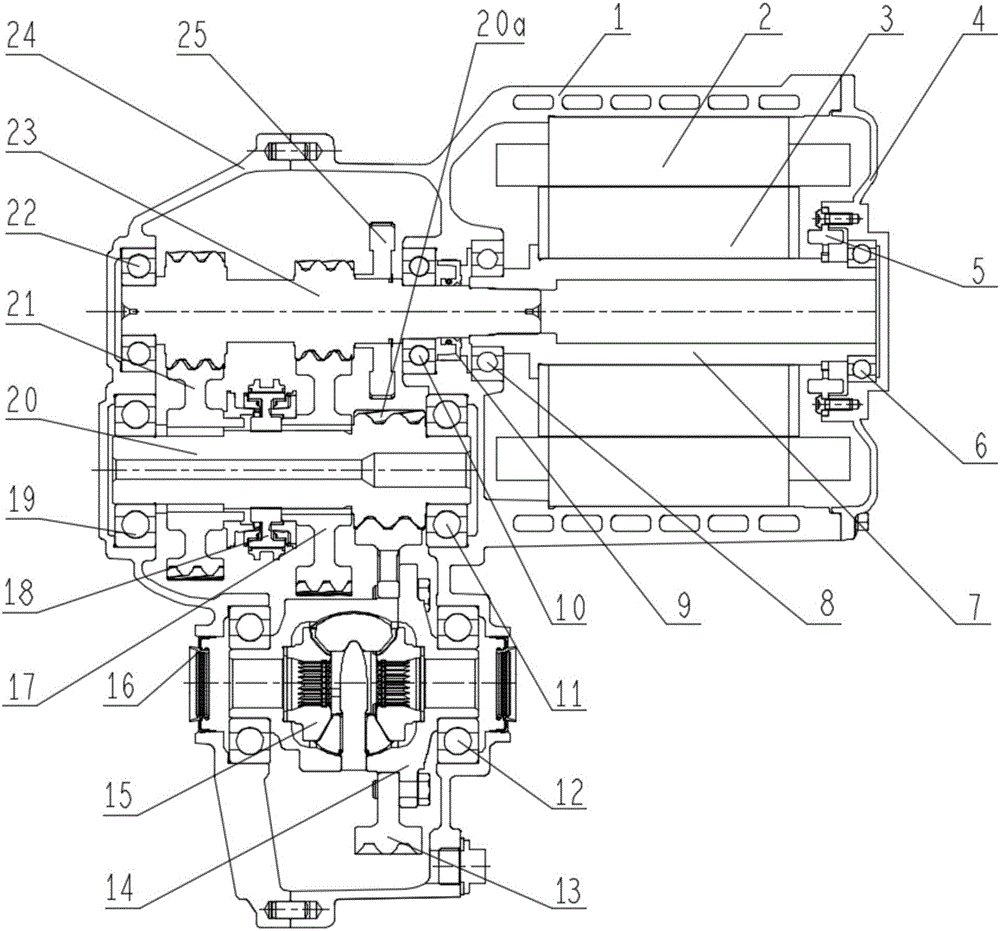

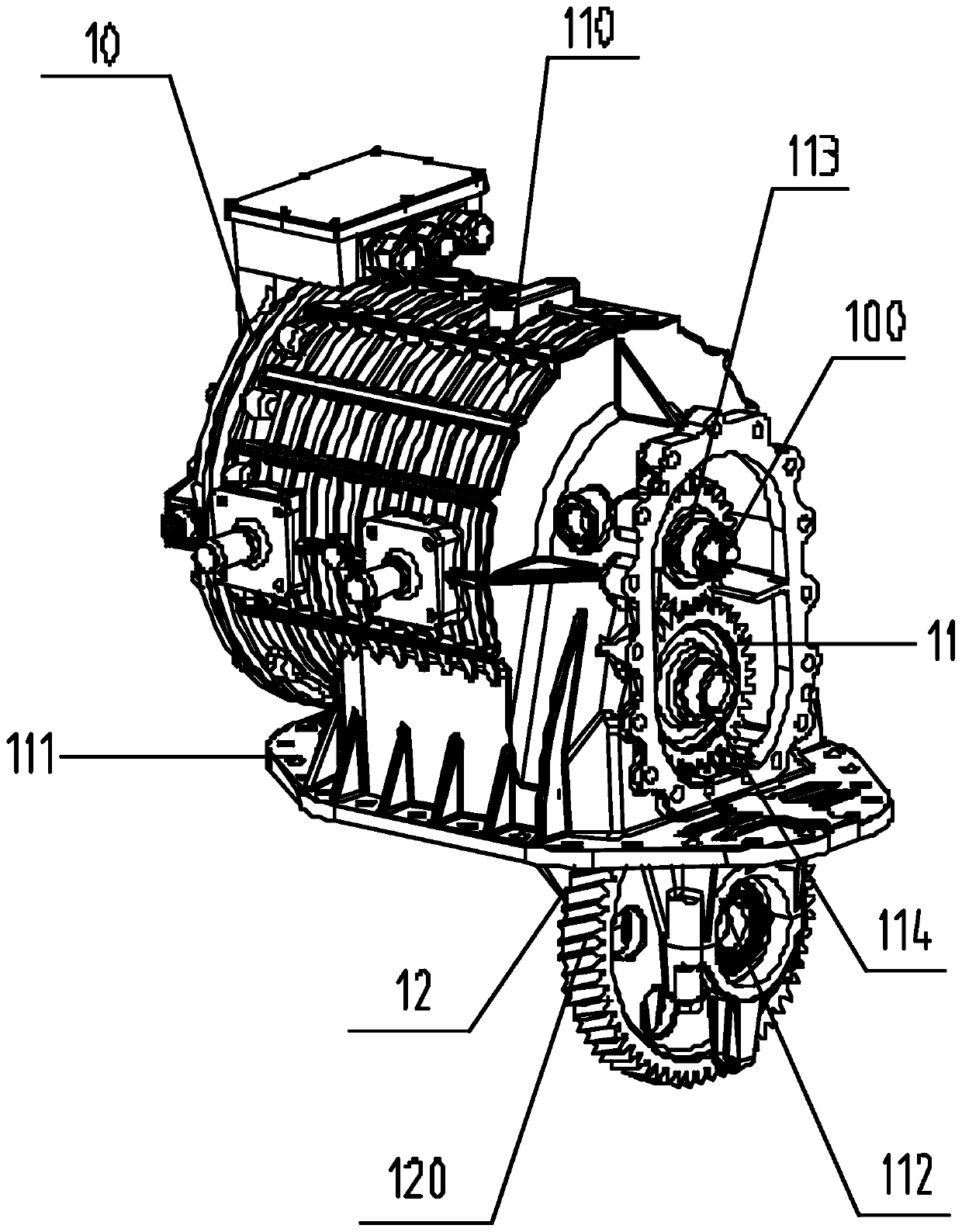

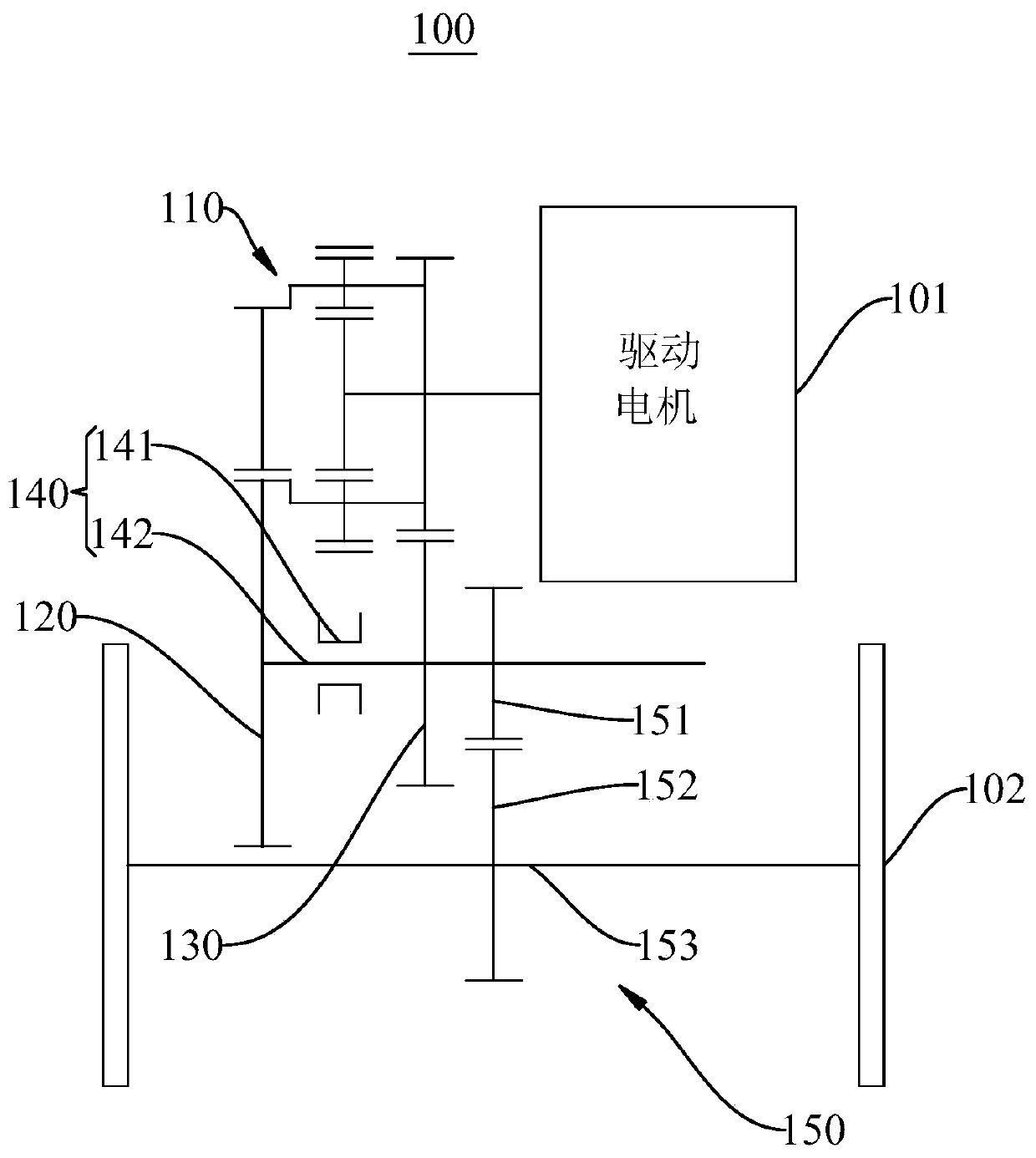

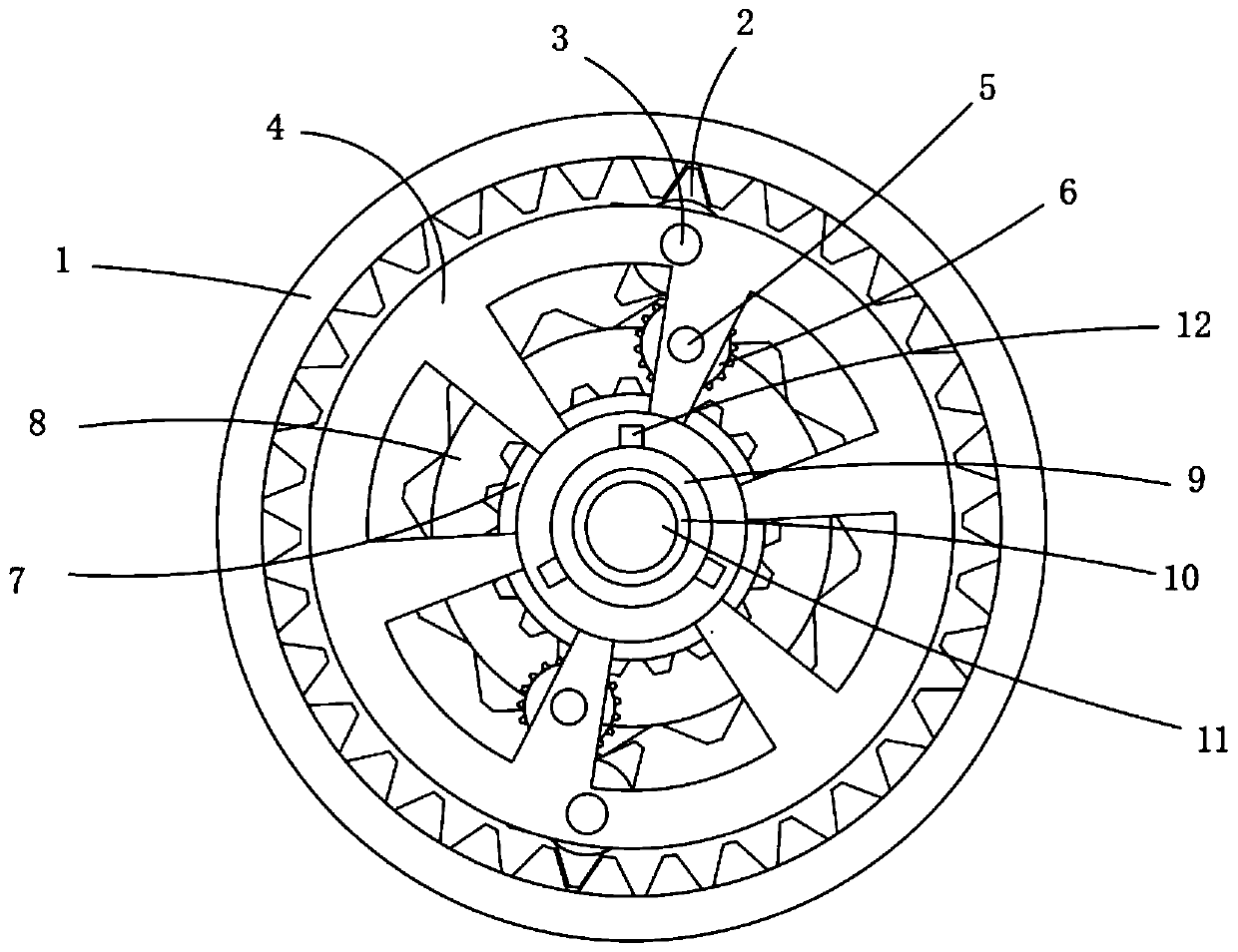

Integrated driving device for new energy vehicle

InactiveCN104377881ACompact structureHighly integratedElectric propulsion mountingMechanical energy handlingReduction driveNew energy

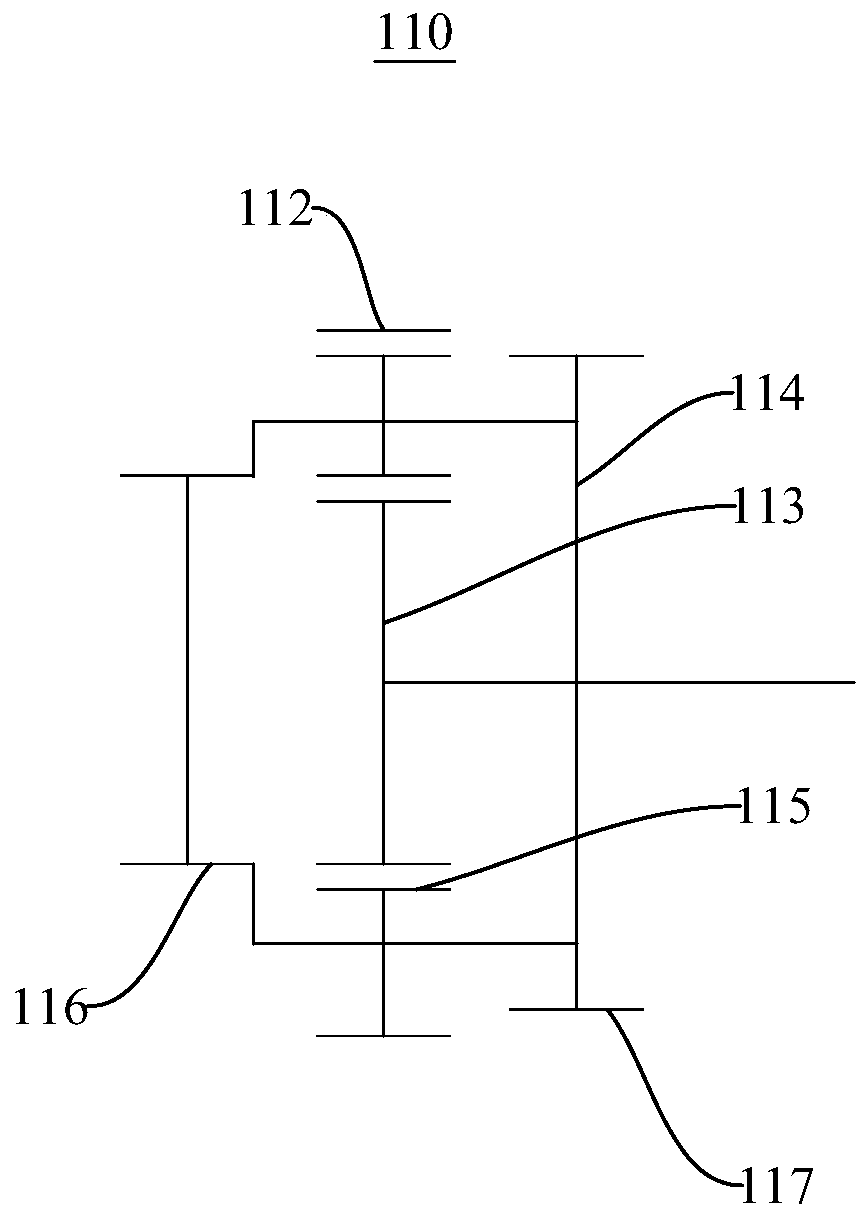

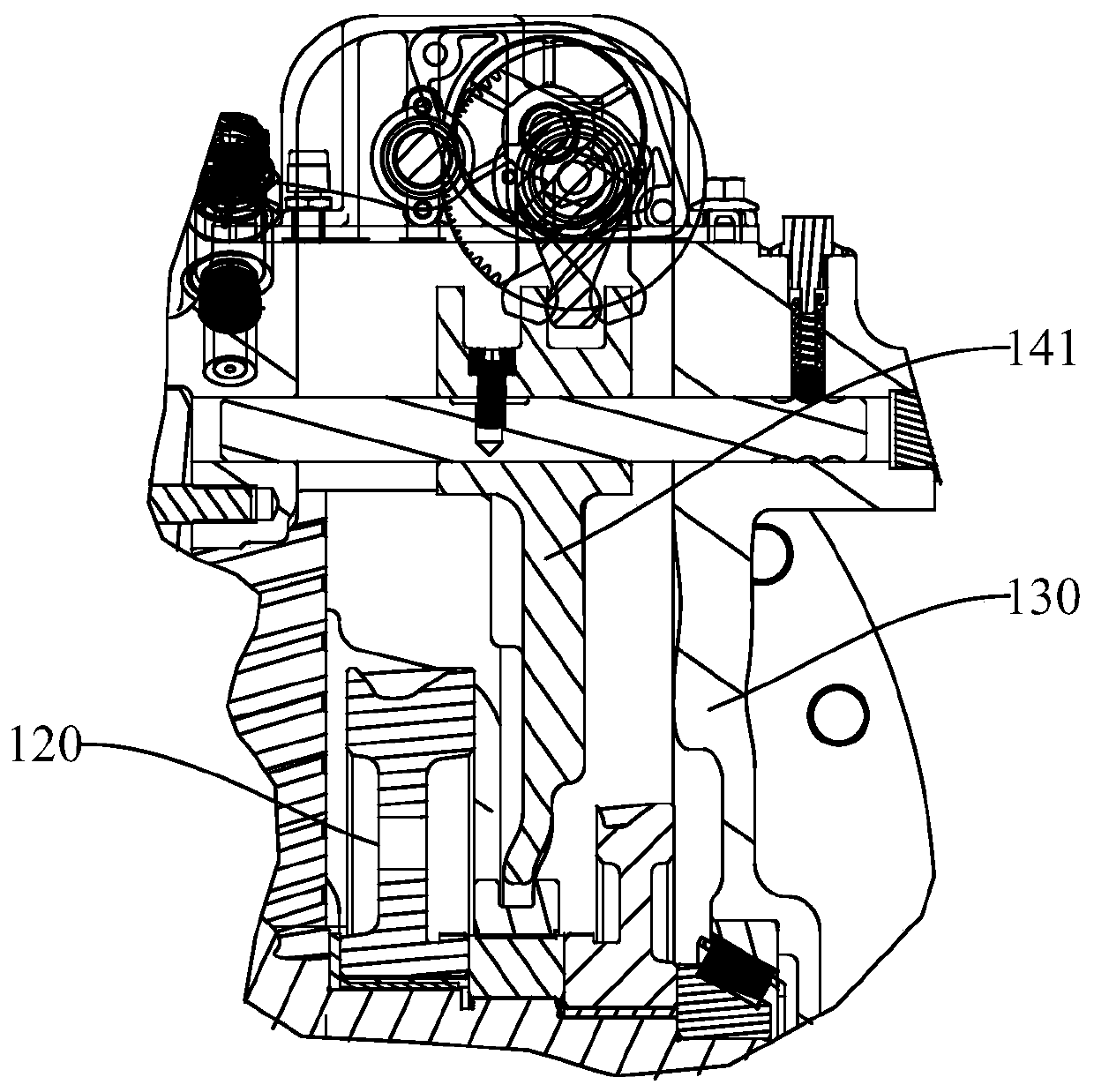

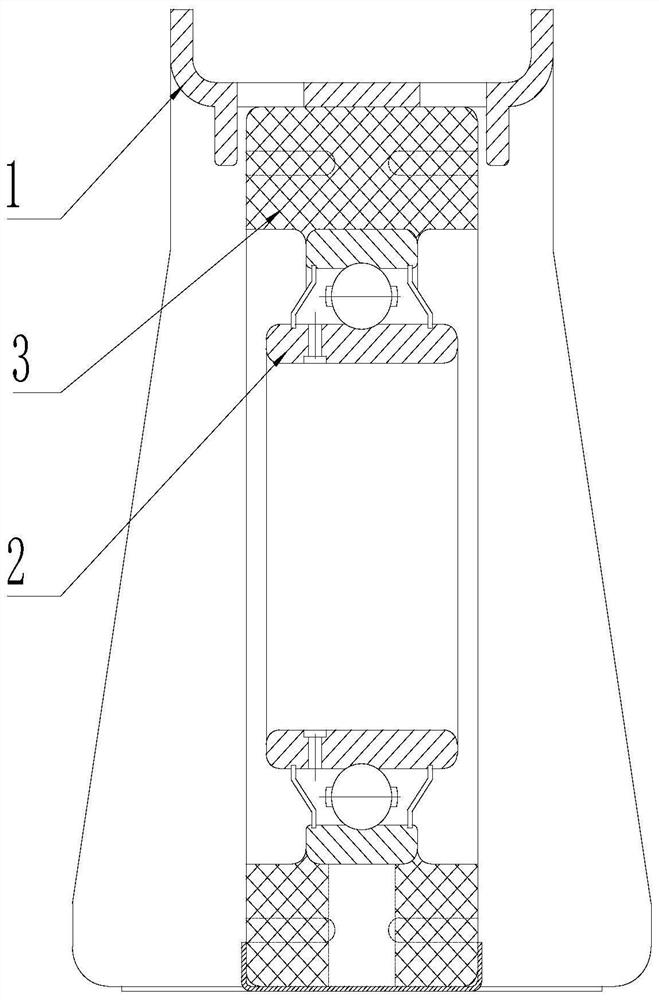

The invention discloses an integrated driving device for a new energy vehicle. Through integrated design, a driving motor, a speed reducer and a differential mechanism are integrated, a shell is shared by the driving motor, the speed reducer and the differential mechanism, a motor shaft serves as not only an output shaft of the driving motor but also an input shaft of the speed reducer, the speed reducer comprises a first-level speed reduction gear set and a second-level speed reduction gear set, a differential mechanism shell is connected with a second-level speed reduction gear, a half axle gear in the differential mechanism is coupled with a vehicle half axle spline, and therefore power generated by the integrated driving device is transmitted to wheel hubs, and the vehicle is driven to run. The integrated driving device for the new energy vehicle is compact in structure and high in integration level, the number of parts is reduced effectively, axial dimensions are shortened, the weight of an assembly is reduced, and the layout flexibility of a power system of the whole vehicle is greatly improved.

