A glass lifter with adjustable buffer block

A glass lifter and buffer block technology, which is applied to the operating mechanism of the wing leaf, construction, door/window accessories, etc., can solve the problems of easy wear and tear of the buffer block, and achieve the effect of reducing weight and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

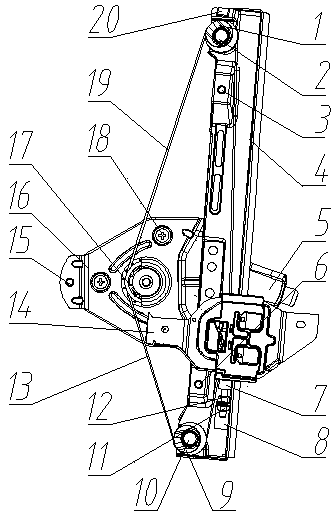

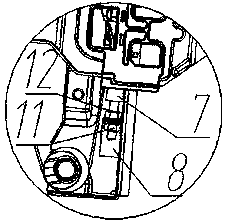

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0017] The invention provides a glass regulator with an adjustable buffer block, which solves the problem that the buffer block is easy to wear: the adjustable buffer block can effectively compensate for the wear of the buffer block, and when the buffer block is worn, the lock nut can be loosened, Rotate the adjusting nut counterclockwise to move the adjustable buffer block up a short distance. After adjustment, tighten the lock nut to realize the compensation for the worn buffer block.

[0018] As an embodiment of the present invention, the present invention provides a glass regulator with an adjustable buffer block, including an upper guide wheel 1, an upper guide wheel shaft 2, a fixing screw 3 on the lifter, a guide rail bracket 4, a motor 5, and a lifter Lower fixing screw 6, adjustable buffer block 7, lower dead center fixing bracket 8, lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com