Manufacturing method of automotive atmosphere ceiling

A production method and technology of the roof, which is applied in chemical instruments and methods, vehicle parts, lamination auxiliary operations, etc., can solve the problems of optical fiber affecting the roof rigidity, waste of labor, irregular trimming, etc., and achieve design operability Strong, increase the weight of the canopy, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0024] This embodiment provides a method for manufacturing an atmosphere roof for a vehicle, which includes the following steps:

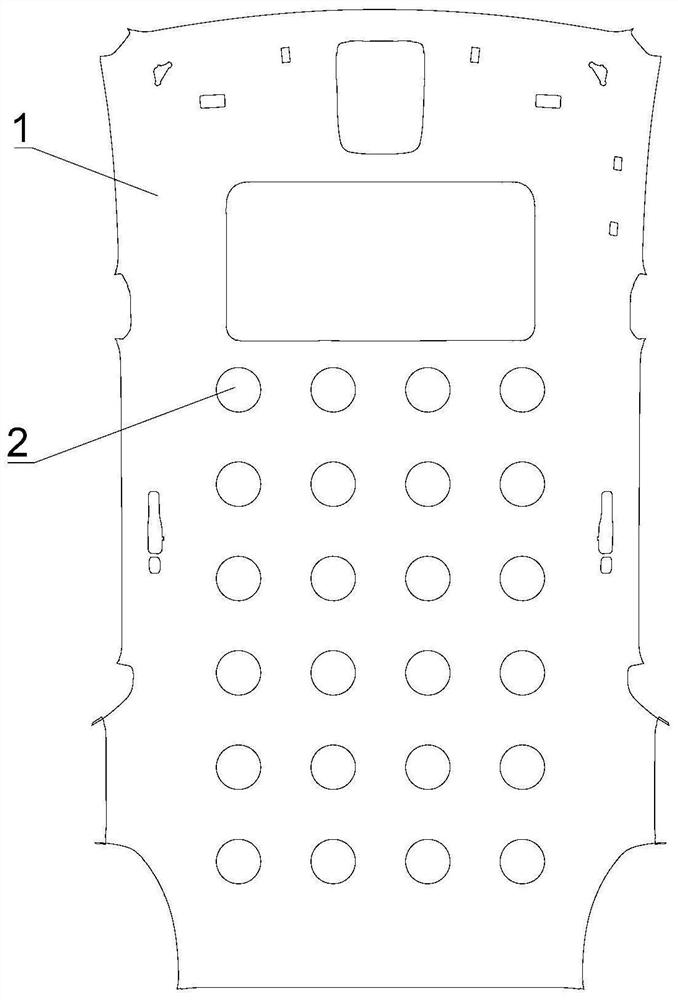

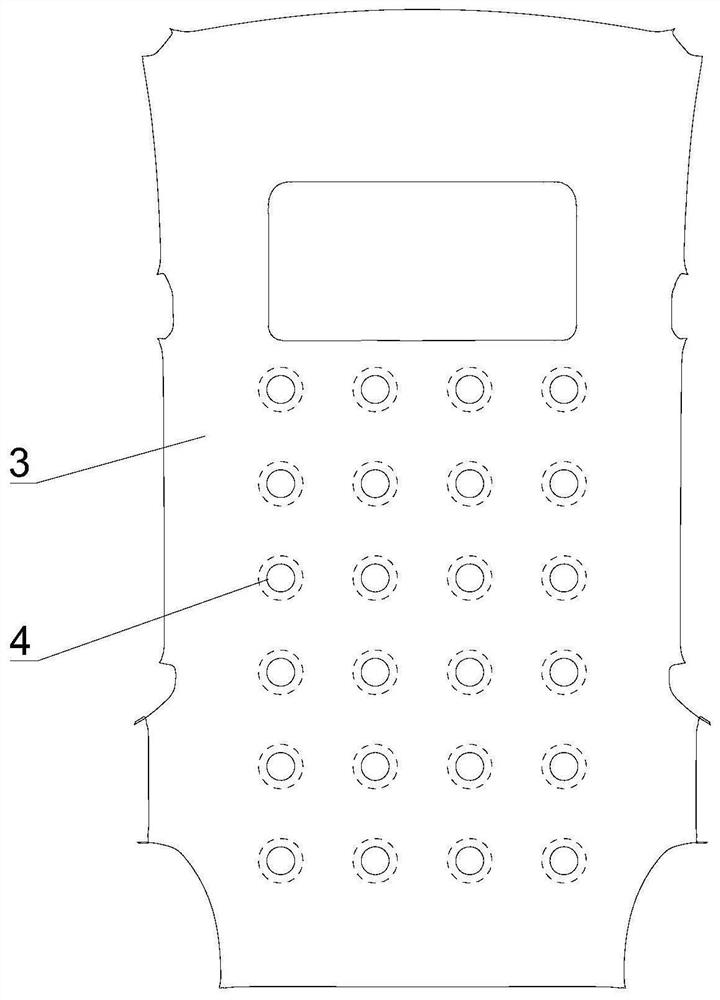

[0025] Step (1): The roof base material 1 is formed.

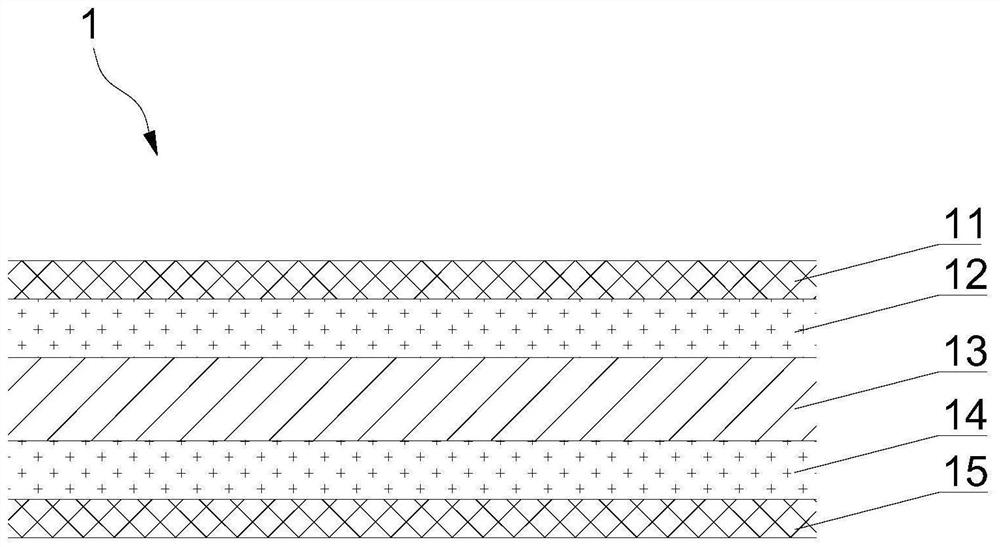

[0026] Take the roof of a certain type of car as an example, the size is 1982mm×1272mm, and the weight is 2850g, such as figure 1 As shown, here the ceiling base material 1 mainly comprises non-woven fabric, glass fiber and polyurethane plate 13, and the both sides of polyurethane plate 13 are coated with MDI glue (glue amount is 80g / m 2 ) and spraying demineralized water, the first non-woven fabric 11, the first glass fiber 12, the polyurethane plate 13, the second glass fiber 14, and the second non-woven fabric 15 are laid up in sequence and then molded. Specifically, the materials of each layer of the base mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com