Owner:CHINA FIRST AUTOMOBILE

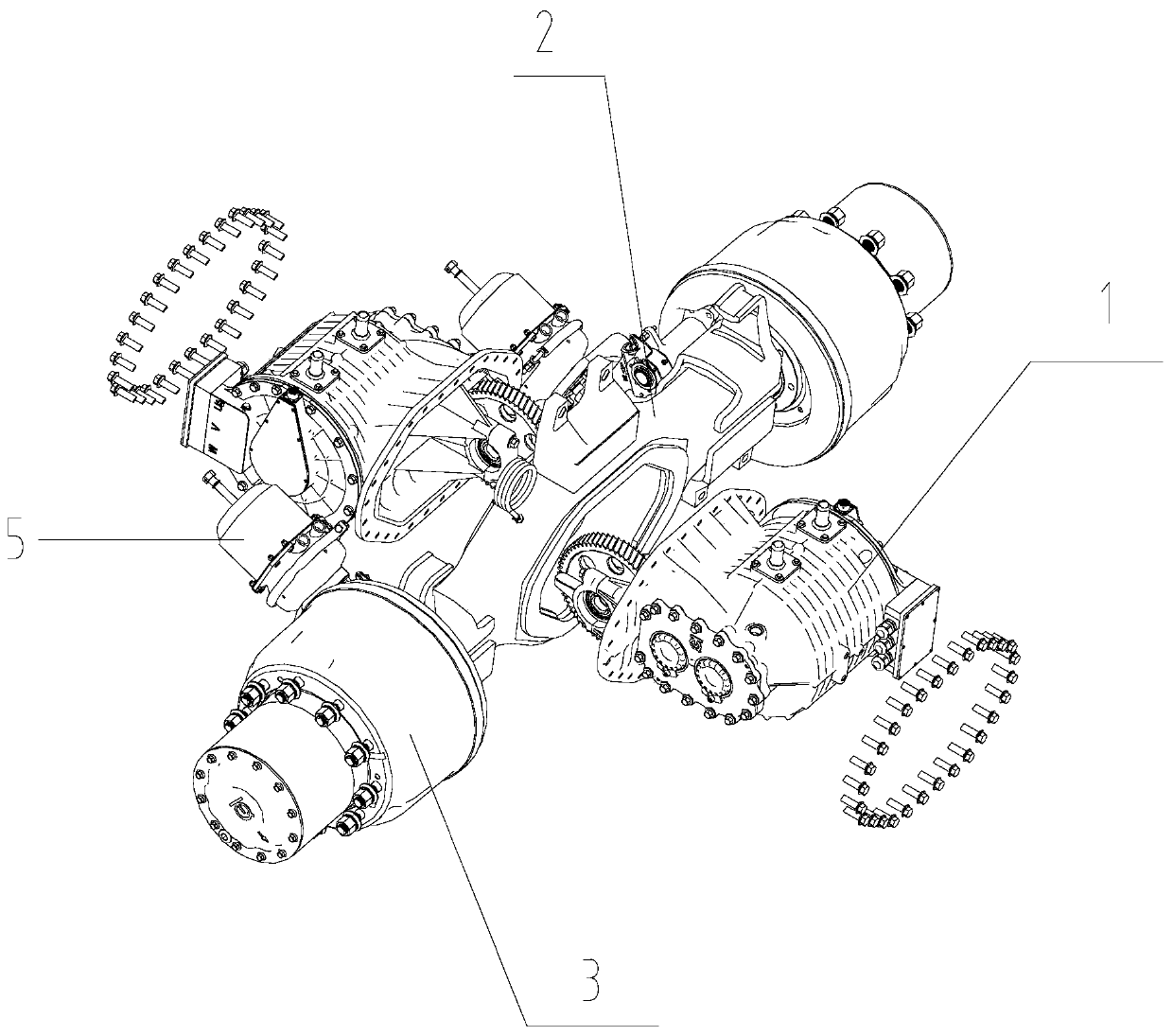

Integrated driving device for two-level electric vehicle

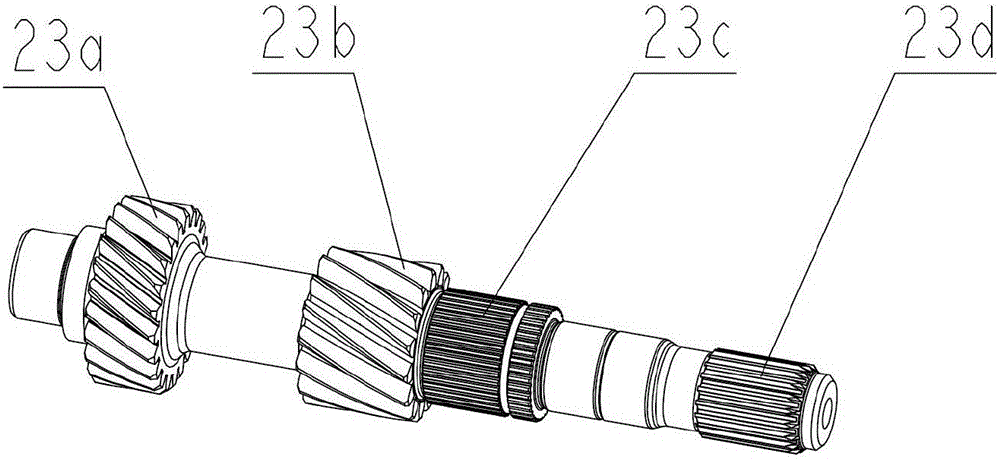

InactiveCN105757210AImprove acceleration performanceImprove climbing abilityGearboxesGearingElectric machineDrive motor

The invention relates to an integrated driving device for a two-level electric vehicle. The integrated driving device is composed of a driving motor, a transmission and a differential mechanism. The transmission comprises an input shaft and an intermediate shaft. An intermediate shaft gear, a first-level reduction gear, a synchronizer and a second-level reduction gear are sequentially arranged on the intermediate shaft from right to left. A first spline, a second spline, a first-level gear and a second-level gear are sequentially arranged on the input shaft from right to left. An output shaft of the driving motor is connected to the first spline of the input shaft of the transmission. The second spline is fixedly sleeved with a parking gear. The first-level reduction gear is meshed with the first-level gear. The second-level reduction gear is meshed with the second-level gear. The second-level reduction gear and the differential mechanism are integrated. The second-level reduction gear is fixedly arranged on a differential mechanism shell in a sleeving mode and meshed with the intermediate shaft gear. Two axle shaft gears are fixedly into the differential mechanism shell. The axle shaft gears are connected with vehicle axle shaft splines. The integrated driving device has the advantages of being compact in structure and high in integration, and the performance of the electric vehicle is greatly improved.

Owner:CHINA FIRST AUTOMOBILE

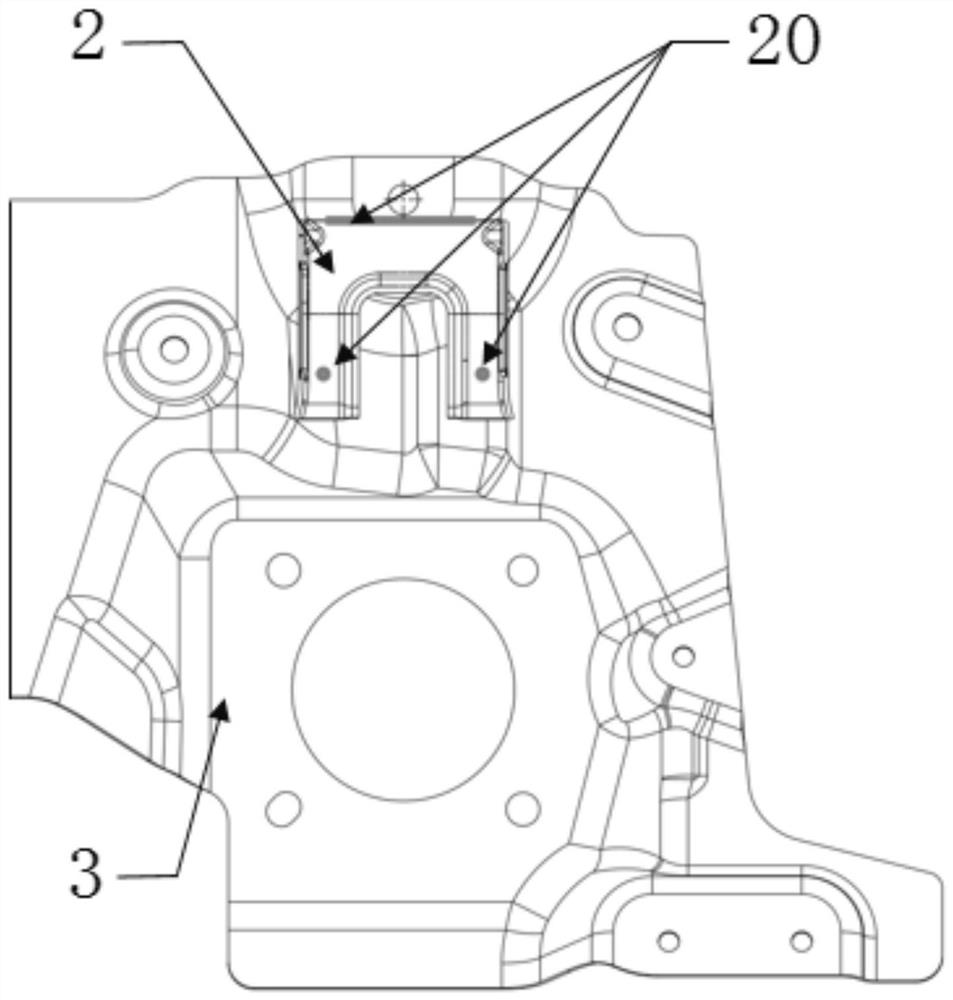

High-voltage PTC liquid heating assembly for heat management of new energy automobiles

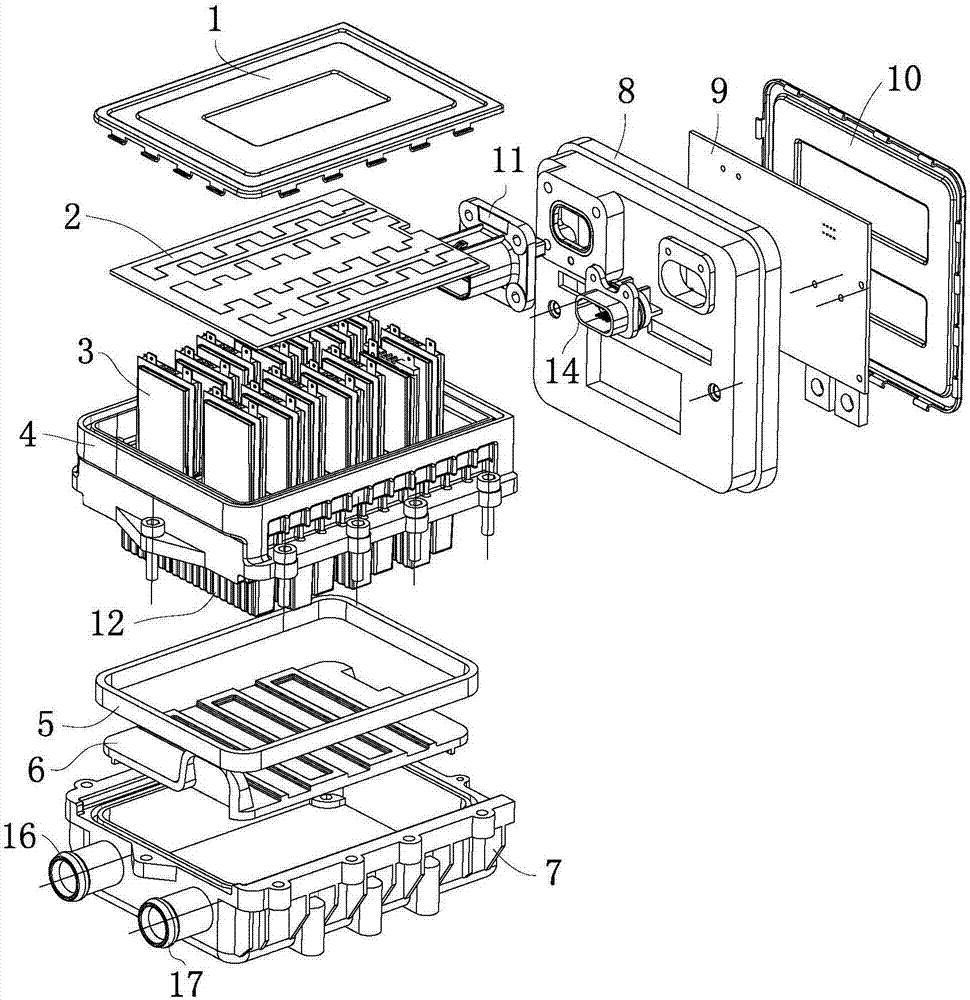

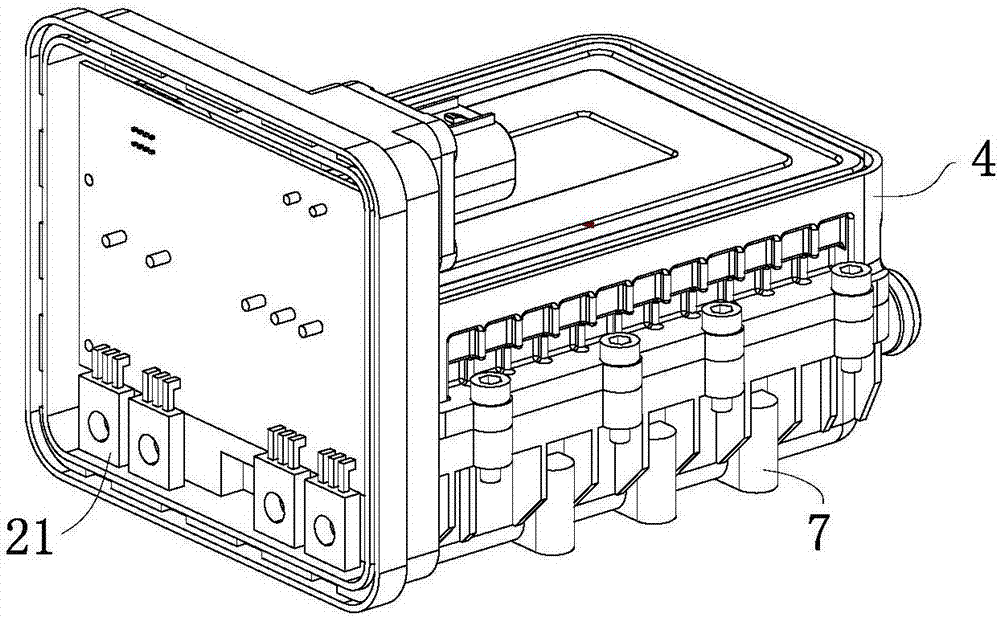

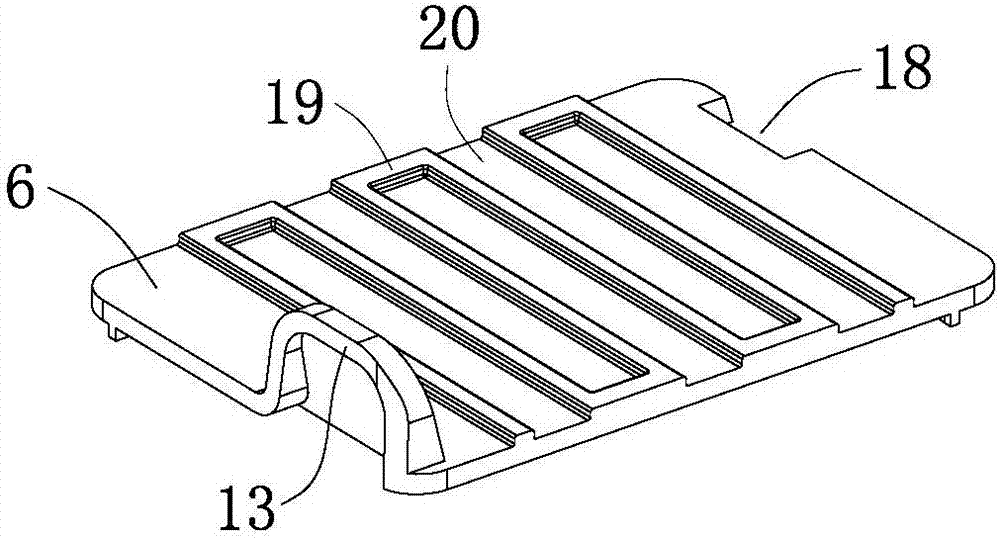

ActiveCN107323215AGuaranteed reliabilityEnsure safetyAir-treating devicesVehicle heating/cooling devicesHeat managementNew energy

The invention provides a high-voltage PTC liquid heating assembly for heat management of new energy automobiles, and solves the technical problem that the existing new energy automobiles are insufficient in heat supply in winter and high in production cost. The high-voltage PTC liquid heating assembly is provided with a control box, and a high-voltage connector and a low-voltage connector are arranged on the control box; a control panel is arranged in the control box, and both the high-voltage connector and the low-voltage connector are connected with the control panel; the high-voltage PTC liquid heating assembly is further provided with a heating aluminum base and a water tank, the heating aluminum base is fixedly connected with the water tank and the control box, a PTC heating component is arranged on the heating aluminum base and is provided with a circuit board, and the circuit board is connected with the control panel; a partition is arranged in the water tank and divides a heating cavity enclosed by the heating aluminum base and the water tank into an upper layer and a lower layer, the water tank is further provided with a water inlet pipe and a water outlet pipe, the water inlet pipe is communicated with the lower layer, and the water outlet pipe is communicated with the upper layer. The high-voltage PTC liquid heating assembly can be widely applied to the field of heating of new energy automobiles.

