Friction welding process for intermediate section of axle cast steel axle housing and shaft heads of heavy-duty truck

A heavy-duty vehicle and friction welding technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of large welding deformation, complicated process, and long shaft head, etc., and achieve high welding efficiency, precise control, and weight reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] According to the processing step of the scheme of the present invention,

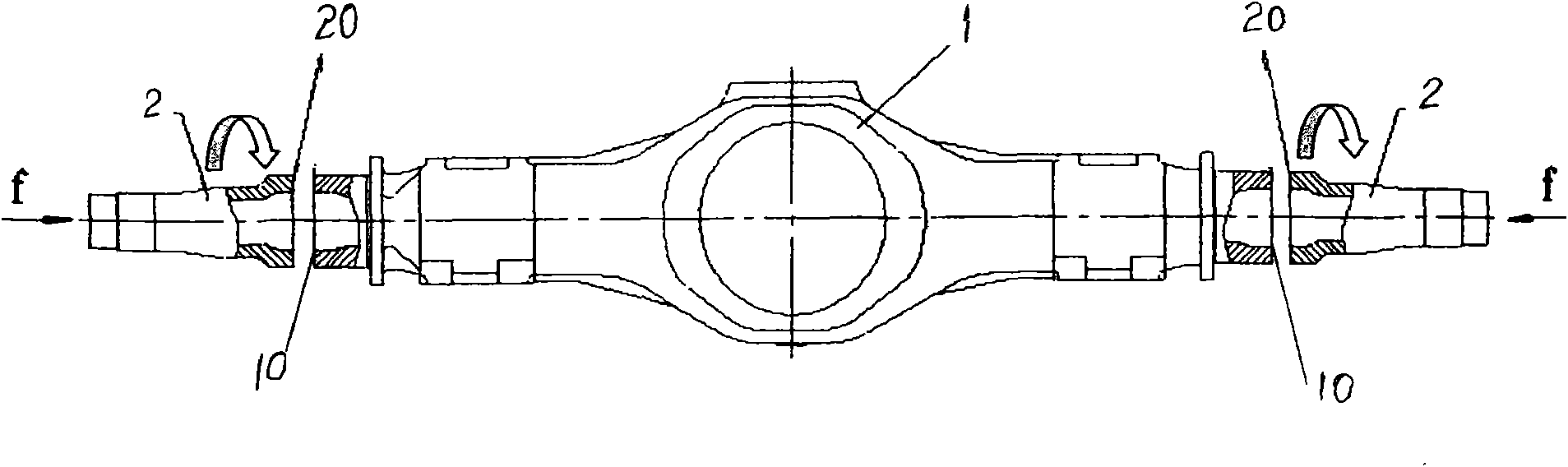

[0035] (1) Turning and processing the welding joint surfaces 10 on both sides of the middle section 1 of the axle housing according to the process design requirements;

[0036] (2) Turning and processing the welding joint surface 20 of the shaft head 2 on both sides of the axle according to the process design requirements;

[0037] (3) Clamp the middle section 1 of the axle housing and the shaft heads 2 on both sides to the special welding equipment (not shown in the figure),

[0038] (4) Start the equipment to rotate the shaft heads 2 at both ends at high speed and apply axial pressure f to perform friction welding divided into four stages: primary, secondary, braking and upsetting, wherein;

[0039] ① In the first-level friction stage, the speed parameter of the shaft head rotation is set to 530 rpm, the pressure parameter of the axial pressure is 30 bar, and the parameter of the friction time...

