Differential mechanism shell and gear assembly

A technology for differentials and housings, which is applied to differential transmissions, belts/chains/gears, transmission parts, etc., which can solve the problem of limited torque transmission capacity of bolts, increased housing quality, and low precision of gear meshing, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0029] It should be noted that, unless otherwise specified, the technical terms or scientific terms used in this application shall have the usual meanings understood by those skilled in the art to which the present invention belongs.

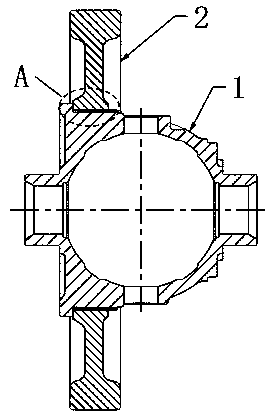

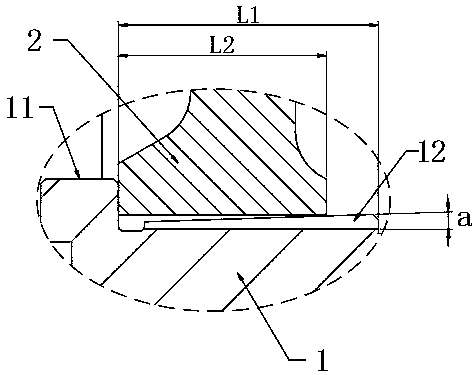

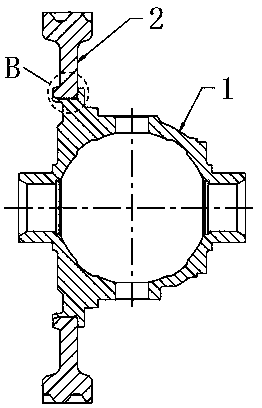

[0030] see Figure 1-5 , a differential case and gear assembly provided in the present application, comprising a case 1 , the outer periphery of the case 1 is sheathed with transmission teeth 2 , and the transmission teeth 2 are arranged coaxially with the case 1 . The outer periphery of the housing 1 is provided with an external spline 12, and the central hole wall of the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com