Owner:WEIHAI KEBOLE AUTOMOBILE ELECTRONICS CO LTD

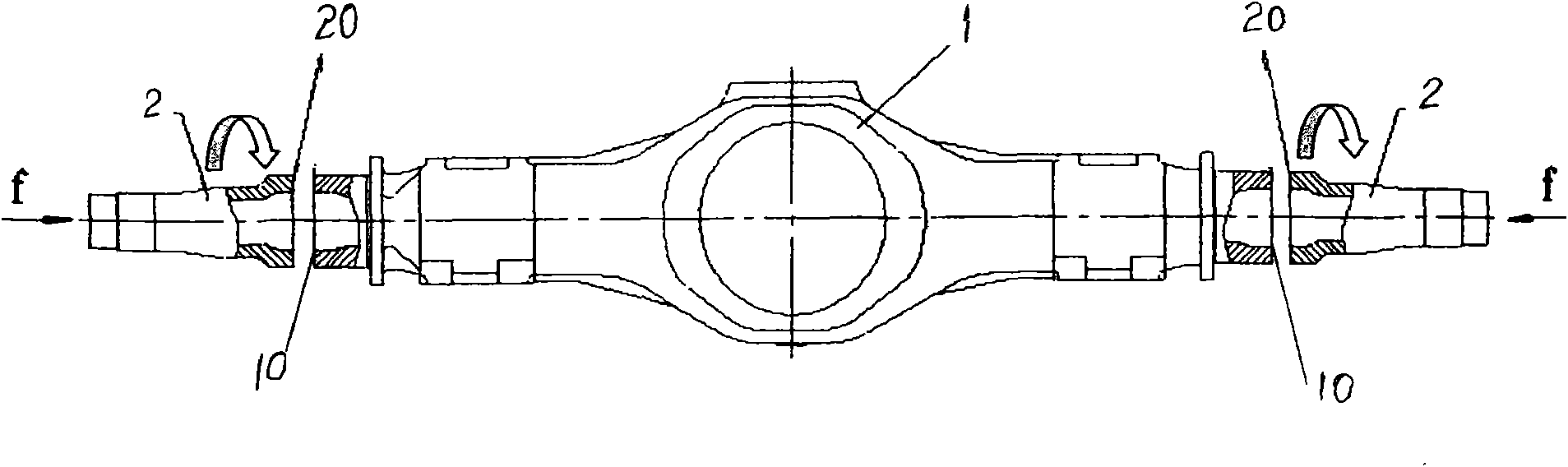

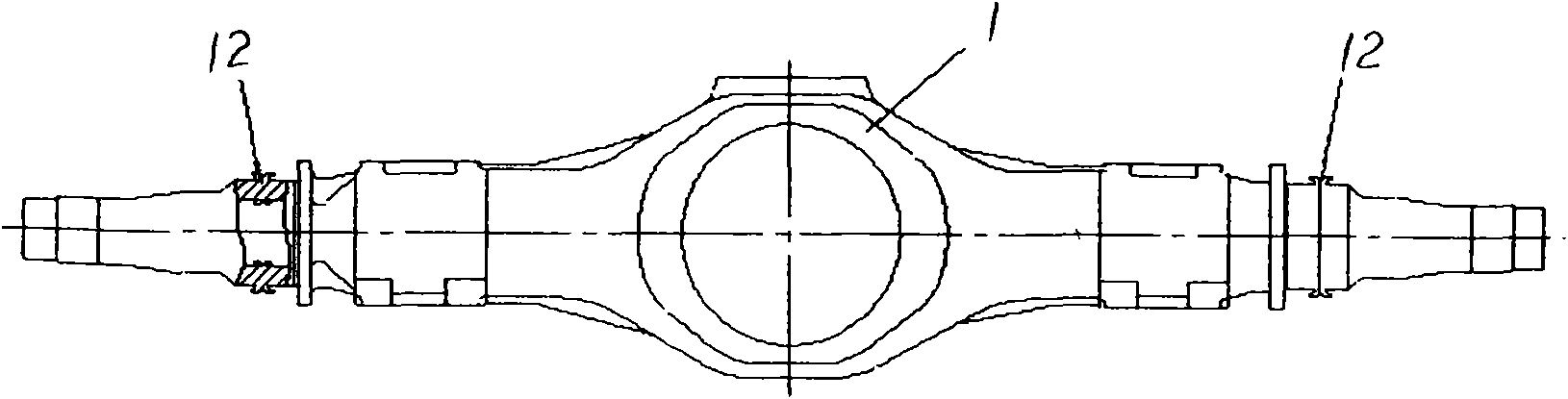

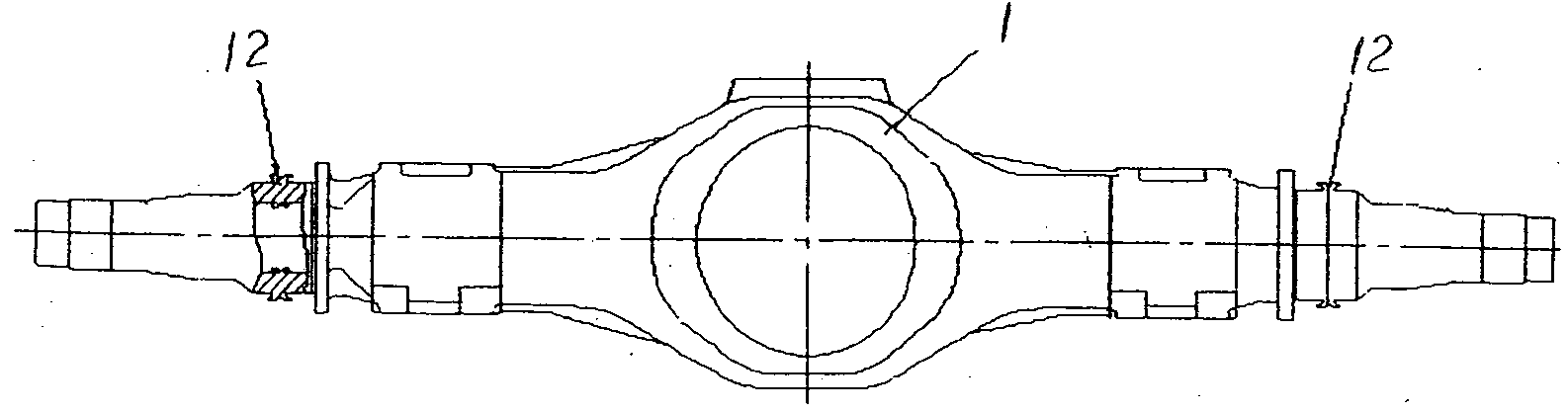

Friction welding process for intermediate section of axle cast steel axle housing and shaft heads of heavy-duty truck

InactiveCN102205460ASimple processEasy to controlNon-electric welding apparatusFriction weldingAxial pressure

The invention relates to a process for welding an intermediate section of an axle housing and shaft heads of a heavy-duty truck, in particular to a friction welding process of an intermediate section of a cast steel axle housing and shaft heads for a heavy-duty truck. The friction welding process is characterized in that the intermediate section and the shaft heads at two sides are clamped in special continuous driving friction welding equipment; the intermediate section of the axle housing is immovable; the shaft heads at the two sides rotate at high speed and apply an axial pressure; and the diffusion and re-crystallizing metallurgy reaction on an interface is realized by using the heat generation by friction and the pressure of the interface to be welded, and finally, the intermediate section of the axle housing is welded together with the shaft heads at the two sides. The invention has the characteristics of simple process, accuracy in control, stable and reliable welding quality, no defects such as melting weld joint air holes, interposition slag and heat cracks existing in the weld joint, fine weld joint tissue, higher strength of the weld joint compared with that of a base material and high welding efficiency. The welded axle housing can meet the requirements for vertical bending fatigue life and vertical static rigidity and has a certain significance on shortening the total lengths of the shaft heads, reducing the weight of an axle housing assembly, prolonging the service life of extrusion dies of the shaft heads and reducing the cost.

Owner:SHAANXI HANDE AXLE CO LTD

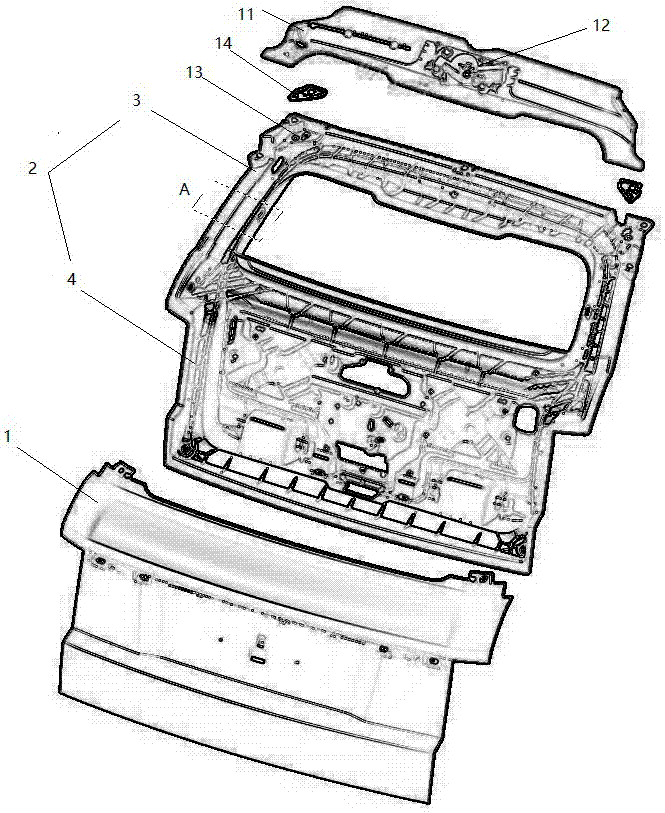

Injection-molding tailgate of vehicle and vehicle

The invention discloses an injection-molding tailgate of a vehicle. The injection-molding tailgate includes an outer decorative plate and an inner plate. The outer decorative plate and the inner plateare injection-molding pieces, and the inner plate includes a rear windshield body part and a door board part; the outer decorative plate is fixedly bonded with the door board part, the rear windshield body part includes inner edges and outer edges, reinforcement slots are formed between the inner edges and the outer edges of the two sides of the rear windshield body part, and the reinforcement slots are internally provided with reinforced separation plates in the length direction; V-shaped reinforcement ribs are arranged between the reinforced separation plates and the inner edges, straight-line-shaped reinforcement ribs are arranged at intervals between the reinforced separation plates and the outer edges, and the width of the reinforced separation plates, the width of the V-shaped reinforcement ribs and the width of the straight-line-shaped reinforcement ribs are all 1.2-1.4 mm. The injection-molding tailgate is light and high in strength, and the bright marks generated on the surface are reduced.

Owner:JIANGSU CHANGSHU AUTOMOTIVE TRIM GRP CO LTD

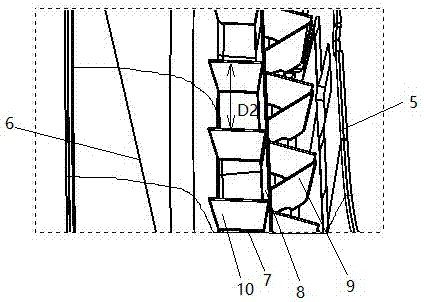

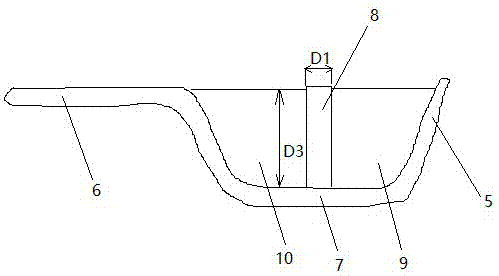

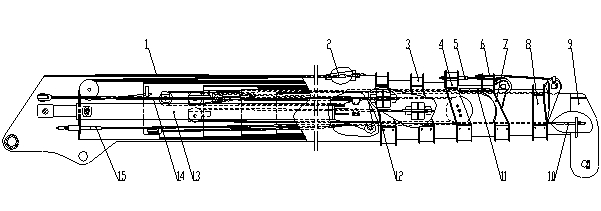

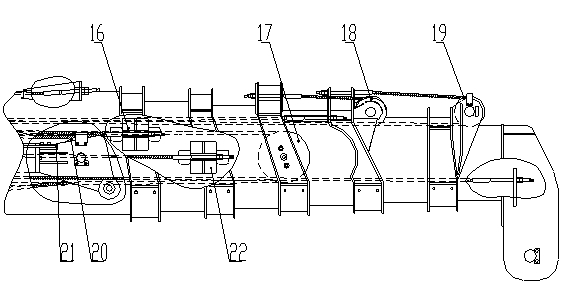

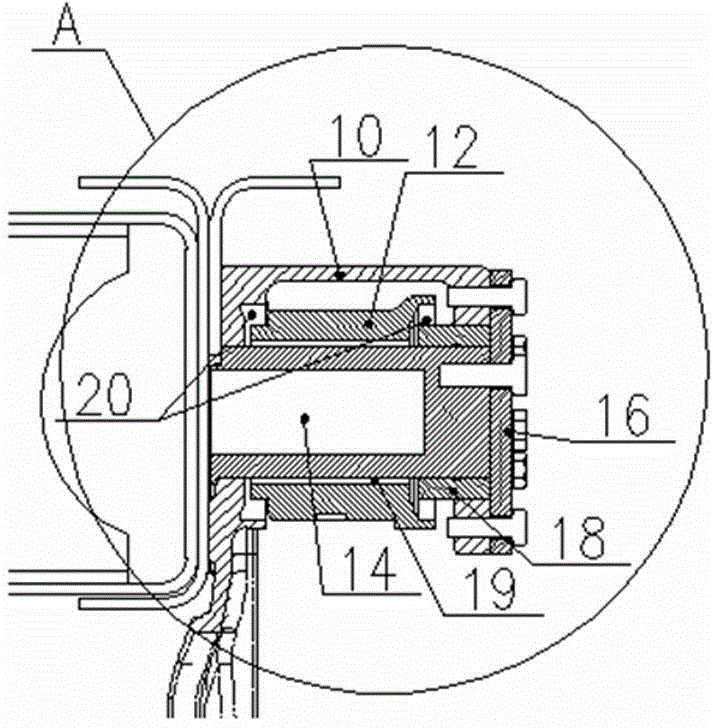

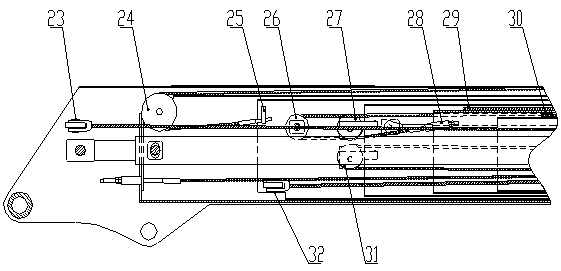

Single cylinder synchronous expansion and contraction device with multiple sets of inhaul cables for lorry-mounted crane

The invention discloses a single cylinder synchronous expansion and contraction device with multiple sets of inhaul cables for a lorry-mounted crane. The device comprises a basic arm and a plurality of telescopic arms which are overlapped and sleeved in the basic arm; a telescopic oil cylinder of which the head is fixed on the tail of the basic arm and the barrel is fixed on a first section of the tail of the telescopic arm is arranged in each of the plurality of telescopic arms; the arm body of each telescopic arm is provided with a pulley, a telescopic arm cable, and a fixed plate; a rope row is arranged in each telescopic oil cylinder; and synchronous extending or contraction of multiple sections of the telescopic arms can be realized by the connection relationship of the parts, and the operation characteristics that the conventional arm can be only extended and contracted sequentially are changed to ensure that the multiple sections of the telescopic arm bodies are extended and contracted synchronously along with the extension and contraction of the inbuilt telescopic cylinders, so that the extension and contraction speed of the arm bodies and the efficiency of the lifting operation are improved greatly. The single cylinder synchronous expansion and contraction device with the multiple sets of inhaul cables for the lorry-mounted crane has a compact structure, the mode of winding steel wire ropes is skilful, the space in the arm body is fully utilized, and the problems that the conventional five-section telescopic arm expansion and contraction system for the lorry-mounted crane is implemented by arranging two inbuilt telescopic oil cylinders are solved.

Owner:XCMG XUZHOU TRUCK MOUNTED CRANE +1

Production method of car engine compartment cover assembly

ActiveCN103331581AReduced assembly weightMeet the requirements of lightweight designMiniaturizationPerformance index

The invention relates to a production method of a car engine compartment cover assembly. An engine compartment cover inner plate finished product can be obtained through the steps such as measuring and cutting of sheet stock, pavement of raw materials, hot pressing forming, mold stripping of a semifinished product, cooling stereotyping and blank processing, and an engine compartment cover outer plate finished product is obtained through the steps such as measuring and cutting of sheet stock, pavement of raw materials, hot pressing forming, mold stripping of a semifinished product, cooling stereotyping and blank processing; and a car engine compartment cover assembly finished product is obtained by assembling and splicing the engine compartment cover inner plate and outer plate. The engine compartment cover assembly produced through the method has the advantages that performance indexes such as sound insulation, environmental protection and miniaturization can meet the requirement that no accumulation of semifinished products in the entire production process, and the manufacturing cost is saved; and the entire production process of the product is free from producing harmful substances.