Embodiment 2

[0044] According to the processing step of the scheme of the present invention,

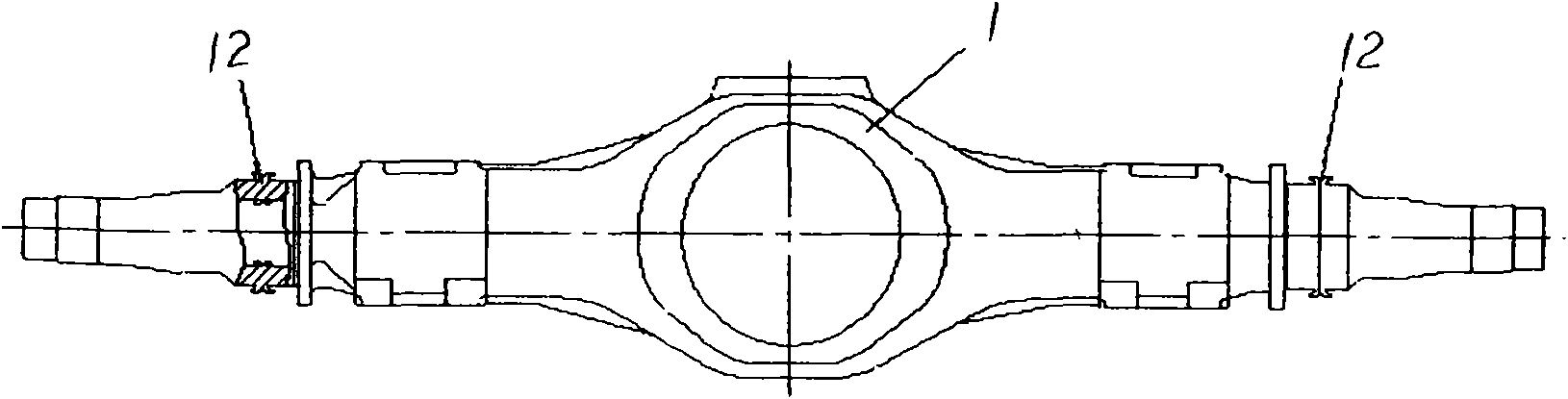

[0045] (1) Turning and processing the welding joint surfaces 10 on both sides of the middle section 1 of the axle housing according to the process design requirements;

[0046] (2) Turning and processing the welding joint surface 20 of the shaft head 2 on both sides of the axle according to the process design requirements;

[0047] (3) Clamp the middle section 1 of the axle housing and the shaft heads 2 on both sides to the special welding equipment (not shown in the figure),

[0048] (4) Start the equipment to make the shaft heads 2 at both ends run at high speed and apply axial pressure f to perform friction welding divided into four stages: primary, secondary, braking and upsetting, wherein;

[0049] ① In the first-level friction stage, the speed parameter of the shaft head rotation is set to 500 rpm, the pressure parameter of the axial pressure is 25 bar, and the parameter of the friction ti...

Embodiment 3

[0054] According to the processing step of the scheme of the present invention,

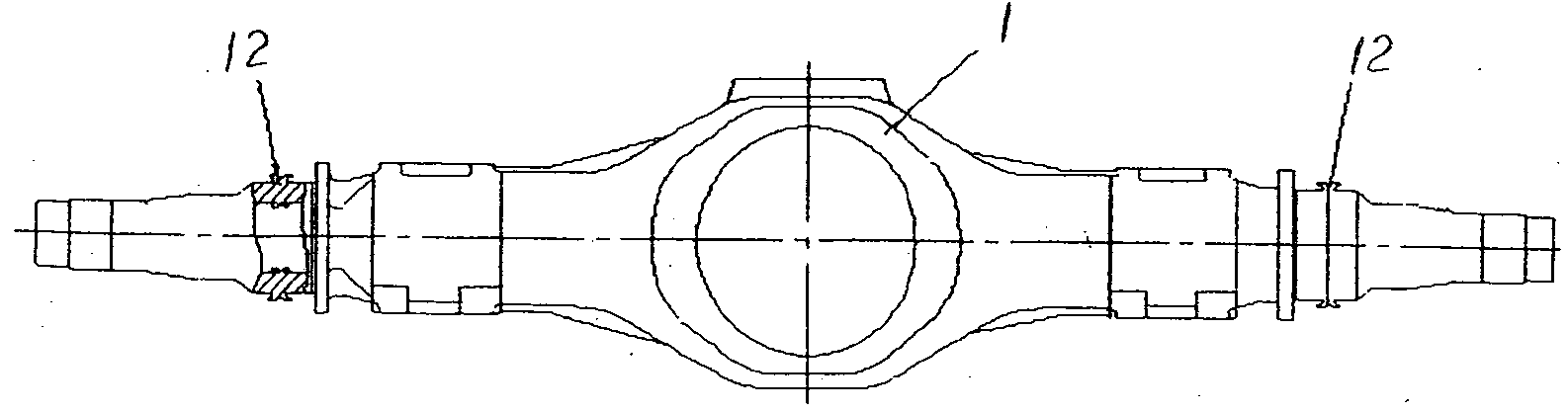

[0055] (1) Turning and processing the welding joint surfaces 10 on both sides of the middle section 1 of the axle housing according to the process design requirements;

[0056] (2) Turning and processing the welding joint surface 20 of the shaft head 2 on both sides of the axle according to the process design requirements;

[0057] (3) Clamp the middle section 1 of the axle housing and the shaft heads 2 on both sides to the special welding equipment (not shown in the figure),

[0058] (4) Start the equipment to rotate the shaft heads 2 at both ends at high speed and apply axial pressure f to perform friction welding divided into four stages: primary, secondary, braking and upsetting, wherein;

[0059] ① In the first-level friction stage, the speed parameter of the shaft head rotation is set to 580 rpm, the pressure parameter of the axial pressure is 35 bar, and the parameter of the friction time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com