Axial riveting clamping structure and clamping process

A riveting and axial technology, which is applied to the steering column and the steering control installed on the car, etc., can solve the problems of increasing the weight of the assembly and increasing the driving cost of the car, and achieve weight reduction of the assembly, good riveting effect, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

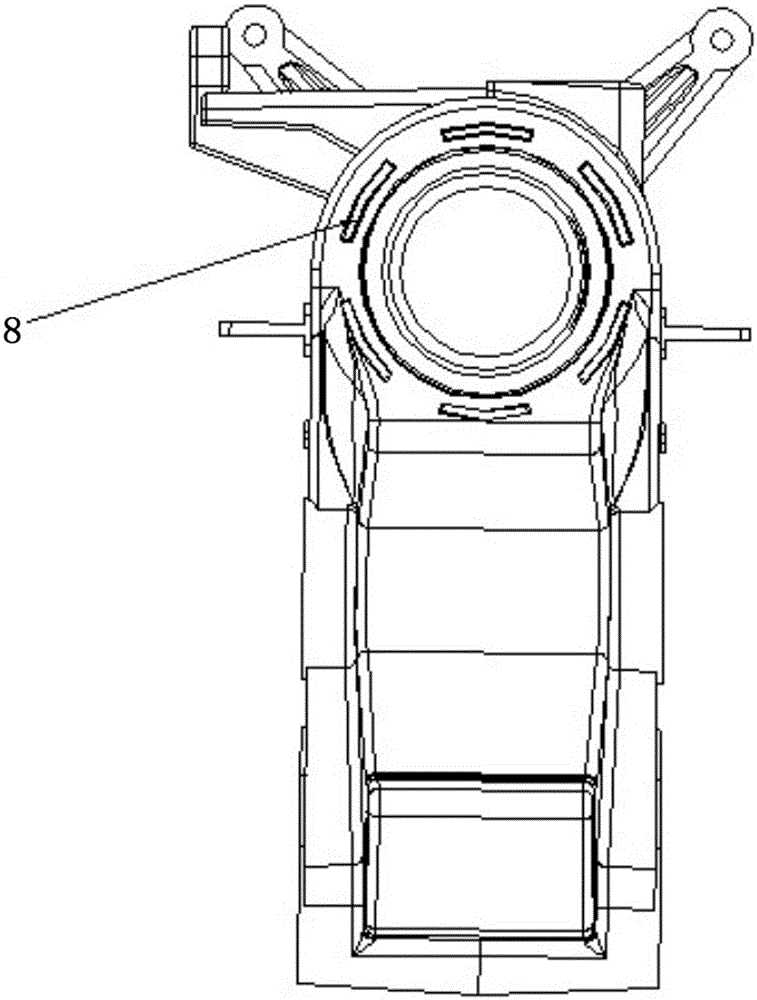

[0018] Embodiment 1: An axial riveting and clamping process. The upper and lower ends of the steering column tube of an automobile are respectively provided with an upper bearing groove and a lower bearing groove. The steering shaft is sleeved in the steering column tube through the upper and lower bearings. A plurality of riveting grooves are evenly distributed on the end surface of the lower bearing groove, and the riveting machine is used to ream each riveting groove so that the inner wall of each riveting groove moves radially toward the center of the circle, so that the lower bearing is clamped and fixed in the lower bearing groove. At the same time, the outer ring of the lower bearing and the lower bearing groove are interference fit. Considering that the axial length of the steering shaft 1 will change with the temperature, the upper bearing can move axially in the upper bearing groove, and the upper bearing has no positioning in the axial direction and is designed to mo...

Embodiment 2

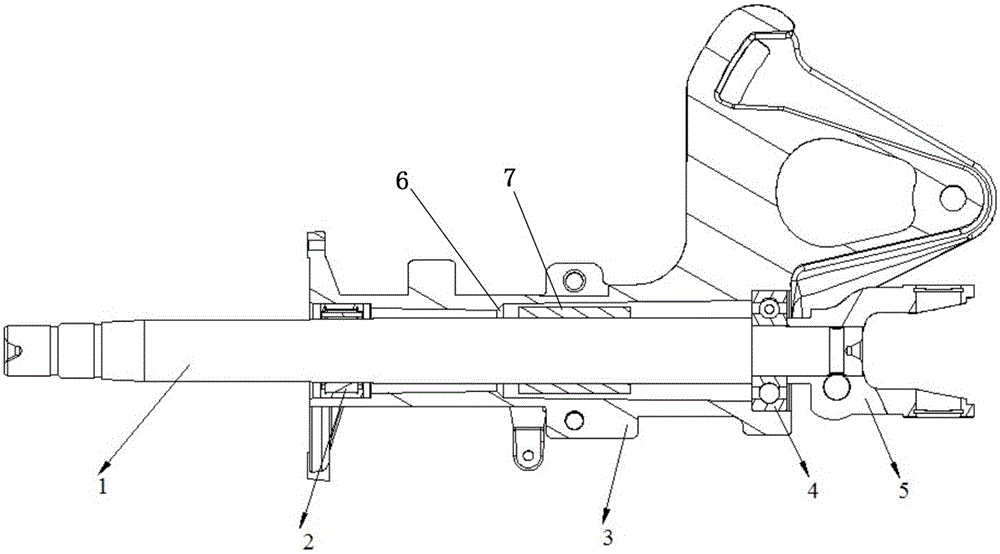

[0019] Example 2: see figure 1 and figure 2 , an axial riveting clamping structure, the upper end and the lower end of the steering column tube 3 are respectively set for the upper bearing groove and the lower bearing groove, the upper bearing 2 is installed in the upper bearing groove, the lower bearing 4 is installed in the lower bearing groove, the steering shaft 1 is sleeved in the steering column tube 3 through the upper and lower bearings, and the lower end of the steering shaft 1 is also connected with a universal joint fork 5 .

[0020] The axial width of the groove of the upper bearing 2 is larger than the width of the outer ring of the upper bearing, so the upper bearing has no positioning in the axial direction and is designed for swimming. to swim.

[0021] There is an interference fit between the outer ring of the lower bearing and the lower bearing groove. And three or six riveting grooves 8 are uniformly arranged on the end face of the lower bearing groove, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com