Owner:WUXI GISSING AUTO PARTS CO LTD

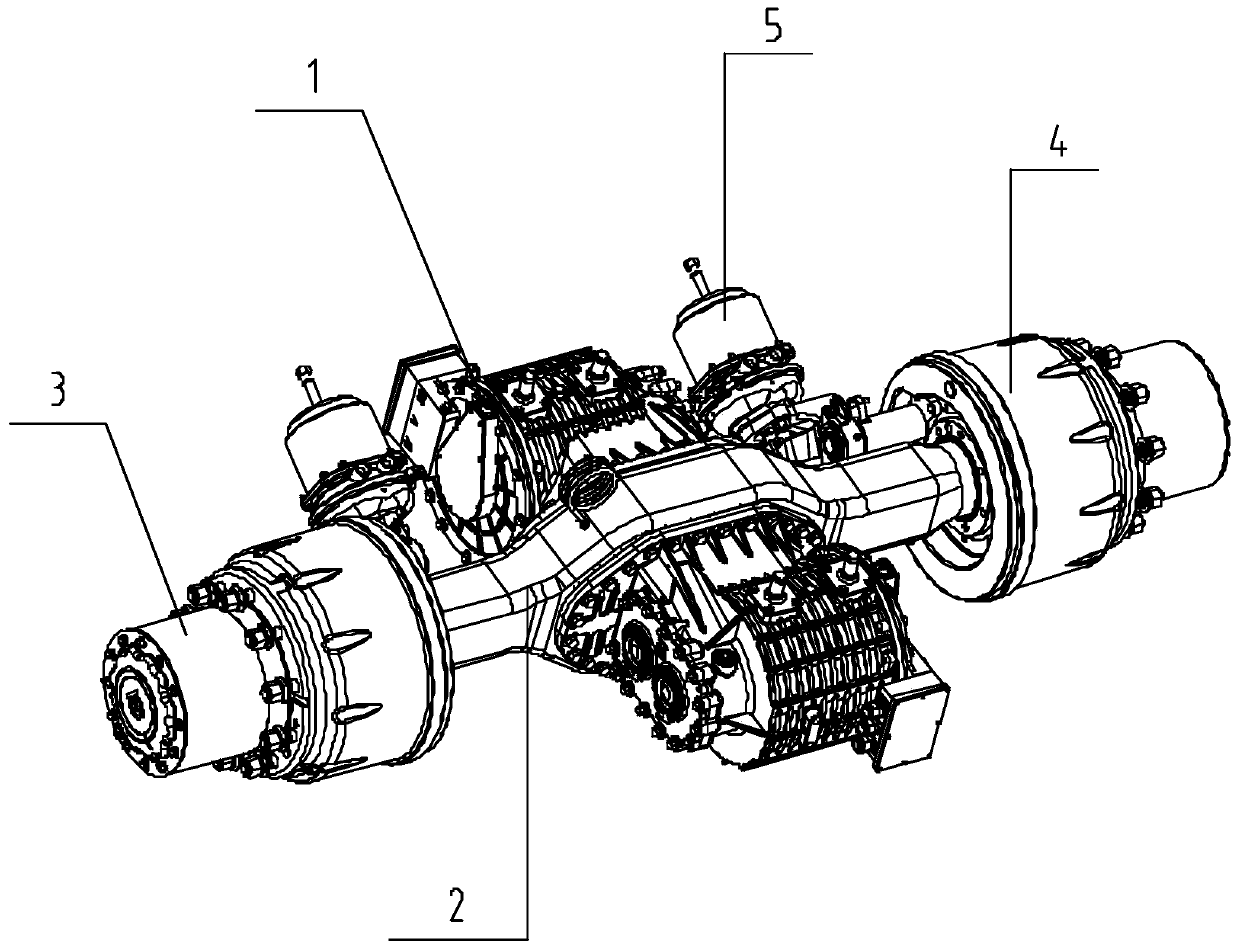

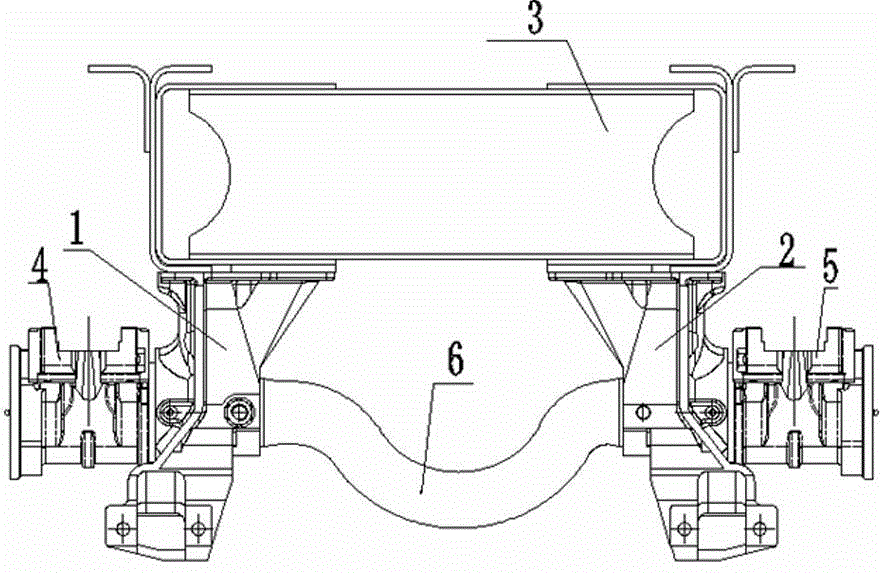

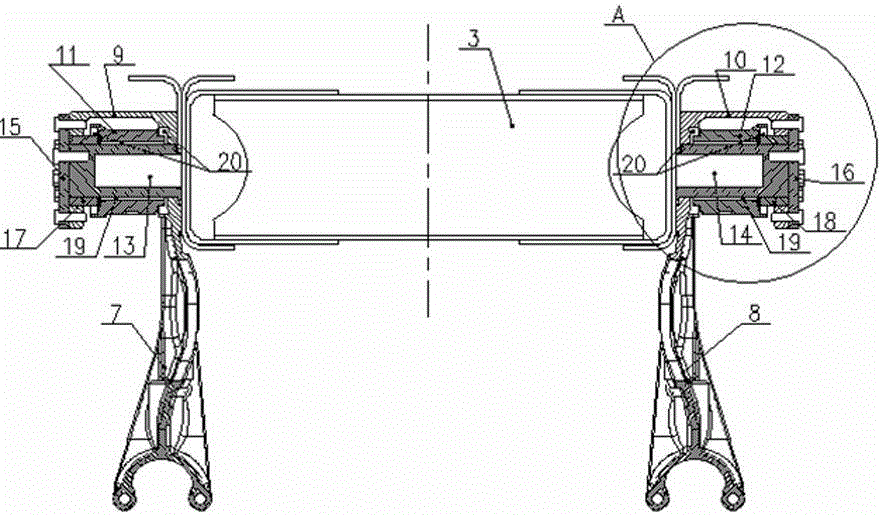

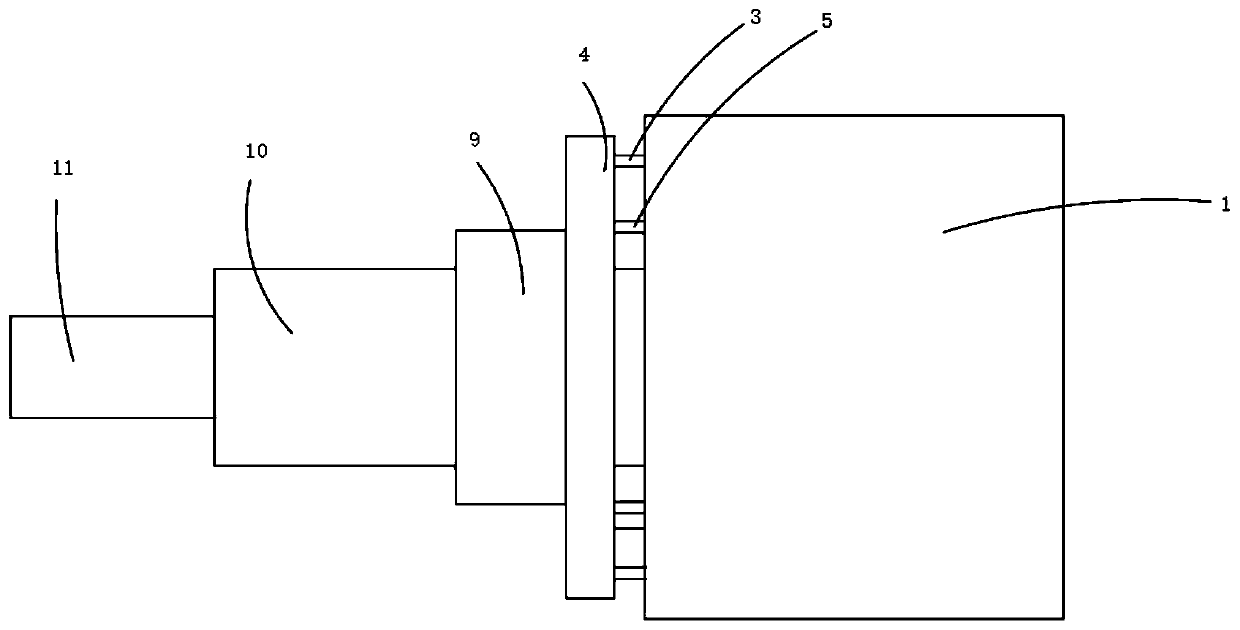

Integrated double-motor distributed drive electric drive axle

InactiveCN111169225AImprove efficiencyImprove space utilizationSpeed controllerElectric propulsion mountingReduction driveElectric machinery

The invention provides an integrated double-motor distributed drive electric drive axle. The drive axle comprises an integrated power assembly, an axle housing and a hub reduction system, the integrated power assemblies are respectively arranged at the front end and the rear end of the axle housing; the integrated power assembly comprises a driving motor, a speed reducer and a differential mechanism; the driving motor drives the speed reducer and the differential; the hub reducers are respectively arranged at the left and right ends of the axle housing; the hub reduction gear arranged at the left end of the axle housing is in transmission connection with the differential mechanism of the integrated power assembly arranged at the rear end of the axle housing through a first half shaft; thehub reduction gear arranged at the right end of the axle housing is in transmission connection with the differential mechanism of the integrated power assembly arranged at the front end of the axle housing through the second half shaft, and therefore the integrated power assembly has the advantages that the weight of the assembly is reduced, the overall efficiency of the axle is improved, and meanwhile the space utilization rate of the whole vehicle is increased.

Owner:青岛汽车零部件科技创新服务有限公司

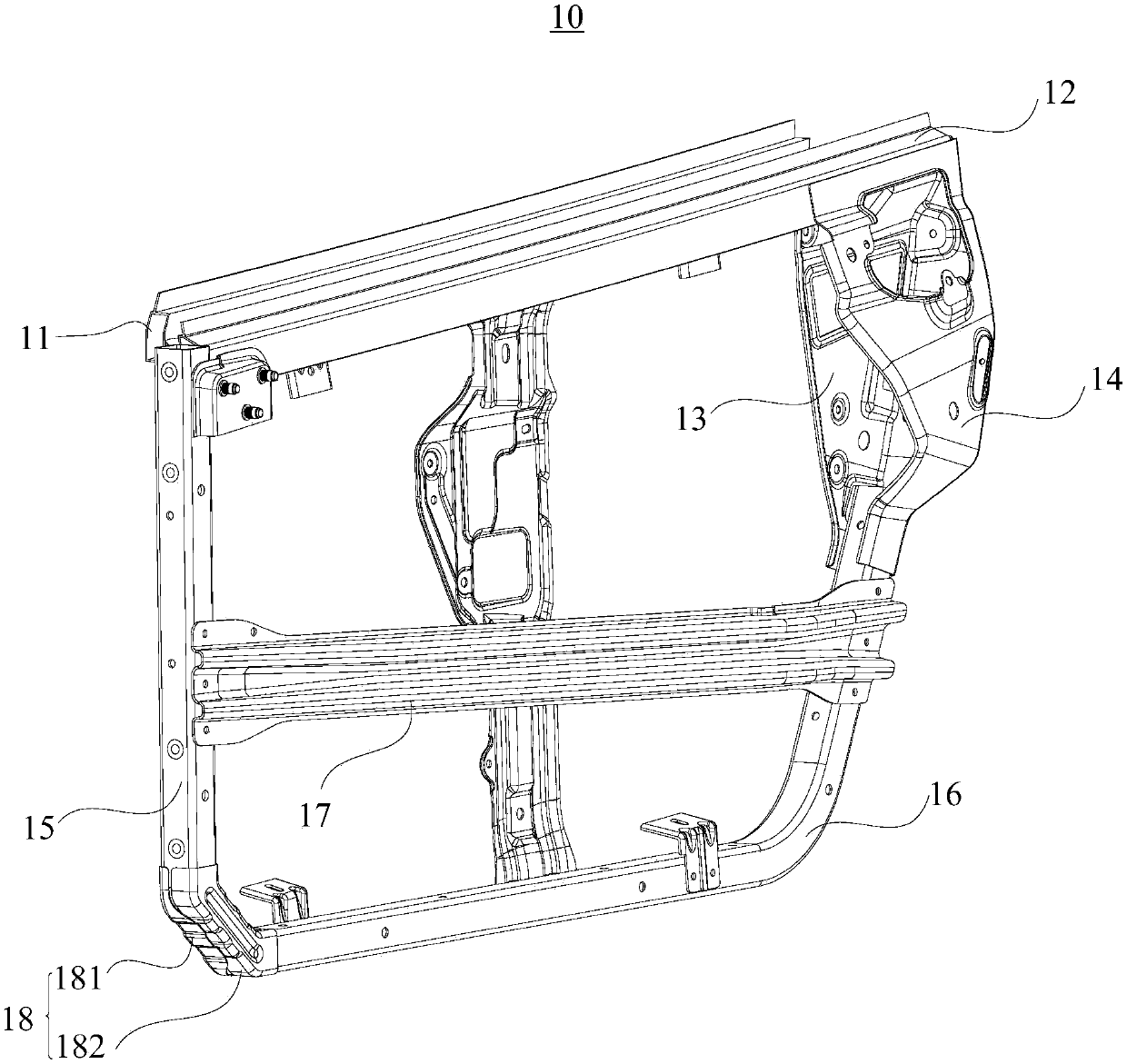

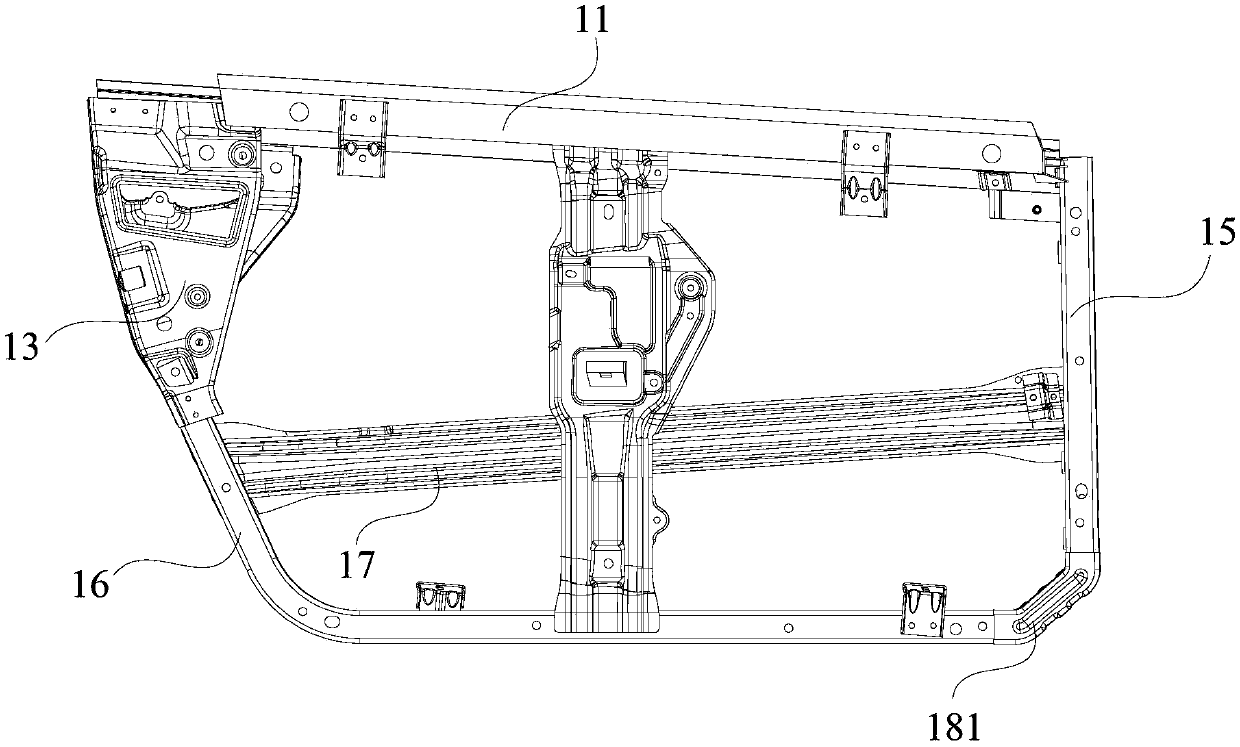

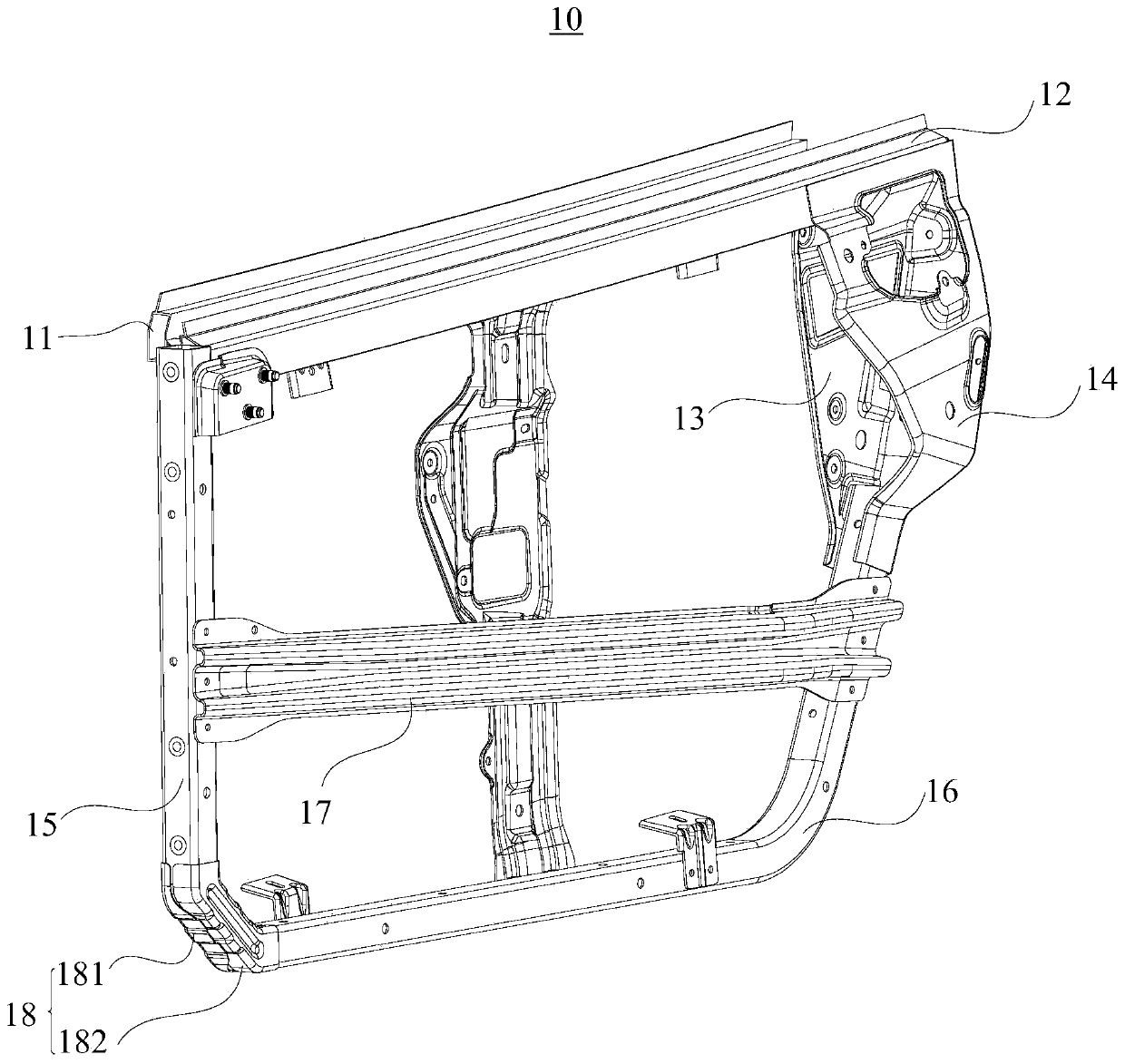

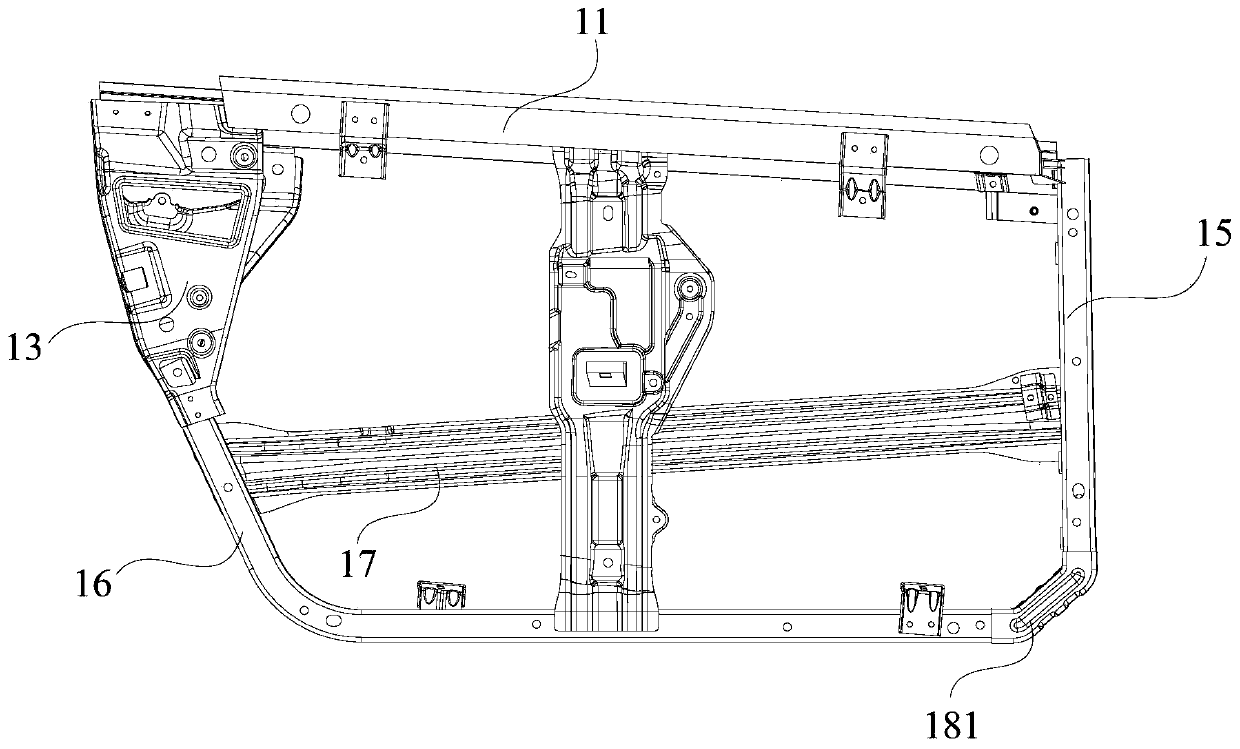

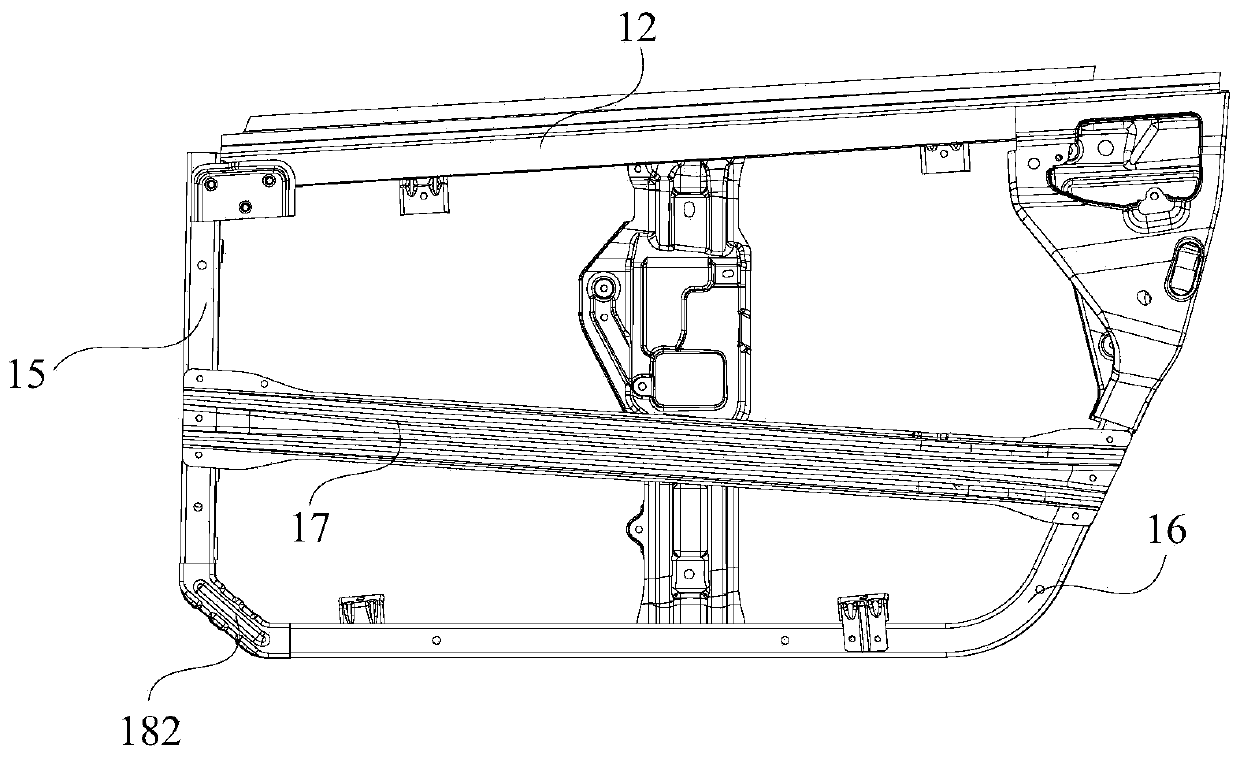

Vehicle door frame assembly of new energy automobile and new energy automobile

The invention discloses a vehicle door frame assembly of a new energy automobile and the new energy automobile. The automobile door frame assembly comprises an inner sealing strip aluminum profile, anouter sealing strip aluminum profile, an inner locking reinforcing steel plate, an outer locking aluminum profile, an automobile door framework front section aluminum profile, an automobile door framework lower rear section aluminum profile and an anti-collision steel beam. The automobile door frame assembly is made of a steel-aluminum mixed material; with the structural design of the inner sealing strip aluminum profile and the outer sealing strip aluminum profile, an upper frame of an automobile door frame is omitted, so that the weight of the automobile door frame assembly can be reduced,and the strength of the automobile door frame assembly can be ensured.

Owner:CH AUTO TECH CORP CO LTD

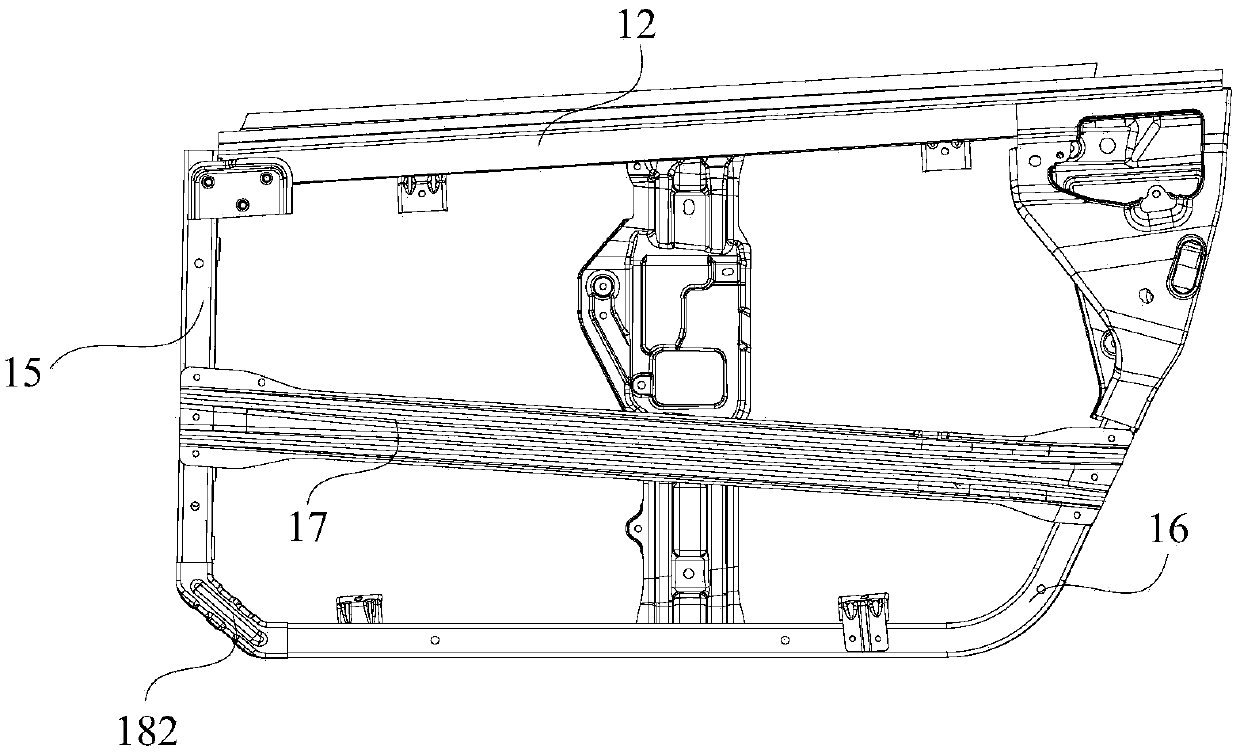

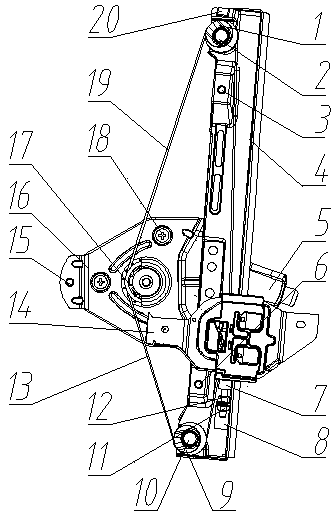

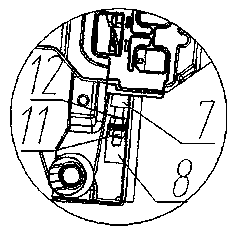

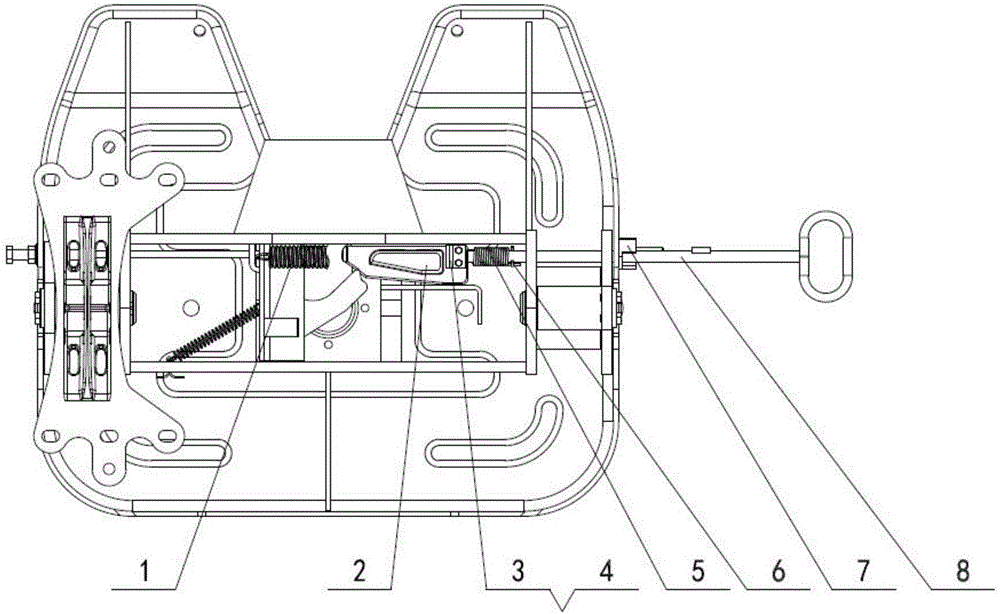

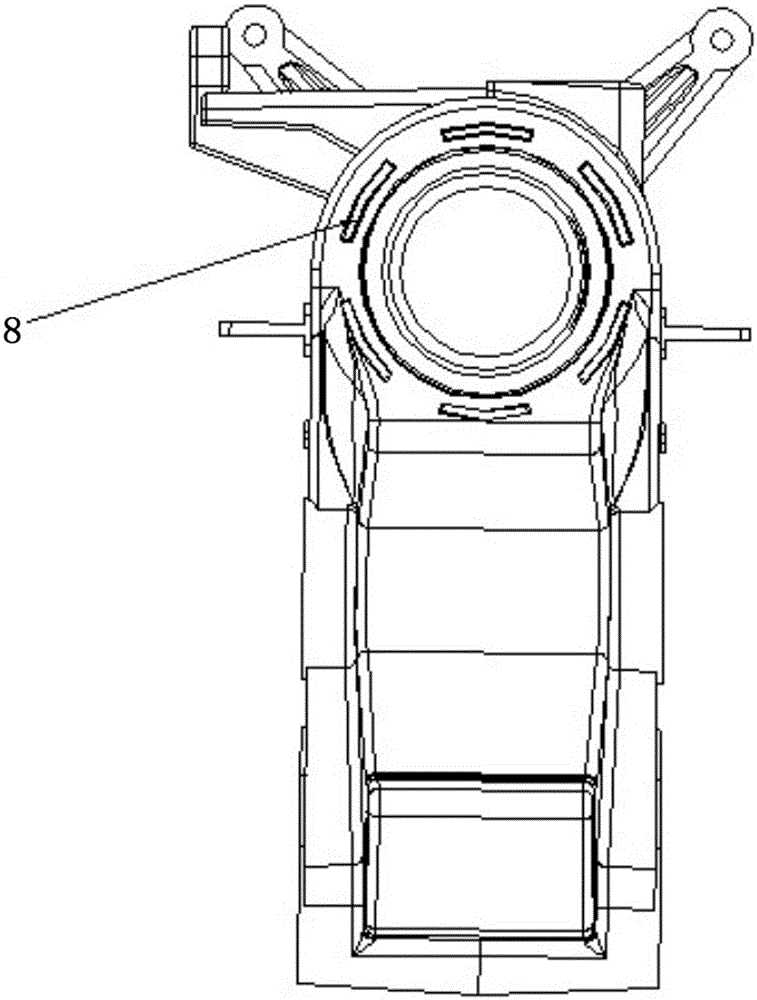

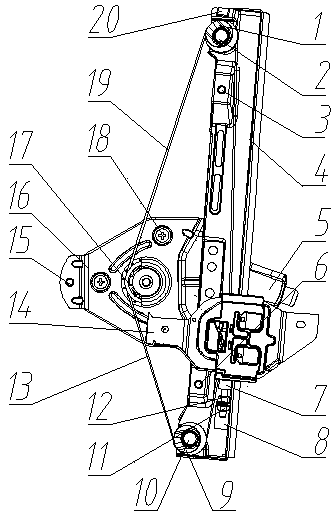

Window regulator with adjustable buffering block

The invention discloses a window regulator with an adjustable buffering block. A motor support of a motor is connected with an installing plate, a reel is installed on one side of the installing platethrough a reel rotating shaft, a guide rail support is arranged on one side of the motor support, a regulator upper fixing screw is arranged on the upper portion of the guide rail support, a regulator lower fixing screw is arranged on the lower portion of the guide rail support, a guide rail is arranged on the guide rail support, an upper guiding wheel is installed on one side of the upper end ofthe guide rail support, a lower guiding wheel is installed on one side of the lower end of the guide rail support, a sliding block is arranged on the guide rail on the guide rail support, a bottom dead center fixing support is arranged on one side of the lower guiding wheel, the bottom end of the adjustable buffering block is inserted into a fixing rack of the bottom dead center fixing support and fixed through a locking nut and an adjusting nut, the sliding block moves to the lower portion and then presses the adjustable buffering block, and an upper steel wire rope and a lower steel wire rope are wound around the reel separately and penetrate through the upper guiding wheel and the lower guiding wheel respectively to be connected with the sliding block. The problem is solved that a buffering block is easily abraded; the adjustable buffering block can effectively compensate for the abrasion of the buffering block.

Owner:周启城

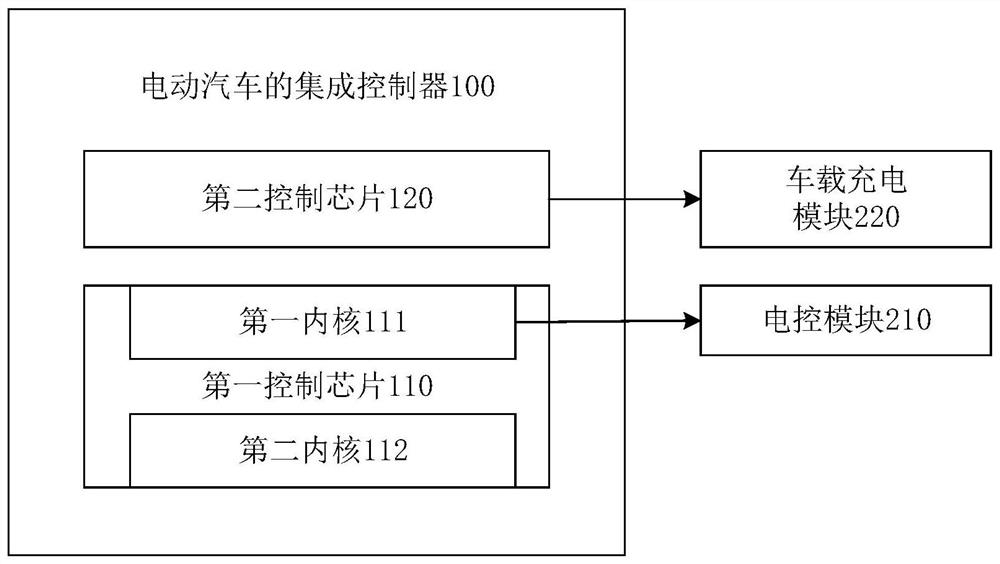

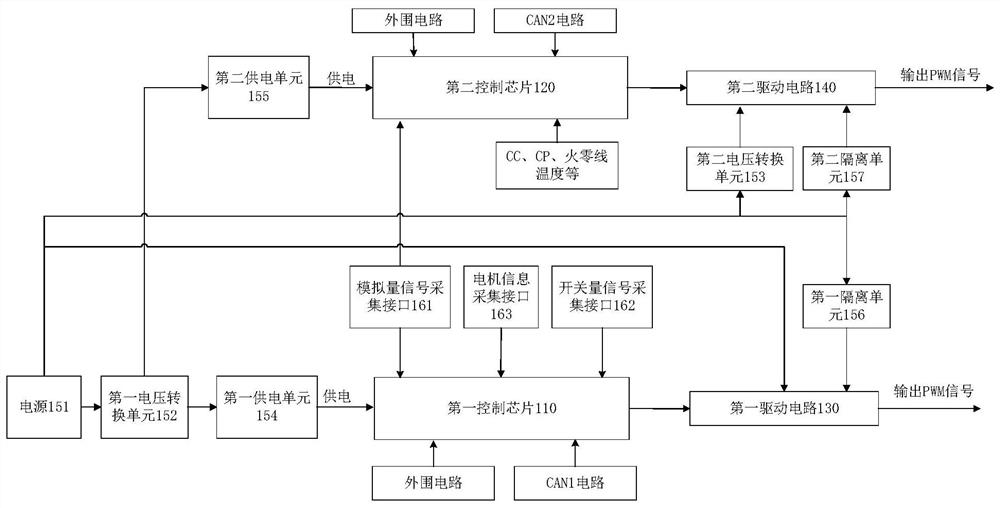

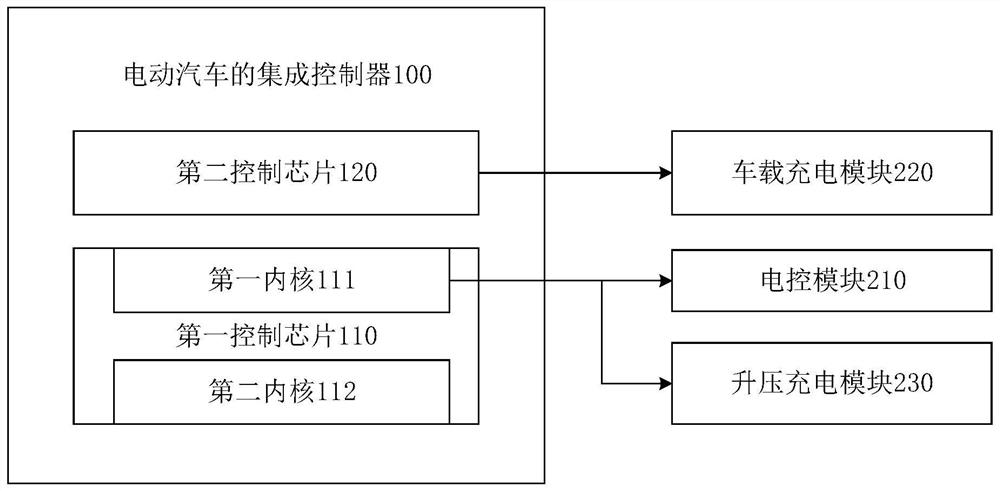

Electric automobile and integrated controller and integrated control system thereof

ActiveCN112389348AReduce usageLow costAc-dc conversionPower to auxillary motorsPower batteryIn vehicle

The invention provides an electric vehicle and an integrated controller and control system thereof, and the integrated controller comprises a first control chip which comprises a first core and a second core, wherein the first core is used for controlling an electric control module so as to drive a motor, and the second core is used as a vehicle control unit; and a second control chip which is used for controlling a vehicle-mounted charging module so as to realize alternating-current charging of the power battery by the external alternating-current power supply, or realize alternating-currentdischarging of the power battery to an external load through the alternating-current charging and discharging port. According to the integrated controller, the use of components can be reduced so thatthe cost can be reduced, the size can be reduced, and the assembly weight can be reduced.

Owner:BYD CO LTD

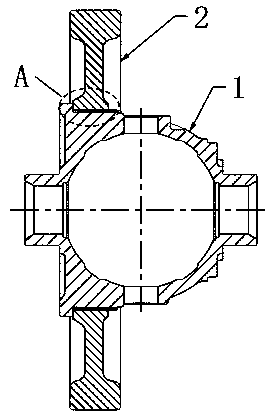

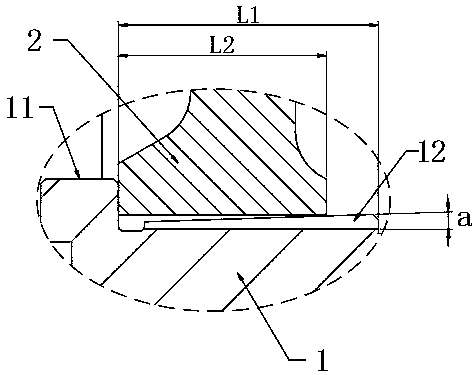

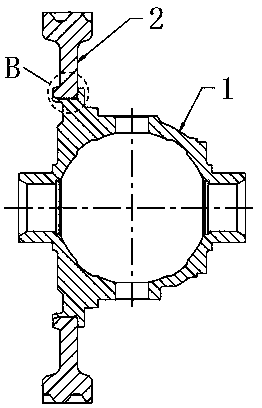

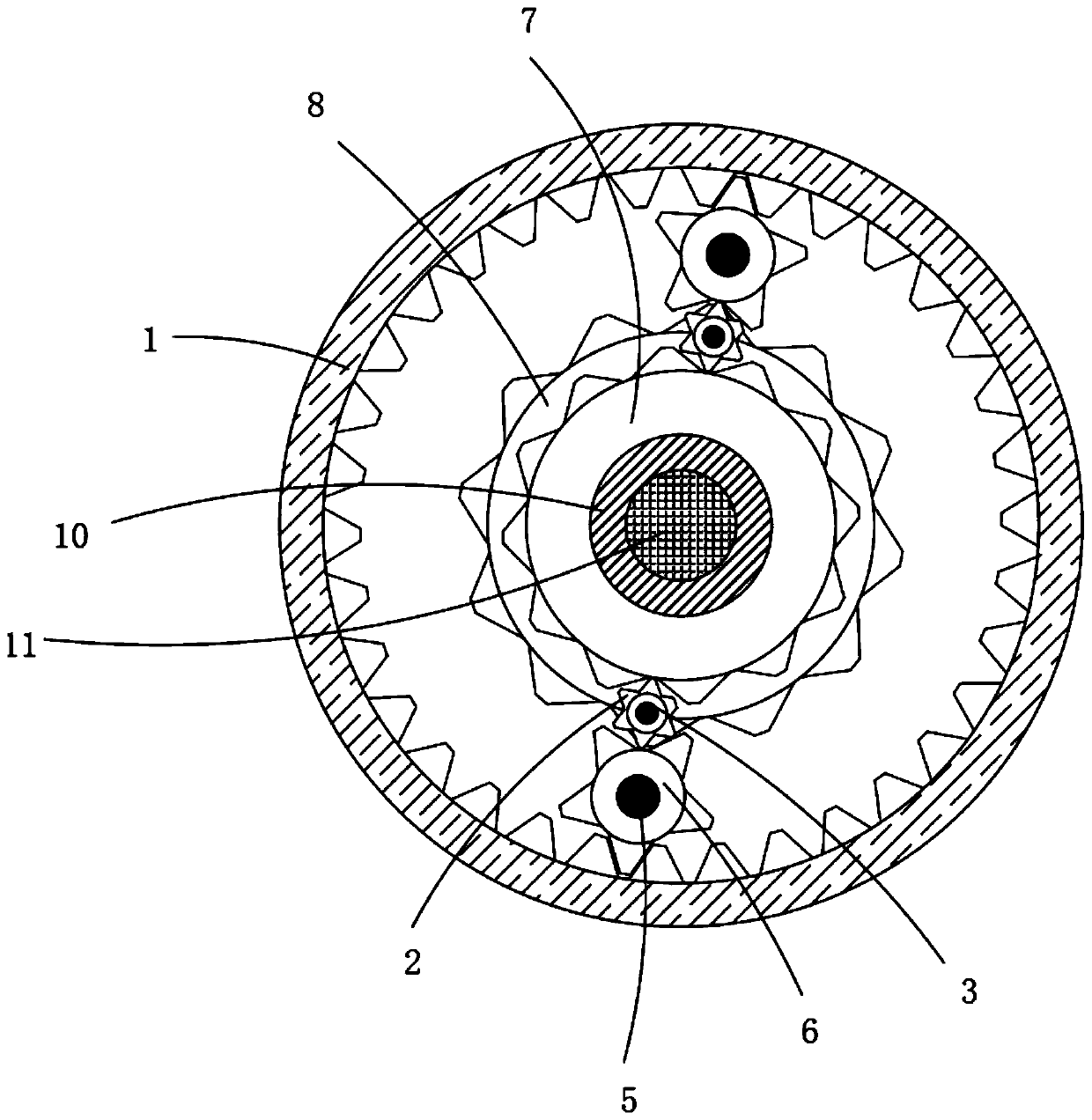

Differential mechanism shell and gear assembly

PendingCN110905989AImprove final meshing accuracyReduce processing stepsDifferential gearingsGearing detailsGear wheelClassical mechanics

The invention provides a differential mechanism shell and gear assembly, which comprises a shell, wherein the periphery of the shell is provided with a transmission gear in a sleeving mode, the periphery of the shell is provided with an external spline, the wall of a center hole of the transmission gear is provided with an internal spline, and the external spline and the internal spline form a spline connection structure for limiting circumferential rotation of the transmission gear relative to the shell; the periphery of the shell is further provided with a flange, the flange is arranged on one side of the external spline and connected with the side surface of the transmission gear in an abutting mode; the side, which is close to the flange, of the external spline is lower than the side,which is away from the flange, of the external spline, the distance L1 between the side surface of the side, which is away from the flange, of the external spline and the flange is greater than the hub width L2 of the transmission gear, and the external spline and the flange jointly act to limit axial movement of the transmission gear relative to the shell. According to the invention, through thearrangement of spline connection and cooperative use of the external spline and the flange, the existing bolt connection mode is replaced, the processing procedures are reduced, the cost and the assembly weight are reduced, and the actual meshing precision of the gear is improved through gear grinding after spline connection.

Owner:双环传动(重庆)精密科技有限责任公司

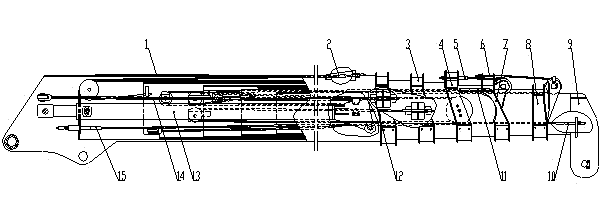

Saddle with separation and connection mechanism being operated in straight-pull and rotation modes

InactiveCN106114657ASimplify detached joinsReduced assembly weightTractor-trailer combinationsStraight pullProcess capability

The invention discloses a saddle for operating a separation and coupling mechanism in a straight-pull rotation mode, which includes a housing, a tension spring is installed in the middle of the housing, the tension spring is connected with the tension spring seat, and the tension spring seat is fixed by a hexagon head bolt On the shell; a wedge is installed on the tension spring seat; a round hole is opened on the head of the hexagonal head bolt, one end of the torsion spring is connected with the hexagonal head bolt through the round hole, and the other end of the torsion spring is connected with the handle rod assembly; The right end of the spring is provided with a torsion spring fixing pin, and the torsion spring is fixed inside the housing through the torsion spring fixing pin; a pin hole is opened on the housing, and the handle rod assembly passes through the pin hole, and the gap between the handle rod assembly and the pin hole There are limit stops. The invention is simple in structure and reasonable in design, simplifies the separation and connection mechanism of the saddle, and can save a large amount of steel materials; the auxiliary consumption of welding seams and the like is reduced, the number of parts is reduced, the process capability is improved, and the production cost is greatly reduced; the action principle of the mechanism is improved , which improves stability.

Owner:DONGFENG SPECIAL PURPOSE VEHICLE

Electric drive axle, axle structure and automobile

The embodiment of the invention provides an electric drive axle, an axle structure and an automobile, and relates to the field of automobiles. The electric drive axle comprises a planetary gear speedreduction mechanism, a first gear mechanism, a second gear mechanism and a gear shifting mechanism, wherein the planetary gear reducing mechanism is in transmission connection with a driving motor; the first gear mechanism and the second gear mechanism are located on the two sides of the planetary gear speed reduction mechanism respectively and are in transmission connection with the planetary gear speed reduction mechanism respectively, and the gear shifting mechanism is selectively connected with the first gear mechanism and the second gear mechanism and used for enabling the first gear mechanism or the second gear mechanism to be in transmission connection with the output end. The structure of the electric drive axle has the characteristics of small size and light weight, the assembly efficiency can be improved, and the assembly weight and cost are reduced.

Owner:DONGFENG DANA AXLE

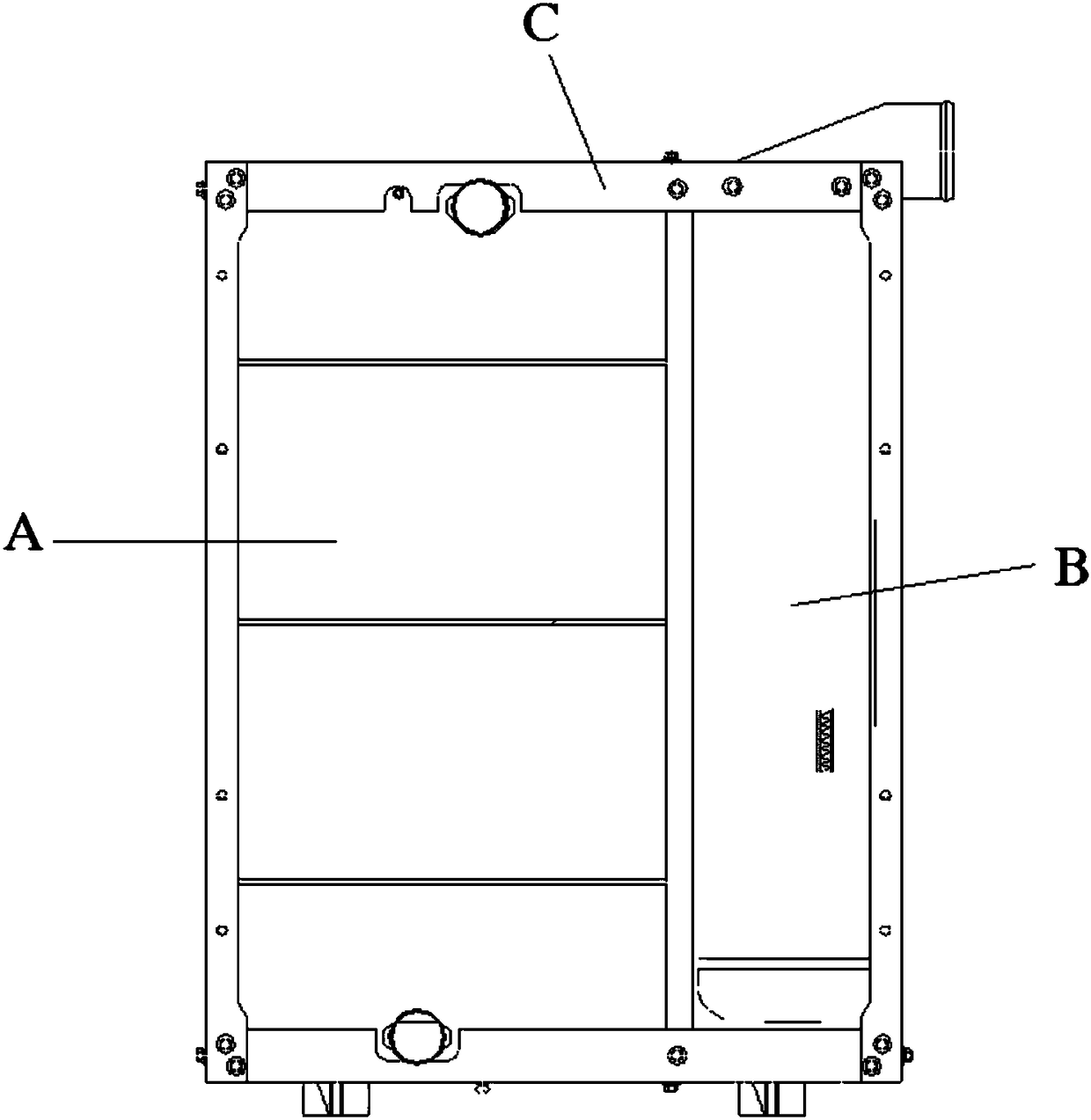

Efficient integrated-type automobile radiator assembly structure

PendingCN108119224ASave labor timeEasy to disassembleInternal combustion piston enginesIndirect heat exchangersFlangingIntercooler

The invention relates to an efficient integrated-type automobile radiator assembly structure. The efficient integrated-type automobile radiator assembly structure comprises a framework, an intercoolerand a radiator. The radiator comprises a radiator core, a water inlet chamber with a water inlet and a water outlet chamber with a water outlet. The radiator core is located between the water inlet chamber and the water outlet chamber and further comprises main blades, radiating pipes and a radiating belt. The intercooler and the radiator are arranged inside the framework in parallel. Flat pipesare adopted as the radiating pipes. Compared with the prior art, the arrangement mode of the intercooler and the radiator is changed into a side-by-side arrangement structure from an original front-back overlapping structure; however, the thickness is reduced, the heat radiating performance is improved, wind resistance is reduced, and space occupancy is decreased; by adoption of the flatter and wider radiating pipes, the laminar flow phenomenon of inner cooling liquid is reduced, and heat can be better transferred to the radiating belt from the pipe wall; and the water chambers are made of copper plates with the thicknesses being larger than 1mm, the flanging heights of the main blades and radiating pipe welding holes are increased, and the leakage condition of the four corners of the radiator can be effectively reduced.

Owner:SHANGHAI SUNLONG BUS

Manufacturing method of automotive atmosphere ceiling

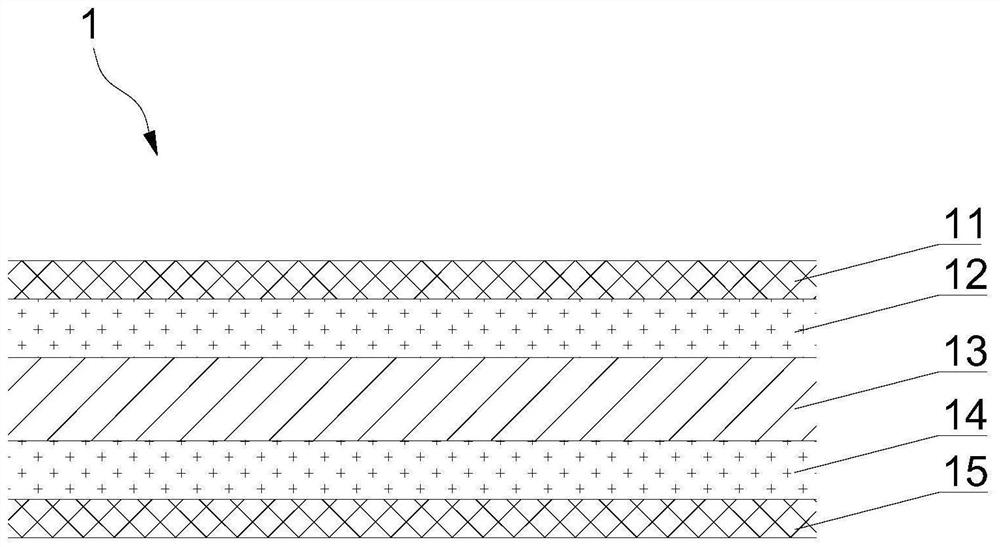

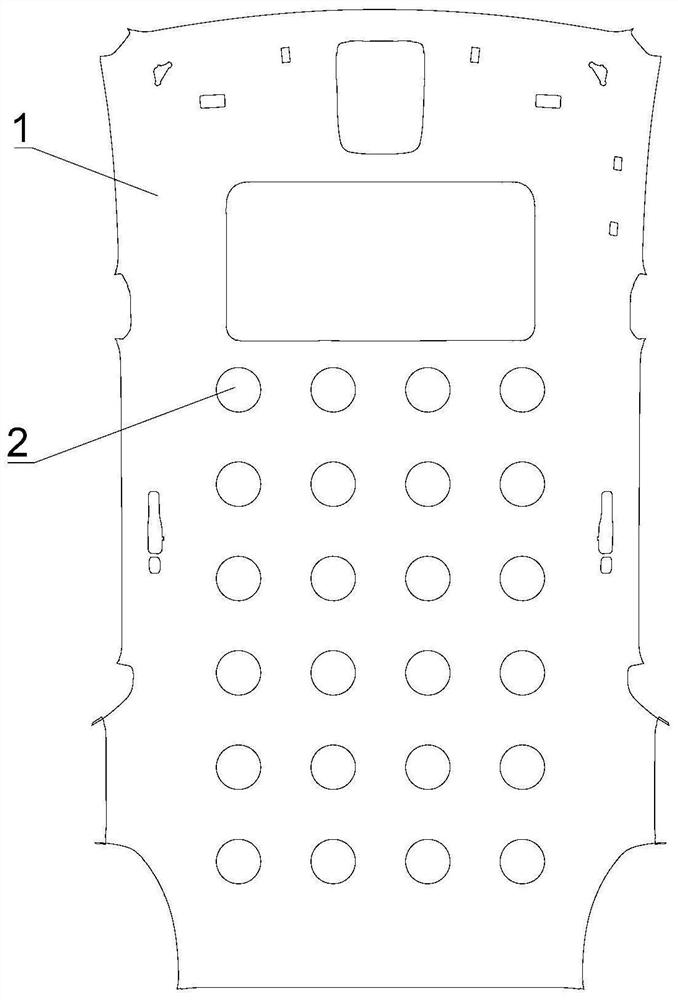

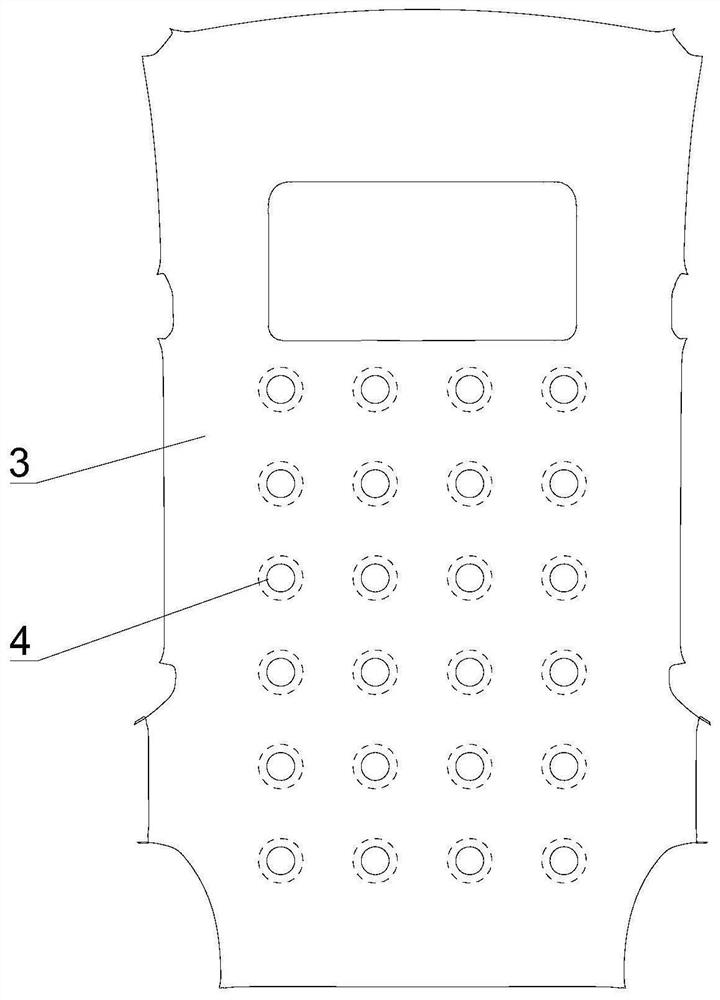

PendingCN112606521ALow priceIncrease the weight of the canopyLamination ancillary operationsLayered product treatmentLight sourceManufacturing engineering

The invention discloses a manufacturing method of an automotive atmosphere roof. The manufacturing method comprises the following steps: forming a roof base material; punching the base material to obtained punched holes with a needed number, needed sizes and needed formation; attaching a ceiling fabric to the front surface of the base material; assembling a light source on the back face of the base material, and allowing light to penetrate through the holes of the base material to present atmosphere effect. According to the manufacturing method of the automotive atmosphere ceiling, atmosphere lamp effect is created by means of automatic equipment punching and the cooperative back light source on the premise that the weight of the automotive ceiling assembly is not increased; and through the changes of the back light source, dynamic ornamental effect can be presented.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

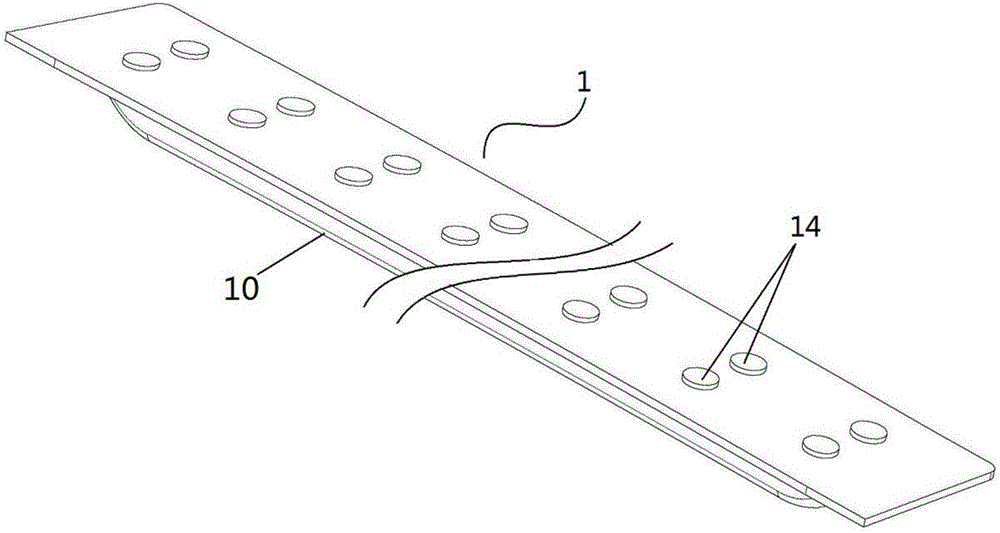

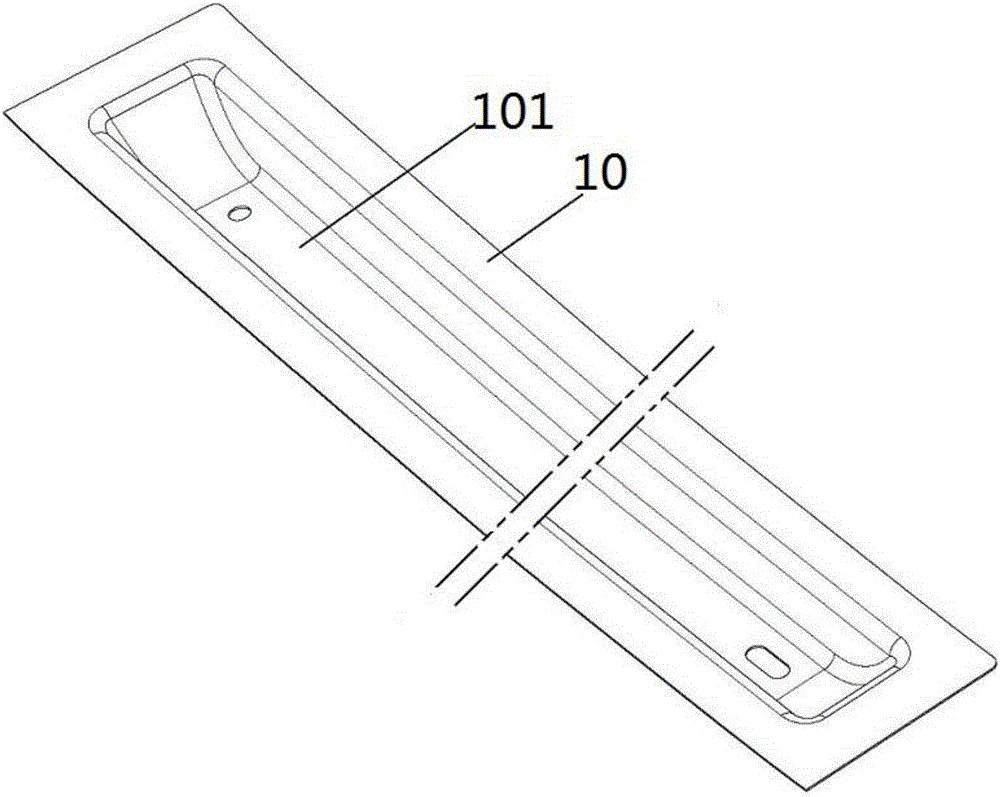

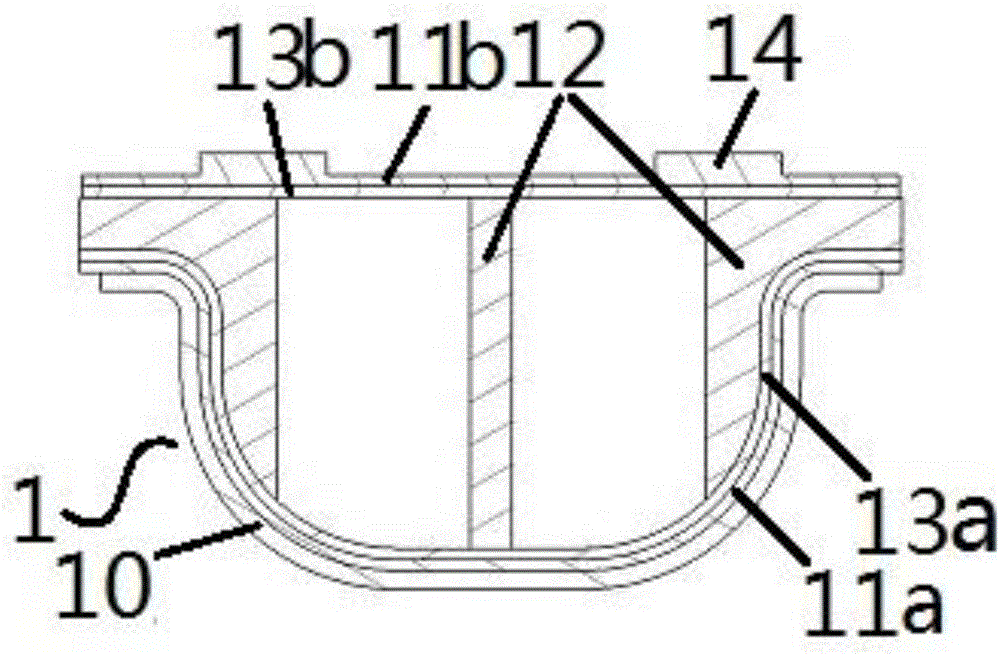

Glass reinforcing plate for automobile skylight and skylight assembly and automobile

The invention discloses a glass reinforcing plate for an automobile skylight and a skylight assembly with same and an automobile. The glass reinforcing plate comprises a molding thin plate. A U-shaped groove is molded in the middle of the molding thin plate in the longitudinal direction. A honeycomb paper core is arranged inside the U-shaped groove in the longitudinal direction of the groove. A first glass fiber layer and a first PU layer are arranged at the lower end of the honeycomb paper core in a padded mode and connected with the molding thin plate into a whole. The upper end of the honeycomb paper core is covered with a second PU layer and a second glass fiber layer in sequence from top to bottom, and the second PU layer and the second glass fiber layer are connected with the molding thin plate into a whole. The glass reinforcing plate is of a sheet-shaped structure provided with the PU layer, the glass fiber layer, the honeycomb paper core, the glass fiber layer and the PU layer from top to bottom in sequence, the weight of the reinforcing plate is lowered, the strength and the rigidity of the reinforcing plate are greatly improved by covering the upper and lower ends of the honeycomb paper core with the glass fiber layers, the glass reinforcing plate has the advantages of being low in weight and high in strength and rigidity, and the automobile adopting the automobile skylight with the reinforcing plate is low in overall weight and small in energy consumption.

Owner:英纳法企业管理(上海)有限公司

Production method of automobile engine hatch assembly

ActiveCN103331581BReduced assembly weightMeet the requirements of lightweight designMiniaturizationWork in process

Owner:WUXI GISSING AUTO PARTS CO LTD

Axial riveting clamping structure and clamping process

The invention discloses an axial riveting and clamping structure and a clamping process thereof. A steering spindle penetrates through a steering column tube through an upper bearing and a lower bearing; the outer ring of the lower bearing is in interference fit with the steering column tube; a stepped groove is processed on the inner surface of the steering column tube and is used for positioning the lower bearing. The axial length size of the shaft is changed along with temperature, so that the upper bearing is not positioned axially and has a free design. Because the clamping effect caused by the interference fit is not reliable enough, multiple grooves are formed on the circumference at the tail end of the steering column tube, and the grooves are extruded by using a riveting machine, so that the lower bearing is riveted and is firmly clamped, and the service performance can be guaranteed in a vibrating environment and the like. The parts are prevented from being tightened by adding the parts, the cost can be saved, and the structure is simple.

Owner:青岛即东汽车零部件有限公司

Door frame assembly of new energy vehicles and new energy vehicles

The invention discloses a vehicle door frame assembly of a new energy automobile and the new energy automobile. The automobile door frame assembly comprises an inner sealing strip aluminum profile, anouter sealing strip aluminum profile, an inner locking reinforcing steel plate, an outer locking aluminum profile, an automobile door framework front section aluminum profile, an automobile door framework lower rear section aluminum profile and an anti-collision steel beam. The automobile door frame assembly is made of a steel-aluminum mixed material; with the structural design of the inner sealing strip aluminum profile and the outer sealing strip aluminum profile, an upper frame of an automobile door frame is omitted, so that the weight of the automobile door frame assembly can be reduced,and the strength of the automobile door frame assembly can be ensured.

Owner:CH AUTO TECH CORP CO LTD

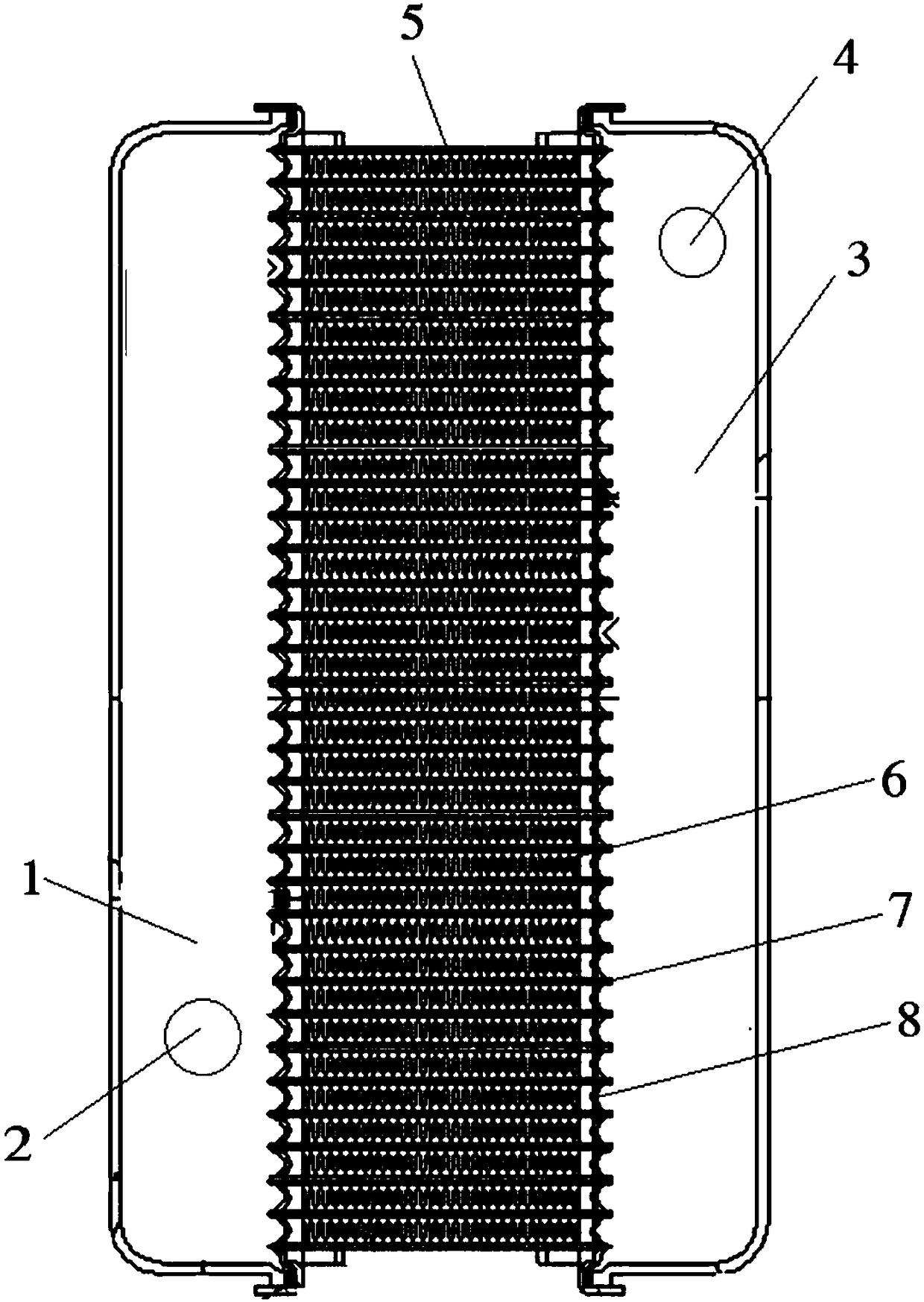

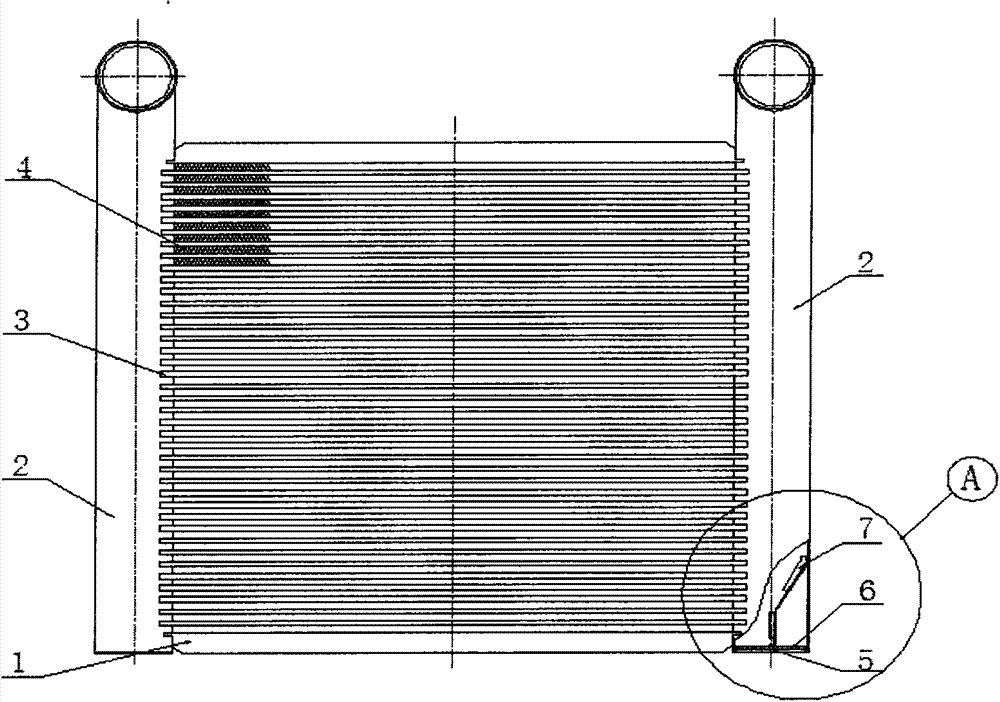

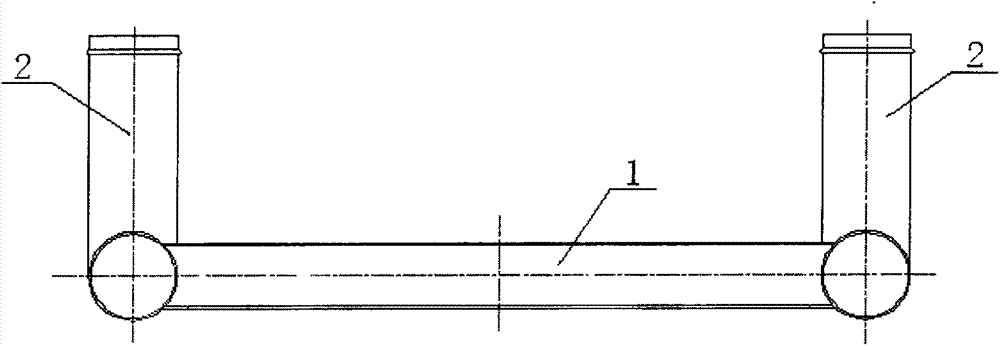

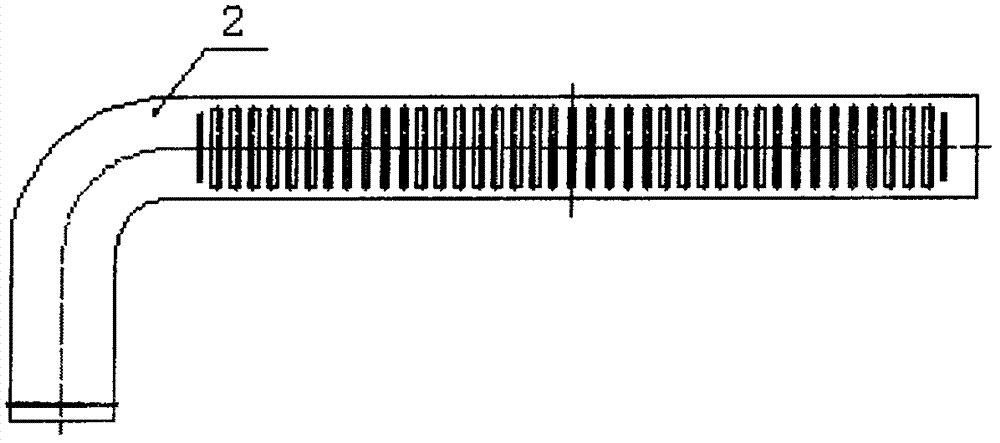

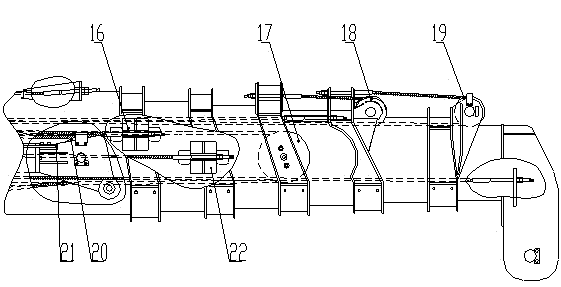

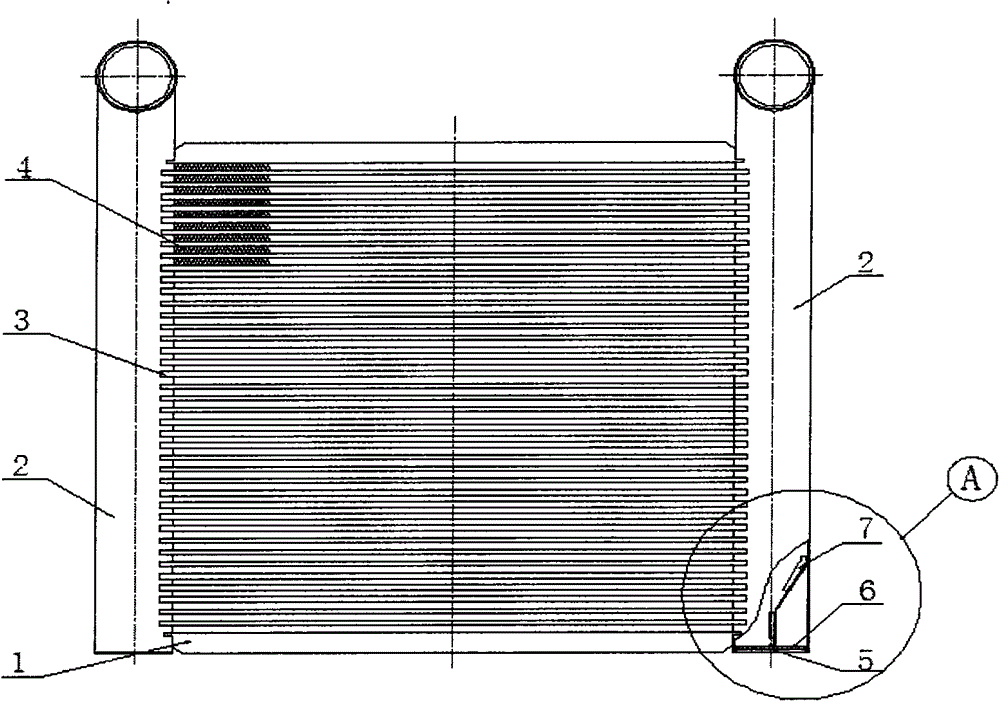

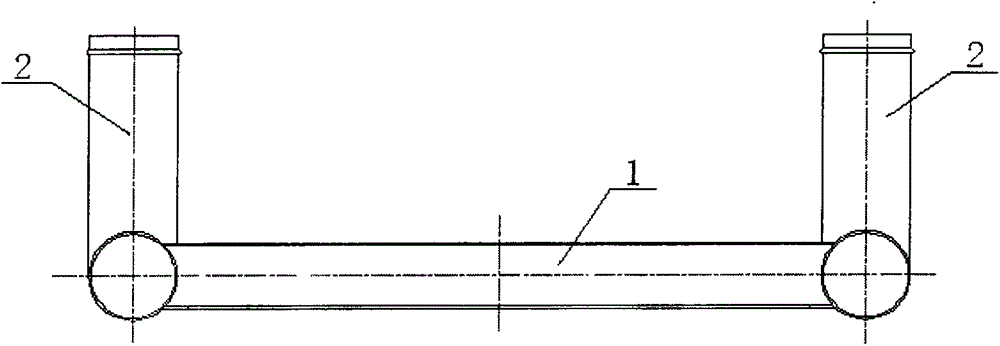

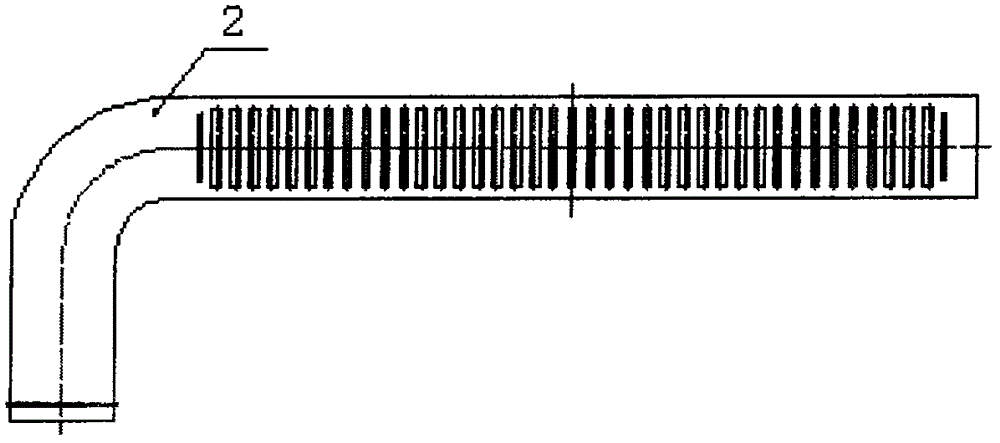

Circular tube air chamber automobile intercooler

ActiveCN104329159ASimple structureShorten the production process routeInternal combustion piston enginesNitrogenIntercooler

The invention discloses a circular tube air chamber automobile intercooler. The circular tube air chamber automobile intercooler adopts aluminum circular tubes to make an air chamber which replaces a cast air chamber and a main piece in an original intercooler. One end of a circular tube air chamber (2) is bent to form a required angle; the bent part serves as an air inlet and outlet section; a straight line part serves as an air chamber section; a mounting hole for a cooling tube (3) and a mounting hole for a side plate (1) are machined in regulated positions on the air chamber section, so that the air chamber section also has the function of a main piece; cooling tubes (3) and side plates (1) are installed in prefabricated holes of left and right circular tube air chambers (2); heat dissipation straps are installed between the cooling tubes (3) and between the cooling tubes (3) and the side plates (1); the other end of the circular tube air chamber (2) is plugged through a blocking cap (6); a guide plate (7) is installed at the tail of the circular tube air chambers (2). An assembled intercooler is fixed through a special clamp, brazing is accomplished in a nitrogen protection brazing furnace, and the clamp is removed after the intercooler is discharged from the furnace, so that the manufacture of an intercooler assembly is accomplished.

Owner:李政

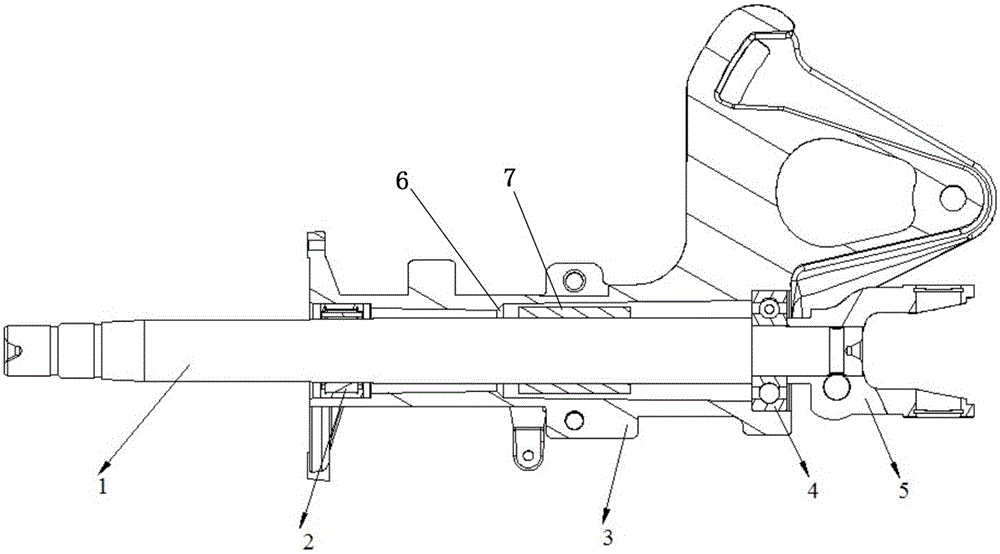

Base-free brake pedal structure

The invention provides a base-free brake pedal structure. The base-free brake pedal structure comprises a front panel, a pedal arm and a booster. The pedal arm is hinged to the booster at the position of the middle structure, and the booster is fixed to the lower portion of the front panel. A support is further included. The support is fixed on the front panel and is positioned above the booster. The upper end of the pedal arm is hinged to the support. Through structural optimization and innovation, a brake pedal base is omitted, and the pedal arm is directly assembled on the automobile front panel, so that on the premise that functionality is not affected, the part complexity is greatly reduced, the assembly weight is reduced, variables are reduced, the generalization rate is increased, meanwhile, the development period is shortened, and the part cost is reduced.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

Heavy transmission shaft middle bracket assembly with rubber vulcanized on bearing outer ring

PendingCN112519573AReduced assembly weightLower assembly costsNon-rotating vibration suppressionControl devicesInterference fitBall bearing

The invention discloses a heavy transmission shaft middle bracket assembly with rubber vulcanized on a bearing outer ring, and relates to the field of middle support assemblies; the heavy transmissionshaft middle bracket assembly comprises a fixed support and a ball bearing, the outer ring of the ball bearing is vulcanized with a rubber buffer pad at a low temperature, so that the ball bearing and the rubber buffer pad form an integrated structure; and the ball bearing is directly mounted and fixed with the fixed support through the rubber buffer pad. The heavy transmission shaft middle bracket assembly has the beneficial effects that the machining and assembling procedures of three parts, namely a bearing seat and a snap ring, are reduced, the assembling period is shortened, and the partproduction procedure is simplified; the weight of the middle support assembly is reduced, and the cost of the middle support assembly is reduced; the rubber buffer pad and the bearing are of an integrated structure, interference fit does not exist between the bearing and the rubber buffer pad, the working clearance of the bearing can be effectively controlled, the service life is prolonged, the bearing is reliably fixed, and the bearing is prevented from being disengaged from the rubber buffer pad.

Owner:WANXIANG QIANCHAO TRANSMISSION SHAFT +1

A glass lifter with adjustable buffer block

InactiveCN108894651BAchieve closureNot easy to wearPower-operated mechanismElectric machineryEngineering

The invention discloses a window regulator with an adjustable buffering block. A motor support of a motor is connected with an installing plate, a reel is installed on one side of the installing platethrough a reel rotating shaft, a guide rail support is arranged on one side of the motor support, a regulator upper fixing screw is arranged on the upper portion of the guide rail support, a regulator lower fixing screw is arranged on the lower portion of the guide rail support, a guide rail is arranged on the guide rail support, an upper guiding wheel is installed on one side of the upper end ofthe guide rail support, a lower guiding wheel is installed on one side of the lower end of the guide rail support, a sliding block is arranged on the guide rail on the guide rail support, a bottom dead center fixing support is arranged on one side of the lower guiding wheel, the bottom end of the adjustable buffering block is inserted into a fixing rack of the bottom dead center fixing support and fixed through a locking nut and an adjusting nut, the sliding block moves to the lower portion and then presses the adjustable buffering block, and an upper steel wire rope and a lower steel wire rope are wound around the reel separately and penetrate through the upper guiding wheel and the lower guiding wheel respectively to be connected with the sliding block. The problem is solved that a buffering block is easily abraded; the adjustable buffering block can effectively compensate for the abrasion of the buffering block.

Owner:周启城

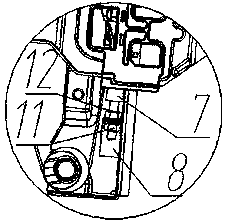

Lightweight balance shaft assembly

InactiveCN104943474AReduce weightReduce half shaft weightAxle unitsWheel-axle combinationsBalance shaftVehicle frame

The invention relates to a lightweight balance shaft assembly. The two edges of a vehicle frame are erected between a left triangular support and a right triangular support. The outer side of the left triangular support and the outer side of the right triangular support are provided with a left bearing hub assembly and a right bearing hub assembly. An outer ring of a left half shaft in the left bearing hub assembly and an outer ring of a right half shaft in the right bearing hub assembly are provided with a left bearing hub and a right bearing hub respectively. The outer side of the left bearing hub assembly and the outer side of the right bearing hub assembly are fixed through a left end cover and a right end cover respectively. The mode that double sealing is conducted on the inner side and outer side of oil seal and left and right sealing rings is adopted for sealing of the left bearing hub assembly and the right bearing hub assembly. The left half shaft outside the left bearing hub and the right half shaft outside the right bearing hub are further provided with nonmetal linings respectively to form a self-lubricating structure. The lightweight balance shaft assembly has stability and guarantees lightweight implementation so that the transmission shaft movement space can be increased, the lightweight balance shaft assembly is simple in structure, low in cost and light in weight, the structure is simplified, and the manufacturing difficulty is lowered.

Owner:星源(十堰)悬架有限公司

Single cylinder synchronous expansion and contraction device with multiple sets of inhaul cables for lorry-mounted crane

Owner:XCMG XUZHOU TRUCK MOUNTED CRANE +1

Round tube air chamber car intercooler

ActiveCN104329159BSimple structureShorten the production process routeInternal combustion piston enginesIntercoolerNitrogen gas

The invention discloses a circular tube air chamber automobile intercooler. The circular tube air chamber automobile intercooler adopts aluminum circular tubes to make an air chamber which replaces a cast air chamber and a main piece in an original intercooler. One end of a circular tube air chamber (2) is bent to form a required angle; the bent part serves as an air inlet and outlet section; a straight line part serves as an air chamber section; a mounting hole for a cooling tube (3) and a mounting hole for a side plate (1) are machined in regulated positions on the air chamber section, so that the air chamber section also has the function of a main piece; cooling tubes (3) and side plates (1) are installed in prefabricated holes of left and right circular tube air chambers (2); heat dissipation straps are installed between the cooling tubes (3) and between the cooling tubes (3) and the side plates (1); the other end of the circular tube air chamber (2) is plugged through a blocking cap (6); a guide plate (7) is installed at the tail of the circular tube air chambers (2). An assembled intercooler is fixed through a special clamp, brazing is accomplished in a nitrogen protection brazing furnace, and the clamp is removed after the intercooler is discharged from the furnace, so that the manufacture of an intercooler assembly is accomplished.

Owner:李政

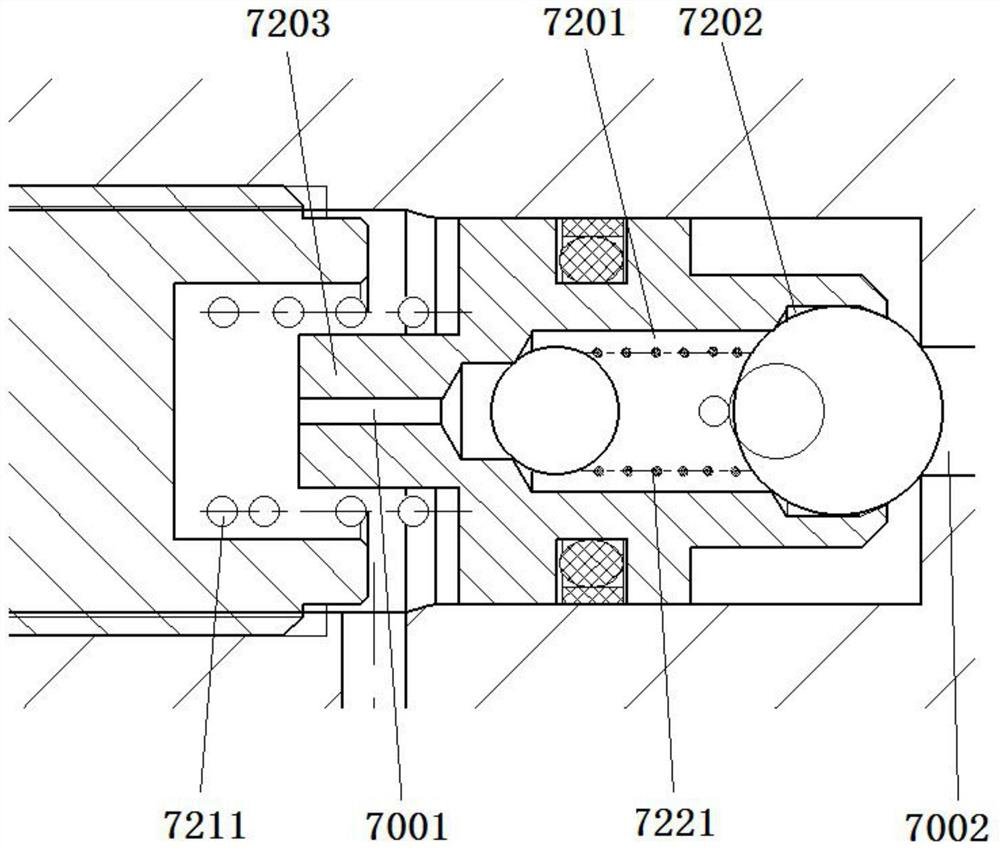

Two-planetary gear mechanism

PendingCN111120594AReduced assembly weightReduce manufacturing costToothed gearingsGear wheelEngineering

Owner:HANTENG AUTOMOBILE CO LTD

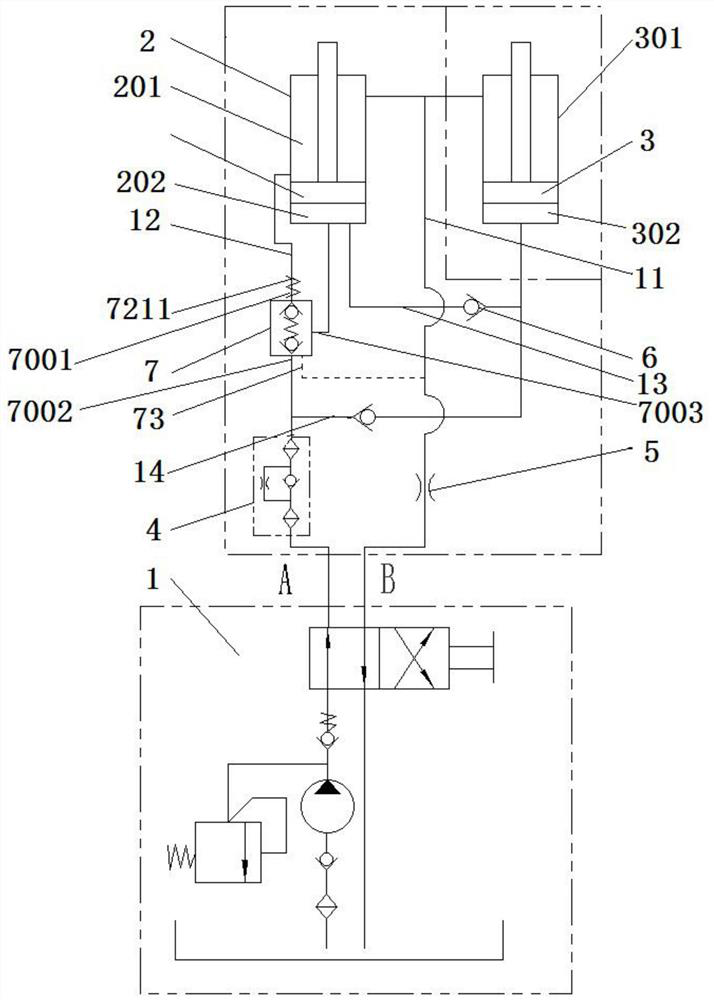

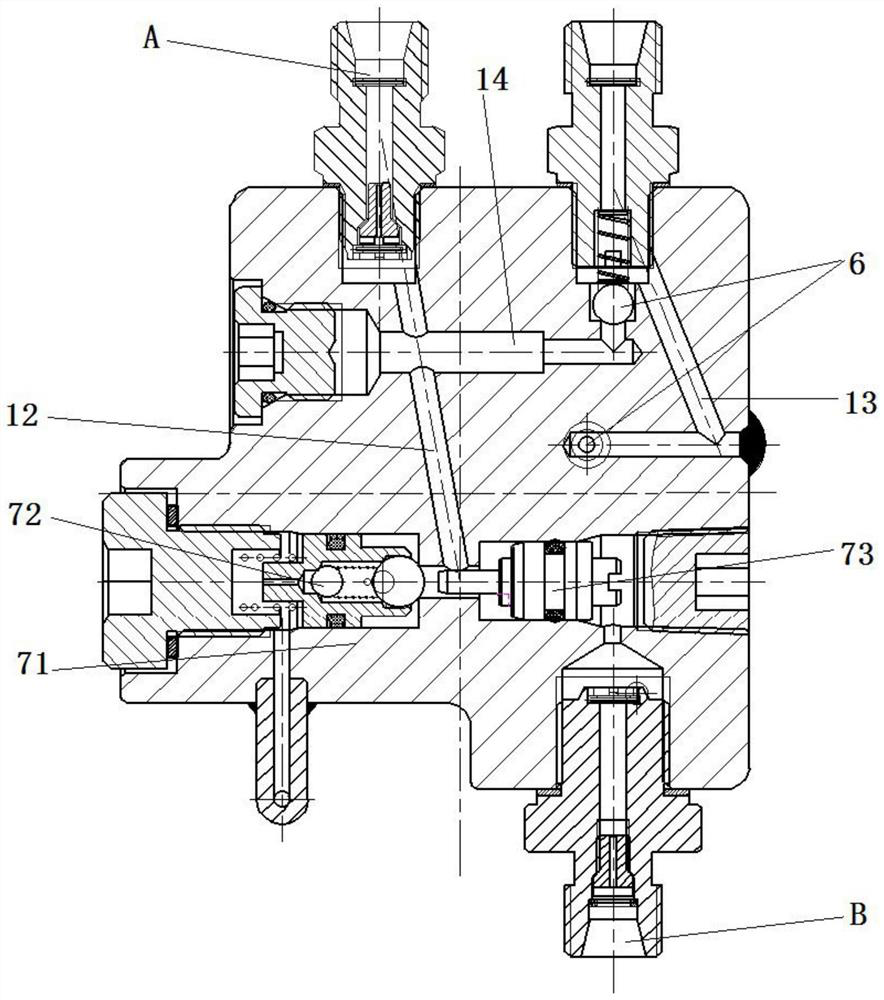

Non-differential follow-up synchronous double-cylinder lifting mechanism

InactiveCN111608978AMeet comfort requirementsGood technical effectServomotor componentsServomotorsLarge applicationsOil pump

The invention relates to the field of lifting devices, and discloses a non-differential follow-up synchronous double-cylinder lifting mechanism. The lifting mechanism comprises an oil pump (1), a reversing valve (10), a main oil cylinder (2), an auxiliary oil cylinder (3), a first oil circuit (11) and a second oil circuit (12), a main upper cavity (201) and an auxiliary upper cavity (301) communicate with each other and are connected to an outer joint A of the reversing valve (10) through the first oil circuit (11), and a main lower cavity (202) of the main oil cylinder (2) and an auxiliary lower cavity (302) of the main oil cylinder (2) communicate with each other and are connected to another outer joint B of the reversing valve (10) through the second oil circuit (12). The non-differential double-cylinder linkage follow-up design structure is adopted, the product assembly weight is reduced, meanwhile, the synchronous stable work of the lifting / falling process of a cab is realized, and the comfort requirement at the vehicle travelling state is met; and the non-differential follow-up synchronous double-cylinder lifting mechanism has the characteristics of simple structure, low cost, high production efficiency and safety and reliability, and a large application and popularization market is achieved.

Owner:ZHEJIANG KELI VEHICLE CONTROL SYST

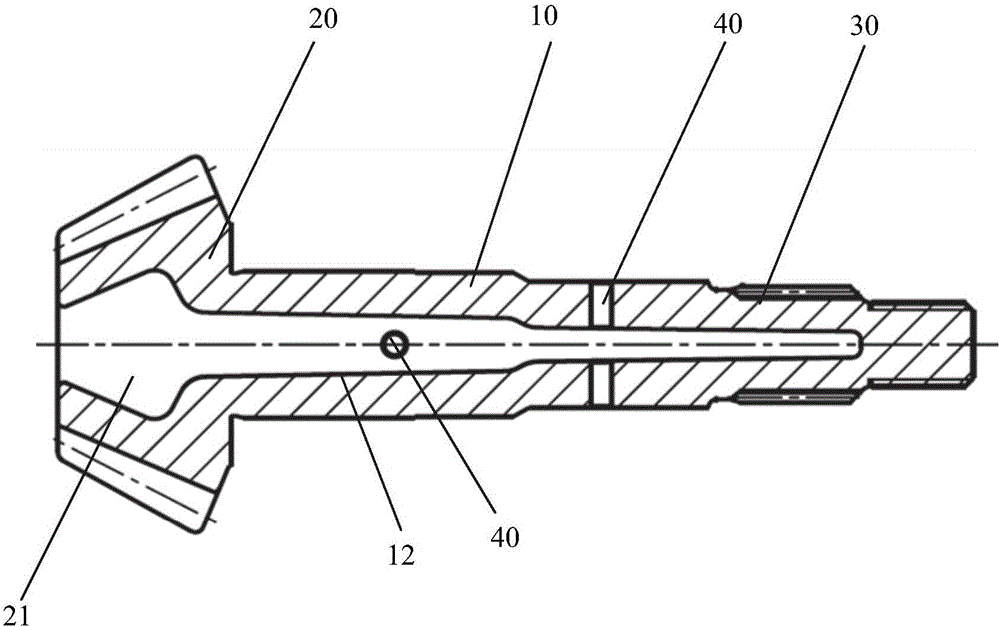

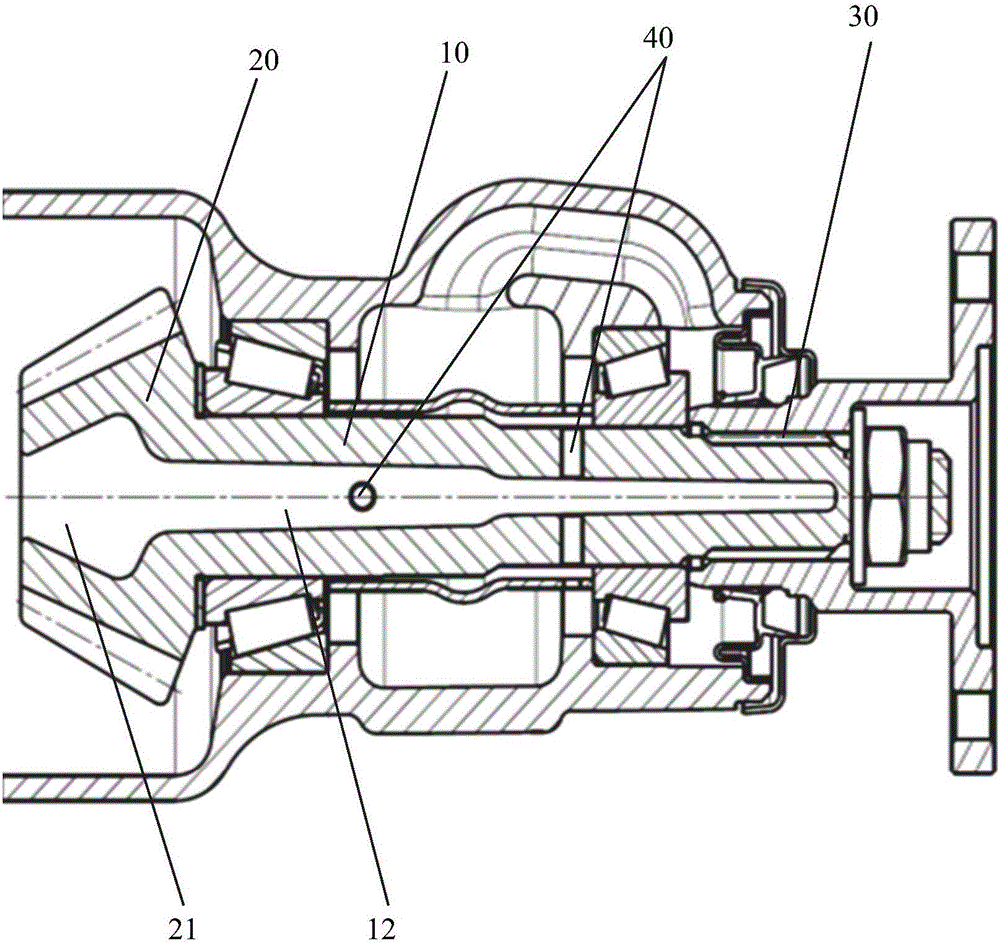

Driving gear hollow mechansim

InactiveCN106286765AReduce weightReduce material costsShaftsPortable liftingEngineeringMechanical engineering

The invention provides a driving gear hollow mechanism. The driving gear hollow mechanism comprises a driving gear and a gear shaft. The driving gear is connected to one end of the gear shaft. A through hollow structure is arranged in the middle of the driving gear and extends along the middle of the gear shaft to the position close to the other end of the gear shaft. According to the driving gear hollow mechanism, the hollow structure is adopted in the middle, and the weight and material cost of a component can be greatly lowered; furthermore, the weight of an assembly is lowered; and fuel oil economical efficiency of a finished automobile is improved.

Owner:SHANGHAI HUIZHONG AUTOMOTIVE MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com